lock FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 904 of 1226

Engine Emission Control - 2.OL Duratec-HE

303-08B-10 (MI41 303-08B-10

REMOVAL AND INSTALLATION

Crankcase Vent Oil Separator

Removal

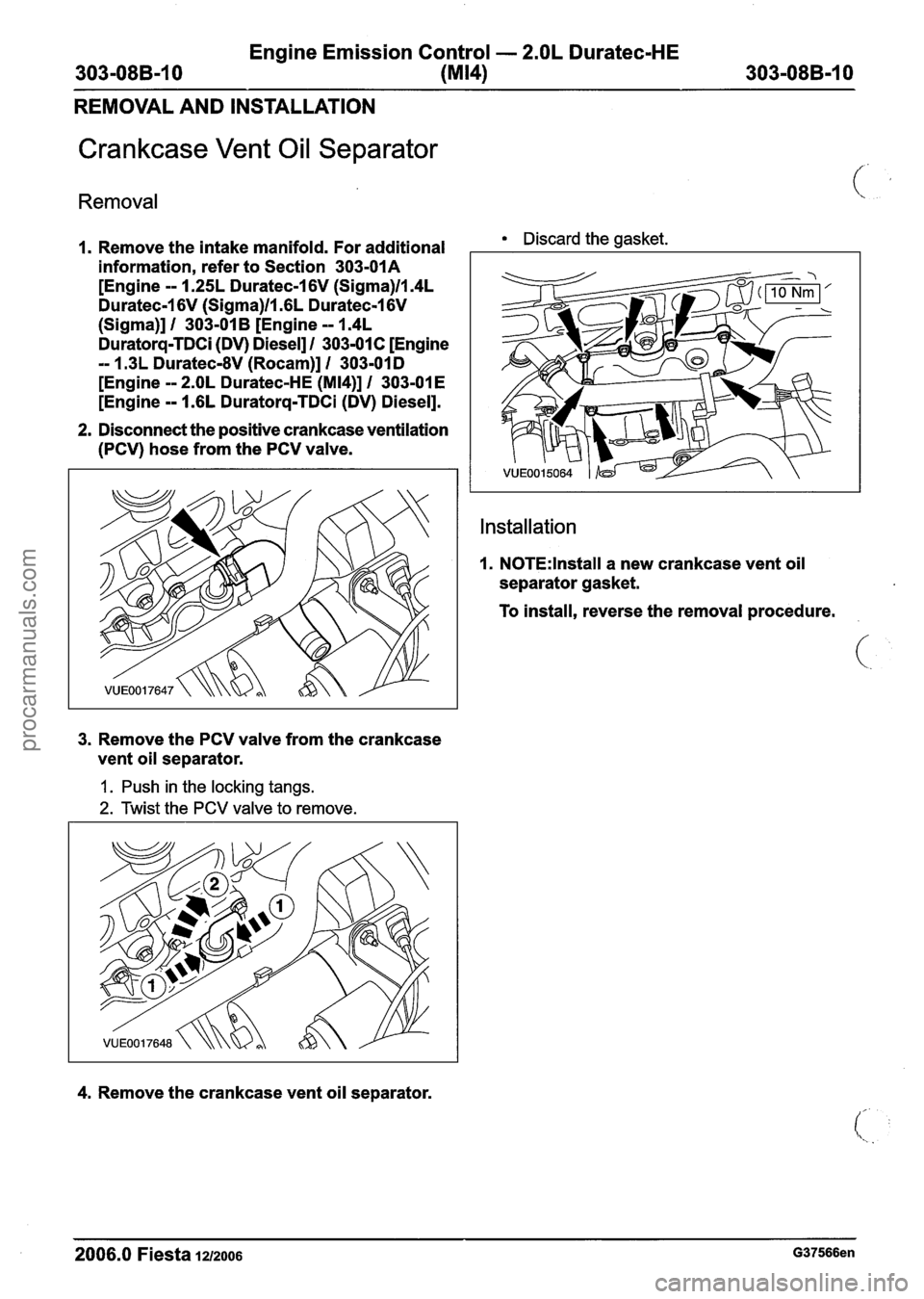

I. Remove the intake manifold. For additional Discard the gasket.

information, refer to Section 303-OIA

[Engine

-- 1.25L Duratec-1 6V (Sigma)ll.4L

Duratec-I 6V (Sigma)ll .6L Duratec-I 6V

(Sigma)] I 303-01 B [Engine -- 1.4L

Duratorq-TDCi (DV) Diesel] I 303-01 C [Engine

-- 1.3L Duratec-8V (Rocam)] I 303-01 D

[Engine

-- 2.OL Duratec-HE (M14)] 1 303-01 E

[Engine

-- 1.6L Duratorq-TDCi (DV) Diesel].

2. Disconnect the positive crankcase ventilation

(PCV) hose from the PCV valve.

Installation

I. N0TE:lnstall a new crankcase vent oil

separator gasket.

To

install, reverse the removal procedure.

3. Remove the PCV

valve from the crankcase

vent

oil separator.

