light FIAT TEMPRA 1988 Service And Owner's Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 48 of 171

• Job 32. Change petrol fuel filter. IMPORTANT NOTES:

• Wear plastic gloves and goggles and have a large rag

and a suitable fire extinguisher ready.

• Place a container beneath the filter to catch fuel

spillage.

• After fitting the new filter in place, refit the casing,

ensure no traces of fuel are left, reconnect the battery and

restart the engine.

• Check carefully to ensure there are no leaks before

refitting the cover.

• Job 33. Drain diesel fuel filter.

IMPORTANT NOTE: Some models are fitted with a water-

in-fuel sensor. Drain the filter when the warning light

comes on. Unplug the sensor from the base of the filter,

first.

FUEL INJECTION

MODELS

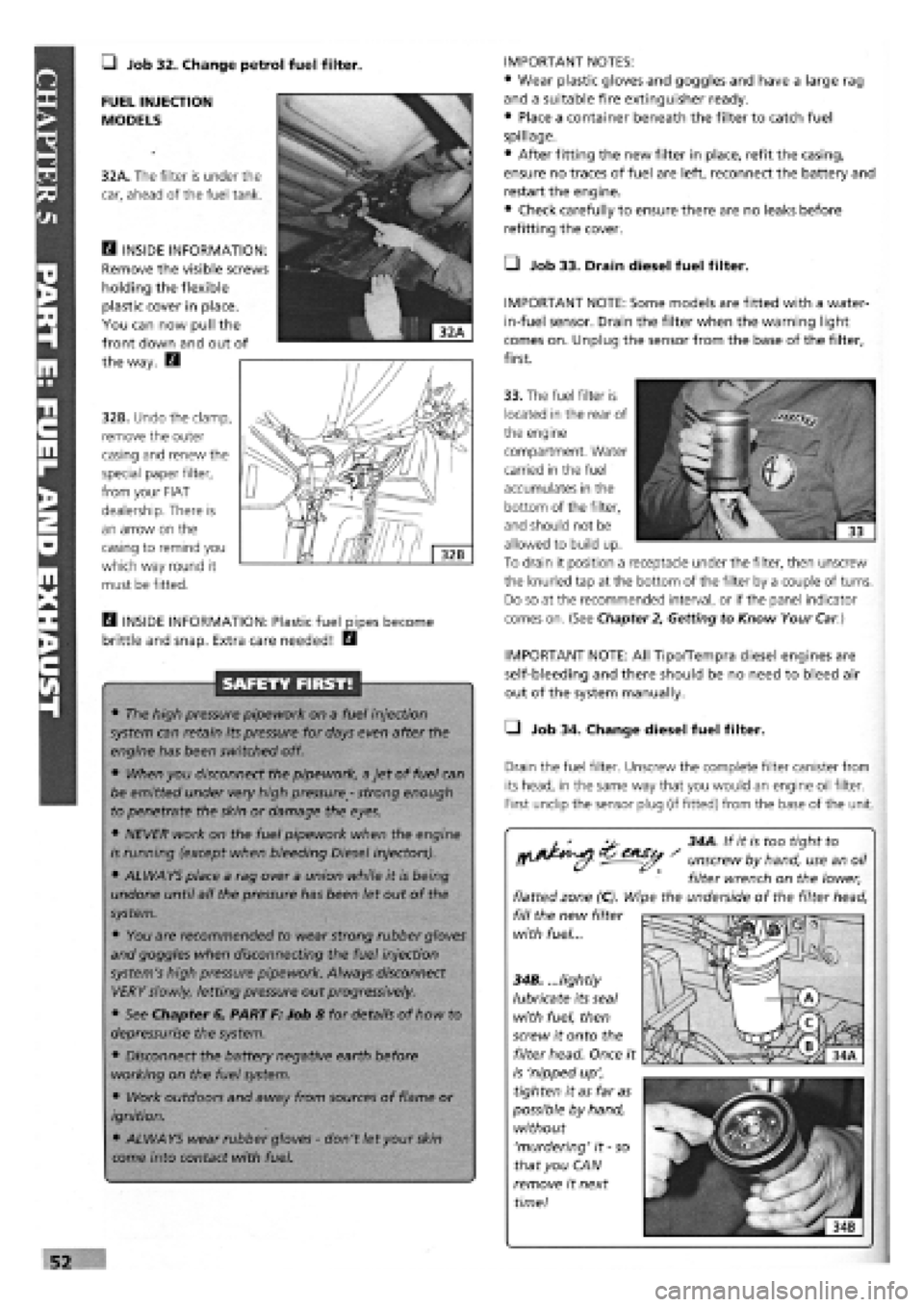

32A. The filter is under the

car, ahead of the fuel tank.

E3 INSIDE INFORMATION:

Remove the visible screws

holding the flexible

plastic cover in place.

You can now pull the

front down and out of

the way. E3

32B. Undo the clamp,

remove the outer

casing and renew the

special paper filter,

from your FIAT

dealership. There is

an arrow on the

casing to remind you

which way round it

must be fitted.

33. The fuel filter is

located in the rear of

the engine

compartment. Water

carried in the fuel

accumulates in the

bottom of the filter,

and should not be

allowed to build up.

To drain it position a receptacle under the filter, then unscrew

the knurled tap at the bottom of the filter by a couple of turns.

Do so at the recommended interval, or if the panel indicator

comes on. (See Chapter

2,

Getting to Know Your

Car.)

H INSIDE INFORMATION: Plastic fuel pipes become

brittle and snap. Extra care needed! E3

SAFETY FIRST!

• The high pressure pipework on a fuel injection

system can retain its pressure for days even after the

engine has been switched off.

• When you disconnect the pipework, a jet of fuel can

be emitted under very high pressure

-

strong enough

to penetrate the skin or damage the eyes.

• NEVER work on the fuel pipework when the engine

is running (except when bleeding Diesel injectors).

• ALWAYS place a rag over a union while it is being

undone until all the pressure has been let out of the

system.

• You are recommended to wear strong rubber gloves

and goggles when disconnecting the fuel injection

system's high pressure pipework. Always disconnect

VERY slowly, letting pressure out progressively.

• See Chapter 6, PART F: Job 8 for details of how to

depressurise the system.

• Disconnect the battery negative earth before

working on the fuel system.

• Work outdoors and away from sources of flame or

ignition.

• ALWAYS wear rubber gloves

-

don't let your

skin

come into contact with fuel.

IMPORTANT NOTE: All Tipo/Tempra diesel engines are

self-bleeding and there should be no need to bleed air

out of the system manually.

• Job 34. Change diesel fuel filter.

Drain the fuel filter. Unscrew the complete filter canister from

its head, in the same way that you would an engine oil filter.

First undip the sensor plug (if fitted) from the base of the unit.

^ 34A. If it is too tight to

^^ - unscrew by hand, use an oil

filter wrench on the lower,

flatted zone (C). Wipe the underside of the filter head,

fill the new filter

with fuel...

34B. ...lightly

lubricate its seal

with fuel, then

screw it onto the

filter head. Once it

is 'nipped up',

tighten it as far as

possible by hand,

without

'murdering' it

-

so

that you CAN

remove it next

time!

Page 56 of 171

49H. ...and push out the nylon bush (arrowed). Reassemble

on the new pad and reattach the wire.

IMPORTANT NOTE: After fitting the pads, apply the

brakes firmly several times to adjust them.

• Job 50. Check rear brakes.

SAFETY FIRST!

Read SAFETY FIRST at the start of Job 49 before

proceeding!

GENERAL. The majority of Tipo/Tempra models are fitted with

rear drum-type rear brakes, but models with ABS anti-lock

braking have a disc-and-caliper arrangement instead.

