sensor FORD FESTIVA 1991 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 1991, Model line: FESTIVA, Model: FORD FESTIVA 1991Pages: 454, PDF Size: 9.53 MB

Page 104 of 454

1. Position new gasket on exhaust manifold, and install turbocharger onto studs. Install 4 retaining nuts and tighten to specification. See

TORQUE SPECIFICATIONS

table at end of article.

2. Remove oil supply line from turbocharger. Position new (2-piece) exhaust gasket on cylinder head with heavy gasket installed first .

Carefully position turbocharger assembly in engine compartment and slide exhaust manifold on studs. Position heater tube bracket onto

exhaust stud. Install 11 retaining nuts onto exhaust manifold and tighten to specification. See TORQUE SPECIFICATIONS

table at

end of article. Tighten heater tube clamp bolt securely.

3. Raise vehicle. Position new gasket and install 2 retaining bolts on heater tube outlet. Install 2 retaining bolts into turbocharger support

bracket and tighten bolts to specification.

4. Connect coolant return hose. Connect oil return hose and secure with clamp. Position exhaust pipe onto turbocharger, and start nuts

and washers. Install 2 retaining bolts on exhaust hanger at engine. Slide on 2 rubber exhaust hangers at catalytic converter. Tighten

exhaust pipe retaining nuts to specification. Lower vehicle.

5. Install retaining bolt and brass washers on oil supply line, carefully position oil line into vehicle and hand-start bolt into engine block.

Connect and finger tighten oil line to turbocharger. Tighten oil line bolt and oil supply line on turbocharger to specification.

6. Connect coolant supply hose. Position air cleaner duct tube on turbocharger and tighten clamp. Install 2 screws retaining air cleaner

duct tube. Position power steering pump bracket on engine, and install 2 retaining bolts and one retaining nut. Tighten to specification.

Position power steering pump on mounting bracket, and install though bolt and adjuster. Connect lower radiator hose. Install power

steering belt. Position upper heat shield and install 2 retaining bolts finger tight.

7. Position lower heat shield and install three retaining bolts finger tight. Tighten all heat shield bolts to specification. Connect O2 sensor

and install connector into its retaining clip. See TORQUE SPECIFICATIONS

table at end of article. Position intercooler hose on

turbocharger and secure with clamp. Install throttle body air intake tube. Connect negative battery cable. Refill cooling system.

CYLINDER HEAD

Removal (1.3L)

1. Disconnect battery ground cable. Mark and disconnect fuel lines at fuel pump. Remove accessory belts, water pump pulley, crankshaft

pulley, timing belt covers, timing belt tensioner, timing belt, valve cover and exhaust and intake manifolds. Drain cooling system.

2. Mark and remove electrical connectors and vacuum hoses. Remove spark plug wires from spark plugs, and remove spark plugs. Remove

distributor cap. Disconnect vacuum hoses and distributor wiring.

3. Index distributor-to-mount position and remove hold-down bolt. Remove distributor assembly. Remove engine ground strap. Remove

front and rear engine lifting hooks. Remove upper radiator hose, by-pass hose and bracket.

4. Remove bolts retaining rocker arm shaft. Remove rocker arm assemblies. Remove cylinder head bolts. Remove head and gasket.

Inspection (1.3L)

1. Thoroughly clean and check gasket mating surface of cylinder head and block. Check cylinder for cracks, nicks, burrs or damage. Using

a straightedge and feeler gauge, check warpage over entire gasket area. Ensure cylinder head and/or block warpage does not

exceed .006" (.15 mm).

2. If warpage exceeds .006" (.15 mm), machine cylinder head and/or block gasket surface. Maximum machining allowed is .008" (.20 mm).

If more machining is required, replace block and/or cylinder head.

Installation (1.3L)

