FIAT UNO 1983 Service Repair Manual

Manufacturer: FIAT, Model Year: 1983, Model line: UNO, Model: FIAT UNO 1983Pages: 303, PDF Size: 10.36 MB

Page 231 of 303

adjustment procedures are the same as those

outlined for the previous model units in

Chapter 9, but ensure that the load

compensation lever is turned to the “O”

(normal load setting) position before making

any adjustments.

Headlamp unit removal - later

models

32The removal and refitting procedures

described in Chapter 9 also apply to the later

headlamp type, but note that later units are

secured in position by three retaining screws.

Headlamp dim-dip system -

description

33On later models, the wiring circuit has

been modified to prevent the car being drivenon parking lamps only in built-up areas.

34Headlamp intensity is reduced by the

transformer located at the front of the engine

compartment (photo).

35Any attempt to start the car with parking

lamps only on will automatically cause the

headlamps to switch on with a low-intensity

dipped beam. Dipped and main beam

function normally.

36The headlamp dim-dip system is a legal

requirement for all UK models registered after

April 1st, 1987.

Front fog lamps - bulb/unit

removal and refitting

and beam adjustment

ª

37Ensure that the front fog lamps are

switched off, then unscrew the two retainingscrews and withdraw the lamp unit from the

underside of the front bumper (photos).

38Undo the retaining screw and remove the

access cover from the unit (photo).

39Disconnect the wiring connector from the

bulb, release the clips and withdraw the bulb

from the lamp (photo).

40Refit in the reverse order of removal.

Check the light for satisfactory operation and

if the beam requires resetting, turn the

adjustment screw in the required direction.

41To adjust the beam, position the car 5 m

from, and square on to, a wall or similar.

42Measure the height of the centre of the

lamp lens from the ground and mark the

position on the wall. Switch on the lamp. The

demarcation line (cut-off) of the light should

be below the mark on the wall by 50 mm plus

one-third of the ground-to-lamp centre

measurement. Adjust the beam as required

using the long centre screw.

Horn - relocation

43The single horn, on applicable models, is

now located behind the grille, bolted on a

bracket attached to the top rail (photo).

Steering column combination

switches (later models) -

removal and refitting

Á

44Disconnect the battery negative lead.

45Undo the retaining screws and remove

the steering column shrouds (photos).

46Remove the steering wheel as described

in Chapter 10.

13•106 Supplement: Revisions and information on later models

15.45B . . . then remove the upper . . .15.45A Undo the retaining screws . . .15.43 Horn location

15.39 . . . detach the wires, extract the bulb15.38 . . . remove the rear cover . . .

15.37B . . . and withdraw the front fog lamp

unit . . .15.37A Undo the retaining bolts . . .15.34 Headlamp dim-dip transformer

Page 232 of 303

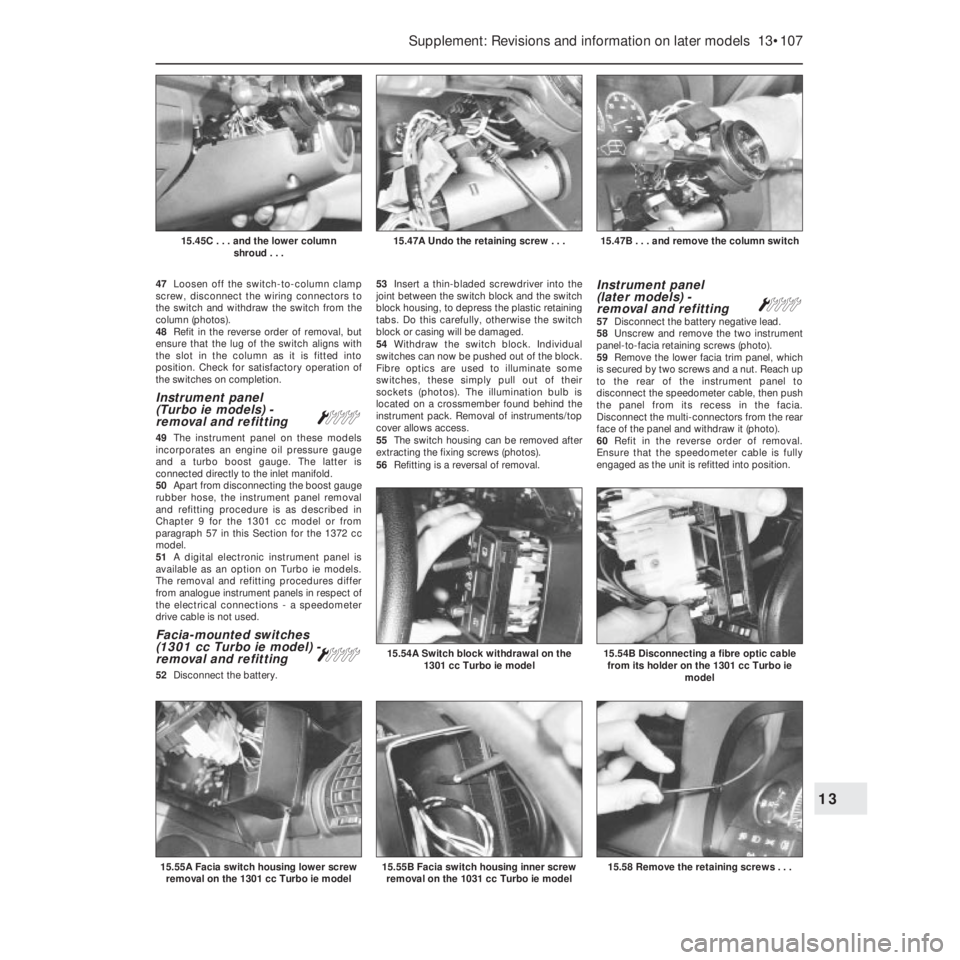

47Loosen off the switch-to-column clamp

screw, disconnect the wiring connectors to

the switch and withdraw the switch from the

column (photos).