Slacken the wheel bolts, raise the wheel, remove it and

support the car with an axle stand. Make sure that the wheels

remaining on the ground are chocked in both directions and

that the handbrake is off.

DRUM REAR BRAKES

If the drum

sticks,

try:

• screwing a pair of

bolts

into the two threaded

holes in the drum. Evenly

tightening the bolts will force the drum off the

shoes.

• tapping carefully around the drum with a hide

mallet to help loosen it.

s Vn order to fit new pads,

r> - the caliper piston must be

pushed back into the bore.

• Use an old battery hydrometer to draw about half

of the fluid from the master cylinder.

• Push the piston back into the caliper, using a G-

clamp.

• Keep an eye on the master cylinder so that it

doesn't overflow as fluid is pushed back up the pipe.

IMPORTANT NOTE: Be very sparing or grease could

migrate to the friction linings!

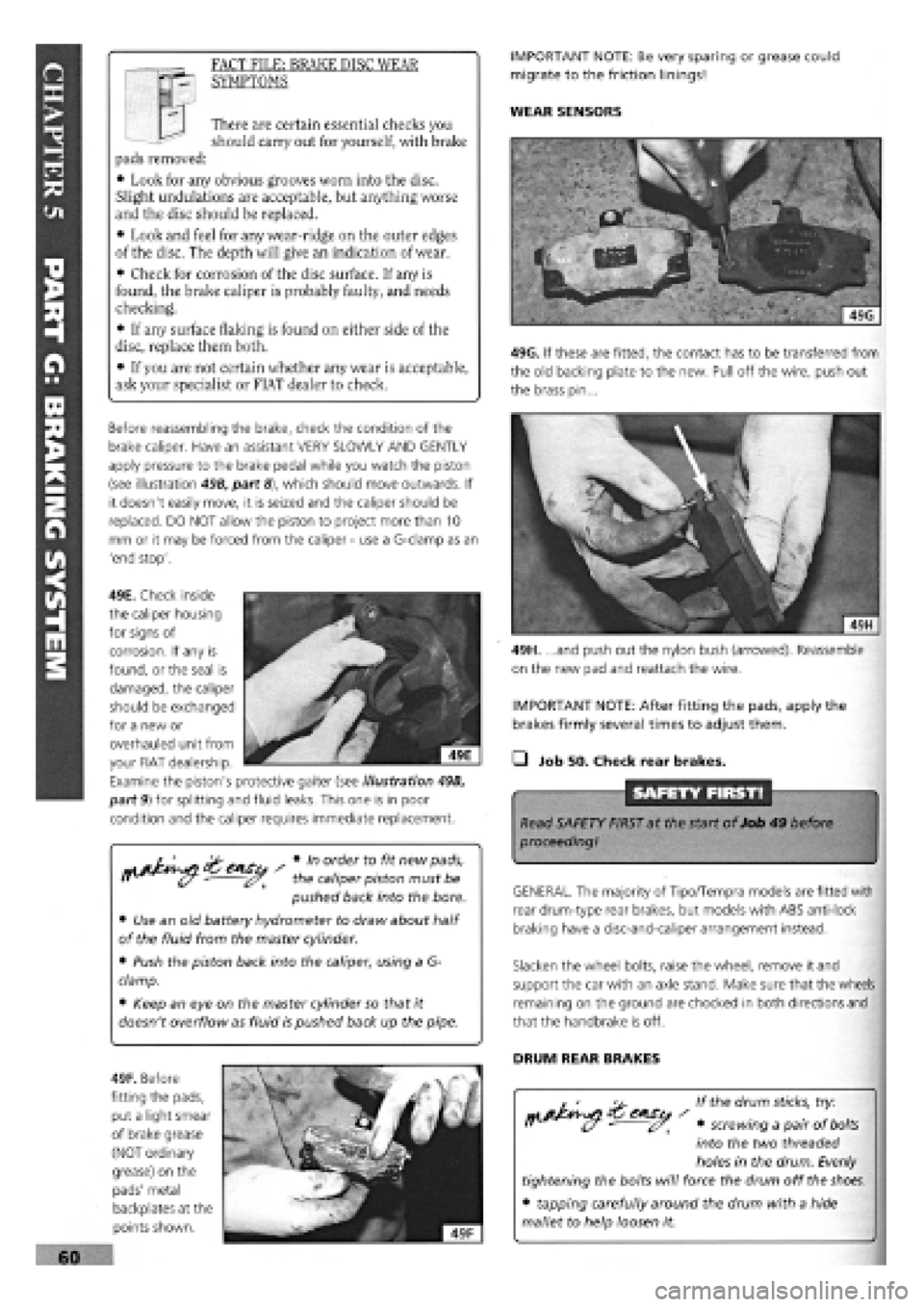

WEAR SENSORS I I There are certain essential checks you

should carry out for yourself, with brake

pads removed:

• Look for any obvious grooves worn into the disc.

Slight undulations are acceptable, but anything worse

and the disc should be replaced.

• Look and feel for any wear-ridge on the outer edges

of the disc. The depth will give an indication of wear.

• Check for corrosion of the disc surface. If any is

found, the brake caliper is probably faulty, and needs

checking.

• If any surface flaking is found on either side of the

disc, replace them both.

• If you are not certain whether any wear is acceptable,

ask your specialist or FIAT dealer to check.

FACT FILE: BRAKE DISC WEAR

SYMPTOMS

Before reassembling the brake, check the condition of the

brake caliper. Have an assistant VERY SLOWLY AND GENTLY

apply pressure to the brake pedal while you watch the piston

(see illustration 49B, part

8),

which should move outwards. If

it doesn't easily move, it is seized and the caliper should be

replaced. DO NOT allow the piston to project more than 10

mm or it may be forced from the caliper

-

use a G-clamp as an

'end stop'.

49F. Before

fitting the pads,

put a light smear

of brake grease

(NOT ordinary

grease) on the

pads' metal

backplates at the

points shown.

49G. If these are fitted, the contact has to be transferred from

the old backing plate to the new. Pull off the wire, push out

the brass pin...

49E. Check inside

the caliper housing

for signs of

corrosion. If any is

found, or the seal is

damaged, the caliper

should be exchanged

for a new or

overhauled unit from

your FIAT dealership.

Examine the piston's protective gaiter (see illustration 49B,

part 9) for splitting and fluid leaks. This one is in poor

condition and the caliper requires immediate replacement.

