lock FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 993 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -33 Transmission (AW81-40) 307-01 -33

DESCRIPTION AND OPERATION

This is influenced by the following variables: Vehicle

speed,

Engine load, Transmission fluid temperature.

Accelerator pedal position, The following are actuated:

Transmission input speed, SSA shift solenoid valve,

Vehicle speed,

Transmission fluid temperature,

Selector lever position.

The

following are actuated:

Main

regulating valve.

Reverse gear safety strategy

SSB shift solenoid valve.

Torque reduction when pulling away

In order to protect the clutches against excessively

high torque when pulling away, the PCM reduces

the engine torque in response to a request from

the transmission

control.

If the accelerator pedal is depressed while the

The transmission control unit prevents shifts into vehicle is pulling away, then the transmission reverse gear while the vehicle is driving forwards, control unit sends a corresponding signal as otherwise serious transmission damage can be requesting a torque reduction via the CAN databus. caused.

The reverse gear safety strategy is active when This

is influenced by the

following variables:

reverse gear is engaged with the selector lever at ' Selector lever position,

vehicle speeds in excess of 11 kmlh. Accelerator pedal position,

In this

case the transmission control unit actuates ' Engine speed,

the shift timing solenoid valve, as a result of which Transmission input speed,

the actuating pressure does not reach the reverse

. Vehicle speed. gear clutch or the reverse gear brake.

The following are actuated:

The reverse gear safety strategy is deactivated

PCM (torque reduction request signal via the

when the vehicle speed is below 9 kmlh. The

actuating pressure can then reach the reverse gear CAN

databus).

clutch and the reverse gear brake and the gearshift

into reverse gear is performed.

Selector lever positions

This is influenced by the following variables:

Vehicle speed,

Selector lever position.

The

following are actuated:

Shift timing solenoid valve.

Selector lever position "P"

No gear is engaged in selector lever position "P".

The parking

pawl is engaged manually via the

selector lever cable and the selector shaft.

Avoidance of gearshift judder during

engagement of a transmission range Selector

lever position "R"

In order to prevent gearshift judder when moving The reverse gear is eWaged in selector lever

the selector lever from N to D, the transmission position "R.

control unit initially shifts into

2nd gear instead of

1 st gear, and then immediately shifts back into I st

gear before the gearshift process is finished. Selector lever position "N"

This reduces the amount of gearshift judder during No gear is engaged in selector lever position WNW. engagement of a forward drive range.

The powertrain is not blocked. This is influenced by the following variables:

Selector lever position,

Accelerator pedal position,

Transmission input speed,

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1000 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -40 Transmission (AW81-40)

307-01 -40

DESCRIPTION AND

OPEMION

Driver's side door ajar switch

The door ajar switch is located in the door lock on

the driver's side.

When the door is closed a ground connection is

signalled to the transmission control unit.

When the door is opened this ground connection

is interrupted.

The transmission control unit uses the signal from

the driver's side door ajar switch to warn the driver

if the selector lever is not in position

"P" and the

driver's door is open.

In this case the transmission control unit transmits

the warning tone request via the CAN

databus to

the instrument cluster.

The instrument cluster passes this request on to

the GEM, which then generates a warning tone.

Consequences of signal failure:

no warning tone request.