48Refit in the reverse order of removal, but

ensure that the lug of the switch aligns with

the slot in the column as it is fitted into

position. Check for satisfactory operation of

the switches on completion.

Instrument panel

(Turbo ie models) -

removal and refitting

Á

49The instrument panel on these models

incorporates an engine oil pressure gauge

and a turbo boost gauge. The latter is

connected directly to the inlet manifold.

50Apart from disconnecting the boost gauge

rubber hose, the instrument panel removal

and refitting procedure is as described in

Chapter 9 for the 1301 cc model or from

paragraph 57 in this Section for the 1372 cc

model.

51A digital electronic instrument panel is

available as an option on Turbo ie models.

The removal and refitting procedures differ

from analogue instrument panels in respect of

the electrical connections - a speedometer

drive cable is not used.

Facia-mounted switches

(1301 cc Turbo ie model) -

removal and refitting

Á

52Disconnect the battery.53Insert a thin-bladed screwdriver into the

joint between the switch block and the switch

block housing, to depress the plastic retaining

tabs. Do this carefully, otherwise the switch

block or casing will be damaged.

54Withdraw the switch block. Individual

switches can now be pushed out of the block.

Fibre optics are used to illuminate some

switches, these simply pull out of their

sockets (photos). The illumination bulb is

located on a crossmember found behind the

instrument pack. Removal of instruments/top

cover allows access.

55The switch housing can be removed after

extracting the fixing screws (photos).

56Refitting is a reversal of removal.

Instrument panel

(later models) -

removal and refitting

Á57Disconnect the battery negative lead.

58Unscrew and remove the two instrument

panel-to-facia retaining screws (photo).

59Remove the lower facia trim panel, which

is secured by two screws and a nut. Reach up

to the rear of the instrument panel to

disconnect the speedometer cable, then push

the panel from its recess in the facia.

Disconnect the multi-connectors from the rear

face of the panel and withdraw it (photo).

60Refit in the reverse order of removal.

Ensure that the speedometer cable is fully

engaged as the unit is refitted into position.

Supplement: Revisions and information on later models 13•107

15.47B . . . and remove the column switch15.47A Undo the retaining screw . . .15.45C . . . and the lower column

shroud . . .

15.58 Remove the retaining screws . . .15.55B Facia switch housing inner screw

removal on the 1031 cc Turbo ie model

15.54B Disconnecting a fibre optic cable

from its holder on the 1301 cc Turbo ie

model15.54A Switch block withdrawal on the

1301 cc Turbo ie model

15.55A Facia switch housing lower screw

removal on the 1301 cc Turbo ie model

13

Page 233 of 303

Auxiliary control panel

(later models) -

removal and refitting

Á

61Disconnect the battery negative lead.

62Insert the flat of a screwdriver under the

trim piece at the end of the auxiliary panel as

shown and prise it free. Repeat the procedure

and remove the trim piece at the other end of

the panel (photo).

63Undo the retaining screws, withdraw the

panel from the facia. Disconnect the wiring

connectors from the panel switches to

remove the panel completely (photo).

64A switch bulb can be renewed by

untwisting the holder and removing the holder

and bulb.

65A switch unit can be removed from the

panel by unscrewing the four retaining screws.66Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and check for satisfactory

operation of the switches on completion.

Heater control panel

(later models) -

removal and refitting

Á

67Disconnect the battery negative lead.

68Pull free the heater/fresh air and blower

control knobs (photo).

69Undo the two retaining screws and

withdraw the control panel from the facia

(photos). Detach the wiring connectors from the

panel illumination lights and remove the panel.

70Refitting is a reversal of the removal

procedure. Ensure that the wiring connections

are securely made and on completion check

that the operation of the controls is satisfactory.

Trip master Á

71This electronic instrument is fitted into the

check panel of 1100SL and 1300SL models

from 1986.

72The device provides information on fuel

consumption, range, speed and elapsed time.

73With the ignition key turned to MAR,

figures are displayed in respect of the last

journey - average fuel consumption, average

speed and elapsed time (up to switching off

the ignition).

74As soon as the engine is started, the

instrument processes the current values to

include fuel consumption, range and the

actual time. 75Fuel consumption is only displayed when

the road speed exceeds 8.0 km/h (5.0 mph).

76The fuel range is only displayed after a

road speed of between 25.0 and 70.0 km/h

(15.0 to 44.0 mph) has been maintained for at

least 90 seconds or at higher speeds for

22 seconds.

77A reset button is provided, also a display

change button (from instant to average or

total values). Should the instrument reading

exceed 99 hours, 59 minutes or 1000 km

(622 miles) depressing the display change

button will display all zeros. Depress button E

to resume normal function.

78Refer to the end of the manual for a wiring

diagram of the check panel, incorporating the

trip master.

Interior roof mounted spotlamp,

switch and/or clock -

removal and refitting

Á

79Disconnect the battery negative lead.

80Prise free the lamp unit from its aperture

in the roof panel using a thin-bladed

screwdriver. The lamp bulb can be inspected

by untwisting the holder and withdrawing it

from the rear of the unit (photos). Extract the

bulb from the holder if it requires renewal.

81To remove the lamp switch from the

panel, reach through the lamp aperture and

press it free from the roof panel (photo).

Detach the wiring connectors.

82To remove the clock, reach through the

lamp aperture and undo the retaining screws

(photo). Withdraw the clock and detach the

wiring connectors.

13•108 Supplement: Revisions and information on later models

15.69B . . . and withdraw the heater control

panel15.69A . . . undo the retaining screws

(arrowed)15.68 Remove the control knobs . . .

15.63 . . . and withdraw the auxiliary

control panel

15.62 Prise free the trim covers for access

to retaining screws . . .15.59B . . . and disconnect the

speedometer cable15.59A . . . withdraw the instrument

panel . . .