Page 58 of 171

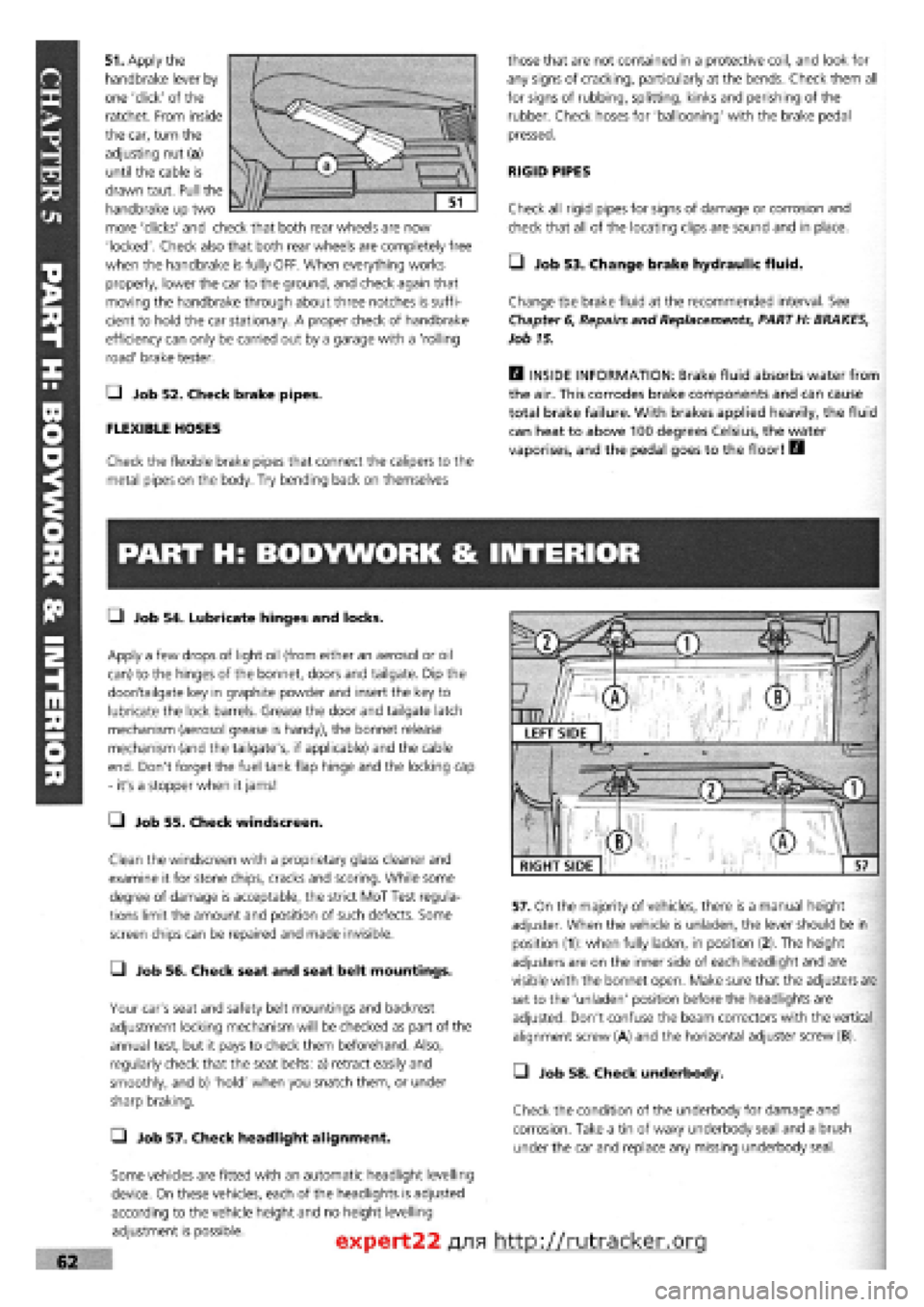

51. Apply the

handbrake lever by

one 'click' of the

ratchet. From inside

the car, turn the

adjusting nut (a)

until the cable is

drawn taut. Pull the

handbrake up two

more 'clicks' and check that both rear wheels are now

'locked'. Check also that both rear wheels are completely free

when the handbrake is fully OFF. When everything works

properly, lower the car to the ground, and check again that

moving the handbrake through about three notches is suffi-

cient to hold the car stationary. A proper check of handbrake

efficiency can only be carried out by a garage with a 'rolling

road' brake tester.

Q Job 52. Check brake pipes.

FLEXIBLE HOSES

Check the flexible brake pipes that connect the calipers to the

metal pipes on the body. Try bending back on themselves

those that are not contained in a protective coil, and look for

any signs of cracking, particularly at the bends. Check them all

for signs of rubbing, splitting, kinks and perishing of the

rubber. Check hoses for 'ballooning' with the brake pedal

pressed.

RIGID PIPES

Check all rigid pipes for signs of damage or corrosion and

check that all of the locating clips are sound and in place.

• Job 53. Change brake hydraulic fluid.

Change the brake fluid at the recommended interval. See

Chapter

6,

Repairs and Replacements, PART H: BRAKES,

Job 15.

H INSIDE INFORMATION: Brake fluid absorbs water from

the air. This corrodes brake components and can cause

total brake failure. With brakes applied heavily, the fluid

can heat to above 100 degrees Celsius, the water

vaporises, and the pedal goes to the floor! B

PART H: BODYWORK & INTERIOR

• Job 54. Lubricate hinges and locks.

Apply a few drops of light oil (from either an aerosol or oil

can) to the hinges of the bonnet, doors and tailgate. Dip the

door/tailgate key in graphite powder and insert the key to

lubricate the lock barrels. Grease the door and tailgate latch

mechanism (aerosol grease is handy), the bonnet release

mechanism (and the tailgate's, if applicable) and the cable

end. Don't forget the fuel tank flap hinge and the locking cap

- it's a stopper when it jams!

• Job 55. Check windscreen.

Clean the windscreen with a proprietary glass cleaner and

examine it for stone chips, cracks and scoring. While some

degree of damage is acceptable, the strict MoT Test regula-

tions limit the amount and position of such defects. Some

screen chips can be repaired and made invisible.

• Job 56. Check seat and seat belt mountings.

Your car's seat and safety belt mountings and backrest

adjustment locking mechanism will be checked as part of the

annual test, but it pays to check them beforehand. Also,

regularly check that the seat belts: a) retract easily and

smoothly, and b) 'hold' when you snatch them, or under

sharp braking.

Q Job 57. Check headlight alignment.

Some vehicles are fitted with an automatic headlight levelling

device. On these vehicles, each of the headlights is adjusted

according to the vehicle height and no height levelling

adjustment is possible.

57. On the majority of vehicles, there is a manual height

adjuster. When the vehicle is unladen, the lever should be in

position (1): when fully laden, in position (2). The height

adjusters are on the inner side of each headlight and are

visible with the bonnet open. Make sure that the adjusters are

set to the 'unladen' position before the headlights are

adjusted. Don't confuse the beam correctors with the vertical

alignment screw (A) and the horizontal adjuster screw (B).

• Job 58. Check underbody.

Check the condition of the underbody for damage and

corrosion. Take a tin of waxy underbody seal and a brush

under the car and replace any missing underbody seal.

expert22 fl/ia http://rutracker.org

RIGHT SIDE

Page 59 of 171

—1 Job 59. Check spare tyre.

This

job should ideally be carried out every month or two

-

you

never know when you're going to need that spare! But if you

haven't remembered, do it at the time shown on the Service

Interval Chart at the latest.

Q INSIDE INFORMATION: Put in the maximum recom-

mended pressure for heavy-duty use

-

it's always easier

to let some air out if necessary, than to put some in. Lift

the spare out check the 'hidden' lower side wall

for cracking. See Job 6. E9

PART I: ROAD TEST

Q Job 62. Road test and specialist check

-

after

every service.

Before you can claim to have 'finished' working on your car,

you must check it, test it, and, if necessary, have a qualified

mechanic check it over for you.

If you

are not a qualified mechanic, we strongly recommend

having someone who is a properly qualified mechanic

-

your

FIAT dealership perhaps

-

inspect all of the car's safety-related

items

after they have been worked on at home and before

using

the car on the road.

You'll have to remove the toolkit and the wheel to get at the

valve

-

under the boot floor on most models but to one side of

the rear compartment on Estate versions.

• Job 60. Change pollen filter.

When fitted to the fresh air intake, replace it at the scheduled

mileage interval.

• Job 61. Replace airbag gas generator.

Have your FIAT dealer replace the airbag gas generator 10

years after the car was built

-

see the label inside the car's

glove compartment door.

• Before setting out, check that the lights, indicators and in-

car controls, as well as seat belts and seat adjustments, all

work correctly.

• Run the car for several minutes before setting out then turn

off, check fluid levels and check underneath for leaks.

• Check that the steering moves freely in both directions and

that the car does not 'pull' one way or the other when driving

in a straight line

-

but do bear in mind the effect of the

camber on the road.

• Make sure that the brakes work effectively, smoothly and

without the need for 'pumping'. There should be no juddering

or squealing.