Actuators

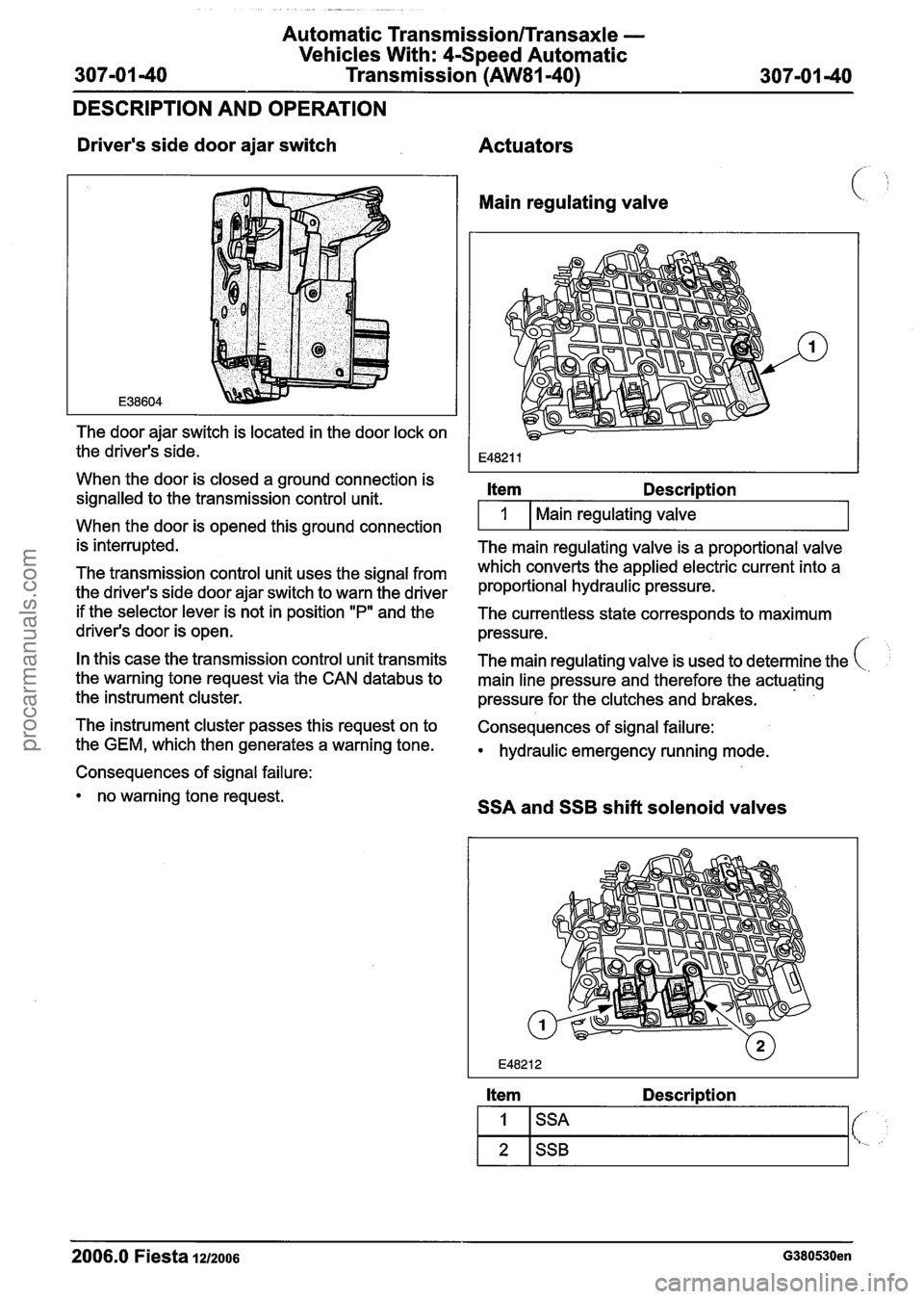

Main regulating valve

Item Description

I 1 I Main regulating valve I

The main regulating valve is a proportional valve

which converts the applied electric current into a

proportional hydraulic pressure.

The currentless state corresponds to maximum

pressure.

/

The main regulating valve is used to determine the

main line pressure and therefore the actuating

pressure for the clutches and brakes.

Consequences of signal failure:

hydraulic emergency running mode.

SSA and SSB shift solenoid valves

Item Description

2006.0 Fiesta 1212006 G380530en

1

2

SSA

SSB

(- t..

procarmanuals.com

Page 1003 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -43 Transmission (AW81-40) 307-01 -43

DESCRIPTION AND OPERATION

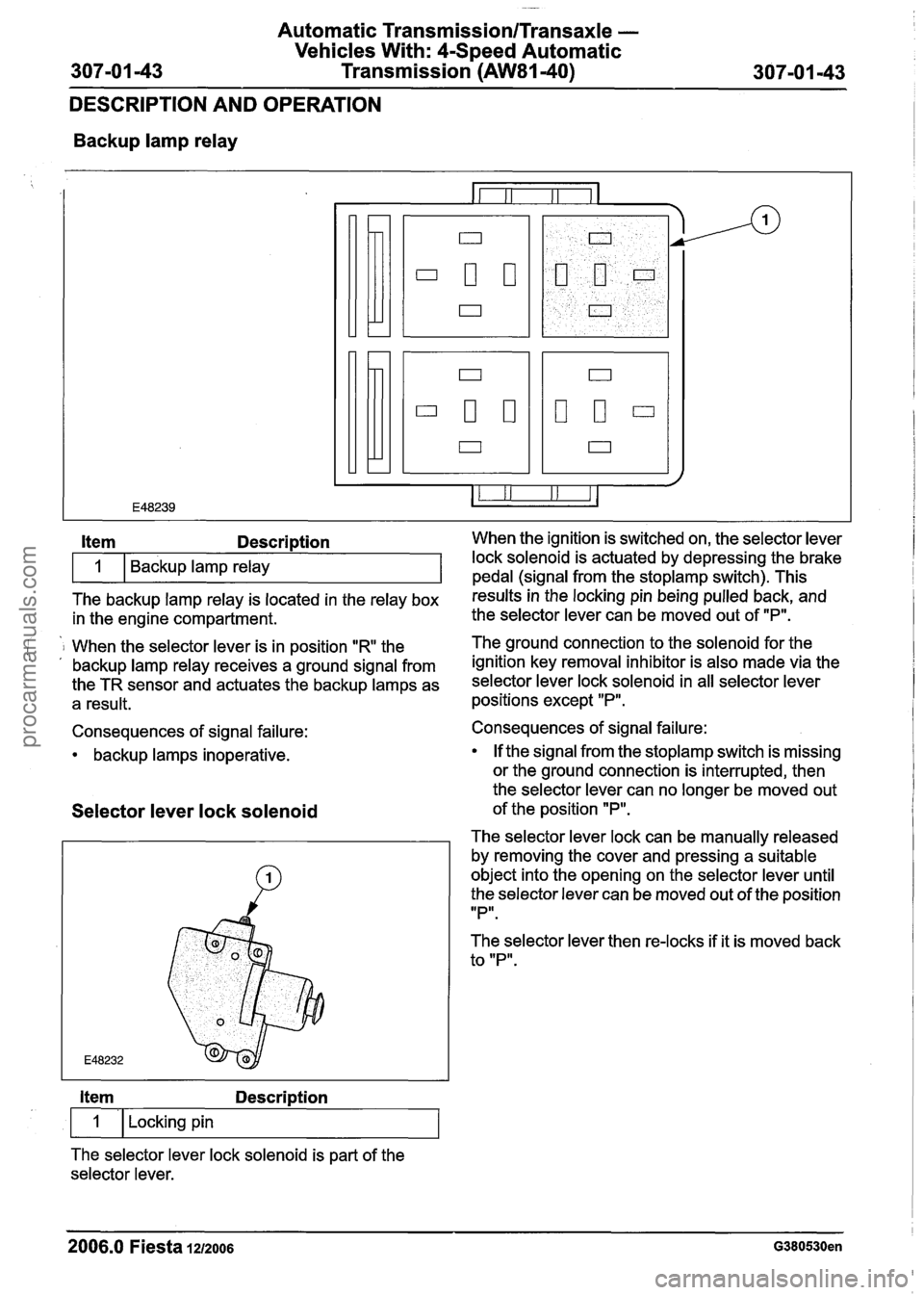

Backup lamp relay

The backup lamp relay is located in the relay box results inthe locking pin being pulled back, and

in the engine compartment. the

selector lever can be moved out of "P".

