head FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 27 of 1226

100-00-1 1 General Information 100-00-1 1

DESCRIPTION AND OPERATION

First Aid

Apart from meeting any legal requirements it is

desirable for someone in the workshop to be

trained in First Aid procedures.

Splashes in the eye should be flushed carefully

with clean water for at least ten minutes.

Soiled skin should be washed with soap and water.

In case of cold burns, from alternative fuels, place

affected area in cool to cold water.

Individuals affected by inhalation of gases and

fumes should be removed to fresh air immediately.

If effects persist, consult a doctor.

If liquids are swallowed inadvertently, consult a

doctor giving him the information on the container

or label. Do not induce vomiting unless this action

is indicated on the label.

Fluoroelastomer

See Viton.

Foams - Polyurethane

See also Fire.

Used in sound and noise insulation. Cured foams

used in seat and trim cushioning.

Follow manufacturers instructions.

Unreacted components are irritating and may be

harmful to the skin and eyes. Wear gloves and

goggles.

Individuals with chronic respiratory diseases,

asthma, bronchial medical problems, or histories

of allergic diseases should not work in or near

uncured materials.

The components, vapors or spray mists can cause

direct irritation, sensitivity reactions and may be

toxic or harmful.

Vapors and spray mists must not be inhaled. These

materials must be applied with adequate ventilation

and respiratory protection. Do not remove the

respirator immediately after spraying; wait until the

vapors/mists have cleared.

Burning of the uncured components and the cured

foams can generate toxic and harmful fumes.

Smoking, naked flames or the use of electrical

equipment during foaming operations and until

vapors/mists have cleared should not be allowed.

Any heat cutting of cured foams or partially cured foams

should be conducted with extraction

ventilation. See also the vehicle Body Repair

Manual.

Freon

See Air Conditioning Refrigerant.

Fuels

See also, Fire, Legal Aspects, Chemicals and

Solvents.

Avoid skin contact with fuel where possible. Should

contact occur, wash the affected skin with soap

and water.

Gasoline (Petrol)

Highly flammable - observe No Smoking policy.

Swallowing can result in mouth and throat irritation

and absorption from the stomach can result in

drowsiness and unconsciousness. Small amounts

can be fatal to children. Aspiration of liquid into the

lungs, through vomiting, is a very serious hazard.

Gasoline dries the skin and can cause irritation

and dermatitis on prolonged or repeated contact.

Liquid in the eye causes severe smarting.

Motor gasoline may contain appreciable quantities

of benzene, which is toxic upon inhalation, and the

concentration of gasoline vapors must be kept very

low. High concentrations will cause eye, nose and

throat irritation, nausea, headache, depression and

symptoms of drunkenness. Very high

concentrations will result in rapid loss of

CO~SC~OUS~~SS.

Make sure there is adequate ventilation when

handling and using gasoline. Great care must be

taken to avoid the serious consequences of

inhalation in the event of vapor build up arising

from spillages in confined spaces.

Special precautions apply to cleaning and

maintenance operations on gasoline storage tanks.

Gasoline should not be used as a cleaning agent.

It must not be siphoned by mouth. See First Aid.

Gasoil (Diesel Fuel)

Com busti ble.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 28 of 1226

100-00-12 General Information 100-00-12

DESCRIPTION AND OPERATION

Gross or prolonged skin contact with high boiling

point gas oils may also cause serious skin

disorders including skin cancer.

Kerosene (Paraffin)

Used also as heating fuel, solvent and cleaning

agent.

Flammable

- observe No Smoking policy.

Irritation of the mouth and throat may result from

swallowing. The main hazard from swallowing

arises if liquid aspiration into the lungs occurs.

Liquid contact dries the skin and can cause

irritation or dermatitis. Splashes in the eye may be

slightly irritating.

In normal circumstances the low volatility does not

give rise to harmful vapors. Exposure to mists and

vapors from kerosene at elevated temperature

should be avoided (mists may arise in dewaxing).

Avoid skin and eye contact and make sure there

is adequate ventilation.