• Check that the car does not 'pull' from one side to the

other when you brake firmly from around 40 mph. (Don't

cause a skid and don't try this if there is any following traffic.)

"V,

WURTH PRODUCTS FROM FIAT

A.

Wurth produce a huge range of very high quality, FIAT-

approved products, from zinc-rich aerosol paints,

rust-proofing products and the safety-related items shown

here...

B. ...to electrical connectors and tools and that wonderful

'shrink-fit' wire insulation tubing

-

slide it on, heat it up, and it

'shrinks' into place and can't come undone again. See your

FIAT dealer or other specialist supplier for the vast range of

top-quality Wurth products.

Page 66 of 171

• Step 26:

Check that

nothing remains

attached to, or

obstructs the

cylinder head and

lift it clear of the

block. If stuck, it

is permissible to

tap the head

lightly with a soft mallet to free it. Never use a wedge

between the joint faces and remember that the head will not

slide off as it is located on dowels.

Job 3. Petrol engine.

Cylinder head and camshaft

housing - refitting.

• Carburettor cleaner

-

or

the purpose-made Loctite

'Chisel' aerosol spray,

available from your FIAT dealer, will help to remove

pieces of

stuck-on

gasket.

o

(

V.

o

o

o

o o o

o o e

• • • • •

0 0 O 0 o

Job

3-4

grease, place it on the block with (on FIAT gaskets) this

copper-ringed hole above the correct water passage. The

gasket only fits correctly one way round.

• Step 3:

Lower the

cylinder head into

position and

locate it on the

two dowels (see

illustration Job

3-2, arrowed).

Refer to the illustration to Job

2-1

in connection with the

work described here.

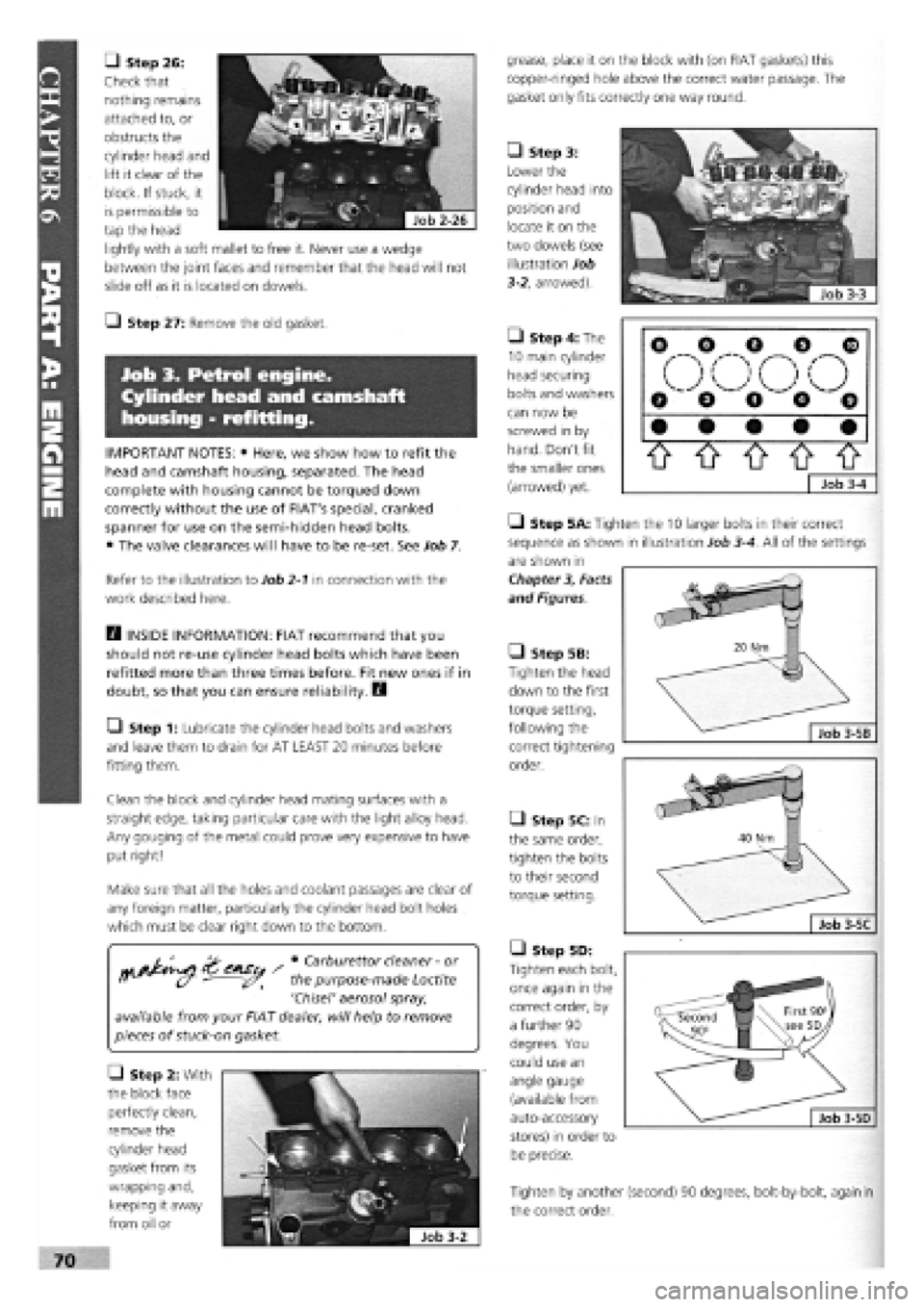

• Step 4: The

10 main cylinder

head securing

bolts and washers

can now be

screwed in by

hand. Don't fit

the smaller ones

(arrowed) yet.

Q INSIDE INFORMATION: FIAT recommend that you

should not re-use cylinder head bolts which have been

refitted more than three times before. Fit new ones if in

doubt, so that you can ensure reliability. B

• Step 1: Lubricate the cylinder head bolts and washers

and leave them to drain for AT LEAST 20 minutes before

fitting them.

• Step 5B:

Tighten the head

down to the first

torque setting,

following the

correct tightening

order.

Q Step 27: Remove the old gasket.

IMPORTANT NOTES: • Here, we show how to refit the

head and camshaft housing, separated. The head

complete with housing cannot be torqued down

correctly without the use of FIAT's special, cranked

spanner for use on the semi-hidden head bolts.

• The valve clearances will have to be re-set. See Job 7.

Clean the block and cylinder head mating surfaces with a

straight edge, taking particular care with the light alloy head.

Any gouging of the metal could prove very expensive to have

put right!

Make sure that all the holes and coolant passages are clear of

any foreign matter, particularly the cylinder head bolt holes

which must be clear right down to the bottom.

• Step 5C: In

the same order,

tighten the bolts

to their second

torque setting.

• Step 2: With

the block face

perfectly clean,

remove the

cylinder head

gasket from its

wrapping and,

keeping it away

from oil or

Tighten by another (second) 90 degrees, bolt-by-bolt, again in

the correct order.

• Step 5D:

Tighten each bolt,

once again in the

correct order, by

a further 90

degrees. You

could use an

angle gauge

(available from

auto-accessory

stores) in order to

be precise.

Q Step 5A: Tighten the 10 larger bolts in their correct

sequence as shown in illustration Job

3-4.

All of the settings

are shown in

Chapter

3,

Facts

and Figures.

Page 68 of 171

&CASU / # Q StGP 101 The ValV6S i* (/ should slide freely out of

their guides. Any resistance

may be caused by a build up of carbon, or a slight burr

on the stem where the collets engage. This can usually

be removed by careful use of fine wet-or-dry paper,

allowing you to

withdraw the valves

without scoring their

guides. Keep the valves

in their correct order by

wrapping a numbered

piece of masking tape

around each stem.