Page 234 of 303

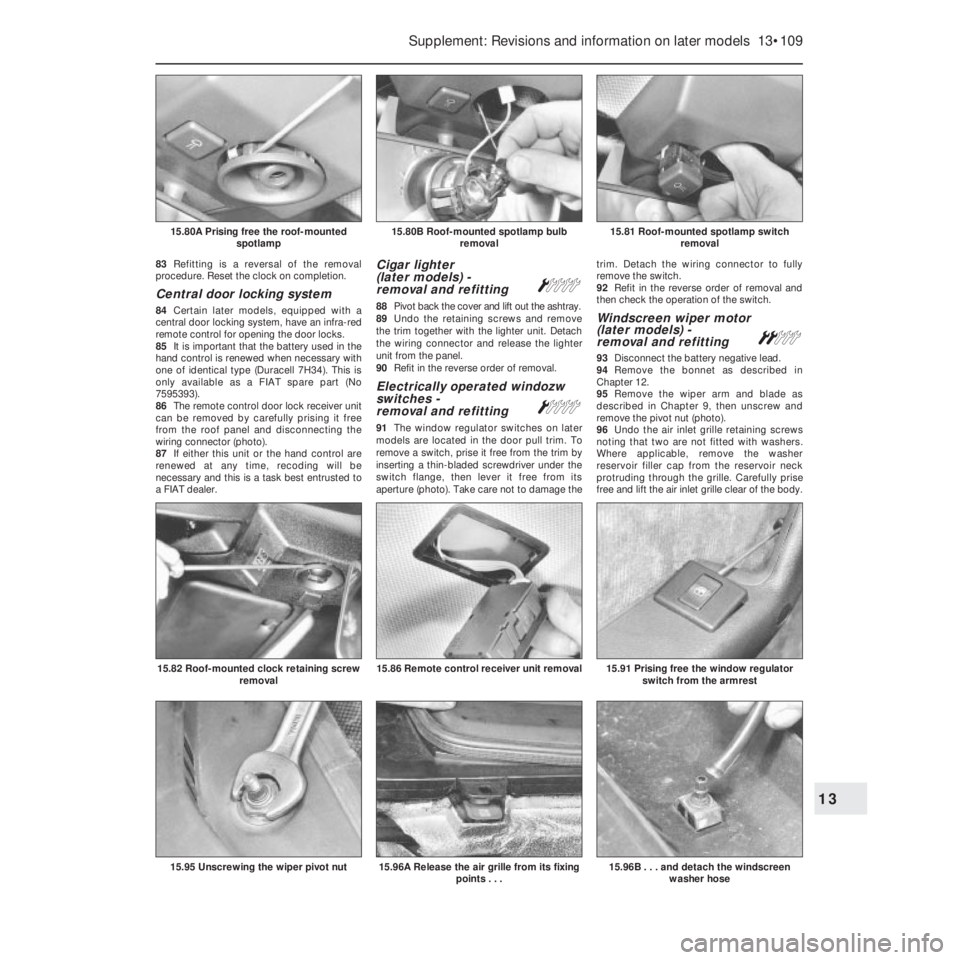

83Refitting is a reversal of the removal

procedure. Reset the clock on completion.

Central door locking system

84Certain later models, equipped with a

central door locking system, have an infra-red

remote control for opening the door locks.

85It is important that the battery used in the

hand control is renewed when necessary with

one of identical type (Duracell 7H34). This is

only available as a FIAT spare part (No

7595393).

86The remote control door lock receiver unit

can be removed by carefully prising it free

from the roof panel and disconnecting the

wiring connector (photo).

87If either this unit or the hand control are

renewed at any time, recoding will be

necessary and this is a task best entrusted to

a FIAT dealer.

Cigar lighter

(later models) -

removal and refitting

Á

88Pivot back the cover and lift out the ashtray.

89Undo the retaining screws and remove

the trim together with the lighter unit. Detach

the wiring connector and release the lighter

unit from the panel.

90Refit in the reverse order of removal.

Electrically operated windozw

switches -

removal and refitting

Á

91The window regulator switches on later

models are located in the door pull trim. To

remove a switch, prise it free from the trim by

inserting a thin-bladed screwdriver under the

switch flange, then lever it free from its

aperture (photo). Take care not to damage thetrim. Detach the wiring connector to fully

remove the switch.

92Refit in the reverse order of removal and

then check the operation of the switch.

Windscreen wiper motor

(later models) -

removal and refitting

ª

93Disconnect the battery negative lead.

94Remove the bonnet as described in

Chapter 12.

95Remove the wiper arm and blade as

described in Chapter 9, then unscrew and

remove the pivot nut (photo).

96Undo the air inlet grille retaining screws

noting that two are not fitted with washers.

Where applicable, remove the washer

reservoir filler cap from the reservoir neck

protruding through the grille. Carefully prise

free and lift the air inlet grille clear of the body.

Supplement: Revisions and information on later models 13•109

15.81 Roof-mounted spotlamp switch

removal15.80B Roof-mounted spotlamp bulb

removal15.80A Prising free the roof-mounted

spotlamp

15.96B . . . and detach the windscreen

washer hose15.96A Release the air grille from its fixing

points . . .15.95 Unscrewing the wiper pivot nut

15.91 Prising free the window regulator

switch from the armrest15.86 Remote control receiver unit removal15.82 Roof-mounted clock retaining screw

