engine FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 995 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -35 Transmission (AW81-40) 307-01 -35

DESCRIPTION AND OPERATION

Engine speed

1 The engine speed is detected by the crankshaft

position (CKP) sensor and passed on to the PCM.

The engine speed is transmitted from the PCM via

the CAN

databus to the transmission control unit.

The transmission control unit uses this signal for:

Torque reduction during gearshifts,

Pressure control during gearshifts.

Engine load

The PCM determines a load signal which is

transmitted via the CAN

databus to the

transmission control unit.

The transmission control unit uses this signal for:

Torque reduction during gearshifts,

Pressure control during gearshifts,

Shift timing adaptation during upshifts,

Shift timing adaptation during shifts from 3rd to

4th gear,

Hill climb mode,

( ' Hill descent mode. ' ,

Torque reduction request signal

Before performing a gearshift, the transmission

control unit sends a signal via the CAN

databus to

the PCM requesting a torque reduction.

The PCM then reduces the engine torque, ensuring

that the gearshift is as smooth and judder-free as

possible.

Brake signal

The PCM receives a signal from the stoplamp

switch when the brake pedal is depressed.

This signal is transmitted via the CAN

databus to

the transmission control unit.

The transmission control unit uses this signal for:

Gearshift control,

Engagement of the TCC

Accelerator pedal position

The PCM receives the current accelerator pedal

position signal from the Accelerator Pedal Position

(APP) sensor.

This signal is transmitted via the CAN

databus to

the transmission control unit.

The transmission control unit uses this signal for:

Controlling the main line pressure,

Gearshift control,

Engagement of the TCC,

Shift timing adaptation during upshifts,

Shift timing adaptation during shifts from 3rd to

4th gear,

Shift timing adaptation during shifts from 4th to

3rd gear,

Avoidance of gearshift judder during

engagement of a transmission range,

Torque reduction when pulling away.

Coolant temperature

The coolant temperature is detected by the Engine

Coolant Temperature (ECT) sensor and passed

on to the PCM.

This signal is transmitted via the CAN

databus to

the transmission control unit.

The transmission control unit uses this signal for:

Cold start mode,

Engagement of the TCC

Selector lever position

The transmission control unit transmits the selector

lever position to the instrument cluster.

The instrument cluster uses the signal to send a

request for a warning tone to the GEM when the

selector lever is not in position "P" and the driver's

door is opened.

-

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1002 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

Transmission

(AW81-40)