Alternative Fuel

Highly flammable. Observe "NO SMOKING" signs.

Make sure there is adequate ventilation when

working on alternative fuelled vehicles. Great care

must be taken to avoid the serious consequences

of inhalation in the event of vapor build up in

confined spaces.

Inhalation in high concentrations may cause

dizziness, headache, nausea and loss of

co-ordination. Very high concentrations may result

in loss of consciousness.

Contact with liquefied petroleum gas (LPG) or

compressed natural gas (CNG) to the skin may

cause cold burns and frost bite.

Long sleeved cotton overalls, steel toe capped

safety boots and rubber neoprene gloves should

be worn during removal and installation of

LPGICNG fuel system components.

LPGICNG fuel leaks could cause a fire and be a

hazard to health that can lead to personal injury,

illness or even death.

If a leak is detected, under no circumstances

attempt to seal the leak by tightening the

unionlconnection until the fuel in the system or

component is depressurized. Once tightened the

system should be checked for integrity following

the specified procedures. If

the fuel tank is to be removed for service or repair

the fuel must be evacuated using dedicated

equipment and following the specified

procedures. (

Gas Cylinders

See also Fire.

Gases such as oxygen, acetylene, argon and

propane are normally stored in cylinders at

pressures of up to

138 bar (2000 psi) and great

care should be taken in handling these cylinders

to avoid mechanical damage to them or to the valve

gear attached. The contents of each cylinder

should be clearly identified by appropriate

markings.

Cylinders should be stored in well-ventilated

enclosures, and protected from ice and snow, or

direct sunlight. Fuel gases, for example acetylene

and propane, should not be stored in close

proximity to oxygen cylinders.

Care should be exercised to prevent leaks from

gas cylinders and lines, and to avoid sources of

ignition.

Only trained personnel should undertake work

involving gas cylinders.

Gases

See Gas Cylinders.

Gaskets (Fluoroelastomer)

See Viton.

General Workshop Tools and

Equipment

It is essential that all tools and equipment are

maintained in good condition and that the correct

safety equipment is used where required.

Never use tools or equipment for any purpose other

than that for which they were designed. Never

overload equipment such as hoists, jacks, axle and

chassis stands or

lifting slings. Damage caused by

overloading is not always immediately apparent

and may result in a fatal failure the next time that

the equipment is used.

2006.0 Fiesta 1212006 GI 7372en

procarmanuals.com

Page 31 of 1226

General Information

DESCRIPTION AND OPERATION

Two Pack

Can also contain harmful and toxic unreacted

resins and resin hardening agents. The

manufacturers instructions should be followed. See

also Resin-based Adhesives and

Isocyanate

Adhesives and Sealers under Adhesives and

Sealers.

Spraying should preferably be carried out in

exhausted ventilated booths removing vapor and

spray mists from the breathing zone. Individuals

working in booths should wear appropriate

respiratory protection. Those doing small-scale

repair work in the open workshop should wear

air-fed respirators.

Pressurized Equipment

See High Pressure Air, Lubrication and Oil Test

Equipment.

Solder

Solders are mixtures of metals such that the

melting point of the mixture is below that of the

constituent metals (normally lead and tin). Solder

application does not normally give rise to toxic lead

fumes, provided a

gaslair flame is used.

Oxy-acetylene flames should not be used, as they

are much hotter and will cause lead fumes to be

produced.

Some fumes may be produced by the application

of any flame to surfaces coated with grease, and

inhalation of these should be avoided.

Removal of excess solder should be undertaken

with care, to make sure that fine lead dust is not

produced, which can give toxic effects if inhaled.

Respiratory protection may be necessary.

Solder spillage and filings should be collected and

removed promptly to prevent general air

contamination by lead.

High standards of personal hygiene are necessary

in order to avoid ingestion of lead or inhalation of

solder dust from clothing.

Solvents

See also Chemical Materials, Fuels (Kerosene),

Fire.

For example acetone, white spirit, toluene, xylene,

trichloroethane.

2006.0 Fiesta 1212006

Used in cleaning and dewaxing materials, paints,

plastics, resins and thinners.

