head FORD FIESTA 2007 Owners Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 714 of 1226

303-01 B-92 Engine - 2.OL Duratec-HE (M14) 303-01 B-92

DISASSEMBLY

Discard the friction washer. Discard the gasket.

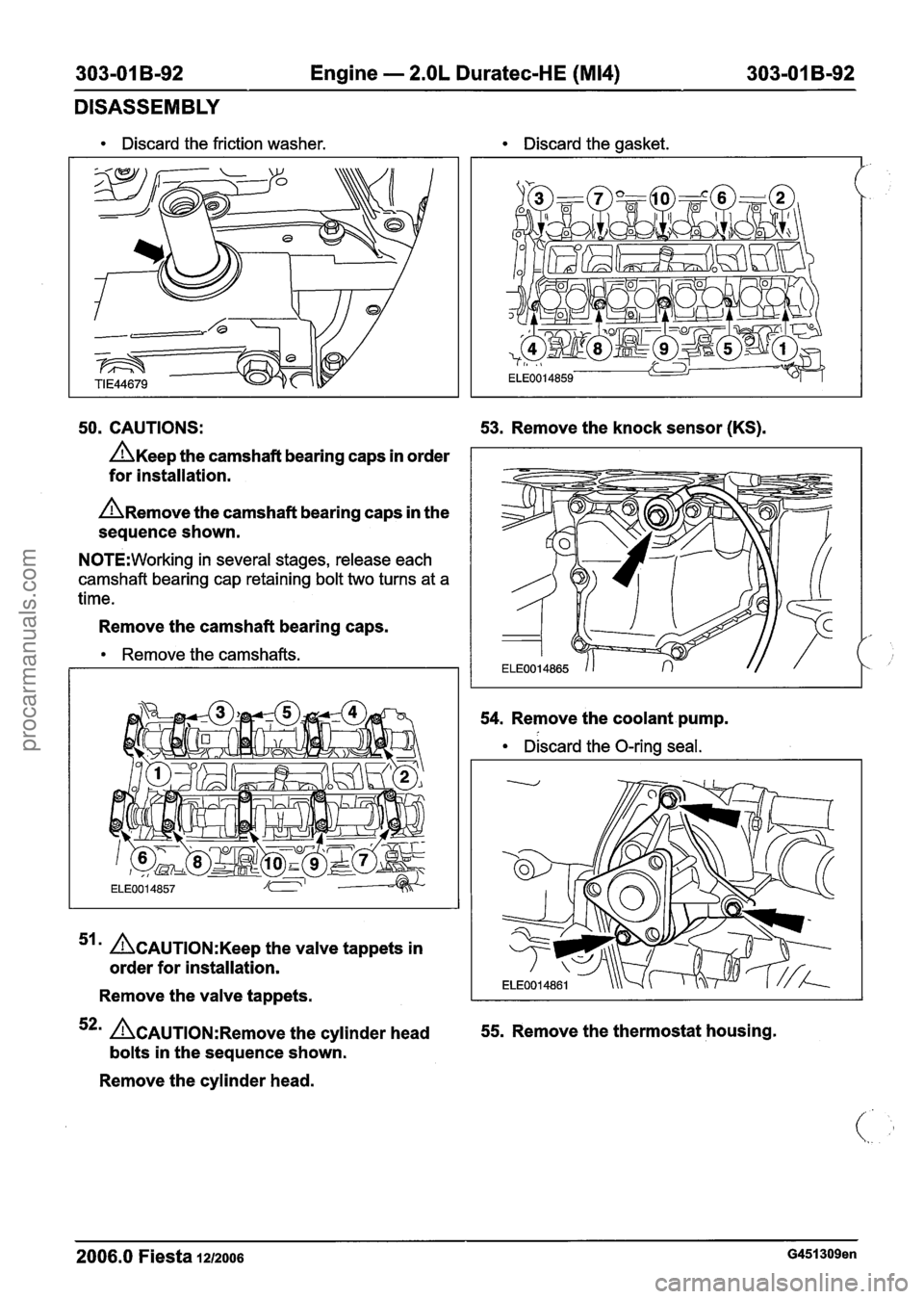

50. CAUTIONS: 53. Remove the knock sensor (KS).

A~eep the camshaft bearing caps in order I - -

for installation.

A~emove the camshaft bearing caps in the

sequence shown.

N0TE:Working in several stages, release each

camshaft bearing cap retaining bolt two turns at

a

time.

Remove the camshaft bearing caps.

Remove the camshafts.

' ACAUTION:K~~~ the valve tappets in

order for installation.

Remove the valve tappets.

52m ACAUTION:R~~~~~ the cylinder head

bolts in the sequence shown.

Remove the cylinder head.

54. Remove the coolant pump.

Discard the O-ring seal.

55. Remove the thermostat housing.

2006.0 Fiesta 1212006 G451309en

procarmanuals.com

Page 719 of 1226

303-01 B-97 Engine - 2.OL Duratec-HE (M14) 303-01 B-97

ASSEMBLY

11. lnstall the clutch disc and pressure plate. 15. N0TE:lnstall a

new thermostat housing

'. For additional information, refer to: Clutch gasket.

Disc and Pressure Plate (308-01 Clutch, Install

the thermostat housing.

Removal and Installation).

12.

N0TE:lnstall a new oil filter adapter gasket.

lnstall the oil filter adapter.

