FORD FIESTA 1989 Service Repair Manual

Manufacturer: FORD, Model Year: 1989, Model line: FIESTA, Model: FORD FIESTA 1989Pages: 296, PDF Size: 10.65 MB

Page 271 of 296

1595 Ford Fiesta Remake

The jack supplied with the vehicle tool kit

should only be used for changing the

roadwheels - see “Wheel changing” at the

front of this manual. When jacking up the

vehicle to carry out repair or maintenance

tasks, a pillar or trolley type jack of suitable

lifting capacity must be used, supplemented

with axle stands positioned only beneath the

appropriate points under the vehicle (see

illustration) . Note that the vehicle must never

be jacked up at the rear under the axle beam. The maximum kerb weight of the vehicle must

not be exceeded when jacking and supporting

the vehicle. Do not under any circumstances

jack up the rear of the vehicle under the rear axle.

Never work under, around or near a raised

vehicle unless it is adequately supported in at

least two places with axle stands.

The radio/cassette unit fitted as standard or

optional equipment may be equipped with a

built-in security code, to deter thieves. If the

power source to the unit is cut, the anti-theft

system will activate. Even if the power source

is immediately reconnected, the radio/

cassette unit will not function until the correct security code has been entered. Therefore,

if you do not know the correct security

code for the radio/cassette unit do not

disconnect either of the battery terminals, or

remove the radio/cassette unit from the

vehicle. To enter the correct security code, follow the instructions provided with the

radio/cassette player or vehicle handbook.

If an incorrect code is entered, the unit will

become locked, and cannot be operated.

If this happens, or if the security code is lost

or forgotten, seek the advice of your Ford

dealer.

Jacking and vehicle supportREF•5

REF

Radio/cassette unit anti-theft system - precaution

Underside view of the vehicle showing the jacking point locations

A Jacking points for trolley jack (always use a suitable block

of wood to protect the

vehicle body)

B Axle stand positions

C Jacking points for owner jack and wheel-free hoist

Buying spare parts

Spare parts are available from many

sources, including maker’s appointed

garages, accessory shops, and motor factors.

To be sure of obtaining the correct parts, it

will sometimes be necessary to quote the

vehicle identification number. If possible, it

can also be useful to take the old parts along

for positive identification. Items such as

starter motors and alternators may be

available under a service exchange scheme -

any parts returned should always be clean.

Our advice regarding spare part sources is

as follows.

Officially-appointed garages

This is the best source of parts which are

peculiar to your car, and which are not

otherwise generally available (eg badges,

interior trim, certain body panels, etc). It is

also the only place at which you should buy

parts if the vehicle is still under warranty.

Accessory shops

These are very good places to buy materials and components needed for the

maintenance of your car (oil, air and fuel

filters, spark plugs, light bulbs, drivebelts, oils

and greases, brake pads, touch-up paint, etc).

Components of this nature sold by a

reputable shop are of the same standard as

those used by the car manufacturer.

Besides components, these shops also sell

tools and general accessories, usually have

convenient opening hours, charge lower

prices, and can often be found not far from

home. Some accessory shops have parts

counters where the components needed for

almost any repair job can be purchased or

ordered.

Motor factors

Good factors will stock all the more

important components which wear out

comparatively quickly, and can sometimes

supply individual components needed for the

overhaul of a larger assembly (eg brake seals

and hydraulic parts, bearing shells, pistons,

valves, alternator brushes). They may also

handle work such as cylinder block reboring,

crankshaft regrinding and balancing, etc.

Tyre and exhaust specialists

These outlets may be independent, or

members of a local or national chain. They

frequently offer competitive prices when

compared with a main dealer or local garage,

but it will pay to obtain several quotes before

making a decision. When researching prices,

also ask what “extras” may be added - for

instance, fitting a new valve and balancing the

wheel are both commonly charged on top of

the price of a new tyre.

Other sources

Beware of parts or materials obtained from

market stalls, car boot sales or similar outlets.

Such items are not invariably sub-standard,

but there is little chance of compensation if

they do prove unsatisfactory. In the case of

safety-critical components such as brake

pads, there is the risk not only of financial loss

but also of an accident causing injury or

death. Second-hand components or assemblies

obtained from a car breaker can be a good

buy in some circumstances, but this sort of

purchase is best made by the experienced

DIY mechanic.

Buying spare parts

procarmanuals.com

http://vnx.su

Page 272 of 296

REF•6Conversion Factors

1595 Ford Fiesta Remake

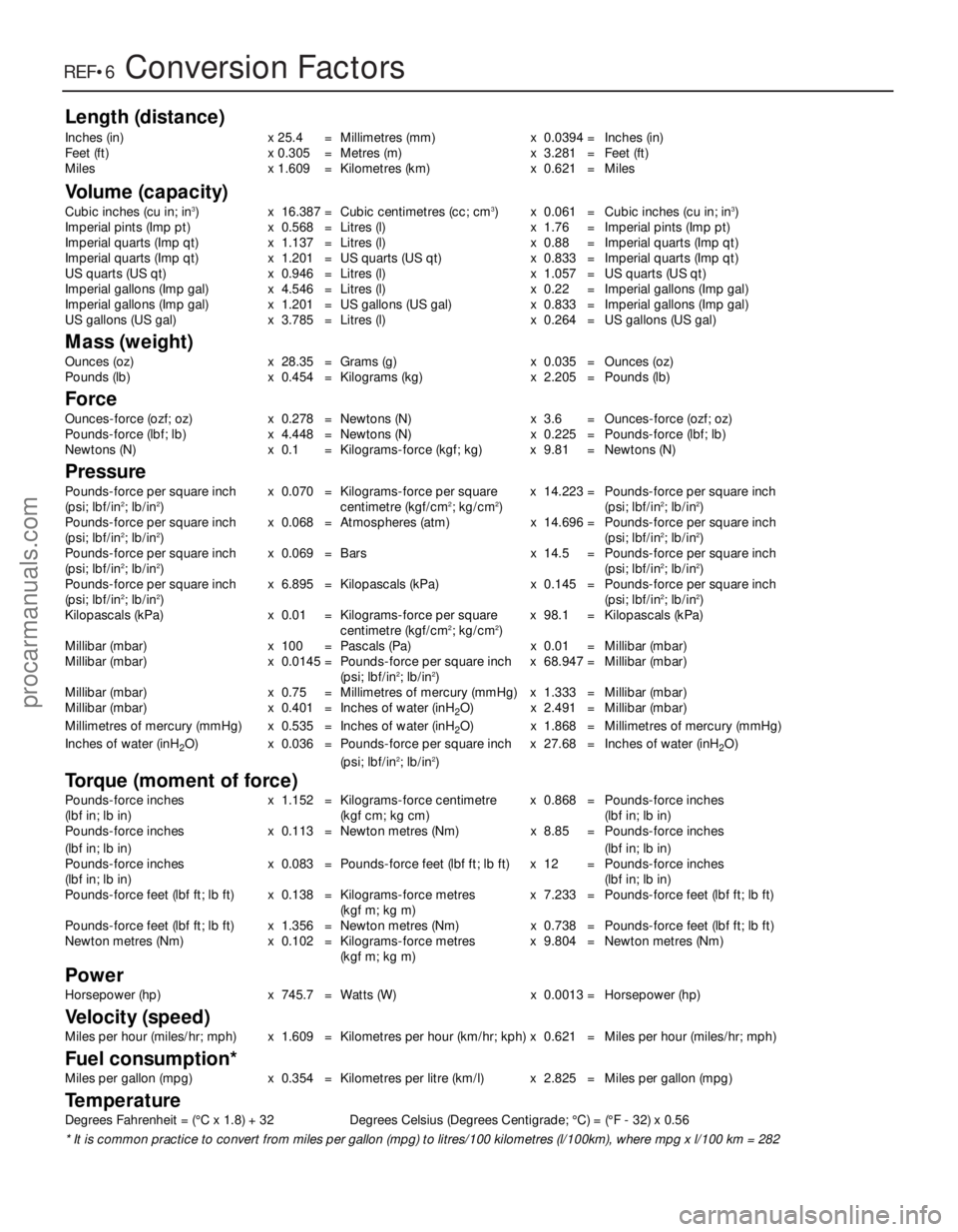

Length (distance)

Inches (in)x 25.4 = Millimetres (mm) x 0.0394 = Inches (in)

Feet (ft) x 0.305 = Metres (m) x 3.281 = Feet (ft)

Miles x 1.609 = Kilometres (km) x 0.621 = Miles

Volume (capacity)

Cubic inches (cu in; in3)x 16.387 = Cubic centimetres (cc; cm3) x 0.061 = Cubic inches (cu in; in3)

Imperial pints (Imp pt) x 0.568 = Litres (l) x 1.76 = Imperial pints (Imp pt)

Imperial quarts (Imp qt) x 1.137 = Litres (l) x 0.88 = Imperial quarts (Imp qt)

