ECU FORD FIESTA 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 155 of 1226

205-04-3 Front Drive Halfshafts 205-04-3

DESCRIPTION AND OPERATION

Front Drive Halfshafts

Drives hafts

Conventional driveshafts are used on the front axle.

For servicing purposes it is important to note that

the inner tripod joints are pressed onto the shaft.

This has made it possible to reduce noise levels

when the vehicle is pulling away from standing.

The outer joint has not been approved for service

repairs, so in the event of a fault it is necessary to

replace the complete shaft and outer joint

assembly. The inner joints are dismantled with the

aid of a puller. The driveshaft needs to be removed

first.

In order to install a new boot on the outer joint, it

is first necessary to remove the driveshaft and then

disassemble the inner joint. A special service kit is

available in service for this purpose, consisting of

the inner and outer boot and the necessary small

parts.

The same amount of grease is used to pack the

inner and outer joints.

- The PAC nut used for securing the driveshaft to ' the wheel hub must not be reused.

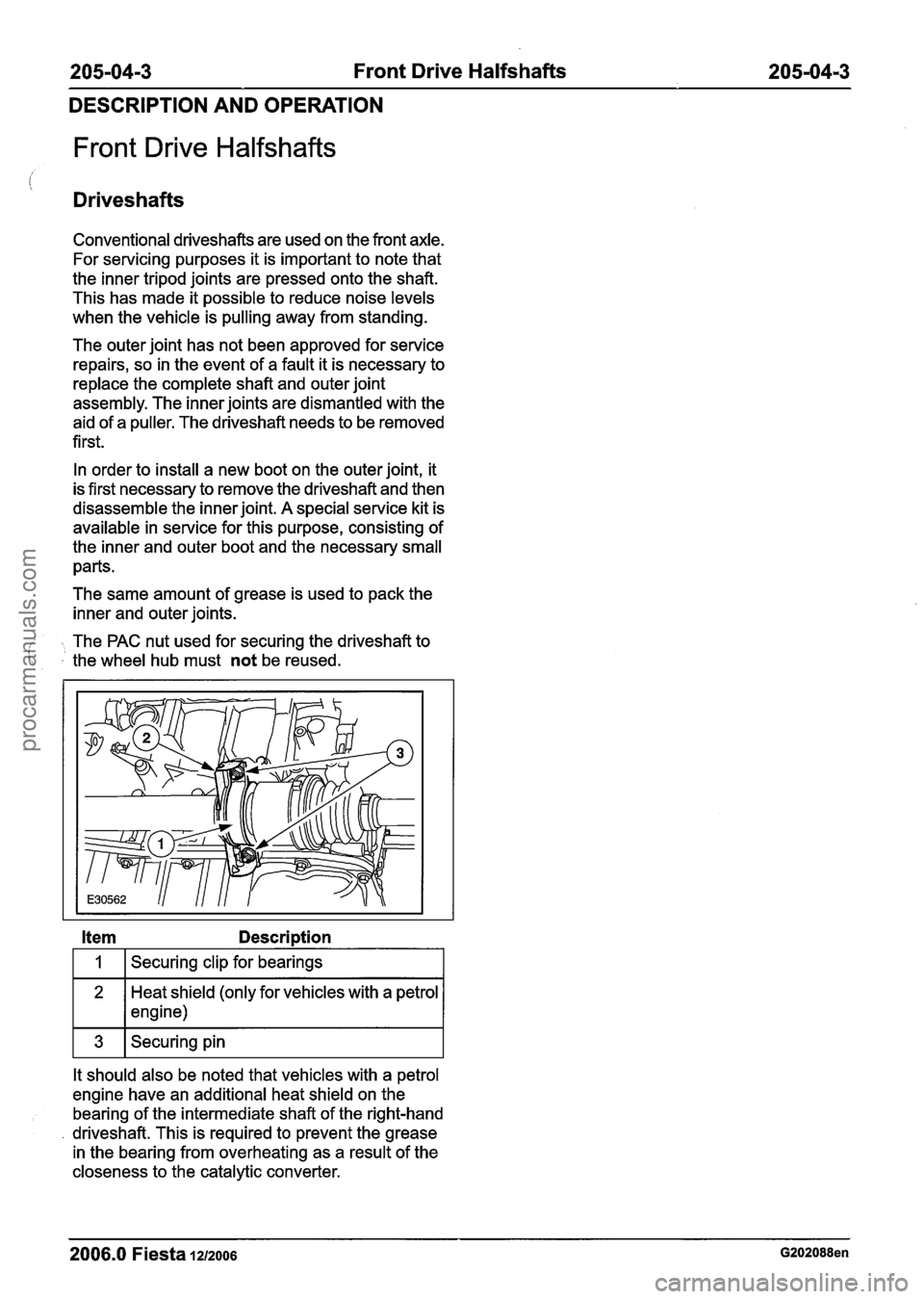

Item Description

I 1 I Securing clip for bearings I

Heat shield (only for vehicles with a petrol

1 * 1 engine)

It should also be noted that vehicles with a petrol

engine have an additional heat shield on the bearing of the intermediate shaft of the right-hand

driveshaft. This is required to prevent the grease

in the bearing from overheating as a result of the

closeness to the catalytic converter.