DESCRIPTION AND OPERATION

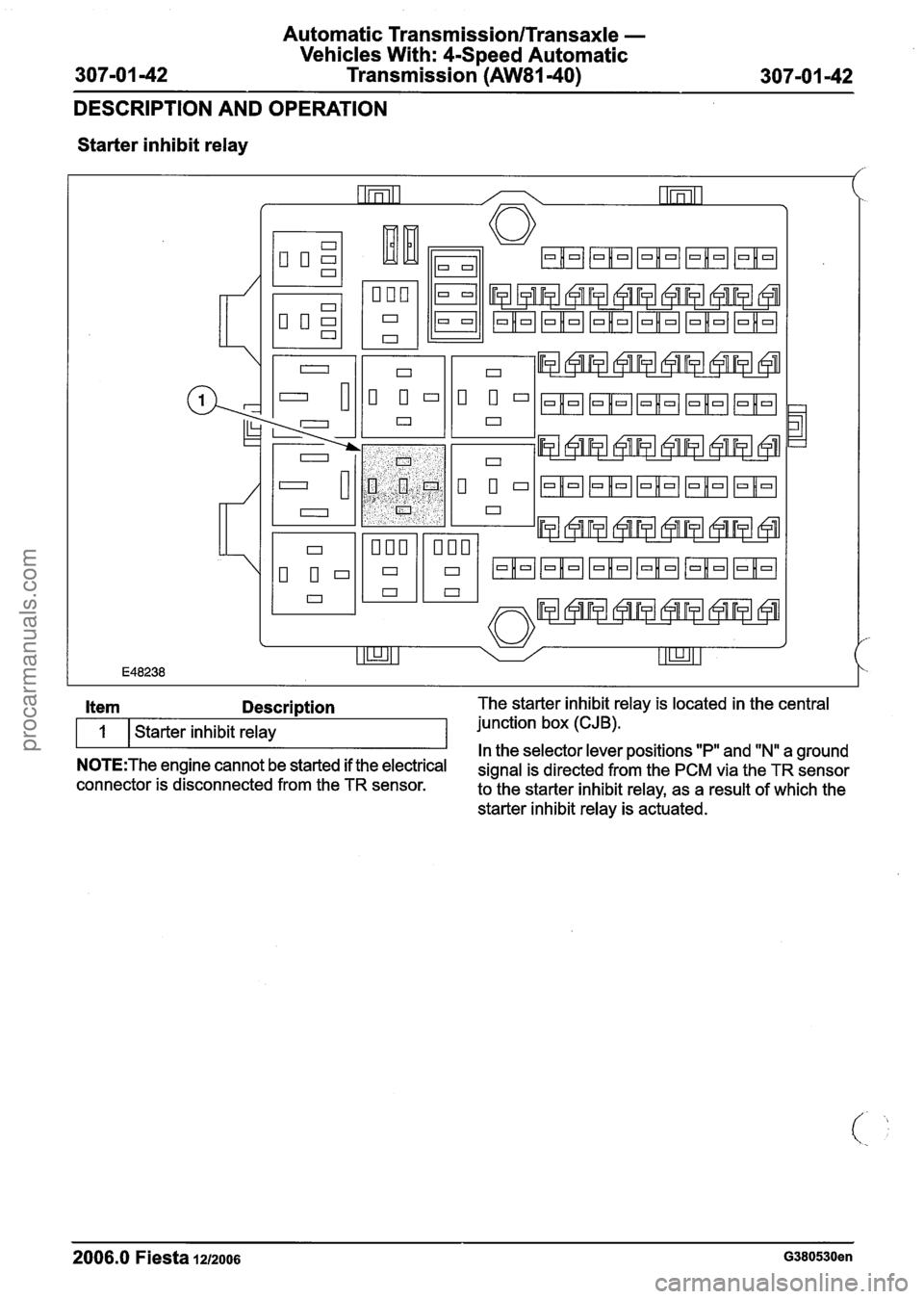

Starter inhibit relay

2006.0 Fiesta

12/2006 G380530en

Item Description The starter inhibit relay is located in the central

1 Starter inhibit relay junction

box (CJB).

In the selector lever positions "P" and "Nu a ground N0TE:The engine cannot be started if the electrical signal is directed from the PCM via the TR sensor connector is disconnected from the TR sensor.

to the starter inhibit relay, as a result of which the

starter inhibit relay is actuated.

procarmanuals.com

Page 1003 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -43 Transmission (AW81-40) 307-01 -43