• Step 12: Clean the

carbon from the valves with

a rotary wire brush and

wash them in paraffin.

Wash the valve springs,

caps, seats and collets and

dry.

/ • Before grinding-in the

valves, clean the tops of the

valve heads back to shiny

metal. Now the sucker on the end of your valve

grinding stick won't keep falling off when you grind-

in the valves!

head. Don't hesitate to seek the advice of your local agent if

you have any doubts.

• Step 14: Examine the valve seats for pitting or burning.

Also, check the valve seats in the cylinder head. Small pits can

be removed by grinding the valves onto their seats. The seats

in the cylinder head will have to be recut (again, by your local

FIAT agent if the pitting is too deep), and new valves fitted.

B INSIDE INFORMATION! These cylinder heads use

hardened valves and seats for use with unleaded petrol.

We advise you to consult your FIAT agent or engine

specialist for machining if anything other than light

valve grinding is required. B

FACT FILE: VALVE GRINDING

• Step 15: Apply a small quantity of

coarse grinding paste evenly round the valve

seat. A valve grinding stick with a suction pad

slightly smaller than the valve head should

be selected. Put a dab of moisture onto the suction pad and

press the grinding stick to the first valve.

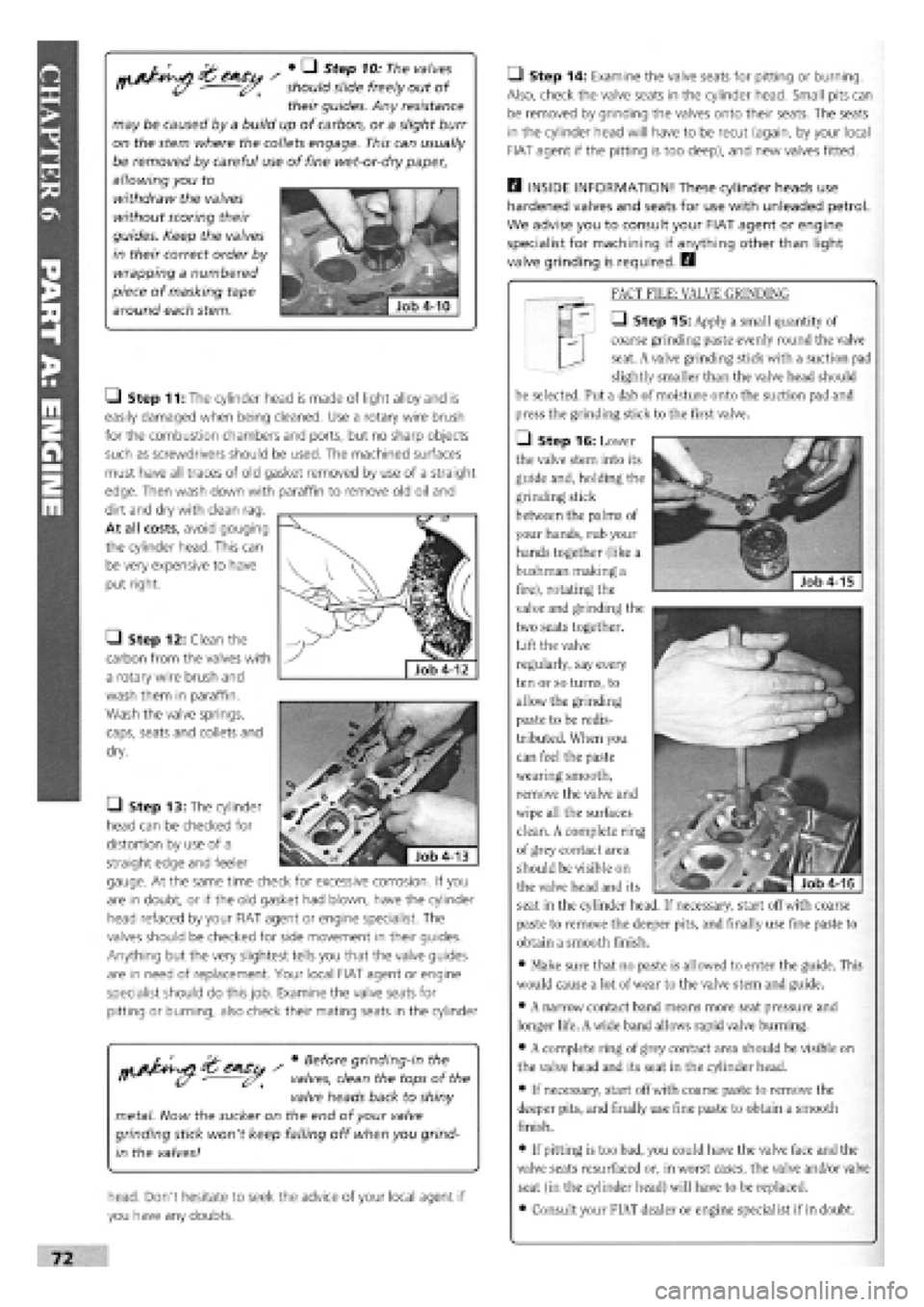

• Step 16: Lower

the valve stem into its

guide and, holding the

grinding stick

between the palms of

your hands, rub your

hands together (like a

bushman making a

fire), rotating the

valve and grinding the

two seats together.

Lift the valve

regularly, say every

ten or so turns, to

allow the grinding

paste to be redis-

tributed. When you

can feel the paste

wearing smooth,

remove the valve and

wipe all the surfaces

clean. A complete ring

of grey contact area

should be visible on

the valve head and its

seat in the cylinder head. If necessary, start off with coarse

paste to remove the deeper pits, and finally use fine paste to

obtain a smooth finish.

• Make sure that no paste is allowed to enter the guide. This

would cause a lot of wear to the valve stem and guide.

• A narrow contact band means more seat pressure and

longer life. A wide band allows rapid valve burning.

• A complete ring of grey contact area should be visible on

the valve head and its seat in the cylinder head.

• If necessary, start off with coarse paste to remove the

deeper pits, and finally use fine paste to obtain a smooth

finish.

• If pitting is too bad, you could have the valve face and the

valve seats resurfaced or, in worst cases, the valve and/or valve

seat (in the cylinder head) will have to be replaced.

• Consult your FIAT dealer or engine specialist if in doubt.

LJ Step 11: The cylinder head is made of light alloy and is

easily damaged when being cleaned. Use a rotary wire brush

for the combustion chambers and ports, but no sharp objects

such as screwdrivers should be used. The machined surfaces

must have all traces of old gasket removed by use of a straight

edge. Then wash down with paraffin to remove old oil and

dirt and dry with clean rag.

At all costs, avoid gouging

the cylinder head. This can

be very expensive to have

put right.

• Step 13: The cylinder

head can be checked for

distortion by use of a

straight edge and feeler

gauge. At the same time check for excessive corrosion. If you

are in doubt, or if the old gasket had blown, have the cylinder

head refaced by your FIAT agent or engine specialist. The

valves should be checked for side movement in their guides.