2006.0 Fiesta 1212006 G202088en

procarmanuals.com

Page 159 of 1226

205-04-7 Front Drive Halfshafts 205-04-7

REMOVAL AND INSTALLATION

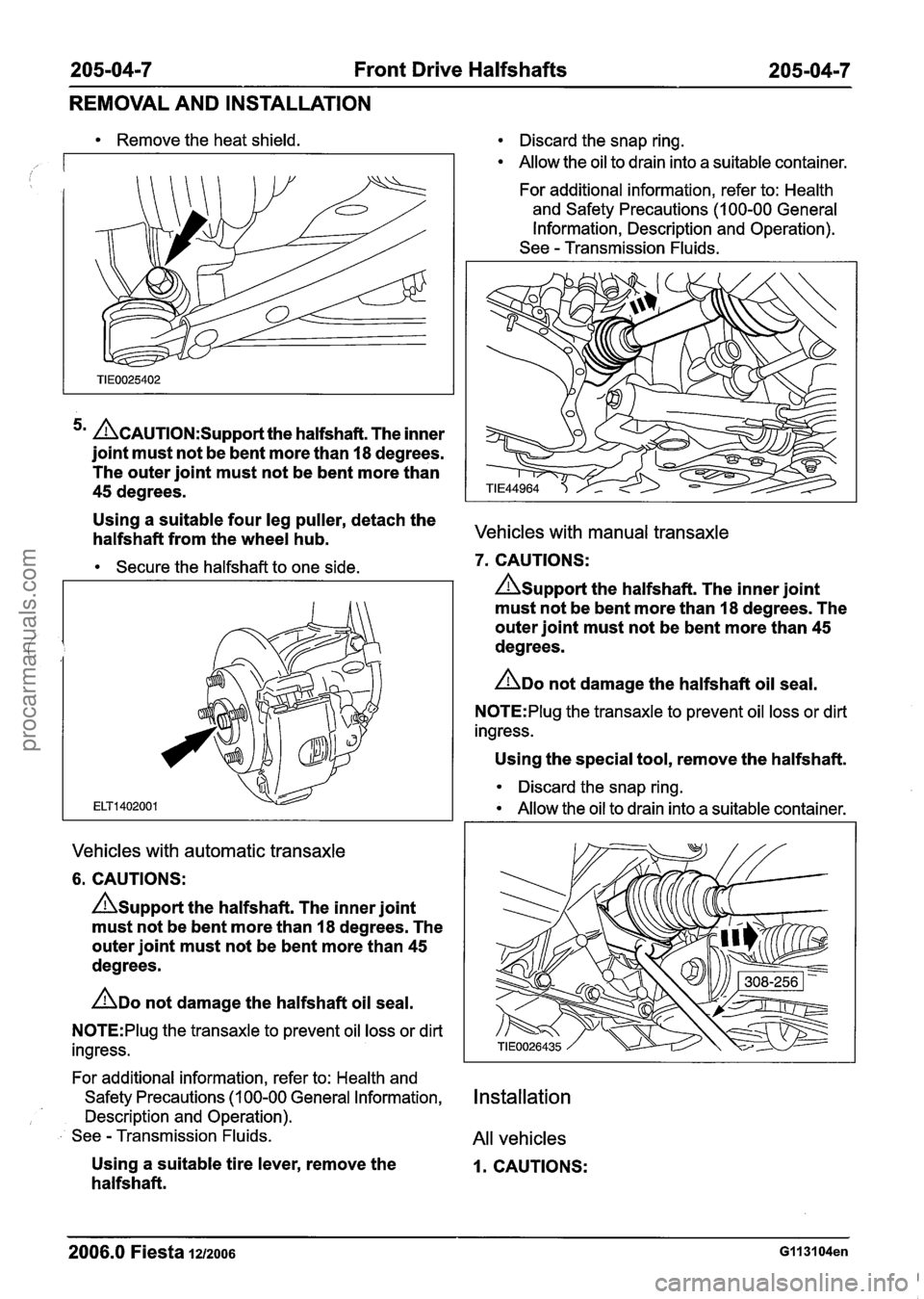

Remove the heat shield.

5m ~~~~~~~~~~~~~~~t the halfshaft. The inner

joint must not be bent more than

18 degrees.

The outer joint must not be bent more than

45 degrees.

Using a suitable four leg puller, detach the

halfshaft from the wheel hub.

Secure the halfshaft to one side.

Vehicles with automatic transaxle

6. CAUTIONS:

A~upport the halfshaft. The inner joint

must not be bent more than

18 degrees. The

outer joint must not be bent more than

45

degrees.

ADO not damage the halfshaft oil seal.

N0TE:Plug the transaxle to prevent oil loss or dirt

ingress.

For additional information, refer to: Health and

Safety Precautions (1 00-00 General Information,

Description and Operation).

See

- Transmission Fluids.

Using a suitable tire lever, remove the

halfs haft.

Discard the snap ring.

Allow the oil to drain into a suitable container.

For additional information, refer to: Health

and Safety Precautions (1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

Vehicles with manual transaxle

7. CAUTIONS:

Asupport the halfshaft. The inner joint

must not be bent more than

I8 degrees. The

outer joint must not be bent more than

45

degrees.

ADO not damage the halfshaft oil seal.

N0TE:Plug the transaxle to prevent oil loss or dirt

ingress.

Using the special tool, remove the halfshaft.

Discard the snap ring.

Allow the oil to drain into a suitable container.

Installation

All vehicles

I. CAUTIONS:

2006.0 Fiesta 1212006 GI 131 04en

procarmanuals.com

Page 162 of 1226

205-04-1 0 Front Drive Halfshafts 205-04-1 0

REMOVAL AND INSTALLATION

Front Halfshaft RH(14 321 0)

('

