FIAT FIORINO 2018 Owner handbook (in English)

Manufacturer: FIAT, Model Year: 2018, Model line: FIORINO, Model: FIAT FIORINO 2018Pages: 196, PDF Size: 4.99 MB

Page 101 of 196

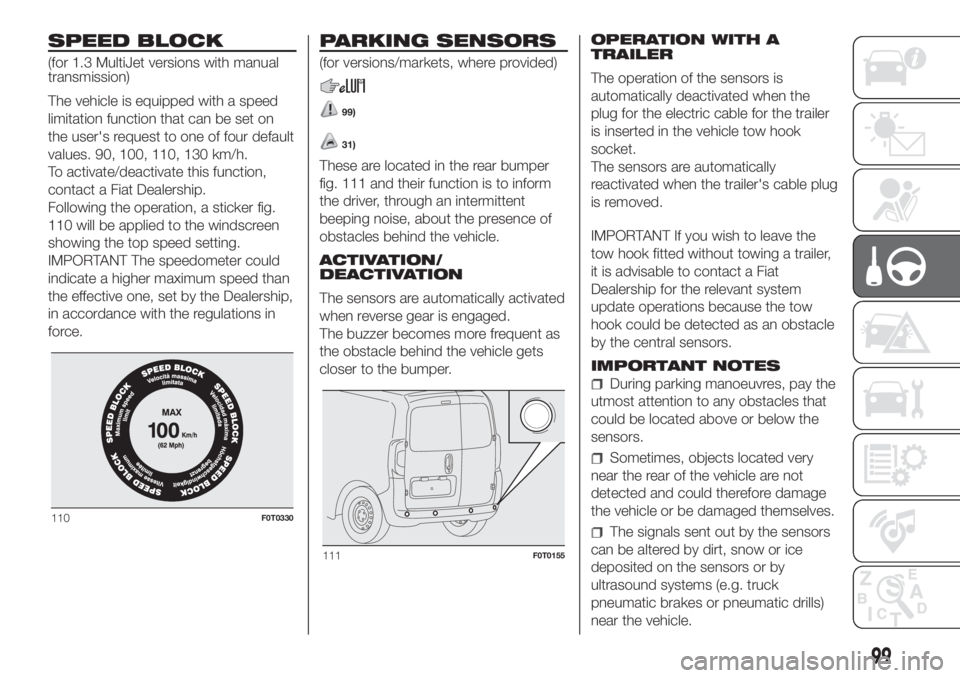

SPEED BLOCK

(for 1.3 MultiJet versions with manual

transmission)

The vehicle is equipped with a speed

limitation function that can be set on

the user's request to one of four default

values. 90, 100, 110, 130 km/h.

To activate/deactivate this function,

contact a Fiat Dealership.

Following the operation, a sticker fig.

110 will be applied to the windscreen

showing the top speed setting.

IMPORTANT The speedometer could

indicate a higher maximum speed than

the effective one, set by the Dealership,

in accordance with the regulations in

force.

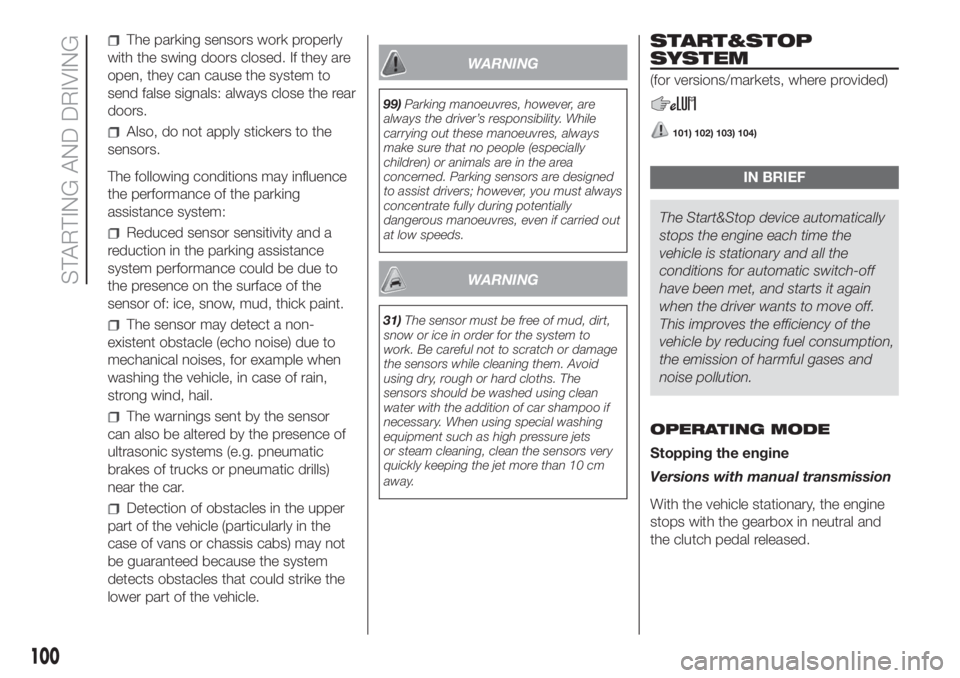

PARKING SENSORS

(for versions/markets, where provided)

