cam FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 939 of 1226

303-1 4-1 5 Electronic Engine Controls 303-1 4-1 5

DIAGNOSIS AND TESTING

Monitors

The purpose of the monitors is to continuously

check the operation of the emission related sensors

and actuators. It then establishes if they are

operating within specified tolerances. All monitors

carry out their functions in such a way as to be

unnoticeable by the driver of the vehicle. Each one

is carried out under specific conditions of load,

speed and engine temperature. The Comprehensive Component Monitor, Combustion

Misfire Monitor and

AirIFuel Ratio Monitor operate

continuously. The remaining monitors are only

invoked under certain operating conditions. On

diesel variants, all of the monitors operate under

normal driving conditions: There are no monitors

which intervene and cause special operating

modes to enable the monitors to work. Some diesel

monitors are non-continuous. This means that in

a drive cycle, monitoring is done as and when

suitable driving conditions exist and potential faults

are accumulated and compared with acceptance

criteria. Examples of this type are the turbocharger

boost pressure and exhaust gas recirculation

(EGR) monitors on vehicles with common rail fuel

injection.

( Comprehensive Component Monitor (CCM)

When the CCM detects a component operating out

of tolerance, it sets a Diagnostic Trouble Code

(DTC), which is stored in the EEPROM. If the same

concern is confirmed during the next trip the MIL

will be switched on. The CCM monitors many

components, sub-systems and signals. The

following is a list of those that can effect emissions

depending on application:

Electronic Ignition (El) System.

Crankshaft Position (CKP) Sensor.

Ignition Coil.

Electronic Throttle Control Unit.

Camshaft Position (CMP) Sensor.

Air Conditioning

(AIC) Clutch.

Idle Air Control (IAC) Valve.

Mass Air Flow (MAF) Sensor.

Manifold Absolute Pressure (MAP) Sensor.

Intake Air Temperature (IAT) Sensor.

Engine Coolant Temperature (ECT) Sensor.

Cylinder Head Temperature (CHT) Sensor.

Heated Oxygen Sensor

(H02S).

Catalyst Monitor Sensor.

Charge Air Temperature Sensor.

Knock Sensor (KS).

Throttle Position (TP) Sensor.

Vehicle Speed Sensor (VSS).

Boost Pressure Sensor.

Cam-Crank Phasing Sensor.

EEPROM.

High Pressure Fuel Injection Pump.

Exhaust Gas Recirculation (EGR) Valve Monitor.

Fuel Injectors.

Turbocharger.

Combustion Noise Monitor.

Barometric Pressure (BARO) Sensor.

Combustion Misfire Monitor (All except vehicles

with diesel engine)

The combustion misfire monitor operates independently of the others, and can detect misfires

caused by the ignition system, fuel system or

mechanical engine components. As each cylinder

fires, a characteristic crankshaft acceleration is

produced. The monitor detects irregularities in the

acceleration pattern using the crankshaft position (CKP) sensor, thus detecting the misfire. It can

also detect which cylinder has misfired.

Combustion misfires can be categorized as follows:

Type

A: These can cause catalytic converter

damage due to excessive internal temperatures.

If a certain number of misfires occur over a

pre-determined number of engine revolutions, the

MIL will be switched on to alert the driver of the

concern.

Type B: These can lead to an increase in emissions

to a point above the EOBD threshold. If the misfire

is detected during a second trip, over a,

pre-determined number of engine revolutions, the

MIL will be switched on. If the misfire does not

occur over the next three trips, the MIL will be

extinguished

AirIFuel Ratio (AFR) Monitor (All except vehicles

with diesel engine)