Some may be highly flammable or flammable.

Skin contact will degrease the skin and may result

in irritation and dermatitis following repeated or

prolonged contact. Some can be absorbed through

the skin in toxic or harmful quantities.

Splashes in the eye may cause severe irritation

and could lead to loss of vision.

Brief exposure of high concentrations of vapors or

mists will cause eye and throat irritation,

drowsiness, dizziness, headaches and, in the worst

circumstances, unconsciousness.

Repeated or prolonged exposure to excessive but

lower concentrations of vapors or mists, for which

there might not be adequate warning indications,

can cause more serious toxic or harmful effects.

Aspiration into the lungs, for example through

vomiting, is the most serious consequence of

swallowing.

Avoid splashes to the skin, eyes and clothing. Wear

protective gloves, goggles and clothing if

necessary.

Make sure there is good ventilation when in use,

avoid breathing fumes, vapors and spray mists and

keep containers tightly sealed. Do not use in

confined spaces.

When spraying materials containing solvents, for

example paints, adhesive, coatings, use extraction

ventilation or personal respiratory protection in the

absence of adequate general ventilation.

Do not apply heat or flame except under specific

and detailed manufacturers instructions.

Sound Insulation

See Fibre Insulation, Foams.

Suspended Loads

A CAUTI0N:Never improvise lifting tackle.

There is always a danger when loads are lifted or

suspended. Never work under an unsupported,

suspended or raised load, for example a

suspended engine.

Always make sure that lifting equipment such as

jacks, hoists, axle stands and slings are adequate

and suitable for the job, in good condition and

regularly maintained.

procarmanuals.com

Page 40 of 1226

100-00-24 General Information 100-00-24

DESCRIPTION AND OPERATION

- that the speedometer, coolant temperature - oil, coolant, hydraulic, air and fuel leaks.

gauge and tachometer (if equipped) register the - abnormal temperature of any moving

correct readings and operate correctly.

components or assemblies, for example wheel

(

- that the switches and controls operate smoothly hubs, transmission and axle, which might

and positively, warning and indicator lamps

indicate over tightness or lack of lubrication.

operate correctly and the direction indicator

control self cancels when the steering is

returned to the straight ahead position.

- that the heating and ventilation systems operate

correctly and effectively.

- the brake operation and efficiency.

Brake Testing

A WARNING:When brake testing, avoid

breathing the fumes from hot brakes, this

may contain asbestos dust which is

hazardous to health. Failure to follow this

instruction may result in personal injury.

For additional information, refer to: Health

and Safety Precautions

(1 00-00 General

Information, Description and Operation).

CAUTIONS:

A Avoid brake testing on busy roads where

it may cause inconvenience or danger to

other road users.

A Brake testing which includes heavy brake

applications should not be carried out with

new brake

padsldiscs or liningsldrums

until the components have bedded-in. New

brake friction components will not reach

full efficiency until the bedding-in process

is complete.

Test the brakes at several speeds within the normal

operating range using both light and heavy pedal

pressure. Note any tendency to snatch, pull or

drag, and any undue delay in application or

release.

Allow the vehicle to coast and note any tendency

to pull to one side, or evidence that the brakes are

binding.

After stopping the vehicle (not immediately after a

period of heavy braking), carefully check the brake

temperature.

A brake disc or brake drum that feels

hot or is appreciably hotter than the others,

indicates that the brake is binding.

After completion of the test, check for:

2006.0 Fiesta 1212006 GI 7375en

procarmanuals.com

Page 101 of 1226

204-01 -3 Front Suspension 204-01 -3

DESCRIPTION AND OPERATION

Front Suspension

Overview

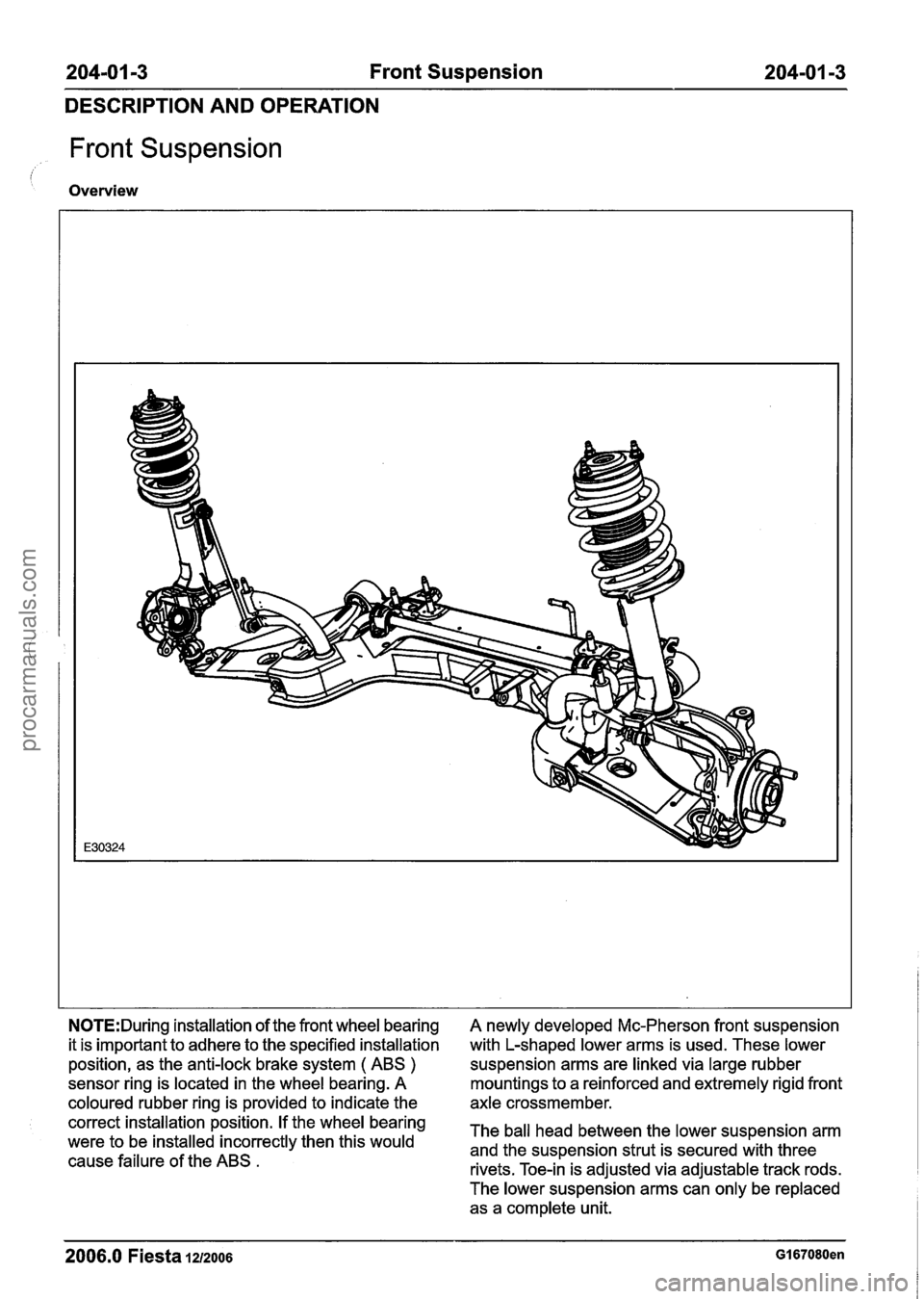

N0TE:During installation of the front wheel bearing

it is important to adhere to the specified installation

position, as the anti-lock brake system

( ABS )

sensor ring is located in the wheel bearing. A

coloured rubber ring is provided to indicate the

correct installation position. If the wheel bearing

were to be installed incorrectly then this would

cause failure of the ABS

.

A newly developed Mc-Pherson front suspension

with L-shaped lower arms is used. These lower

suspension arms are linked via large rubber

mountings to a reinforced and extremely rigid front

axle crossmember.