Anything but the very slightest tells you that the valve guides

are in need of replacement. Your local FIAT agent or engine

specialist should do this job. Examine the valve seats for

pitting or burning, also check their mating seats in the cylinder

72

Page 74 of 171

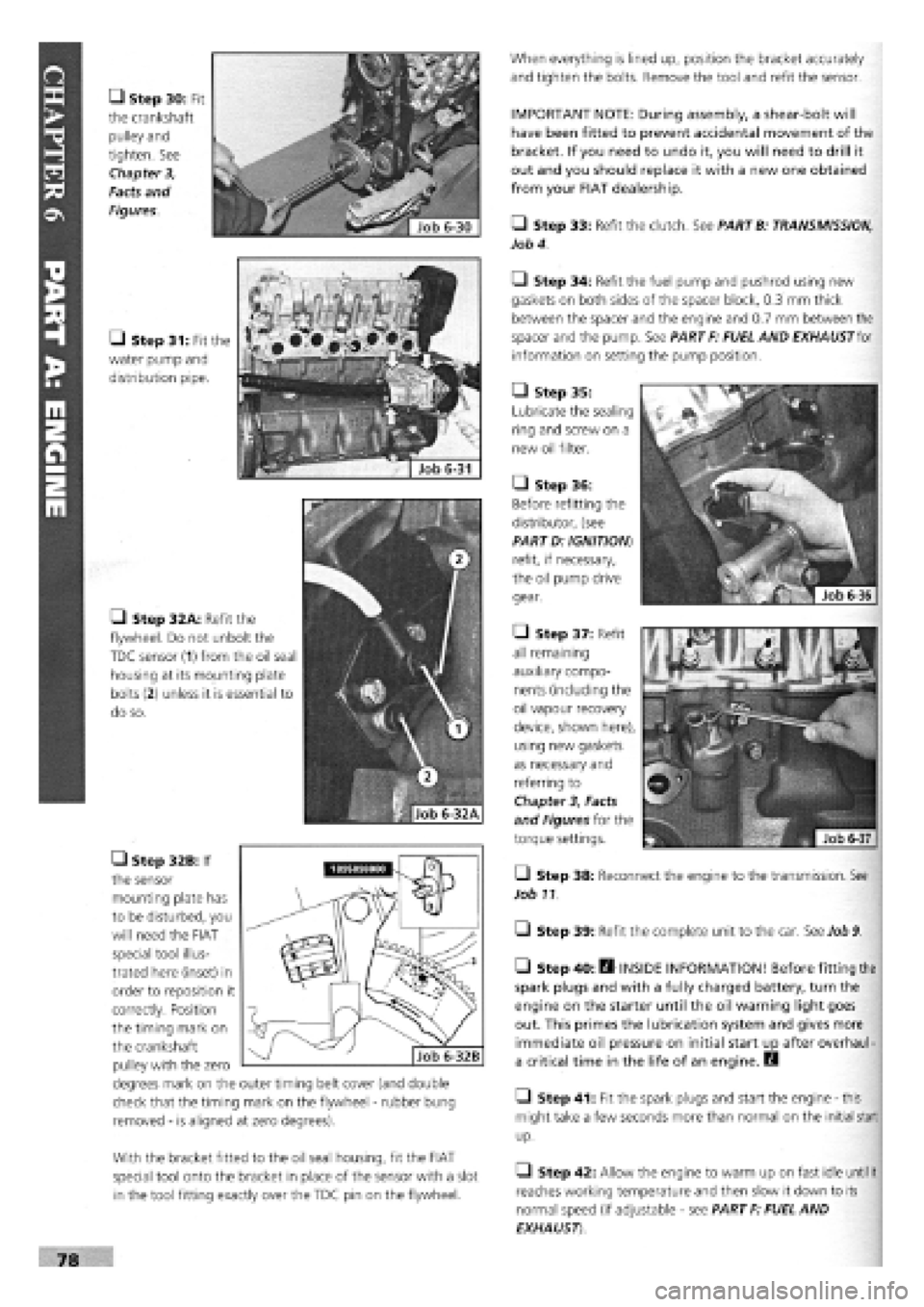

• Step 30: Fit

the crankshaft

pulley and

tighten. See

Chapter 3,

Facts and

Figures.

• Step 31: Fit the

water pump and

distribution pipe.

• Step 32A: Refit the

flywheel. Do not unbolt the

TDC sensor (1) from the oil seal

housing at its mounting plate

bolts

(2)

unless it is essential to

do so.

• Step 32B: If

the sensor

mounting plate has

to be disturbed, you

will need the FIAT

special tool illus-

trated here (inset) in

order to reposition it

correctly. Position

the timing mark on

the crankshaft

pulley with the zero

degrees mark on the outer timing belt cover (and double

check that the timing mark on the flywheel

-

rubber bung

removed

-

is aligned at zero degrees).

With the bracket fitted to the oil seal housing, fit the FIAT

special tool onto the bracket in place of the sensor with a slot

in the tool fitting exactly over the TDC pin on the flywheel.

When everything is lined up, position the bracket accurately

and tighten the bolts. Remove the tool and refit the sensor.

IMPORTANT NOTE: During assembly, a shear-bolt will

have been fitted to prevent accidental movement of the

bracket. If you need to undo it, you will need to drill it

out and you should replace it with a new one obtained

from your FIAT dealership.

• Step 33: Refit the clutch. See PARTB: TRANSMISSION,

Job 4.

Q Step 34: Refit the fuel pump and pushrod using new

gaskets on both sides of the spacer block, 0.3 mm thick

between the spacer and the engine and 0.7 mm between the

spacer and the pump. See PART F: FUEL AND EXHAUST for

information on setting the pump position.

• Step 35:

Lubricate the sealing

ring and screw on a

new oil filter.

• Step 36:

Before refitting the

distributor, (see

PART D: IGNITION)

refit, if necessary,

the oil pump drive

gear.

• Step 37: Refit

all remaining

auxiliary compo-

nents (including the

oil vapour recovery

device, shown here),

using new gaskets

as necessary and

referring to

Chapter

3,

Facts

and Figures for the

torque settings.

Q Step 38: Reconnect the engine to the transmission. See

Job 11.

Q Step 39: Refit the complete unit to the car. See Job

9.

• Step 40: fl INSIDE INFORMATION! Before fitting the

spark plugs and with a fully charged battery, turn the

engine on the starter until the oil warning light goes

out. This primes the lubrication system and gives more

immediate oil pressure on initial start up after overhaul-

a critical time in the life of an engine. B

• Step 41: Fit the spark plugs and start the engine

-

this

might take a few seconds more than normal on the initial start

up.

• Step 42: Allow the engine to warm up on fast idle

until

it

reaches working temperature and then slow it down to its

normal speed (if adjustable

-

see PART F: FUEL AND

EXHAUST)

