engine FIAT DUCATO 2006 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2006, Model line: DUCATO, Model: FIAT DUCATO 2006Pages: 238, PDF Size: 3.29 MB

Page 144 of 238

143

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

To change a wheel proceed as

follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safe-

ly. The ground should be flat and ad-

equately firm;

❒turn the engine off and pull up the

handbrake;

❒engage first gear or reverse;

❒wear the reflecting safety jacket (com-

pulsory by law in certain countries) be-

fore getting out of the vehicle;

❒alert other drivers that the vehicle is

stationary, using the proper devices in

compliance with the regulations in

force (e.g.: warning triangle, hazard

warning lights, etc …);

❒take the extension and the wrench

from the tool bag under the passen-

ger’s seat (see “Compartment under

the front passenger’s seat” in section

“dashboard and controls”);

❒loosen one turn the bolts of the wheel

to change;

❒turn the ring nut to extend the jack

partially;

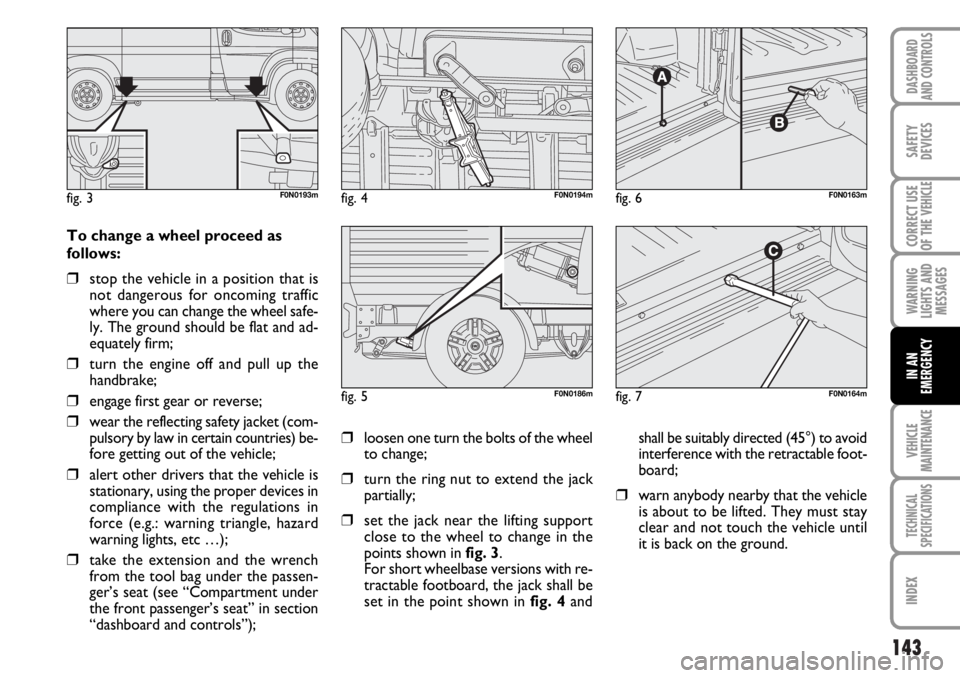

❒set the jack near the lifting support

close to the wheel to change in the

points shown in fig. 3.

For short wheelbase versions with re-

tractable footboard, the jack shall be

set in the point shown in fig. 4andshall be suitably directed (45°) to avoid

interference with the retractable foot-

board;

❒warn anybody nearby that the vehicle

is about to be lifted. They must stay

clear and not touch the vehicle until

it is back on the ground.

fig. 3F0N0193mfig. 4F0N0194m

fig. 5F0N0186m

fig. 6F0N0163m

fig. 7F0N0164m

Page 150 of 238

149

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

❒if at laest 3 bar pressure is read, re-

store proper pressure specified in

paragraph” Tyre pressure” in section

“Technical Specifications” (with engine

running and handbrake on) and

restart;

❒drive with the utmost care to the

nearest Fiat Dealership.