Imperial quarts (Imp qt) x 1.201 = US quarts (US qt) x 0.833 = Imperial quarts (Imp qt)

US quarts (US qt) x 0.946 = Litres (l) x 1.057 = US quarts (US qt)

Imperial gallons (Imp gal) x 4.546 = Litres (l) x 0.22 = Imperial gallons (Imp gal)

Imperial gallons (Imp gal) x 1.201 = US gallons (US gal) x 0.833 = Imperial gallons (Imp gal)

US gallons (US gal) x 3.785 = Litres (l) x 0.264 = US gallons (US gal)

Mass (weight)

Ounces (oz)x 28.35 = Grams (g) x 0.035 = Ounces (oz)

Pounds (lb) x 0.454 = Kilograms (kg) x 2.205 = Pounds (lb)

Force

Ounces-force (ozf; oz)x 0.278 = Newtons (N) x 3.6 = Ounces-force (ozf; oz)

Pounds-force (lbf; lb) x 4.448 = Newtons (N) x 0.225 = Pounds-force (lbf; lb)

Newtons (N) x 0.1 = Kilograms-force (kgf; kg) x 9.81 = Newtons (N)

Pressure

Pounds-force per square inch x 0.070 = Kilograms-force per square x 14.223 = Pounds-force per square inch

(psi; lbf/in2; lb/in2)centimetre (kgf/cm2; kg/cm2)(psi; lbf/in2; lb/in2)

Pounds-force per square inch x 0.068 = Atmospheres (atm) x 14.696 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2) (psi; lbf/in2; lb/in2)

Pounds-force per square inch x 0.069 = Bars x 14.5 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2) (psi; lbf/in2; lb/in2)

Pounds-force per square inch x 6.895 = Kilopascals (kPa) x 0.145 = Pounds-force per square inch

(psi; lbf/in

2; lb/in2) (psi; lbf/in2; lb/in2)

Kilopascals (kPa) x 0.01 = Kilograms-force per square x 98.1 = Kilopascals (kPa)

centimetre (kgf/cm

2; kg/cm2)

Millibar (mbar) x 100 = Pascals (Pa) x 0.01 = Millibar (mbar)

Millibar (mbar) x 0.0145 = Pounds-force per square inch x 68.947 = Millibar (mbar)

(psi; lbf/in

2; lb/in2)

Millibar (mbar) x 0.75 = Millimetres of mercury (mmHg) x 1.333 = Millibar (mbar)

Millibar (mbar) x 0.401 = Inches of water (inH

2O) x 2.491 = Millibar (mbar)

Millimetres of mercury (mmHg) x 0.535 = Inches of water (inH

2O) x 1.868 = Millimetres of mercury (mmHg)

Inches of water (inH

2O) x 0.036 = Pounds-force per square inch x 27.68 = Inches of water (inH2O)

(psi; lbf/in2; lb/in2)

Torque (moment of force)

Pounds-force inches x 1.152 = Kilograms-force centimetre x 0.868 = Pounds-force inches

(lbf in; lb in) (kgf cm; kg cm)(lbf in; lb in)

Pounds-force inches x 0.113 = Newton metres (Nm) x 8.85 = Pounds-force inches

(lbf in; lb in) (lbf in; lb in)

Pounds-force inches x 0.083 = Pounds-force feet (lbf ft; lb ft) x 12 =Pounds-force inches

(lbf in; lb in) (lbf in; lb in)

Pounds-force feet (lbf ft; lb ft) x 0.138 = Kilograms-force metres x 7.233 = Pounds-force feet (lbf ft; lb ft) (kgf m; kg m)

Pounds-force feet (lbf ft; lb ft) x 1.356 = Newton metres (Nm) x 0.738 = Pounds-force feet (lbf ft; lb ft)

Newton metres (Nm) x 0.102 = Kilograms-force metres x 9.804 = Newton metres (Nm)

(kgf m; kg m)

Power

Horsepower (hp) x 745.7 = Watts (W) x 0.0013 = Horsepower (hp)

Velocity (speed)

Miles per hour (miles/hr; mph) x 1.609 = Kilometres per hour (km/hr; kph) x 0.621 = Miles per hour (miles/hr; mph)

Fuel consumption*

Miles per gallon (mpg)x 0.354 = Kilometres per litre (km/l) x 2.825 = Miles per gallon (mpg)

Temperature

Degrees Fahrenheit = (°C x 1.8) + 32 Degrees Celsius (Degrees Centigrade; °C) = (°F - 32) x 0.56

* It is common practice to convert from miles per gallon (mpg) to litr\

es/100 kilometres (l/100km), where mpg x l/100 km = 282

procarmanuals.com

http://vnx.su

Page 273 of 296

Introduction

A selection of good tools is a fundamental

requirement for anyone contemplating the

maintenance and repair of a motor vehicle.

For the owner who does not possess any,

their purchase will prove a considerable

expense, offsetting some of the savings made

by doing-it-yourself. However, provided that

the tools purchased meet the relevant national

safety standards and are of good quality, they

will last for many years and prove an

extremely worthwhile investment. To help the average owner to decide which

tools are needed to carry out the various tasks

detailed in this manual, we have compiled

three lists of tools under the following

headings: Maintenance and minor repair,

Repair and overhaul , and Special. Newcomers

to practical mechanics should start off with

the Maintenance and minor repair tool kit, and

confine themselves to the simpler jobs around

the vehicle. Then, as confidence and

experience grow, more difficult tasks can be

undertaken, with extra tools being purchased

as, and when, they are needed. In this way, a

Maintenance and minor repair tool kit can be

built up into a Repair and overhaul tool kit over

a considerable period of time, without any

major cash outlays. The experienced do-it-

yourselfer will have a tool kit good enough for

most repair and overhaul procedures, and will

add tools from the Specialcategory when it is

felt that the expense is justified by the amount

of use to which these tools will be put.

Maintenance and minor repair

tool kit

The tools given in this list should be

considered as a minimum requirement if

routine maintenance, servicing and minor

repair operations are to be undertaken. We

recommend the purchase of combination

spanners (ring one end, open-ended the

other); although more expensive than open-

ended ones, they do give the advantages of

both types of spanner.

M Combination spanners: 8, 9, 10, 11, 12, 13,

14, 15, 16, 17, 19, 21, 22, 24 & 26 mm

M Adjustable spanner - 35 mm jaw (approx)

M Engine sump/gearbox drain plug key

(where applicable)

M Set of feeler gauges

M Spark plug spanner (with rubber insert)

M Spark plug gap adjustment tool

M Brake bleed nipple spanner

M Screwdrivers: Flat blade and cross blade –

approx 100 mm long x 6 mm dia

M Combination pliers

M Hacksaw (junior)

M Tyre pump

M Tyre pressure gauge

M Grease gun

M Oil can

M Oil filter removal tool

M Fine emery cloth

M Wire brush (small)

M Funnel (medium size)

