ESP FORD FIESTA 2007 User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 60 of 1226

100-04-4 Noise, Vibration and Harshness 100-0414

DIAGNOSIS AND TESTING

Noise, Vibration and Harshness (NVH)

Inspection and Verification

1. Verify the customer concern. Identify the Condition

2. Visually inspect for obvious signs of mechanical NVH usually occur in four areas:

or electrical damage.

tires

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible) engine accessories

before proceeding to the next step.

suspension

4. If the concern is not visually evident, verify the

symptom and REFER to the Symptom Chart.

How to Use this Diagnostic Procedure

Section

Noise, vibration and harshness (NVH) concerns

have become more important as

vehjcles have

become more sensitive to these vibrations. This

section is designed to aid in identifying these

concerns.

The section provides diagnostic procedures based on symptom. If the condition occurs at

high speed, for instance, the most likely place

to start is under Shake and Vibration While

Driving.

The road test procedure will tell how to sort the

conditions into categories and how to tell a

vibration from a shake.

A series of Road Test Quick Checks are

provided to make sure that a cause is either

pinpointed or eliminated.

Name the condition, proceed to the appropriate

section and locate the correct diagnosis. When

the condition is identified, the job is partly done.

Follow the diagnostic procedure as outlined.

Quick Checks are described within the step,

while more involved tests and adjustments are

outlined in General Procedures.

Always follow each step exactly and make notes

to recall important findings later.

driveline

It is important, therefore, that an NVH concern be

isolated into its specific

area(s) as soon as

possible. The easiest and quickest way to do this

is to carry out the Road Test as outlined. To assist

in the diagnosis and testing

procedure(s), use a

suitable approved NVH diagnosis tester.

Noise Diagnostic Procedure

Non-Axle Noise

The five most common sources of non-axle noise

are exhaust, tires, roof racks, trim panels and

( transmission.

Therefore, make sure that none of the following

conditions are the cause of the noise before

proceeding with a driveline

teardown and

diagnosis.

In certain conditions, the pitch of the exhaust

may sound very much like gear noise. At other

times, it can be mistaken for a wheel bearing

rumble.

Tires, especially snow tires, can have a high

pitched tread whine or roar, similar to gear

noise. Radial tires may have this characteristic.

Also, any non-standard tire with an unusual

tread construction may emit a roar or whine

noise.

Trim panels can also cause whistling or whining

noise.

Clunk may be a metallic noise heard when the

Customer Interview automatic transaxle is engaged in "R

(REVERSE) or "D" (DRIVE) or it may occur

The road test and customer interview (if available) when

the throttle is applied or released. It is

provide information that will help identify the caused

by backlash somewhere in the driveline.

,

concern and will provide direction to the correct Bearing rumble sounds like marbles being

starting point for diagnosis. (

tumbled. This condition is usually caused by a

damaged wheel bearing.