DESCRIPTION AND OPERATION

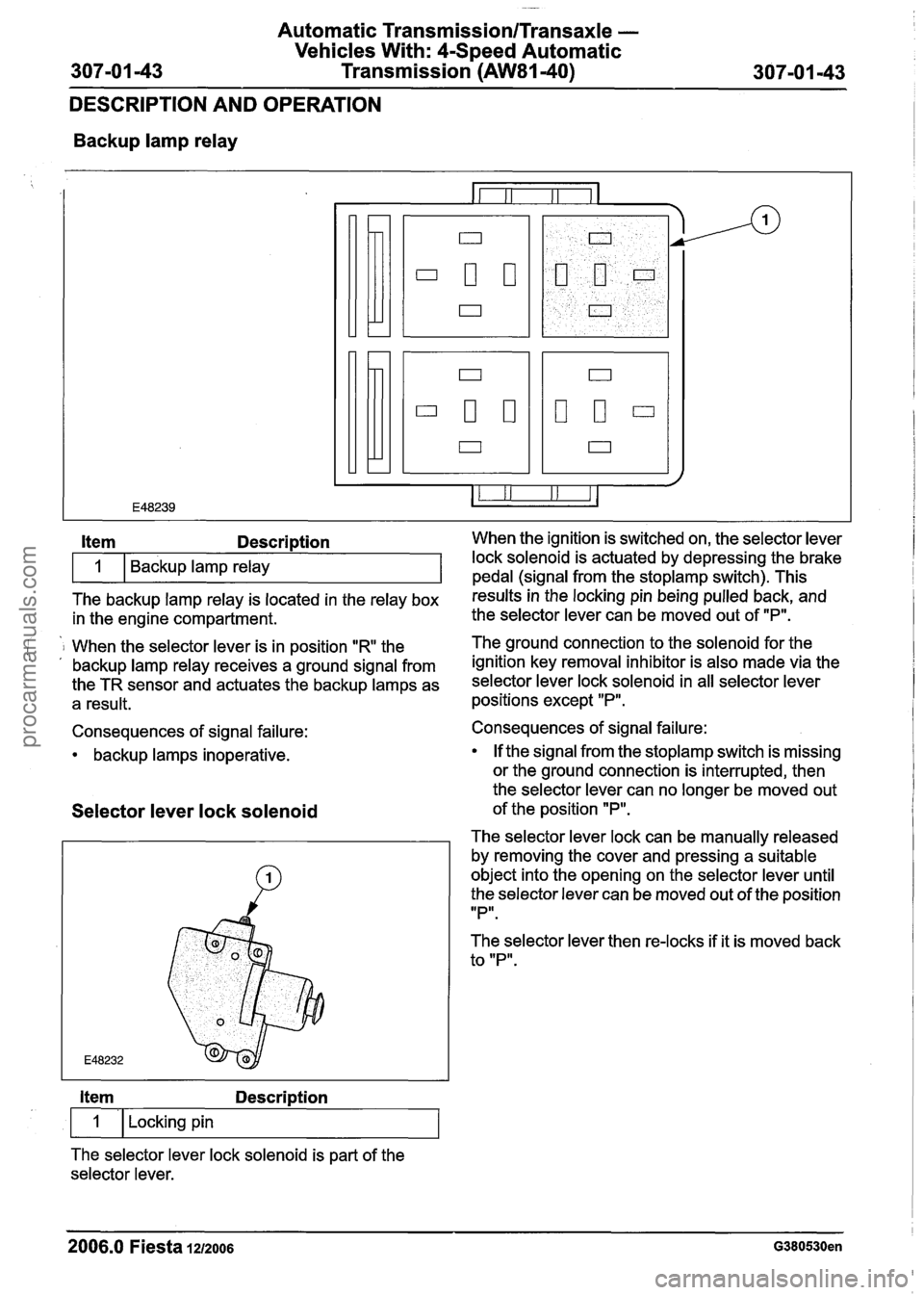

Backup lamp relay

The backup lamp relay is located in the relay box results inthe locking pin being pulled back, and

in the engine compartment. the

selector lever can be moved out of "P".

Item Description When the ignition is switched on, the selector lever

i 1 When the selector lever is in position "R the The ground connection to the solenoid for

the . , backup lamp relay receives a ground signal from ignition key removal inhibitor is also made via the

the TR sensor and actuates the backup lamps as selector lever lock solenoid in all selector lever

a result. positions except "P".

1

Consequences of signal failure:

backup lamps inoperative. Backup lamp relay

Selector

lever lock solenoid

lock solenoid is actuated by depressing the brake

pedal (sianal from the stoplamp switch). This

Item Description

1 I Locking pin

The selector lever lock solenoid is part of the

selector lever. Consequences of signal failure:

If the signal from the

stoplamp switch is missing

or the ground connection is interrupted, then

the selector lever can no longer be moved out

of the position

"P".

The selector lever lock can be manually released

by removing the cover and pressing a suitable

object into the opening on the selector lever until

the selector lever can be moved out of the position

IIPlr.

The selector lever then re-locks if it is moved back

to "P".