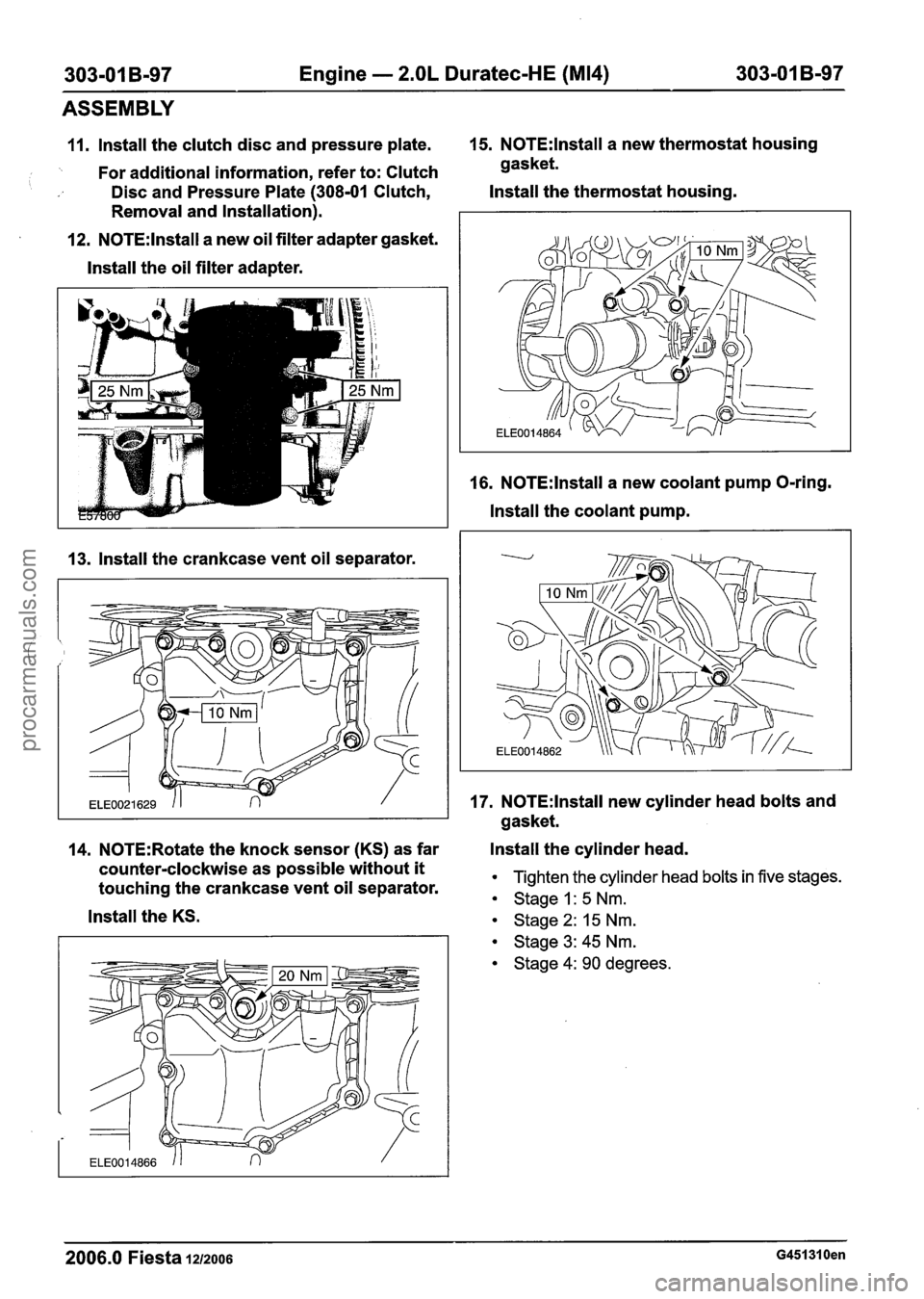

13. lnstall the crankcase vent oil separator. 16.

N0TE:lnstall a

new coolant pump O-ring.

lnstall the coolant pump.

17.

N0TE:lnstall new cylinder head bolts and

gasket.

14.

N0TE:Rotate the knock sensor (KS) as far Install

the cylinder head.

counter-clockwise as possible without

it Tighten the cylinder head bolts in five stages. touching the crankcase vent oil separator. Stage I: 5 Nm.

lnstall the KS. stage 2: 15 Nm.

Stage 3: 45 Nm.

Stage 4: 90 degrees.