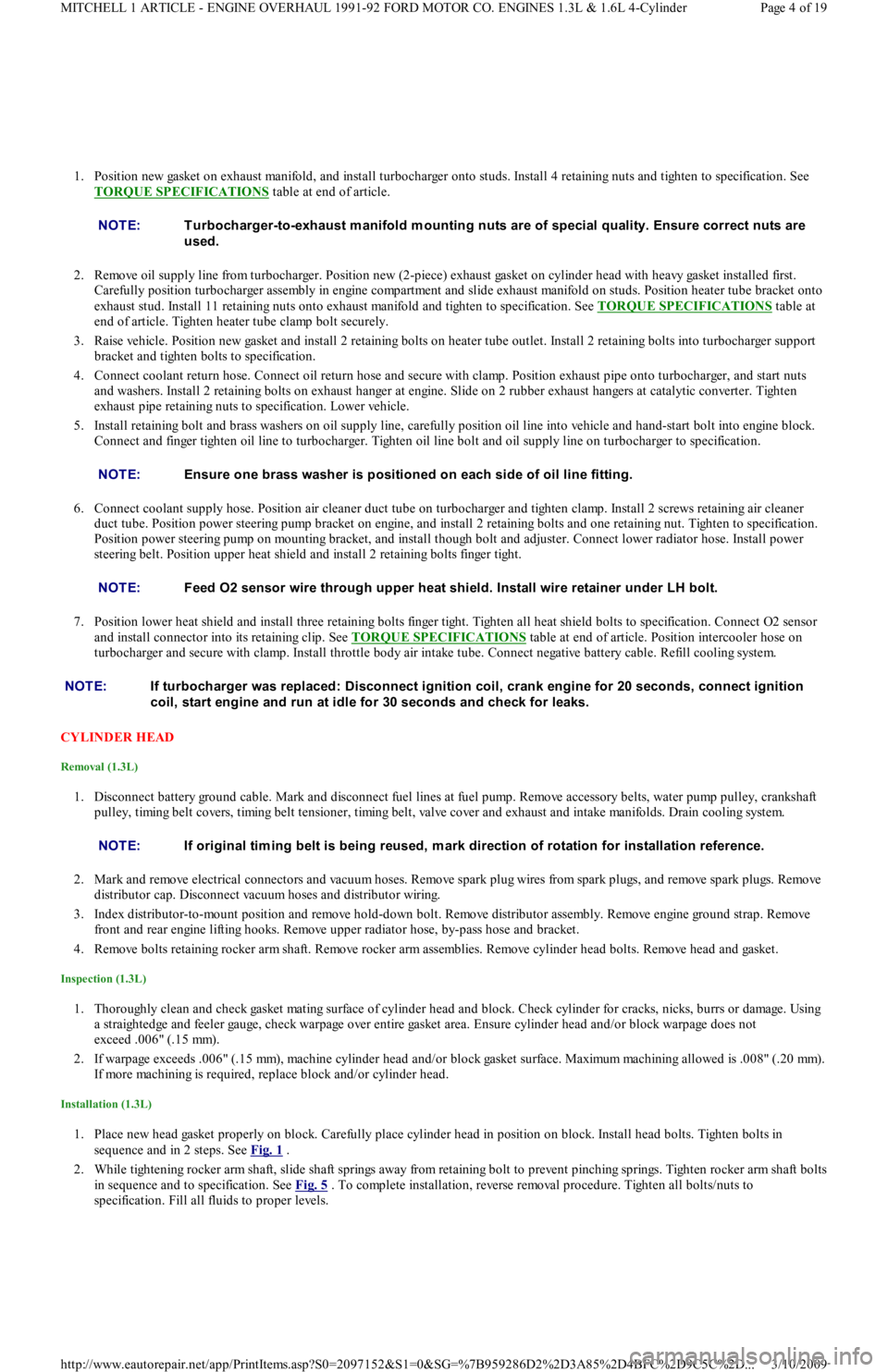

1. Place new head gasket properly on block. Carefully place cylinder head in position on block. Install head bolts. Tighten bolts in

sequence and in 2 steps. See Fig. 1

.

2. While tightening rocker arm shaft, slide shaft springs away from retaining bolt to prevent pinching springs. Tighten rocker arm shaft bolts

in sequence and to specification. See Fig. 5

. To complete installation, reverse removal procedure. Tighten all bolts/nuts to

specification. Fill all fluids to proper levels. NOTE:T urbocharger-to-exhaust m anifold m ounting nuts are of special quality. Ensure correct nuts are

used.

NOTE:Ensure one brass washer is positioned on each side of oil line fitting.

NOTE:Feed O2 sensor wire through upper heat shield. Install wire retainer under LH bolt.

NOTE:If turbocharger was replaced: Disconnect ignition coil, crank engine for 20 seconds, connect ignition

coil, start engine and run at idle for 30 seconds and check for leaks.

NOTE:If original tim ing belt is being reused, m ark direction of rotation for installation reference.

Page 4 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 105 of 454

Fig. 1: Installing Cylinder Head Bolts (1.3L)

Courtesy of FORD MOTOR CO.

Removal (1.6L)

1. Release fuel pressure. Drain cooling system. Disconnect negative battery terminal. Remove intake air tube from throttle body.

Disconnect air by-pass hoses. Remove spark plug wires and retainers. Remove intake air tube from air cleaner assembly. Disconnect

coolant hose from thermostat cover. Disconnect vacuum hoses and coolant hoses from throttle body and intake manifold.

2. Disconnect throttle cable and remove retaining brackets and cable. Disconnect fuel lines at fuel filter and pressure regulator. Disconnect

main harness connector. Disconnect O2 sensor connector and remove ground connection retaining screw at bracket. Disconnect

intercooler tubes from turbocharger (if equipped). Remove ground wire and strap retaining bolts at front sides of cylinder head.

3. Remove timing belt covers and timing belt. On turbocharged vehicles, remove exhaust manifold and turbocharger as an assembly. On

non-turbocharged vehicles, disconnect front exhaust pipe from exhaust manifold. Remove intake manifold support upper retaining bolts.

4. Remove cam cover. Remove cylinder head and intake manifold as an assembly. Separate intake manifold from cylinder head (if

required).

Installation (1.6L)

1. Position new (2-piece) exhaust gasket on cylinder head with heavy gasket installed first. Install exhaust manifold to head. Install intake

manifold to head using new gasket. Tighten all manifold nuts to specification. See TORQUE SPECIFICATIONS

table at end of

article.

