FIAT DUCATO BASE CAMPER 2018 Owner handbook (in English)

Manufacturer: FIAT, Model Year: 2018, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2018Pages: 304, PDF Size: 14.93 MB

Page 171 of 304

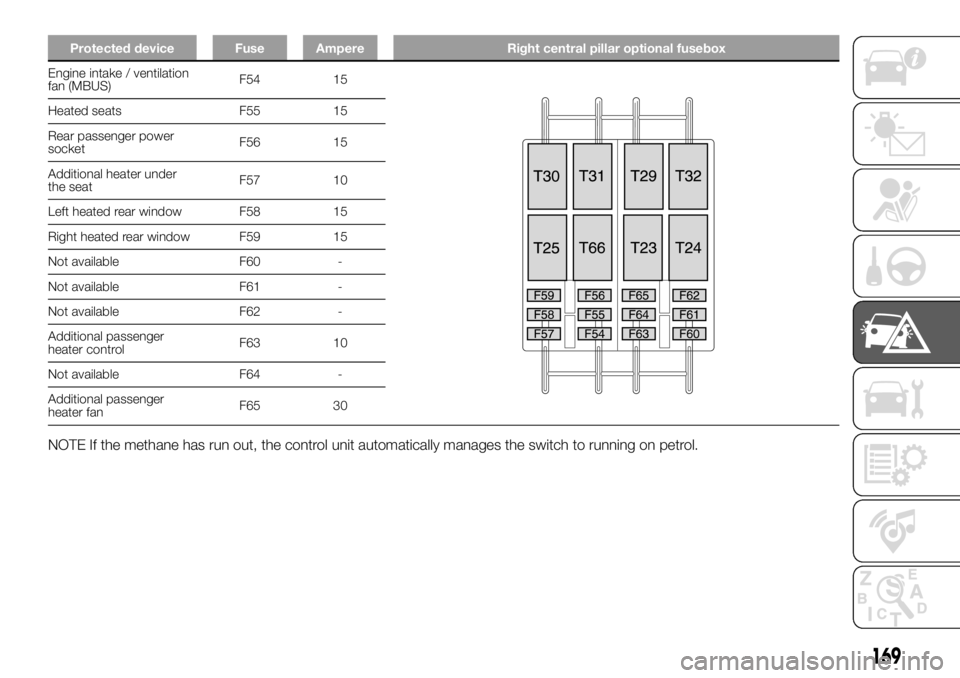

Protected device Fuse Ampere Right central pillar optional fusebox

Engine intake / ventilation

fan (MBUS)F54 15

Heated seats F55 15

Rear passenger power

socketF56 15

Additional heater under

the seatF57 10

Left heated rear window F58 15

Right heated rear window F59 15

Not available F60 -

Not available F61 -

Not available F62 -

Additional passenger

heater controlF63 10

Not available F64 -

Additional passenger

heater fanF65 30

NOTE If the methane has run out, the control unit automatically manages the switch to running on petrol.

169

Page 172 of 304

WARNING

142)Never replace a fuse with another with a higher amp rating; DANGER OF FIRE. If a general protection fuse (MEGA-FUSE, MIDI-FUSE) is

activated, contact a Fiat Dealership.

143)Before replacing a fuse, make sure that the ignition key has been removed and that all the other services are switched off and/or

disengaged.

144)If the replaced fuse blows again, contact a Fiat Dealership.

145)Contact Fiat Dealership if a safety system (airbags, brakes), engine system (engine, gearbox) or steering system general protection fuse

blows.

WARNING

48)Never replace a faulty fuse with metal wires or anything else.

170

IN AN EMERGENCY

Page 173 of 304

GATEWAY FMS

MODULE

The Gateway FMS Module provides the

interface between the vehicle data

network and the FMS standard.