2006.0 Fiesta 1212006 G380530en

procarmanuals.com

Page 1006 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4Speed Automatic

307-01 -46 Transmission

(AW81-40) 307101 -46

DIAGNOSIS AND TESTING

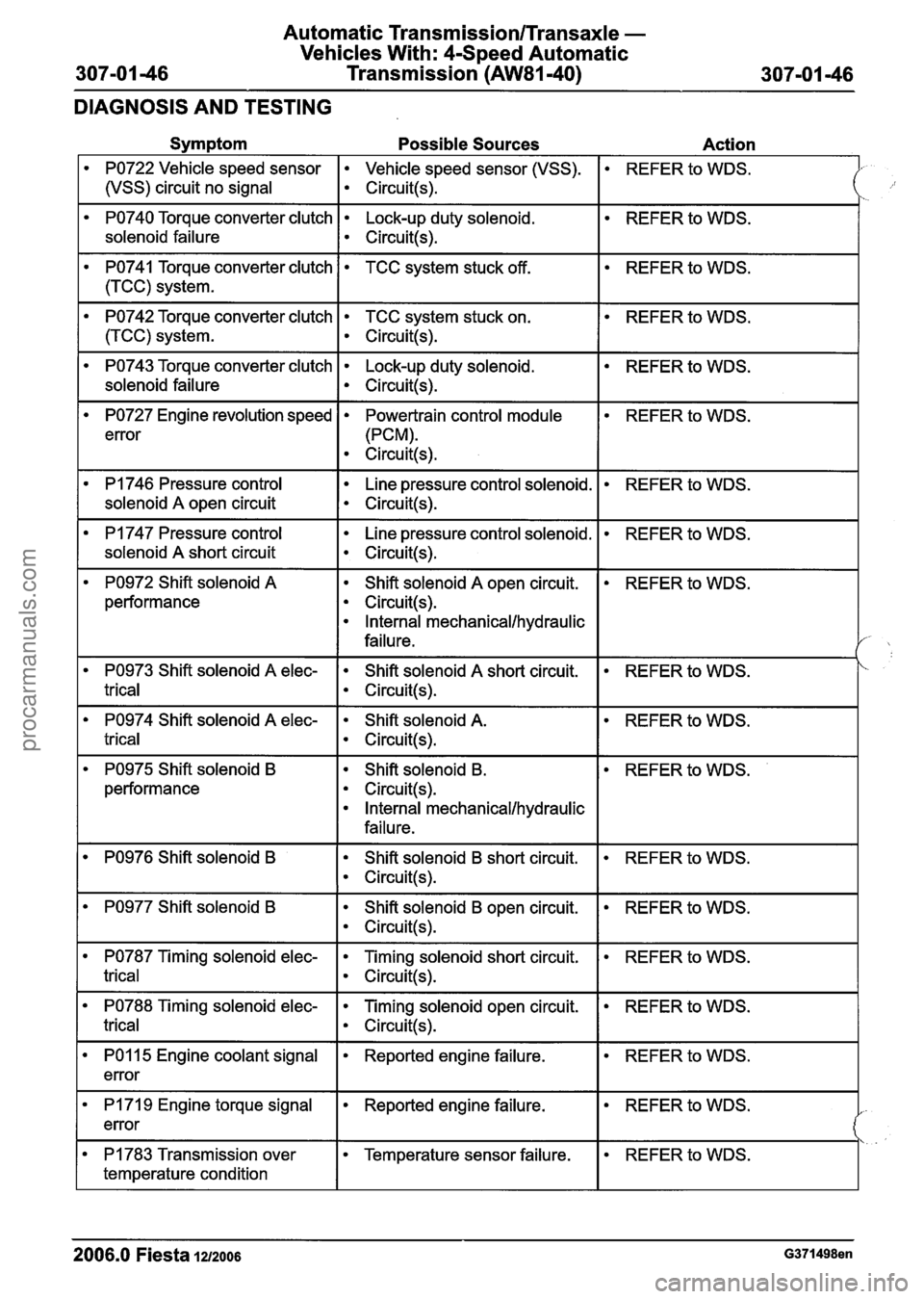

Symptom Possible Sources Action

PO722 Vehicle speed sensor Vehicle speed sensor (VSS).

1 (vSS) circuit no signal I circuit(+

REFER to WDS.

PO740 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I ~ircuit(s).

REFER to WDS.

REFER to WDS.

PO741 Torque converter clutch

1 (TCC) system.

PO742 Torque converter clutch TCC system stuck on.

I circuit(s).

TCC system stuck off.

REFER to WDS.

PO743 Torque converter clutch Lock-up duty solenoid.

solenoid failure

I circuit(s).

REFER to WDS.

REFER to WDS.

PO727 Engine revolution speed

error

PI 746 Pressure control

I solenoid A open circuit

Powertrain control module

(PCM).

Circuit(s).

I

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PI 747 Pressure control

solenoid

A short circuit

Line pressure control solenoid.

Circuit(s).

REFER to WDS.

PO972 Shift solenoid A

performance Shift solenoid

A open

circuit.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER to WDS.

REFER to WDS.

PO974 Shift solenoid A elec- Shift solenoid A.

trical I circuit(!+

PO973 Shift solenoid A elec-

trical

REFER to WDS. Shift solenoid A short circuit.

Circuit(s).

PO975 Shift solenoid B

performance Shift solenoid

B.

Circuit(s).

Internal mechanical/hydraulic

failure.

REFER

to WDS.

PO976 Shift solenoid B Shift solenoid B short circuit.

Circuit(s).

REFER to WDS.

PO977 Shift solenoid B Shift solenoid B open circuit.

Circuit(s).

REFER to WDS.

PO787 Timing solenoid elec- Timing solenoid short circuit.

trical I circuit(s).

REFER to WDS.

REFER to WDS. PO788 Timing solenoid elec-

trical

-- - -

Timing solenoid open circuit.

Circuit(s).

REFER to WDS. PO1 15 Engine coolant signal

error Reported engine failure.

REFER to WDS. I PI 71 9 Engine torque signal

error Reported engine failure.

REFER to WDS. PI 783 Transmission over

temperature condition

2006.0 Fiesta 12/2006 G371498en

Temperature sensor failure.

procarmanuals.com

Page 1007 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 47 Transmission (AW81-40) 307-01 -47

DIAGNOSIS AND TESTING

Symptom Possible Sources Action

'

U2516 CAN bus off transmit

error

I 5750 Throttle open malfunction 1 . CAN bus. 1. REFER to WDS. I

CAN bus.