The ball head between the lower suspension arm

and the suspension strut is secured with three

rivets. Toe-in is adjusted via adjustable track rods.

The lower suspension arms can only be replaced as a complete unit.

2006.0 Fiesta IZIZOO~ GI 67080en

procarmanuals.com

Page 107 of 1226

204-01 -9 Front Suspension 204-0 I -9

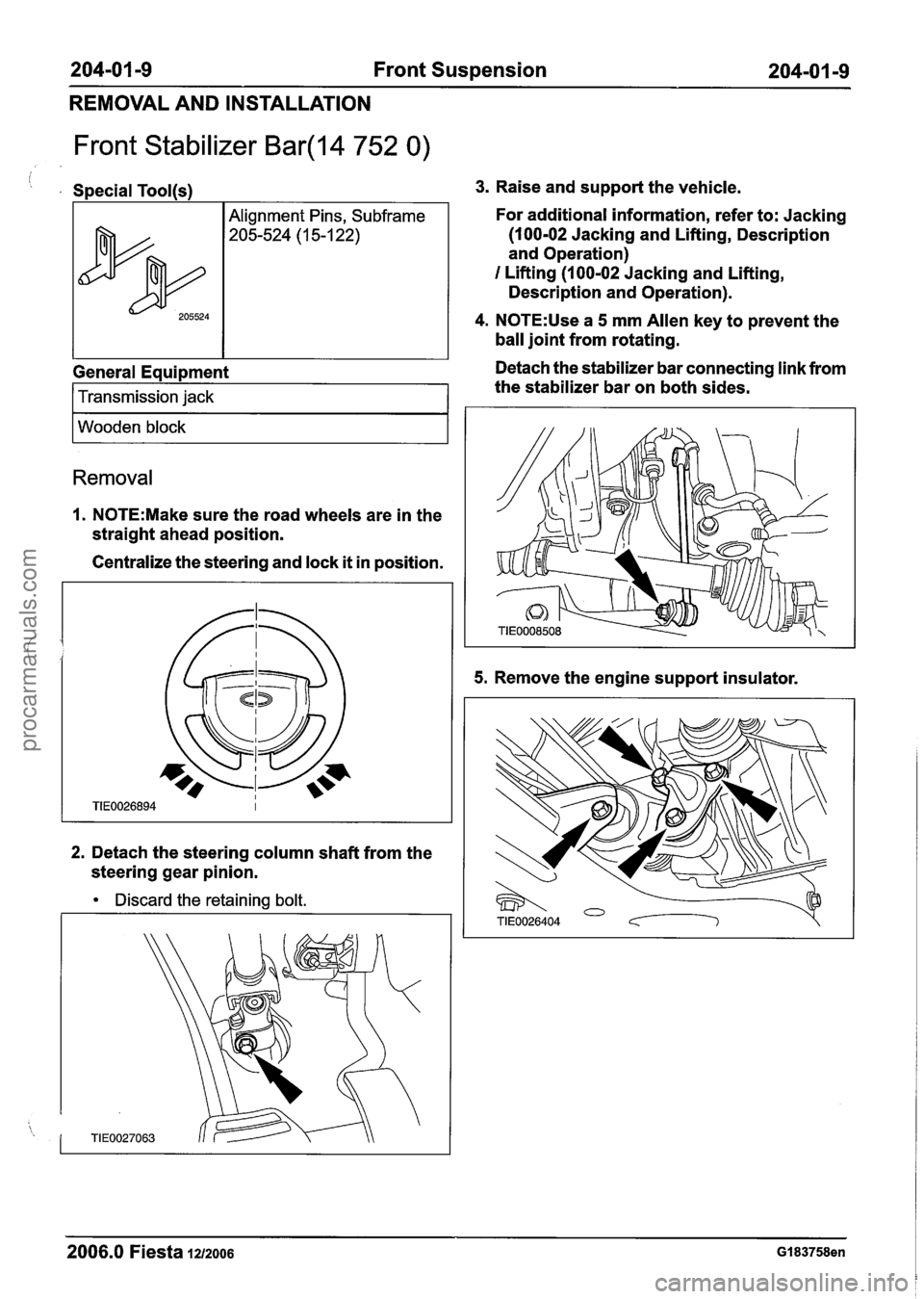

REMOVAL AND INSTALLATION

Front Stabilizer Bar(l4 752 0)

i , Special Tool(s1

General Equipment

205524

I Transmission jack 1

Alignment Pins, Subframe

205-524 (1 5-1 22)

I Wooden block I

Removal

1. N0TE:Make sure the road wheels are in the

straight ahead position.