2006.0 Fiesta 1212006 G451310en

procarmanuals.com

Page 741 of 1226

303-01 B-1/19 Engine - 2.OL Duratec-HE (M14) 303-01 B-119

INSTALLATION

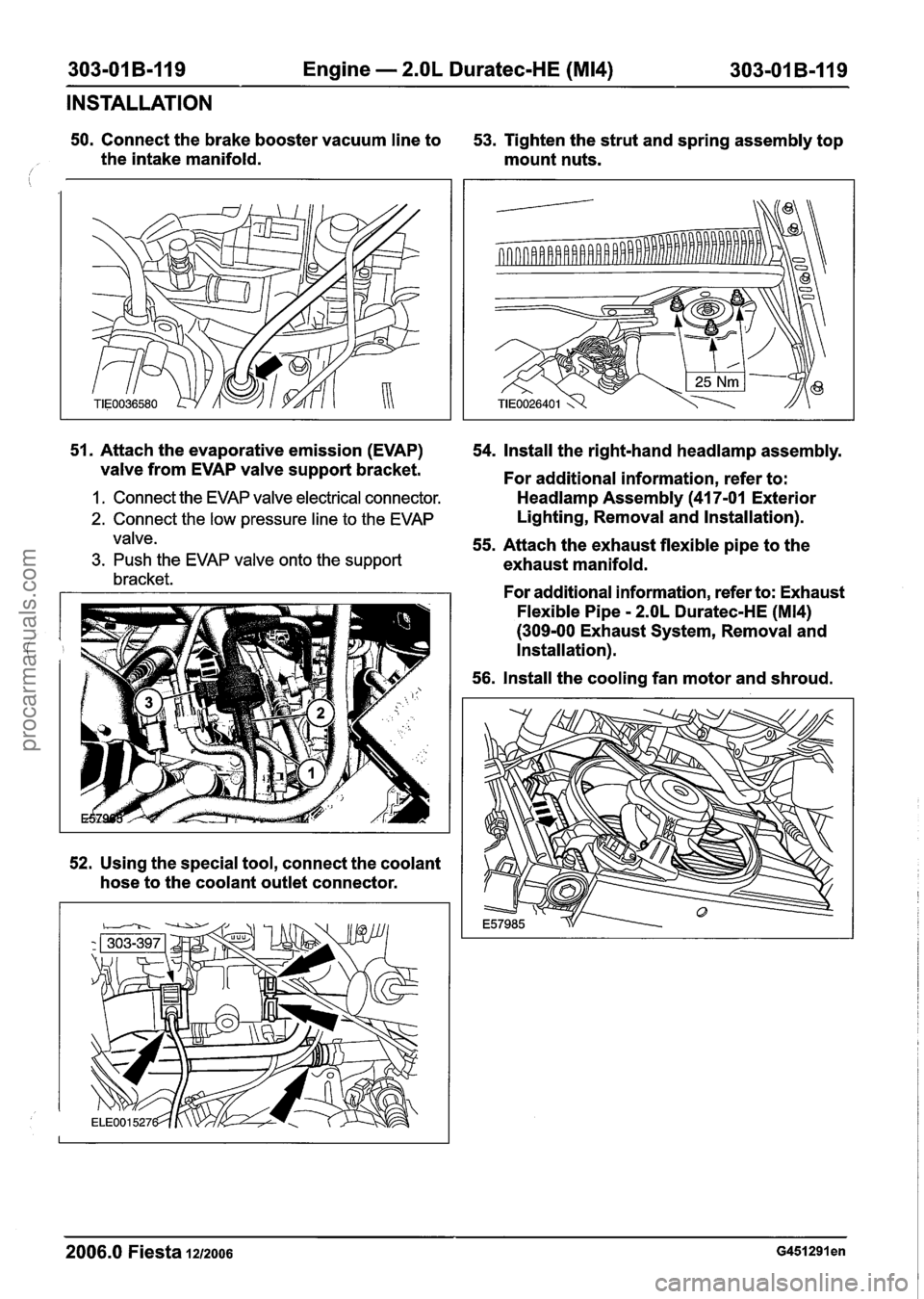

50. Connect the brake booster vacuum line to

53. Tighten the strut and spring assembly top

the intake manifold. mount nuts.

/

51. Attach the evaporative emission (EVAP)

valve from EVAP valve support bracket.

I. Connect the EVAP valve electrical connector.

2. Connect the low pressure line to the EVAP

valve.

3. Push the EVAP valve onto the support

bracket.

52. Using the special tool, connect the coolant

hose to the coolant outlet connector. 54.

Install the right-hand

headlamp assembly.

For additional information, refer to:

Headlamp Assembly (41 7-01 Exterior

Lighting, Removal and Installation).

55. Attach the exhaust flexible pipe to the

exhaust manifold.

For additional information, refer to: Exhaust

Flexible Pipe

- 2.OL Duratec-HE (M14)

(309-00 Exhaust System, Removal and

Installation).

56. Install the cooling fan motor and shroud.

2006.0 Fiesta 1212006 ~451291 en

procarmanuals.com

Page 749 of 1226

Enaine Cooling - 1.3L Duratec-8V

(~ocah)ll.25L ~Cratec-1 6~ (Sigma)ll.4L

303-03A-7 Duratec-1 6V (Sigma)ll .6L Duratec-1 6V (Sigma) 303-03A-7

DESCRIPTION AND OPERATION

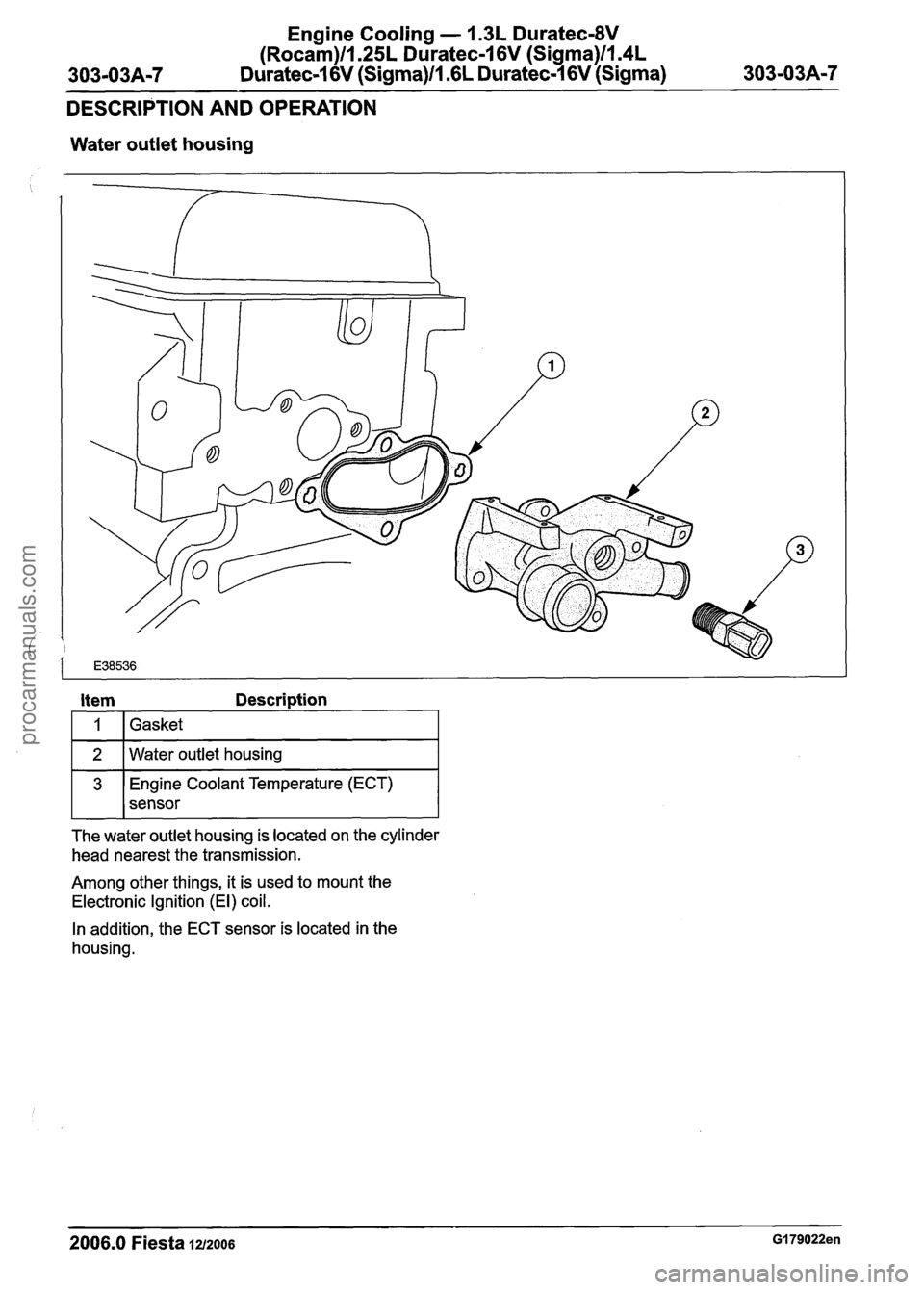

Water outlet housing

Coolant Temperature (ECT)

sensor

Item Description

The water outlet housing is located on the cylinder

head nearest the transmission.

1

2

Among other things, it is used to mount the

Electronic Ignition (El) coil.

Gasket

Water outlet housing

In addition, the ECT sensor is located in the

housing.

