technical specifications FIAT DUCATO 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2012, Model line: DUCATO, Model: FIAT DUCATO 2012Pages: 287, PDF Size: 4.5 MB

Page 178 of 287

174

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

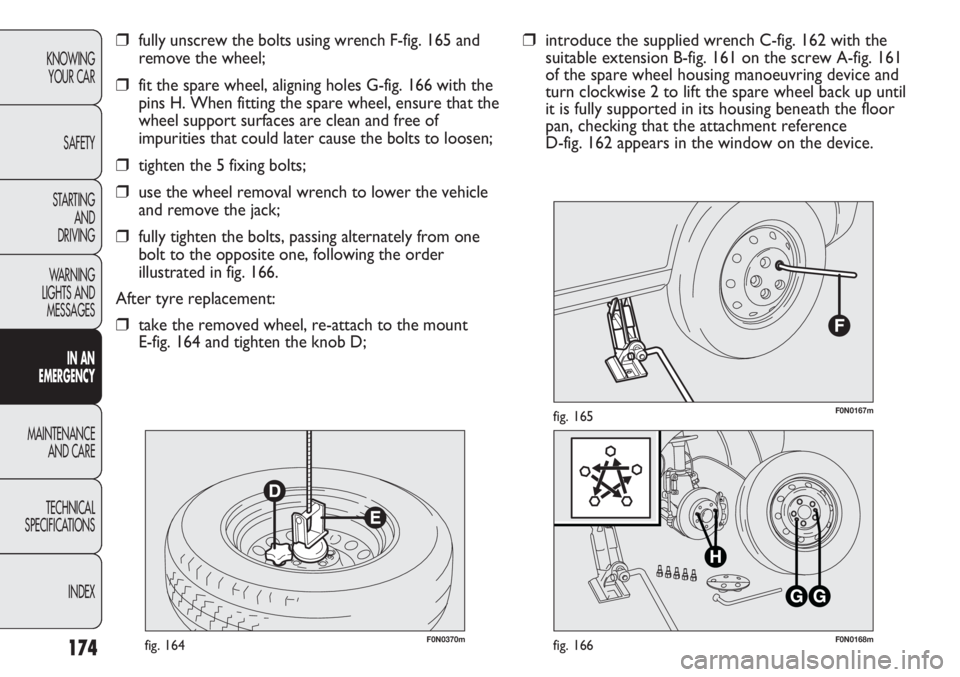

F0N0370mfig. 164F0N0168mfig. 166

F0N0167mfig. 165

âintroduce the supplied wrench C-fig. 162 with the

suitable extension B-fig. 161 on the screw A-fig. 161

of the spare wheel housing manoeuvring device and

turn clockwise 2 to lift the spare wheel back up until

it is fully supported in its housing beneath the floor

pan, checking that the attachment reference

D-fig. 162 appears in the window on the device.âfully unscrew the bolts using wrench F-fig. 165 and

remove the wheel;

âfit the spare wheel, aligning holes G-fig. 166 with the

pins H. When fitting the spare wheel, ensure that the

wheel support surfaces are clean and free of

impurities that could later cause the bolts to loosen;

âtighten the 5 fixing bolts;

âuse the wheel removal wrench to lower the vehicle

and remove the jack;

âfully tighten the bolts, passing alternately from one

bolt to the opposite one, following the order

illustrated in fig. 166.

After tyre replacement:

âtake the removed wheel, re-attach to the mount

E-fig. 164 and tighten the knob D;

