FIAT DUCATO BASE CAMPER 2018 Owner handbook (in English)

Manufacturer: FIAT, Model Year: 2018, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2018Pages: 304, PDF Size: 14.93 MB

Page 211 of 304

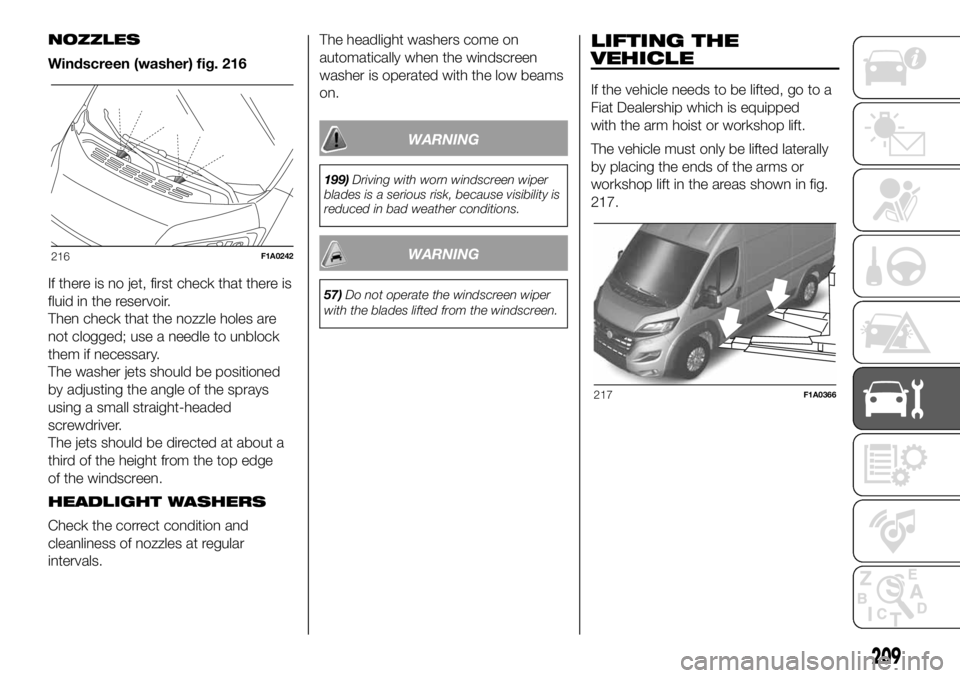

NOZZLES

Windscreen (washer) fig. 216

If there is no jet, first check that there is

fluid in the reservoir.

Then check that the nozzle holes are

not clogged; use a needle to unblock

them if necessary.

The washer jets should be positioned

by adjusting the angle of the sprays

using a small straight-headed

screwdriver.

The jets should be directed at about a

third of the height from the top edge

of the windscreen.

HEADLIGHT WASHERS

Check the correct condition and

cleanliness of nozzles at regular

intervals.The headlight washers come on

automatically when the windscreen

washer is operated with the low beams

on.

WARNING

199)Driving with worn windscreen wiper

blades is a serious risk, because visibility is

reduced in bad weather conditions.

WARNING

57)Do not operate the windscreen wiper

with the blades lifted from the windscreen.