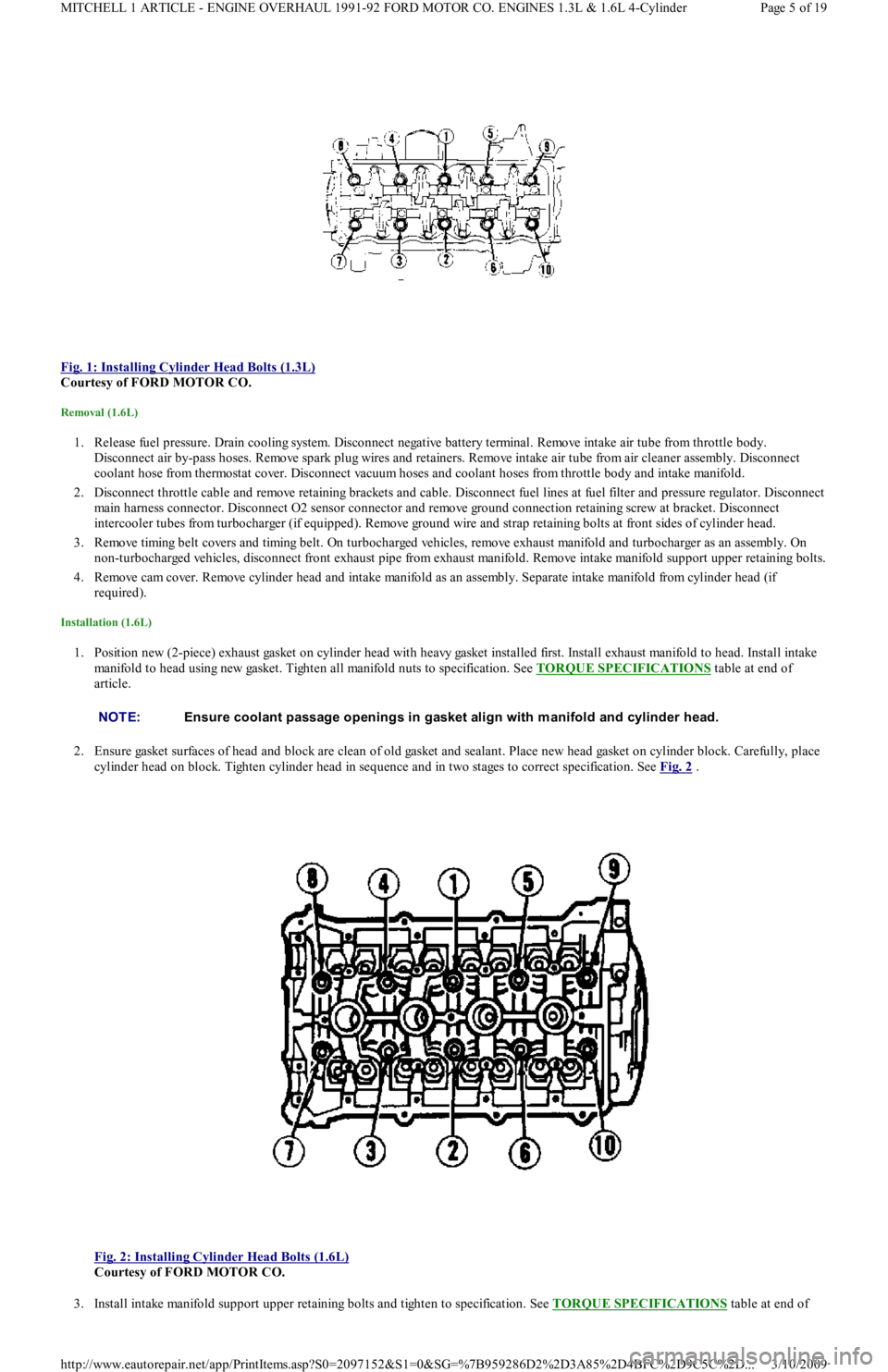

2. Ensure gasket surfaces of head and block are clean of old gasket and sealant. Place new head gasket on cylinder block. Carefully, place

cylinder head on block. Tighten cylinder head in sequence and in two stages to correct specification. See Fig. 2

.

Fig. 2: Installing Cylinder Head Bolts (1.6L)

Courtesy of FORD MOTOR CO.

3. Install intake manifold support upper retaining bolts and tighten to specification. See TORQUE SPECIFICATIONS

table at end of

NOTE:Ensure coolant passage openings in gasket align with m anifold and cylinder head.

Page 5 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 106 of 454

article. Install timing belt and covers. Install cam cover. On non-turbo engines, connect front exhaust pipe to exhaust manifold. Tighten

nuts to specification.

4. On turbocharged engines, install exhaust manifold and turbocharger assembly. Install ground wire and strap to cylinder head with

retaining bolts. Connect intercooler tubes (if equipped). Connect O2 sensor connector, and install ground wires to bracket on cylinder

head with retaining screw. Connect main engine harness connector. Connect fuel lines to fuel filter and pressure regulator. Install

throttle cable and retaining brackets.

5. Install coolant hoses and vacuum lines to intake manifold and throttle body. Install coolant hose to thermostat cover. Install intake air

tube to air cleaner. Install spark plug wires and retainers. Install intake air tube to throttle body, and connect by-pass hoses. Fill cooling

system. Connect negative battery terminal. Start engine, check for leaks and system operation.

TIMING BELT COVER

Removal & Installation (1.3L)

Remove accessory belts. Remove water pump pulley. Remove crankshaft damper. Remove bolts retaining upper and lower cover halves to

engine front. Remove both covers. To install, reverse removal procedure.

Removal & Installation (1.6L)

Raise vehicle on hoist. Remove RF tire and wheel assembly. Remove RF splash guard. Lower vehicle. Remove spark plugs and set camsh aft

timing to TDC No. 1 cylinder. Remove oil dipstick. Remove water pump pulley. Remove crankshaft pulley, damper and baffle plate. Remove

upper timing belt cover. Remove center and lower timing belt covers. To install, reverse removal procedure.

TIMING BELT

Removal (1.3L)

Remove accessory belts, water pump pulley, crankshaft damper and upper and lower timing belt covers. Mark timing belt direction of rotation

for installation reference. Remove timing belt tensioner pulley bolt. Remove tensioner pulley, spring and spring cover. Remove timing belt.