U1900 CAN Communication

bus fault error

Line Pressure Test

C1750 Accelerator pedal posi-

tion signal malfunction

. CAN bus.

CAUTIONS:

A Carry out the line pressure test before

carrying out the stall speed test.

If line

pressure is low at idle, do not carry out the

stall speed test or further transaxle damage

will occur.

Accelerator pedal position

sensor.

A Do not maintain wide open throttle (WOT)

in any range for more than five seconds.

REFER to WDS.

A After testing each of the following ranges

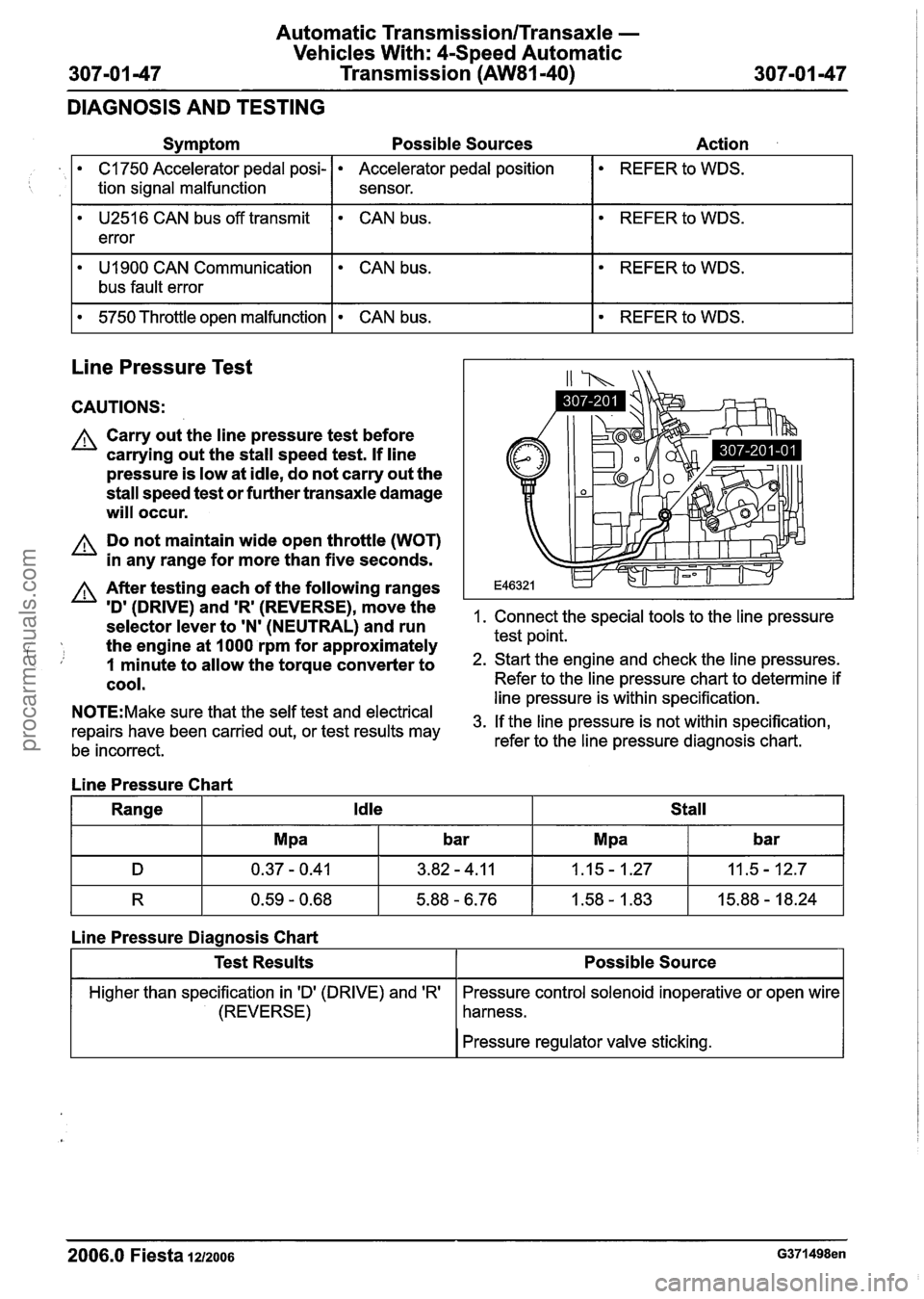

ID' (DRIVE) and 'R' (REVERSE)r move the 1. Connect the special tools to the line pressure selector lever to 'N' (NEUTRAL) and run

the engine at

I000 rpm for approximately test point.

i, 1 minute to allow the torque converter to 2. Start the engine and check the line pressures.

cool. Refer to the line pressure chart to determine if -- --- line pressure is within specification. N0TE:Make sure that the self test and electrical 3m If the line pressure is not within specification, repairs have been carried out, or test results may

be incorrect. refer to the

line pressure diagnosis chart.