The H02S fitted before the catalytic converter

(upstream) measures the oxygen content of the

exhaust gas and the variations in it. This then

enables the PCM to adjust the opening times of

the fuel injectors to maintain the correct AFR. This

is known as Short Term Fuel Trim (STFT). If the

same variation is registered a pre-determined

number of times, a permanent correction factor is

applied. This is known as Long Term Fuel Trim

(LTFT), which is stored in the EEPROM. When the

correction factors exceed pre-determined limits a

DTC will be set in the EEPROM. If a concern is

2006.0 Fiesta 1212006 G384566en

procarmanuals.com

Page 943 of 1226

Electronic Engine Controls

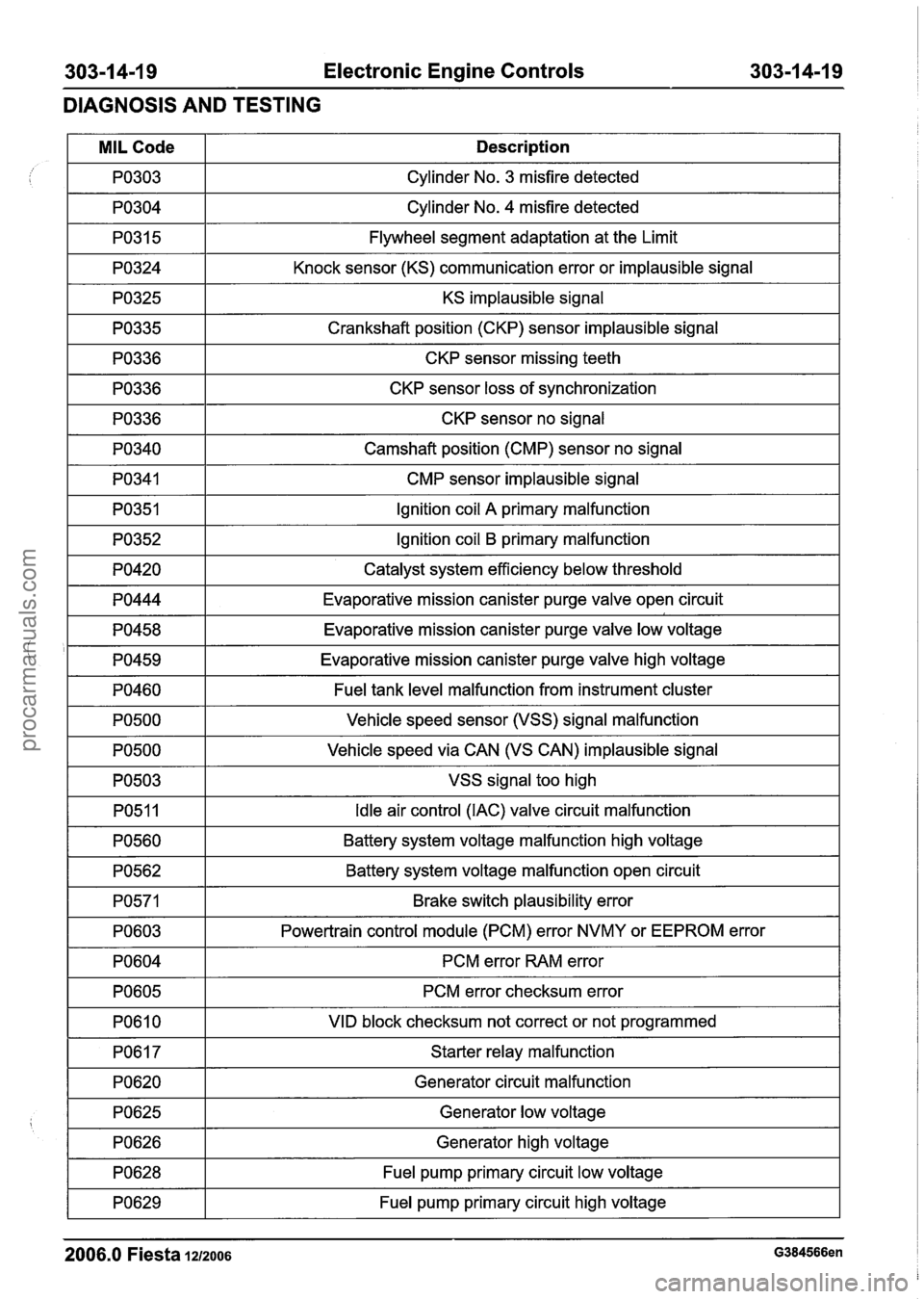

DIAGNOSIS AND TESTING

I PO304 I Cylinder No. 4 misfire detected I

/ I

KS implausible signal I

MIL Code

PO303

PO31 5

PO324

1 PO335 1 Crankshaft position (CKP) sensor implausible signal I

Description

Cylinder No. 3 misfire detected

Flywheel segment adaptation at the Limit

Knock sensor (KS) communication error or implausible signal

1 PO336 1 CKP sensor missing teeth I

1 PO336 1 CKP sensor loss of synchronization I

1 PO336 1 CKP sensor no signal I

I PO340 I Camshaft position (CMP) sensor no signal I

I PO341 I CMP sensor implausible signal I

I PO351 I Ignition coil A primary malfunction I

1 PO352 1 Ignition coil B primary malfunction I

I PO420 I Catalyst system efficiency below threshold I

1 PO444 1 Evaporative mission canister purge valve open circuit I

1 PO458 1 Evaporative mission canister purge valve low voltage I

I '1 PO459 1 Evaporative mission canister purge valve high voltage I

I PO460 I Fuel tank level malfunction from instrument cluster I

-3 I VSS signal too high I

PO500

PO500

Vehicle speed sensor (VSS) signal malfunction

Vehicle speed via CAN (VS CAN) implausible signal

PO51 1

PO560

I PO603 I Powertrain control module (PCM) error NVMY or EEPROM error 1

Idle air control (IAC) valve circuit malfunction

Battery system voltage malfunction high voltage

PO562

PO571

I PO604 I PCM error RAM error I

Battery system voltage malfunction open circuit

Brake switch plausibility error

PO605 I PCM error checksum error I

I PO610 I VID block checksum not correct or not programmed I

I PO617 I Starter relay malfunction I

I PO620 I Generator circuit malfunction I

1 PO628 1 Fuel pump primary circuit low voltage I

I

7 1 Fuel pump primary circuit high voltage I

2006.0 Fiesta 1212006 G384566en

PO625

PO626

Generator low voltage

Generator high voltage

procarmanuals.com

Page 973 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -1 3 Transmission (AW81-40) 307-01 -1 3