99)

31)

These are located in the rear bumper

fig. 111 and their function is to inform

the driver, through an intermittent

beeping noise, about the presence of

obstacles behind the vehicle.

ACTIVATION/

DEACTIVATION

The sensors are automatically activated

when reverse gear is engaged.

The buzzer becomes more frequent as

the obstacle behind the vehicle gets

closer to the bumper.OPERATION WITH A

TRAILER

The operation of the sensors is

automatically deactivated when the

plug for the electric cable for the trailer

is inserted in the vehicle tow hook

socket.

The sensors are automatically

reactivated when the trailer's cable plug

is removed.

IMPORTANT If you wish to leave the

tow hook fitted without towing a trailer,

it is advisable to contact a Fiat

Dealership for the relevant system

update operations because the tow

hook could be detected as an obstacle

by the central sensors.

IMPORTANT NOTES

During parking manoeuvres, pay the

utmost attention to any obstacles that

could be located above or below the

sensors.

Sometimes, objects located very

near the rear of the vehicle are not

detected and could therefore damage

the vehicle or be damaged themselves.

The signals sent out by the sensors

can be altered by dirt, snow or ice

deposited on the sensors or by

ultrasound systems (e.g. truck

pneumatic brakes or pneumatic drills)

near the vehicle.110F0T0330

111F0T0155

99

Page 102 of 196

The parking sensors work properly

with the swing doors closed. If they are

open, they can cause the system to

send false signals: always close the rear

doors.

Also, do not apply stickers to the

sensors.

The following conditions may influence

the performance of the parking

assistance system:

Reduced sensor sensitivity and a

reduction in the parking assistance

system performance could be due to

the presence on the surface of the

sensor of: ice, snow, mud, thick paint.

The sensor may detect a non-

existent obstacle (echo noise) due to

mechanical noises, for example when

washing the vehicle, in case of rain,

strong wind, hail.

The warnings sent by the sensor

can also be altered by the presence of

ultrasonic systems (e.g. pneumatic

brakes of trucks or pneumatic drills)

near the car.

Detection of obstacles in the upper

part of the vehicle (particularly in the

case of vans or chassis cabs) may not

be guaranteed because the system

detects obstacles that could strike the

lower part of the vehicle.

WARNING

99)Parking manoeuvres, however, are

always the driver’s responsibility. While

carrying out these manoeuvres, always

make sure that no people (especially

children) or animals are in the area

concerned. Parking sensors are designed

to assist drivers; however, you must always

concentrate fully during potentially

dangerous manoeuvres, even if carried out

at low speeds.

WARNING

31)The sensor must be free of mud, dirt,

snow or ice in order for the system to

work. Be careful not to scratch or damage

the sensors while cleaning them. Avoid

using dry, rough or hard cloths. The

sensors should be washed using clean

water with the addition of car shampoo if

necessary. When using special washing

equipment such as high pressure jets

or steam cleaning, clean the sensors very

quickly keeping the jet more than 10 cm

away.

START&STOP

SYSTEM

(for versions/markets, where provided)

101) 102) 103) 104)

IN BRIEF

The Start&Stop device automatically

stops the engine each time the

vehicle is stationary and all the

conditions for automatic switch-off

have been met, and starts it again

when the driver wants to move off.

This improves the efficiency of the

vehicle by reducing fuel consumption,

the emission of harmful gases and

noise pollution.

OPERATING MODE

Stopping the engine

Versions with manual transmission

With the vehicle stationary, the engine

stops with the gearbox in neutral and

the clutch pedal released.

100

STARTING AND DRIVING

Page 103 of 196

Versions with Comfort-matic

transmission

With the vehicle stationary and the

brake pedal pressed, the engine stops

if the gear lever is in position other

thanR. In the event of stops uphill,

engine switching off is disabled to make

the "Hill Holder" function available

(works only with the engine running).

The warning light on the instrument

panel switches on to signal that the

engine has stopped.

Restarting the engine

Versions with manual transmission

Depress the clutch pedal to restart

the engine.