Centralize the steering and lock

it in position.

2. Detach the steering column shaft from the

steering gear pinion.

Discard the retaining bolt.

3. Raise and support the vehicle.

For additional information, refer to: Jacking

(100-02 Jacking and Lifting, Description

and Operation)

I Lifting (1 00-02 Jacking and Lifting,

Description and Operation).

4. N0TE:Use a 5 mm Allen key to prevent the

ball joint from rotating.

Detach the stabilizer bar connecting link from

the stabilizer bar on both sides.

5. Remove the engine support insulator.

2006.0 Fiesta 1212006 GI 83758en

procarmanuals.com

Page 267 of 1226

206-0713 Power Brake Actuation 206-0713

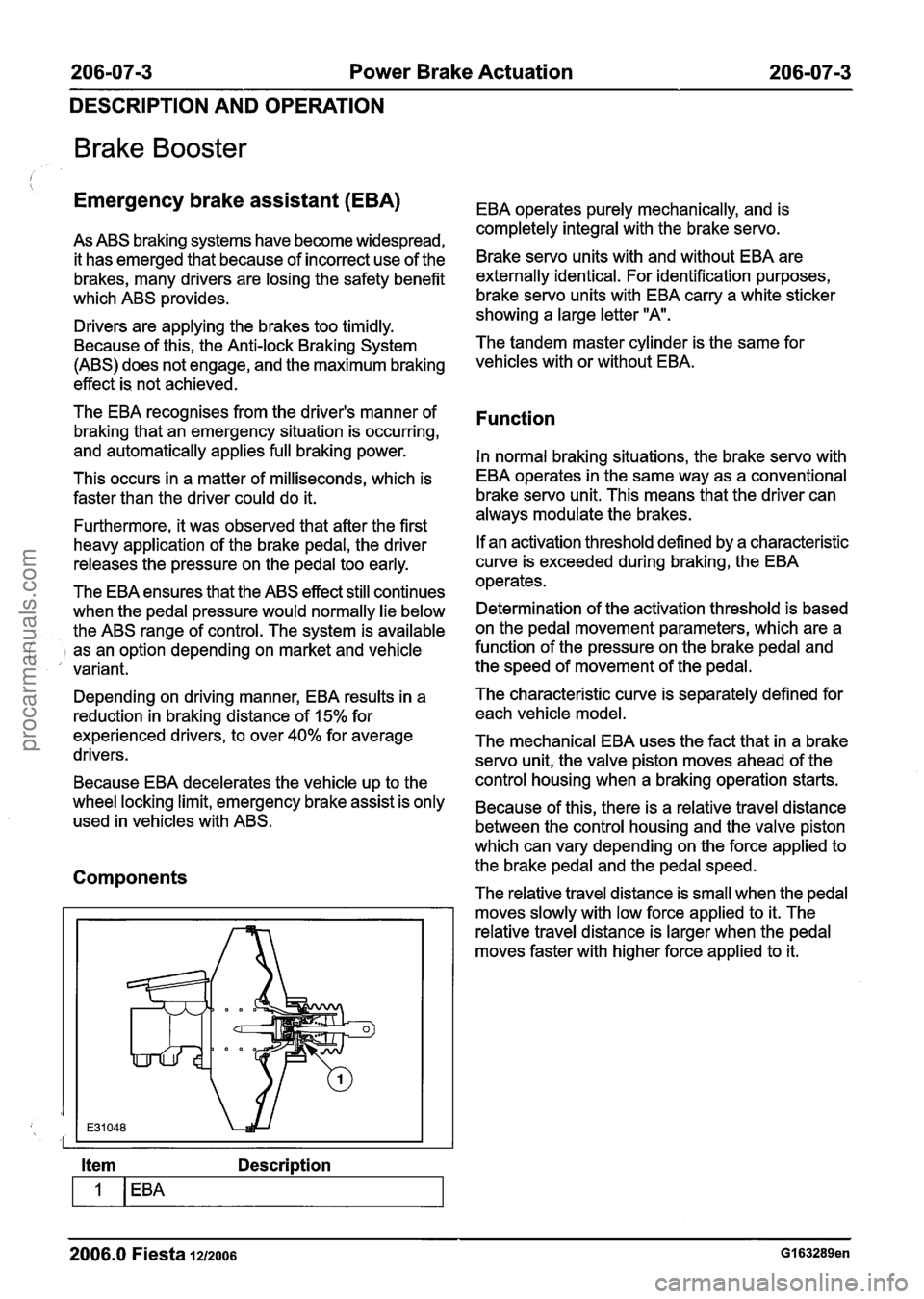

DESCRIPTION AND OPERATION

Brake Booster

Emergency brake assistant (EBA) EBA operates purely mechanically, and is

completely integral with the brakeservo.

As ABS braking systems have become widespread,

it has emerged that because of incorrect use of the

Brake servo units with and without EBA are

brakes, many drivers are losing the safety benefit externally identical. For identification purposes,

which ABS

~rovides. brake servo units with EBA carry a white sticker I showing a large letter "A. Drivers are applying the brakes too timidly.

Because of this, the Anti-lock Braking System The tandem master cylinder

is the same for

(ABS) does not engage, and the maximum braking

vehicles with or without

effect is not achieved.

The EBA recognises from the driver's manner of

braking that an emergency situation is occurring,

and automatically applies full braking power.

This occurs in a matter of milliseconds, which is

faster than the driver could do it.

Furthermore, it was observed that after the first