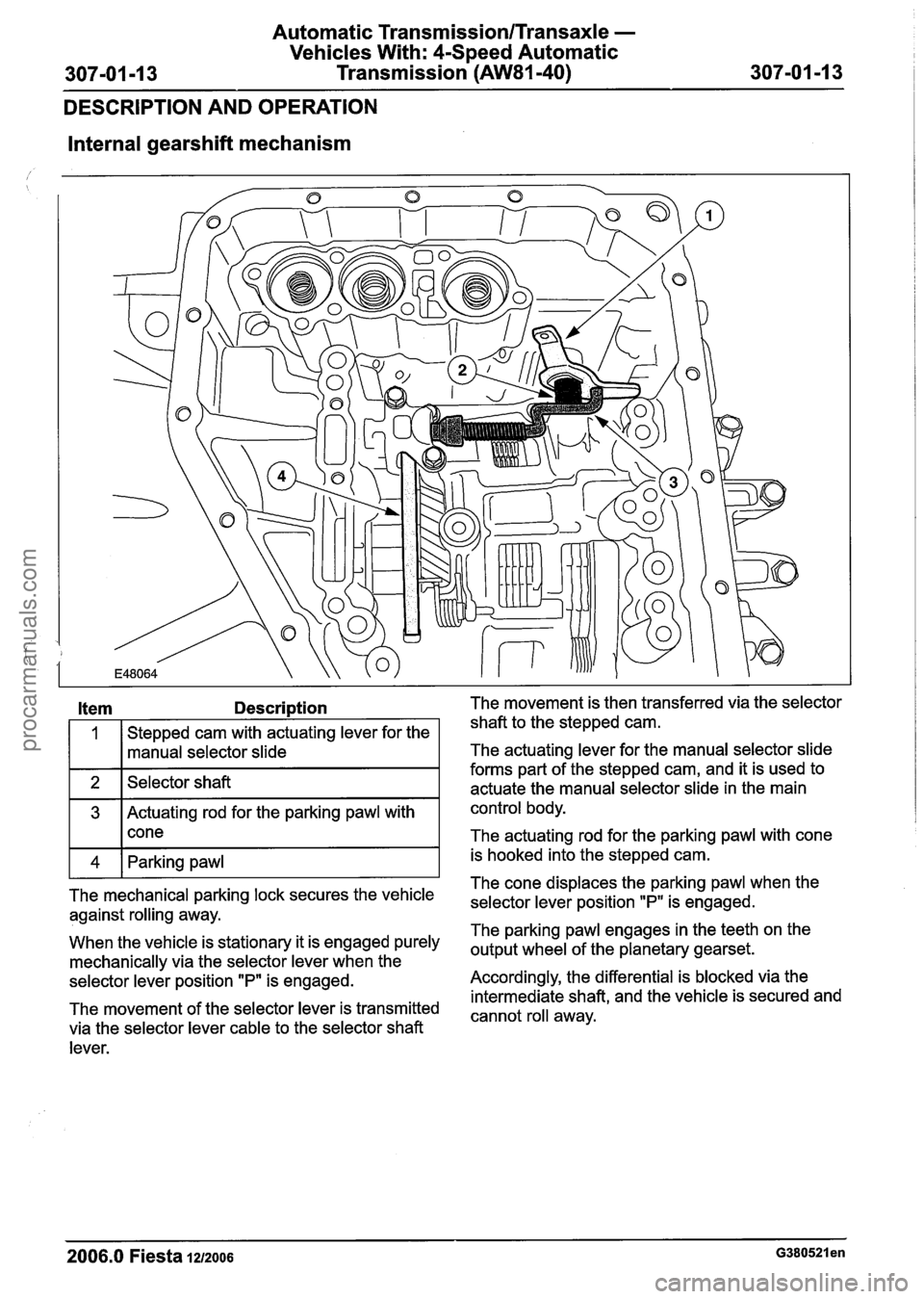

DESCRIPTION AND OPERATION

Internal gearshift mechanism

Item Description The movement is then transferred via the selector

1

2

I I I The cone displaces the parking pawl when the

The mechanical parking lock secures the vehicle

selector lever position wPw is against rolling away.

The parking pawl engages in the teeth on the

When the vehicle is stationary it is engaged purely

output wheel of the planetary gearset. mechanically via the selector lever when the

selector lever position "P" is engaged. Accordingly,

the differential is blocked via the

intermediate shaft, and the vehicle is secured and

The movement of the selector lever is transmitted

cannot roll away. via the selector lever cable to the selector shaft Stepped cam

with actuating lever for the

3

4

lever. Selector

shaft

2006.0 Fiesta 1212006 G380521 en

shaft to the stepped cam.

forms part of the stepped cam, and it is used to

actuate the manual selector slide in the main

Actuating rod for the parking pawl with cone

Parking pawl

manual

selector slide

control body.

The actuating rod for the parking pawl with cone

is hooked into the stepped cam.