Line Pressure Chart

Range

Idle Stall

R 0.59 - 0.68 5.88 - 6.76 1.58 - 1.83 15.88 - 18.24

Line Pressure Diagnosis Chart

I I Pressure regulator valve sticking. I

Test Results

Higher than specification in 'D' (DRIVE) and 'R'

(REVERSE)

2006.0 Fiesta 1212006 G371498en

Possible Source

Pressure control solenoid inoperative or open wire

harness.

procarmanuals.com

Page 1008 of 1226

Automatic TransmissionlTransaxle -

Vehicles With: 4-Speed Automatic

307-01 -48 Transmission (AW81-40) 307-01 -48

DIAGNOSIS AND TESTING

Stall Speed Test

This test checks the operation of the following

components:

1

Test Results

Lower than specification in 'Dl (DRIVE) and 'R'

(REVERSE)

Lower than specification in

'Dl (DRIVE)

Lower than specification in

'R' (REVERSE)

torque converter

forward clutch

low one way clutch assembly

engine performance

Possible Source

Pressure control solenoid inoperative or open wire

harness.

Pressure regulator valve sticking.

Worn oil pump.

Oil strainer blocked.

Fluid leak from each clutch hydraulic circuit.

Drive hydraulic circuit failure.

Forward clutch failure.

Reverse hydraulic circuit failure. Reverse clutch failure.

First and reverse brake failure.

WARNINGS:

A Do not maintain wide open throttle (WOT)

in any range for more than five seconds.

A If the engine speed (rpm) recorded by the

tachometer exceeds maximum specified

rpm, release the accelerator pedal

immediately. Clutch or band slippage is

indicated.

N0TE:The stall speed test should be carried out

with the engine and transaxle at normal operating

temperatures (50°C to 80°C).

A Apply the parking brake firmly while N0TE:Prolonged use of this procedure may set

carrying out each stall test. DTC PO71 2. After carrying out the stall speed test,

A Apply the foot brake firmly while carrying run the OBD test and clear the DTCs.

out each stall test. I. Connect a tachometer to the engine.

CAUTIONS:

A Always carry out the line pressure test

before carrying out the stall speed test. If

the line pressure is low at idle, do not carry

out the stall speed test or further transaxle

damage will occur.

A After testing each of the following ranges

'D'

(DRIVE) and 'R' (REVERSE), move the

selector lever to

'N' (NEUTRAL) and run

the engine at 1000 rpm for approximately

one minute to allow the torque converter

to cool.

2. Press the accelerator pedal to the floor WOT in

each selected range. Record the rpm reached

in each selected range and refer to the stall

speed chart.

3. If the stall speed is not within specification, refer

to the stall speed diagnosis chart.

Stall S~eed Chart

I Engine 1.6L I Speed (rpm) I

I 'Dl (DRIVE) I 2500 2 150 1

'R' (REVERSE) 2420 +, 150 -

Stall

Speed Diagnosis Chart

2006.0 Fiesta 1212006 G371498en

Test Results

Lower than specification in ID' (DRIVE) and 'R'

(REVERSE)

Possible Source

Low engine power.

Torque converter one-way clutch failure.

procarmanuals.com

Page 1009 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 49 Transmission (AW81-40) 307-01 -49

DIAGNOSIS AND TESTING

Test Results

Higher than specification in 'Dl (DRIVE)

Higher than specification in

'R' (REVERSE)

Lower than specification in 'D' (DRIVE)

Lower than specification in

'R' (REVERSE)

Possible Source

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Forward clutch failure (slipping).

One-way clutch No.2 failure.

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Reverse clutch failure (slipping).

First and reverse brake failure (slipping).

Drive hydraulic circuit failure.

Forward clutch failure.

Pressure control solenoid inoperative.

Pressure regulator valve sticking.

Worn oil pump.

Oil strainer blocked.

Fluid leak from each clutch hydraulic circuit.

( Time Lag Test 1. Using a suitable stop watch, measure the time

lag three times and calculate the average time.

Time lag is the time between moving the selector Record the

time lag and refer to the time lag

lever from

IN' (NEUTRAL) to ID' (DRIVE) or IN' chart.