1. Push in the locking tangs.

2. Twist the PCV valve to remove.

4. Remove the crankcase vent oil separator.

- - --

2006.0 Fiesta la2006 G37566en

procarmanuals.com

Page 912 of 1226

303-1 2-8 Intake Air Distribution and Filtering 303-1 2-8

DIAGNOSIS AND TESTING

Svm~tom Possible Sources Action

Oil in the air intake system Blocked or damaged positive

crankcase

ventilation (PCV)

valve.

Blocked or damaged PCV

pipe(s)/hose(s).

Blocked or damaged crankcase

vent

oil separator.

Vehicles with 1.25L Duratec-

16V

(Sigma)/l.3L Duratec-8V (

(Rocam)/l.4L Duratec-I 6V

(Sigma)/l .6L Duratec-1 6V

(Sigma) engine.

REFER to: Crankcase Vent

Oil

Separator (303-08 Engine

Emission

Control - 1.3L

Duratec-8V (Rocam)/l.25L

Duratec-I 6V (Sigma)/l.4L

Duratec-I 6V (Sigma)/l .6L

Duratec-1

6V (Sigma),

Removal and Installation).

Vehicles with 2.0L Duratec-HE

(M14) engine.

REFER to: Crankcase Vent

Oil

Separator (303-08C Engine

Emission

Control - 2.OL

Duratec-HE (M14), Removal

and Installation).

Turbocharger (Vehicles with

Duratorq-TDCi (DV)

Diesel

engine or 1.6L Duratorq-TDCi

(DV)

Diesel engine).

Vehicles with 1.4L Duratorq-

TDCi (DV)

Diesel engine.

REFER to: Turbocharger (303- 04

Fuel Charging and

Controls - Turbocharger -

1.4L Duratorq-TDCi (DV)

Diesel, Removal and Installa-

tion).

Vehicles with I .6L Duratorq-

TDCi (DV)

Diesel engine.

REFER to: Turbocharger

- I .6L

Duratorq-TDCi (DV)

Diesel

(303-04 Fuel Charging and

Controls - Turbocharger -

1.6L Duratorq-TDCi (DV)

Diesel, Removal and Installa-

tion).

Water in the air cleaner Detached air cleaner intake

pipe. CHECK

the air cleaner intake

pipe for security. INSTALL new

intake air system components

as necessary. TEST the

system for

normal operation.

Blocked air cleaner drain. CLEAN

the air cleaner drain.

TEST the system for

normal

operation.

Engine lacks power

Air cleaner element blocked. INSPECT the air cleaner for ,.

new air cleaner element as

i signs of blockage. INSTALL a .

necessary. I_

2006.0 Fiesta 1212006 G421937en

procarmanuals.com

Page 913 of 1226

303-1 2-9 Intake Air Distribution and Filtering 303-1 2-9

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

2006.0 Fiesta 1212006 G421937en

Charge air cooler pipe(s)

(Vehicles with 1.6L Duratorq-

TDCi (DV) Diesel engine).

Charge air cooler blocked

(Vehicles with

1.6L Duratorq-

TDCi (DV) Diesel engine).

INSPECT the charge air cooler

pipes for damage. INSTALL a

new charge air cooler

pipe(s)

as necessary.

INSPECT the charge air cooler

for blockage. INSTALL a new

charge air cooler as necessary.

REFER to: Charge Air Cooler

- 1.6L Duratorq-TDCi (DV)

Diesel (303-12 Intake Air

Distribution and Filtering,

Removal and Installation).