removal

13

Page 235 of 303

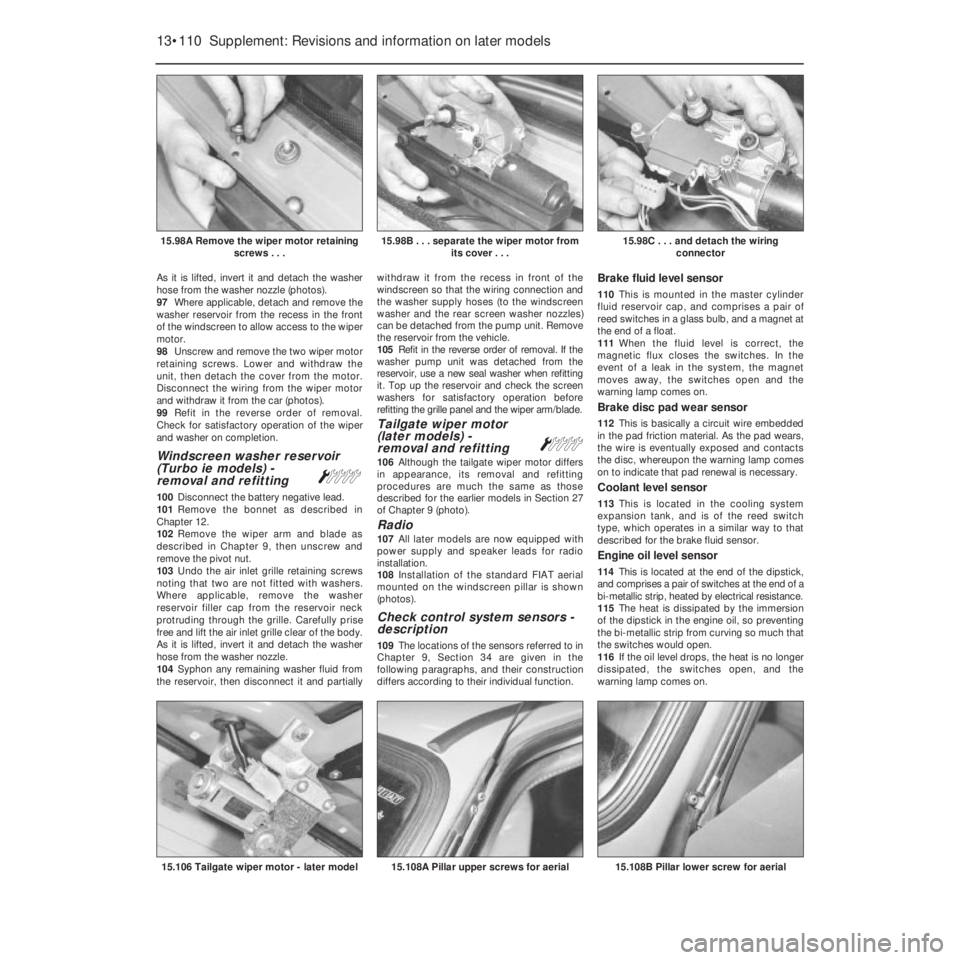

As it is lifted, invert it and detach the washer

hose from the washer nozzle (photos).

97Where applicable, detach and remove the

washer reservoir from the recess in the front

of the windscreen to allow access to the wiper

motor.

98Unscrew and remove the two wiper motor

retaining screws. Lower and withdraw the

unit, then detach the cover from the motor.

Disconnect the wiring from the wiper motor

and withdraw it from the car (photos).

99Refit in the reverse order of removal.

Check for satisfactory operation of the wiper

and washer on completion.

Windscreen washer reservoir

(Turbo ie models) -

removal and refitting

Á

100Disconnect the battery negative lead.

101Remove the bonnet as described in

Chapter 12.

102Remove the wiper arm and blade as

described in Chapter 9, then unscrew and

remove the pivot nut.

103Undo the air inlet grille retaining screws

noting that two are not fitted with washers.

Where applicable, remove the washer

reservoir filler cap from the reservoir neck

protruding through the grille. Carefully prise

free and lift the air inlet grille clear of the body.

As it is lifted, invert it and detach the washer

hose from the washer nozzle.

104Syphon any remaining washer fluid from

the reservoir, then disconnect it and partiallywithdraw it from the recess in front of the

windscreen so that the wiring connection and

the washer supply hoses (to the windscreen

washer and the rear screen washer nozzles)

can be detached from the pump unit. Remove

the reservoir from the vehicle.

105Refit in the reverse order of removal. If the

washer pump unit was detached from the

reservoir, use a new seal washer when refitting

it. Top up the reservoir and check the screen

washers for satisfactory operation before

refitting the grille panel and the wiper arm/blade.

Tailgate wiper motor

(later models) -

removal and refitting

Á

106Although the tailgate wiper motor differs

in appearance, its removal and refitting

procedures are much the same as those

described for the earlier models in Section 27

of Chapter 9 (photo).

Radio

107All later models are now equipped with

power supply and speaker leads for radio

installation.

108Installation of the standard FIAT aerial

mounted on the windscreen pillar is shown

(photos).

Check control system sensors -

description

109The locations of the sensors referred to in

Chapter 9, Section 34 are given in the

following paragraphs, and their construction

differs according to their individual function.

Brake fluid level sensor

110This is mounted in the master cylinder

fluid reservoir cap, and comprises a pair of

reed switches in a glass bulb, and a magnet at

the end of a float.

111When the fluid level is correct, the

magnetic flux closes the switches. In the

event of a leak in the system, the magnet

moves away, the switches open and the

warning lamp comes on.

Brake disc pad wear sensor

112This is basically a circuit wire embedded

in the pad friction material. As the pad wears,

the wire is eventually exposed and contacts

the disc, whereupon the warning lamp comes

on to indicate that pad renewal is necessary.

Coolant level sensor

113This is located in the cooling system

expansion tank, and is of the reed switch

type, which operates in a similar way to that

described for the brake fluid sensor.

Engine oil level sensor

114This is located at the end of the dipstick,

and comprises a pair of switches at the end of a

bi-metallic strip, heated by electrical resistance.

115The heat is dissipated by the immersion

of the dipstick in the engine oil, so preventing

the bi-metallic strip from curving so much that

the switches would open.

116If the oil level drops, the heat is no longer

dissipated, the switches open, and the

warning lamp comes on.

13•110 Supplement: Revisions and information on later models

15.108B Pillar lower screw for aerial15.108A Pillar upper screws for aerial15.106 Tailgate wiper motor - later model

15.98C . . . and detach the wiring

connector15.98B . . . separate the wiper motor from

its cover . . .15.98A Remove the wiper motor retaining

screws . . .