Installation (1.3L)

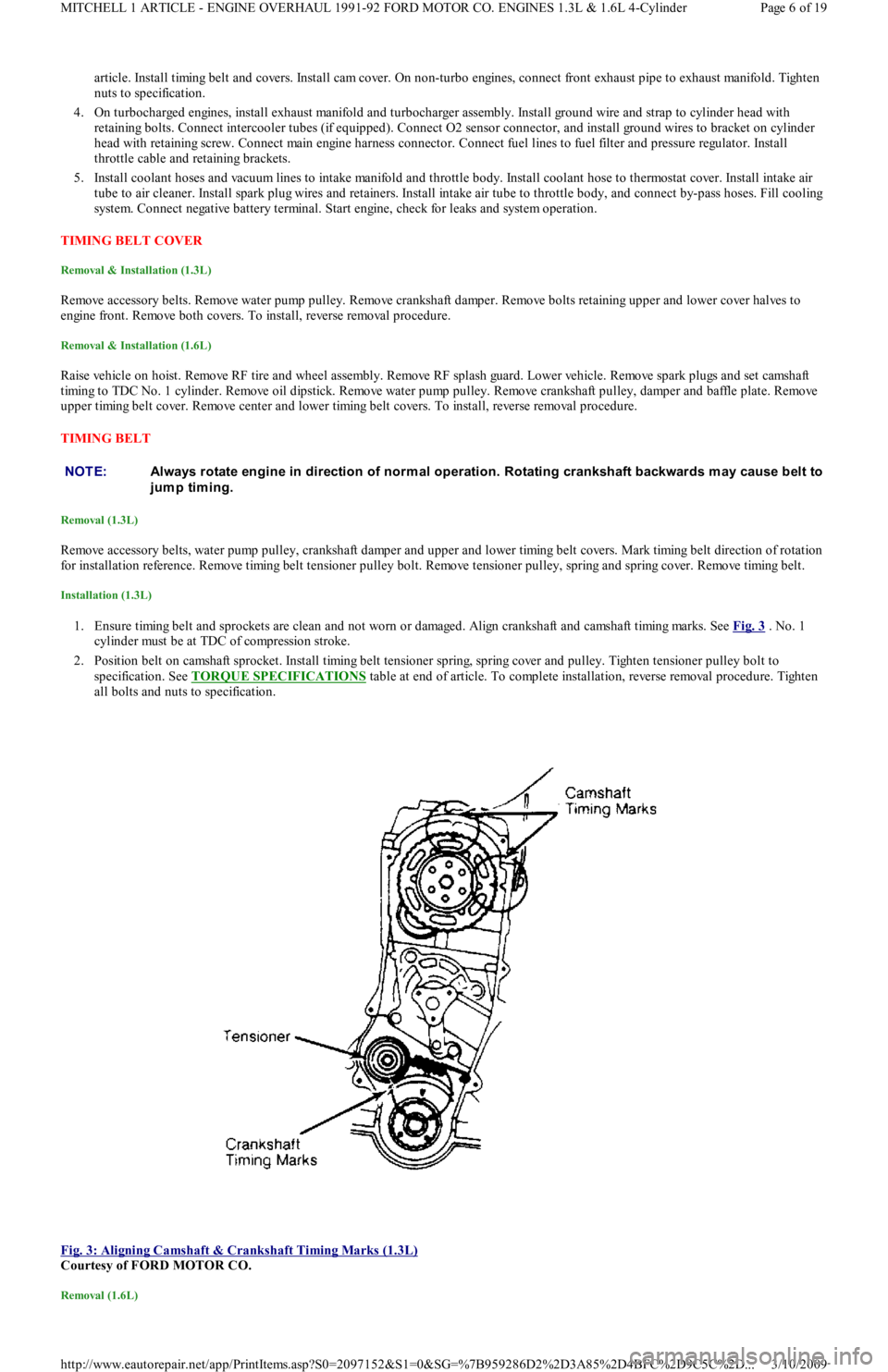

1. Ensure timing belt and sprockets are clean and not worn or damaged. Align crankshaft and camshaft timing marks. See Fig. 3 . No. 1

cylinder must be at TDC of compression stroke.

2. Position belt on camshaft sprocket. Install timing belt tensioner spring, spring cover and pulley. Tighten tensioner pulley bolt to

specification. See TORQUE SPECIFICATIONS

table at end of article. To complete installation, reverse removal procedure. Tighten

all bolts and nuts to specification.

Fig. 3: Aligning Camshaft & Crankshaft Timing Marks (1.3L)

Courtesy of FORD MOTOR CO.

Removal (1.6L)

NOTE:Always rotate engine in direction of norm al operation. Rotating crankshaft backwards m ay cause belt to

jump timing.

Page 6 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 115 of 454

Installation

1. Install pressure regulator valve, spring, retainer and new cotter pin. Press a new seal in front cover housing. Install outer and inner gears

in housing. Install pump cover. Coat bolts with Loctite and tighten to specification. See TORQUE SPECIFICATIONS

table at end of

article.

2. Install new gasket and install front cover housing. Install new gasket and install pick-up tube and screen. Tighten all bolts/nuts to

specification. To complete installation, reverse removal procedure.