2006.0 Fiesta 1212006 GI 79022en

procarmanuals.com

Page 750 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V (Sigma)ll.4L

303-03A-8 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-03A-8

DIAGNOSIS AND TESTING

Engine Cooling

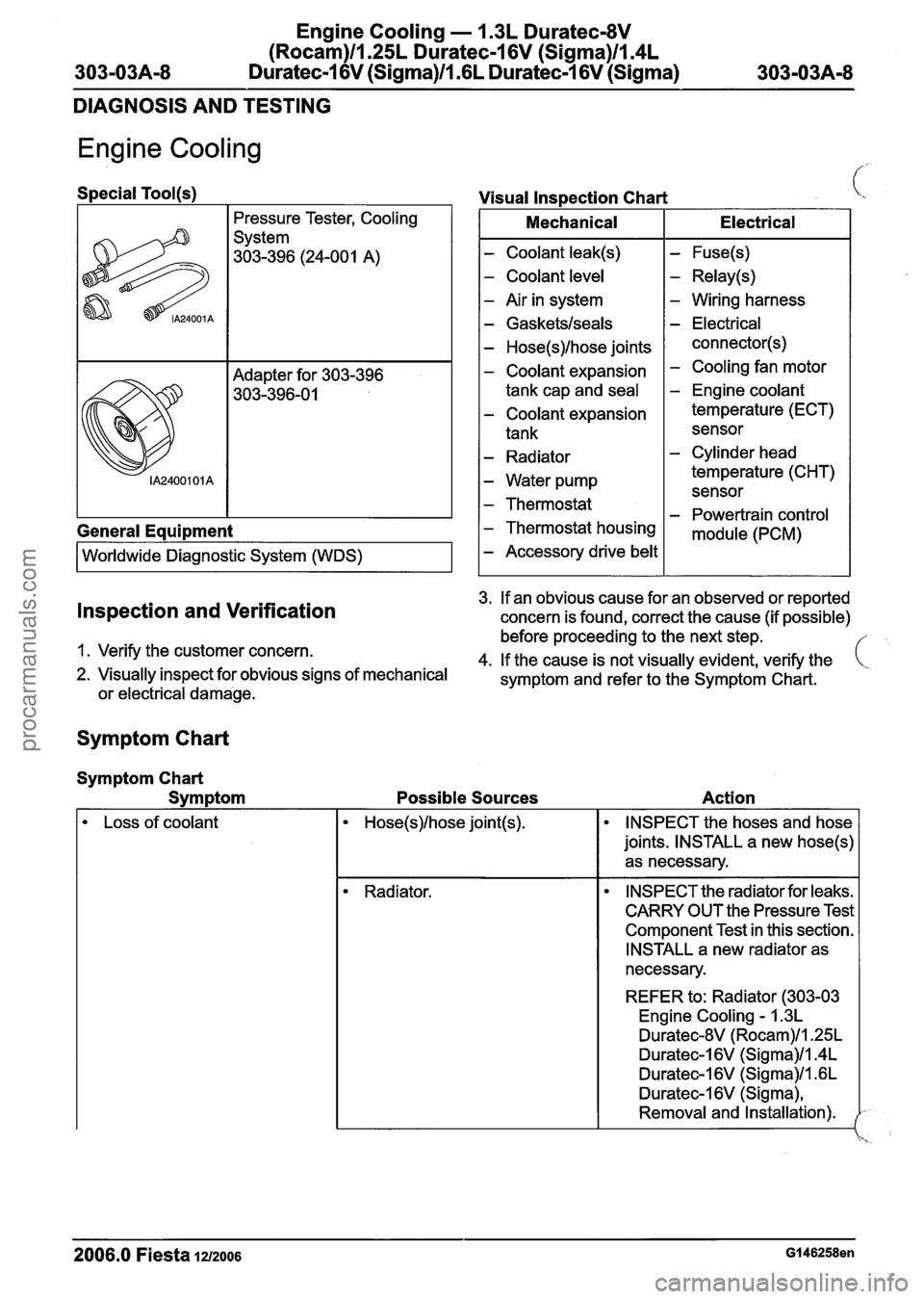

Special Tool(~)

Pressure Tester,

Cooling

System

303-396 (24-001 A)

General

Equipment

I Worldwide Diagnostic System (WDS) I

Visual Inspection Chart i,

I Mechanical I Electrical I

- Coolant leak(s)

- Coolant level

- Air in system

- Gasketslseals

- Hose(s)lhose joints

- Coolant expansion

tank cap and

seal

- Coolant expansion

tank

- Radiator

- Water pump

- Thermostat

- Thermostat housing

- Accessory drive belt

- Fuse(s)

- Relay(s)

- Wiring harness

- Electrical

connector(s)

- Cooling fan motor

- Engine coolant

temperature (ECT)

sensor

- Cylinder head

temperature (CHT) sensor

- Powertrain control

module (PCM)

3.

If an obvious cause for an observed or reported Inspection and Verification concern is found, correct the cause (if possible)

before proceeding to the next step.

1. Verify the customer concern.

4.

If the cause is not visually evident, verify the ( 2. Visually inspect for obvious signs of mechanical

symptom and refer to the Symptom Chart.

or

electrical damage.

Symptom Chart

Symptom Chart

Svm

ptom Possible Sources Action

Loss of

coolant INSPECT the hoses and hose

joints. INSTALL a new

hose(s)

as necessary.

Radiator. INSPECT the radiator for leaks.

CARRY OUT the Pressure Test

Component Test in this section.

INSTALL a new radiator as

necessary.

REFER to: Radiator (303-03 Engine

Cooling - 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-1 6V (Sigma)1ln4L

Duratec-1 6V (Sigma)ll .6L

Duratec-I 6V (Sigma),

Removal and Installation).