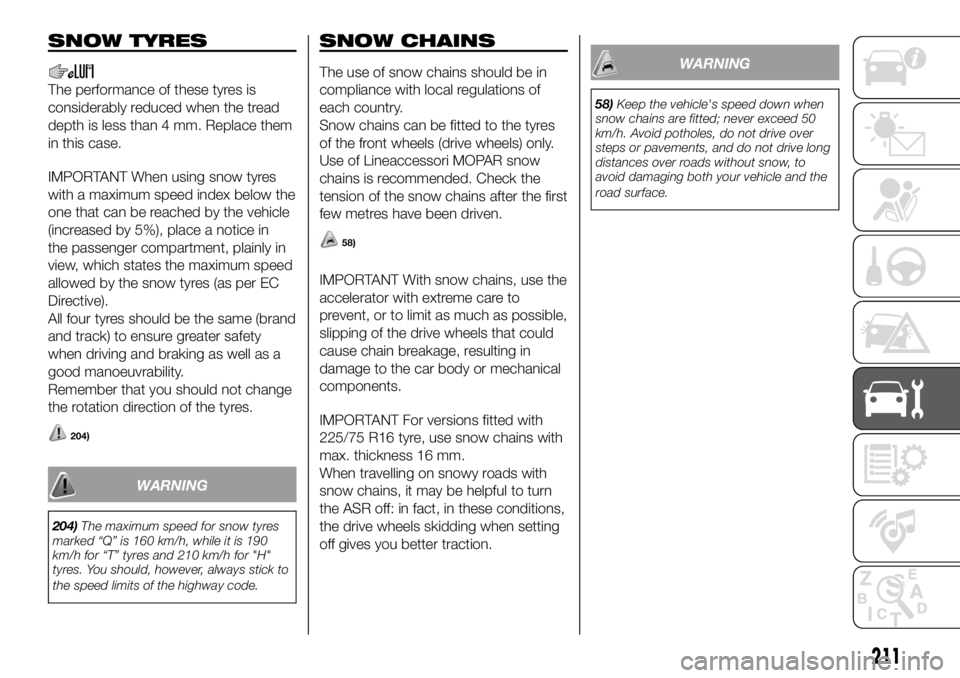

LIFTING THE

VEHICLE

If the vehicle needs to be lifted, go to a

Fiat Dealership which is equipped

with the arm hoist or workshop lift.

The vehicle must only be lifted laterally

by placing the ends of the arms or

workshop lift in the areas shown in fig.

217.

216F1A0242

217F1A0366

209

Page 212 of 304

WHEELS AND TYRES

Check the pressure of each tyre,

including the space-saver wheel,

approximately every two weeks and

before long journeys: the pressure

should be checked with the tyre rested

and cold.

It is normal for the pressure to increase

when the vehicle is used; for the correct

tyre inflation pressure, see “Wheels” in

the “Technical specifications” section.

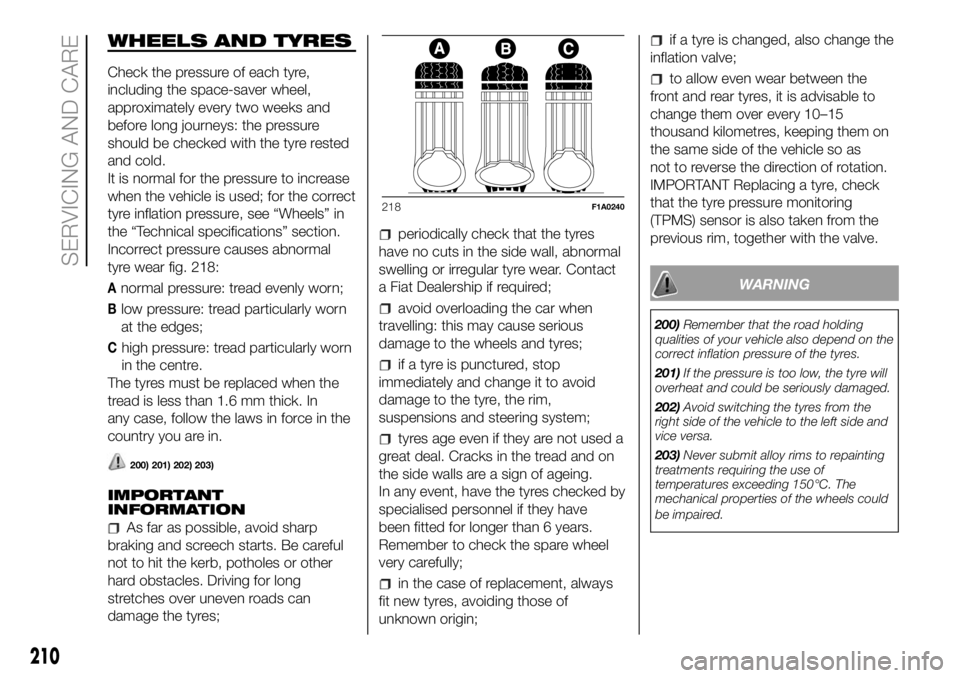

Incorrect pressure causes abnormal

tyre wear fig. 218:

Anormal pressure: tread evenly worn;

Blow pressure: tread particularly worn

at the edges;

Chigh pressure: tread particularly worn

in the centre.