Page 236 of 303

Door closure sensor

117The sensor consists of a microswitch

within the lock. The switch actuates the

warning lamp according to whether the lock is

in the open or closed mode.

Check control system sensors -

testing

Brake fluid level sensor

118With the fluid level correct, switch on the

ignition and depress the centre of the

reservoir cap. If the sensor switches are

working correctly, then “FAULT” should be

indicated on the check panel.

Coolant level sensor

119With the coolant level in the expansion

tank correct, switch on the ignition and then

pull the wiring plug from the sensor. “FAULT”

should be indicated on the check panel. If it is

not, then it is the panel which is faulty.

120An ohmmeter should be used to check

for continuity, holding the float in both the full

and low level positions.

Engine oil level sensor

121With the oil level correct, disconnect the

wiring plug from the dipstick, and then bridge

the plug terminals (not dipstick side) with a 12

ohm resistor. Switch on the ignition.

122If the red light on the check panel goes

out, then the fault is due to the sensor.

123If the light stays on, then it is the check

panel module which is faulty.

Door closure sensor

124Any fault in the lock microswitch can best

be detected using an ohmmeter.

16 Suspension

Front anti-roll bar -

removal and refittingª

1A front anti-roll bar is fitted to the 1301 cc,

1372 cc ie and 1372 cc Turbo ie engined

models. Removal of the bar on all models isas follows. Firstly loosen off the front

roadwheel bolts, then raise the front of the

car, securely support it on axle stands and

remove the front roadwheels.

2Disconnect the two gearchange rods from

the transmission.

3Unbolt and disconnect the anti-roll bar

insulating clamps from the floorpan (photo).

4Unbolt the end links from the track control

arms and withdraw the anti-roll bar (photo).

5Refitting is a reversal of removal, but only

tighten the nuts and bolts to the specified

torque with the car parked on level ground,

with four passengers and 40 kg of luggage

inside.

Suspension strut - later models

6The suspension strut upper mounting nuts

on later models also secure the brackets for

the mounting of ancillary components such as

the fuel filter, fuel system relays and fuses,

etc. (depending on model).

7When removing the suspension strut units,

it will therefore be necessary to detach and

support these brackets and their fittings

(photo).

17 Bodywork

Plastic components

1With the use of more and more plastic

body components by the vehicle

manufacturers (e.g. bumpers, spoilers, and in

some cases major body panels), rectification

of more serious damage to such items has

become a matter of either entrusting repair

work to a specialist in this field, or renewing

complete components. Repair of such

damage by the DIY owner is not really

feasible owing to the cost of the equipment

and materials required for effecting such

repairs. The basic technique involves making

a groove along the line of the crack in the

plastic using a rotary burr in a power drill. The

damaged part is then welded back togetherby using a hot air gun to heat up and fuse a

plastic filler rod into the groove. Any excess

plastic is then removed and the area rubbed

down to a smooth finish. It is important that a

filler rod of the correct plastic is used, as

body components can be made of a variety

of different types (e.g. polycarbonate, ABS,

polypropylene). Damage of a less serious

nature (abrasions, minor cracks, etc.) can be

repaired by the DIY owner using a two-part

epoxy filler repair material. Once mixed in

equal proportions, this is used in similar

fashion to the bodywork filler used on metal

panels. The filler is usually cured in twenty to

thirty minutes, ready for sanding and

painting.

2If the owner is renewing a complete

component himself, or if he has repaired it

with epoxy filler, he will be left with the

problem of finding a suitable paint for

finishing which is compatible with the type of

plastic used. At one time the use of a

universal paint was not possible owing to the

complex range of plastics encountered in

body component applications. Standard

paints, generally speaking, will not bond to

plastic or rubber satisfactorily. However, it is

now possible to obtain a plastic body parts

finishing kit which consists of a pre-primer

treatment, a primer and coloured top coat.

Full instructions are normally supplied with a

kit, but basically the method of use is to first

apply the pre-primer to the component

concerned and allow it to dry for up to

30 minutes. Then the primer is applied and

left to dry for about an hour before finally

applying the special coloured top coat. The

result is a correctly coloured component

where the paint will flex with the plastic or

rubber, a property that standard paint does

not normally possess.