2006.0 Fiesta 1212006 G37349en

procarmanuals.com

Page 174 of 1226

206-00-2 Brake System - General Information 206-00-2

DESCRIPTION AND OPERATION

Brake System

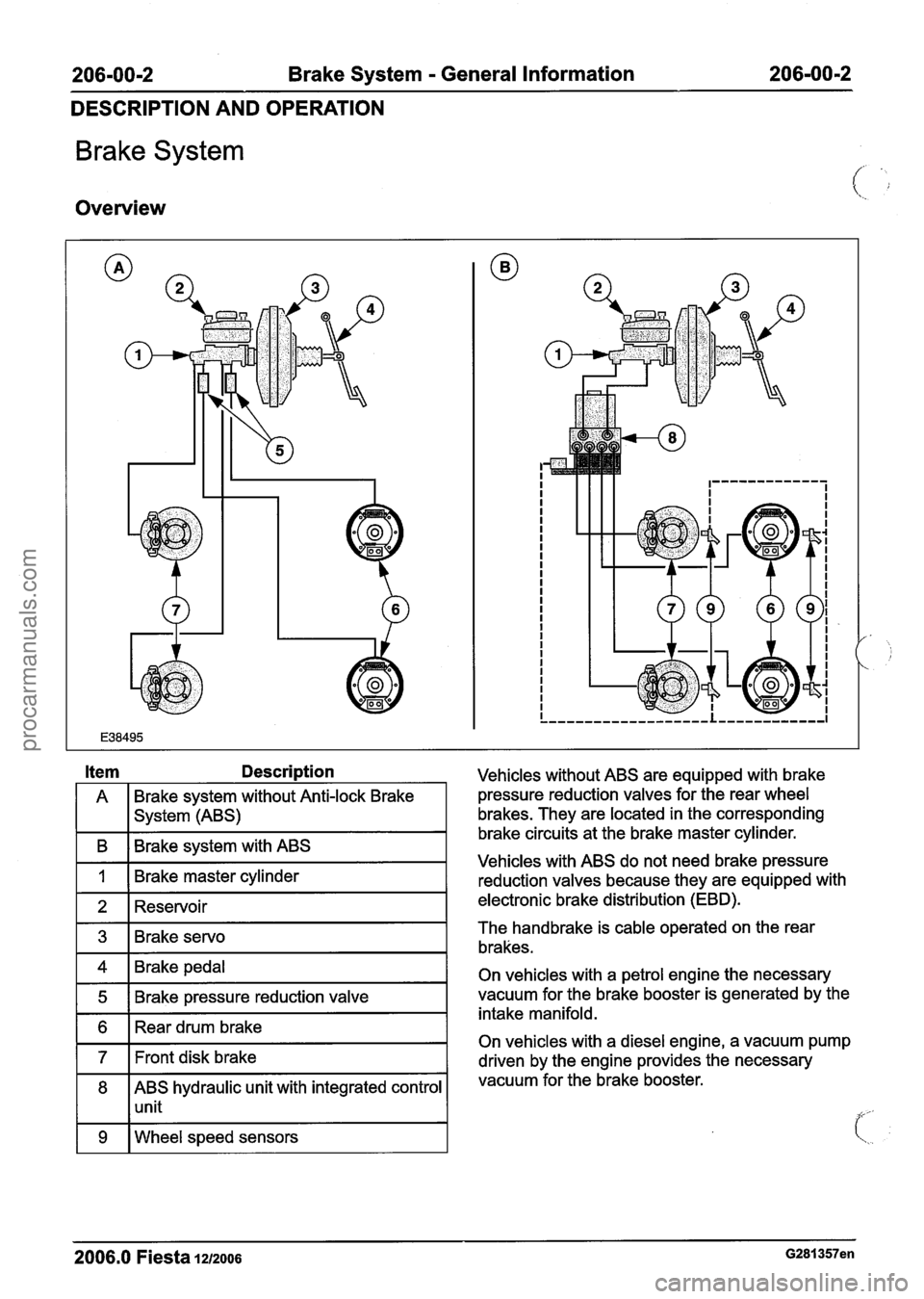

Overview

A Brake system without Anti-lock

Brake

I I system (ABS)

I B I Brake system with ABS I

I 1 I Brake master cylinder I -

1 2 1 Reservoir I

1 4 1 Brake pedal I

1 5 1 Brake pressure reduction valve I

1 6 1 Rear drum brake I

171t disk brake I

8 ABS hydraulic unit with integrated control

1 1 unit

1 9 I Wheel speed sensors I

Vehicles without ABS are equipped with brake

pressure reduction valves for the rear wheel

brakes. They are located in the corresponding

brake circuits at the brake master cylinder.

Vehicles with ABS do not need brake pressure

reduction valves because they are equipped with

electronic brake distribution (EBD).

The handbrake is cable operated on the rear

brakes.

On vehicles with a petrol engine the necessary

vacuum for the brake booster is generated by the

intake manifold.