Versions with Comfort-matic

transmission

Releasing the brake pedal the engine

restarts automatically; the icon switches

off on the display. If the engine is

restarted with the “Hill Holder” function

off, move the lever towards (+), (-)or

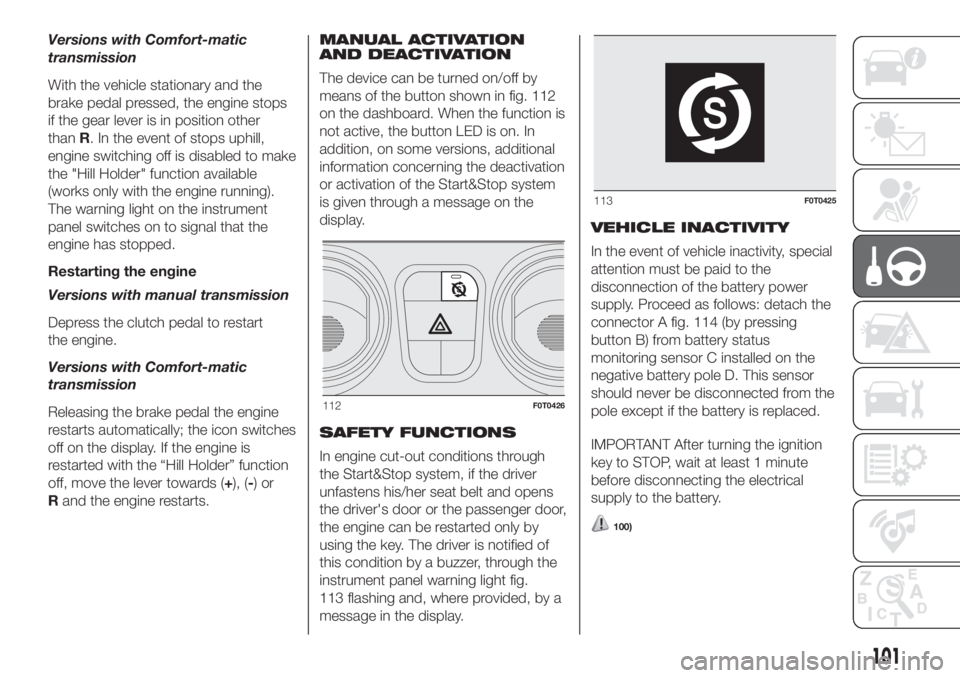

Rand the engine restarts.MANUAL ACTIVATION

AND DEACTIVATION

The device can be turned on/off by

means of the button shown in fig. 112

on the dashboard. When the function is

not active, the button LED is on. In

addition, on some versions, additional

information concerning the deactivation

or activation of the Start&Stop system

is given through a message on the

display.

SAFETY FUNCTIONS

In engine cut-out conditions through

the Start&Stop system, if the driver

unfastens his/her seat belt and opens

the driver's door or the passenger door,

the engine can be restarted only by

using the key. The driver is notified of

this condition by a buzzer, through the

instrument panel warning light fig.