ENGINE COOLING

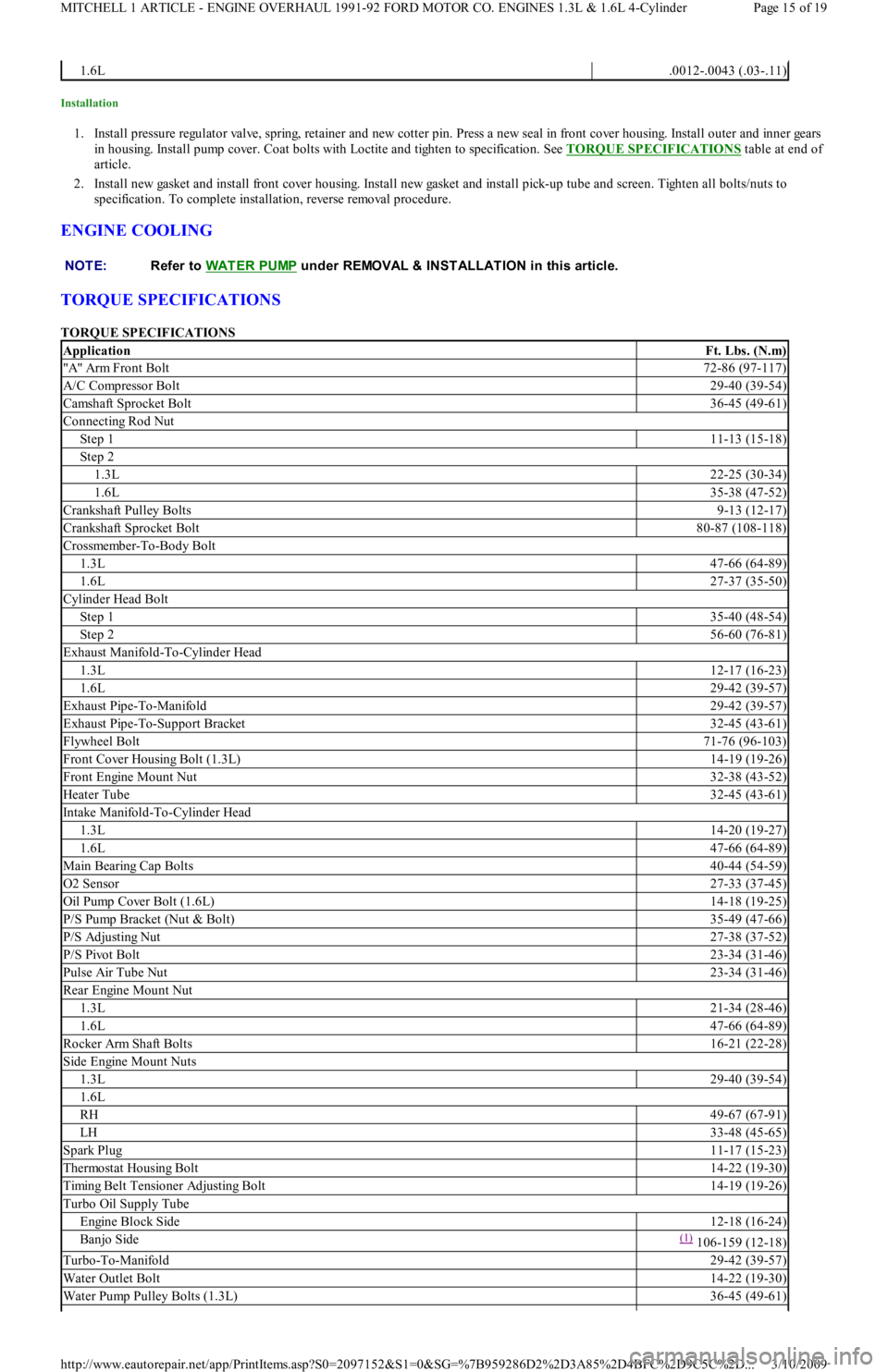

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

1.6L.0012-.0043 (.03-.11)

NOTE:Refer to WAT ER PUMP

under REMOVAL & INSTALLATION in this article.

ApplicationFt. Lbs. (N.m)

"A" Arm Front Bolt72-86 (97-117)

A/C Compressor Bolt29-40 (39-54)

Camshaft Sprocket Bolt36-45 (49-61)

Connecting Rod Nut

Step 111-13 (15-18)

Step 2

1.3L22-25 (30-34)

1.6L35-38 (47-52)

Crankshaft Pulley Bolts9-13 (12-17)

Crankshaft Sprocket Bolt80-87 (108-118)

Crossmember-To-Body Bolt

1.3L47-66 (64-89)

1.6L27-37 (35-50)

Cylinder Head Bolt

Step 135-40 (48-54)

Step 256-60 (76-81)

Exhaust Manifold-To-Cylinder Head

1.3L12-17 (16-23)

1.6L29-42 (39-57)

Exhaust Pipe-To-Manifold29-42 (39-57)

Exhaust Pipe-To-Support Bracket32-45 (43-61)

Flywheel Bolt71-76 (96-103)

Front Cover Housing Bolt (1.3L)14-19 (19-26)

Front Engine Mount Nut32-38 (43-52)

Heater Tube32-45 (43-61)

Intake Manifold-To-Cylinder Head

1.3L14-20 (19-27)

1.6L47-66 (64-89)

Main Bearing Cap Bolts40-44 (54-59)

O2 Sensor27-33 (37-45)

Oil Pump Cover Bolt (1.6L)14-18 (19-25)

P/S Pump Bracket (Nut & Bolt)35-49 (47-66)

P/S Adjusting Nut27-38 (37-52)

P/S Pivot Bolt23-34 (31-46)

Pulse Air Tube Nut23-34 (31-46)

Rear Engine Mount Nut

1.3L21-34 (28-46)

1.6L47-66 (64-89)

Rocker Arm Shaft Bolts16-21 (22-28)

Side Engine Mount Nuts

1.3L29-40 (39-54)

1.6L

RH49-67 (67-91)

LH33-48 (45-65)

Spark Plug11-17 (15-23)

Thermostat Housing Bolt14-22 (19-30)

Timing Belt Tensioner Adjusting Bolt14-19 (19-26)

Turbo Oil Supply Tube

Engine Block Side12-18 (16-24)

Banjo Side(1) 106-159 (12-18)

Turbo-To-Manifold29-42 (39-57)

Water Outlet Bolt14-22 (19-30)

Water Pump Pulley Bolts (1.3L)36-45 (49-61)

Page 15 of 19 MITCHELL 1 ARTICLE - ENGINE OVERHAUL 1991-92 FORD MOTOR CO. ENGINES 1.3L & 1.6L 4-Cylinder

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 130 of 454

IDLE SPEED & MIXTURE

IDLE MIXTURE

IDLE SPEED

1. Turn off all accessories. Place automatic transmission in Park or manual transmission in Neutral. Set parking brake. Connect tachometer

to engine. Warm engine to normal operating temperature. Connect a jumper wire between single-wire STI test connector (Green on

Capri; Black on Festiva) and ground. See Fig. 1

.