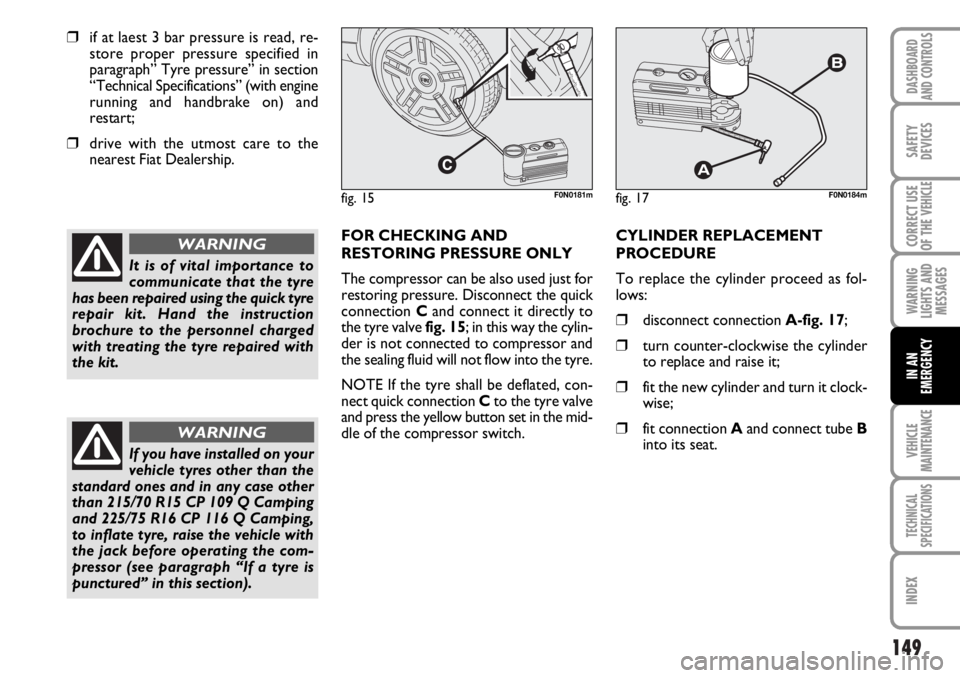

FOR CHECKING AND

RESTORING PRESSURE ONLY

The compressor can be also used just for

restoring pressure. Disconnect the quick

connection Cand connect it directly to

the tyre valve fig. 15; in this way the cylin-

der is not connected to compressor and

the sealing fluid will not flow into the tyre.

NOTE If the tyre shall be deflated, con-

nect quick connection Cto the tyre valve

and press the yellow button set in the mid-

dle of the compressor switch.CYLINDER REPLACEMENT

PROCEDURE

To replace the cylinder proceed as fol-

lows:

❒disconnect connection A-fig. 17;

❒turn counter-clockwise the cylinder

to replace and raise it;

❒fit the new cylinder and turn it clock-

wise;

❒fit connection Aand connect tube B

into its seat.

It is of vital importance to

communicate that the tyre

has been repaired using the quick tyre

repair kit. Hand the instruction

brochure to the personnel charged

with treating the tyre repaired with

the kit.

WARNING

fig. 17F0N0184mfig. 15F0N0181m

If you have installed on your

vehicle tyres other than the

standard ones and in any case other

than 215/70 R15 CP 109 Q Camping

and 225/75 R16 CP 116 Q Camping,

to inflate tyre, raise the vehicle with

the jack before operating the com-

pressor (see paragraph “If a tyre is

punctured” in this section).