113 flashing and, where provided, by a

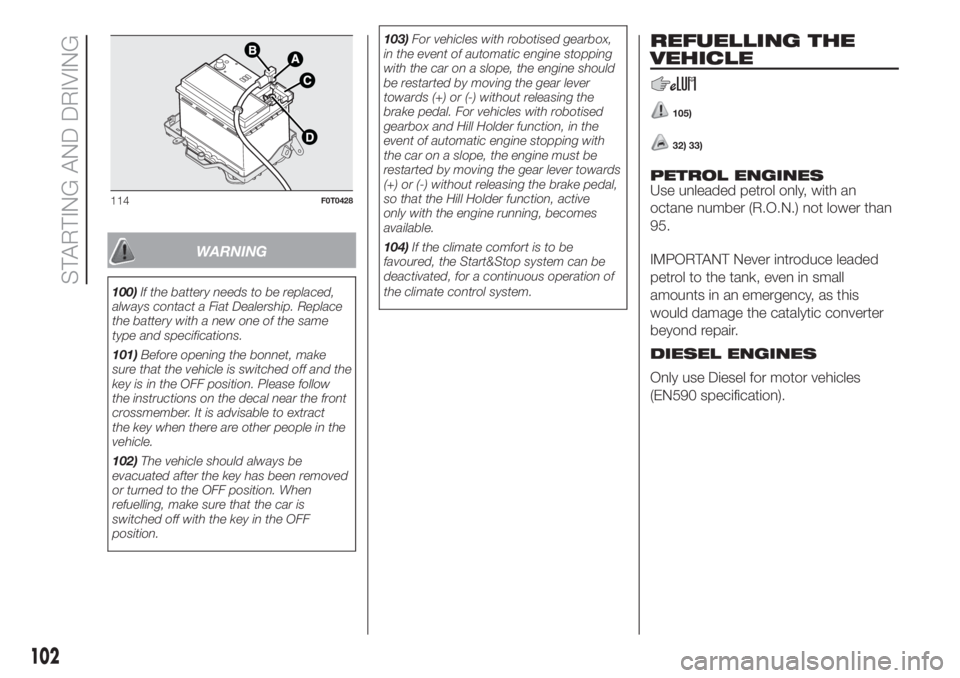

message in the display.VEHICLE INACTIVITY

In the event of vehicle inactivity, special

attention must be paid to the

disconnection of the battery power

supply. Proceed as follows: detach the

connector A fig. 114 (by pressing

button B) from battery status

monitoring sensor C installed on the

negative battery pole D. This sensor

should never be disconnected from the

pole except if the battery is replaced.

IMPORTANT After turning the ignition

key to STOP, wait at least 1 minute

before disconnecting the electrical

supply to the battery.

100)

112F0T0426

113F0T0425

101

Page 104 of 196

WARNING

100)If the battery needs to be replaced,

always contact a Fiat Dealership. Replace

the battery with a new one of the same

type and specifications.

101)Before opening the bonnet, make

sure that the vehicle is switched off and the

key is in the OFF position. Please follow

the instructions on the decal near the front

crossmember. It is advisable to extract

the key when there are other people in the

vehicle.

102)The vehicle should always be

evacuated after the key has been removed

or turned to the OFF position. When

refuelling, make sure that the car is

switched off with the key in the OFF

position.103)For vehicles with robotised gearbox,

in the event of automatic engine stopping

with the car on a slope, the engine should

be restarted by moving the gear lever

towards (+) or (-) without releasing the

brake pedal. For vehicles with robotised

gearbox and Hill Holder function, in the

event of automatic engine stopping with

the car on a slope, the engine must be

restarted by moving the gear lever towards

(+) or (-) without releasing the brake pedal,

so that the Hill Holder function, active

only with the engine running, becomes

available.

104)If the climate comfort is to be

favoured, the Start&Stop system can be

deactivated, for a continuous operation of

the climate control system.

REFUELLING THE

VEHICLE

105)

32) 33)

PETROL ENGINES

Use unleaded petrol only, with an

octane number (R.O.N.) not lower than

95.

IMPORTANT Never introduce leaded

petrol to the tank, even in small

amounts in an emergency, as this

would damage the catalytic converter

beyond repair.

DIESEL ENGINES

Only use Diesel for motor vehicles

(EN590 specification).

114F0T0428

102

STARTING AND DRIVING

Page 105 of 196

Operation at low temperatures

In order to avoid these problems,

different types of diesel are distributed

according to the season: summer type,

winter type and arctic type (cold/

mountain areas). If refuelling with diesel

whose specifications are not suitable

for the usage temperature, it is

advisable to mix PETRONAS

DURANCE DIESEL ART additive in the

proportions shown on the container

with the fuel. Pour the additive into the

tank before the fuel.

When using or parking the vehicle for a

long time in the mountains or cold

areas, it is advisable to refuel using

locally available diesel fuel.

In this case, it is also advisable to keep

the tank over 50% full.

REFUELLING CAPACITY

To ensure that you fill the tank

completely, top up twice after the first

click of the fuel supply gun. Further

top-ups could cause faults in the fuel

feeding system.