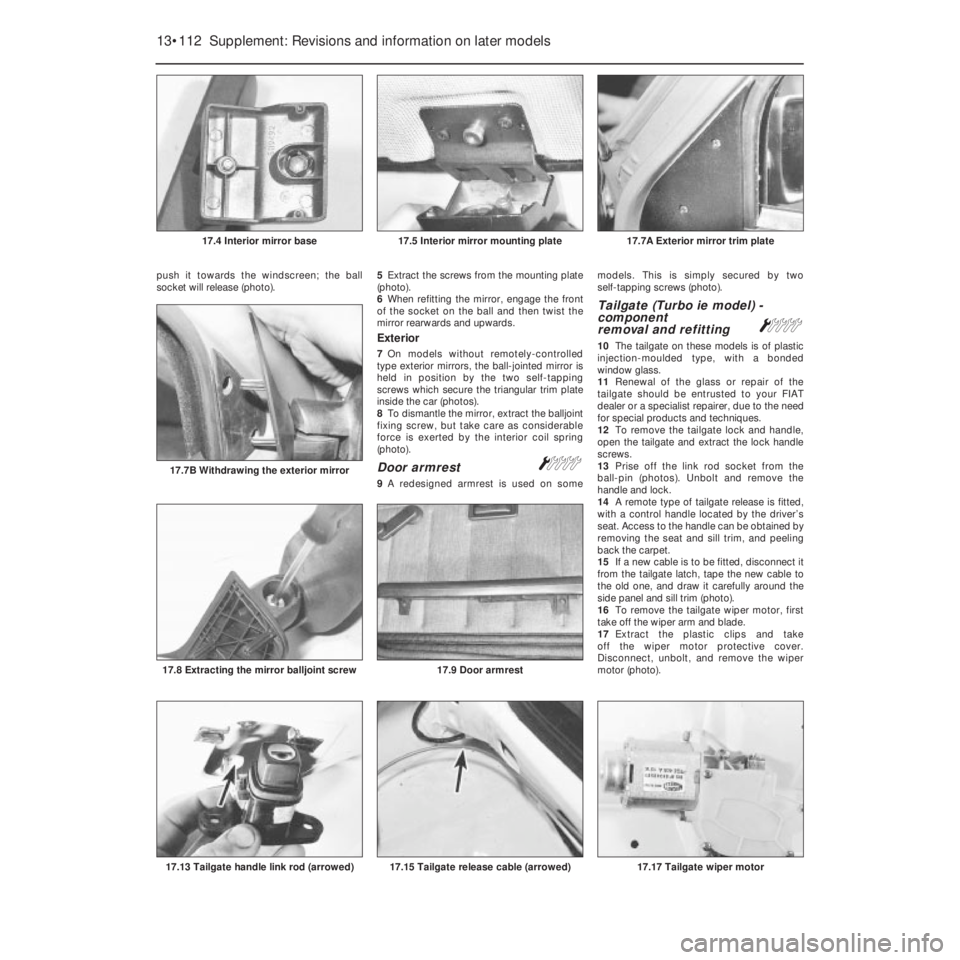

Rear view mirrors Á

Interior

3The mirror is of safety type, “breaking” off

its ball fixing upon impact from a front seat

occupant.

4To remove the mirror, grip the head and

Supplement: Revisions and information on later models 13•111

16.7 Suspension strut upper mounting

nuts, showing bracket and cable clip on

the 1372 cc ie model16.4 Anti-roll bar fixing nuts (arrowed)16.3 Anti-roll bar clamp

13

Page 237 of 303

push it towards the windscreen; the ball

socket will release (photo).5Extract the screws from the mounting plate

(photo).

6When refitting the mirror, engage the front

of the socket on the ball and then twist the

mirror rearwards and upwards.

Exterior

7On models without remotely-controlled

type exterior mirrors, the ball-jointed mirror is

held in position by the two self-tapping

screws which secure the triangular trim plate

inside the car (photos).

8To dismantle the mirror, extract the balljoint

fixing screw, but take care as considerable

force is exerted by the interior coil spring

(photo).

Door armrestÁ

9A redesigned armrest is used on somemodels. This is simply secured by two

self-tapping screws (photo).

Tailgate (Turbo ie model) -

component

removal and refitting

Á

10The tailgate on these models is of plastic

injection-moulded type, with a bonded

window glass.

11Renewal of the glass or repair of the

tailgate should be entrusted to your FIAT

dealer or a specialist repairer, due to the need

for special products and techniques.

12To remove the tailgate lock and handle,

open the tailgate and extract the lock handle

screws.

13Prise off the link rod socket from the

ball-pin (photos). Unbolt and remove the

handle and lock.

14A remote type of tailgate release is fitted,

with a control handle located by the driver’s

seat. Access to the handle can be obtained by

removing the seat and sill trim, and peeling

back the carpet.

15If a new cable is to be fitted, disconnect it

from the tailgate latch, tape the new cable to

the old one, and draw it carefully around the

side panel and sill trim (photo).

16To remove the tailgate wiper motor, first

take off the wiper arm and blade.

17Extract the plastic clips and take

off the wiper motor protective cover.

Disconnect, unbolt, and remove the wiper

motor (photo).

13•112 Supplement: Revisions and information on later models

17.17 Tailgate wiper motor17.15 Tailgate release cable (arrowed)17.13 Tailgate handle link rod (arrowed)

17.9 Door armrest17.8 Extracting the mirror balljoint screw

17.7B Withdrawing the exterior mirror

17.7A Exterior mirror trim plate17.5 Interior mirror mounting plate17.4 Interior mirror base

Page 238 of 303

18Refitting of all components is a reversal of

removal.