Page 179 of 287

175

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

F0N0251mfig. 168

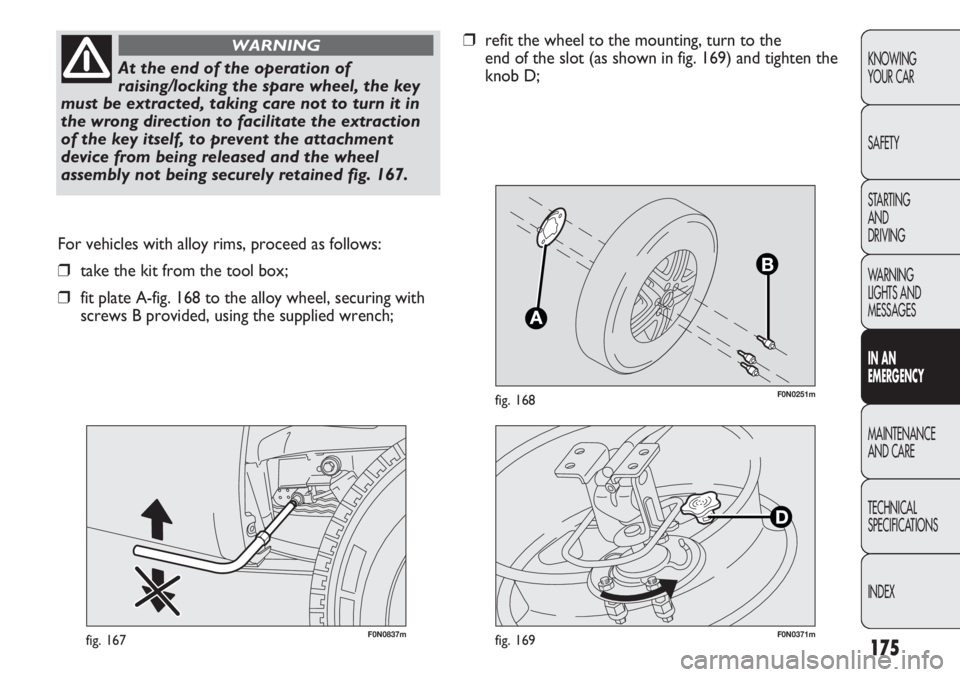

F0N0837mfig. 167

For vehicles with alloy rims, proceed as follows:

âtake the kit from the tool box;

âfit plate A-fig. 168 to the alloy wheel, securing with

screws B provided, using the supplied wrench;

At the end of the operation of

raising/locking the spare wheel, the key

must be extracted, taking care not to turn it in

the wrong direction to facilitate the extraction

of the key itself, to prevent the attachment

device from being released and the wheel

assembly not being securely retained fig. 167.

WARNINGârefit the wheel to the mounting, turn to the

end of the slot (as shown in fig. 169) and tighten the

knob D;