WARNING

Page 160 of 238

159

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

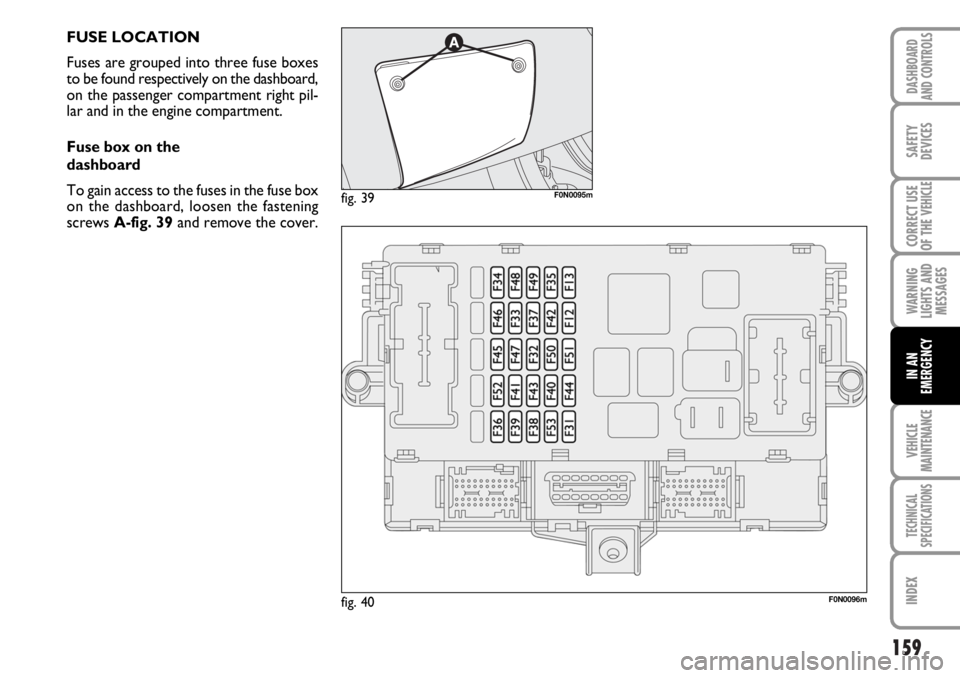

FUSE LOCATION

Fuses are grouped into three fuse boxes

to be found respectively on the dashboard,

on the passenger compartment right pil-

lar and in the engine compartment.

Fuse box on the

dashboard

To gain access to the fuses in the fuse box

on the dashboard, loosen the fastening

screws A-fig. 39and remove the cover.

fig. 40F0N0096m

fig. 39F0N0095m

Page 161 of 238

160

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

fig. 42F0N0097m

fig. 41F0N0098m

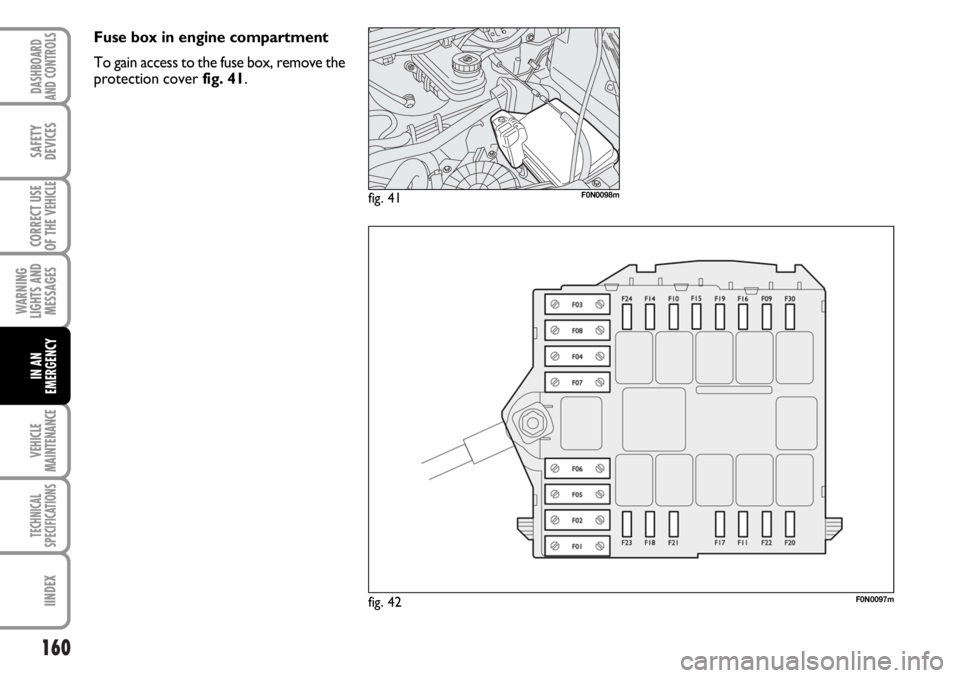

Fuse box in engine compartment

To gain access to the fuse box, remove the

protection cover fig. 41.