On vehicles with a diesel engine, a vacuum pump

driven by the engine provides the necessary

vacuum for the brake booster.

2006.0 Fiesta lu2006 G281357en

procarmanuals.com

Page 210 of 1226

206-0214 Drum Brake 206-02-4

DESCRIPTION AND OPERATION

The heat generated during braking is passed to

the bi-metallic strip. If the heat exceeds a critical

point, the bi-metallic strip bends upwards into the

corresponding nib and prevents further adjustment.

After the brake has cooled again, the bi-metallic

strip returns to the initial position. Adjustment is

now possible again.

2006.0 Fiesta 1212006 G250944en

procarmanuals.com

Page 219 of 1226

206-03-3 Front Disc Brake 206-03-3

DESCRIPTION AND OPERATION

Front Disc Brake

Overview

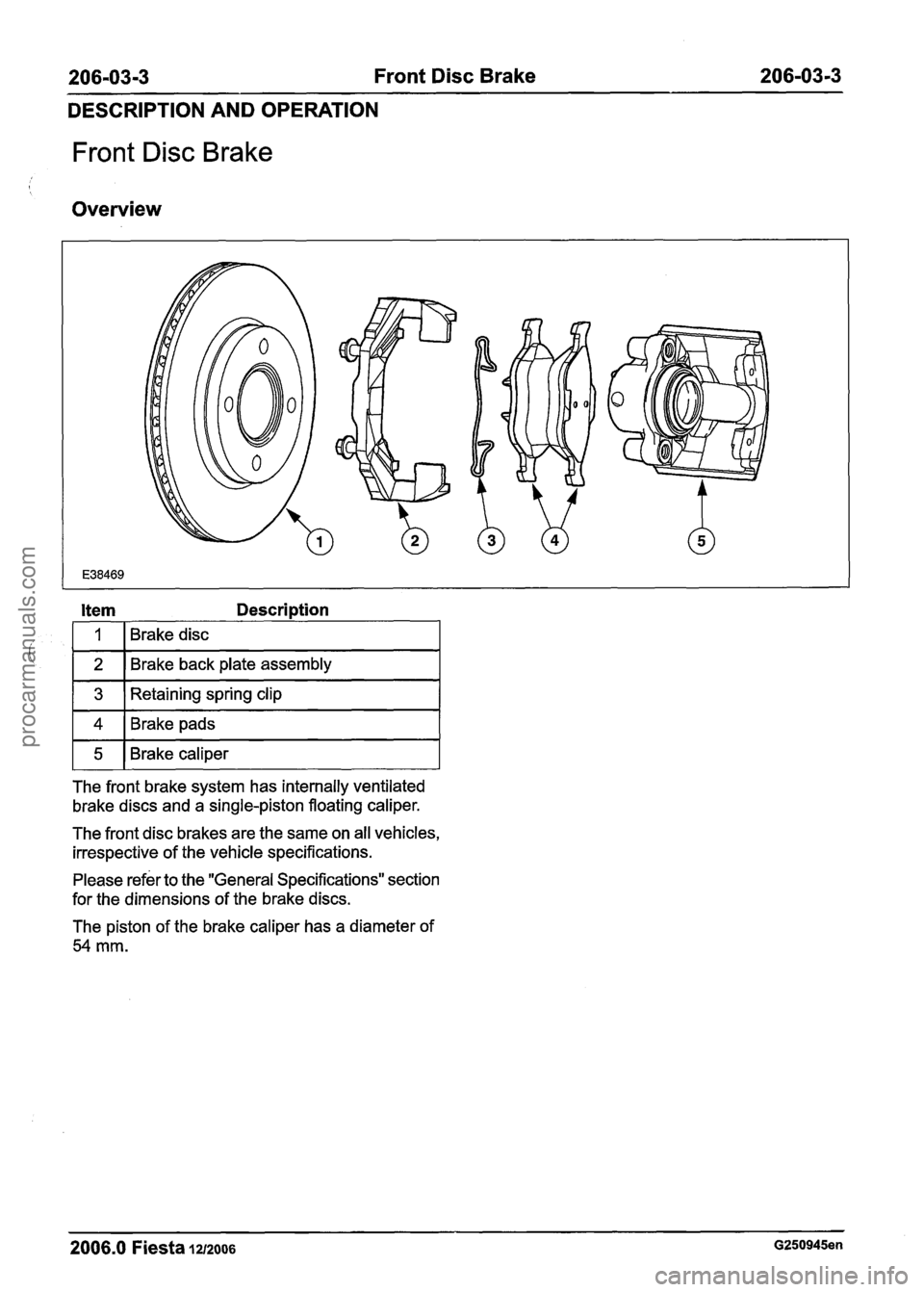

Item Description

i

The front brake system has internally ventilated

brake discs and a single-piston floating caliper.

3

4

5

The front disc brakes are the same on all vehicles,

irrespective of the vehicle specifications.

1

2

Retaining spring clip

Brake pads

Brake caliper

Please refer to the "General Specifications" section

for the dimensions of the brake discs.

Brakedisc

Brake back plate assembly

The piston of the brake caliper has a diameter of

54 mm.

2006.0 Fiesta 1212006 G250945en

procarmanuals.com

Page 267 of 1226

206-0713 Power Brake Actuation 206-0713

DESCRIPTION AND OPERATION

Brake Booster

Emergency brake assistant (EBA) EBA operates purely mechanically, and is

completely integral with the brakeservo.

As ABS braking systems have become widespread,

it has emerged that because of incorrect use of the

Brake servo units with and without EBA are

brakes, many drivers are losing the safety benefit externally identical. For identification purposes,

which ABS

~rovides. brake servo units with EBA carry a white sticker I showing a large letter "A. Drivers are applying the brakes too timidly.

Because of this, the Anti-lock Braking System The tandem master cylinder

is the same for

(ABS) does not engage, and the maximum braking

vehicles with or without

effect is not achieved.

The EBA recognises from the driver's manner of

braking that an emergency situation is occurring,