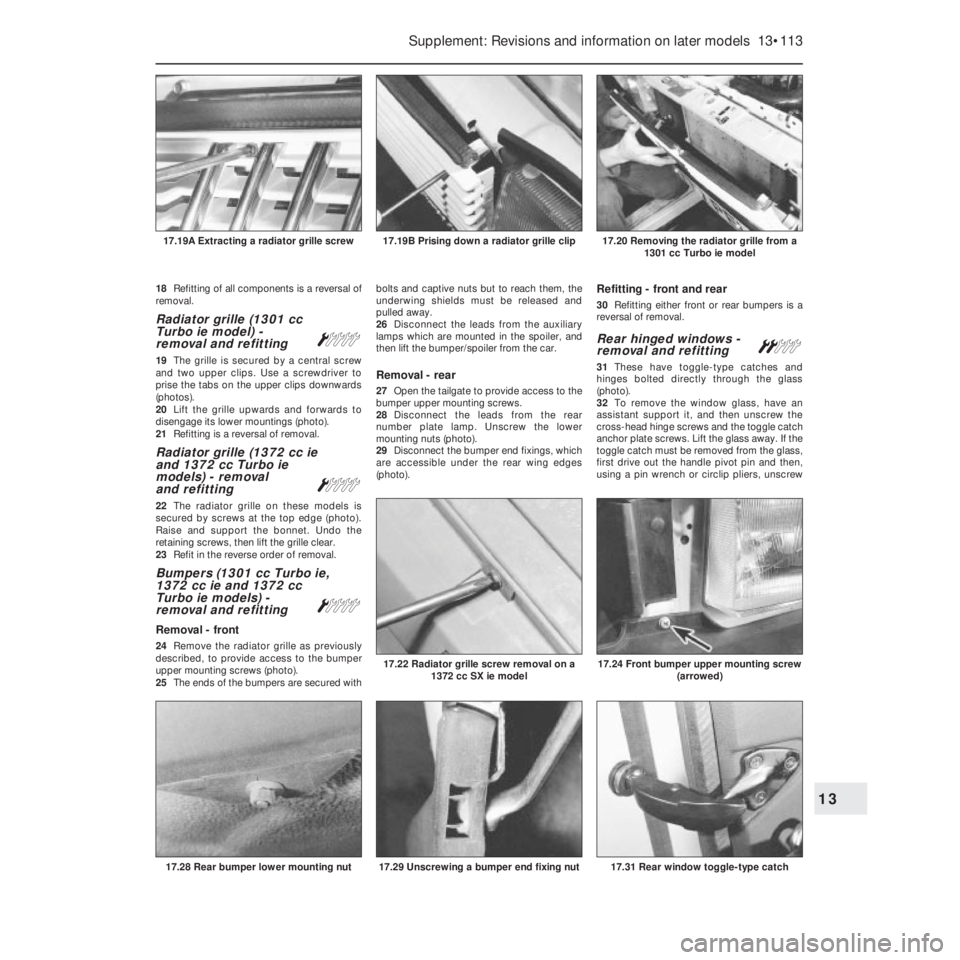

Radiator grille (1301 cc

Turbo ie model) -

removal and refitting

Á

19The grille is secured by a central screw

and two upper clips. Use a screwdriver to

prise the tabs on the upper clips downwards

(photos).

20Lift the grille upwards and forwards to

disengage its lower mountings (photo).

21Refitting is a reversal of removal.

Radiator grille (1372 cc ie

and 1372 cc Turbo ie

models) - removal

and refitting

Á

22The radiator grille on these models is

secured by screws at the top edge (photo).

Raise and support the bonnet. Undo the

retaining screws, then lift the grille clear.

23Refit in the reverse order of removal.

Bumpers (1301 cc Turbo ie,

1372 cc ie and 1372 cc

Turbo ie models) -

removal and refitting

Á

Removal - front

24Remove the radiator grille as previously

described, to provide access to the bumper

upper mounting screws (photo).

25The ends of the bumpers are secured withbolts and captive nuts but to reach them, the

underwing shields must be released and

pulled away.

26Disconnect the leads from the auxiliary

lamps which are mounted in the spoiler, and

then lift the bumper/spoiler from the car.

Removal - rear

27Open the tailgate to provide access to the

bumper upper mounting screws.

28Disconnect the leads from the rear

number plate lamp. Unscrew the lower

mounting nuts (photo).

29Disconnect the bumper end fixings, which

are accessible under the rear wing edges

(photo).

Refitting - front and rear

30Refitting either front or rear bumpers is a

reversal of removal.

Rear hinged windows -

removal and refittingª

31These have toggle-type catches and

hinges bolted directly through the glass

(photo).

32To remove the window glass, have an

assistant support it, and then unscrew the

cross-head hinge screws and the toggle catch

anchor plate screws. Lift the glass away. If the

toggle catch must be removed from the glass,

first drive out the handle pivot pin and then,

using a pin wrench or circlip pliers, unscrew

Supplement: Revisions and information on later models 13•113

17.20 Removing the radiator grille from a

1301 cc Turbo ie model17.19B Prising down a radiator grille clip17.19A Extracting a radiator grille screw

17.31 Rear window toggle-type catch17.29 Unscrewing a bumper end fixing nut

17.24 Front bumper upper mounting screw

(arrowed)17.22 Radiator grille screw removal on a

1372 cc SX ie model

17.28 Rear bumper lower mounting nut

13

Page 239 of 303

the ring nut which secures the handle to the

glass.

33When refitting the screws or ring nut to

the glass, make sure that the insulating

washers are in good condition to prevent

metal-to-glass contact.Door trim panel

(Turbo ie model) -

removal and refitting

Á34The operations are similar to those

described in Chapter 12, Section 11, except

that electric windows are fitted instead of aconventional mechanical regulator and

handle. Before the trim panel can be

withdrawn, the window control switches

must be disconnected from the wiring plug,

and the plug fed through the panel aperture

(photos).