heavy application of the brake pedal, the driver

releases the pressure on the pedal too early.

The EBA ensures that the ABS effect still continues

when the pedal pressure would normally lie below

the ABS range of control. The system is available

j as an option depending on market and vehicle

variant.

Function

In normal braking situations, the brake servo with

EBA operates in the same way as a conventional

brake servo unit. This means that the driver can

always modulate the brakes.

If an activation threshold defined by a characteristic

curve is exceeded during braking, the EBA

operates.

Determination of the activation threshold is based

on the pedal movement parameters, which are a

function of the pressure on the brake pedal and

the speed of movement of the pedal.

Depending on driving manner, EBA results in a The characteristic curve

is separately defined for

reduction in braking distance of 15% for each vehicle model.

experienced drivers, to over

40% for average The mechanical EBA uses the fact that in a brake

drivers. servo unit, the valve piston moves ahead of the

Because EBA decelerates the vehicle up to the control housing

when a braking operation starts.

wheel locking limit, emergency brake assist is only Because of this, there is a relative travel distance used in vehicles with ABS.

between the control housing and the valve piston

which can vary depending on the force applied to

Components the brake pedal and the pedal speed.

The relative travel distance is small when the pedal

moves slowly with low force applied to it. The

relative travel distance is larger when the pedal

moves faster with higher force applied to it.