and automatically applies full braking power.

This occurs in a matter of milliseconds, which is

faster than the driver could do it.

Furthermore, it was observed that after the first

heavy application of the brake pedal, the driver

releases the pressure on the pedal too early.

The EBA ensures that the ABS effect still continues

when the pedal pressure would normally lie below

the ABS range of control. The system is available

j as an option depending on market and vehicle

variant.

Function

In normal braking situations, the brake servo with

EBA operates in the same way as a conventional

brake servo unit. This means that the driver can

always modulate the brakes.

If an activation threshold defined by a characteristic

curve is exceeded during braking, the EBA

operates.

Determination of the activation threshold is based

on the pedal movement parameters, which are a

function of the pressure on the brake pedal and

the speed of movement of the pedal.

Depending on driving manner, EBA results in a The characteristic curve

is separately defined for

reduction in braking distance of 15% for each vehicle model.

experienced drivers, to over

40% for average The mechanical EBA uses the fact that in a brake

drivers. servo unit, the valve piston moves ahead of the

Because EBA decelerates the vehicle up to the control housing

when a braking operation starts.

wheel locking limit, emergency brake assist is only Because of this, there is a relative travel distance used in vehicles with ABS.

between the control housing and the valve piston

which can vary depending on the force applied to

Components the brake pedal and the pedal speed.

The relative travel distance is small when the pedal

moves slowly with low force applied to it. The

relative travel distance is larger when the pedal

moves faster with higher force applied to it.

Item Description

-

2006.0 Fiesta 1212006 GI 63289en

procarmanuals.com

Page 277 of 1226

206-09A-3 Anti-Lock Control 206-09A-3

DESCRIPTION AND OPERATION

Anti-Lock Control

Overview

Function

The ABS is a closed loop control system in the

brake system which prevents the wheels from

1 4 1 Ignition lock I situations.