13•114 Supplement: Revisions and information on later models

17.34C Door interior showing electric

window motor (arrowed)17.34B Disconnecting an electric window

regulator switch plug17.34A Armrest electric window switches

Page 240 of 303

Wiring diagrams 14•1

14

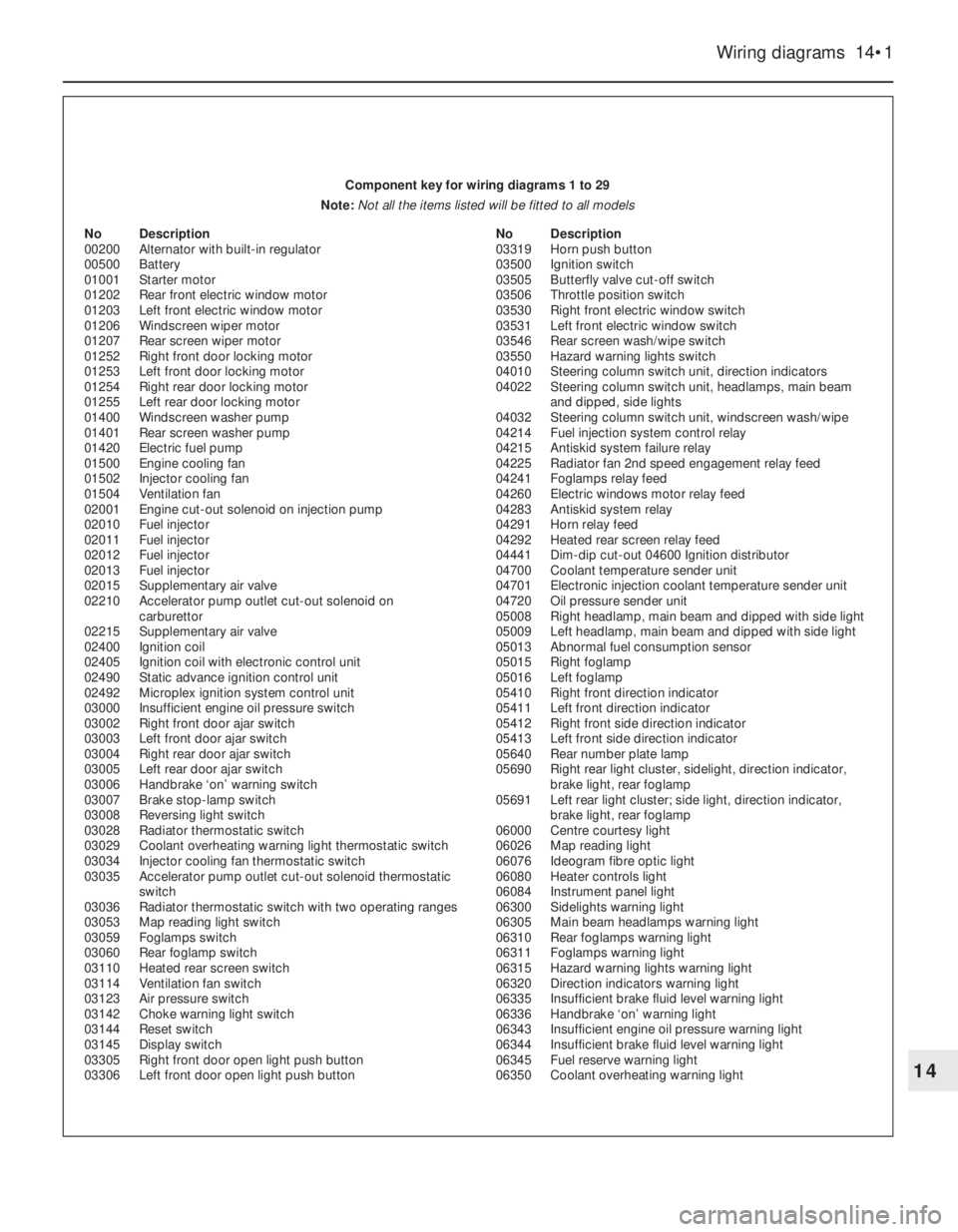

Component key for wiring diagrams 1 to 29

Note: Not all the items listed will be fitted to all models

No Description

00200 Alternator with built-in regulator

00500 Battery

01001 Starter motor

01202 Rear front electric window motor

01203 Left front electric window motor

01206 Windscreen wiper motor

01207 Rear screen wiper motor

01252 Right front door locking motor

01253 Left front door locking motor

01254 Right rear door locking motor

01255 Left rear door locking motor

01400 Windscreen washer pump

01401 Rear screen washer pump

01420 Electric fuel pump

01500 Engine cooling fan

01502 Injector cooling fan

01504 Ventilation fan

02001 Engine cut-out solenoid on injection pump

02010 Fuel injector

02011 Fuel injector

02012 Fuel injector

02013 Fuel injector

02015 Supplementary air valve

02210 Accelerator pump outlet cut-out solenoid on

carburettor

02215 Supplementary air valve

02400 Ignition coil

02405 Ignition coil with electronic control unit

02490 Static advance ignition control unit

02492 Microplex ignition system control unit

03000 Insufficient engine oil pressure switch

03002 Right front door ajar switch

03003 Left front door ajar switch

03004 Right rear door ajar switch

03005 Left rear door ajar switch

03006 Handbrake ‘on’ warning switch

03007 Brake stop-lamp switch

03008 Reversing light switch

03028 Radiator thermostatic switch

03029 Coolant overheating warning light thermostatic switch

03034 Injector cooling fan thermostatic switch

03035 Accelerator pump outlet cut-out solenoid thermostatic

switch

03036 Radiator thermostatic switch with two operating ranges

03053 Map reading light switch

03059 Foglamps switch

03060 Rear foglamp switch

03110 Heated rear screen switch

03114 Ventilation fan switch

03123 Air pressure switch

03142 Choke warning light switch

03144 Reset switch

03145 Display switch

03305 Right front door open light push button

03306 Left front door open light push button No Description

03319 Horn push button

03500 Ignition switch

03505 Butterfly valve cut-off switch

03506 Throttle position switch

03530 Right front electric window switch

03531 Left front electric window switch

03546 Rear screen wash/wipe switch

03550 Hazard warning lights switch

04010 Steering column switch unit, direction indicators

04022 Steering column switch unit, headlamps, main beam

and dipped, side lights

04032 Steering column switch unit, windscreen wash/wipe

04214 Fuel injection system control relay

04215 Antiskid system failure relay

04225 Radiator fan 2nd speed engagement relay feed

04241 Foglamps relay feed

04260 Electric windows motor relay feed

04283 Antiskid system relay

04291 Horn relay feed

04292 Heated rear screen relay feed

04441 Dim-dip cut-out 04600 Ignition distributor

04700 Coolant temperature sender unit

04701 Electronic injection coolant temperature sender unit

04720 Oil pressure sender unit

05008 Right headlamp, main beam and dipped with side light

05009 Left headlamp, main beam and dipped with side light

05013 Abnormal fuel consumption sensor

05015 Right foglamp

05016 Left foglamp

05410 Right front direction indicator

05411 Left front direction indicator

05412 Right front side direction indicator

05413 Left front side direction indicator

05640 Rear number plate lamp

05690 Right rear light cluster, sidelight, direction indicator,

brake light, rear foglamp

05691 Left rear light cluster; side light, direction indicator,

brake light, rear foglamp

06000 Centre courtesy light

06026 Map reading light

06076 Ideogram fibre optic light

06080 Heater controls light

06084 Instrument panel light

06300 Sidelights warning light

06305 Main beam headlamps warning light

06310 Rear foglamps warning light

06311 Foglamps warning light

06315 Hazard warning lights warning light

06320 Direction indicators warning light

06335 Insufficient brake fluid level warning light

06336 Handbrake ‘on’ warning light

06343 Insufficient engine oil pressure warning light

06344 Insufficient brake fluid level warning light

06345 Fuel reserve warning light

06350 Coolant overheating warning light