FMS: The Fleet Management Systems

Interface (FMS) is a standard interface

that allows the vehicle’s digital

electronic control unit signals to be

read. The information in these signals

can be used to facilitate the vehicle’s

personalisation or special outfitting. The

Gateway FMS Module supports the

following FMS Standard versions:

FMS - Standard Interface

description Vers. 02 (available on

http://www.fms-standard.com/Truck/

index.htm)

Bus FMS - Standard Interface

description Vers. 02 (available

onhttp://www.fms-standard.com/Bus/

index.htm)

We advise having the Gateway FMS

Module installed by the Fiat Dealership

or specialist technicians. The fitting

instructions are in the Fitters/Installers

Manual on the HYPERLINK website

"http://www.fiatprofessional-

converters.com"www.fiatprofessional-

converters.com.The following table shows all signals

available to control units interfaced with

the Gateway FMS Module.

171

Page 174 of 304

Message Signal Description

CCVSParking Brake Switch Indicates parking brake engaged

Wheel based speed Indicates vehicle speed

Clutch switch Indicates clutch pedal pressed

Brake switch Indicates brake pedal pressed

Cruise control active Indicates Cruise Control active

EEC2Accelerator pedal position 1 Indicates accelerator pedal position

Engine Percent Load At Current SpeedIndicates percentage ratio between engine torque and

maximum indicated torque at current engine speed

LFC Engine total fuel used Indicates total fuel used during vehicle operation

DD Fuel Level Indicates ratio of fuel volume to total tank volume

EEC1 Engine speed Indicates engine speed

VDHR High resolution total vehicle distance Indicates total vehicle distance travelled

ET1 Engine coolant temperature Indicates temperature of engine coolant

AMB Ambient Air Temperature Indicates temperature outside of vehicle

LFEFuel Rate Indicates quantity of fuel used by engine per time unit

Instantaneous Fuel EconomyIndicates ratio between quantity of fuel used and

current vehicle speed

SERV Service distanceIndicates distance that can be travelled by vehicle

before scheduled servicing

HOURS Total engine hours Indicates total engine operating time

DC1 Position of doors Indicates current door status

AS Alternator Status 1 Indicates current alternator status

172

IN AN EMERGENCY

Page 175 of 304

Message Signal Description

ETC2Selected Gear(1)Indicates next awaited gear

Current Gear

(1)Indicates current gear

TDMinutes Indicates minutes

Hours Indicates hours

Month Indicates month

Day Indicates day

Year Indicates year

(1) Available on vehicle versions with Comfort-Matic transmission

173

Page 176 of 304

Message Signal Description

FMS1(2)

High beam, main beam Indicates active main beam headlight status

Low beam Indicates active dipped headlight status

Turn signals Indicates active direction indicator status

Hazard warning Indicates active hazard warning light status

Parking Brake Indicates parking brake engaged

Brake failure / brake system malfunction Indicates braking system fault

Hatch open Indicates rear door not shut

Fuel level Indicates fuel reserve warning light on

Engine coolant temperature Indicates engine coolant overheating warning light on

Battery charging condition Indicates insufficient battery charge warning light on

Engine oilIndicates insufficient engine oil pressure warning light

on

Position lights, side lights Indicates active side light status

Front fog lights Indicates active fog light status

Rear fog light Indicates active rear fog light status

Engine / Mil indicatorIndicates EOBD/injection system failure warning light

on

Service, call for maintenance Indicates scheduled service indicator displayed

Transmission failure / malfunction Indicates transmission system fault

Anti-lock brake system failure Indicates ABS failure warning light on

(2) The signal values are derived from information shown on the instrument panel

174

IN AN EMERGENCY

Page 177 of 304

Message Signal Description

FMS1(2)

Worn brake linings Indicates brake pad wear warning light on

Malfunction / general failure Indicates general failure warning light on

Height Control (Levelling) Indicates self-levelling suspension indicator displayed

Engine Emission system failure (Mil indicator) Indicates particulate filter blocked warning light on