Item Description When the ignition is switched on, the selector lever

i 1 When the selector lever is in position "R the The ground connection to the solenoid for

the . , backup lamp relay receives a ground signal from ignition key removal inhibitor is also made via the

the TR sensor and actuates the backup lamps as selector lever lock solenoid in all selector lever

a result. positions except "P".

1

Consequences of signal failure:

backup lamps inoperative. Backup lamp relay

Selector

lever lock solenoid

lock solenoid is actuated by depressing the brake

pedal (sianal from the stoplamp switch). This

Item Description

1 I Locking pin

The selector lever lock solenoid is part of the

selector lever. Consequences of signal failure:

If the signal from the

stoplamp switch is missing

or the ground connection is interrupted, then

the selector lever can no longer be moved out

of the position

"P".

The selector lever lock can be manually released

by removing the cover and pressing a suitable

object into the opening on the selector lever until

the selector lever can be moved out of the position

IIPlr.

The selector lever then re-locks if it is moved back

to "P".

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1004 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01

-44 Transmission (AW81-40) 307-01 -44

DESCRIPTION AND OPERATION

Solenoid for the ignition key removal

inhibitor

Solenoid for the ignition key removal

inhibitor

The solenoid for the ignition key removal inhibitor

is integrated in the ignition lock.

With the selector lever in position

"P", the ground

connection via the selector lever lock solenoid is

interrupted.

The ignition key can be turned to

"0" and removed

from the ignition lock.

In all other selector lever positions the ground

connection is made via the selector lever lock

solenoid.

The locking pin of the solenoid for the ignition key

removal inhibitor engages in the ignition lock.

The ignition key cannot be turned to

"0" and

removed from the ignition lock.

Consequences of signal failure:

A short to ground will make it impossible to

remove the ignition key from the ignition lock.

A break in the electrical circuit will make it

possible to remove the ignition key from the

ignition lock in all selector lever positions.

2006.0 Fiesta 12/2006 G380530en

procarmanuals.com

Page 1006 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -46 Transmission

(AW81-40) 307101 -46

DIAGNOSIS AND TESTING

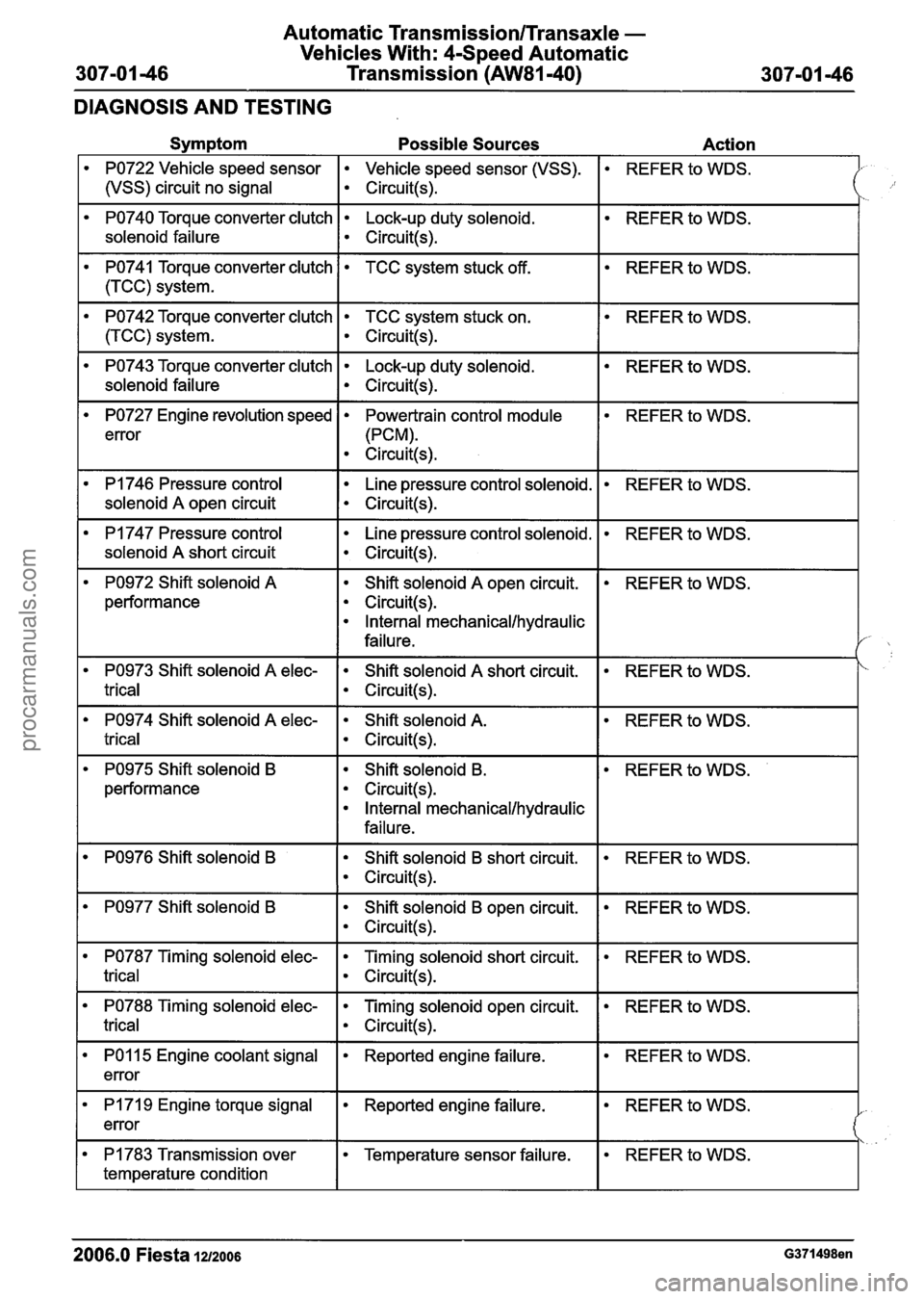

Symptom Possible Sources Action

PO722 Vehicle speed sensor Vehicle speed sensor (VSS).