FUEL TANK CAP

Opening

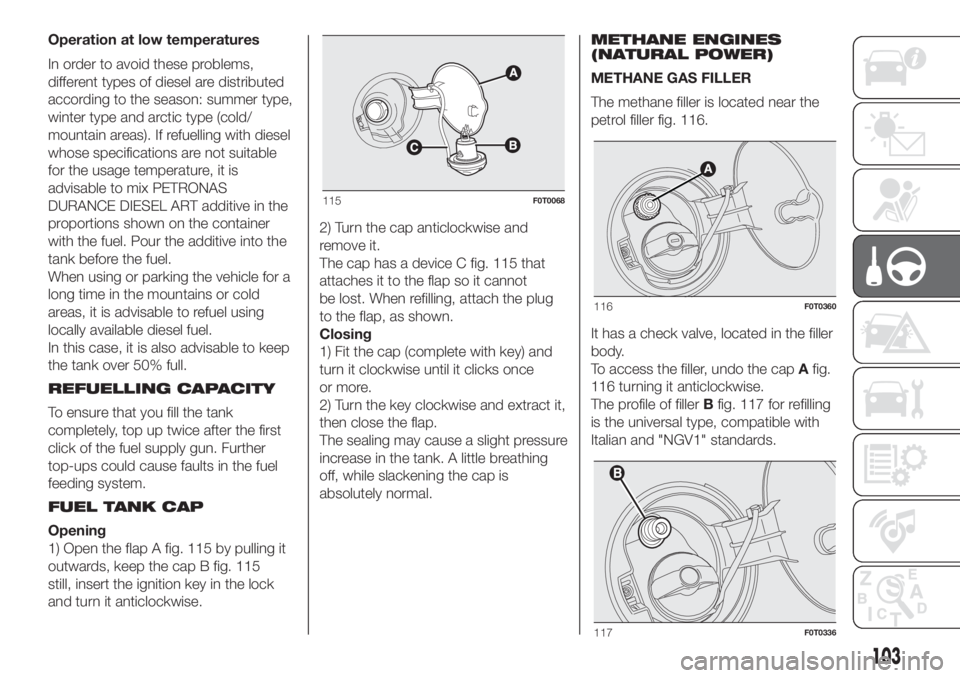

1) Open the flap A fig. 115 by pulling it

outwards, keep the cap B fig. 115

still, insert the ignition key in the lock

and turn it anticlockwise.2) Turn the cap anticlockwise and

remove it.

The cap has a device C fig. 115 that

attaches it to the flap so it cannot

be lost. When refilling, attach the plug

to the flap, as shown.

Closing

1) Fit the cap (complete with key) and

turn it clockwise until it clicks once

or more.

2) Turn the key clockwise and extract it,

then close the flap.

The sealing may cause a slight pressure

increase in the tank. A little breathing

off, while slackening the cap is

absolutely normal.METHANE ENGINES

(NATURAL POWER)

METHANE GAS FILLER

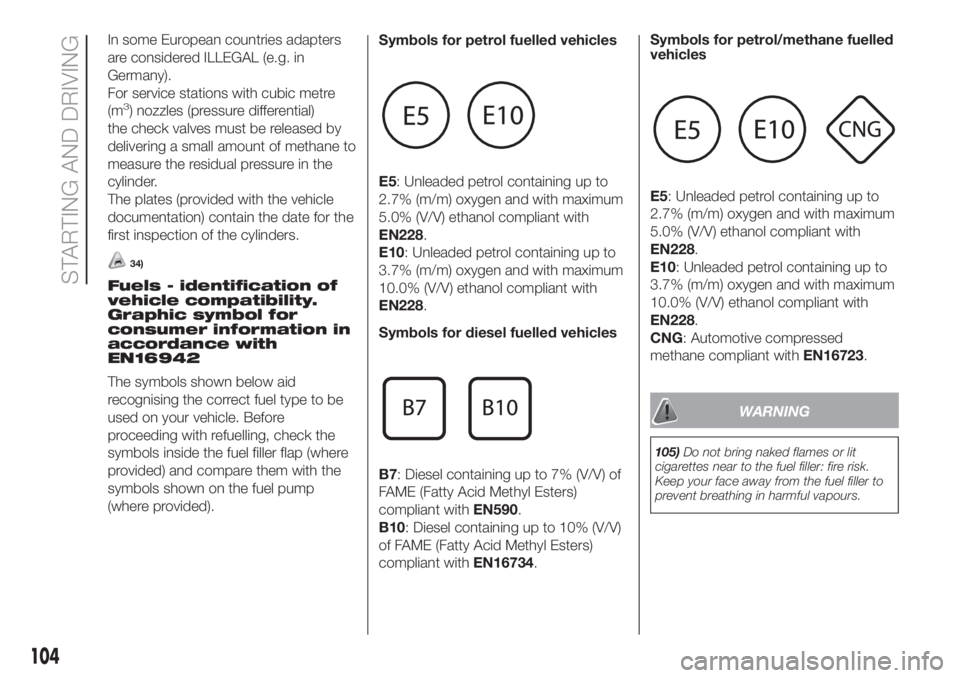

The methane filler is located near the

petrol filler fig. 116.

It has a check valve, located in the filler

body.

To access the filler, undo the capAfig.

116 turning it anticlockwise.