3

1 5 1 Stoplamp switch I

6 ABS warning lamp in the instrument

I 1 cluster

Wheel

speed sensors

In addition to the conventional brake system with

two diagonally split brake circuits, the ABS consists

of an ABS hydraulic unit with integrated control

unit, four wheel sensors and the ABS warning lamp

in the instrument cluster. locking up under

braking and therefore maintains

steerability and driving stability in extreme

Electronic brake force distribution is integrated in

the software of the ABS control unit', which

electronically regulates and optimises the pressure

applied to the wheel brakes on the front and rear

axles in accordance with the operating conditions.

ABS control unit

The ABS control unit continuously compares stored

physical deceleration values with those detected

by the wheel sensors. This allows the lock-up

tendency of each wheel to be detected separately.

If the ABS control unit detects that a wheel is

threatening to lock up, then the corresponding

hydraulic valves in the valve block are either closed

or opened.

The ABS control unit then also passes on the

vehicle speed signal obtained from the wheel sensors to the Powertrain Control Module (PCM).

2006.0 Fiesta 1212oo6 GI 63290en

procarmanuals.com

Page 278 of 1226

206-09A-4 Anti-Lock Control 206-09A-4

DESCRIPTION AND OPERATION

The warning lamp in the instrument cluster is

actuated by the ABS control unit after switching on

the ignition. It remains on up to the end of the ABS

self-test, and is also actuated in the event of

system errors.

It continuously monitors the system for possible

faults and stores these as and when they occur.

The corresponding trouble codes can be

interrogated with the aid of WDS via the DLC

.

The ABS control unit is directly connected via a

diagnostic data link to the DLC.

Valve block

The valve block contains four inlet valves and four

outlet valves. There is one inlet valve and one

outlet valve for each wheel.

When there is no electrical supply the inlet valves

are open and the outlet valves are closed.

The valve block also contains the low-pressure

reservoir and sound damping chambers.

Pump motor

In the event of an ABS intervention the pump motor

ensures that the pressure can be provided to the

regulating channels independently of the brake

master cylinder.

ABS regulating cycle

An ABS regulating cycle has three phases:

Phase

1 - holding pressure

The inlet valve is closed, and the brake pressure

to the wheel brake cannot be increased any

further, even if the actuation pressure (brake

pedal) is increased further.

Phase

2 - pressure reduction

The outlet valve is temporarily opened, and the

brake pressure to the wheel brake is reduced

in a controlled manner.

Phase

3 - pressure build-up

The inlet valve is opened in stages, and the

brake pressure is increased in a controlled

manner to achieve the greatest possible

deceleration.