1 (vSS) circuit no signal I circuit(+

REFER to WDS.

PO740 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I ~ircuit(s).

REFER to WDS.

REFER to WDS.

PO741 Torque converter clutch

1 (TCC) system.

PO742 Torque converter clutch TCC system stuck on.

I circuit(s).

TCC system stuck off.

REFER to WDS.

PO743 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I circuit(s).

REFER to WDS.

REFER to WDS.

PO727 Engine revolution speed

error

PI 746 Pressure control

I solenoid A open circuit

Powertrain control module

(PCM).

Circuit(s).

I

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PI 747 Pressure control

solenoid

A short circuit

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PO972 Shift solenoid A

performance Shift solenoid

A open

circuit.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER to WDS.

REFER to WDS.

PO974 Shift solenoid A elec- Shift solenoid A.

trical I circuit(!+

PO973 Shift solenoid A elec-

trical

REFER to WDS. Shift solenoid A short circuit.

Circuit(s).

PO975 Shift solenoid B

performance Shift solenoid

B.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER

to WDS.

PO976 Shift solenoid B Shift solenoid B short circuit.

Circuit(s).

REFER to WDS.

PO977 Shift solenoid B Shift solenoid B open circuit.

Circuit(s).

REFER to WDS.

PO787 Timing solenoid elec- Timing solenoid short circuit.

trical I circuit(s).

REFER to WDS.

REFER to WDS. PO788 Timing solenoid elec-

trical

-- - -

Timing solenoid open circuit.

Circuit(s).

REFER to WDS. PO1 15 Engine coolant signal

error Reported engine failure.

REFER to WDS. I PI 71 9 Engine torque signal

error Reported engine failure.

REFER to WDS. PI 783 Transmission over

temperature condition

2006.0 Fiesta 12/2006 G371498en

Temperature sensor failure.

procarmanuals.com

Page 1008 of 1226

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

307-01 -48 Transmission (AW81-40) 307-01 -48

DIAGNOSIS AND TESTING

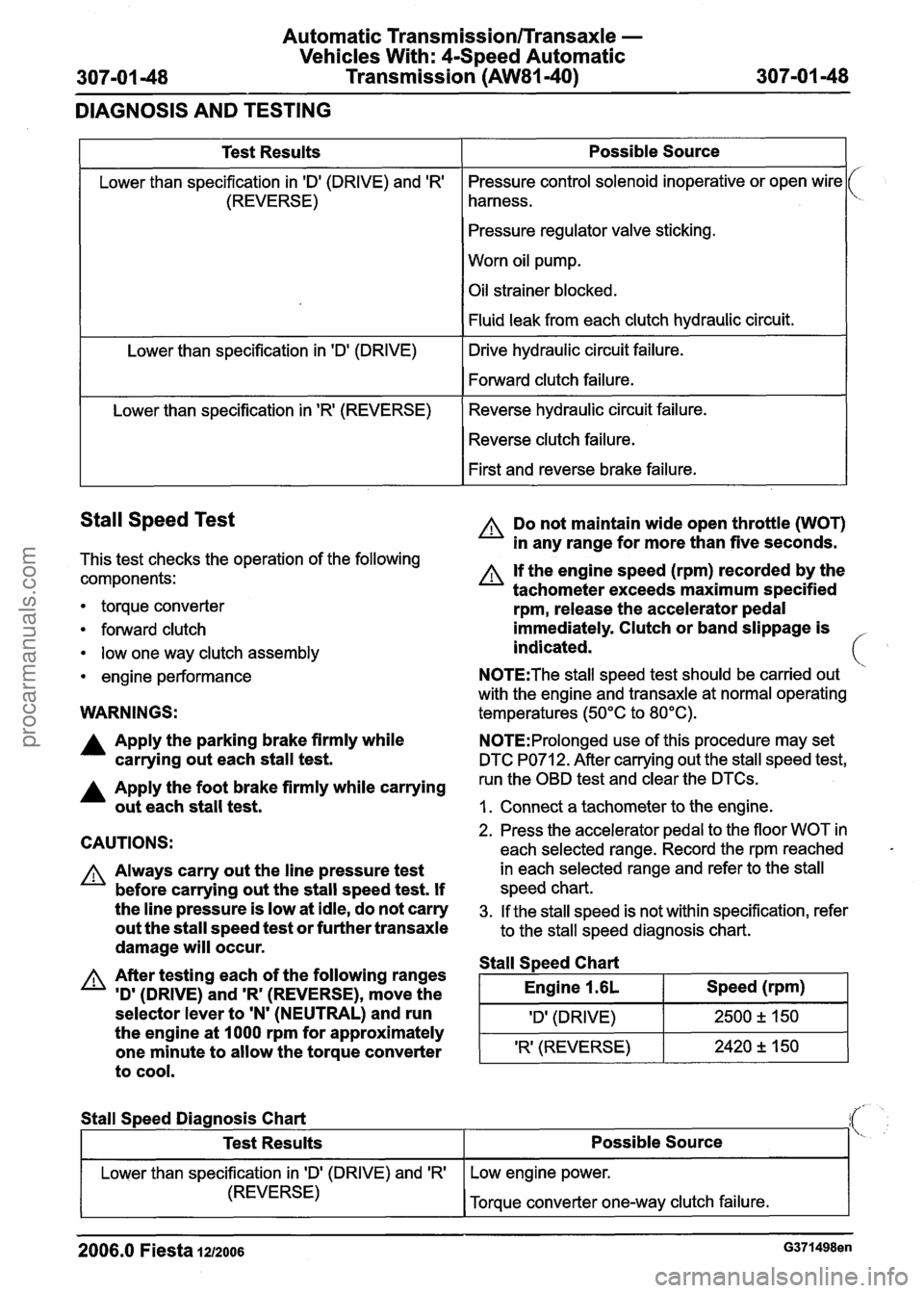

Stall Speed Test

This test checks the operation of the following

components:

1

Test Results

Lower than specification in 'Dl (DRIVE) and 'R'

(REVERSE)

Lower than specification in

'Dl (DRIVE)

Lower than specification in

'R' (REVERSE)

torque converter

forward clutch

low one way clutch assembly

engine performance

Possible Source

Pressure control solenoid inoperative or open wire

harness.