The actuating lever for

the manual selector slide

procarmanuals.com

Page 1060 of 1226

Manual Transmission/Transaxle and Clutch -

General Information

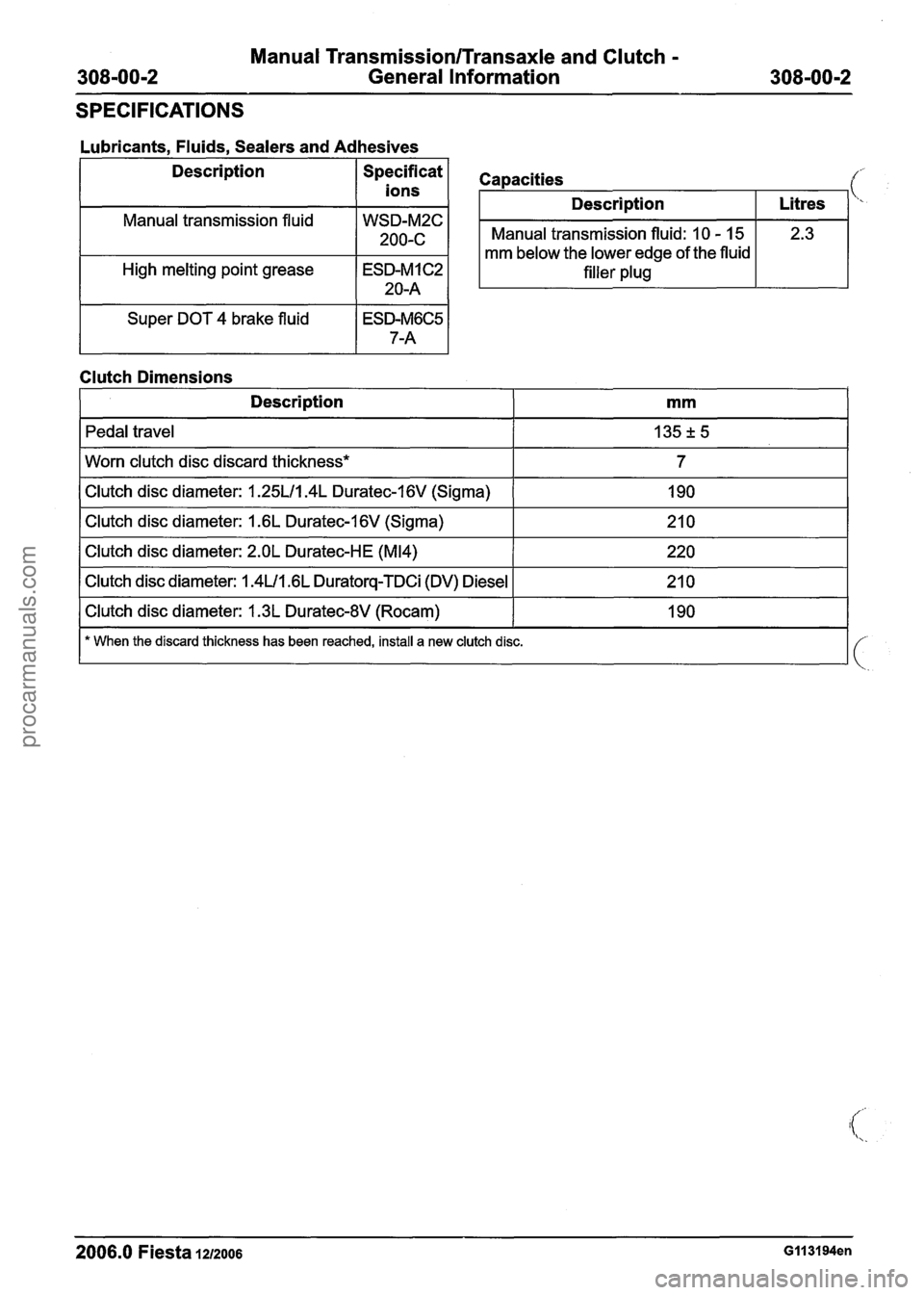

SPECIFICATIONS

Lubricants, Fluids, Sealers and Adhesives

Description Specificat

I ions I

Manual transmission fluid

I High melting point grease

Super DOT 4 brake fluid

Clutch Dimensions

I Description I Litres 1 '"<

fluid: 10 - 15

mm below the lower edge of the fluid

filler plug

--

2.3

Description

Pedal travel

Worn clutch disc discard thickness*

Clutch disc diameter:

1.25Ll1.4L Duratec-1 6V (Sigma)

Clutch disc diameter:

1.6L Duratec-I 6V (Sigma)

Clutch disc diameter:

2.OL Duratec-HE (M14)

Clutch disc diameter: 1.4U1.6L Duratorq-TDCi (DV) Diesel

Clutch disc diameter:

1.3L Duratec-8V (Rocam)

mm

135k5

7

190

210

220

210 190

* When the discard thickness has been reached, install a new clutch disc.

procarmanuals.com

Page 1086 of 1226

308-02-6 Clutch Controls 308-02-6

REMOVAL AND INSTALLATION

Clutch Slave Cylinder(l6 862 4) /'

Materials Alf brake fluid is spilt on the paintwork, the

Name Specification affected

area must be

immediately washed

ESDM-1 C220-A down with cold water. High-temperature

grease

ADO not apply grease on any area of the

clutch slave cylinder.