F0N0371mfig. 169

Page 180 of 287

176

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

E

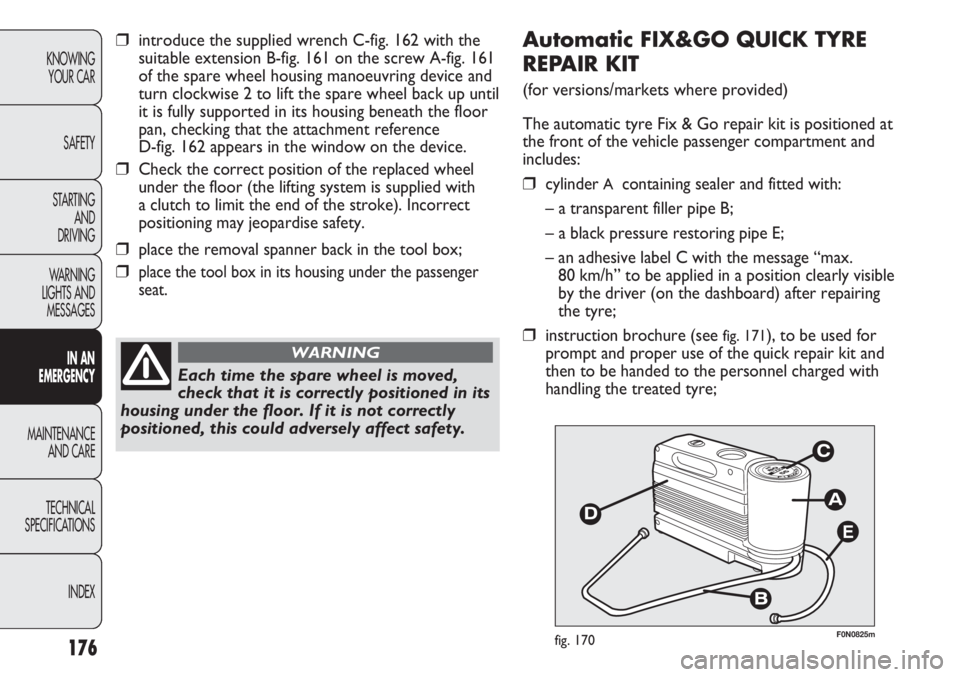

F0N0825mfig. 170

Automatic FIX&GO QUICK TYRE

REPAIR KIT

(for versions/markets where provided)

The automatic tyre Fix & Go repair kit is positioned at

the front of the vehicle passenger compartment and

includes:

âcylinder A containing sealer and fitted with:

â a transparent filler pipe B;

â a black pressure restoring pipe E;

â an adhesive label C with the message âmax.

80 km/hâ to be applied in a position clearly visible

by the driver (on the dashboard) after repairing

the tyre;

âinstruction brochure (see fig. 171), to be used for

prompt and proper use of the quick repair kit and

then to be handed to the personnel charged with

handling the treated tyre;

Each time the spare wheel is moved,

check that it is correctly positioned in its

housing under the floor. If it is not correctly

positioned, this could adversely affect safety.

WARNING

âintroduce the supplied wrench C-fig. 162 with the

suitable extension B-fig. 161 on the screw A-fig. 161

of the spare wheel housing manoeuvring device and

turn clockwise 2 to lift the spare wheel back up until

it is fully supported in its housing beneath the floor

pan, checking that the attachment reference

D-fig. 162 appears in the window on the device.

âCheck the correct position of the replaced wheel

under the floor (the lifting system is supplied with

a clutch to limit the end of the stroke). Incorrect

positioning may jeopardise safety.

âplace the removal spanner back in the tool box;

âplace the tool box in its housing under the passenger

seat.

Page 181 of 287

177

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

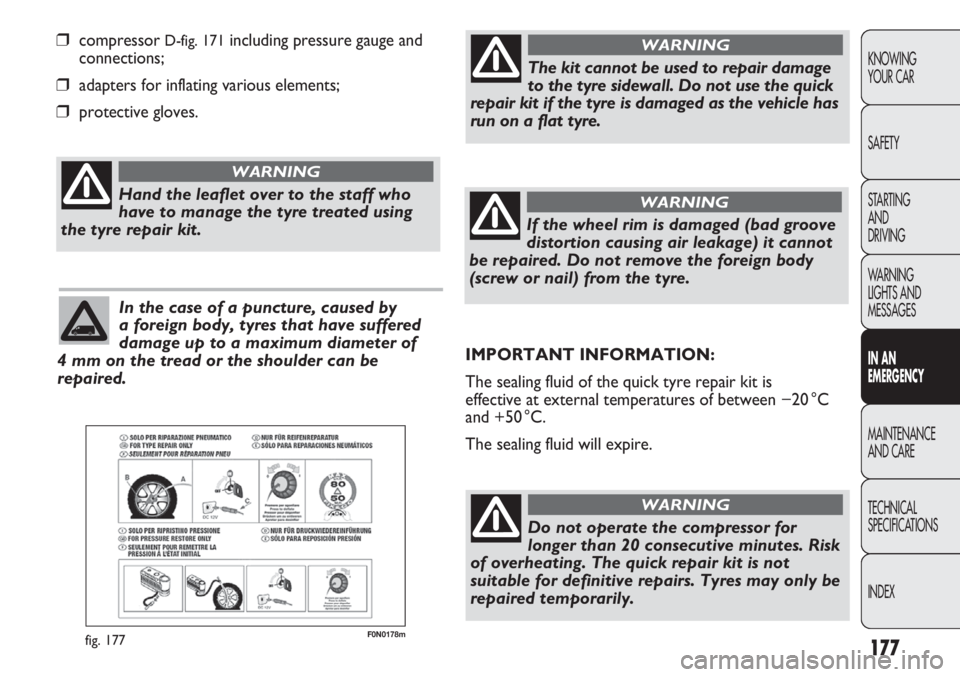

F0N0178mfig. 177

âcompressor D-fig. 171including pressure gauge and

connections;

âadapters for inflating various elements;

âprotective gloves.