The tyres must be replaced when the

tread is less than 1.6 mm thick. In

any case, follow the laws in force in the

country you are in.

200) 201) 202) 203)

IMPORTANT

INFORMATION

As far as possible, avoid sharp

braking and screech starts. Be careful

not to hit the kerb, potholes or other

hard obstacles. Driving for long

stretches over uneven roads can

damage the tyres;

periodically check that the tyres

have no cuts in the side wall, abnormal

swelling or irregular tyre wear. Contact

a Fiat Dealership if required;

avoid overloading the car when

travelling: this may cause serious

damage to the wheels and tyres;

if a tyre is punctured, stop

immediately and change it to avoid

damage to the tyre, the rim,

suspensions and steering system;

tyres age even if they are not used a

great deal. Cracks in the tread and on

the side walls are a sign of ageing.

In any event, have the tyres checked by

specialised personnel if they have

been fitted for longer than 6 years.

Remember to check the spare wheel

very carefully;

in the case of replacement, always

fit new tyres, avoiding those of

unknown origin;

if a tyre is changed, also change the

inflation valve;

to allow even wear between the

front and rear tyres, it is advisable to

change them over every 10–15

thousand kilometres, keeping them on

the same side of the vehicle so as

not to reverse the direction of rotation.

IMPORTANT Replacing a tyre, check

that the tyre pressure monitoring

(TPMS) sensor is also taken from the

previous rim, together with the valve.

WARNING

200)Remember that the road holding

qualities of your vehicle also depend on the

correct inflation pressure of the tyres.

201)If the pressure is too low, the tyre will

overheat and could be seriously damaged.

202)Avoid switching the tyres from the

right side of the vehicle to the left side and

vice versa.

203)Never submit alloy rims to repainting

treatments requiring the use of

temperatures exceeding 150°C. The

mechanical properties of the wheels could

be impaired.

218F1A0240

210

SERVICING AND CARE

Page 213 of 304

SNOW TYRES

The performance of these tyres is

considerably reduced when the tread

depth is less than 4 mm. Replace them

in this case.

IMPORTANT When using snow tyres

with a maximum speed index below the

one that can be reached by the vehicle

(increased by 5%), place a notice in

the passenger compartment, plainly in

view, which states the maximum speed

allowed by the snow tyres (as per EC

Directive).

All four tyres should be the same (brand

and track) to ensure greater safety

when driving and braking as well as a

good manoeuvrability.

Remember that you should not change

the rotation direction of the tyres.

204)

WARNING

204)The maximum speed for snow tyres

marked “Q” is 160 km/h, while it is 190

km/h for “T” tyres and 210 km/h for "H"

tyres. You should, however, always stick to

the speed limits of the highway code.

SNOW CHAINS

The use of snow chains should be in

compliance with local regulations of

each country.

Snow chains can be fitted to the tyres

of the front wheels (drive wheels) only.

Use of Lineaccessori MOPAR snow

chains is recommended. Check the

tension of the snow chains after the first

few metres have been driven.

58)

IMPORTANT With snow chains, use the

accelerator with extreme care to

prevent, or to limit as much as possible,

slipping of the drive wheels that could

cause chain breakage, resulting in

damage to the car body or mechanical

components.

IMPORTANT For versions fitted with

225/75 R16 tyre, use snow chains with

max. thickness 16 mm.

When travelling on snowy roads with

snow chains, it may be helpful to turn

the ASR off: in fact, in these conditions,

the drive wheels skidding when setting

off gives you better traction.

WARNING

58)Keep the vehicle's speed down when

snow chains are fitted; never exceed 50

km/h. Avoid potholes, do not drive over

steps or pavements, and do not drive long

distances over roads without snow, to

avoid damaging both your vehicle and the

road surface.

211

Page 214 of 304

BODYWORK

PROTECTION AGAINST

ATMOSPHERIC AGENTS

The main causes of corrosion are the

following:

atmospheric pollution;

salty air and humidity (coastal areas,

or hot humid climates);

seasonal environmental conditions.

ADVICE FOR

PRESERVING THE

BODYWORK

Paintwork

Paintwork does not only serve an

aesthetic purpose, but also protects the

underlying sheet metal.

Touch up abrasions and scratches

immediately to prevent rust formation.