2006.0 Fiesta 1212006 GI 63290en

procarmanuals.com

Page 279 of 1226

206-0949-5 Anti-Lock Control 206-09A-5 -- -

DESCRIPTION AND OPERATION

Anti-Lock Control

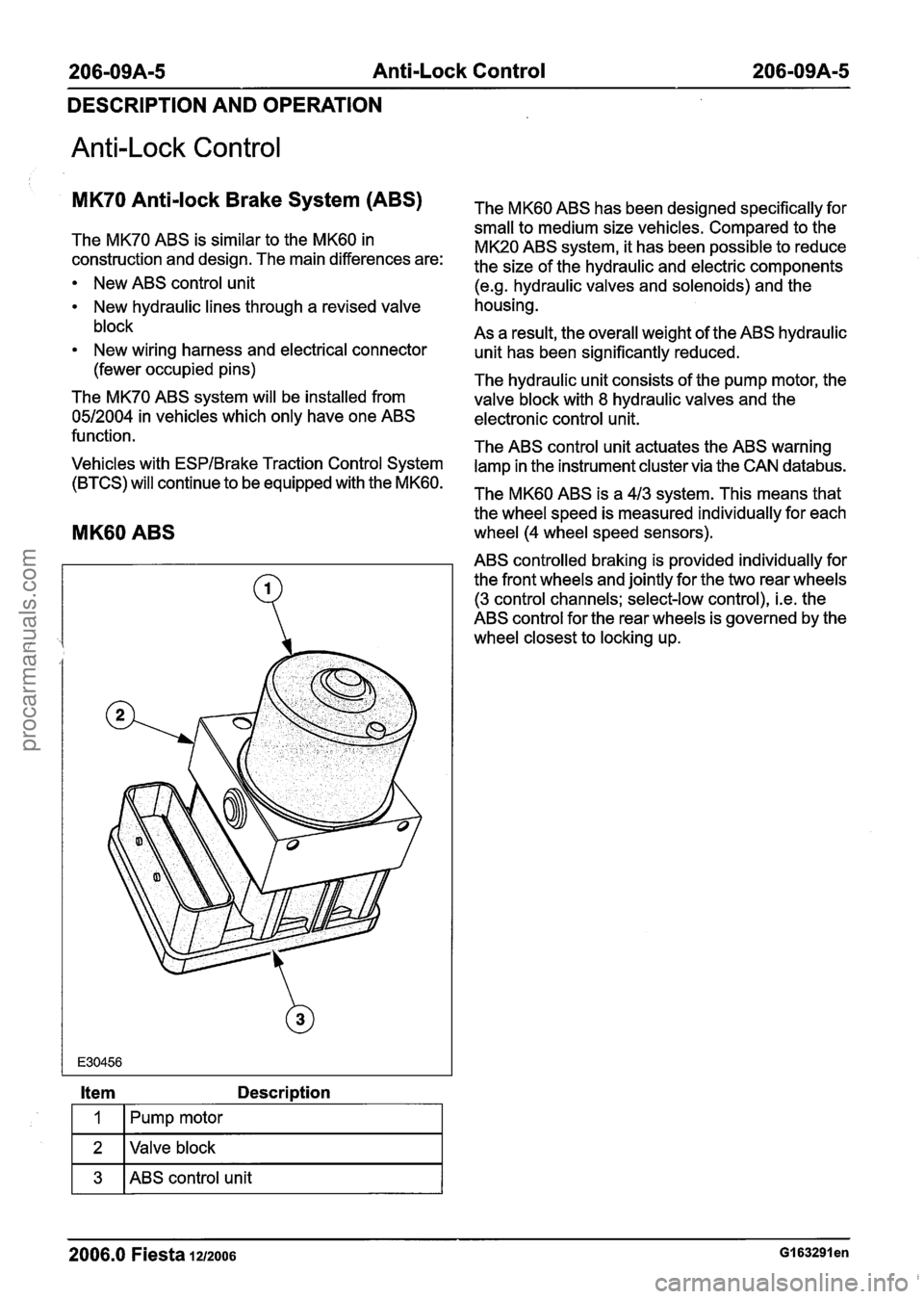

MK70 Anti-lock Brake System (ABS)

The MK70 ABS is similar to the MK60 in

construction and design. The main differences are:

New ABS control unit

New hydraulic lines through a revised valve

block

New wiring harness and electrical connector

(fewer occupied pins)

The MK70 ABS system will be installed from

0512004 in vehicles which only have one ABS

function.

Vehicles with

ESPlBrake Traction Control System

(BTCS) will continue to be equipped with the

MK60.

MK60 ABS

Item Description

Fpump motor I

1 2 I Valve block I

1 3 1 ABS control unit I

The MK60 ABS has been designed specifically for

small to medium size vehicles. Compared to the

MK20 ABS system, it has been possible to reduce

the size of the hydraulic and electric components

(e.g. hydraulic valves and solenoids) and the

housing.

As a result, the overall weight of the ABS hydraulic

unit has been significantly reduced.

The hydraulic unit consists of the pump motor, the

valve block with

8 hydraulic valves and the

electronic control unit.