Hand the leaflet over to the staff who

have to manage the tyre treated using

the tyre repair kit.

WARNING

In the case of a puncture, caused by

a foreign body, tyres that have suffered

damage up to a maximum diameter of

4 mm on the tread or the shoulder can be

repaired.

The kit cannot be used to repair damage

to the tyre sidewall. Do not use the quick

repair kit if the tyre is damaged as the vehicle has

run on a flat tyre.

WARNING

If the wheel rim is damaged (bad groove

distortion causing air leakage) it cannot

be repaired. Do not remove the foreign body

(screw or nail) from the tyre.

WARNING

IMPORTANT INFORMATION:

The sealing fluid of the quick tyre repair kit is

effective at external temperatures of between â20 °C

and +50 °C.

The sealing fluid will expire.

Do not operate the compressor for

longer than 20 consecutive minutes. Risk

of overheating. The quick repair kit is not

suitable for definitive repairs. Tyres may only be

repaired temporarily.

WARNING

Page 182 of 287

178

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

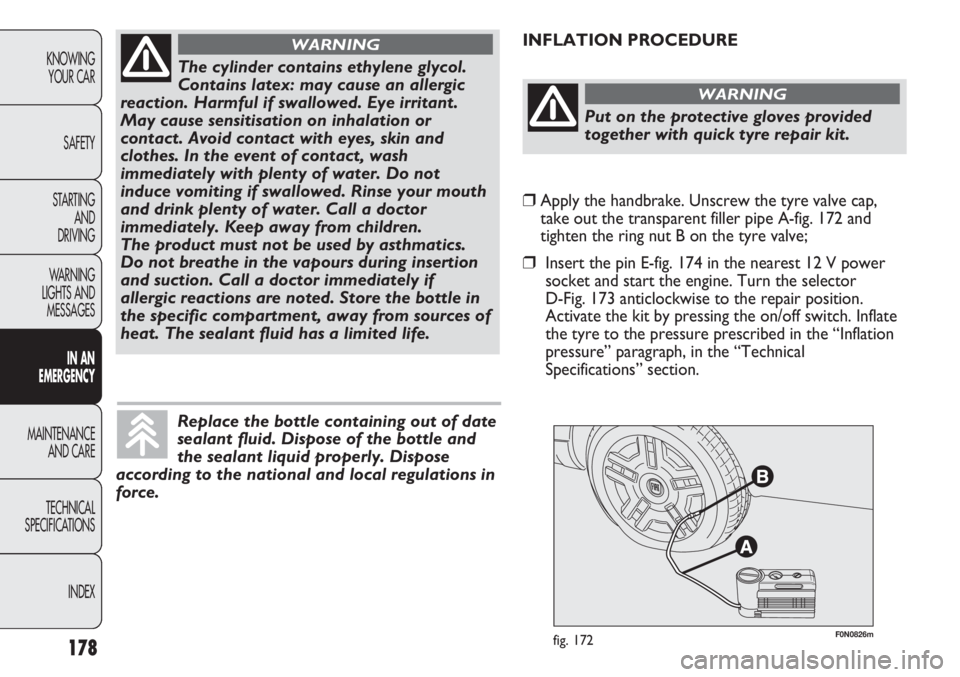

F0N0826mfig. 172

INFLATION PROCEDURE

The cylinder contains ethylene glycol.

Contains latex: may cause an allergic

reaction. Harmful if swallowed. Eye irritant.

May cause sensitisation on inhalation or

contact. Avoid contact with eyes, skin and

clothes. In the event of contact, wash

immediately with plenty of water. Do not

induce vomiting if swallowed. Rinse your mouth

and drink plenty of water. Call a doctor

immediately. Keep away from children.