procarmanuals.com

Page 930 of 1226

303-1 4-6 Electronic Engine Controls 303-1 4-6

DESCRIPTION

AND OPERATION

Item Descri~tion

1 5 1 Crankshaft Position (CKP) sensor 1

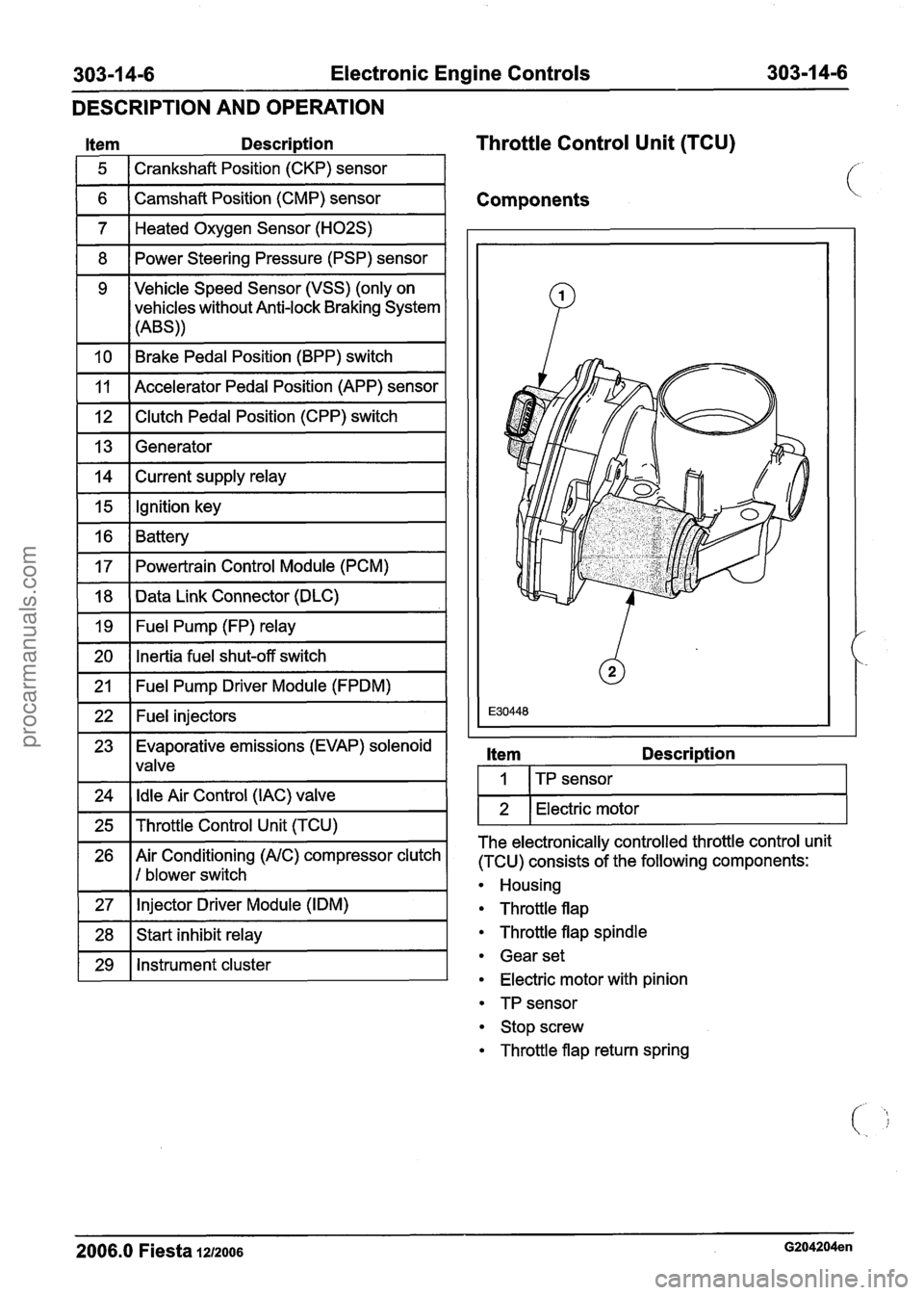

Throttle Control Unit (TCU)

1 6 ( Camshaft Position (CMP) sensor I Components

1 7 1 Heated Oxygen Sensor (H02S) I

1 8 1 Power Steering Pressure (PSP) sensor I

1 10 1 Brake Pedal Position (BPP) switch I

9 Vehicle Speed Sensor (VSS)

(only on

vehicles without Anti-lock Braking System

(ABS))

1 12 1 Clutch Pedal Position (CPP) switch I

11

1 13 1 Generator I

Accelerator Pedal Position (APP) sensor

1 14 1 Current supply relay I

1 15 1 Ignition key I -

16

17

1 20 1 Inertia fuel shut-off switch I

Battery

Powertrain Control Module (PCM)

-

18

19

1 21 1 Fuel Pump Driver Module (FPDM) I

Data Link Connector (DLC)

Fuel Pump (FP) relay

1 22 1 Fuel injectors I

23 Evaporative emissions (EVAP) solenoid

1 lvalve

1 24 1 Idle Air Control (IAC) valve 1

1 25 1 Throttle Control Unit (TCU) I

26 Air Conditioning (AIC) compressor clutch

1 I 1 blower switch

1 27 1 Injector Driver

Module (IDM) I

1 28 1 Start inhibit relay I

1 29 1 Instrument cluster I

Item Descri~tion

I I ITP sensor I

1 2 1 Electric motor I

The electronically controlled throttle control unit

(TCU) consists of the following components:

Housing

Throttle flap

Throttle flap spindle

Gear set

Electric motor with pinion

TP sensor

Stop screw

Throttle flap return spring

2006.0 Fiesta 1212006 G204204en

procarmanuals.com

Page 936 of 1226

303-1 4-1 2 Electronic Engine Controls 303-1 4-1 2

DESCRIPTION AND OPERATION

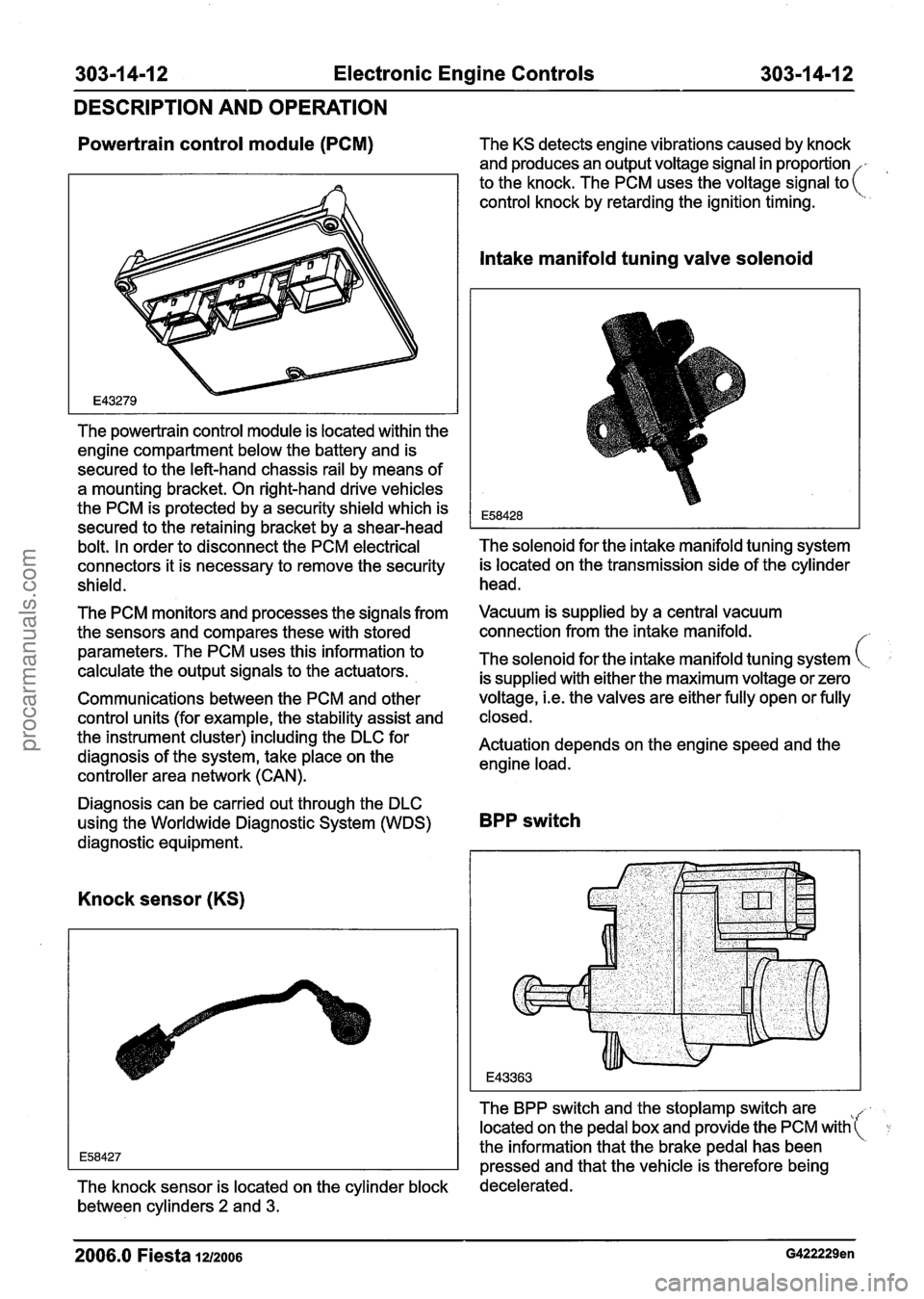

Powertrain control module (PCM) The KS detects engine vibrations caused by knock

and produces an output voltage signal in proportion

, to the knock. The PCM uses the voltage signal to(

control knock by retarding the ignition timing.

The powertrain control module is located within the

engine compartment below the battery and is

secured to the left-hand chassis rail by means of

a mounting bracket. On right-hand drive vehicles

the PCM is protected by a security shield which is

secured to the retaining bracket by a shear-head

bolt. In order to disconnect the PCM electrical

connectors it is necessary to remove the security

shield.

The PCM monitors and processes the signals from

the sensors and compares these with stored

parameters. The PCM uses this information to

calculate the output signals to the actuators.

Communications between the PCM and other

control units (for example, the stability assist and

the instrument cluster) including the DLC for

diagnosis of the system, take place on the

controller area network (CAN).

Intake manifold tuning valve solenoid

The solenoid for the intake manifold tuning system

is located on the transmission side of the cylinder

head.

Vacuum is supplied by a central vacuum

connection from the intake manifold.

The solenoid for the intake manifold tuning system

is supplied with either the maximum voltage or zero

voltage,

i.e. the valves are either fully open or fully

closed.

Actuation depends on the engine speed and the

engine load.

Diagnosis can be carried out through the DLC

using the Worldwide Diagnostic System (WDS)

BPP switch

diagnostic equipment.

Knock sensor (KS)

The BPP switch and the stoplamp switch are tt(r located on the pedal box and provide the PCM with

the information that the brake pedal has been

pressed and that the vehicle is therefore being

The knock sensor is located on the cylinder block decelerated.

between cylinders

2 and 3.