Page 76 of 171

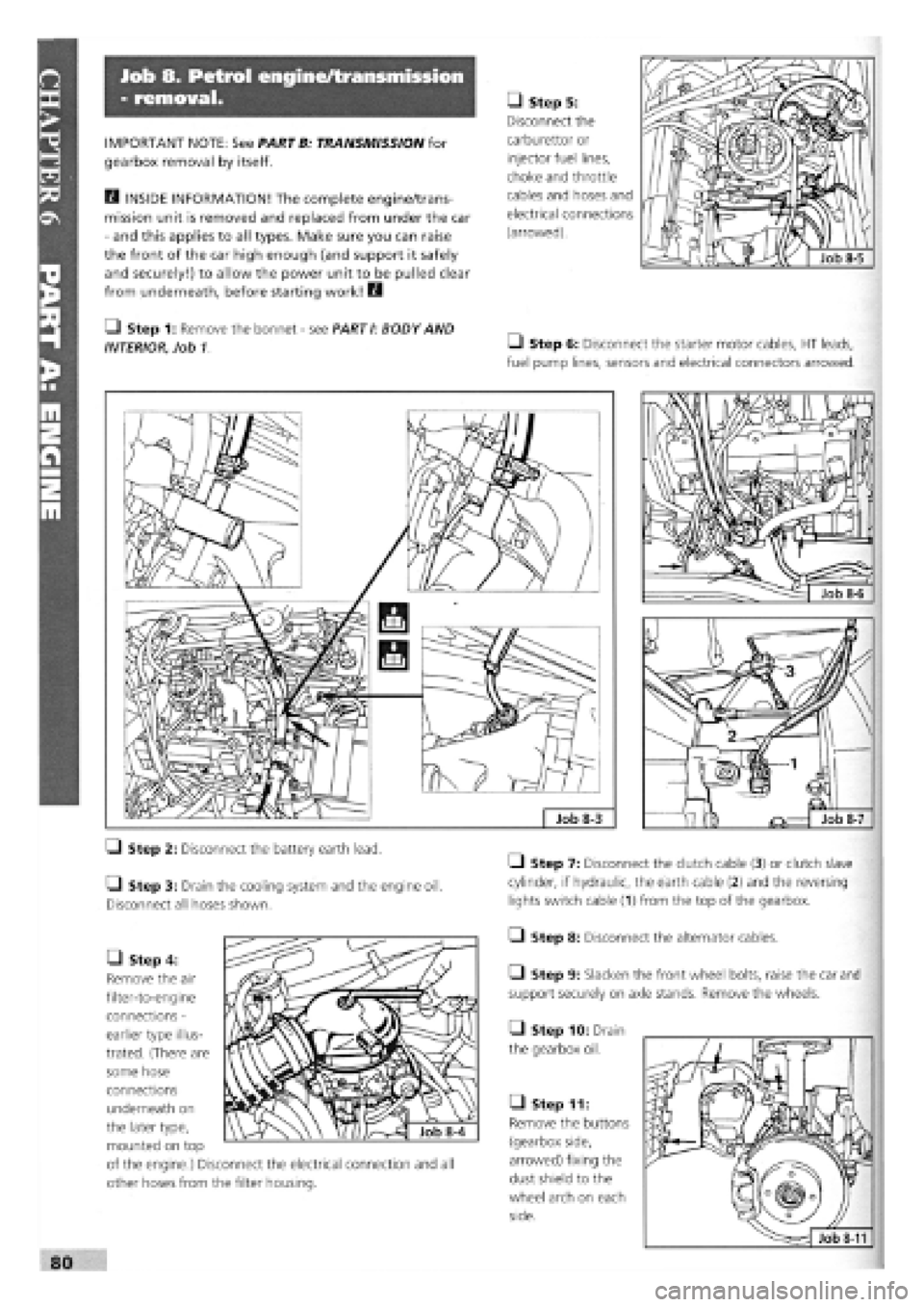

Job 8. Petrol engine/transmission

- removal.

IMPORTANT NOTE: See PARTB: TRANSMISSION for

gearbox removal by itself.

H INSIDE INFORMATION! The complete engine/trans-

mission unit is removed and replaced from under the car

- and this applies to all types. Make sure you can raise

the front of the car high enough (and support it safely

and securely!) to allow the power unit to be pulled clear

from underneath, before starting work! 13

• Step 1: Remove the bonnet

-

see PARTI: BODY AND

INTERIOR, Job 1.

• Step 5:

Disconnect the

carburettor or

injector fuel lines,

choke and throttle

cables and hoses and

electrical connections

(arrowed).

Q Step 6: Disconnect the starter motor cables, HT leads,

fuel pump lines, sensors and electrical connectors arrowed.

Job

8-7

• Step 2: Disconnect the battery earth lead.

• Step 3: Drain the cooling system and the engine oil.

Disconnect all hoses shown.

• Step 7: Disconnect the clutch cable (3) or clutch slave

cylinder, if hydraulic, the earth cable (2) and the reversing

lights switch cable

(1)

from the top of the gearbox.

• Step 8: Disconnect the alternator cables.

Q Step 9: Slacken the front wheel bolts, raise the car and

support securely on axle stands. Remove the wheels.

• Step 10: Drain

the gearbox oil.

• Step 4:

Remove the air

filter-to-engine

connections

-

earlier type illus-

trated. (There are

some hose

connections

underneath on

the later type,

mounted on top

of the engine.) Disconnect the electrical connection and all

other hoses from the filter housing.

• Step 11:

Remove the buttons

(gearbox side,

arrowed) fixing the

dust shield to the

wheel arch on each

side.

Page 84 of 171

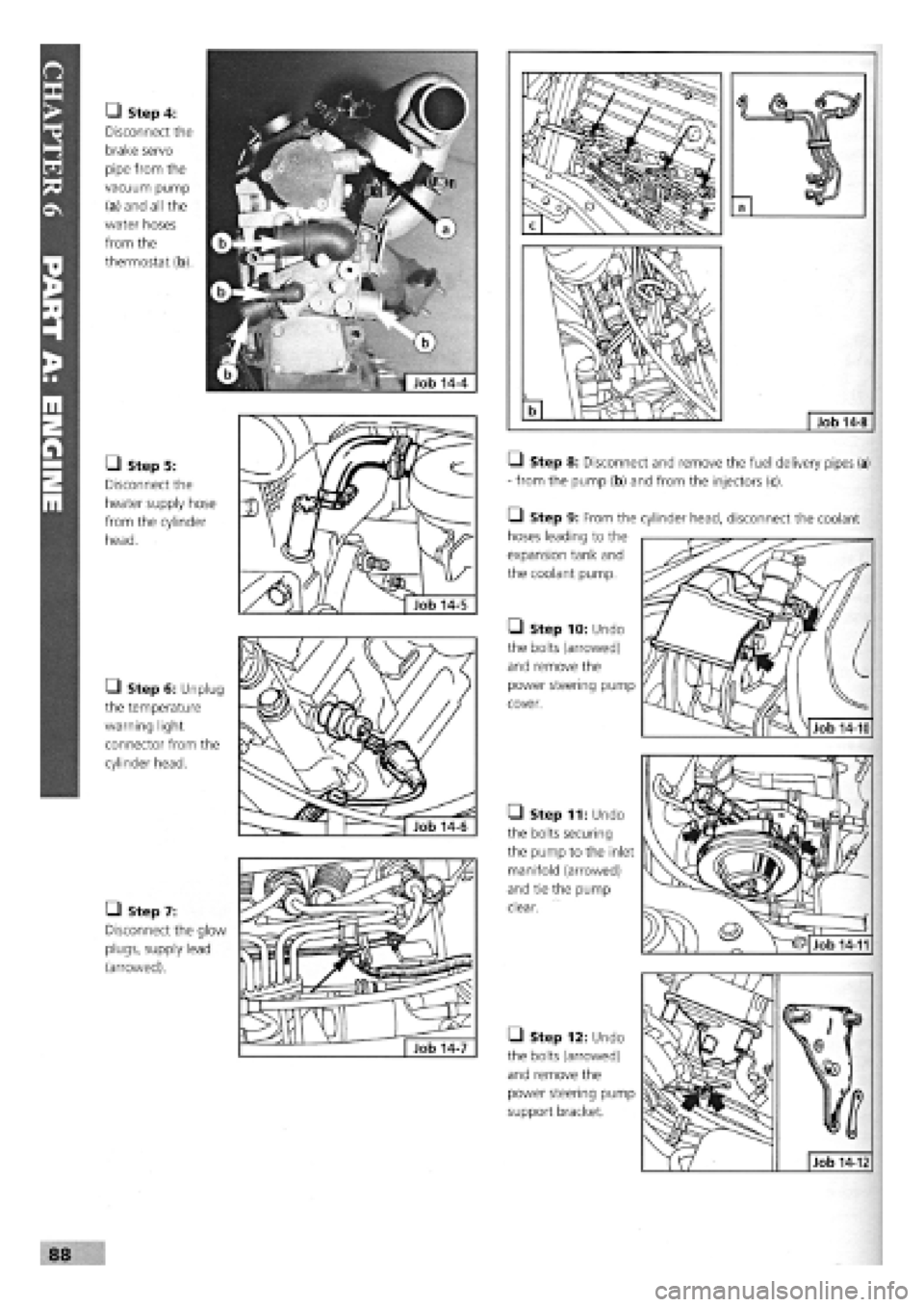

• Step 4:

Disconnect the

brake servo

pipe from the

vacuum pump

(a) and all the

water hoses

from the

thermostat (b).