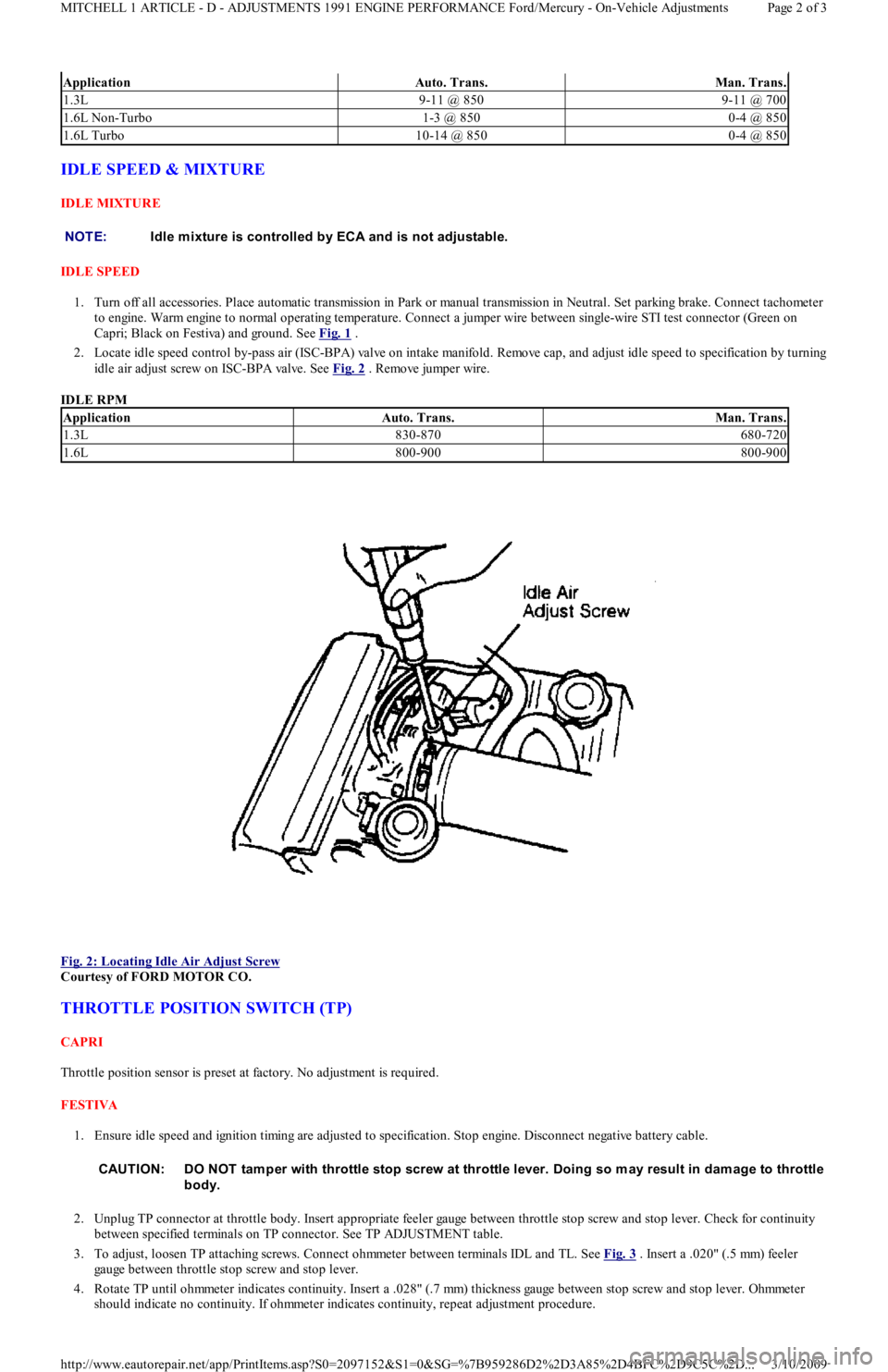

2. Locate idle speed control by-pass air (ISC-BPA) valve on intake manifold. Remove cap, and adjust idle speed to specification by turning

idle air adjust screw on ISC-BPA valve. See Fig. 2

. Remove jumper wire.

IDLE RPM

Fig. 2: Locating Idle Air Adjust Screw

Courtesy of FORD MOTOR CO.

THROTTLE POSITION SWITCH (TP)

CAPRI

Throttle position sensor is preset at factory. No adjustment is required.

FESTIVA

1. Ensure idle speed and ignition timing are adjusted to specification. Stop engine. Disconnect negative battery cable.

2. Unplug TP connector at throttle body. Insert appropriate feeler gauge between throttle stop screw and stop lever. Check for continuity

between specified terminals on TP connector. See TP ADJUSTMENT table.

3. To adjust, loosen TP attaching screws. Connect ohmmeter between terminals IDL and TL. See Fig. 3

. Insert a .020" (.5 mm) feeler

gauge between throttle stop screw and stop lever.

4. Rotate TP until ohmmeter indicates continuity. Insert a .028" (.7 mm) thickness gauge between stop screw and stop lever. Ohmmeter

should indicate no continuity. If ohmmeter indicates continuity, repeat adjustment procedure.