Pressure regulator valve sticking.

Worn oil pump.

Oil strainer blocked.

Fluid leak from each clutch hydraulic circuit.

Drive hydraulic circuit failure.

Forward clutch failure.

Reverse hydraulic circuit failure. Reverse clutch failure.

First and reverse brake failure.

WARNINGS:

A Do not maintain wide open throttle (WOT)

in any range for more than five seconds.

A If the engine speed (rpm) recorded by the

tachometer exceeds maximum specified

rpm, release the accelerator pedal

immediately. Clutch or band slippage is

indicated.

N0TE:The stall speed test should be carried out

with the engine and transaxle at normal operating

temperatures (50°C to 80°C).

A Apply the parking brake firmly while N0TE:Prolonged use of this procedure may set

carrying out each stall test. DTC PO71 2. After carrying out the stall speed test,

A Apply the foot brake firmly while carrying run the OBD test and clear the DTCs.

out each stall test. I. Connect a tachometer to the engine.

CAUTIONS:

A Always carry out the line pressure test

before carrying out the stall speed test. If

the line pressure is low at idle, do not carry

out the stall speed test or further transaxle

damage will occur.

A After testing each of the following ranges

'D'

(DRIVE) and 'R' (REVERSE), move the

selector lever to

'N' (NEUTRAL) and run

the engine at 1000 rpm for approximately

one minute to allow the torque converter

to cool.

2. Press the accelerator pedal to the floor WOT in

each selected range. Record the rpm reached

in each selected range and refer to the stall

speed chart.

3. If the stall speed is not within specification, refer

to the stall speed diagnosis chart.

Stall S~eed Chart

I Engine 1.6L I Speed (rpm) I

I 'Dl (DRIVE) I 2500 2 150 1

'R' (REVERSE) 2420 +, 150 -

Stall

Speed Diagnosis Chart

2006.0 Fiesta 1212006 G371498en

Test Results

Lower than specification in ID' (DRIVE) and 'R'

(REVERSE)

Possible Source

Low engine power.

Torque converter one-way clutch failure.

procarmanuals.com

Page 1009 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 49 Transmission (AW81-40) 307-01 -49

DIAGNOSIS AND TESTING

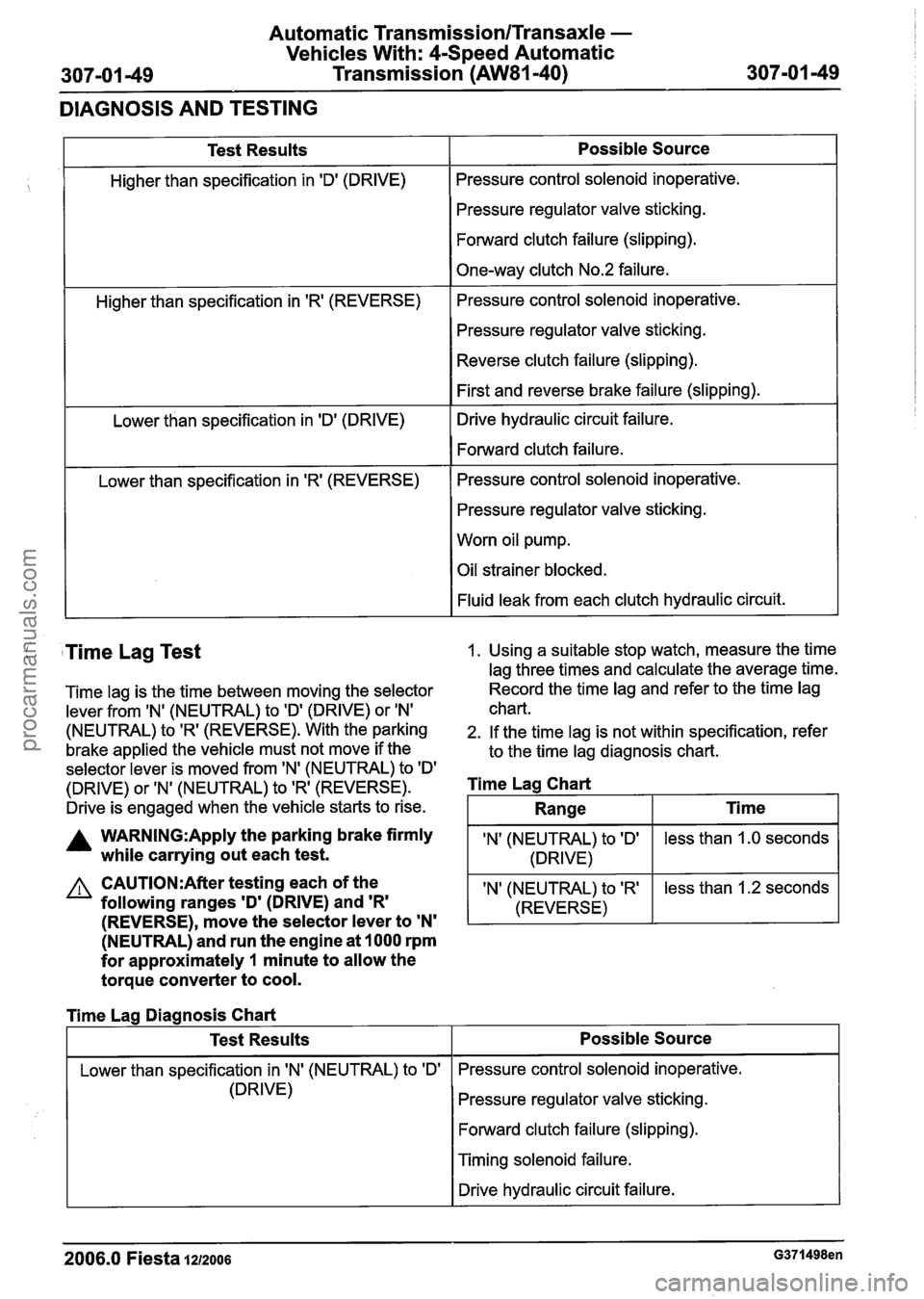

Test Results

Higher than specification in 'Dl (DRIVE)