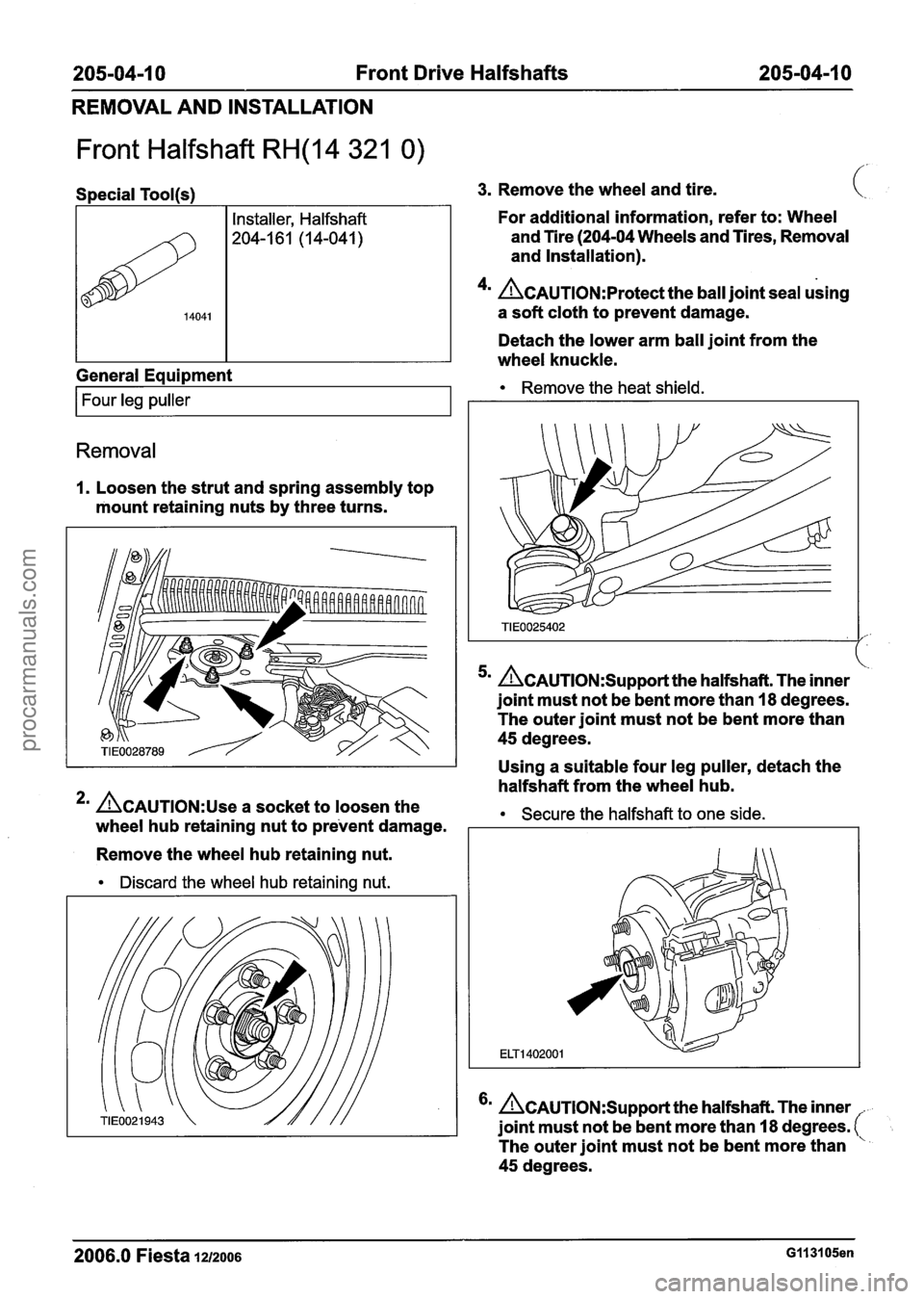

Special Tool(s) 3. Remove the wheel and tire. (.

I I Installer, Halfshaft For additional information, refer to: Wheel

and Tire

(204-04 Wheels and Tires, Removal

and Installation).

4m A~AU~l0N:~rotect the ball joint seal using

a soft cloth to prevent damage.

I I I Detach the lower arm ball joint from the I wheel knuckle.

General Equipment

Remove the heat shield.

Four leg puller

Removal

I. Loosen the strut and spring assembly top

mount retaining nuts by three turns.

5m ACAUTION:S~~~~~~ the halfshaft. The inner

joint must not be bent more than

18 degrees.

The outer joint must not be bent more than

45 degrees.

Using a suitable four leg puller, detach the

halfshaft from the wheel hub.

" ~CAUTION:US~ a socket to loosen the Secure the halfshaft to one side. wheel hub retaining nut to prevent damage.

Remove the wheel hub retaining nut.

Discard the wheel hub retaining nut.

6m ACAUTION:S~~~~~~ the halfshaft. The inner .

joint must not be bent more than 18 degrees. (

The outer joint must not be bent more than

45 degrees.