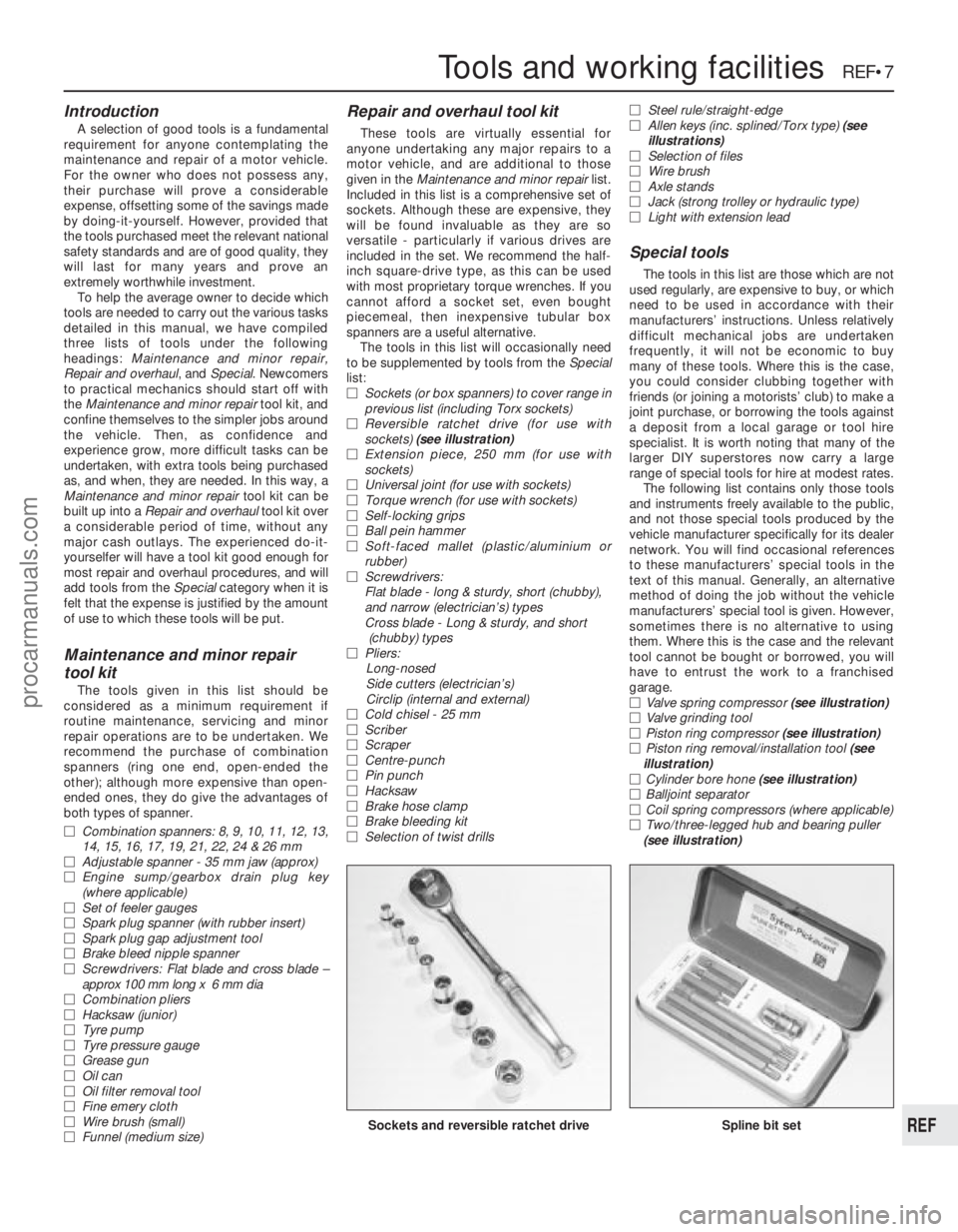

Repair and overhaul tool kit

These tools are virtually essential for

anyone undertaking any major repairs to a

motor vehicle, and are additional to those

given in the Maintenance and minor repair list.

Included in this list is a comprehensive set of

sockets. Although these are expensive, they

will be found invaluable as they are so

versatile - particularly if various drives are

included in the set. We recommend the half-

inch square-drive type, as this can be used

with most proprietary torque wrenches. If you

cannot afford a socket set, even bought

piecemeal, then inexpensive tubular box

spanners are a useful alternative. The tools in this list will occasionally need

to be supplemented by tools from the Special

list:

M Sockets (or box spanners) to cover range in

previous list (including Torx sockets)

M Reversible ratchet drive (for use with

sockets) (see illustration)

M Extension piece, 250 mm (for use with

sockets)

M Universal joint (for use with sockets)

M Torque wrench (for use with sockets)

M Self-locking grips

M Ball pein hammer

M Soft-faced mallet (plastic/aluminium or

rubber)

M Screwdrivers:

Flat blade - long & sturdy, short (chubby),

and narrow (electrician’s) types

Cross blade - Long & sturdy, and short

(chubby) types

M Pliers:

Long-nosed

Side cutters (electrician’s)

Circlip (internal and external)

M Cold chisel - 25 mm

M Scriber

M Scraper

M Centre-punch

M Pin punch

M Hacksaw

M Brake hose clamp

M Brake bleeding kit

M Selection of twist drills M

Steel rule/straight-edge

M Allen keys (inc. splined/Torx type) (see

illustrations)

M Selection of files

M Wire brush

M Axle stands

M Jack (strong trolley or hydraulic type)

M Light with extension lead

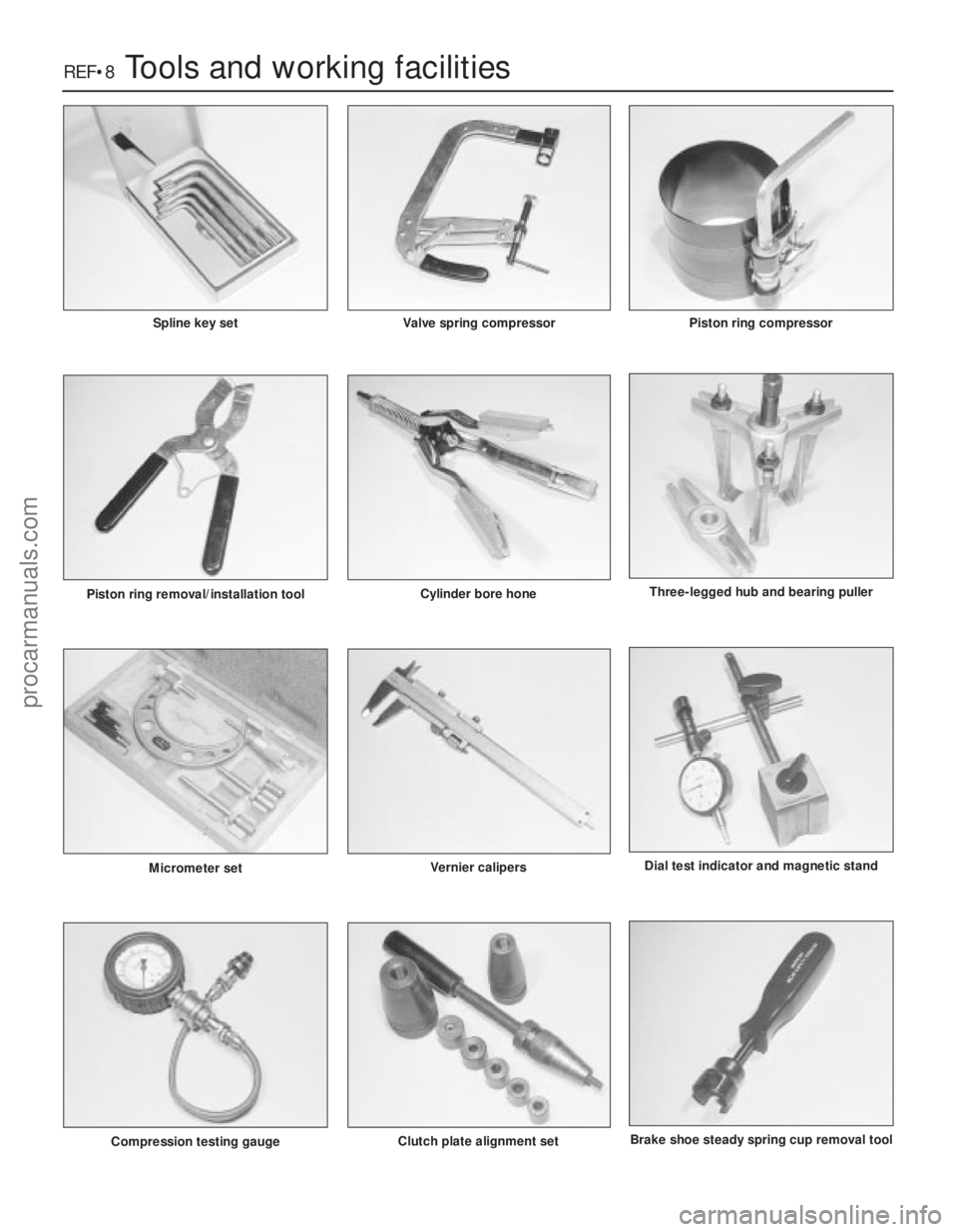

Special tools

The tools in this list are those which are not

used regularly, are expensive to buy, or which

need to be used in accordance with their

manufacturers’ instructions. Unless relatively

difficult mechanical jobs are undertaken

frequently, it will not be economic to buy

many of these tools. Where this is the case,

you could consider clubbing together with

friends (or joining a motorists’ club) to make a

joint purchase, or borrowing the tools against

a deposit from a local garage or tool hire

specialist. It is worth noting that many of the

larger DIY superstores now carry a large

range of special tools for hire at modest rates. The following list contains only those tools

and instruments freely available to the public,

and not those special tools produced by the

vehicle manufacturer specifically for its dealer

network. You will find occasional references

to these manufacturers’ special tools in the

text of this manual. Generally, an alternative

method of doing the job without the vehicle

manufacturers’ special tool is given. However,

sometimes there is no alternative to using

them. Where this is the case and the relevant

tool cannot be bought or borrowed, you will

have to entrust the work to a franchised

garage.