2006.0 Fiesta 1212006 G422229en

procarmanuals.com

Page 943 of 1226

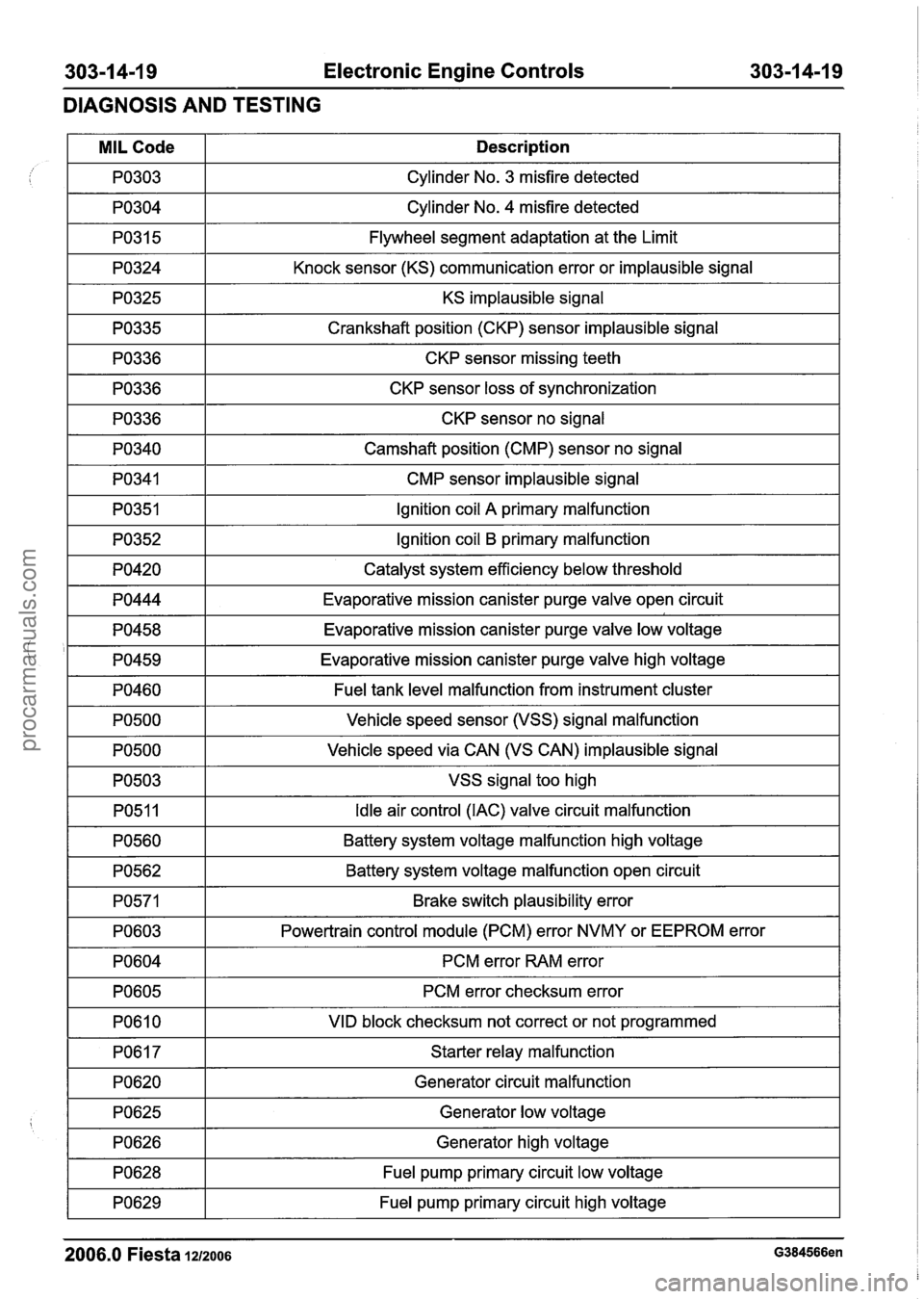

Electronic Engine Controls

DIAGNOSIS AND TESTING

I PO304 I Cylinder No. 4 misfire detected I

/ I

KS implausible signal I

MIL Code

PO303

PO31 5

PO324

1 PO335 1 Crankshaft position (CKP) sensor implausible signal I

Description

Cylinder No. 3 misfire detected

Flywheel segment adaptation at the Limit

Knock sensor (KS) communication error or implausible signal

1 PO336 1 CKP sensor missing teeth I

1 PO336 1 CKP sensor loss of synchronization I

1 PO336 1 CKP sensor no signal I

I PO340 I Camshaft position (CMP) sensor no signal I

I PO341 I CMP sensor implausible signal I

I PO351 I Ignition coil A primary malfunction I

1 PO352 1 Ignition coil B primary malfunction I

I PO420 I Catalyst system efficiency below threshold I

1 PO444 1 Evaporative mission canister purge valve open circuit I

1 PO458 1 Evaporative mission canister purge valve low voltage I

I '1 PO459 1 Evaporative mission canister purge valve high voltage I

I PO460 I Fuel tank level malfunction from instrument cluster I

-3 I VSS signal too high I

PO500

PO500

Vehicle speed sensor (VSS) signal malfunction

Vehicle speed via CAN (VS CAN) implausible signal

PO51 1

PO560

I PO603 I Powertrain control module (PCM) error NVMY or EEPROM error 1