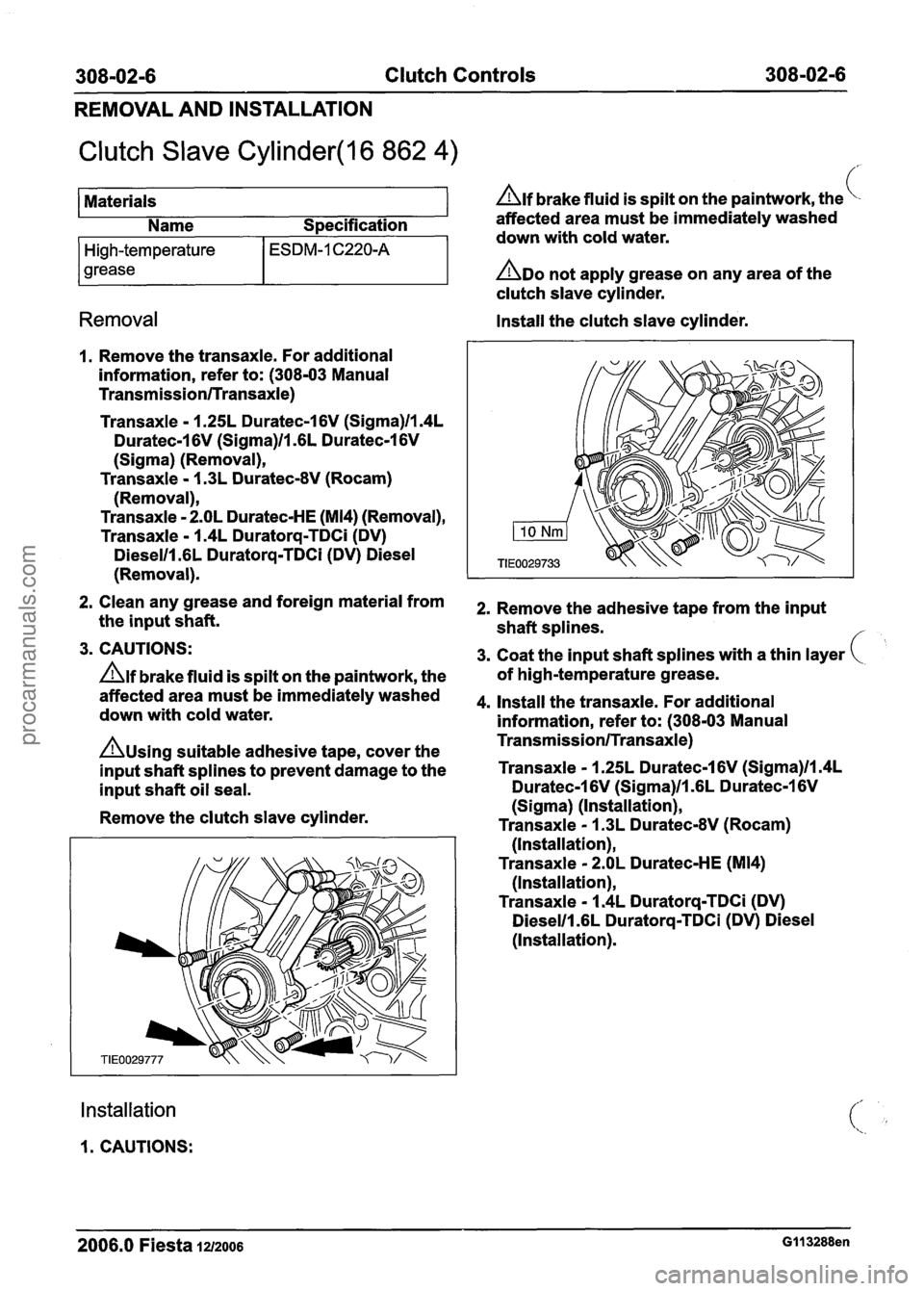

Removal Install the clutch slave cylinder.

I. Remove the transaxle. For additional

information, refer to: (308-03 Manual

TransmissionlTransaxle)

Transaxle - 1.2 5L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (Removal),

Transaxle - 1.3L Duratec-8V (Rocam)

(Re m ova I),

Transaxle - 2.OL Duratec-HE (M14) (Removal),

Transaxle - 1.4L Duratorq-TDCi (DV)

Dieselll.6L Duratorq-TDCi (DV) Diesel

(Removal).

2. Clean any grease and foreign material from

the input shaft.

3. CAUTIONS:

Alf brake fluid is spilt on the paintwork, the

affected area must be

immediately washed

down with

cold water.

Ausing suitable adhesive tape, cover the

input shaft

splines to prevent damage to the

input shaft

oil seal.

Remove the clutch slave cylinder.

Installation

1. CAUTIONS: 2.

Remove the adhesive tape from the input

shaft

splines.

3. Coat the input shaft splines with a thin layer

of high-temperature grease.

4.

Install the transaxle. For additional

information, refer to: (308-03 Manual

TransmissionlTransaxle)

Transaxle - 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (Installation),

Transaxle - 1.3L Duratec-8V (Rocam)

(Installation),

Transaxle - 2.OL Duratec-HE (M14)

(Installation),

Transaxle - 1.4L Duratorq-TDCi (DV)

Dieselll.6L Duratorq-TDCi (DV) Diesel

(Installation).

2006.0 Fiesta 1212006 GI1 3288en

procarmanuals.com

Page 1087 of 1226

308-02-7 Clutch Controls 308-02-7

REMOVAL AND INSTALLATION

Clutch Master Cylinder(l6 856 0) /

Removal 4. Remove the battery tray. For additional

information, refer to:

CAUTI0N:H brake fluid is spilt on the

paintwork, the affected area must be Battery

Tray (41 4-01, Removal and

immediately washed down with cold water. Installation),

Battery Tray - 2.OL Duratec-HE (M14) (414-01

All vehicles Battery, Mounting and Cables, Removal

and Installation).

Left-hand drive vehicles

1. Using a suitable syringe, remove brake fluid

from the brake fluid reservoir until the brake All vehicles

fluid level is at the MIN mark.