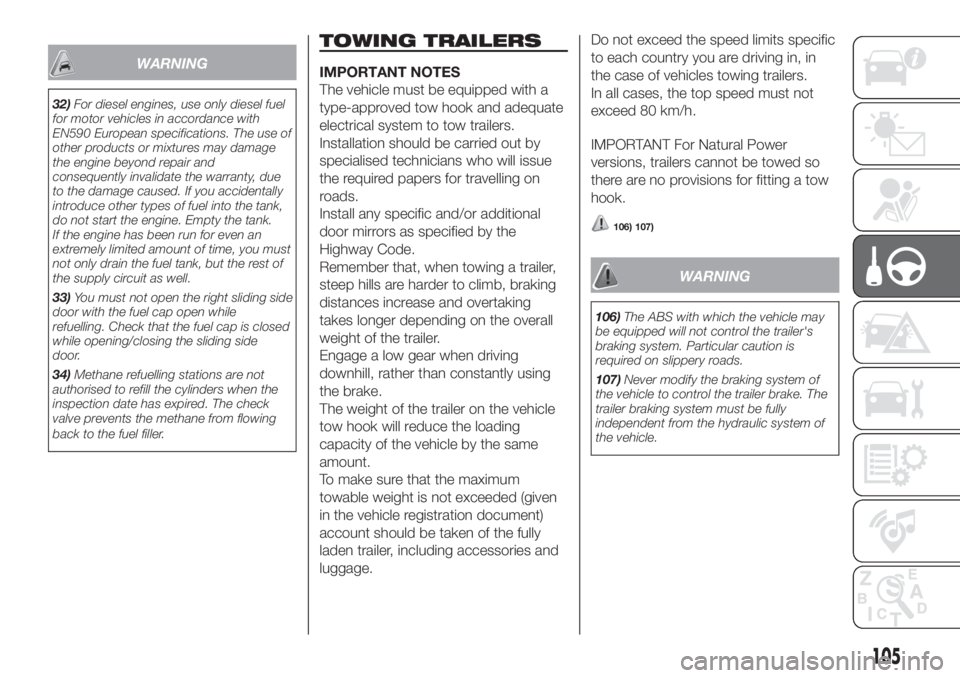

The profile of fillerBfig. 117 for refilling

is the universal type, compatible with

Italian and "NGV1" standards.

115F0T0068

116F0T0360

117F0T0336

103

Page 106 of 196

In some European countries adapters

are considered ILLEGAL (e.g. in

Germany).

For service stations with cubic metre

(m

3) nozzles (pressure differential)

the check valves must be released by

delivering a small amount of methane to

measure the residual pressure in the

cylinder.

The plates (provided with the vehicle

documentation) contain the date for the

first inspection of the cylinders.

34)

Fuels - identification of

vehicle compatibility.

Graphic symbol for

consumer information in

accordance with

EN16942

The symbols shown below aid

recognising the correct fuel type to be

used on your vehicle. Before

proceeding with refuelling, check the

symbols inside the fuel filler flap (where

provided) and compare them with the

symbols shown on the fuel pump

(where provided).Symbols for petrol fuelled vehicles

E5: Unleaded petrol containing up to

2.7% (m/m) oxygen and with maximum

5.0% (V/V) ethanol compliant with

EN228.

E10: Unleaded petrol containing up to

3.7% (m/m) oxygen and with maximum

10.0% (V/V) ethanol compliant with

EN228.

Symbols for diesel fuelled vehicles

B7: Diesel containing up to 7% (V/V) of

FAME (Fatty Acid Methyl Esters)

compliant withEN590.

B10: Diesel containing up to 10% (V/V)

of FAME (Fatty Acid Methyl Esters)

compliant withEN16734.Symbols for petrol/methane fuelled

vehicles

E5: Unleaded petrol containing up to

2.7% (m/m) oxygen and with maximum

5.0% (V/V) ethanol compliant with

EN228.

E10: Unleaded petrol containing up to

3.7% (m/m) oxygen and with maximum

10.0% (V/V) ethanol compliant with

EN228.

CNG: Automotive compressed

methane compliant withEN16723.

WARNING

105)Do not bring naked flames or lit

cigarettes near to the fuel filler: fire risk.

Keep your face away from the fuel filler to

prevent breathing in harmful vapours.

104

STARTING AND DRIVING

Page 107 of 196

WARNING

32)For diesel engines, use only diesel fuel

for motor vehicles in accordance with

EN590 European specifications. The use of

other products or mixtures may damage

the engine beyond repair and

consequently invalidate the warranty, due

to the damage caused. If you accidentally

introduce other types of fuel into the tank,

do not start the engine. Empty the tank.

If the engine has been run for even an

extremely limited amount of time, you must

not only drain the fuel tank, but the rest of

the supply circuit as well.

33)You must not open the right sliding side

door with the fuel cap open while

refuelling. Check that the fuel cap is closed

while opening/closing the sliding side

door.