M Valve spring compressor (see illustration)

M Valve grinding tool

M Piston ring compressor (see illustration)

M Piston ring removal/installation tool (see

illustration)

M Cylinder bore hone (see illustration)

M Balljoint separator

M Coil spring compressors (where applicable)

M Two/three-legged hub and bearing puller

(see illustration)

Sockets and reversible ratchet driveSpline bit set

Tools and working facilities REF•7

REF

1595 Ford Fiesta Remakeprocarmanuals.com

http://vnx.su

Page 274 of 296

Spline key setValve spring compressor Piston ring compressor

Compression testing gauge Clutch plate alignment setBrake shoe steady spring cup removal tool

Piston ring removal/installation tool

Cylinder bore honeThree-legged hub and bearing puller

Micrometer set

Vernier calipersDial test indicator and magnetic stand

1595 Ford Fiesta Remake

REF•8Tools and working facilities

procarmanuals.com

http://vnx.su

Page 275 of 296

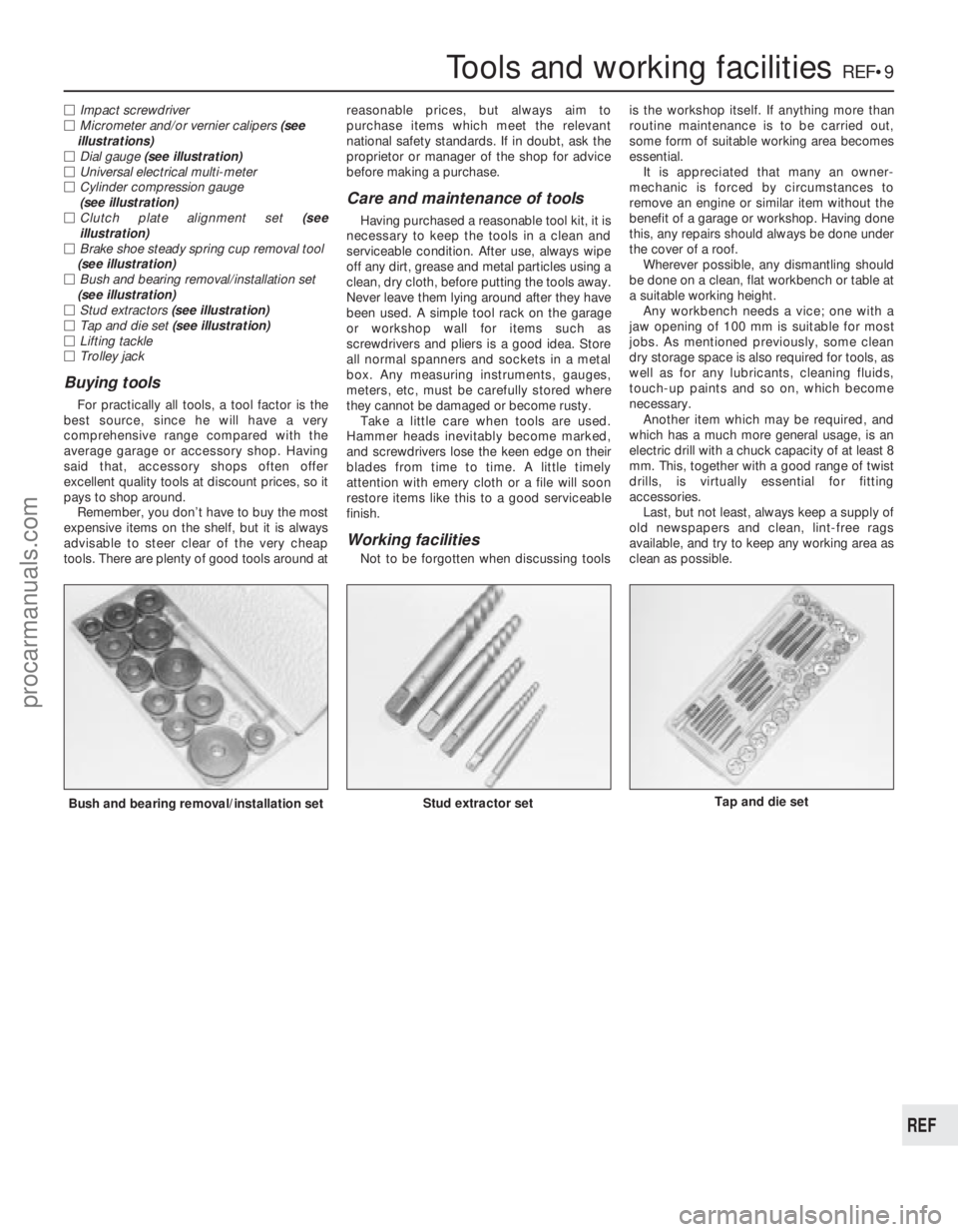

MImpact screwdriver

M Micrometer and/or vernier calipers (see

illustrations)

M Dial gauge (see illustration)

M Universal electrical multi-meter

M Cylinder compression gauge

(see illustration)

M Clutch plate alignment set (see

illustration)

M Brake shoe steady spring cup removal tool

(see illustration)

M Bush and bearing removal/installation set

(see illustration)

M Stud extractors (see illustration)

M Tap and die set (see illustration)

M Lifting tackle

M Trolley jack

Buying tools

For practically all tools, a tool factor is the

best source, since he will have a very

comprehensive range compared with the

average garage or accessory shop. Having

said that, accessory shops often offer

excellent quality tools at discount prices, so it

pays to shop around. Remember, you don’t have to buy the most

expensive items on the shelf, but it is always

advisable to steer clear of the very cheap

tools. There are plenty of good tools around at reasonable prices, but always aim to

purchase items which meet the relevant

national safety standards. If in doubt, ask the

proprietor or manager of the shop for advice

before making a purchase.

Care and maintenance of tools

Having purchased a reasonable tool kit, it is

necessary to keep the tools in a clean and

serviceable condition. After use, always wipe

off any dirt, grease and metal particles using a

clean, dry cloth, before putting the tools away.

Never leave them lying around after they have

been used. A simple tool rack on the garage

or workshop wall for items such as

screwdrivers and pliers is a good idea. Store

all normal spanners and sockets in a metal

box. Any measuring instruments, gauges,

meters, etc, must be carefully stored where

they cannot be damaged or become rusty. Take a little care when tools are used.

Hammer heads inevitably become marked,

and screwdrivers lose the keen edge on their

blades from time to time. A little timely

attention with emery cloth or a file will soon

restore items like this to a good serviceable

finish.

Working facilities

Not to be forgotten when discussing tools is the workshop itself. If anything more than

routine maintenance is to be carried out,

some form of suitable working area becomes

essential.

It is appreciated that many an owner-

mechanic is forced by circumstances to

remove an engine or similar item without the

benefit of a garage or workshop. Having done

this, any repairs should always be done under

the cover of a roof. Wherever possible, any dismantling should

be done on a clean, flat workbench or table at

a suitable working height. Any workbench needs a vice; one with a

jaw opening of 100 mm is suitable for most

jobs. As mentioned previously, some clean

dry storage space is also required for tools, as

well as for any lubricants, cleaning fluids,

touch-up paints and so on, which become

necessary.

Another item which may be required, and

which has a much more general usage, is an

electric drill with a chuck capacity of at least 8

mm. This, together with a good range of twist

drills, is virtually essential for fitting

accessories.

Last, but not least, always keep a supply of

old newspapers and clean, lint-free rags

available, and try to keep any working area as

clean as possible.