The ABS control unit actuates the ABS warning lamp in the instrument cluster via the CAN

databus.

The MK60 ABS is a 413 system. This means that

the wheel speed is measured individually for each

wheel (4 wheel speed sensors).

ABS controlled braking is provided individually for the front wheels and jointly for the two rear wheels

(3 control channels; select-low control), i.e. the

ABS control for the rear wheels is governed by the

wheel closest to locking up.

- --

2006.0 Fiesta 1212006 GI 63291 en

procarmanuals.com

Page 325 of 1226

211 -00-5 Steering System - General Information 211 -00-5

DIAGNOSIS AND TESTING

Steering System

/ Special Tool(s)

Alignment Pins, Subframe

205-524

Simulator, Driver and

passenger ~ir Bags and Side

Air Curtains 50

1 -073A

General Eaui~ment

I Worldwide Diagnostic System (WDS) I

Principles of Operation

The steering wheel rotational movement is

transferred to the steering gear through the steering

column shaft. The steering gear converts this

rotational movement, through the action of the rack

and pinion gear into lateral movement. This

movement in turn is transferred to the wheel

knuckles through the tie-rods and tie-rod ends.

Hydraulic fluid under pressure is supplied to the

steering gear by the power steering pump. As the

steering wheel is rotated, the hydraulic fluid is

allowed to pass through the steering gear valve to

one side of a double acting piston, dependent on

which direction the steering wheel is rotated. The

fluid moves the piston, which forms part of the

steering gear, giving power assistance to the effort

required to rotate the steering wheel.

Vehicles with petrol engines, due to the extra load

on the engine imposed by the power steering

pump, have a power steering pressure (PSP)

switch. The switch, which is normally closed, sends a signal

to the powertrain control module (PCM)

during low speed parking manoeuvres. The PCM

responds by maintaining the engine idle speed.

lnspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual lnspection Chart

I Mechanical I Electrical I

Tire pressure(s)

Accessory drive belt

Tie-rod ends

Tie-rod (s)

Steering gear housing

Front strut and

spring assemblies

Front suspension

lower arm ball joints

Front suspension

lower arm bushings

Pinch bolt on

steering column

shaft flexible coup-

ling Power

steering pres-

sure (PSP) switch

Wheels and tires

Power steering line

fluid leaks

Steering gear

bellows

3. If an obvious cause for an observed or reported

concern is found, correct the cause (if possible)

before proceeding to the next step.

4. If the cause is not visually evident, verify the

symptom and refer to the Symptom Chart.

Symptom Chart

Symptom Possible Sources Action

Drift left or right

2006.0 Fiesta 1212006 Gl49906en

Vehicle attitude incorrect (front

or rear is high or low). CHECK for abnormal loading,

coil spring sag or non-standard

springs.