The product must not be used by asthmatics.

Do not breathe in the vapours during insertion

and suction. Call a doctor immediately if

allergic reactions are noted. Store the bottle in

the specific compartment, away from sources of

heat. The sealant fluid has a limited life.

WARNING

Replace the bottle containing out of date

sealant fluid. Dispose of the bottle and

the sealant liquid properly. Dispose

according to the national and local regulations in

force.

Put on the protective gloves provided

together with quick tyre repair kit.

WARNING

âApply the handbrake. Unscrew the tyre valve cap,

take out the transparent filler pipe A-fig. 172 and

tighten the ring nut B on the tyre valve;

âInsert the pin E-fig. 174 in the nearest 12 V power

socket and start the engine. Turn the selector

D-Fig. 173 anticlockwise to the repair position.

Activate the kit by pressing the on/off switch. Inflate

the tyre to the pressure prescribed in the âInflation

pressureâ paragraph, in the âTechnical

Specificationsâ section.

Page 183 of 287

179

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

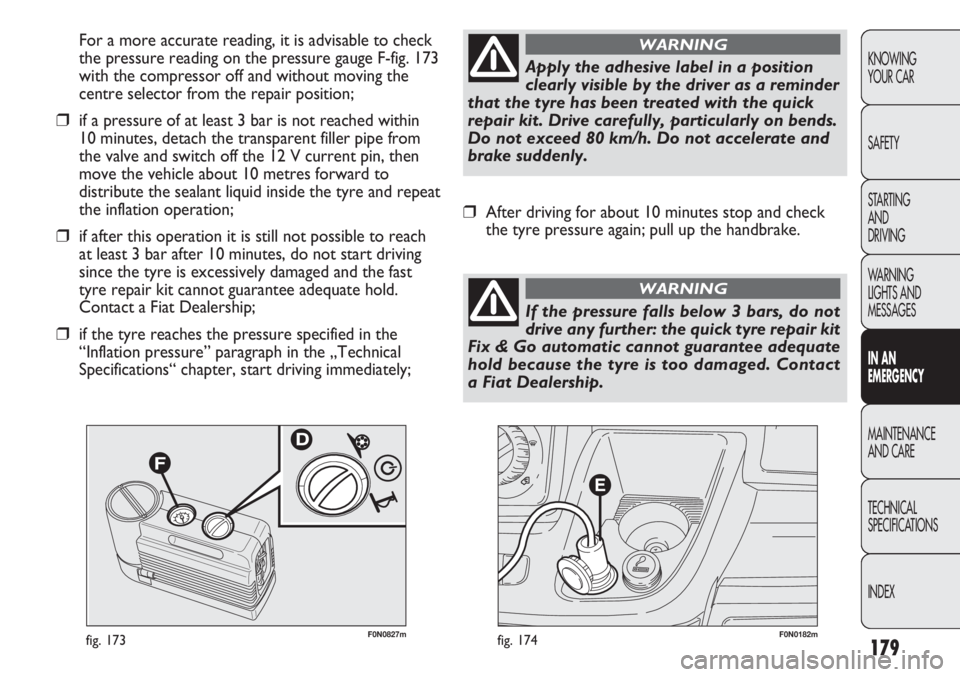

F0N0182mfig. 174F0N0827mfig. 173

For a more accurate reading, it is advisable to check

the pressure reading on the pressure gauge F-fig. 173

with the compressor off and without moving the

centre selector from the repair position;

âif a pressure of at least 3 bar is not reached within

10 minutes, detach the transparent filler pipe from

the valve and switch off the 12 V current pin, then

move the vehicle about 10 metres forward to

distribute the sealant liquid inside the tyre and repeat

the inflation operation;

âif after this operation it is still not possible to reach

at least 3 bar after 10 minutes, do not start driving

since the tyre is excessively damaged and the fast

tyre repair kit cannot guarantee adequate hold.