(NEUTRAL) to 'R' (REVERSE). With the parking 2. If the time lag is not within specification, refer

brake applied the vehicle must not move if the

to the time lag diagnosis chart.

selector lever is moved from 'N' (NEUTRAL) to

ID'

(DRIVE) or 'N' (NEUTRAL) to 'R' (REVERSE). Time Lag Chart

Drive is engaged when the vehicle starts to rise.

A WARN1NG:Apply the parking brake firmly IN' (NEUTRAL) to ID' while carrying out each test. 1 (DRIVE)

(NEUTRAL) and run the engine at 1000 rpm

for approximately

1 minute to allow the

torque converter to cool.

less than 1.0 seconds

CAUTI0N:After testing each of the

following ranges

'D' (DRIVE) and 'R'

Range

I Lower than specification in IN' (NEUTRAL) to 'Dl I Pressure control solenoid inoperative.

Ti me

(REVERSE), move the selector lever to 'N'

'N' (NEUTRAL) to 'R'

(REVERSE)

Time Lag Diagnosis Chart

(DRIVE) less

than 1.2 seconds

Test Results

Pressure regulator valve sticking.

Forward clutch failure (slipping).

Possible Source

I Timing solenoid failure.

I I Drive hydraulic circuit failure. I

2006.0 Fiesta IZIZOO~ G371498en

procarmanuals.com

Page 1011 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -51 Transmission (AW81-40) 307-01 -51 -