Page 163 of 238

162

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

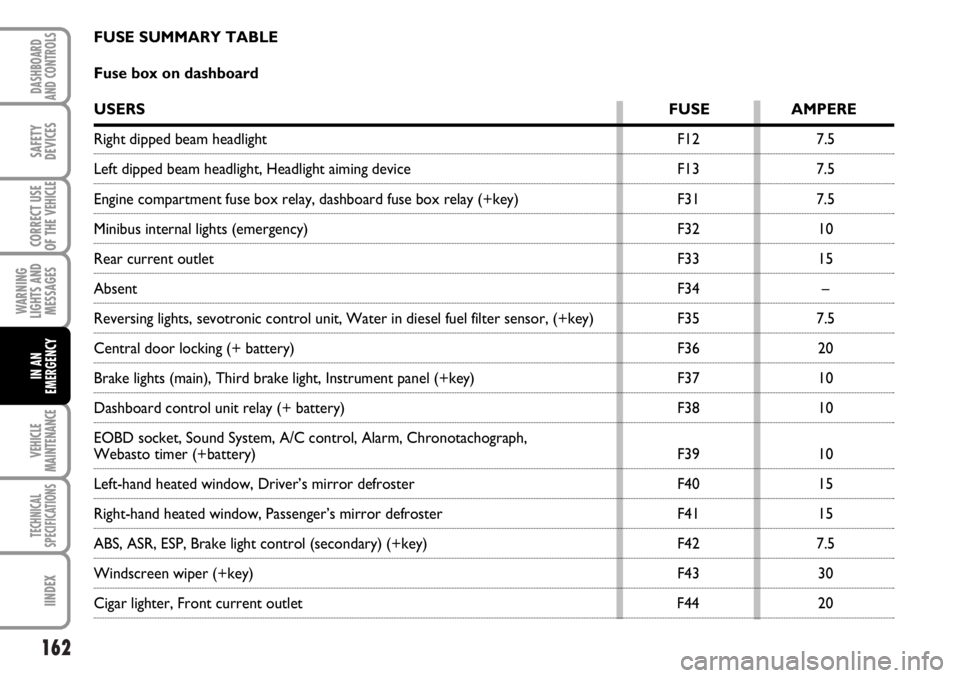

FUSE SUMMARY TABLE

Fuse box on dashboard

USERSFUSE AMPERE

Right dipped beam headlight F12 7.5

Left dipped beam headlight, Headlight aiming device F13 7.5

Engine compartment fuse box relay, dashboard fuse box relay (+key) F31 7.5

Minibus internal lights (emergency) F32 10

Rear current outlet F33 15

AbsentF34 –

Reversing lights, sevotronic control unit, Water in diesel fuel filter sensor, (+key) F35 7.5