Use only original paint products for

touch-ups (see “Bodywork paint

identification plate” in the “Technical

specifications” section).

Normal maintenance of paintwork

consists in washing the car: the

frequency depends on the conditions

and environment where the car is used.

For example, it is advisable to wash

the vehicle more often in areas with

high levels of environmental pollution or

on roads spread with salt.To correctly wash the vehicle, proceed

as follows:

wash the bodywork using a low

pressure jet of water;

wipe a sponge with a slightly soapy

solution over the bodywork, frequently

rinsing the sponge;

rinse well with water and dry with a

jet of air or a chamois leather.

If you put the vehicle through a car

wash, follow these recommendations:

remove the aerial from the roof

so it does not get damaged;

the vehicle should be washed with

water added to a soapy solution;

rinse thoroughly to avoid soap

marks remaining on the bodywork or

less visible parts.

Windows

To clean glasses, use specific cleaning

products. Use clean cloths to avoid

scratching the glass or altering the

transparency.

IMPORTANT Wipe the rear window

inside gently with a cloth following the

direction of the filaments to avoid

damaging the heating device.Front headlights

IMPORTANT Never use aromatic

substances (e.g. petrol) or ketones (e.g.

acetone) for cleaning the plastic lenses

of the headlights.

59)

6)

WARNING

59)Some automatic systems equipped

with old generation blades and/or with

a poor maintenance can damage the paint,

promoting the creation of microscoring

which give an opaque/coated appearance

to the paint, especially on dark colours.

In this case, just lightly polish with specific

products.

WARNING

6)Detergents pollute the water. The

vehicle should be washed in areas

equipped for collecting and purifying the

liquid used in the washing process.

212

SERVICING AND CARE

Page 215 of 304

INTERIOR

Regularly check that water is not

trapped under the mats (due to water

dripping off shoes, umbrellas, etc.),

as this could cause oxidation of the

sheet metal.

205) 206)

SEATS AND FABRIC

PARTS

Remove dust with a soft brush or a

vacuum cleaner. It is advisable to use a

moist brush on velvet upholstery.

Rub the seats with a sponge moistened

with a solution of water and neutral

detergent.

PLASTIC PARTS

It is advisable to clean interior plastic

parts with a moist cloth and a solution

of water and non-abrasive mild soap.

Use specific products for cleaning

plastic, without solvents and specifically

designed to prevent damage to the

appearance and colour of the treated

parts, to remove grease and tough

stains.

IMPORTANT Do not use alcohol,

petrols or derivatives to clean

the instrument panel glass.LEATHER STEERING

WHEEL/GEAR LEVER

KNOB/HANDBRAKE

(for versions/markets, where provided)

These components must be cleaned

with mild soap and water only. Never

use alcohol or alcohol-based products.

WARNING

205)Never use flammable products, such

as petroleum ether or modified petrol, to

clean the inside of the car. The

electrostatic charges which are generated

by rubbing during the cleaning operation

may cause a fire.

206)Do not keep aerosol cans in the

vehicle: they might explode. Aerosol cans

must not be exposed to a temperature

exceeding 50°C. When the vehicle is

exposed to sunlight, the internal

temperature can greatly exceed this value.

RUBBER HOSES

As far as the brake system and fuel

supply system rubber hoses are

concerned, follow the "Scheduled

Servicing Plan" in this chapter carefully.

Ozone, high temperatures and

prolonged lack of fluid in the system

may cause hardening and cracking of

the hoses, with possible leaks. Careful

checking is therefore necessary.

213

Page 216 of 304

TECHNICAL DATA

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.IDENTIFICATION DATA....................215