Higher than specification in

'R' (REVERSE)

Lower than specification in 'D' (DRIVE)

Lower than specification in

'R' (REVERSE)

Possible Source

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Forward clutch failure (slipping).

One-way clutch No.2 failure.

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Reverse clutch failure (slipping).

First and reverse brake failure (slipping).

Drive hydraulic circuit failure.

Forward clutch failure.

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Worn oil pump.

Oil strainer blocked.

Fluid leak from each clutch hydraulic circuit.

( Time Lag Test 1. Using a suitable stop watch, measure the time

lag three times and calculate the average time.

Time lag is the time between moving the selector Record the

time lag and refer to the time lag

lever from

IN' (NEUTRAL) to ID' (DRIVE) or IN' chart.

(NEUTRAL) to 'R' (REVERSE). With the parking 2. If the time lag is not within specification, refer

brake applied the vehicle must not move if the

to the time lag diagnosis chart.

selector lever is moved from 'N' (NEUTRAL) to

ID'

(DRIVE) or 'N' (NEUTRAL) to 'R' (REVERSE). Time Lag Chart

Drive is engaged when the vehicle starts to rise.

A WARN1NG:Apply the parking brake firmly IN' (NEUTRAL) to ID' while carrying out each test. 1 (DRIVE)

(NEUTRAL) and run the engine at 1000 rpm

for approximately

1 minute to allow the

torque converter to cool.

less than 1.0 seconds

CAUTI0N:After testing each of the

following ranges

'D' (DRIVE) and 'R'

Range

I Lower than specification in IN' (NEUTRAL) to 'Dl I Pressure control solenoid inoperative.

Ti me

(REVERSE), move the selector lever to 'N'

'N' (NEUTRAL) to 'R'

(REVERSE)

Time Lag Diagnosis Chart

(DRIVE) less

than 1.2 seconds

Test Results

Pressure regulator valve sticking.

Forward clutch failure (slipping).

Possible Source

I Timing solenoid failure.

I I Drive hydraulic circuit failure. I

2006.0 Fiesta IZIZOO~ G371498en

procarmanuals.com

Page 1015 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307101 -55 Transmission (AW81-40) 307-01 -55