Contact a Fiat Dealership;

âif the tyre reaches the pressure specified in the

âInflation pressureâ paragraph in the âTechnical

Specificationsâ chapter, start driving immediately;

Apply the adhesive label in a position

clearly visible by the driver as a reminder

that the tyre has been treated with the quick

repair kit. Drive carefully, particularly on bends.

Do not exceed 80 km/h. Do not accelerate and

brake suddenly.

WARNING

âAfter driving for about 10 minutes stop and check

the tyre pressure again; pull up the handbrake.

If the pressure falls below 3 bars, do not

drive any further: the quick tyre repair kit

Fix & Go automatic cannot guarantee adequate

hold because the tyre is too damaged. Contact

a Fiat Dealership.

WARNING

Page 184 of 287

180

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

F0N0828mfig. 175

âIf at least 3 bar pressure is read, restore the correct

pressure specified in the paragraph âInflation

pressureâ in the âTechnical Specificationsâ section

(with engine running and handbrake on) and restart.

âdrive with the utmost care to the nearest Fiat

Dealership.

You must inform the dealership that the

tyre has been repaired using the quick

tyre repair kit. Hand the leaflet over to the staff

who will be dealing with the the tyre treated

using the tyre repair kit.

WARNING

If different tyres from the ones supplied

with the vehicle are used, the repair

cannot be carried out. If the tyres are replaced,

it is advisable to use those approved by the

manufacturer. Contact a Fiat Dealership .

WARNING

âUndo the cap for the tyre valve, extract the pipe

C-fig. 175 with the quick connector and connect it

directly to the valve of the tyre to be inflated.

âInsert the pin in the nearest 12 V power socket and

start the engine.

âRotate the selector clockwise to the pressure

renewal position.

âActivate the kit by pressing the on/off switch. Inflate

the tyre to the pressure specified in the âInflation

pressureâ paragraph, in the âTechnical Dataâ

chapter.

NOTE If the tyre has to be deflated, press the dedicated

button B illustrated in fig. 176. For a more accurate

reading, it is advisable to check the pressure reading on

the pressure gauge with the compressor off and without

moving the centre selector from the pressure restoring

position.

FOR CHECKING AND RESTORING

PRESSURE ONLY

The compressor can be also used solely for restoring

pressure.