ENGINE CODES - BODYWORK

VERSION ........................................217

ENGINE ..........................................219

STEERING SYSTEM .......................222

WHEELS .........................................223

DIMENSIONS ..................................227

PERFORMANCE .............................237

WEIGHTS AND LOADS...................240

REFUELLING ..................................243

FLUIDS AND LUBRICANTS ............248

FUEL CONSUMPTION ....................251

CO2 EMISSIONS ...........................258

214

TECHNICAL DATA

Page 217 of 304

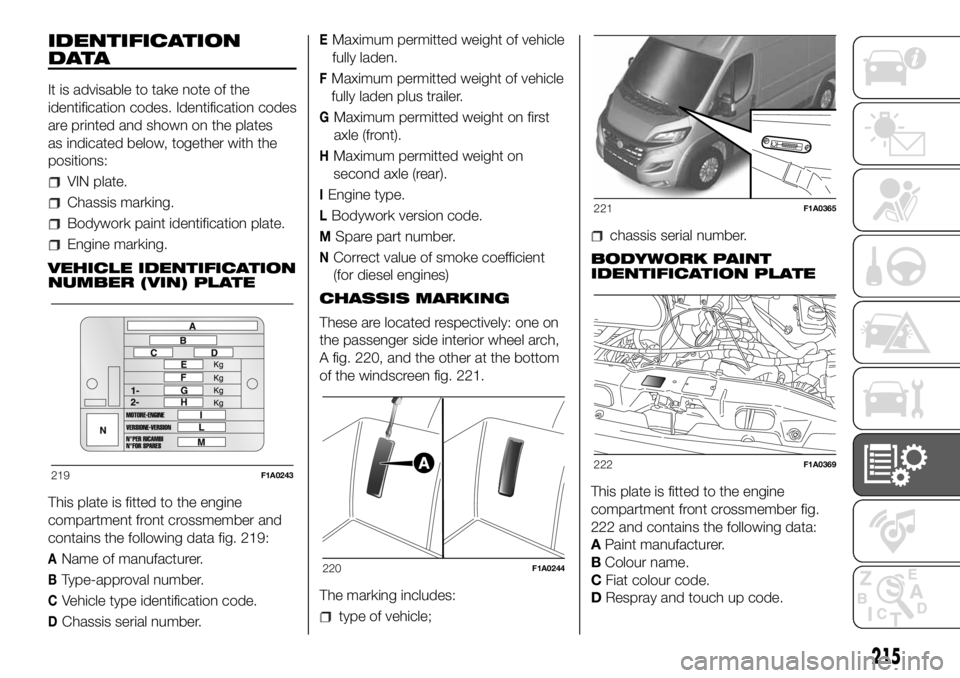

IDENTIFICATION

DATA

It is advisable to take note of the

identification codes. Identification codes

are printed and shown on the plates

as indicated below, together with the

positions:

VIN plate.

Chassis marking.

Bodywork paint identification plate.

Engine marking.

VEHICLE IDENTIFICATION

NUMBER (VIN) PLATE

This plate is fitted to the engine

compartment front crossmember and

contains the following data fig. 219:

AName of manufacturer.

BType-approval number.

CVehicle type identification code.

DChassis serial number.

EMaximum permitted weight of vehicle

fully laden.

FMaximum permitted weight of vehicle

fully laden plus trailer.

GMaximum permitted weight on first

axle (front).

HMaximum permitted weight on

second axle (rear).

IEngine type.

LBodywork version code.

MSpare part number.

NCorrect value of smoke coefficient

(for diesel engines)

CHASSIS MARKING

These are located respectively: one on

the passenger side interior wheel arch,

A fig. 220, and the other at the bottom

of the windscreen fig. 221.

The marking includes:

type of vehicle;

chassis serial number.

BODYWORK PAINT

IDENTIFICATION PLATE

This plate is fitted to the engine

compartment front crossmember fig.

222 and contains the following data:

APaint manufacturer.

BColour name.

CFiat colour code.

DRespray and touch up code.

219F1A0243

220F1A0244

221F1A0365

222F1A0369

215

Page 218 of 304

ENGINE MARKING

It is stamped on the cylinder block and

includes the type and the engine serial

number.