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 752 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)llI25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma)

DIAGNOSIS AND TESTING

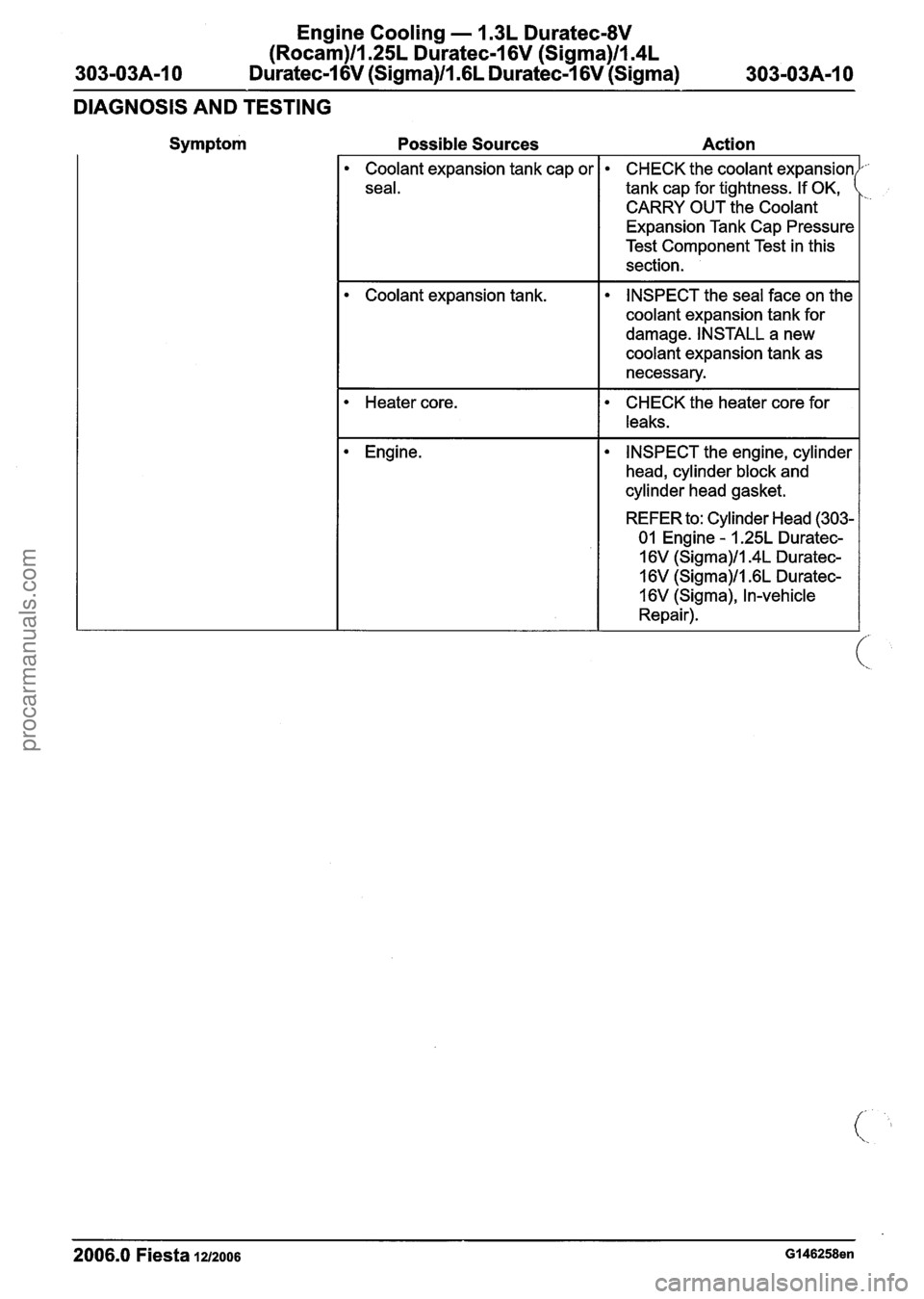

Symptom

Possible Sources Action

Coolant expansion tank cap or

seal.

Coolant expansion tank.

Heater core.

Engine. CHECK

the

coolant expansion

tank cap for tightness. If OK,

I

CARRY OUT the Coolant

Expansion Tank Cap Pressure

Test Component Test in this

section.

INSPECT the seal face on the

coolant expansion tank for

damage. INSTALL a new

coolant expansion tank as

necessary.

CHECK the heater core for

leaks.

INSPECT the engine, cylinder

head, cylinder block and

cylinder head gasket.

REFER to:

Cylinder Head (303-

01 Engine

- I .25L Duratec-

16V

(Sigma)/l.4L Duratec-

16V

(Sigma)/l .6L Duratec-

16V (Sigma),

In-vehicle

Repair).

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 753 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)llI25L Duratec-1 6V (Sigma)llI4L