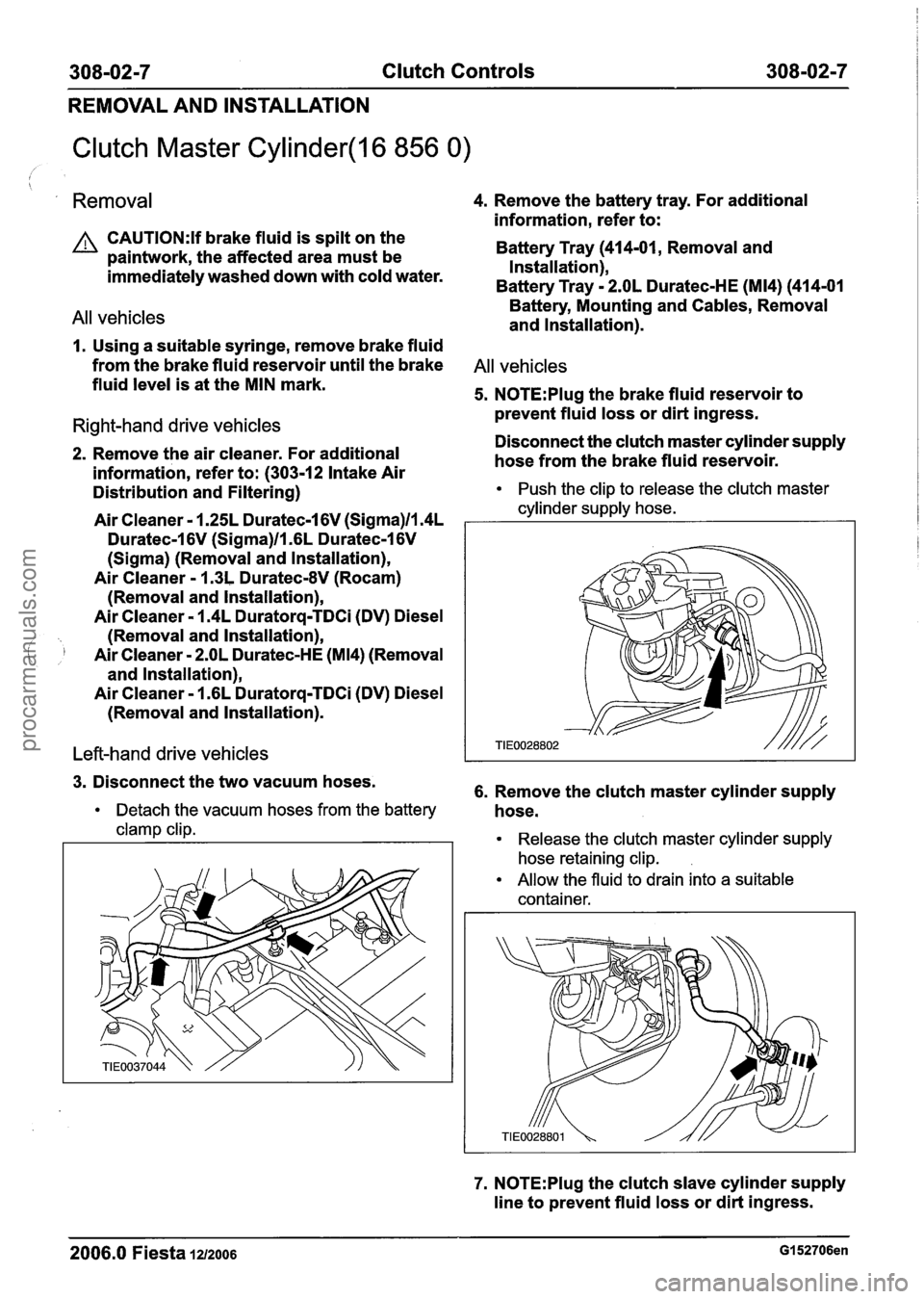

5. N0TE:Plug the brake fluid reservoir to

prevent

fluid loss or dirt ingress. Right-hand drive vehicles Disconnect the clutch master cylinder supply 2. Remove the air cleaner. For additional hose from the brake fluid reservoir.

information, refer to: (303-1 2 Intake Air

Distribution and Filtering)

Push the clip to release the clutch master

cylinder supply hose.