GENERAL PROCEDURES

~ransmission Fluid Level Check

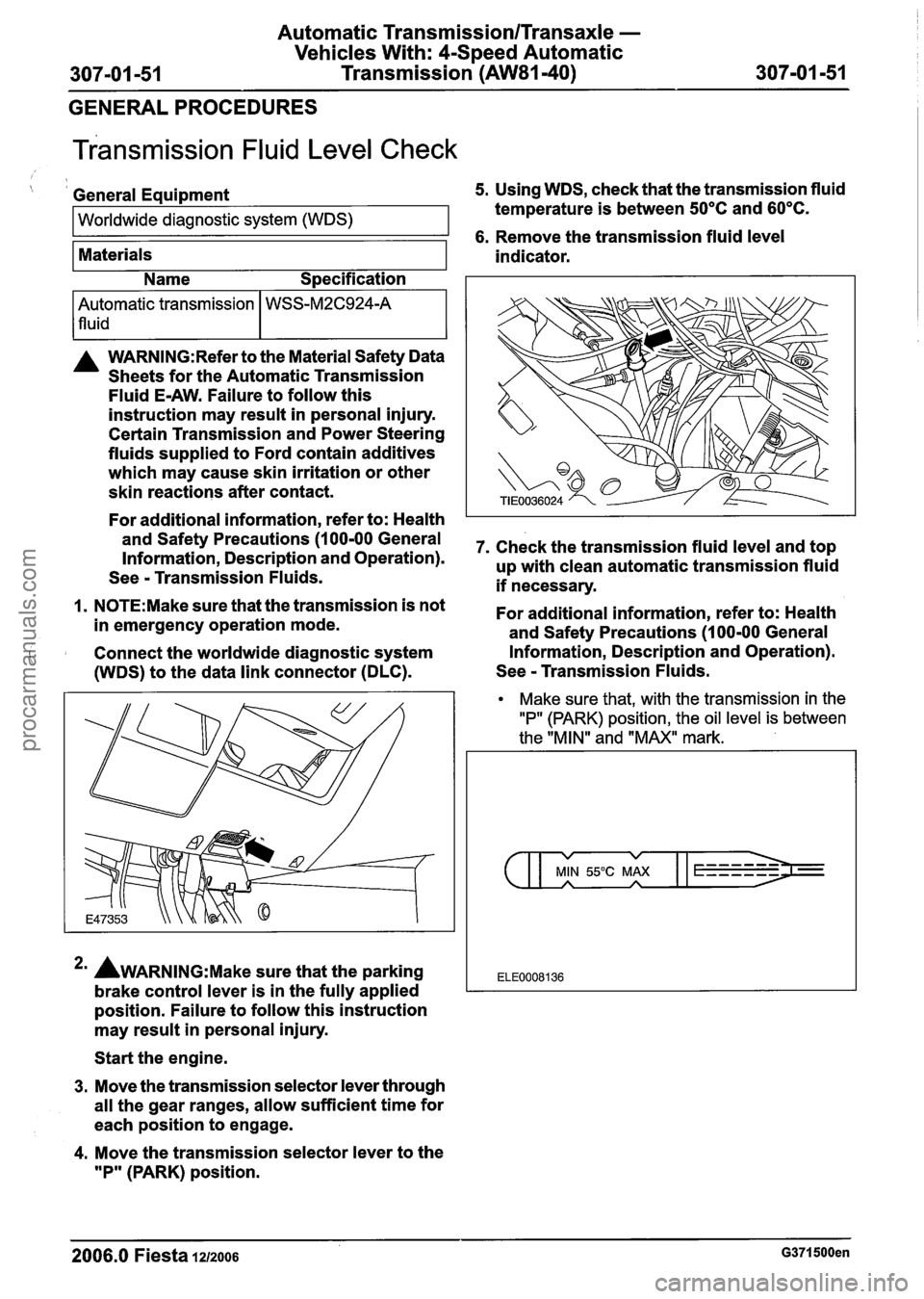

( I General Equipment 5. Using WDS, check that the transmission fluid

Worldwide diagnostic system (WDS) temperature is between 50°C and 60°C.

1 6. Remove the transmission fluid level

Materials

A WARN1NG:Refer to the Material Safety Data

Sheets for the Automatic Transmission

Fluid

E-AW. Failure to follow this

instruction may result in personal injury.

Certain Transmission and Power Steering

fluids supplied to Ford contain additives

which may cause skin irritation or other

skin reactions after contact.

For additional information, refer to: Health

and Safety Precautions (1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

1. N0TE:Make sure that the transmission is not

in emergency operation mode.

Connect the worldwide diagnostic system

(WDS) to the data link connector (DLC). indicator.

Automatic transmission

lfluid

*' AWARNING:M~~~ sure that

the parking

brake control lever is in the fully applied

position. Failure to follow this instruction

may result in personal injury.

Name

Specification

WSS-M2C924-A

Start the engine.

3. Move the transmission selector lever through

all the gear ranges, allow sufficient time for

each position to engage.

4. Move the transmission selector lever to the

"P" (PARK) position. 7.

Check the transmission fluid level and top

up with clean automatic transmission fluid

if necessary.

For additional information, refer to: Health

and Safety Precautions (1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids.

Make sure that, with the transmission in the

"P" (PARK) position, the oil level is between

the "MIN" and "MAX" mark.

v v

MIN 55°C MAX A A

ELE0008136

2006.0 Fiesta 1212006 G371500en

procarmanuals.com

Page 1012 of 1226

Automatic Transmission/Transaxle -

Vehicles With: CSpeed Automatic

307-01 -52 Transmission (AW81-40) 307-01 -52

GENERAL PROCEDURES

8. Install the transmission fluid level indicator.

9. Switch the engine off.

10. Disconnect the WDS from the DLC.

2006.0 Fiesta 1212006 G371500en

procarmanuals.com

Page 1022 of 1226

Automatic Transmission/Transaxle -

Vehicles With: 4-Speed Automatic

307-01 -62 Transmission (AW81-40) 307-01 -62

REMOVAL AND INSTALLATION

Transaxle

Special Tool(s)

I I Separator, Ball Joint

Support Bar, Engine

303-290A

Adapter for 303-290A

303-290-01 (21 -1 40-01

)

General Eaui~ment

I Securing strap I

General Equipment

Transmission jack

I Worldwide diagnostic system (WDS) I

Materials

Name S~ecification

1 Grease I WSD-MI C230-A I

Removal

A WARN1NG:Refer to the Material Safety Data

Sheets for the Automatic Transmission

Fluid E-AW. Failure to follow this

instruction may

result in personal injury.

Certain Transmission and Power Steering

fluids supplied to Ford contain additives

which may cause skin irritation or other

skin reactions after contact.

For

additional information, refer to: Health

and Safety Precautions (1 00-00 General

Information, Description and Operation).

See

- Transmission Fluids. f

1. Remove the air cleaner. \.

For additional information, refer to: Air

Cleaner - 1.25L Duratec-1 6V (Sigma)/ln4L

Duratec-1 6V (Sigma)ll .6L Duratec-1 6V

(Sigma) (303-12 Intake Air Distribution and

Filtering, Removal and Installation).

2. Disconnect the powertrain control module

(PCM) electrical connector.

For

additional information, refer to:

Powertrain

Control Module (PCM) - 1.25L

Duratec-1 6V (Sigma)ll.4L Duratec-1 6V

(Sigma)ll .6L Duratec-1 6V (Sigma) (303-1 4

Electronic Engine Controls, Removal and

Installation).

3. Remove the battery tray.

For

additional information, refer to: Battery

Tray (41 4-01 Battery, Mounting and

Cables,

Removal and Installation).

2006.0 Fiesta 1212006 G371506en

procarmanuals.com