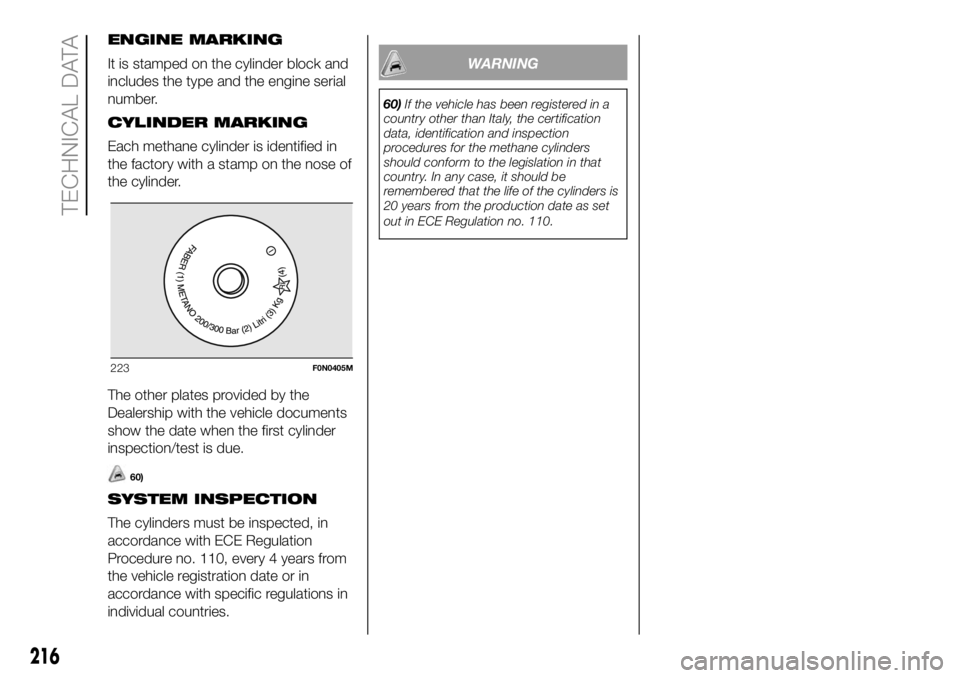

CYLINDER MARKING

Each methane cylinder is identified in

the factory with a stamp on the nose of

the cylinder.

The other plates provided by the

Dealership with the vehicle documents

show the date when the first cylinder

inspection/test is due.

60)

SYSTEM INSPECTION

The cylinders must be inspected, in

accordance with ECE Regulation

Procedure no. 110, every 4 years from

the vehicle registration date or in

accordance with specific regulations in

individual countries.

WARNING

60)If the vehicle has been registered in a

country other than Italy, the certification

data, identification and inspection

procedures for the methane cylinders

should conform to the legislation in that

country. In any case, it should be

remembered that the life of the cylinders is

20 years from the production date as set

out in ECE Regulation no. 110.

223F0N0405M

216

TECHNICAL DATA

Page 219 of 304

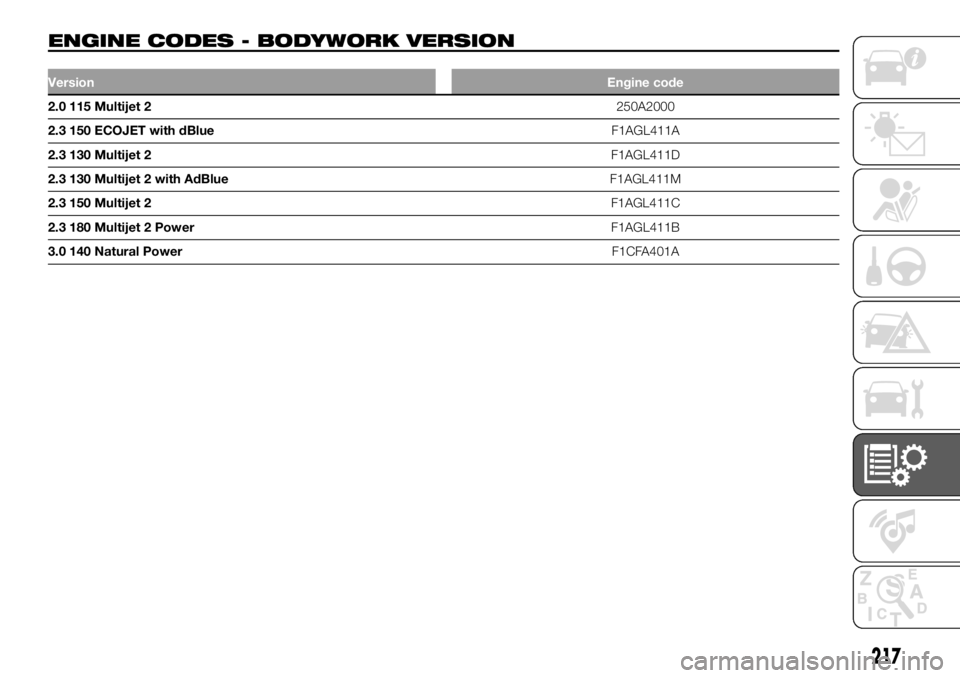

ENGINE CODES - BODYWORK VERSION.