Bush and bearing removal/installation set Stud extractor setTap and die set

1595 Ford Fiesta Remake

Tools and working facilitiesREF•9

REF

procarmanuals.com

http://vnx.su

Page 276 of 296

1595 Ford Fiesta Remake

REF•10MOT test checks

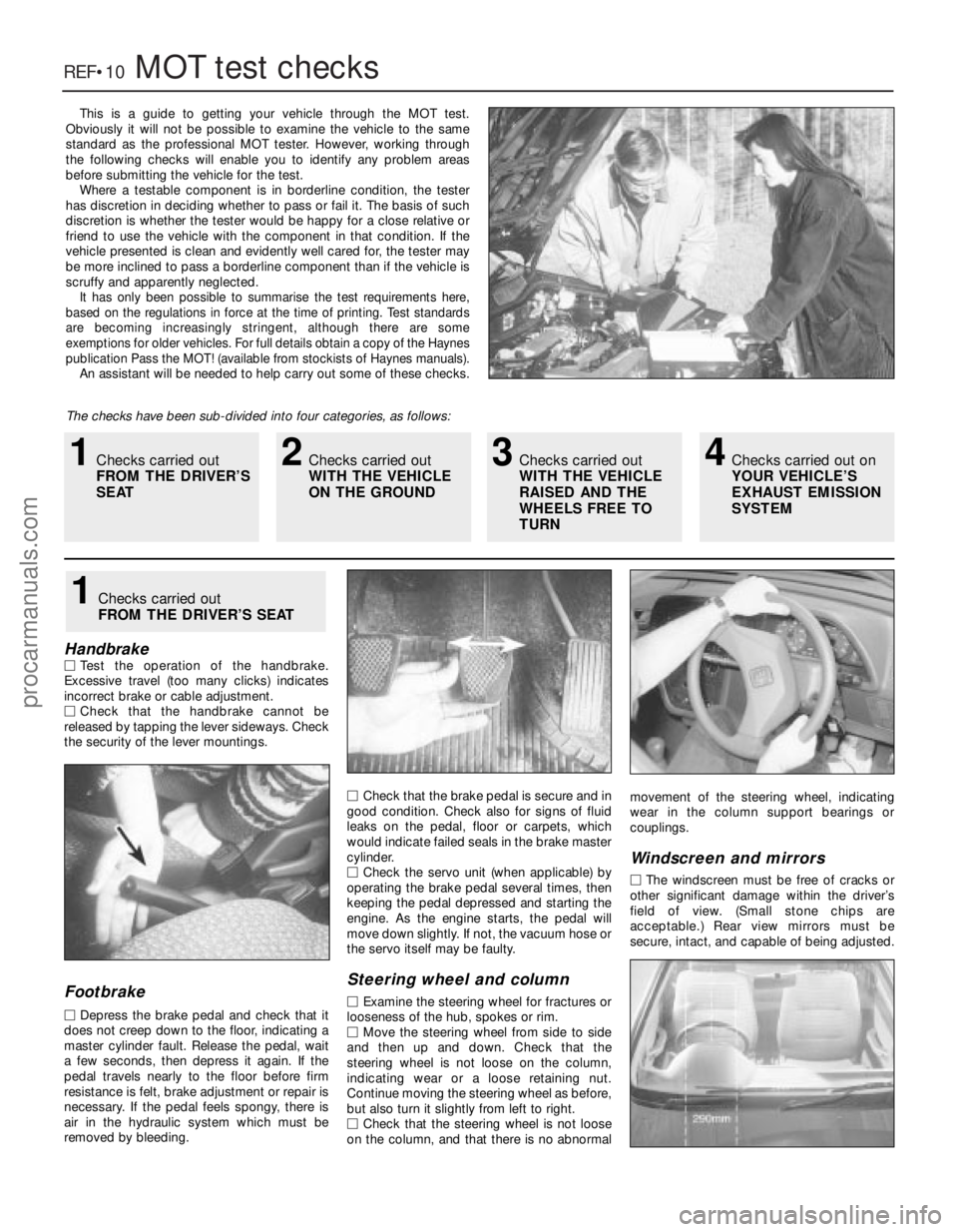

This is a guide to getting your vehicle through the MOT test.

Obviously it will not be possible to examine the vehicle to the same

standar d as the professional MOT tester. However, working through

the following checks will enable you to identify any problem areas

befor e submitting the vehicle for the test.

Wher e a testable component is in borderline condition, the tester

has discretion in deciding whether to pass or fail it. The basis of such

discr etion is whether the tester would be happy for a close relative or

friend to use the vehicle with the component in that condition. If the

vehicle presented is clean and evidently well cared for, the tester may

be more inclined to pass a borderline component than if the vehicle is

scruffy and apparently neglected.

It has only been possible to summarise the test requirements her e,

based on the regulations in force at the time of printing. Test standards ar e becoming increasingly stringent, although there are some

exemptions for older vehicles. For full details obtain a copy of the Hay\

nes

publication Pass the MOT! (available from stockists of Haynes manuals).

An assistant will be needed to help carry out some of these checks.

The checks have been sub-divided into four categories, as follows:

HandbrakeM Test the operation of the handbrake.

Excessive travel (too many clicks) indicates

incorr ect brake or cable adjustment.

M Check that the handbrake cannot be

r eleased by tapping the lever sideways. Check

the security of the lever mountings.

Footbrake

M Depr ess the brake pedal and check that it

does not creep down to the floor, indicating a master cylinder fault. Release the pedal, wait

a few seconds, then depress it again. If the

pedal travels nearly to the floor before firm

r esistance is felt, brake adjustment or repair is

necessary . If the pedal feels spongy, there is

air in the hydraulic system which must be

r emoved by bleeding. M

Check that the brake pedal is secure and in

good condition. Check also for signs of fluid

leaks on the pedal, floor or carpets, which

would indicate failed seals in the brake master

cylinder.

M Check the servo unit (when applicable) by

operating the brake pedal several times, then

keeping the pedal depressed and starting the

engine. As the engine starts, the pedal will

move down slightly. If not, the vacuum hose or

the servo itself may be faulty.

Steering wheel and column

M Examine the steering wheel for fractures or

looseness of the hub, spokes or rim.

M Move the steering wheel from side to side

and then up and down. Check that the

steering wheel is not loose on the column,

indicating wear or a loose retaining nut.

Continue moving the steering wheel as before,

but also turn it slightly from left to right.

M Check that the steering wheel is not loose

on the column, and that there is no abnormal movement of the steering wheel, indicating

wear in the column support bearings or

couplings.

W

indscreen and mirrors

M The windscreen must be free of cracks or

other significant damage within the driver’s

field of view. (Small stone chips are

acceptable.) Rear view mirrors must be

secur e, intact, and capable of being adjusted.

1Checks carried out

FROM THE DRIVER’S SEAT

1Checks carried out

FROM THE DRIVER’S

SEAT2Checks carried out

WITH THE VEHICLE

ON THE GROUND3Checks carried out

WITH THE VEHICLE

RAISED AND THE

WHEELS FREE TO

TURN4Checks carried out on

YOUR VEHICLE’S

EXHAUST EMISSION

SYSTEM

procarmanuals.com

http://vnx.su

Page 277 of 296

1595 Ford Fiesta Remake

MOT test checksREF•11

REF

Seat belts and seats

Note: The following checks are applicable to

all seat belts, front and rear.

M Examine the webbing of all the belts

(including rear belts if fitted) for cuts, serious

fraying or deterioration. Fasten and unfasten

each belt to check the buckles. If applicable,

check the retracting mechanism. Check the

security of all seat belt mountings accessible

fr om inside the vehicle.

M The front seats themselves must be

secur ely attached and the backrests must

lock in the upright position.

Doors

M Both front doors must be able to be opened

and closed from outside and inside, and must

latch securely when closed.

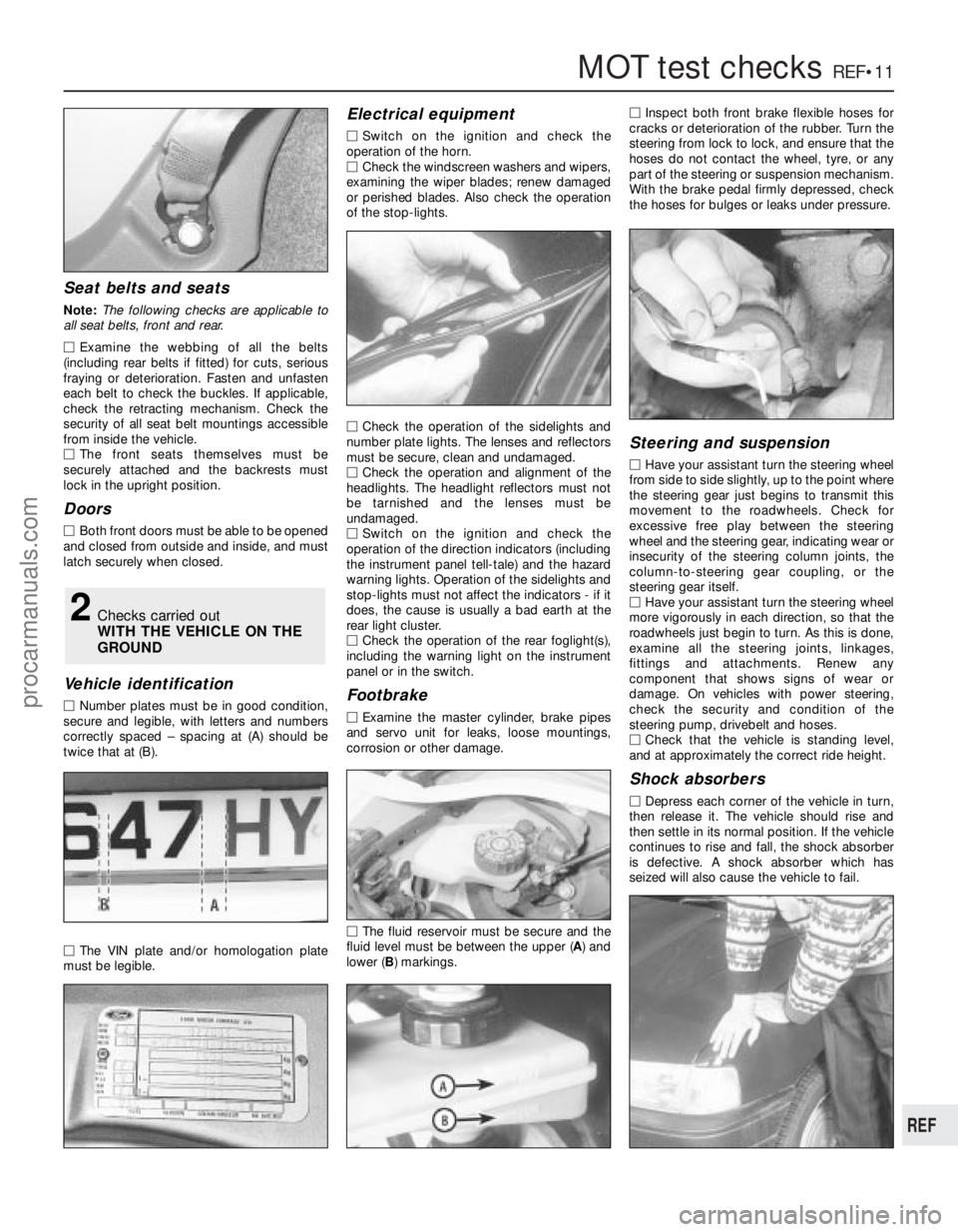

V ehicle identification

M Number plates must be in good condition,

secur e and legible, with letters and numbers

corr ectly spaced – spacing at (A) should be

twice that at (B).