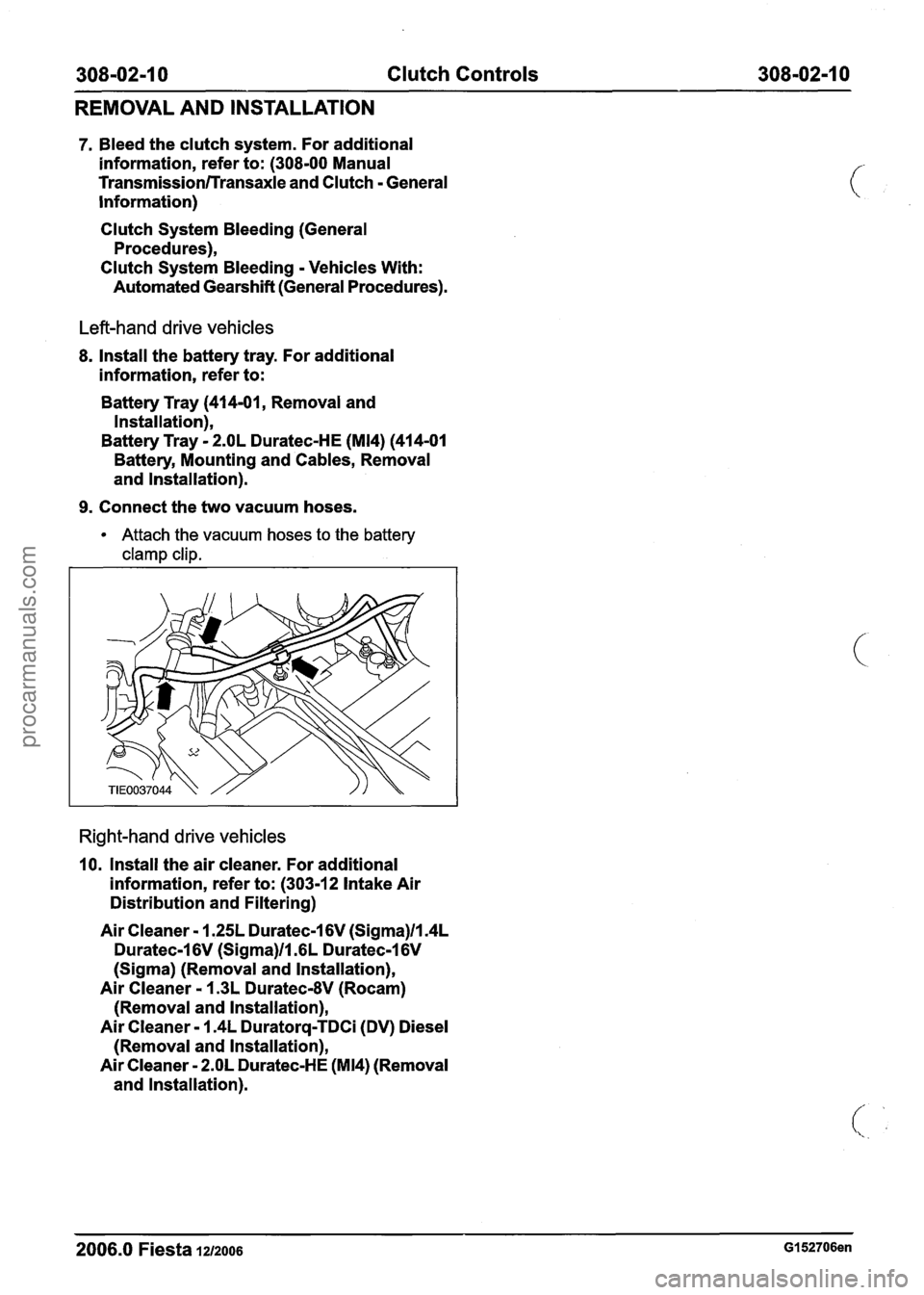

3. Disconnect the two vacuum hoses.

6. Remove the clutch master cylinder supply

Detach the vacuum hoses from the battery hose.

clamp clip. Release the clutch master cylinder supply

hose retaining clip.

Allow the fluid to drain into a suitable

container.

Air Cleaner - 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-1 6V (Sigma)/l .6L Duratec-I 6V

(Sigma) (Removal and lnstallation),

Air Cleaner - 1.3L Duratec-8V (Rocam)

(Removal and lnstallation),

Air Cleaner - 1.4L Duratorq-TDCi (DV) Diesel

(Removal and lnstallation),

(, I Air Cleaner - 2.OL Duratec-HE (M14) (Removal

and

Installation),

Air Cleaner - 1.6L Duratorq-TDCi (DV) Diesel

(Removal and lnstallation).

7. N0TE:Plug the clutch slave cylinder supply

line to prevent fluid loss or dirt ingress.

1

2006.0 Fiesta 1212006 GI 52706en

procarmanuals.com

Page 1090 of 1226

308-02-1 0 Clutch Controls 308-02-1 0

REMOVAL AND INSTALLATION

7. Bleed the clutch system. For additional

information, refer to: (308-00 Manual

Transmission/Transaxle and Clutch - General

Information)

Clutch System Bleeding (General

Procedures),

Clutch System Bleeding - Vehicles With:

Automated Gearshift

(General Procedures).

Left-hand drive vehicles

8. Install the battery tray. For additional

information, refer to:

Battery Tray (414-01,

Removal and

Installation),

Battery Tray - 2.OL Duratec-HE (M14) (414-01

Battery, Mounting and

Cables, Removal

and Installation).

9. Connect the two vacuum hoses.

Attach the vacuum hoses to the battery

clamp clip.

Right-hand drive vehicles

10. Install the air cleaner. For additional

information, refer to: (303-12 Intake Air

Distribution and

Filtering)

Air Cleaner - 1.25L Duratec-1 6V (Sigma)/l.4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (Removal and lnstallation),

Air Cleaner - 1.3L Duratec-8V (Rocam)

(Removal and lnstallation),

Air Cleaner - 1.4L Duratorq-TDCi (DV) Diesel

(Removal and lnstallation),

Air Cleaner - 2.OL Duratec-HE (M14) (Removal

and lnstallation).

2006.0 Fiesta 12/2006 GI 52706en

procarmanuals.com

Page 1187 of 1226

31 0-00-1 Fuel System - General Information 31 0-OO=l

SECTION 31 0-00 Fuel System - General lnformation

VEHICLE APPLICATION:2006.0 Fiesta

CONTENTS PAGE

DIAGNOSIS AND TESTING

Fuel System - 1.3L Duratec-8V (Rocam)ll.25L Duratec-I 6V (Sigma)/2.0L Duratec-HE

(M14)/1.4L Duratec-1 6V (Sigma)/l .6L

Duratec-1 6V (Sigma) ............................................ 3 1 0-00-2

........................................................................\

......................... Inspection and Verification. 3 1

0-00-2

GENERAL PROCEDURES

Fuel System Pressure Release .................................................................... (23 420 0) 3 1 0-00-3

Fuel Tank Draining

........................................................................\

.................. (23 551 0) 3 1 0-00-4

Quick Release Coupling

........................................................................\

............................. 3 1 0-00-5

................................................... Fuel System Pressure Check - 2.OL Duratec-HE (M14) 31 0-00-1 0

procarmanuals.com

Page 1188 of 1226

31 0-00-2 Fuel System - General Information 31 0-00-2

DIAGNOSIS AND TESTING

Fuel System - 1.3L Duratec-8V (Rocam)/l.25L Duratec-1 6V

(Sigma)/2.0L Duratec-HE (M14)/1.4L Duratec-I 6V

(Sigma)/l.GL Duratec-1 6V (Sigma)