2006.0 Fiesta IZIZOO~ ~1131 05en

procarmanuals.com

Page 167 of 1226

205-04-1 5 Front Drive Halfshafts 205-04-1 5

REMOVAL AND INSTALLATION

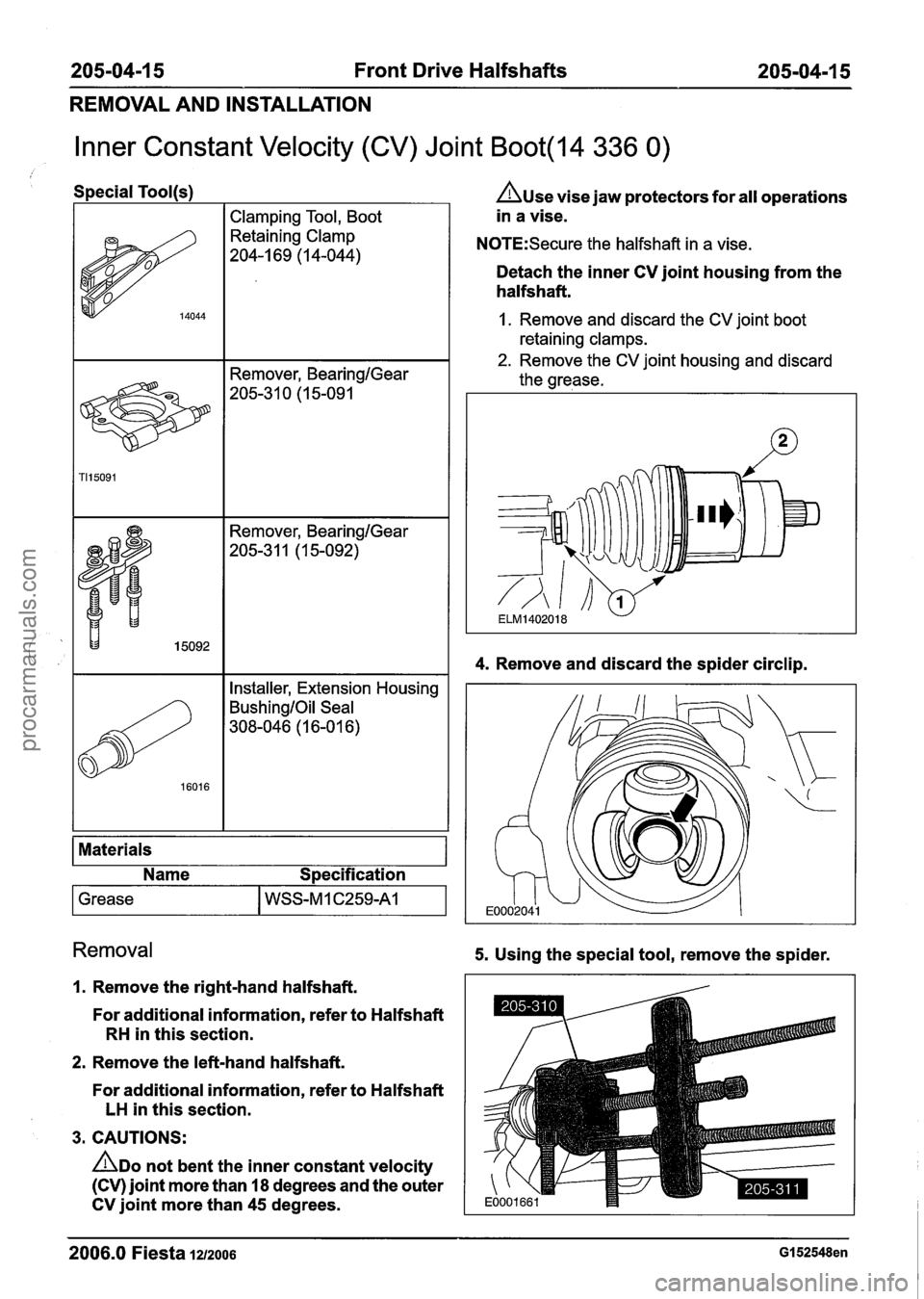

Inner Constant Velocity (CV) Joint Boot(l4 336 0)

Special Tool(s)

I I Clamping Tool, Boot I

Remover, BearingIGear

205-3 1 0 (1 5-09 1

A~se vise jaw protectors for all operations

in a vise.

N0TE:Secure the halfshaft in a vise.

Detach the inner CV joint housing from the

halfshaft.

1. Remove and discard the CV joint boot

retaining clamps.

2. Remove the CV joint housing and discard

the grease.

I I Installer, Extension Housing I

BushingIOil Seal

308-046 (1 6-0 1 6)

Materials

Name Specification

1 Grease I WSS-M 1 C259A1 I

4. Remove and discard the spider circlip.

Removal 5. Using the special tool, remove the spider.

I. Remove the right-hand halfshaft.

For additional information, refer to Halfshaft

RH in this section.

2. Remove the left-hand halfshaft.

For additional information, refer to Halfshaft

LH in this section.

3. CAUTIONS:

ADO not bent the inner constant velocity

(CV) joint more than

18 degrees and the outer

CV joint more than

45 degrees.

2006.0 Fiesta 1212006 GI 52548en

procarmanuals.com

Page 170 of 1226

205-04-1 8 Front Drive Halfshafts 205-04-1 8

REMOVAL AND INSTALLATION

Outer Constant Velocity (CV) Joint Boot(l4 338 0)

Special Tool(~)

I

-

I Clamping Tool, Boot

Retaining Clamp

204-1 69 (1 4-044)

14044

Materials

Name Specification

1 Grease I WSS-MI ~259-v

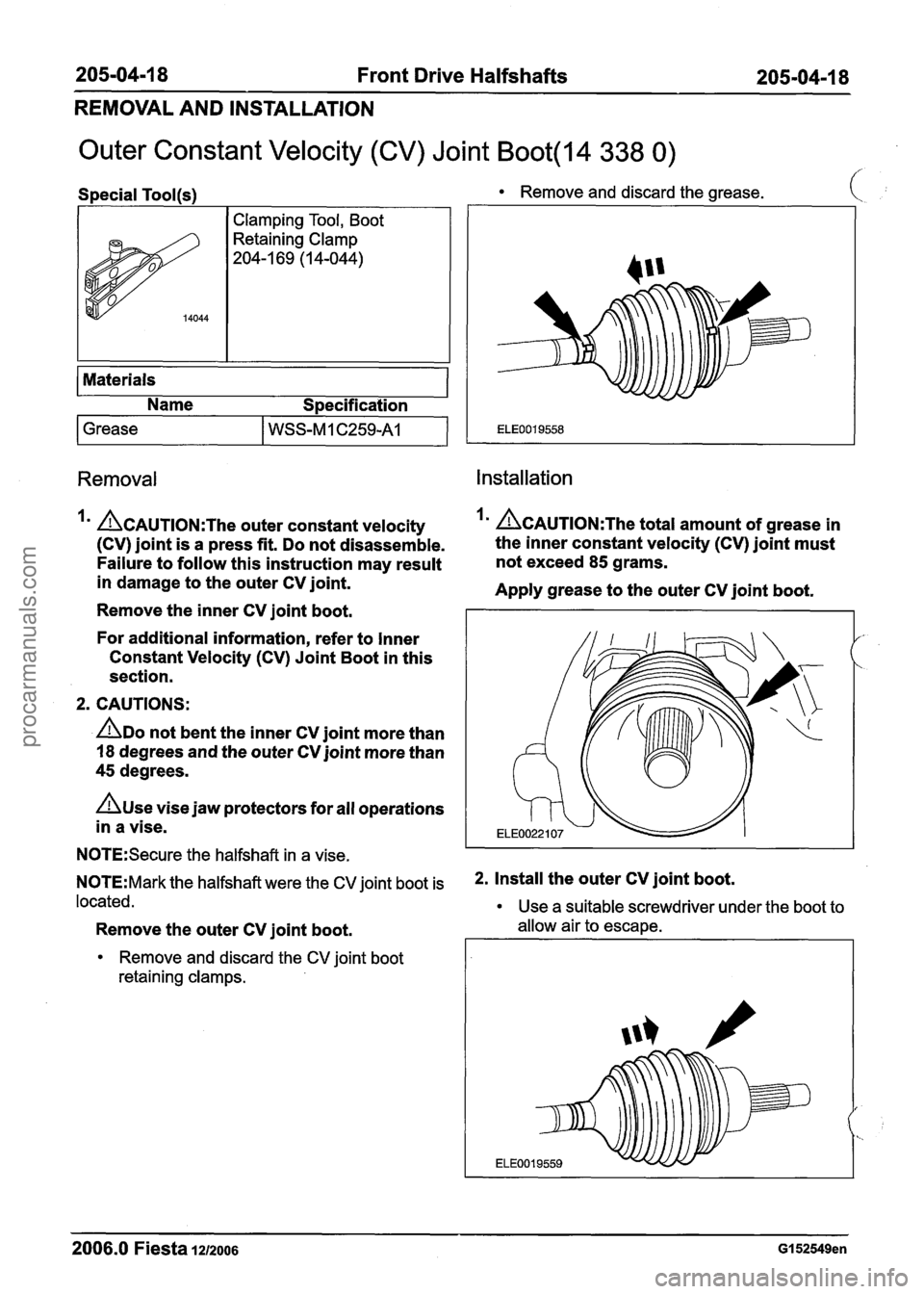

Remove and discard the grease. I

Removal Installation

&AUTION:The outer constant velocity I' ~CAUTION:T~~ total amount of grease in

(CV) joint is a press fit. Do not disassemble. the

inner constant velocity (CV) joint must

Failure to follow this instruction may result not

exceed

85 grams.

in damage to the outer CV joint.