34)Methane refuelling stations are not

authorised to refill the cylinders when the

inspection date has expired. The check

valve prevents the methane from flowing

back to the fuel filler.

TOWING TRAILERS

IMPORTANT NOTES

The vehicle must be equipped with a

type-approved tow hook and adequate

electrical system to tow trailers.

Installation should be carried out by

specialised technicians who will issue

the required papers for travelling on

roads.

Install any specific and/or additional

door mirrors as specified by the

Highway Code.

Remember that, when towing a trailer,

steep hills are harder to climb, braking

distances increase and overtaking

takes longer depending on the overall

weight of the trailer.

Engage a low gear when driving

downhill, rather than constantly using

the brake.

The weight of the trailer on the vehicle

tow hook will reduce the loading

capacity of the vehicle by the same

amount.

To make sure that the maximum

towable weight is not exceeded (given

in the vehicle registration document)

account should be taken of the fully

laden trailer, including accessories and

luggage.Do not exceed the speed limits specific

to each country you are driving in, in

the case of vehicles towing trailers.

In all cases, the top speed must not

exceed 80 km/h.

IMPORTANT For Natural Power

versions, trailers cannot be towed so

there are no provisions for fitting a tow

hook.

106) 107)

WARNING

106)The ABS with which the vehicle may

be equipped will not control the trailer's

braking system. Particular caution is

required on slippery roads.

107)Never modify the braking system of

the vehicle to control the trailer brake. The

trailer braking system must be fully

independent from the hydraulic system of

the vehicle.

105

Page 108 of 196

IN AN EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere

with our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the toll-free number found

on the Warranty Booklet.

It is also possible to call the 00 800

3428 0000 freephone number to

search the nearest Fiat Dealership.HAZARD WARNING LIGHTS...........107

REPLACING A WHEEL ...................107

FIX & GO AUTOMATIC KIT ..............111

CHANGING A BULB .......................113

REPLACING AN EXTERIOR BULB ..116

REPLACING INTERIOR BULBS ......119

REPLACING FUSES........................120

JUMP STARTING ............................127

FUEL CUT-OFF SYSTEM ................128

TOWING THE VEHICLE ..................128

106

IN AN EMERGENCY

Page 109 of 196

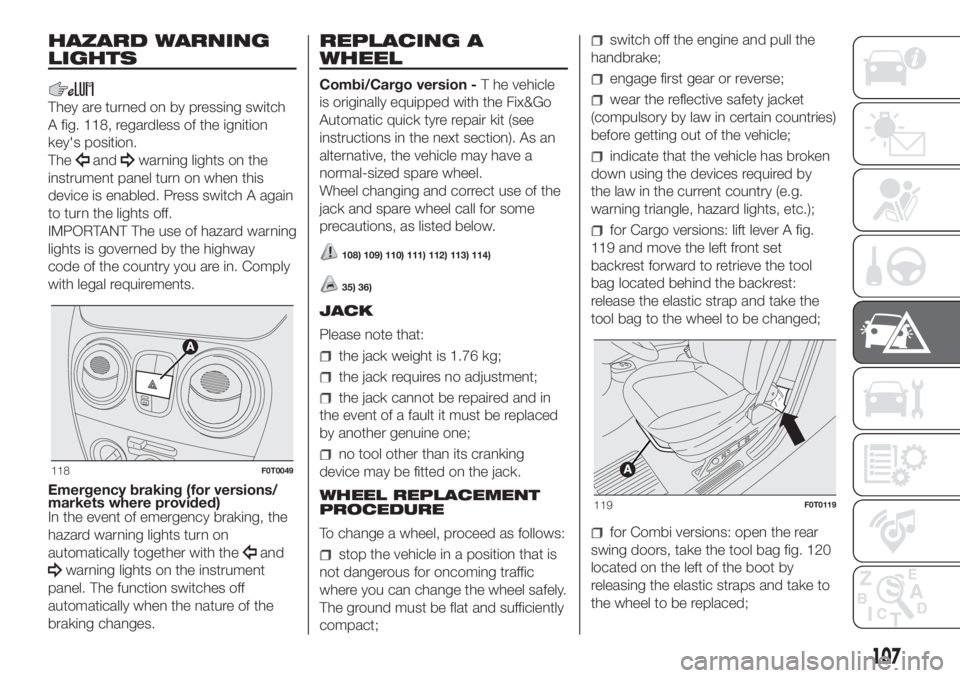

HAZARD WARNING

LIGHTS

They are turned on by pressing switch

A fig. 118, regardless of the ignition

key's position.

The

andwarning lights on the

instrument panel turn on when this

device is enabled. Press switch A again

to turn the lights off.