M The VIN plate and/or homologation plate

must be legible.

Electrical equipment

M Switch on the ignition and check the

operation of the horn.

M Check the windscreen washers and wipers,

examining the wiper blades; renew damaged

or perished blades. Also check the operation

of the stop-lights.

M Check the operation of the sidelights and

number plate lights. The lenses and reflectors

must be secure, clean and undamaged.

M Check the operation and alignment of the

headlights. The headlight reflectors must not

be tarnished and the lenses must be

undamaged.

M Switch on the ignition and check the

operation of the direction indicators (including

the instrument panel tell-tale) and the hazard

war ning lights. Operation of the sidelights and

stop-lights must not affect the indicators - if it

does, the cause is usually a bad earth at the

r ear light cluster.

M Check the operation of the rear foglight(s),

including the warning light on the instrument

panel or in the switch.

Footbrake

M Examine the master cylinder, brake pipes

and servo unit for leaks, loose mountings,

corr osion or other damage.

M The fluid reservoir must be secure and the

fluid level must be between the upper ( A) and

lower ( B) markings. M

Inspect both front brake flexible hoses for

cracks or deterioration of the rubber . Turn the

steering from lock to lock, and ensure that the

hoses do not contact the wheel, tyre, or any

part of the steering or suspension mechanism.

With the brake pedal firmly depressed, check

the hoses for bulges or leaks under pressure.

Steering and suspension

M Have your assistant turn the steering wheel

fr om side to side slightly, up to the point where

the steering gear just begins to transmit this

movement to the roadwheels. Check for

excessive free play between the steering

wheel and the steering gear, indicating wear or

insecurity of the steering column joints, the

column-to-steering gear coupling, or the

steering gear itself.

M Have your assistant turn the steering wheel

mor e vigorously in each direction, so that the

r oadwheels just begin to turn. As this is done,

examine all the steering joints, linkages,

fittings and attachments. Renew any

component that shows signs of wear or

damage. On vehicles with power steering,

check the security and condition of the

steering pump, drivebelt and hoses.

M Check that the vehicle is standing level,

and at approximately the correct ride height.

Shock absorbers

M Depr ess each corner of the vehicle in turn,

then release it. The vehicle should rise and

then settle in its normal position. If the vehicle

continues to rise and fall, the shock absorber

is defective. A shock absorber which has

seized will also cause the vehicle to fail.

2Checks carried out

WITH THE VEHICLE ON THE

GROUND

procarmanuals.com

http://vnx.su

Page 278 of 296

1595 Ford Fiesta Remake

REF•12MOT test checks

Exhaust system

MStart the engine. With your assistant

holding a rag over the tailpipe, check the

entir e system for leaks. Repair or renew

leaking sections.

Jack up the front and rear of the vehicle,

and securely support it on axle stands.

Position the stands clear of the suspension

assemblies. Ensure that the wheels are

clear of the ground and that the steering

can be turned from lock to lock.

Steering mechanism

M Have your assistant turn the steering fr om

lock to lock. Check that the steering turns

smoothly , and that no part of the steering

mechanism, including a wheel or tyre, fouls

any brake hose or pipe or any part of the body

structure.

M Examine the steering rack rubber gaiters

for damage or insecurity of the retaining clips.

If power steering is fitted, check for signs of

damage or leakage of the fluid hoses, pipes or

connections. Also check for excessive

stif fness or binding of the steering, a missing

split pin or locking device, or severe corrosion

of the body structure within 30 cm of any

steering component attachment point.

Front and rear suspension and

wheel bearings

M Starting at the front right-hand side, grasp

the roadwheel at the 3 o’clock and 9 o’clock

positions and shake it vigorously. Check for

fr ee play or insecurity at the wheel bearings,

suspension balljoints, or suspension mount-

ings, pivots and attachments.

M Now grasp the wheel at the 12 o’clock and

6 o’clock positions and repeat the previous

inspection. Spin the wheel, and check for

r oughness or tightness of the front wheel

bearing.

M If excess free play is suspected at a

component pivot point, this can be confirmed

by using a large screwdriver or similar tool and

levering between the mounting and the

component attachment. This will confirm

whether the wear is in the pivot bush, its

r etaining bolt, or in the mounting itself (the bolt

holes can often become elongated).

M Carry out all the above checks at the other

fr ont wheel, and then at both rear wheels.

Springs and shock absorbers

M Examine the suspension struts (when

applicable) for serious fluid leakage, corrosion,

or damage to the casing. Also check the

security of the mounting points.

M If coil springs are fitted, check that the

spring ends locate in their seats, and that the

spring is not corroded, cracked or broken.

M If leaf springs are fitted, check that all

leaves are intact, that the axle is securely

attached to each spring, and that there is no

deterioration of the spring eye mountings,

bushes, and shackles. M

The same general checks apply to vehicles

fitted with other suspension types, such as

torsion bars, hydraulic displacer units, etc.

Ensur e that all mountings and attachments are

secur e, that there are no signs of excessive

wear , corrosion or damage, and (on hydraulic

types) that ther e are no fluid leaks or damaged

pipes.

M Inspect the shock absorbers for signs of

serious fluid leakage. Check for wear of the

mounting bushes or attachments, or damage

to the body of the unit.

Driveshafts

(fwd vehicles only)

M Rotate each front wheel in turn and inspect

the constant velocity joint gaiters for splits or

damage. Also check that each driveshaft is

straight and undamaged.

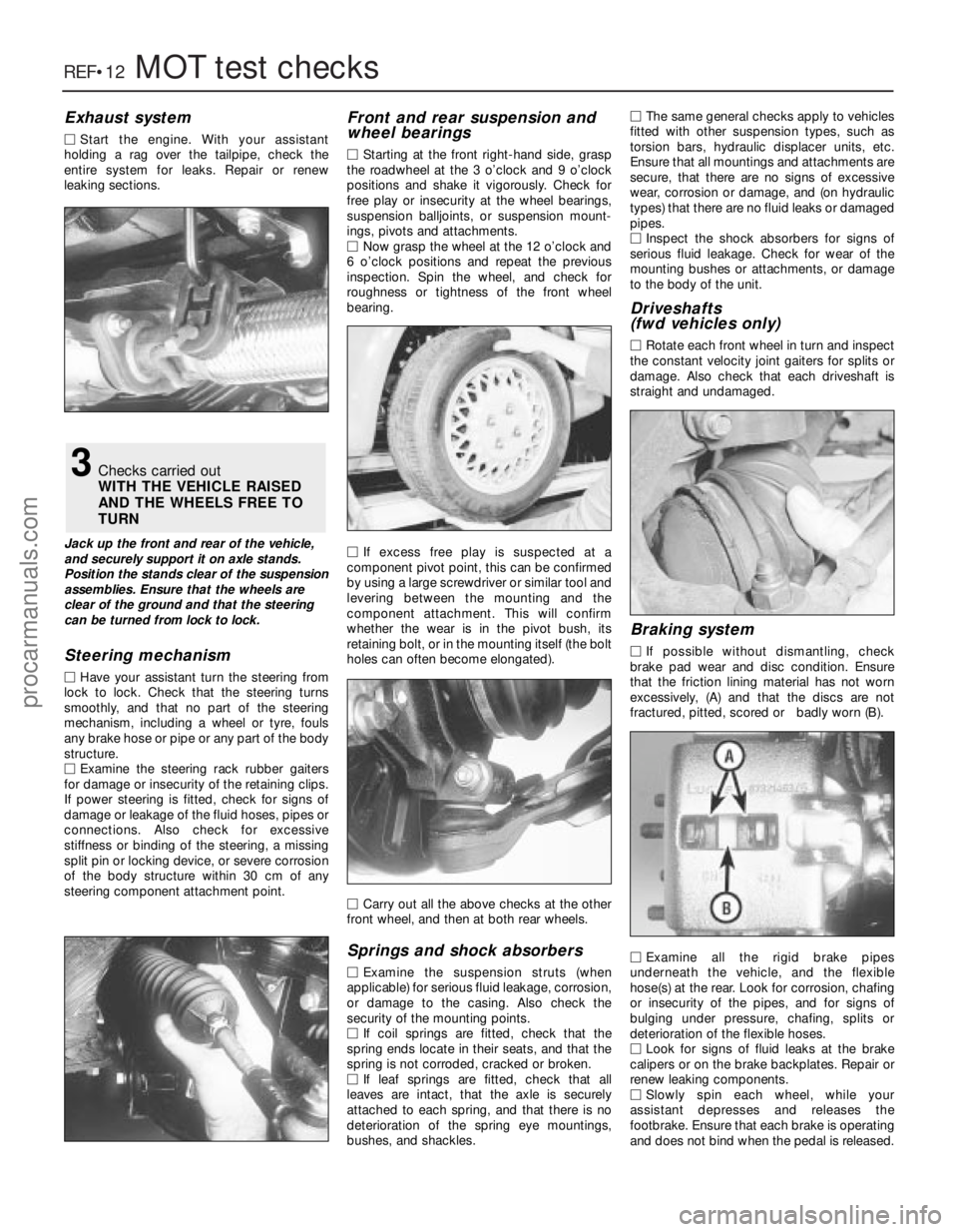

Braking system

M If possible without dismantling, check

brake pad wear and disc condition. Ensure

that the friction lining material has not worn

excessively , (A) and that the discs are not

fractur ed, pitted, scored or badly worn (B).