Apply grease to the outer CV joint boot.

Remove the inner CV joint boot.

For additional information, refer to Inner

Constant Velocity (CV) Joint Boot in this

section.

2. CAUTIONS:

ADO not bent the inner CV joint more than

18 degrees and the outer CV joint more than

45 degrees.

n~se vise jaw protectors for all operations

in a vise.

N0TE:Secure the halfshaft in a vise.

N0TE:Mark the halfshaft were the CV joint boot is *. Install the Outer CV joint boot=

located.

Use a suitable screwdriver under the boot to

Remove the outer CV joint boot. allow air to escape.

Remove and discard the CV joint boot

retaining clamps.

2006.0 Fiesta 1212006 GI 52549en

procarmanuals.com

Page 201 of 1226

206-00-29 Brake System - General Information 206-00-29

DIAGNOSIS AND TESTING

and repair the external leak. If the fluid level drops

and no external leak can be found, check for a

brake master cylinder bore end seal leak.

Brake System Check

Brake Pedal Reserve Check

Where a low brake pedal or the feel of a

bottomed-out condition exists, check for brake

pedal reserve.

1. Operate the engine at idle with the transaxle in

NEUTRAL.

2. Apply the brake pedal lightly three or four times.

3. Allow 15 seconds for vacuum to replenish the

brake booster.

N0TE:This increased resistance may feel like

something has bottomed out.

4. Apply the brake pedal until it stops moving

downward or an increased resistance to the

pedal travel occurs.

5. Hold the brake pedal in the applied position and

raise the engine speed to approximately 2000

rpm.

N0TE:The additional movement of the brake pedal

is the result of the increased engine intake manifold

vacuum which exerts more force on the brake

booster during engine rundown. This means that

additional stroke is available in the brake master

cylinder and the brake system is not bottoming out.

6. Release the accelerator pedal and observe that

the brake pedal moves downward as the engine

returns to idle speed.

Brake Booster Functional Test

lnspect all hoses and connections. All unused

vacuum connectors should be capped. Hoses and

their connections should be correctly secured and

in good condition with no holes and no collapsed 2.

With the transaxle in NEUTRAL, stop the engine

and apply the parking brake. Apply the brake

pedal several times to exhaust all vacuum in

the system.

3. With the engine turned off and all vacuum in the

system exhausted, apply the brake pedal and hold it down. Start the engine. If the vacuum

system is operating, the brake pedal will tend

to move downward under constant foot

pressure. If no motion is felt, the vacuum

booster system is not functioning.

4. Remove the vacuum hose from the brake

booster.

Intake manifold vacuum should be

available at the brake booster end of the hose

with the engine at idle speed and the transaxle

in NEUTRAL. Make sure that all unused vacuum

outlets are correctly capped, hose connectors

are correctly secured and vacuum hoses are in

good condition. When it is established that

manifold vacuum is available to the brake

booster, connector the vacuum hose to the

brake booster and repeat Step

3. If no

downward movement of the brake pedal is felt,

install a new brake booster. REFER to: (206-07

Power Brake Actuation)

Brake Booster

- LHD (Removal and lnstallation),

Brake Booster

- RHD (Removal and lnstallation).

5. Operate the engine a minimum of 10 seconds

at fast idle. Stop the engine and let the vehicle

stand for

10 minutes. Then, apply the brake

pedal with approximately 89

N (20 lb) force. The

pedal feel (brake application) should be the

same as that noted with the engine operating.

If the brake pedal feels hard (no power assist),

install a new vacuum check valve and then

repeat the test. If the brake pedal still feels hard,

install a new brake booster. REFER to: (206-07

Power Brake Actuation)

Brake Booster

- LHD (Removal and Installation),

Brake Booster

- RHD e em oval and installation).

If the brake pedal movement feels spongy, bleed

the brake system. REFER to: (206-00 Brake

System

- General Information)

areas. Inspect the check valve on the brake booster Brake System Bleeding (General Procedures),

for damage. Brake

System Pressure Bleeding (General

Procedures).