IMPORTANT The use of hazard warning

lights is governed by the highway

code of the country you are in. Comply

with legal requirements.

Emergency braking (for versions/

markets where provided)

In the event of emergency braking, the

hazard warning lights turn on

automatically together with the

and

warning lights on the instrument

panel. The function switches off

automatically when the nature of the

braking changes.

REPLACING A

WHEEL

Combi/Cargo version -T he vehicle

is originally equipped with the Fix&Go

Automatic quick tyre repair kit (see

instructions in the next section). As an

alternative, the vehicle may have a

normal-sized spare wheel.

Wheel changing and correct use of the

jack and spare wheel call for some

precautions, as listed below.

108) 109) 110) 111) 112) 113) 114)

35) 36)

JACK

Please note that:

the jack weight is 1.76 kg;

the jack requires no adjustment;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

no tool other than its cranking

device may be fitted on the jack.

WHEEL REPLACEMENT

PROCEDURE

To change a wheel, proceed as follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground must be flat and sufficiently

compact;

switch off the engine and pull the

handbrake;

engage first gear or reverse;

wear the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

for Cargo versions: lift lever A fig.

119 and move the left front set

backrest forward to retrieve the tool

bag located behind the backrest:

release the elastic strap and take the

tool bag to the wheel to be changed;

for Combi versions: open the rear

swing doors, take the tool bag fig. 120

located on the left of the boot by

releasing the elastic straps and take to

the wheel to be replaced;

118F0T0049

119F0T0119

107

Page 110 of 196

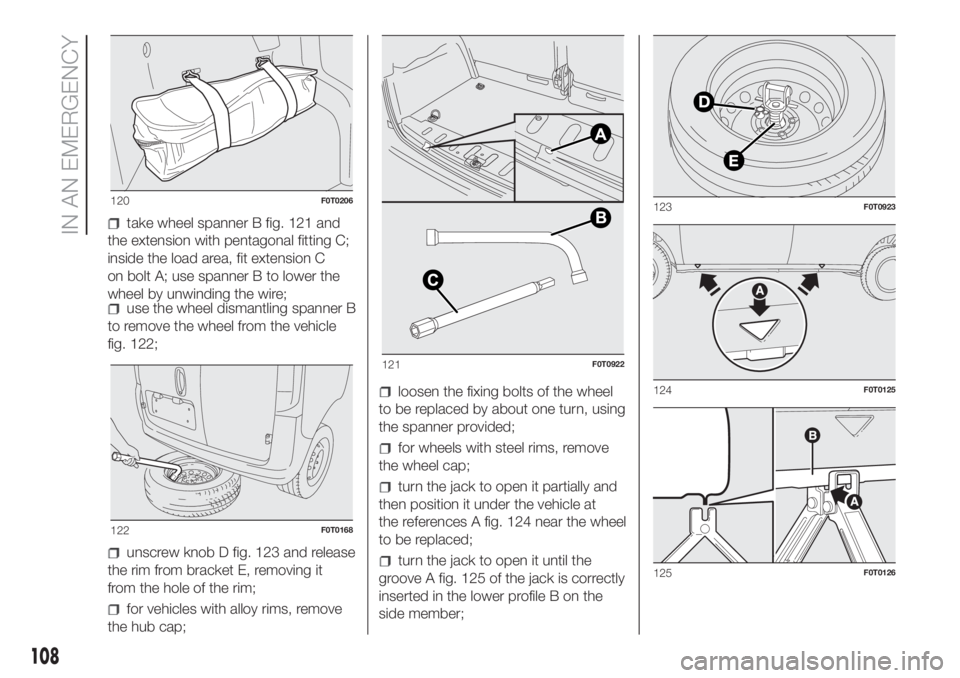

take wheel spanner B fig. 121 and

the extension with pentagonal fitting C;

inside the load area, fit extension C

on bolt A; use spanner B to lower the

wheel by unwinding the wire;

use the wheel dismantling spanner B

to remove the wheel from the vehicle

fig. 122;

unscrew knob D fig. 123 and release

the rim from bracket E, removing it

from the hole of the rim;

for vehicles with alloy rims, remove

the hub cap;

loosen the fixing bolts of the wheel

to be replaced by about one turn, using

the spanner provided;

for wheels with steel rims, remove

the wheel cap;

turn the jack to open it partially and

then position it under the vehicle at

the references A fig. 124 near the wheel

to be replaced;

turn the jack to open it until the

groove A fig. 125 of the jack is correctly

inserted in the lower profile B on the

side member;

120F0T0206

122F0T0168

121F0T0922

123F0T0923

124F0T0125

125F0T0126

108

IN AN EMERGENCY