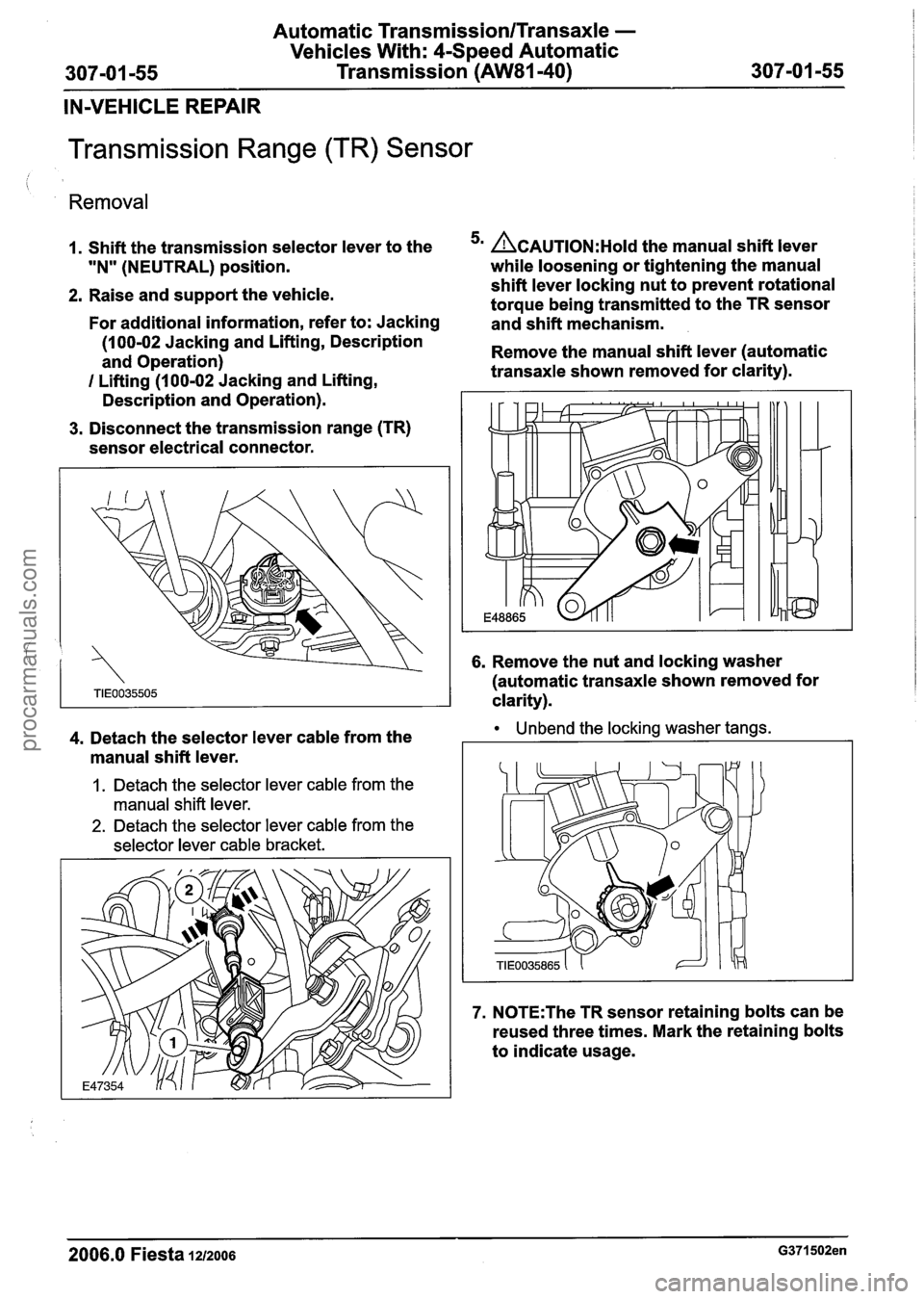

IN-VEHICLE REPAIR

Transmission Range (TR) Sensor

Removal

1. Shift the transmission selector lever to the ACAUTION:H~I~ the manual shift lever

"N" (NEUTRAL) position. while loosening

or tightening the manual - -

2. Raise and support the vehicle. shift

lever locking nut to prevent rotational

torque being transmitted to the TR sensor

For additional information, refer to: Jacking

and shift mechanism.

(1

00-02 Jacking and Lifting, Description

and Operation) Remove

the manual shift lever (automatic

I Lifting (1 00-02 Jacking and Lifting, transaxle

shown removed for clarity).

Description and Operation).

3. Disconnect the transmission range (TR)

sensor electrical connector.

6. Remove the nut and locking washer

(automatic transaxle shown removed for

clarity).

4. Detach the selector lever cable from the Unbend the locking washer tangs.

manual shift lever.

1. Detach the selector lever cable from the

manual shift lever.

2. Detach the selector lever cable from the

selector lever cable bracket.

7. N0TE:The TR sensor retaining bolts can be

reused three times. Mark the retaining bolts

to indicate usage.

2006.0 Fiesta 1212006 G371502en

procarmanuals.com

Page 1016 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -56 Transmission (AW81-40) 307-01 -56

IN-VEHICLE REPAIR

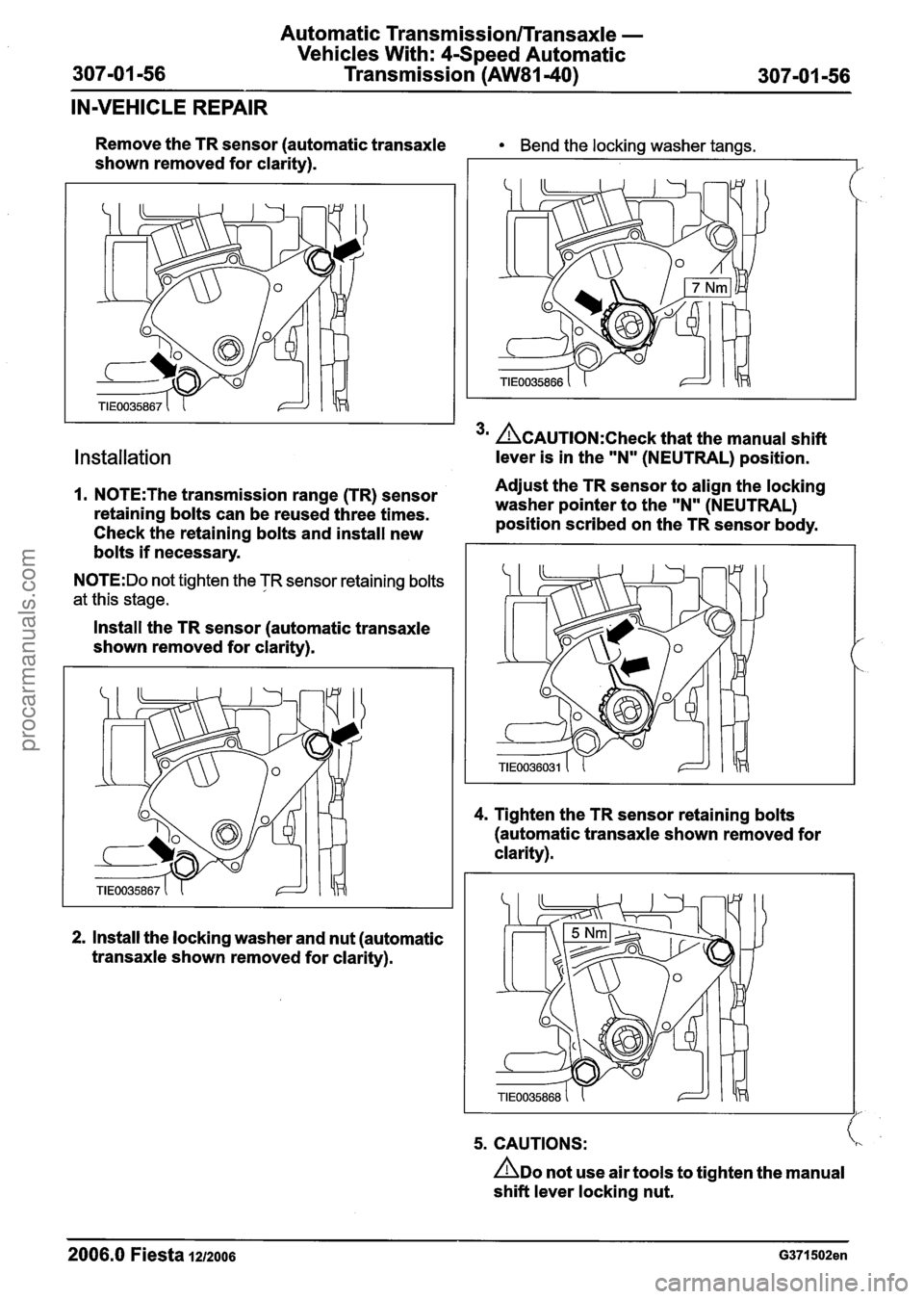

Remove the TR sensor (automatic transaxle Bend the locking washer tangs.

shown removed for clarity).