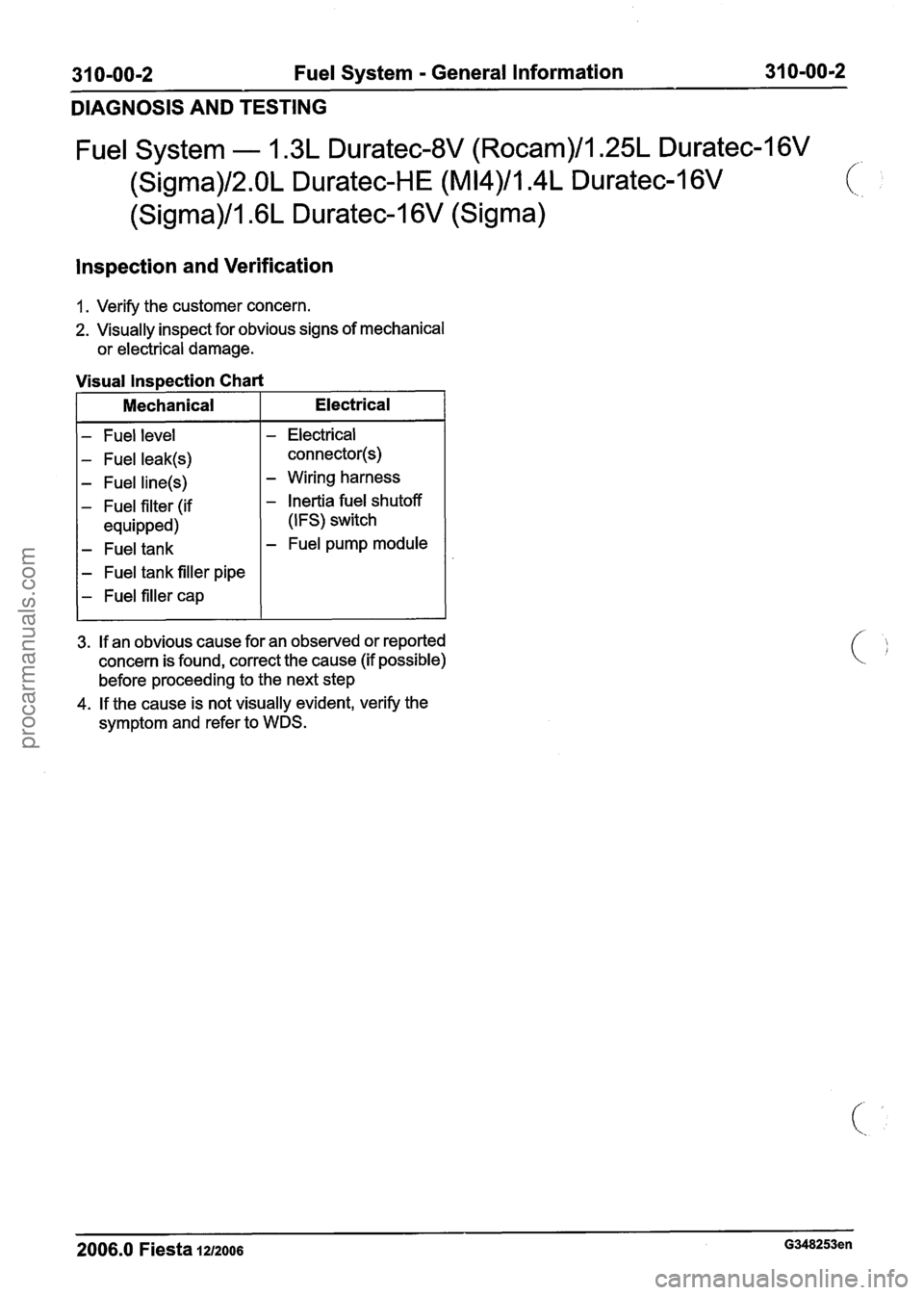

lnspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

- Fuel level

- Fuel leak(s)

- Fuel line(s)

- Fuel filter (if

equipped)

- Fuel tank

- Fuel tank filler pipe

- Fuel filler cap

Visual lnspection Chart

- Electrical

connector(s)

- Wiring harness

- Inertia fuel shutoff

(IFS) switch

- Fuel pump module

I Mechanical

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step

4. If the cause is not visually evident, verify the

symptom and refer to WDS.

Electrical

-

2006.0 Fiesta 1212006 G348253en

procarmanuals.com

Page 1203 of 1226

31 0-01 -5 Fuel Tank and Lines 31 0-01 -5

DIAGNOSIS AND TESTING

Fuel Tank and Lines

All except vehicles with diesel engine,

REFER to:

Fuel System - 1.3L Duratec-8V

(Rocam)/l.25L Duratec-1 6V (Sigma)/Z.OL

Duratec-HE (M14)/1.4L Duratec-1 6V (Sigma)/l .6L

Duratec-1 6V (Sigma) (31 0-00 Fuel System -

General Information, Diagnosis and Testing).

Vehicles with diesel engine,

REFER to:

Fuel System - 1.4L Duratorq-TDCi (DV)

Dieselll.6L Duratorq-TDCi (DV) Diesel (31 0-00

Fuel System - General Information, Diagnosis

and Testing).

2006.0 Fiesta 1212006 G453196en

procarmanuals.com