M Examine all the rigid brake pipes

under neath the vehicle, and the flexible

hose(s) at the rear. Look for corrosion, chafing

or insecurity of the pipes, and for signs of

bulging under pressure, chafing, splits or

deterioration of the flexible hoses.

M Look for signs of fluid leaks at the brake

calipers or on the brake backplates. Repair or

r enew leaking components.

M Slowly spin each wheel, while your

assistant depresses and releases the

footbrake. Ensure that each brake is operating

and does not bind when the pedal is released.

3Checks carried out

WITH THE VEHICLE RAISED

AND THE WHEELS FREE TO

TURN

procarmanuals.com

http://vnx.su

Page 279 of 296

1595 Ford Fiesta Remake

MOT test checksREF•13

REF

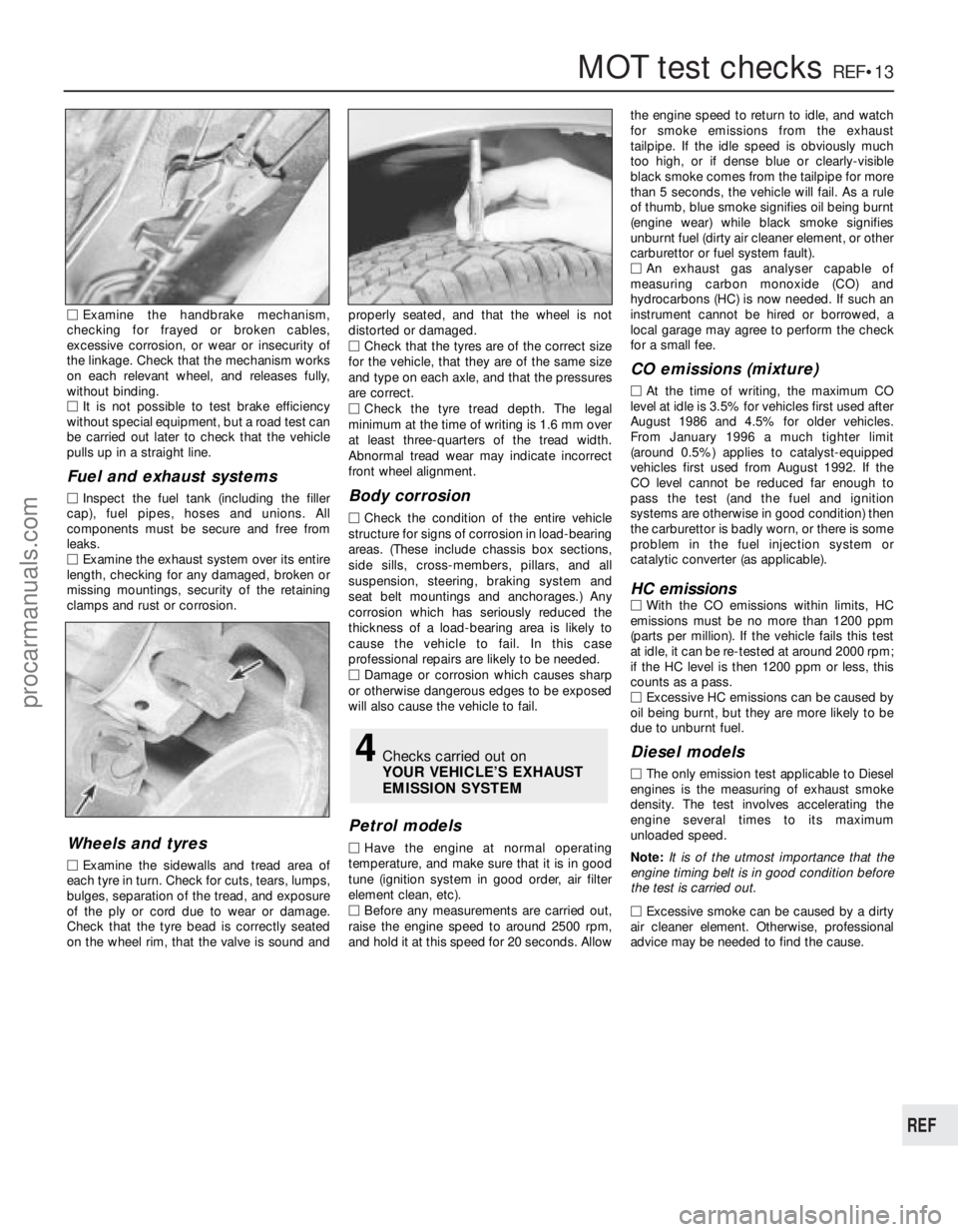

MExamine the handbrake mechanism,

checking for frayed or broken cables,

excessive corrosion, or wear or insecurity of

the linkage. Check that the mechanism works

on each relevant wheel, and releases fully,

without binding.

M It is not possible to test brake efficiency

without special equipment, but a road test can

be carried out later to check that the vehicle

pulls up in a straight line.

Fuel and exhaust systems

M Inspect the fuel tank (including the filler

cap), fuel pipes, hoses and unions. All

components must be secure and free fr om

leaks.

M Examine the exhaust system over its entire

length, checking for any damaged, broken or

missing mountings, security of the retaining

clamps and rust or corrosion.

Wheels and tyres

M Examine the sidewalls and tread area of

each tyre in turn. Check for cuts, tears, lumps,

bulges, separation of the tread, and exposure

of the ply or cord due to wear or damage.

Check that the tyre bead is correctly seated

on the wheel rim, that the valve is sound and pr

operly seated, and that the wheel is not

distorted or damaged.

M Check that the tyres are of the correct size

for the vehicle, that they are of the same size

and type on each axle, and that the pressur es

ar e correct.

M Check the tyre tread depth. The legal

minimum at the time of writing is 1.6 mm over

at least three-quarters of the tread width.

Abnormal tread wear may indicate incorrect

fr ont wheel alignment.

Body corrosion

M Check the condition of the entire vehicle

structur e for signs of corrosion in load-bearing

ar eas. (These include chassis box sections,

side sills, cross-members, pillars, and all

suspension, steering, braking system and

seat belt mountings and anchorages.) Any

corrosion which has seriously reduced the

thickness of a load-bearing area is likely to

cause the vehicle to fail. In this case

pr ofessional repairs are likely to be needed.

M Damage or corrosion which causes sharp

or otherwise dangerous edges to be exposed

will also cause the vehicle to fail.

Petrol models

M Have the engine at normal operating

temperatur e, and make sure that it is in good

tune (ignition system in good order, air filter

element clean, etc).

M Befor e any measurements are carried out,

raise the engine speed to around 2500 rpm,

and hold it at this speed for 20 seconds. Allow the engine speed to return to idle, and watch

for smoke emissions from the exhaust

tailpipe. If the idle speed is obviously much

too high, or if dense blue or clearly-visible

black smoke comes from the tailpipe for more

than 5 seconds, the vehicle will fail. As a rule

of thumb, blue smoke signifies oil being burnt

(engine wear) while black smoke signifies

unbur nt fuel (dirty air cleaner element, or other

carbur ettor or fuel system fault).

M An exhaust gas analyser capable of

measuring carbon monoxide (CO) and

hydr ocarbons (HC) is now needed. If such an

instrument cannot be hired or borrowed, a

local garage may agree to perform the check

for a small fee.

CO emissions (mixture)

M At the time of writing, the maximum CO

level at idle is 3.5% for vehicles first used after

August 1986 and 4.5% for older vehicles.

Fr om January 1996 a much tighter limit

(ar ound 0.5%) applies to catalyst-equipped

vehicles first used from August 1992. If the

CO level cannot be reduced far enough to

pass the test (and the fuel and ignition

systems are otherwise in good condition) then

the carburettor is badly worn, or there is some

pr oblem in the fuel injection system or

catalytic converter (as applicable).