âEngage the handbrake

Page 185 of 287

181

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

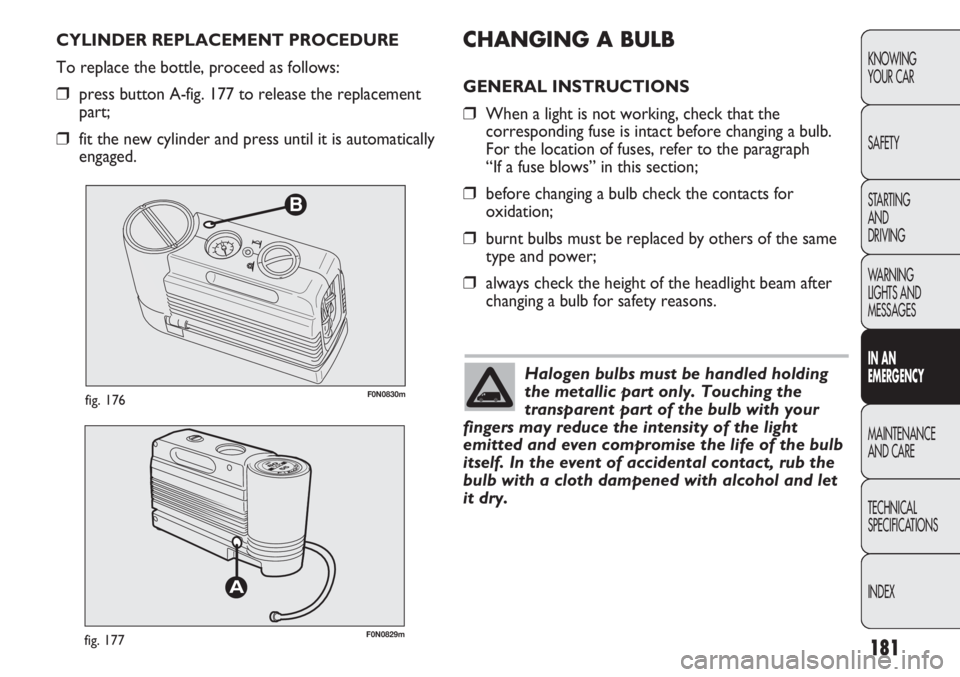

B

F0N0830mfig. 176

F0N0829mfig. 177

CHANGING A BULB

GENERAL INSTRUCTIONS

âWhen a light is not working, check that the

corresponding fuse is intact before changing a bulb.

For the location of fuses, refer to the paragraph

âIf a fuse blowsâ in this section;

âbefore changing a bulb check the contacts for

oxidation;

âburnt bulbs must be replaced by others of the same

type and power;

âalways check the height of the headlight beam after

changing a bulb for safety reasons. CYLINDER REPLACEMENT PROCEDURE

To replace the bottle, proceed as follows:

âpress button A-fig. 177 to release the replacement

part;

âfit the new cylinder and press until it is automatically

engaged.

Halogen bulbs must be handled holding

the metallic part only. Touching the

transparent part of the bulb with your

fingers may reduce the intensity of the light

emitted and even compromise the life of the bulb

itself. In the event of accidental contact, rub the

bulb with a cloth dampened with alcohol and let

it dry.

Page 186 of 287

182

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

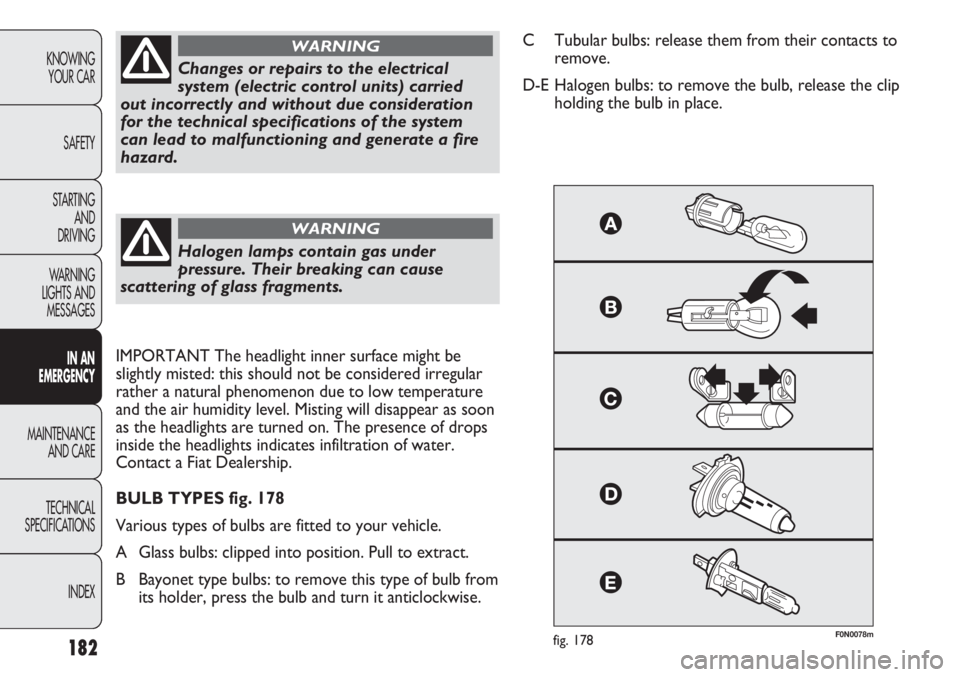

F0N0078mfig. 178

Changes or repairs to the electrical

system (electric control units) carried

out incorrectly and without due consideration

for the technical specifications of the system

can lead to malfunctioning and generate a fire

hazard.

WARNING

Halogen lamps contain gas under

pressure. Their breaking can cause

scattering of glass fragments.

WARNING

C Tubular bulbs: release them from their contacts to

remove.