Brake Booster Operation Check

Brake Master Cylinder

1. Check the hydraulic brake system for leaks or

low fluid. Usually,

the first and strongest indicator of anything

wrong with the braking system is a feeling through

the brake pedal. In diagnosing the condition of the

brake master cylinder, check pedal feel as

2006.0 Fiesta 1212006 G28494en I

i

procarmanuals.com

Page 251 of 1226

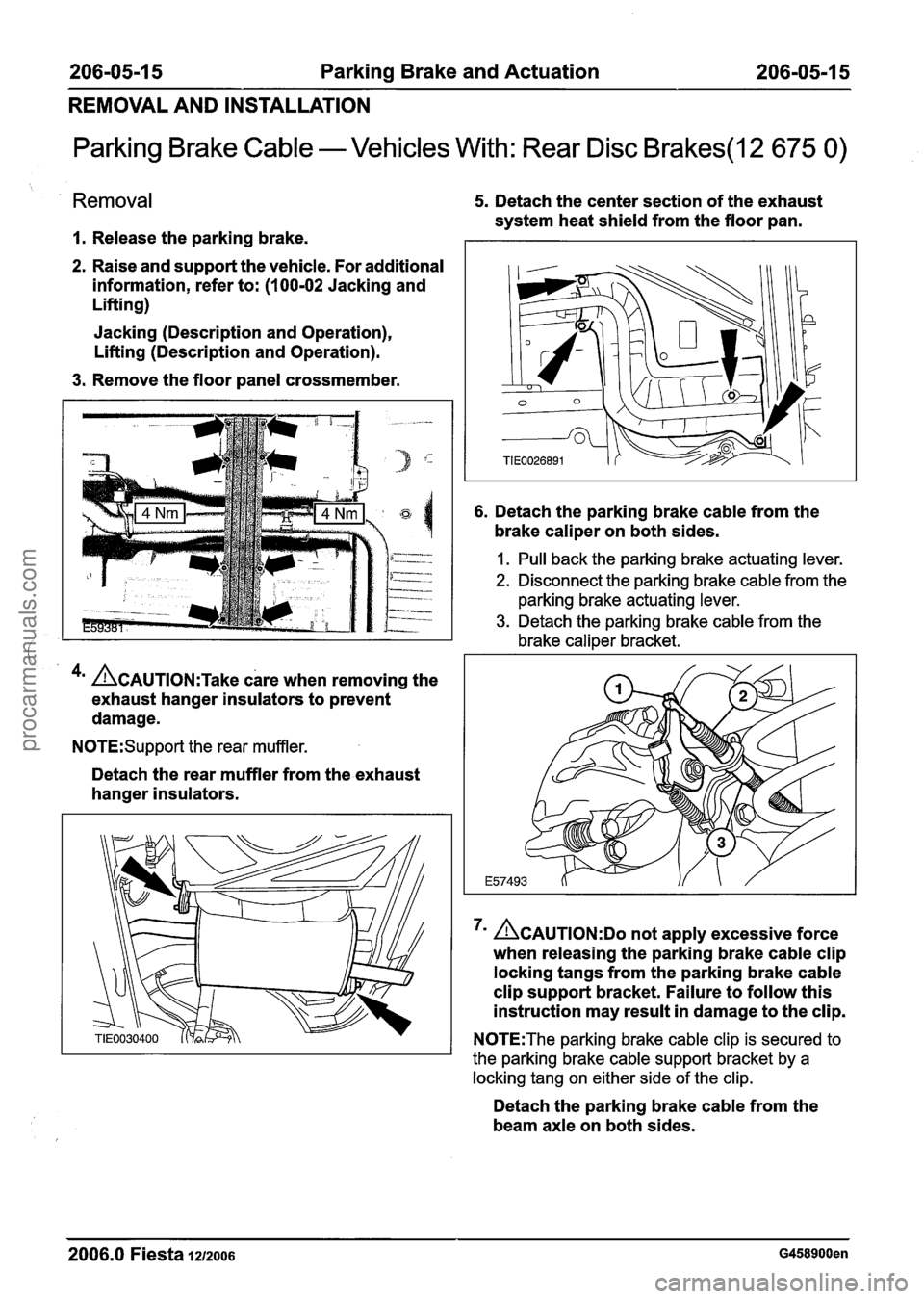

206-05-1 5 Parking Brake and Actuation 206-05-1 5

REMOVAL AND INSTALLATION

Parking Brake Cable - Vehicles With: Rear Disc Brakes(l2 675 0)

Removal

I. Release the parking brake.

2. Raise and support the vehicle. For additional

information, refer to:

(1 00-02 Jacking and

Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

3. Remove the floor panel crossmember.

4m ACAUTION:T~~~ care when removing the

exhaust hanger insulators to prevent

damage.

N0TE:Support the rear muffler.

Detach the rear muffler from the exhaust

hanger insulators.

5. Detach the center section of the exhaust

system heat shield from the floor pan.

6. Detach the parking brake cable from the

brake caliper on both sides.

I. Pull back the parking brake actuating lever.

2. Disconnect the parking brake cable from the

parking brake actuating lever.

3. Detach the parking brake cable from the

brake caliper bracket.

ACAUTION:DO not apply excessive force

when releasing the parking brake cable clip

locking tangs from the parking brake cable

clip support bracket. Failure to follow this

instruction may result in damage to the clip.

N0TE:The parking brake cable clip is secured to

the parking brake cable support bracket by a

locking tang on either side of the clip.

Detach the parking brake cable from the

beam axle on both sides.