HC emissionsM With the CO emissions within limits, HC

emissions must be no more than 1200 ppm

(parts per million). If the vehicle fails this test

at idle, it can be re-tested at around 2000 rpm;

if the HC level is then 1200 ppm or less, this

counts as a pass.

M Excessive HC emissions can be caused by

oil being burnt, but they are more likely to be

due to unburnt fuel.

Diesel models

M The only emission test applicable to Diesel

engines is the measuring of exhaust smoke

density . The test involves accelerating the

engine several times to its maximum

unloaded speed.

Note: It is of the utmost importance that the

engine timing belt is in good condition before

the test is carried out.

M

Excessive smoke can be caused by a dirty

air cleaner element. Otherwise, professional

advice may be needed to find the cause.

4Checks carried out on

YOUR VEHICLE’S EXHAUST

EMISSION SYSTEM

procarmanuals.com

http://vnx.su

Page 280 of 296

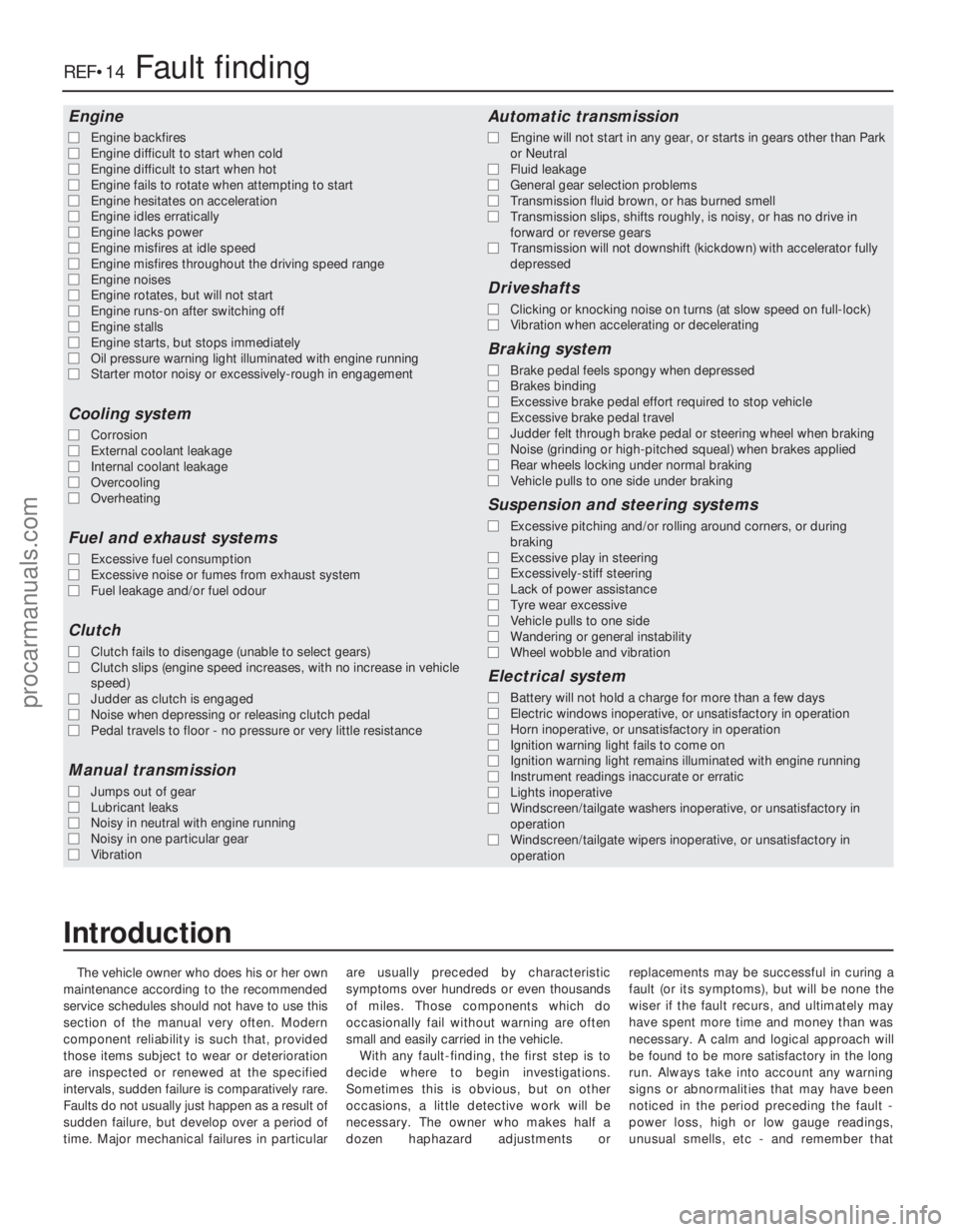

The vehicle owner who does his or her own

maintenance according to the recommended

service schedules should not have to use this

section of the manual very often. Modern

component reliability is such that, provided

those items subject to wear or deterioration

are inspected or renewed at the specified

intervals, sudden failure is comparatively rare.

Faults do not usually just happen as a result of

sudden failure, but develop over a period of

time. Major mechanical failures in particular are usually preceded by characteristic

symptoms over hundreds or even thousands

of miles. Those components which do

occasionally fail without warning are often

small and easily carried in the vehicle.

With any fault-finding, the first step is to

decide where to begin investigations.

Sometimes this is obvious, but on other

occasions, a little detective work will be

necessary. The owner who makes half a

dozen haphazard adjustments or replacements may be successful in curing a

fault (or its symptoms), but will be none the

wiser if the fault recurs, and ultimately may

have spent more time and money than was

necessary. A calm and logical approach will

be found to be more satisfactory in the long

run. Always take into account any warning

signs or abnormalities that may have been

noticed in the period preceding the fault -

power loss, high or low gauge readings,

unusual smells, etc - and remember that

Engine

m

m

Engine backfires

m

m Engine difficult to start when cold

m

m Engine difficult to start when hot

m

m Engine fails to rotate when attempting to start

m

m Engine hesitates on acceleration

m

m Engine idles erratically

m

m Engine lacks power

m

m Engine misfires at idle speed

m

m Engine misfires throughout the driving speed range

m

m Engine noises

m

m Engine rotates, but will not start

m

m Engine runs-on after switching off

m

m Engine stalls

m

m Engine starts, but stops immediately

m

m Oil pressure warning light illuminated with engine running

m

m Starter motor noisy or excessively-rough in engagement

Cooling system

m

mCorrosion

m

m External coolant leakage

m

m Internal coolant leakage

m

m Overcooling

m

m Overheating

Fuel and exhaust systems

m

mExcessive fuel consumption

m

m Excessive noise or fumes from exhaust system

m

m Fuel leakage and/or fuel odour

Clutch

m

mClutch fails to disengage (unable to select gears)

m

m Clutch slips (engine speed increases, with no increase in vehicle

speed)

m m Judder as clutch is engaged

m

m Noise when depressing or releasing clutch pedal

m

m Pedal travels to floor - no pressure or very little resistance

Manual transmission

m

mJumps out of gear

m

m Lubricant leaks

m

m Noisy in neutral with engine running

m

m Noisy in one particular gear

m

m Vibration

Automatic transmission

m

mEngine will not start in any gear, or starts in gears other than Park

or Neutral

m m Fluid leakage

m

m General gear selection problems

m

m Transmission fluid brown, or has burned smell

m

m Transmission slips, shifts roughly, is noisy, or has no drive in

forward or reverse gears

m m Transmission will not downshift (kickdown) with accelerator fully

depressed

Driveshafts

m mClicking or knocking noise on turns (at slow speed on full-lock)

m

m Vibration when accelerating or decelerating

Braking system

m

mBrake pedal feels spongy when depressed

m

m Brakes binding

m

m Excessive brake pedal effort required to stop vehicle

m

m Excessive brake pedal travel

m

m Judder felt through brake pedal or steering wheel when braking

m

m Noise (grinding or high-pitched squeal) when brakes applied

m

m Rear wheels locking under normal braking

m

m Vehicle pulls to one side under braking

Suspension and steering systems

m

mExcessive pitching and/or rolling around corners, or during

braking

m m Excessive play in steering

m

m Excessively-stiff steering

m

m Lack of power assistance

m

m Tyre wear excessive

m

m Vehicle pulls to one side

m

m Wandering or general instability

m

m Wheel wobble and vibration

Electrical system

m

mBattery will not hold a charge for more than a few days

m

m Electric windows inoperative, or unsatisfactory in operation

m

m Horn inoperative, or unsatisfactory in operation

m

m Ignition warning light fails to come on

m

m Ignition warning light remains illuminated with engine running

m

m Instrument readings inaccurate or erratic

m

m Lights inoperative

m

m Windscreen/tailgate washers inoperative, or unsatisfactory in

operation

m m Windscreen/tailgate wipers inoperative, or unsatisfactory in

operation

REF•14Fault finding

1595 Ford Fiesta Remake

Introduction

procarmanuals.com

http://vnx.su