303-03A-I I Duratec-1 6V (Sigma)/lI6L Duratec-I 6V (Sigma) 303-03A-1 I

DIAGNOSIS AND TESTING

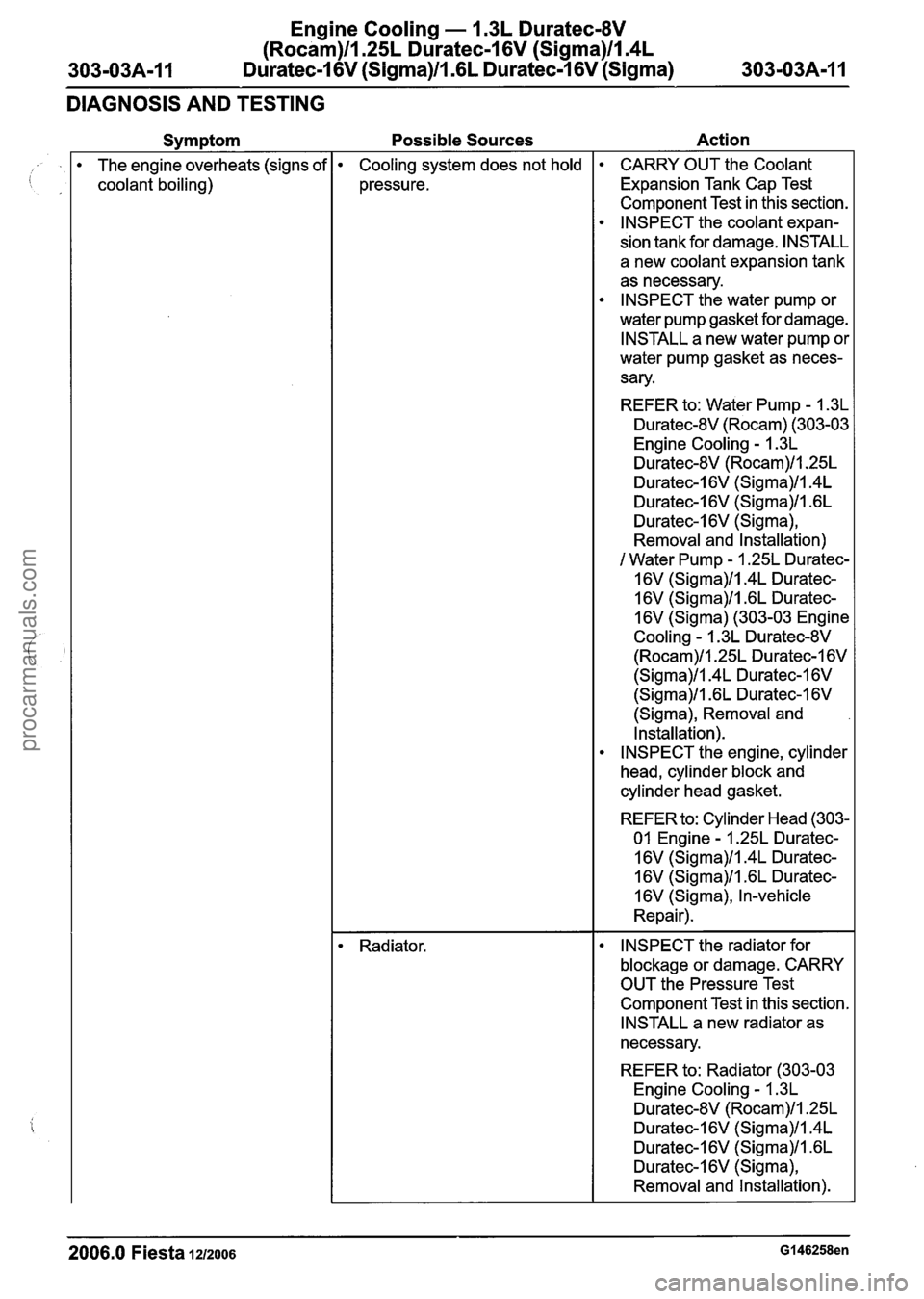

Symptom

The engine overheats (signs of

coolant boiling)

Possible Sources Action

Cooling system does not hold

pressure.

Radiator. CARRY

OUT the Coolant

Expansion Tank Cap Test

Component Test in this section.

INSPECT the coolant expan-

sion tank for damage. INSTALL

a new coolant expansion tank

as necessary.

INSPECT the water pump or

water pump gasket for damage.

INSTALL a new water pump or

water pump gasket as neces-

sary.

REFER to: Water Pump

- 1.3L

Duratec-8V (Rocam) (303-03

Engine Cooling

- 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L

Duratec-I 6V (Sigma),

Removal and Installation)

/ Water Pump - 1.25L Duratec-

16V

(Sigma)ll.4L Duratec-

16V

(Sigma)/l .6L Duratec-

16V (Sigma) (303-03 Engine

Cooling

- 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V

(Sigma), Removal and

Installation).

INSPECT the engine, cylinder

head, cylinder block and

cylinder head gasket.

REFER to: Cylinder Head (303-

01 Engine

- 1.25L Duratec-

16V

(Sigma)/l.4L Duratec-

1 6V

(Sigma)/l .6L Duratec-

16V (Sigma), In-vehicle

Repair).

INSPECT the radiator for

blockage or damage. CARRY

OUT the Pressure Test

Component Test in this section.

INSTALL a new radiator as

necessary.

REFER to: Radiator (303-03

Engine Cooling

- 1.3L

Duratec-8V (Rocam)ll.25L

Duratec-I 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L

Duratec-I 6V (Sigma),

Removal and Installation).

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 757 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)llI25L Duratec-1 6V (Sigma)llI4L

303-03A-I 5 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-0344-15

DIAGNOSIS AND TESTING

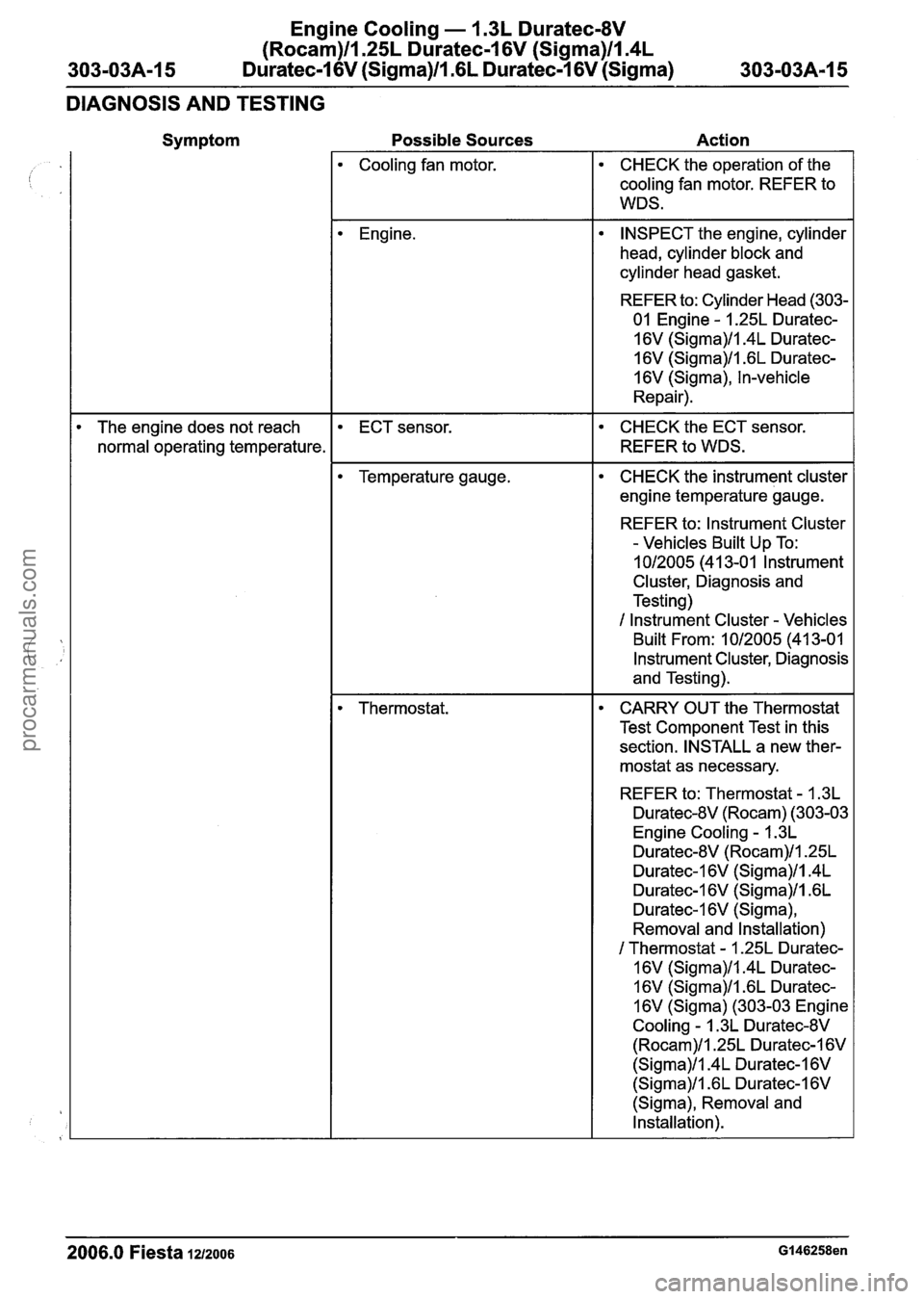

Symptom Possible Sources Action

Cooling fan motor. CHECK the operation of the

cooling fan motor. REFER to

WDS.