Central door locking (+ battery) F36 20

Brake lights (main), Third brake light, Instrument panel (+key) F37 10

Dashboard control unit relay (+ battery) F38 10

EOBD socket, Sound System, A/C control, Alarm, Chronotachograph,

Webasto timer (+battery) F39 10

Left-hand heated window, Driver’s mirror defroster F40 15

Right-hand heated window, Passenger’s mirror defroster F41 15

ABS, ASR, ESP, Brake light control (secondary) (+key) F42 7.5

Windscreen wiper (+key) F43 30

Cigar lighter, Front current outlet F44 20

Page 165 of 238

164

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

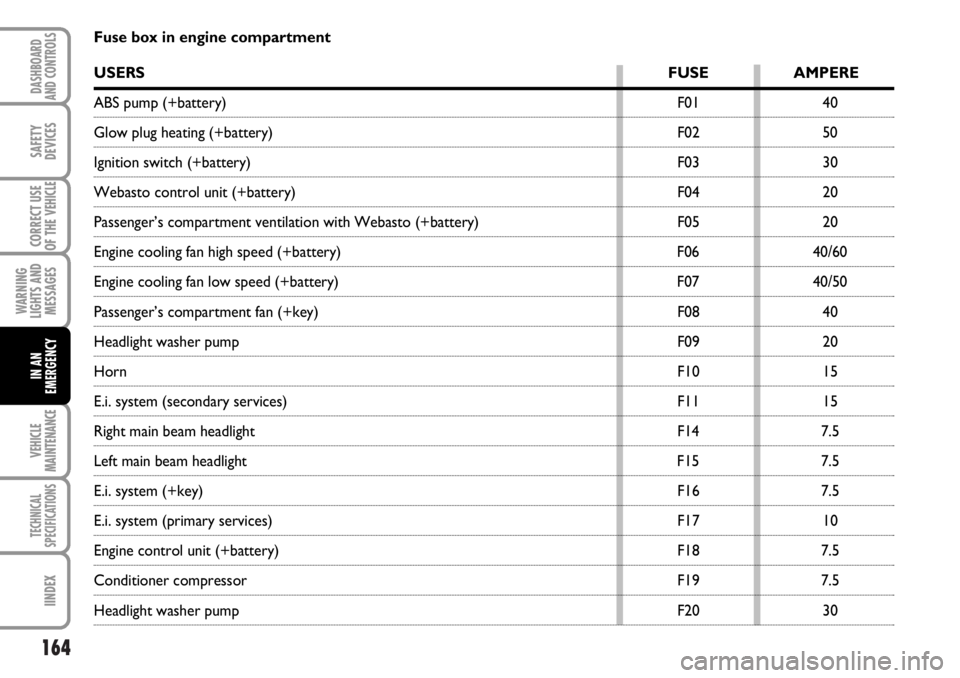

Fuse box in engine compartment

USERSFUSE AMPERE

ABS pump (+battery) F01 40

Glow plug heating (+battery) F02 50

Ignition switch (+battery) F03 30

Webasto control unit (+battery) F04 20

Passenger’s compartment ventilation with Webasto (+battery) F05 20

Engine cooling fan high speed (+battery) F06 40/60

Engine cooling fan low speed (+battery) F07 40/50

Passenger’s compartment fan (+key) F08 40

Headlight washer pump F09 20

HornF10 15

E.i. system (secondary services) F11 15

Right main beam headlight F14 7.5

Left main beam headlight F15 7.5

E.i. system (+key) F16 7.5