Idle air control (IAC) valve circuit malfunction

Battery system voltage malfunction high voltage

PO562

PO571

I PO604 I PCM error RAM error I

Battery system voltage malfunction open circuit

Brake switch plausibility error

PO605 I PCM error checksum error I

I PO610 I VID block checksum not correct or not programmed I

I PO617 I Starter relay malfunction I

I PO620 I Generator circuit malfunction I

1 PO628 1 Fuel pump primary circuit low voltage I

I

7 1 Fuel pump primary circuit high voltage I

2006.0 Fiesta 1212006 G384566en

PO625

PO626

Generator low voltage

Generator high voltage

procarmanuals.com

Page 956 of 1226

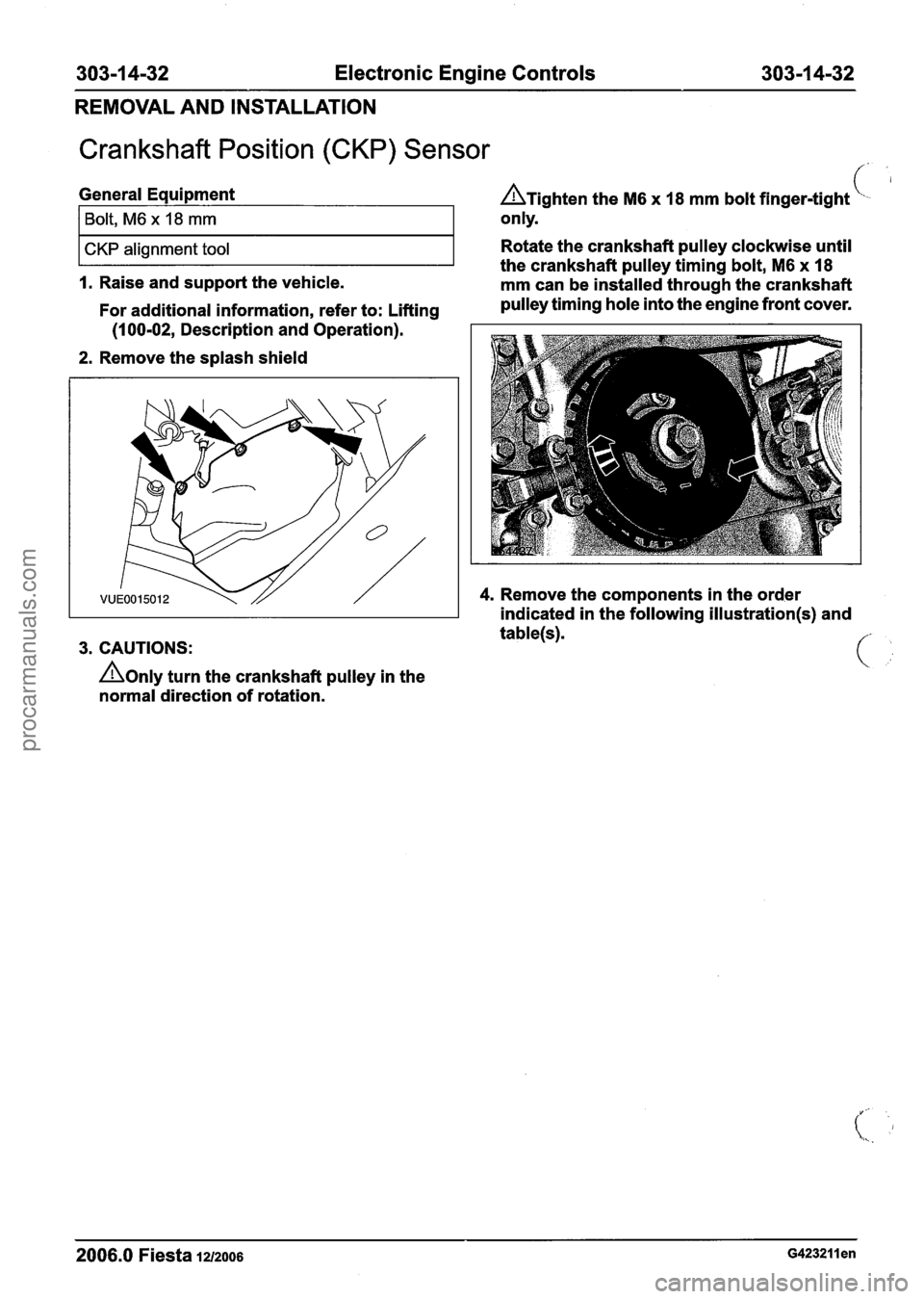

303-1 4-32 Electronic Engine Controls 303-1 4-32

REMOVAL AND INSTALLATION

Crankshaft Position (CKP) Sensor

General Equipment A~i~hten the M6 x 18 mm bolt finger-tight L,. '

2. Remove the splash shield

I ~olt, ~6 x 18 mm

CKP alignment tool

3. CAUTIONS: only.

Rotate the crankshaft pulley clockwise until

A0nly turn the crankshaft pulley in the

normal direction of rotation. the

crankshaft pulley timing bolt,

M6 x 18

I. Raise and support the vehicle.

mm can be installed through the crankshaft

For additional information, refer to: Lifting pulley

timing hole into the engine front cover.