• Step 5:

Disconnect the

heater supply hose

from the cylinder

head.

• Step 6: Unplug

the temperature

warning light

connector from the

cylinder head.

• Step 7:

Disconnect the glow

plugs, supply lead

(arrowed).

Q Step 8: Disconnect and remove the fuel delivery pipes (a)

- from the pump (b) and from the injectors (c).

• Step 9: From the

hoses leading to the

expansion tank and

the coolant pump.

• Step 10: Undo

the bolts (arrowed)

and remove the

power steering pump

cover.

• Step 11: Undo

the bolts securing

the pump to the inlet

manifold (arrowed)

and tie the pump

clear.

• Step 12: Undo

the bolts (arrowed)

and remove the

power steering pump

support bracket.

88

cylinder head, disconnect the coolant

Job 14-10

Job 14-12

Job 14-11

Page 89 of 171

Job 17. Diesel engine.

Valve clearances - adjustment.

D INSIDE INFORMATION! After carrying out Job 16,

valve clearance measurement and adjustment is now

needed. Both measurement and shim replacement are

carried out in the same manner as for the petrol engine

(.Job

7), so refer to this and also to Chapter 3, Facts

and Figures for specifications. B

Job 18. Diesel engine - removal.

moving parts with engine oil during assembly. See Chapter 3,

Facts

and Figures for specified tightening torques.

luei suppiy diiu leium pipe;>

at the injection pump...

• Step 9: ...and the stop

control supply cable. Also

disconnect the cable from

the injection pump hydraulic

advance control sensor and

the alternator cables.

• Step 10:

Disconnect the oil

feed and return

pipes between the

thermostatic valve

and the radiator

and tie clear.

I

This should

be read in connection with Job 8

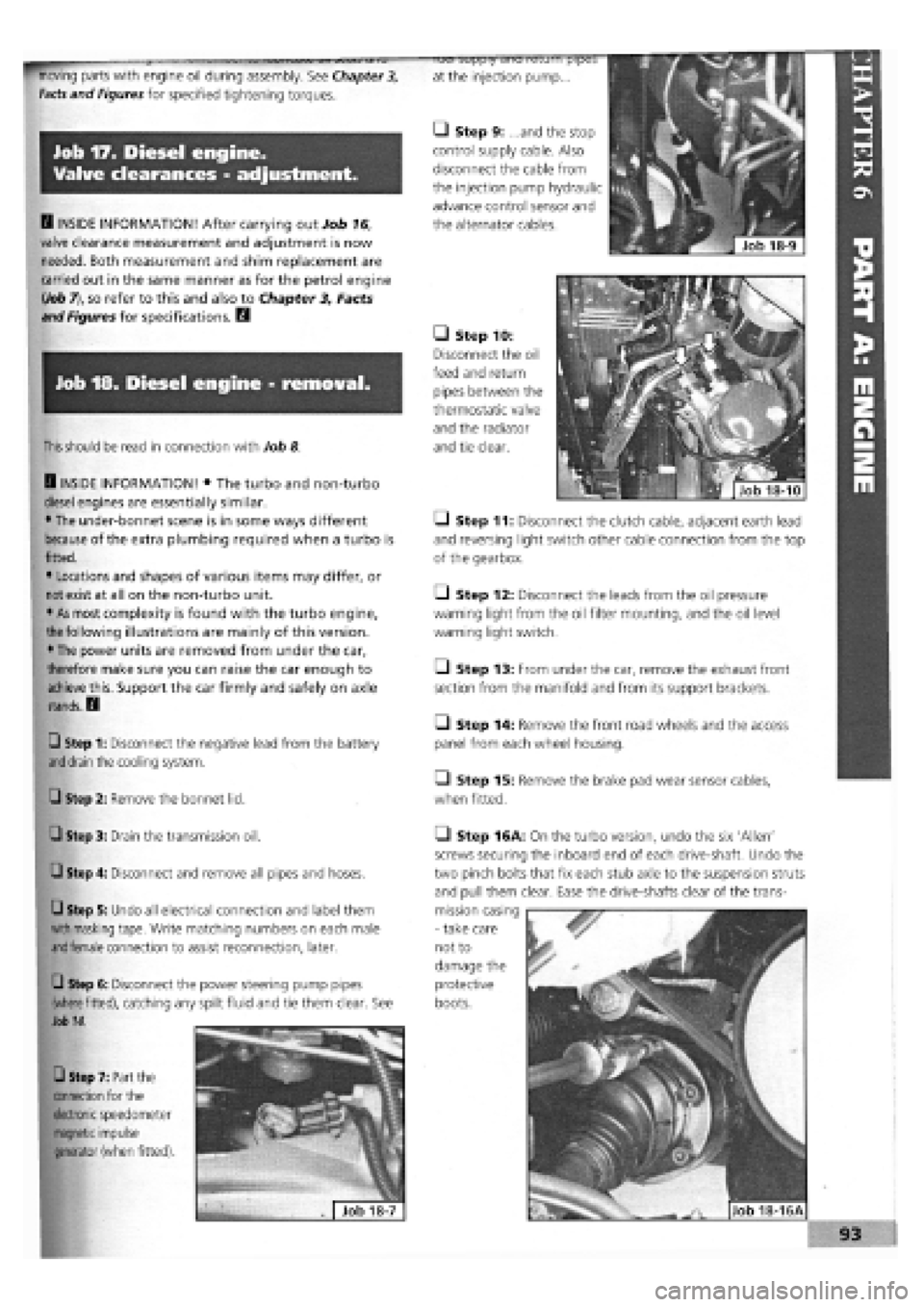

Q INSIDE INFORMATION! • The turbo and non-turbo

diesel engines are essentially similar.

• The under-bonnet scene is in some ways different

because of the extra plumbing required when a turbo is

fitted.

• Locations and shapes of various items may differ, or

not exist at all on the non-turbo unit.

• As most complexity is found with the turbo engine,

I

the

following illustrations are mainly of this version.

• The power units are removed from under the car,

therefore make sure you can raise the car enough to

achieve this. Support the car firmly and safely on axle

stands. D

Q Step 1: Disconnect the negative lead from the battery

and drain

the cooling system. Q Step 2: Remove the bonnet lid.

• Step 3: Drain the transmission oil.

Q Step 4: Disconnect and remove all pipes and hoses.

Q Step 5: Undo all electrical connection and label them

with masking

tape. Write matching numbers on each male

and female

connection to assist reconnection, later.

Q Step 6: Disconnect the power steering pump pipes

(where fitted),

catching any spilt fluid and tie them clear. See

Job 14.

• Step 7: Part the

connection for the

electronic

speedometer

magnetic impulse

generator

(when fitted).

Q Step 11: Disconnect the clutch cable, adjacent earth lead

and reversing light switch other cable connection from the top

of the gearbox.

• Step 12: Disconnect the leads from the oil pressure

warning light from the oil filter mounting, and the oil level

warning light switch.

• Step 13: From under the car, remove the exhaust front

section from the manifold and from its support brackets.

O Step 14: Remove the front road wheels and the access

panel from each wheel housing.

• Step 15: Remove the brake pad wear sensor cables,

when fitted.

Q Step 16A: On the turbo version, undo the six 'Allen'

screws securing the inboard end of each drive-shaft. Undo the

two pinch bolts that fix each stub axle to the suspension struts

and pull them clear. Ease the drive-shafts clear of the trans-

mission casing

-

take care

not to

damage the

protective

boots.