2006.0 Fiesta 1212006 G458900en

procarmanuals.com

Page 332 of 1226

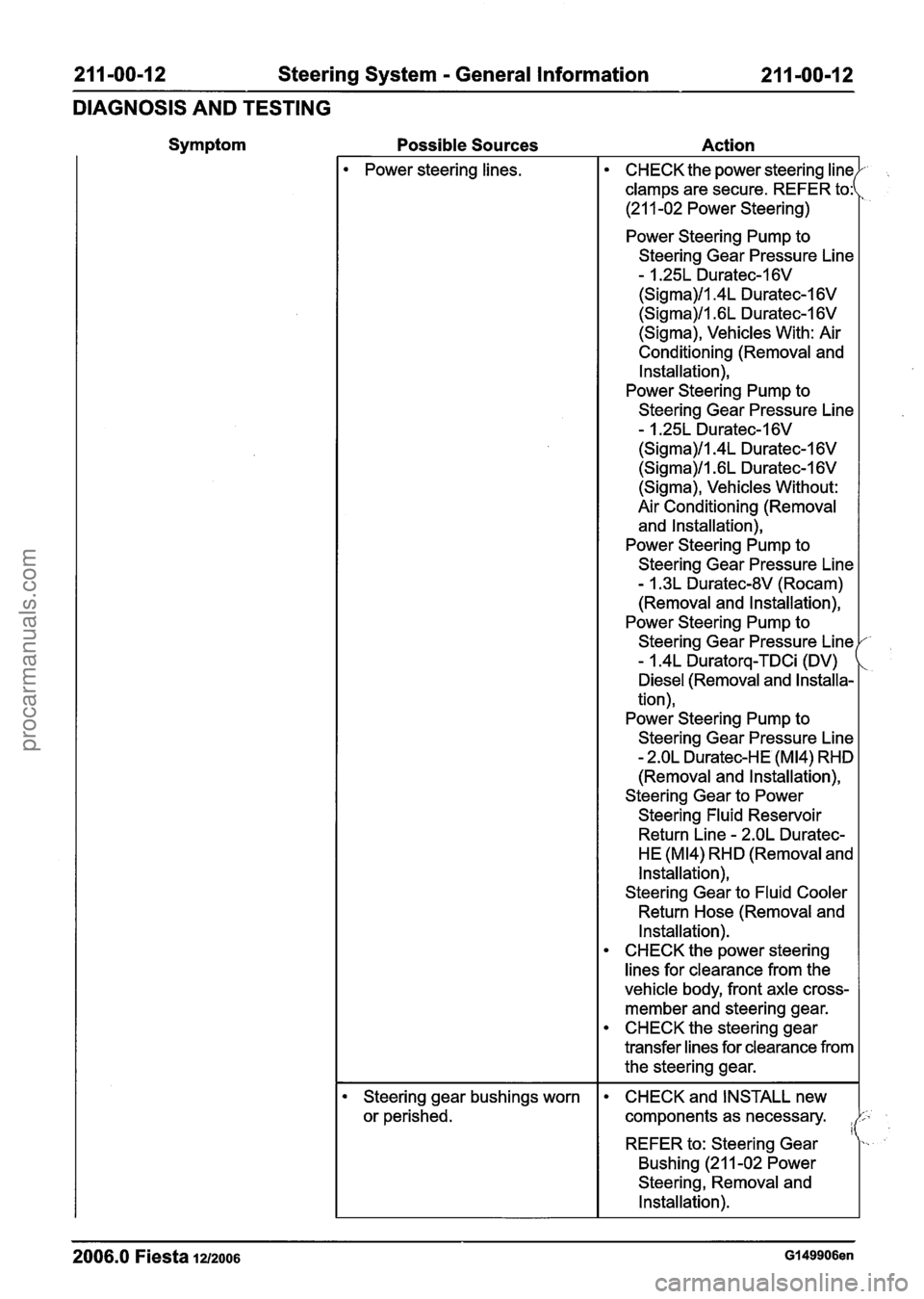

211 -00-12 Steering System - General Information 211-00-12

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

Power steering lines.

Steering gear bushings worn

or perished.

2006.0 Fiesta 12/2006 Gl49906en

CHECK the power steering lin

clamps are secure. REFER to:

(21 1-02 Power Steering)

Power Steering Pump to

Steering Gear Pressure Line

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma), Vehicles With: Air

Conditioning

(Removal and

Installation),

Power Steering Pump to

Steering Gear Pressure Line

- 1.25L Duratec-1 6V

(Sigma)/l.4L Duratec-1 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma), Vehicles Without:

Air Conditioning

(Removal

and Installation),

Power Steering Pump to

Steering Gear Pressure Line

- I .3L Duratec-8V (Rocam)

(Removal and Installation),

Power Steering Pump to

Steering Gear Pressure Line

- I .4L Duratorq-TDCi (DV)

Diesel (Removal and Installa-

tion),

Power Steering Pump to

Steering Gear Pressure Line

- 2.OL Duratec-HE (M14) RHD

(Removal and Installation),

Steering Gear to Power

Steering

Fluid Reservoir

Return Line

- 2.OL Duratec-

HE

(M14) RHD (Removal and

Installation),

Steering Gear to Fluid Cooler

Return Hose (Removal and

Installation).

CHECK the power steering

lines for clearance from the

vehicle body, front axle cross-

member and steering gear.

CHECK the steering gear

transfer

lines for clearance from

the steering gear.

CHECK and INSTALL new

components as necessary.

I REFER to: Steering Gear

Bushing (21 1-02 Power

Steering,

Removal and

Installation).

procarmanuals.com

Page 397 of 1226

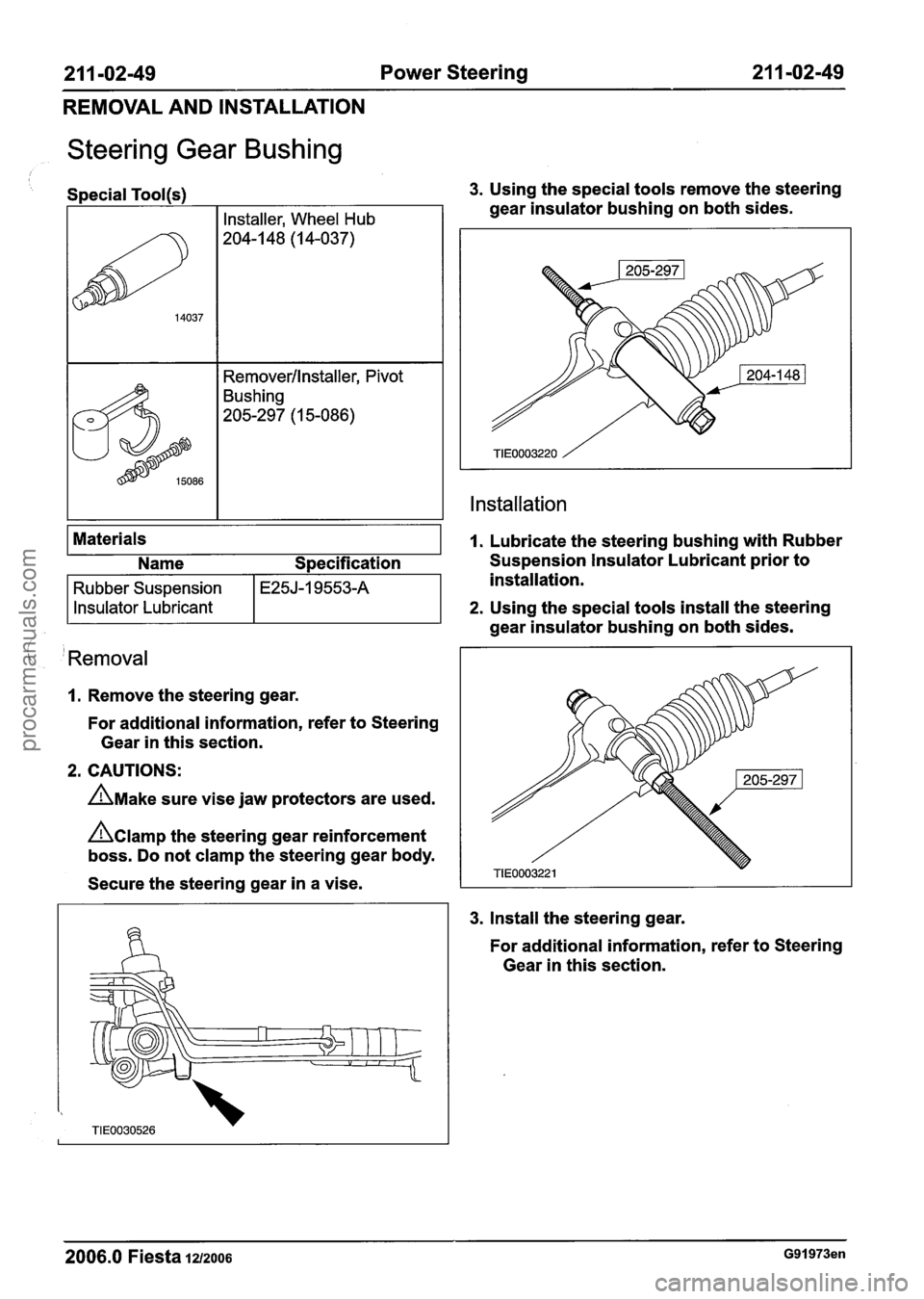

21 1 -02-49 Power Steering 21 I -02-49

REMOVAL AND INSTALLATION

Steering Gear Bushing

/ I

Special Tool(s) 3. Using the special tools remove the steering

( 'Removal

1. Remove the steering gear.

For additional information, refer to Steering

Gear in this section.