procarmanuals.com

Page 455 of 1226

303-00-33 Engine System - General Information 303-00-33

GENERAL PROCEDURES

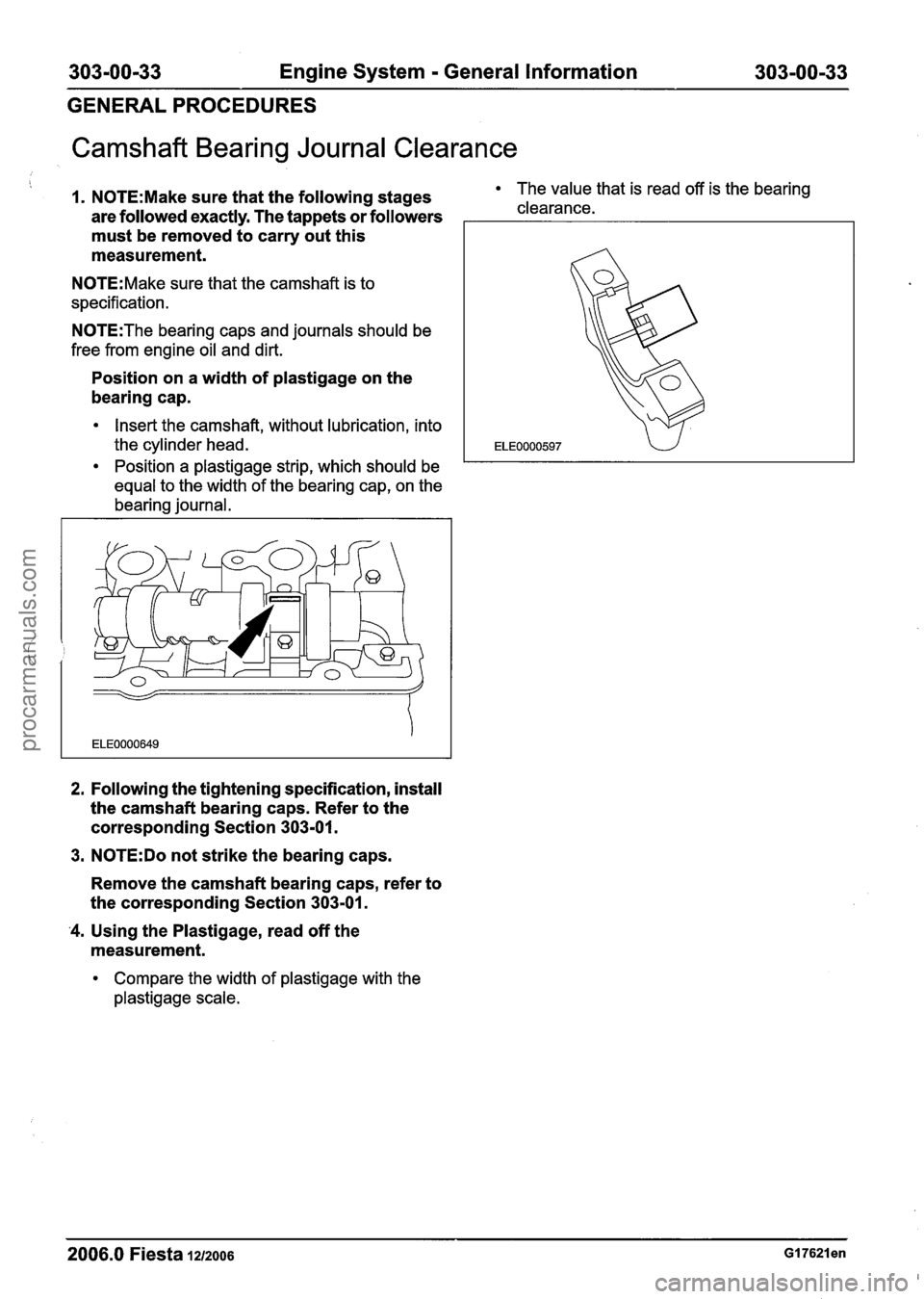

Camshaft Bearing Journal Clearance

1. N0TE:Make sure that the following stages The value that is read off is the bearing

are followed exactly. The tappets or followers clearance.

must be removed to carry out this

measurement.

N0TE:Make sure that the camshaft is to

specification.

N0TE:The bearing caps and journals should be

free from engine oil and dirt.

Position on a width of plastigage on the

bearing cap.

Insert the camshaft, without lubrication, into

the cylinder head.

Position

a plastigage strip, which should be

equal to the width of the bearing cap, on the

bearing journal.

2. Following the tightening specification, install

the camshaft bearing caps. Refer to the

corresponding Section 303-01.

3.

N0TE:Do not strike the bearing caps.

Remove the camshaft bearing caps, refer to

the corresponding Section 303-01.

'4. Using the Plastigage, read off the

measurement.

Compare the width of plastigage with the

plastigage scale.

2006.0 Fiesta 1212006

procarmanuals.com