E.i. system (primary services) F17 10

Engine control unit (+battery) F18 7.5

Conditioner compressor F19 7.5

Headlight washer pump F20 30

Page 170 of 238

169

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

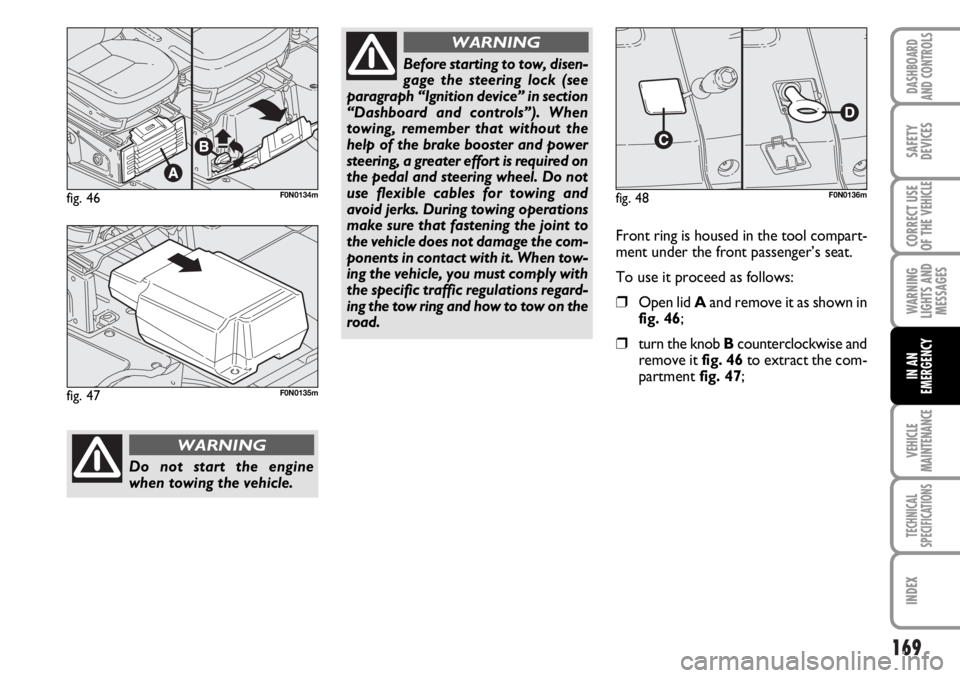

fig. 46F0N0134m

Do not start the engine

when towing the vehicle.

WARNING

Before starting to tow, disen-

gage the steering lock (see

paragraph “Ignition device” in section

“Dashboard and controls”). When

towing, remember that without the

help of the brake booster and power

steering, a greater effort is required on

the pedal and steering wheel. Do not

use flexible cables for towing and

avoid jerks. During towing operations

make sure that fastening the joint to

the vehicle does not damage the com-

ponents in contact with it. When tow-

ing the vehicle, you must comply with

the specific traffic regulations regard-

ing the tow ring and how to tow on the

road.

WARNING

fig. 47F0N0135m

fig. 48F0N0136m

Front ring is housed in the tool compart-

ment under the front passenger’s seat.

To use it proceed as follows:

❒Open lid Aand remove it as shown in

fig. 46;

❒turn the knob Bcounterclockwise and

remove it fig. 46 to extract the com-

partment fig. 47;