ESC indication Indicates stability control warning light on

TC01

Tachogr. vehicle speed

(3)Indicates vehicle speed stored by chronotachograph

DC2Open Status Door 1 Indicates driver door status

Open Status Door 2 Indicates passenger door status

Open Status Door 3

(4)Indicates rear door(s) status

Open Status Door 4

(4)Indicates sliding side door status

Open Status Door 5

(4)Indicates sliding side door status

FMSRequests supportedIndicates whether Gateway FMS Module can respond

to requests from external FMS module

Diagnostics supportedIndicates whether Gateway FMS Module supports

requests for sending diagnosis information

FMS-standard SW - version supportedIndicates the FMS Standard version supported by the

Gateway FMS Module

(2) The signal values are derived from information shown on the instrument panel

(3) The vehicle speed signal is still available even if there is no chronotachograph

(4) If the content is not present, the signal value transmitted is ‘closed’

175

Page 178 of 304

CHANGING A WHEEL

GENERAL

INSTRUCTIONS

Wheel replacement and correct use of

the jack and spare wheel (for

versions/markets, where provided) call

for some precautions, which are listed

below.

146) 147) 148) 149) 150)

Please note that:

the jack weight is 4.5 kg;

the jack requires no adjustment;

the jack cannot be repaired: in the

event of a fault it must be replaced

by another original one;

no tool other than its cranking

device may be fitted on the jack.

151)

To change a wheel, proceed as

follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground must be flat and sufficiently

compact;

switch off the engine and pull the

handbrake;

engage first gear or reverse;

put on the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

in the event of a wheel change on a

slope or on unsurfaced roads, put

any object as stop under the wheels;

take the tool bag from under the

passenger seat (see "Compartment

under the front passenger side seat" in

the "Internal equipment" chapter in

"Knowing the vehicle").

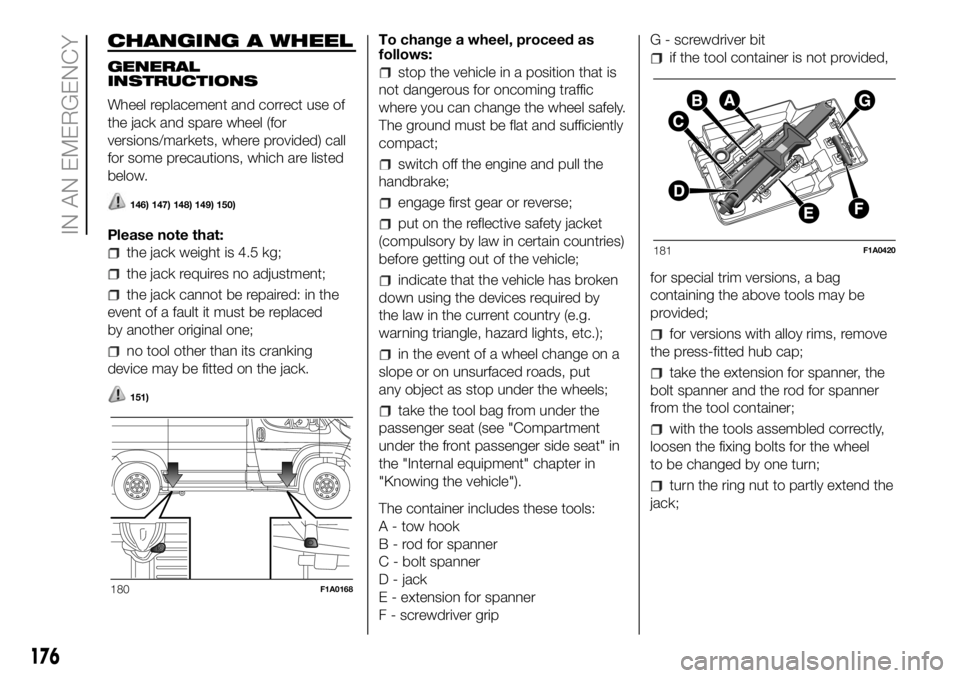

The container includes these tools:

A - tow hook

B - rod for spanner

C - bolt spanner

D - jack

E - extension for spanner

F - screwdriver gripG - screwdriver bit

if the tool container is not provided,

for special trim versions, a bag

containing the above tools may be

provided;

for versions with alloy rims, remove

the press-fitted hub cap;

take the extension for spanner, the

bolt spanner and the rod for spanner

from the tool container;

with the tools assembled correctly,

loosen the fixing bolts for the wheel

to be changed by one turn;

turn the ring nut to partly extend the

jack;

180F1A0168

181F1A0420

176

IN AN EMERGENCY

Page 179 of 304

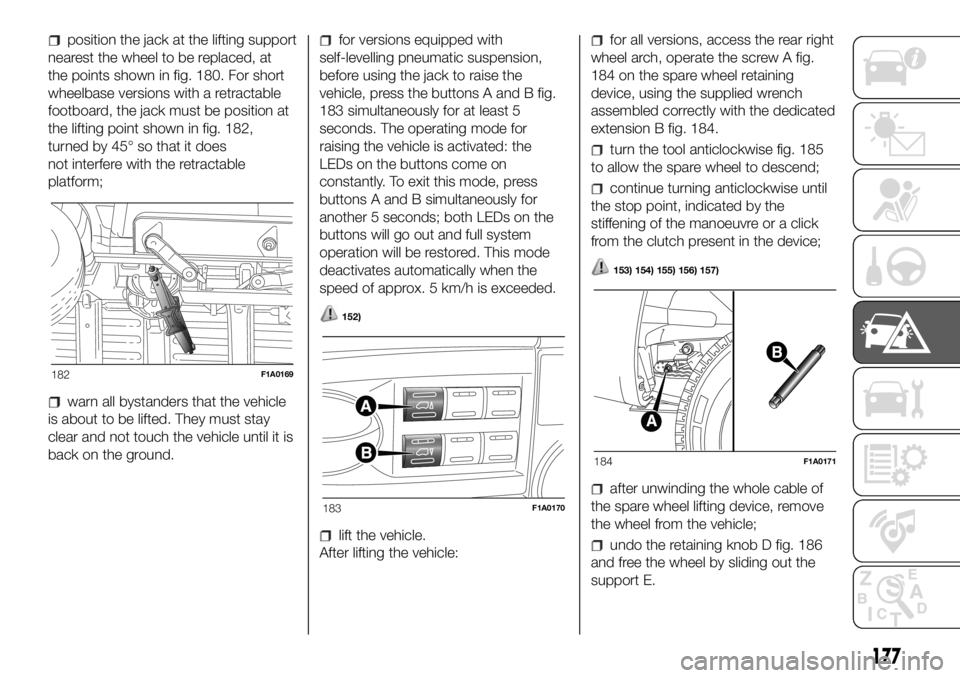

position the jack at the lifting support

nearest the wheel to be replaced, at

the points shown in fig. 180. For short

wheelbase versions with a retractable

footboard, the jack must be position at

the lifting point shown in fig. 182,

turned by 45° so that it does

not interfere with the retractable

platform;

warn all bystanders that the vehicle

is about to be lifted. They must stay

clear and not touch the vehicle until it is

back on the ground.

for versions equipped with

self-levelling pneumatic suspension,

before using the jack to raise the

vehicle, press the buttons A and B fig.

183 simultaneously for at least 5

seconds. The operating mode for

raising the vehicle is activated: the

LEDs on the buttons come on

constantly. To exit this mode, press

buttons A and B simultaneously for

another 5 seconds; both LEDs on the

buttons will go out and full system

operation will be restored. This mode

deactivates automatically when the

speed of approx. 5 km/h is exceeded.

152)

lift the vehicle.

After lifting the vehicle:

for all versions, access the rear right

wheel arch, operate the screw A fig.