D-E Halogen bulbs: to remove the bulb, release the clip

holding the bulb in place.

IMPORTANT The headlight inner surface might be

slightly misted: this should not be considered irregular

rather a natural phenomenon due to low temperature

and the air humidity level. Misting will disappear as soon

as the headlights are turned on. The presence of drops

inside the headlights indicates infiltration of water.

Contact a Fiat Dealership.

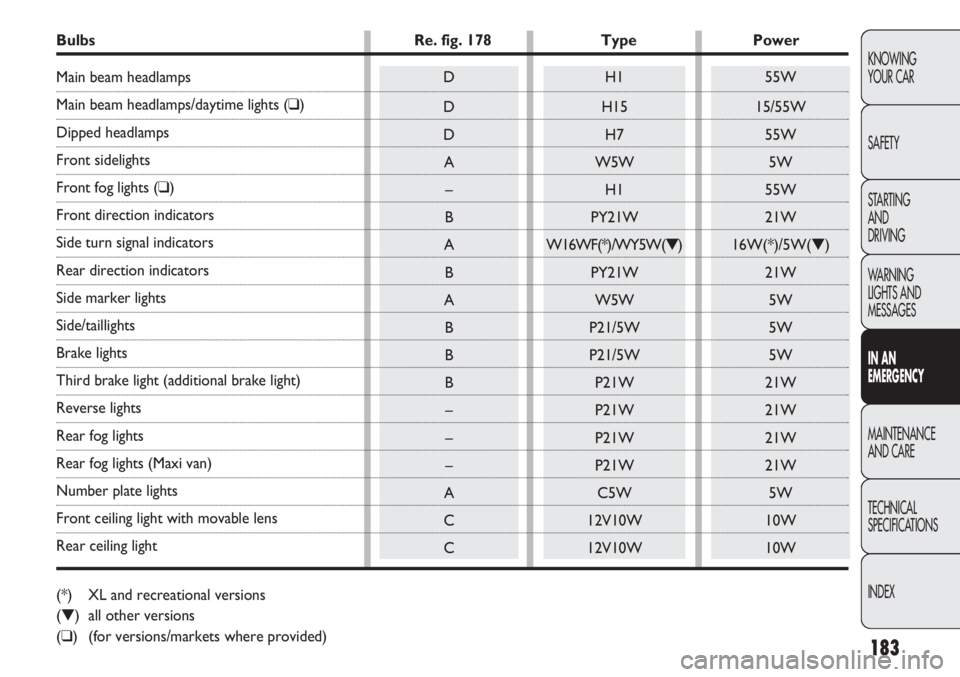

BULB TYPES fig. 178

Various types of bulbs are fitted to your vehicle.

A Glass bulbs: clipped into position. Pull to extract.

B Bayonet type bulbs: to remove this type of bulb from

its holder, press the bulb and turn it anticlockwise.

Page 187 of 287

183

KNOWING

YOUR CAR

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICATIONS

INDEX

H1

H15

H7

W5W

H1

PY21W

W16WF(*)/WY5W(â¼)

PY21W

W5W

P21/5W

P21/5W

P21W

P21W

P21W

P21W

C5W

12V10W

12V10WD

D

D

A

â

B

A

B

A

B

B

B

â

â

â

A

C

C55W

15/55W

55W

5W

55W

21W

16W(*)/5W(â¼)

21W

5W

5W

5W

21W

21W

21W

21W

5W

10W

10W

(*) XL and recreational versions

(â¼) all other versions

(â) (for versions/markets where provided)

Bulbs Re. fig. 178 Type Power

Main beam headlamps

Main beam headlamps/daytime lights (â)

Dipped headlamps

Front sidelights

Front fog lights (â)

Front direction indicators

Side turn signal indicators

Rear direction indicators

Side marker lights

Side/taillights

Brake lights

Third brake light (additional brake light)

Reverse lights

Rear fog lights

Rear fog lights (Maxi van)

Number plate lights

Front ceiling light with movable lens

Rear ceiling light