(1 00-02, Description and Operation).

4. Remove the components in the order

indicated in the following

illustration(s) and

2006.0 Fiesta 1212006 ~423211 en

procarmanuals.com

Page 960 of 1226

303-1 4-36 Electronic Engine Controls 303-1 4-36

REMOVAL AND INSTALLATION

Ifem 2 Coolant hose kern 3 KS

I. Detach the coolant hose from the coolant N0TE:Make a note of the position of the KS and

hose retaining clip and position it to one

when installed.

make sure

it is positioned in the same position

.

side.

Installation Details

ltem 3 KS

NOTE: Prior to installing the KS, clean the engine

block and KS mating surfaces.

N0TE:Make sure the KS is installed in the same

position as removed.

(I.

2006.0 Fiesta 1212006 G426587en

procarmanuals.com

Page 964 of 1226

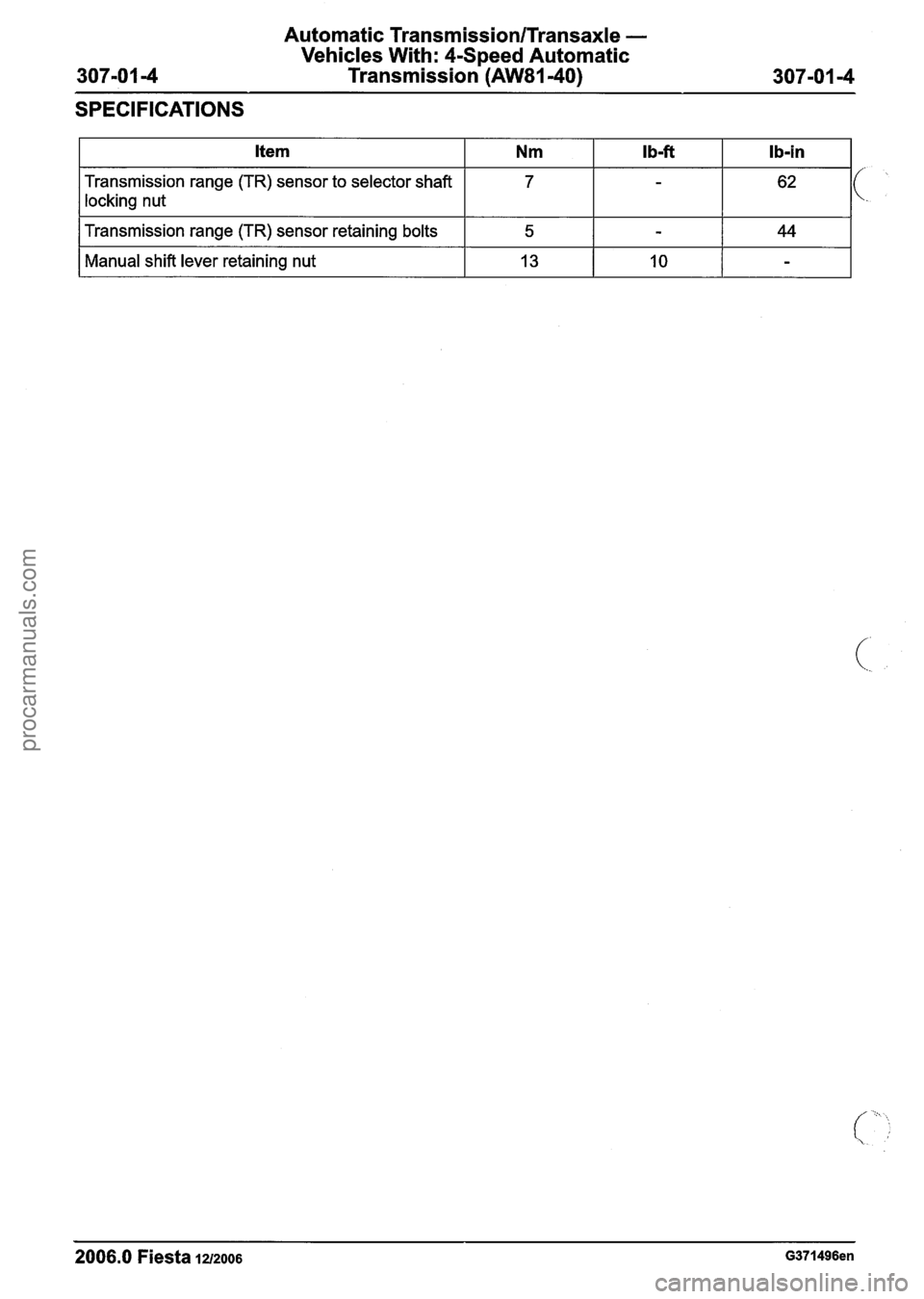

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

SPECIFICATIONS

Transmission range (TR) sensor to selector shaft 7 -

locking nut

I Transmission range (TR) sensor retaining bolts I 5 I - I 44 I

I Manual shift lever retaining nut I 13 I 10 I - I

2006.0 Fiesta 1212006 G371496en

procarmanuals.com

Page 973 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -1 3 Transmission (AW81-40) 307-01 -1 3