VersionEngine code

2.0 115 Multijet 2250A2000

2.3 150 ECOJET with dBlueF1AGL411A

2.3 130 Multijet 2F1AGL411D

2.3 130 Multijet 2 with AdBlueF1AGL411M

2.3 150 Multijet 2F1AGL411C

2.3 180 Multijet 2 PowerF1AGL411B

3.0 140 Natural PowerF1CFA401A

217

Page 220 of 304

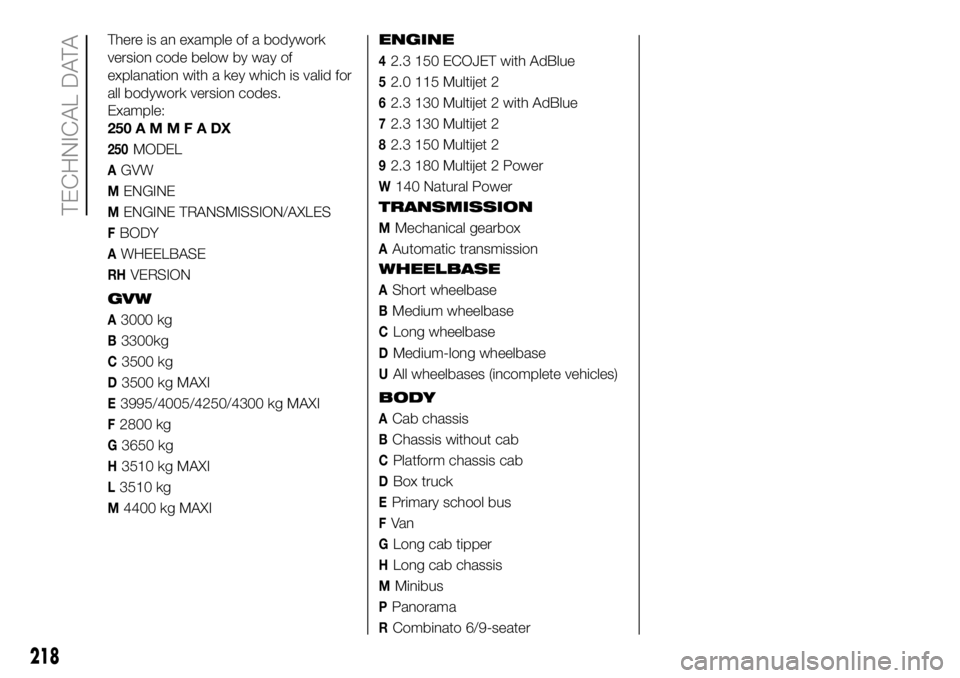

There is an example of a bodywork

version code below by way of

explanation with a key which is valid for

all bodywork version codes.

Example:

250AMMFADX

250MODEL

AGVW

MENGINE

MENGINE TRANSMISSION/AXLES

FBODY

AWHEELBASE

RHVERSION

GVW

A3000 kg

B3300kg

C3500 kg

D3500 kg MAXI

E3995/4005/4250/4300 kg MAXI

F2800 kg

G3650 kg

H3510 kg MAXI

L3510 kg

M4400 kg MAXIENGINE

42.3 150 ECOJET with AdBlue

52.0 115 Multijet 2

62.3 130 Multijet 2 with AdBlue

72.3 130 Multijet 2

82.3 150 Multijet 2

92.3 180 Multijet 2 Power

W140 Natural Power

TRANSMISSION

MMechanical gearbox

AAutomatic transmission

WHEELBASE

AShort wheelbase

BMedium wheelbase

CLong wheelbase

DMedium-long wheelbase

UAll wheelbases (incomplete vehicles)

BODY

ACab chassis

BChassis without cab

CPlatform chassis cab

DBox truck

EPrimary school bus

FVa n

GLong cab tipper

HLong cab chassis

MMinibus

PPanorama

RCombinato 6/9-seater

218

TECHNICAL DATA