184 on the spare wheel retaining

device, using the supplied wrench

assembled correctly with the dedicated

extension B fig. 184.

turn the tool anticlockwise fig. 185

to allow the spare wheel to descend;

continue turning anticlockwise until

the stop point, indicated by the

stiffening of the manoeuvre or a click

from the clutch present in the device;

153) 154) 155) 156) 157)

after unwinding the whole cable of

the spare wheel lifting device, remove

the wheel from the vehicle;

undo the retaining knob D fig. 186

and free the wheel by sliding out the

support E.

182F1A0169

183F1A0170

184F1A0171

177

Page 180 of 304

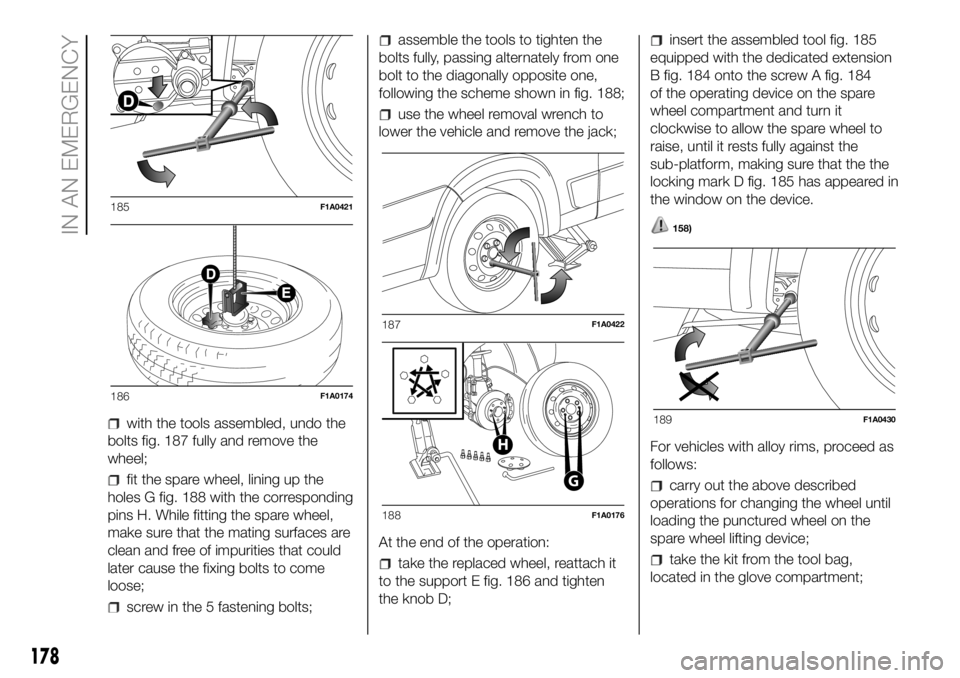

with the tools assembled, undo the

bolts fig. 187 fully and remove the

wheel;

fit the spare wheel, lining up the

holes G fig. 188 with the corresponding

pins H. While fitting the spare wheel,

make sure that the mating surfaces are

clean and free of impurities that could

later cause the fixing bolts to come

loose;

screw in the 5 fastening bolts;

assemble the tools to tighten the

bolts fully, passing alternately from one

bolt to the diagonally opposite one,

following the scheme shown in fig. 188;

use the wheel removal wrench to

lower the vehicle and remove the jack;

At the end of the operation:

take the replaced wheel, reattach it

to the support E fig. 186 and tighten

the knob D;

insert the assembled tool fig. 185

equipped with the dedicated extension

B fig. 184 onto the screw A fig. 184

of the operating device on the spare

wheel compartment and turn it

clockwise to allow the spare wheel to

raise, until it rests fully against the

sub-platform, making sure that the the

locking mark D fig. 185 has appeared in

the window on the device.

158)

For vehicles with alloy rims, proceed as

follows:

carry out the above described

operations for changing the wheel until

loading the punctured wheel on the

spare wheel lifting device;

take the kit from the tool bag,

located in the glove compartment;

185F1A0421

186F1A0174

187F1A0422

G

H

188F1A0176

189F1A0430

178

IN AN EMERGENCY