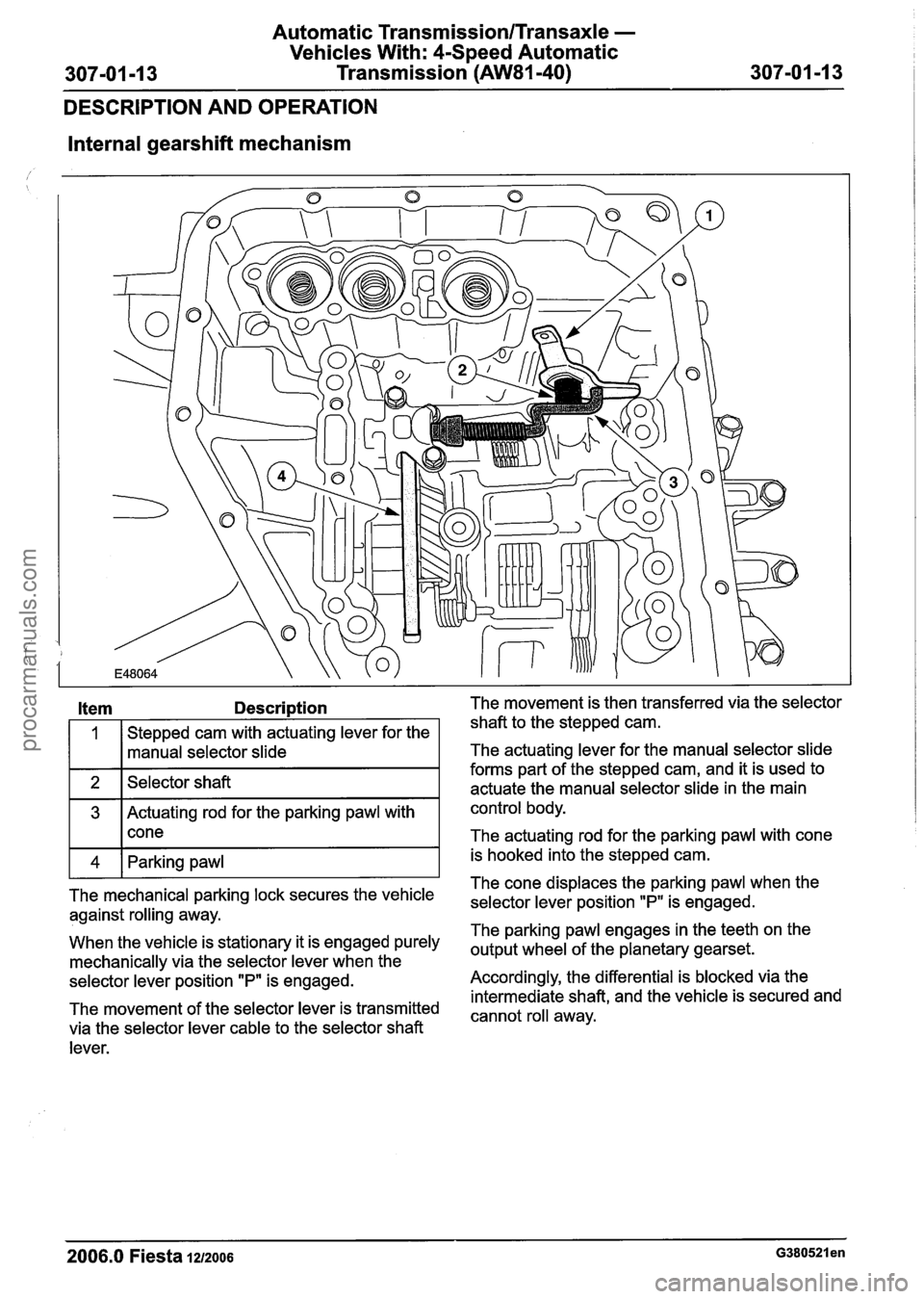

DESCRIPTION AND OPERATION

Internal gearshift mechanism

Item Description The movement is then transferred via the selector

1

2

I I I The cone displaces the parking pawl when the

The mechanical parking lock secures the vehicle

selector lever position wPw is against rolling away.

The parking pawl engages in the teeth on the

When the vehicle is stationary it is engaged purely

output wheel of the planetary gearset. mechanically via the selector lever when the

selector lever position "P" is engaged. Accordingly,

the differential is blocked via the

intermediate shaft, and the vehicle is secured and

The movement of the selector lever is transmitted

cannot roll away. via the selector lever cable to the selector shaft Stepped cam

with actuating lever for the

3

4

lever. Selector

shaft

2006.0 Fiesta 1212006 G380521 en

shaft to the stepped cam.

forms part of the stepped cam, and it is used to

actuate the manual selector slide in the main

Actuating rod for the parking pawl with cone

Parking pawl

manual

selector slide

control body.

The actuating rod for the parking pawl with cone

is hooked into the stepped cam.

The actuating lever for

the manual selector slide

procarmanuals.com