Engine. INSPECT

the engine, cylinder

head, cylinder block and

cylinder head gasket.

REFER to: Cylinder Head (303-

01 Engine - 1.25L Duratec-

16V (Sigma)/l.4L Duratec-

16V (Sigma)/l.GL Duratec-

16V (Sigma), In-vehicle

Repair).

, The engine does not reach

normal operating temperature. ECT sensor. CHECK the ECT sensor.

I REFER to WDS.

Temperature gauge. CHECK

the instrument cluster

engine temperature gauge.

REFER to: lnstrument Cluster

- Vehicles Built Up To:

1012005 (41 3-01 lnstrument

Cluster, Diagnosis and

Testing)

I lnstrument Cluster - Vehicles

Built From:

1012005 (41 3-01

lnstrument Cluster, Diagnosis

and Testing).

Thermostat. CARRY OUT the Thermostat

Test Component Test in this

section. INSTALL a new ther-

mostat as necessary.

REFER to: Thermostat

- I .3L

Duratec-8V

(Rocam) (303-03

Engine Cooling

- 1.3L

Duratec-8V (Rocam)ll.25L

Duratec-16V (Sigma)/l.4L

Duratec-1 6V (Sigma)ll .6L

Duratec-16V (Sigma),

Removal and Installation)

I Thermostat - 1.25L Duratec-

16V (Sigma)/l.4L Duratec-

16V (Sigma)ll .6L Duratec-

16V (Sigma) (303-03 Engine

Cooling

- 1.3L Duratec-8V

(Rocam)ll.25L Duratec-1 6V

(Sigma)ll.4L Duratec-1 6V

(Sigma)/l .6L Duratec-I 6V

(Sigma), Removal and

Installation).

2006.0 Fiesta 1212oo6 GI 46258en

procarmanuals.com

Page 758 of 1226

Engine Cooling - 1.3L Duratec-8V

(Rocam)ll.25L Duratec-I 6V (Sigma)ll.4L

303-03A-16 Duratec-1 6V (Sigma)/l .6L Duratec-1 6V (Sigma) 303-03A-16

DIAGNOSIS AND TESTING

Component Tests

Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2.

Install the special tools to the coolant expansion

tank.

3. Pressurize the system to the

coolant expansion

tank cap

release pressure.

REFER to: Specifications (303-03 Engine

Cooling - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma),

Specifications).

4. Observe the

cooling system pressure tester

gauge reading for

approximately two minutes.

The pressure

should not drop during this time.

If the system holds pressure, proceed to step

6.

If the system does not hold pressure, check

it

thoroughly for coolant leaks.

5. Check the engine for coolant leaks. Drain the

cooling system, repair any coolant leaks found

and

fill and bleed the cooling system as

necessary.

REFER to:

Cooling System Draining, Filling and

Bleeding - 1.3L Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V (Sigma) (303-03

Engine

Cooling - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)/l .6L Duratec-1 6V

(Sigma), General Procedures).

Clean the radiator thoroughly before leak testing

it, to prevent contamination of the water in the test

tank. Leak test the radiator in

clean water with 138(

kpa (20 psi) air pressure. Check it thoroughly for

air

leaks. INSTALL a new radiator if necessary.

REFER to: Radiator (303-03 Engine

Cooling - 1.3L

Duratec-8V (Rocam)/l.25L Duratec-I 6V

(Sigma)/l.4L Duratec-I 6V (Sigma)ll .6L

Duratec-I 6V (Sigma), Removal and Installation).

Coolant Expansion Tank Cap Pressure Test

A WARNING:When releasing the system

pressure, cover the expansion tank cap

with a thick cloth to prevent the possibility

of coolant scalding, Failure to follow this

instruction may result in personal injury.

1. Remove the coolant expansion tank cap.

2. Use water to clean the area of the rubber seal

and pressure relief valve. Install the pressure

tester and adapter and immerse the

coolant

expansion tank cap in water .

N0TE:lf the plunger of the pump is depressed too

quickly, an erroneous pressure reading will result. l-

3. Slowly depress the plunger of the pressure test

pump until the pressure gauge reading stops

increasing, and note the highest pressure

reading obtained.

4.

Release pressure by turning the pressure relief

screw counterclockwise. Tighten the pressure

relief screw and repeat step 3 at least twice to

make sure the pressure test reading is

repeatable and within acceptable gauge reading

limits of the coolant expansion tank cap.

5.

If the pressure test gauge readings are not

within the

acceptable gauge reading limits,

INSTALL a new coolant expansion tank cap.

6. Recheck the system by repeating steps 3 and

4 at least twice.

Thermostat Test

Radiator Leak Test, Removed From Vehicle

A CAUTI0N:Radiator internal pressure must

not exceed

130 kpa (20 psi) or damage may

result.

1. Connect the WDS to the data link connector

(DLC).

2. Using the WDS

datalogger function, SELECT

the

following sensors (as applicable to the

application):

IAT - intake air temperature (IAT) sensor

ECT

- engine coolant temperature (ECT) sensort

CHT - cylinder head temperature (CHT) sensori

LOAD - engine load

VSS - vehicle speed sensor (VSS)

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com

Page 759 of 1226

Engine Cooling - I .3L Duratec-8V

(Rocam)llm25L Duratec-1 6V (Sigma)ll.4L

303-03A-17 Duratec-1 6V (Sigma)/lm6L Duratec-1 6V (Sigma) 303-03A-17

DIAGNOSIS AND TESTING

RPM - engine speed

i DSRPM - desired engine speed

The IAT sensor output is useful if the engine being

tested is cold or after an over-night cold soak. The

ECT sensor or CHT sensor and the IAT sensor

should either indicate the same value or be within

1 to 2 degrees Celsius of each other.