2. CAUTIONS:

A~ake sure vise jaw protectors are used.

hamp the steering gear reinforcement

boss. Do not clamp the steering gear body.

Secure the steering gear in a vise.

Materials

3. Install the

steering gear.

gear

insulator bushing on both sides.

Installation

14037

1. Lubricate the steering bushing with Rubber

For additional information, refer to Steering

Gear in this section.

Installer, Wheel Hub

204-1 48 (1 4-037)

Removerllnstaller, Pivot

Bushing

205-297 (1 5-086)

2006.0 Fiesta 1212006 G91973en

Name Specification Suspension Insulator Lubricant prior to

installation.

2. Using the special tools install the steering

Rubber Suspension

Insulator Lubricant

gear insulator bushing on both sides.

E25J-I 9553-A

procarmanuals.com

Page 407 of 1226

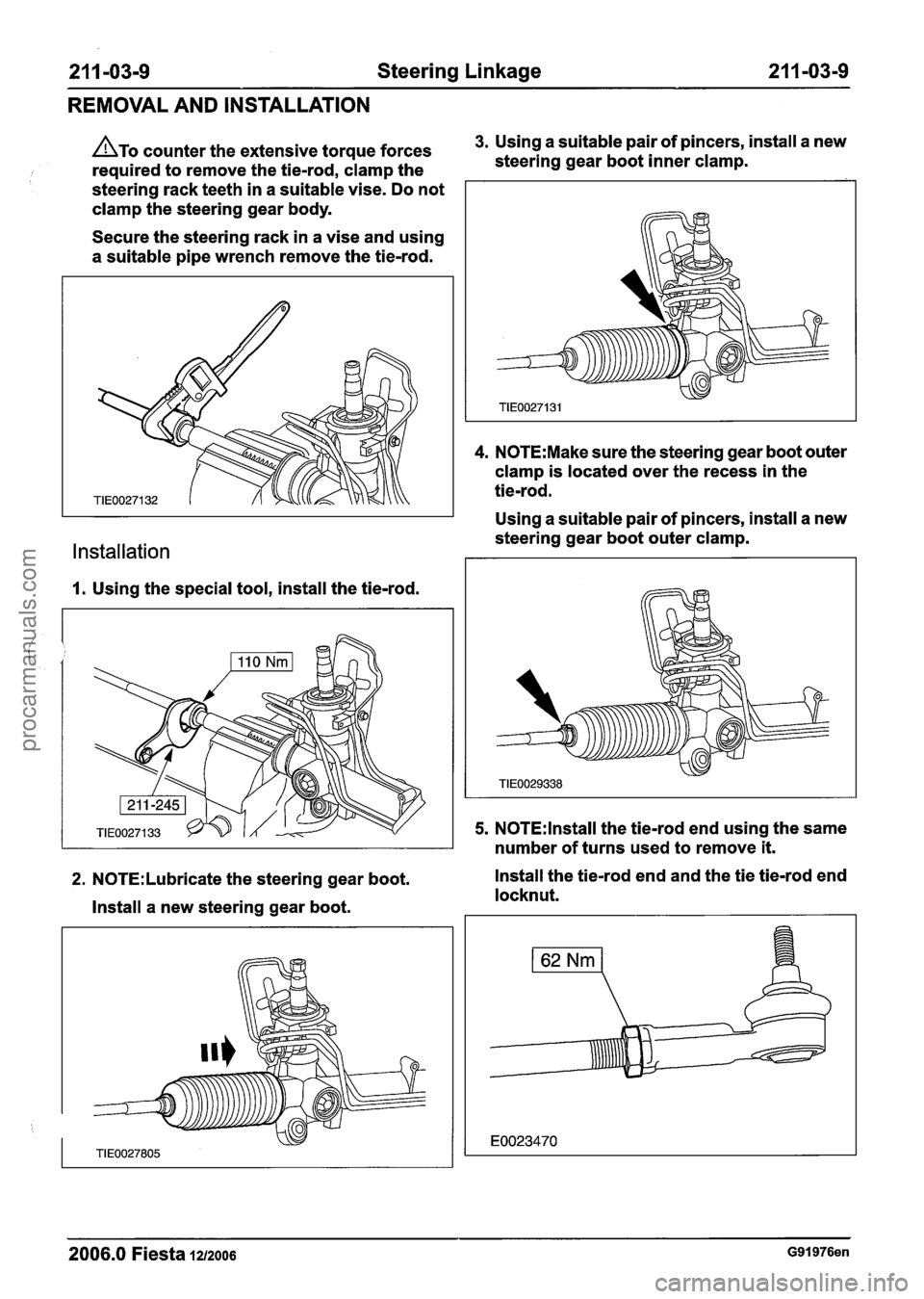

211 -03-9 Steering Linkage 21 1-03-9

REMOVAL AND INSTALLATION

ATO counter the extensive torque forces 3. Using a suitable pair of pincers, install a new

required to remove the tie-rod, clamp the steering

gear boot inner clamp.

steering rack teeth in a suitable vise. Do not

clamp the steering gear body.

Secure the steering rack in a vise and using

a suitable pipe wrench remove the tie-rod.

Installation

1. Using the special tool, install the tie-rod.

4. N0TE:Make sure the steering gear boot outer

clamp is located over the recess in the

tie-rod.

Using a suitable pair of pincers, install a new

steering gear boot outer clamp.

5. N0TE:lnstall the tie-rod end using the same

number of turns used to remove

it.

2. N0TE:Lubricate the steering gear boot. Install the tie-rod end and the

tie tie-rod end

locknut.

Install a new steering gear boot.

2006.0 Fiesta 1212006 G91976en

procarmanuals.com