ApplicationAuto. Trans.Man. Trans.

1.3L9-11 @ 8509-11 @ 700

1.6L Non-Turbo1-3 @ 8500-4 @ 850

1.6L Turbo10-14 @ 8500-4 @ 850

NOTE:Idle m ixture is controlled by ECA and is not adjustable.

ApplicationAuto. Trans.Man. Trans.

1.3L830-870680-720

1.6L800-900800-900

CAUT ION: DO NOT tam per with throttle stop screw at throttle lever. Doing so m ay result in dam age to throttle

body.

Page 2 of 3 MITCHELL 1 ARTICLE - D - ADJUSTMENTS 1991 ENGINE PERFORMANCE Ford/Mercury - On-Vehicle Adjustments

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...

Page 137 of 454

AIS-VCV

AIS Vacuum Control Valve

AIS-VSV

AIS Vacuum Switching Valve

AIS-VT

AIS Vacuum Tank

AIS-VCV

AIS Vacuum Control Valve

AIS-VSV

AIS Vacuum Switching Valve

AP

Air Pump Injection System

AP-ACV

AP Air Control Valve

AP-AMV

AP Air Management Valve

AP-BPV

AP By-Pass Valve

AP-CKV

AP Check Valve

AP-CS

AP Control Solenoid

BP/EGR

Backpressure EGR System

BP/EGR-BPS

BP/EGR Backpressure Sensor

BP/EGR-BPT

BP/EGR Backpressure Transducer

BP/EGR-BPV

BP/EGR Backpressure Valve

BP/EGR-BS

BP/EGR Bleed Solenoid

BP/EGR-BVSV

BP/EGR Bimetallic Vacuum Switching Valve

BP/EGR-C

BP/EGR Controller

BP/EGR-CLR

BP/EGR Cooler

BP/EGR-CS

BP/EGR Control Solenoid

Page 5 of 9 MITCHELL 1 ARTICLE - EMISSION CONTROL APPLICATIONS Emission Applications - Ford Motor Co. - Imports (1968-

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 139 of 454

EVAP-CPCV

EVAP Canister Purge Control Valve

EVAP-CPRV

EVAP Canister Purge Regulator Valve

EVAP-CPSV

EVAP Canister Vent Shut Valve

EVAP-CPT

EVAP Canister Purge Timer

EVAP-CPTVS

EVAP Canister Purge Thermal Vacuum Switch

EVAP-CPV

EVAP Canister Vent Valve

EVAP-CPVCSV

EVAP Canister Purge Volume Control

EVAP-CPVDV

EVAP Canister Purge Vacuum Delay Valve

EVAP-CS

EVAP Control Solenoid

EVAP-CSPS

EVAP Control System Pressure Sensor

EVAP-ORVR

Evaporative On-Board Refueling Vapor Recovery System

EVAP-ORVRFTVRV

EVAP-ORVR Fuel Tank Vapor Recirculation

EVAP-OVCV

EVAP Outer Vent Control Valve

EVAP-OW V

EVAP One-Way Valve

EVAP-PCSV

EVAP Purge Cut-Off Solenoid Valve

EVAP-PFS

EVAP Purge Flow Sensor

EVAP-PFSVVSV

EVAP Purge Flow Switching Valve Vacuum Switching Valve

EVAP-PRRV

EVAP Pressure Relief Rollover Valve

EVAP-VC

EVAP Vapor Canister

FF

Flexible Fuel

Page 7 of 9 MITCHELL 1 ARTICLE - EMISSION CONTROL APPLICATIONS Emission Applications - Ford Motor Co. - Imports (1968-

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 140 of 454

FLV

Fill Limit Valve

FR

Fill Pipe Restrictor

FVV

Fuel Vapor Valve

HO2S

Heated Oxygen Sensor

MFI

Multiport Fuel Injection

MFI-MAF

MFI Mass Airflow Sensor

MIL

Malfunction Indicator Light

OC

Oxidation Catalytic Converter

OHC

Overhead Cam

ORVR

On-Board Refueling Vapor Recovery

ORVR-COV

ORVR Cut-Off Valve

ORVR-CV

ORVR Control Valve

ORVR-FMV

ORVR Flow Management Valve

ORVR-FTVCV

ORVR Fuel Tank Vapor Control Valve

ORVR-FTVRV

ORVR Fuel Tank Vapor Recirculation Valve

ORVR-LV

ORVR Leveling Valve

ORVR-OCKV

ORVR Overfill Check Valve

ORVR-RCV

ORVR Refueling Control Valve

ORVR-VCV

ORVR Vapor Cut Valve

ORVR-VRV

ORVR Vapor Recirculating Valve

Page 8 of 9 MITCHELL 1 ARTICLE - EMISSION CONTROL APPLICATIONS Emission Applications - Ford Motor Co. - Imports (1968-

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 141 of 454

ORVR-VSV

ORVR Vent Shut Valve

ORVR-VV

ORVR Vent Valve

OVCV

Outer Vent Control Valve

O2S

Oxygen Sensor

PAIR

Pulsed Secondary Air Injection

PCV

Positive Crankcase Ventilation

SFI

Sequential Multiport Fuel Injection

SFI-MAF

SFI Mass Airflow Sensor

SPK

Spark Controls

SPK-AVM

SPK Advance Vacuum Modulator

SPK-BVSV

SPK Bimetal Vacuum Switching Valve

SPK-CC

SPK Computer Controlled

SPK-CKV

SPK Check Valve

TWC

Three-Way Catalytic Converter

Copyr ight 2009 Mitchell Repair Information Company, LLC. All Rights Reserved.