Page 174 of 238

173

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

45 90 135 180 225

●●●●●

●●●●●

●●●●●

●●●●●

●●●●●

●●

●●●●●

●●

●●●●●

●●●●●

●●●●●

●●●●●

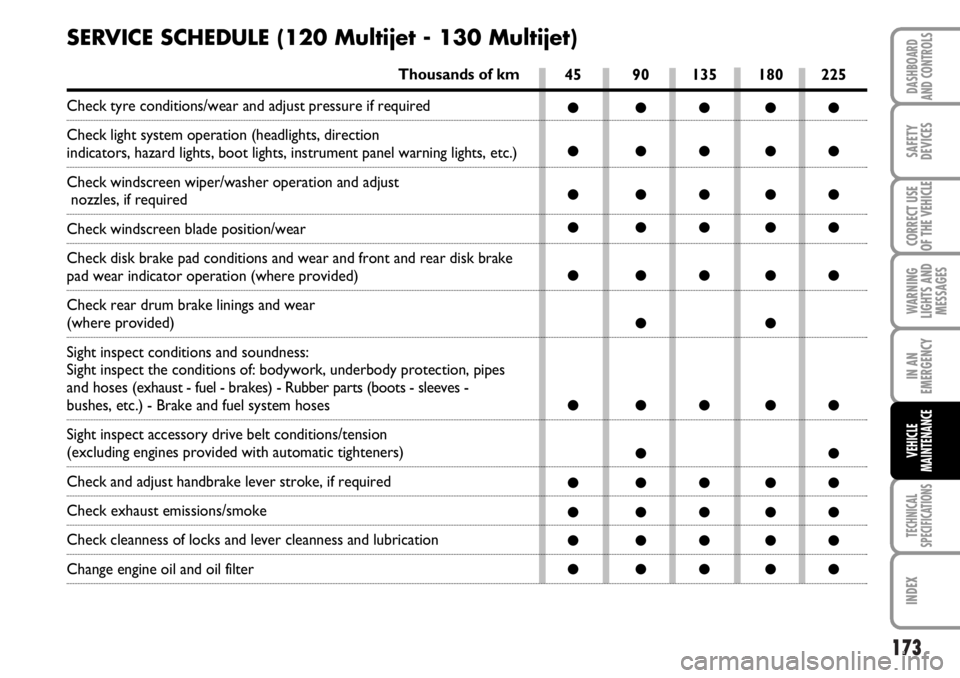

SERVICE SCHEDULE (120 Multijet - 130 Multijet)

Thousands of km

Check tyre conditions/wear and adjust pressure if required

Check light system operation (headlights, direction

indicators, hazard lights, boot lights, instrument panel warning lights, etc.)

Check windscreen wiper/washer operation and adjust

nozzles, if required

Check windscreen blade position/wear

Check disk brake pad conditions and wear and front and rear disk brake

pad wear indicator operation (where provided)

Check rear drum brake linings and wear

(where provided)

Sight inspect conditions and soundness:

Sight inspect the conditions of: bodywork, underbody protection, pipes

and hoses (exhaust - fuel - brakes) - Rubber parts (boots - sleeves -

bushes, etc.) - Brake and fuel system hoses

Sight inspect accessory drive belt conditions/tension

(excluding engines provided with automatic tighteners)

Check and adjust handbrake lever stroke, if required

Check exhaust emissions/smoke

Check cleanness of locks and lever cleanness and lubrication

Change engine oil and oil filter

Page 175 of 238

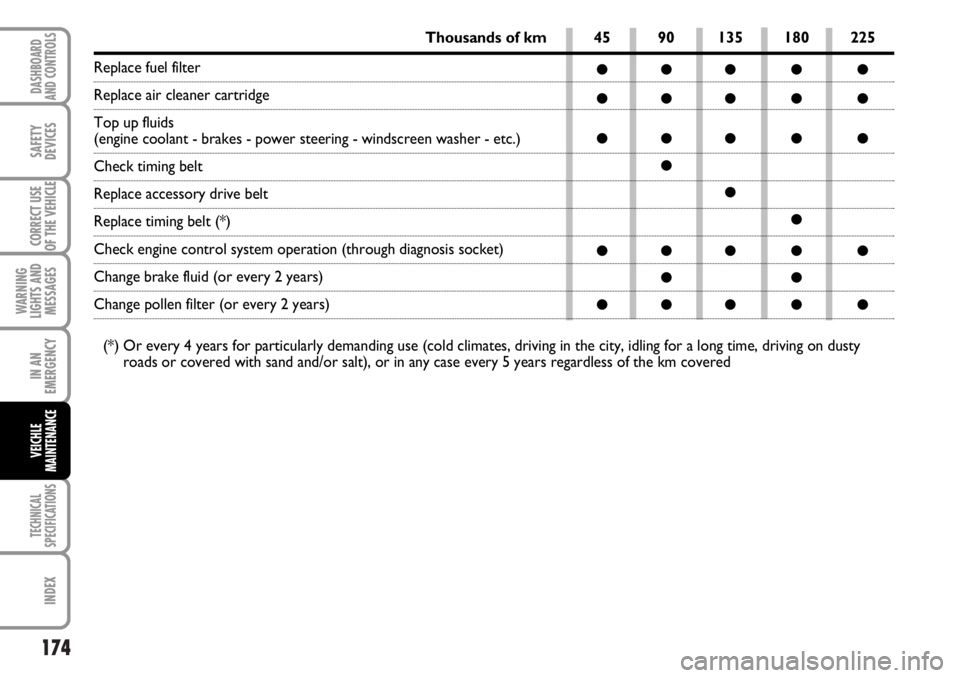

174

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

IN AN

EMERGENCY

VEICHLE

MAINTENANCE

45 90 135 180 225

●●●●●

●●●●●

●●●●●

●

●

●

●●●●●

●●

●●●●●

Thousands of km

Replace fuel filter

Replace air cleaner cartridge

Top up fluids

(engine coolant - brakes - power steering - windscreen washer - etc.)