Installation

3m &LCAUTION:C~~~~ that the manual shift

lever is in the "N" (NEUTRAL) position.

1. N0TE:The transmission range (TR) sensor Adjust

the TR sensor to align the locking

retaining bolts can be reused three times. washer

pointer to the "N" (NEUTRAL)

Check the retaining bolts and install new position scribed on the

TR sensor body.

bolts

if necessary.

N0TE:Do not tighten the TR sensor retaining bolts

at this stage.

Install the TR sensor (automatic transaxle

shown removed for clarity).

4. Tighten the TR sensor retaining bolts

(automatic transaxle shown removed for

clarity).

2. Install the locking washer and nut (automatic

transaxle shown removed for clarity).

I

5. CAUTIONS:

ADO not use air tools to tighten the manual

shift lever locking nut.

--

2006.0 Fiesta 1212006 G371502en

procarmanuals.com

Page 1017 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -57 Transmission (AW81-40) 307-01 -57

IN-VEHICLE REPAIR

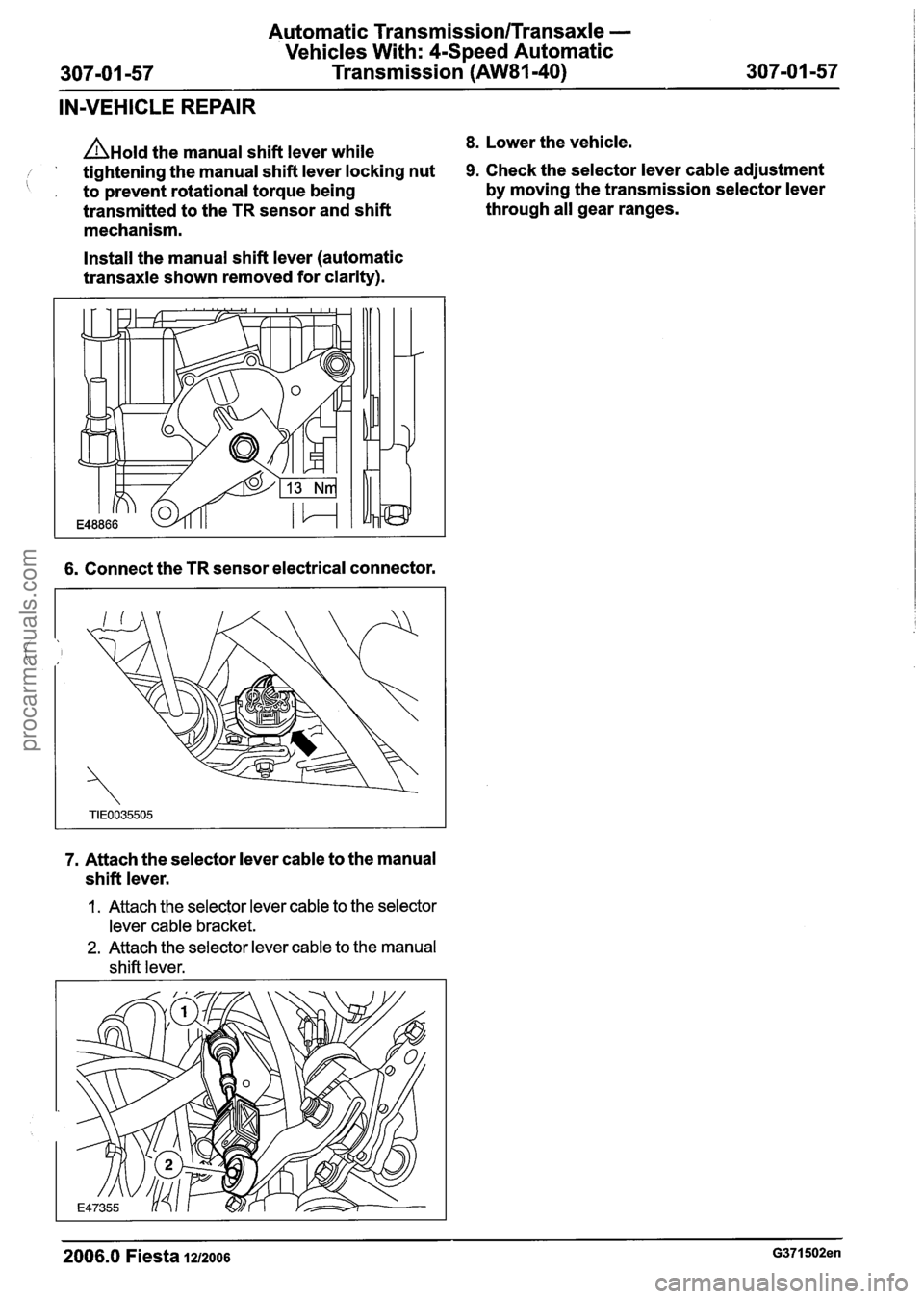

A~old the manual shift lever while 8. Lower the vehicle.

' tightening the manual shift lever locking nut 9. Check the selector lever cable adjustment to prevent rotational torque being by

moving the transmission selector lever

transmitted to the

TR sensor and shift through

all gear ranges.

mechanism.

Install the manual shift lever (automatic

transaxle shown removed for clarity).

6. Connect the TR sensor electrical connector.

7. Attach the selector lever cable to the manual

shift lever.

1. Attach the selector lever cable to the selector

lever cable bracket.

2. Attach the selector lever cable to the manual

shift lever.

2006.0 Fiesta 1212006 G371502en

procarmanuals.com