Article GUID: A00157498

Page 9 of 9 MITCHELL 1 ARTICLE - EMISSION CONTROL APPLICATIONS Emission Applications - Ford Motor Co. - Imports (1968-

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B7DD6473C%2DB5BB%2D4F20%2D9D70%2D

...

Page 148 of 454

Removal

Drain radiator and remove negative battery cable. Disconnect throttle cable. Remove air duct from throttle body. Disconnect throttle position

sensor/switch connector. Mark all coolant and vacuum hoses for reassembly reference and remove from throttle body. See Fig. 4

. Remove

intake plenum bolts and remove intake plenum and gasket.

Installation

To install, reverse removal procedure. Use NEW intake plenum-to-intake manifold gasket. Tighten bolts to specification, see TORQUE

SPECIFICATIONS at end of article.

OXYGEN (O2) SENSOR

Removal & Installation

Disconnect negative battery cable. Disconnect wire harness connector, and remove oxygen sensor. If exhaust sensor is difficult to remove, use

rust penetrant to avoid possible damage to exhaust threads. If new sensor is not pre-coated with anti-seize, apply anti-seize compound to

sensor threads. DO NOT remove anti-seize from sensor. To install, tighten sensor and attach wire harness connector.

THROTTLE BODY

Removal & Installation

Drain radiator and remove negative battery cable. Remove resonance chamber. Disconnect throttle cable. Remove air duct. Mark all coolant

and vacuum hoses for reassembly reference and remove from throttle body. Disconnect throttle position sensor/switch connector. Remove

throttle body nuts and bolts. Remove throttle body and gasket. To install, reverse removal procedure using NEW throttle body-to-intake

plenum gasket.

THROTTLE POSITION SENSOR/SWITCH

Removal & Installation

Disconnect negative battery cable. Disconnect throttle position sensor/switch connector. Remove attaching bolts. Remove sensor/switch from

throttle body. To install, reverse removal procedure.

TURBOCHARGER

Removal

1. Drain radiator and remove negative battery cable. Remove throttle body air intake tube. Disconnect intercooler hose from turbocharger

assembly. Disconnect O2 sensor. Remove lower heat shield retaining bolts and lower heat shield from turbocharger. Remove upper heat

shield retaining bolts and upper heat shield from exhaust manifold.

2. Slide O2 sensor wire and guide through upper heat shield. Remove side heat shield retaining bolts from turbocharger, and remove sid e

heat shield. Remove power steering belt. Remove power steering pump through bolt and adjuster nuts and bolts. Disconnect lower

radiator hose from water pump.

3. Pull pump from bracket, and position pump to access mounting bracket retaining nut and bolts. Remove mounting bracket-to-engine nut

and bolts and remove bracket. Remove air cleaner duct retaining screws. Loosen clamp at turbocharger and move duct tube out of way.

Disconnect coolant supply hose at turbocharger.

4. Remove bolt and sealing washers attaching oil supply line at engine block. Raise vehicle on hoist. Remove nuts and washers from

exhaust pipe flange. Remove bolts attaching exhaust hanger to engine block. Slide rubber exhaust hangers from catalytic converter. Pull

exhaust pipe downward and to left side of vehicle. Disconnect oil return hose from turbocharger. Disconnect coolant return hose fro m

turbocharger.

5. Remove turbocharger support bracket retaining bolts. Remove coolant by-pass tube outlet-to-water pump bolts. Lower vehicle. Loosen

retaining clamp bolt on coolant by-pass tube at rear of cylinder head. Remove 11 retaining nuts from exhaust manifold. Position coolant

by-pass tube out of way after pulling bracket from exhaust stud.

6. Remove exhaust manifold by pulling off studs and moving assembly towards right side of engine compartment, clearing cooling fan.

With assembly removed from vehicle, remove turbocharger-to-exhaust manifold nuts. Separate assembly and discard gasket.

Installation

1. Install NEW gasket on exhaust manifold and install turbocharger onto studs. Install turbocharger-to-exhaust manifold nuts. Remo ve o il

supply line from turbocharger. Install NEW exhaust gasket on cylinder head. Install turbocharger and exhaust manifold assembly onto

studs. Install coolant by-pass tube bracket onto exhaust stud. Install 11 retaining nuts onto exhaust manifold.

2. Securely tighten heater tube clamp bolt. Raise vehicle. Install coolant by-pass tube outlet-to-water pump bolts. Install turbocharger

support bracket retaining bolts. Connect coolant return hose to turbocharger. Connect oil return hose to turbocharger. Install exhaust

pipe onto turbocharger, and hand tighten nuts and washers. Install bolts attaching exhaust hanger to engine block.

3. Slide rubber exhaust hangers onto catalytic converter. Tighten exhaust pipe nuts and washers. Lower vehicle. Install bolt and sealing

washers attaching oil supply line at engine block. Install oil supply line onto turbocharger. To complete installation, reverse removal

procedure. Tighten bolts and nuts to specification, see TORQUE SPECIFICATIONS

at end of article. NOTE:T o prevent dust and dirt from entering intake m anifold ports, cover ports with clean cloth after

rem oving intake plenum .

WARNING:DO NOT rem ove oxygen sensor when engine is hot.

NOTE:Clean throttle body exterior before rem oval.

CAUT ION: Before installing turbocharger, put .8 oz. (25 m l) engine oil into turbocharger oil inlet.

Page 4 of 5 MITCHELL 1 ARTICLE - N - REMOVE/INSTALL/OVERHAUL 1991 ENGINE PERFORMANCE Ford/Mercury Removal, O

...

3/10/2009 http://www.eautorepair.net/app/PrintItems.asp?S0=2097152&S1=0&SG=%7B959286D2%2D3A85%2D4BFC%2D9C5C%2D

...