Check timing belt

Replace accessory drive belt

Replace timing belt (*)

Check engine control system operation (through diagnosis socket)

Change brake fluid (or every 2 years)

Change pollen filter (or every 2 years)

(*) Or every 4 years for particularly demanding use (cold climates, driving in the city, idling for a long time, driving on dusty

roads or covered with sand and/or salt), or in any case every 5 years regardless of the km covered

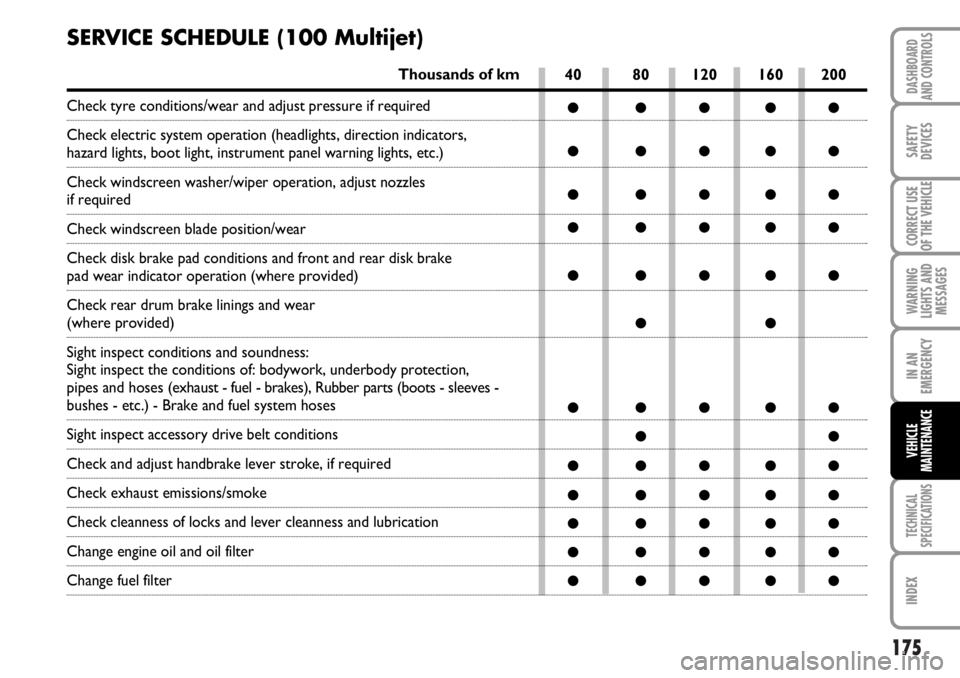

Page 176 of 238

175

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

40 80 120 160 200

●●●●●

●●●●●

●●●●●

●●●●●

●●●●●

●●

●●●●●

●●

●●●●●

●●●●●

●●●●●

●●●●●

●●●●●

SERVICE SCHEDULE (100 Multijet)

Thousands of km

Check tyre conditions/wear and adjust pressure if required

Check electric system operation (headlights, direction indicators,

hazard lights, boot light, instrument panel warning lights, etc.)

Check windscreen washer/wiper operation, adjust nozzles

if required

Check windscreen blade position/wear

Check disk brake pad conditions and front and rear disk brake

pad wear indicator operation (where provided)

Check rear drum brake linings and wear

(where provided)

Sight inspect conditions and soundness:

Sight inspect the conditions of: bodywork, underbody protection,

pipes and hoses (exhaust - fuel - brakes), Rubber parts (boots - sleeves -

bushes - etc.) - Brake and fuel system hoses

Sight inspect accessory drive belt conditions

Check and adjust handbrake lever stroke, if required

Check exhaust emissions/smoke

Check cleanness of locks and lever cleanness and lubrication

Change engine oil and oil filter

Change fuel filter