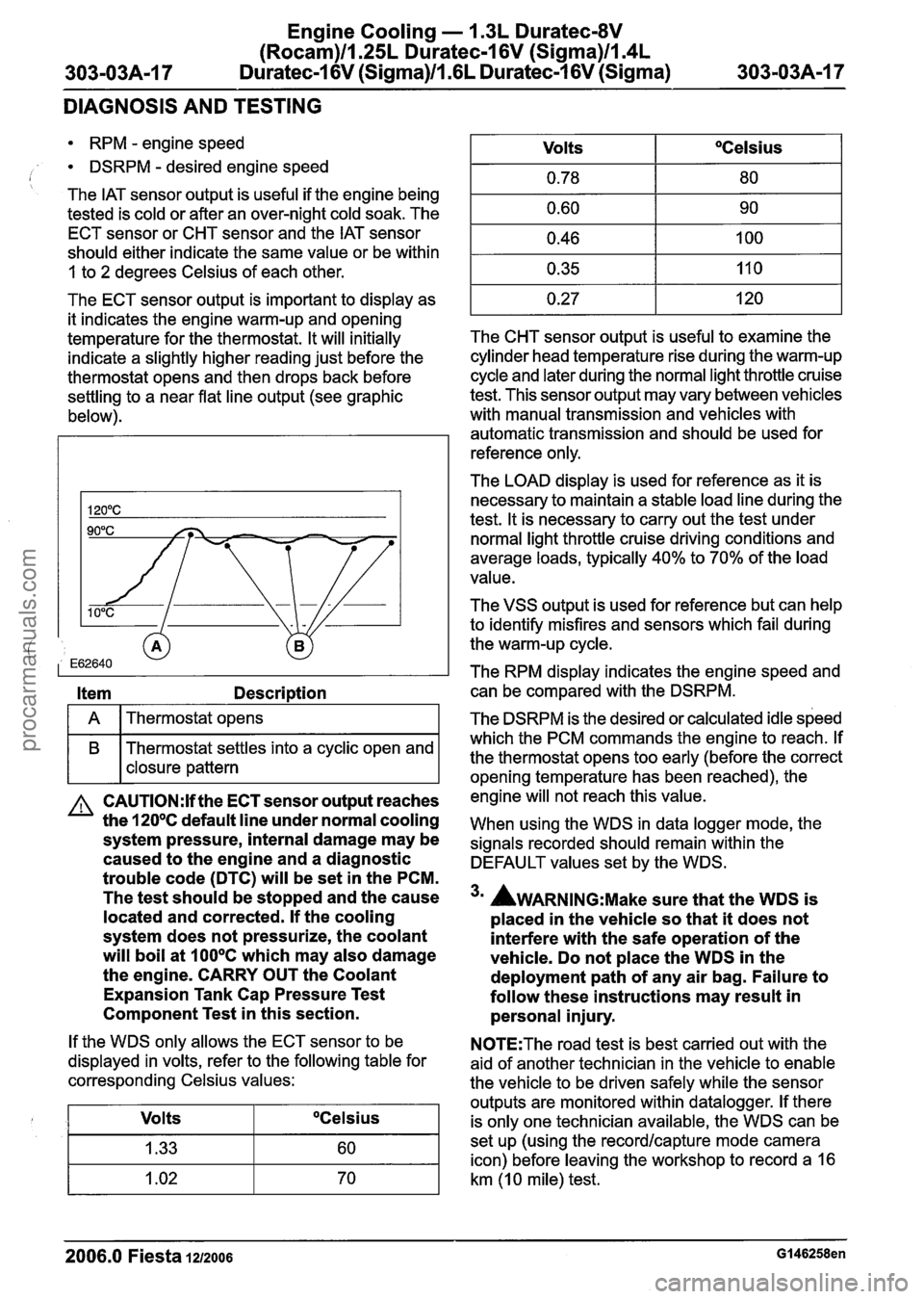

The ECT sensor output is important to display as

it indicates the engine warm-up and opening

temperature for the thermostat. It will initially

indicate a slightly higher reading just before the

thermostat opens and then drops back before

settling to a near flat line output (see graphic

below).

Item Description

I A I Thermostat opens I

B Thermostat settles into a cyclic open and

I I closure pattern

A CAUTI0N:lf the ECT sensor output reaches

the

120°C default line under normal cooling

system pressure, internal damage may be

caused to the engine and a diagnostic

trouble code (DTC) will be set in the PCM.

The test should be stopped and the cause

located and corrected. If the cooling

system does not pressurize, the coolant

will boil at

100°C which may also damage

the engine. CARRY OUT the Coolant

Expansion Tank Cap Pressure Test

Component Test in this section.

If the WDS only allows the ECT sensor to be

displayed in volts, refer to the following table for

corresponding Celsius values:

Volts

OCelsius

The CHT sensor output is useful to examine the

cylinder head temperature rise during the warm-up

cycle and later during the normal light throttle cruise

test. This sensor output may vary between vehicles

with manual transmission and vehicles with

automatic transmission and should be used for

reference only.

Volts

0.78

0.60

0.46

0.35

0.27

The

LOAD display is used for reference as it is

necessary to maintain a stable load line during the

test. It is necessary to carry out the test under

normal light throttle cruise driving conditions and

average loads, typically

40% to 70% of the load

value.

OCelsius

80

90

100

11 0

120

The VSS output is used for reference but can help

to identify misfires and sensors which fail during

the warm-up cycle.

The RPM display indicates the engine speed and can be compared with the DSRPM.

The DSRPM is the desired or calculated idle speed

which the PCM commands the engine to reach. If

the thermostat opens too early (before the correct

opening temperature has been reached), the

engine will not reach this value.

When using the WDS in data logger mode, the

signals recorded should remain within the

DEFAULT values set by the WDS.

3m AWARNING:M~~~ sure that the WDS is

placed in the vehicle so that it does not

interfere with the safe operation of the

vehicle. Do not place the WDS in the

deployment path of any air bag. Failure to

follow these instructions may result in personal injury.

N0TE:The road test is best carried out with the

aid of another technician in the vehicle to enable

the vehicle to be driven safely while the sensor

outputs are monitored within datalogger. If there

is only one technician available, the WDS can be

set up (using the

recordlcapture mode camera

icon) before leaving the workshop to record a

16

km (1 0 mile) test.

2006.0 Fiesta 1212006 GI 46258en

procarmanuals.com