Item Description

-

2006.0 Fiesta 1212006 GI 63289en

procarmanuals.com

Page 283 of 1226

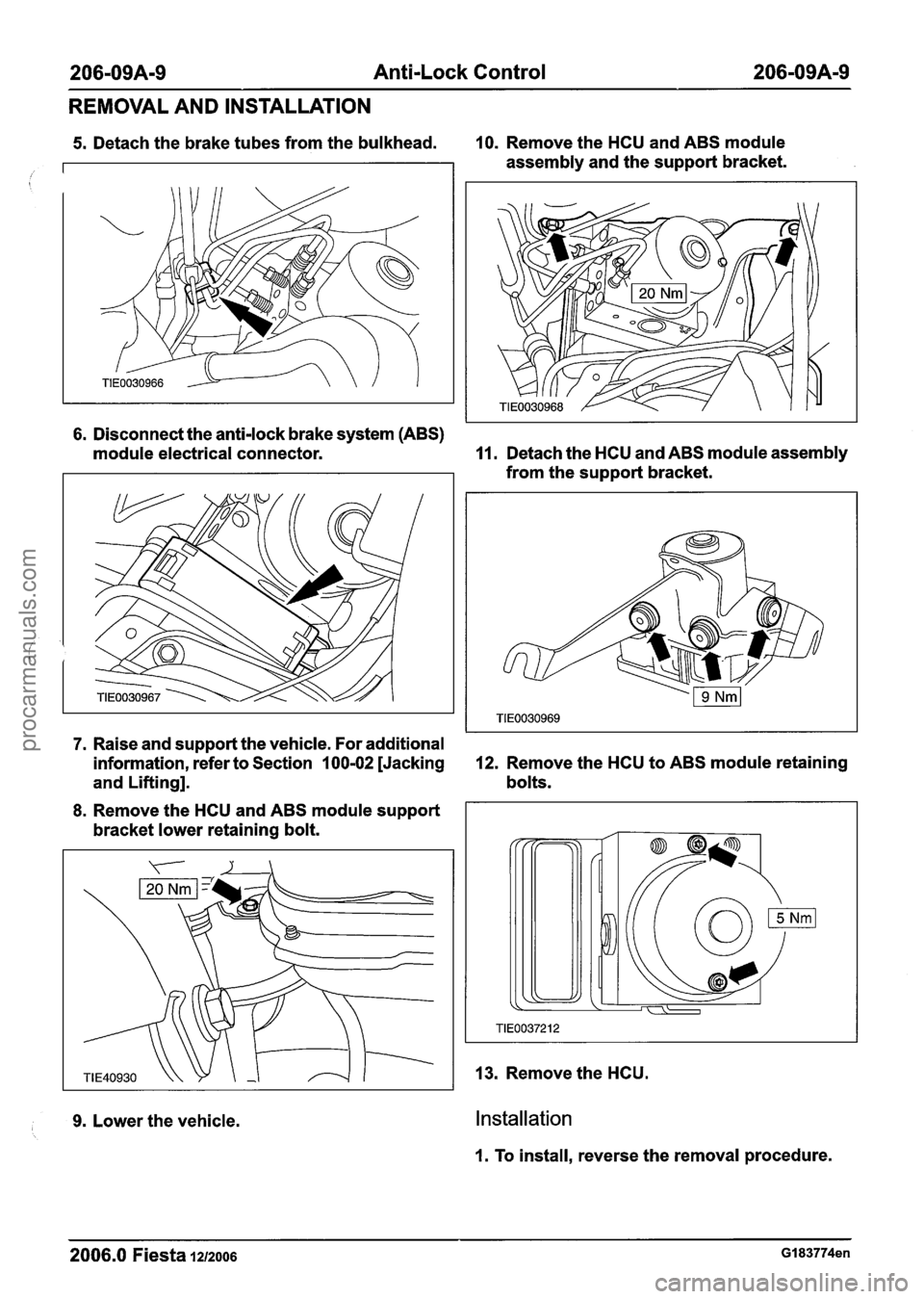

206-09A-9 Anti-Lock Control 206-09A-9

REMOVAL AND INSTALLATION

6. Disconnect the anti-lock brake system (ABS)

module electrical connector.

11. Detach the HCU and ABS module assembly

from the support bracket.

5. Detach the brake tubes from the bulkhead. 10. Remove the HCU and ABS module

7. Raise and support the vehicle. For additional

information, refer to Section

100-02 [Jacking 12. Remove the HCU to ABS module retaining

and Lifting]. bolts.

/

8. Remove the HCU and ABS module support

bracket lower retaining bolt. assembly

and the support bracket.

9. Lower the vehicle.

13. Remove the HCU.

Installation

1. To install, reverse the removal procedure.

2006.0 Fiesta 1212006 GI 83774en

procarmanuals.com

Page 286 of 1226

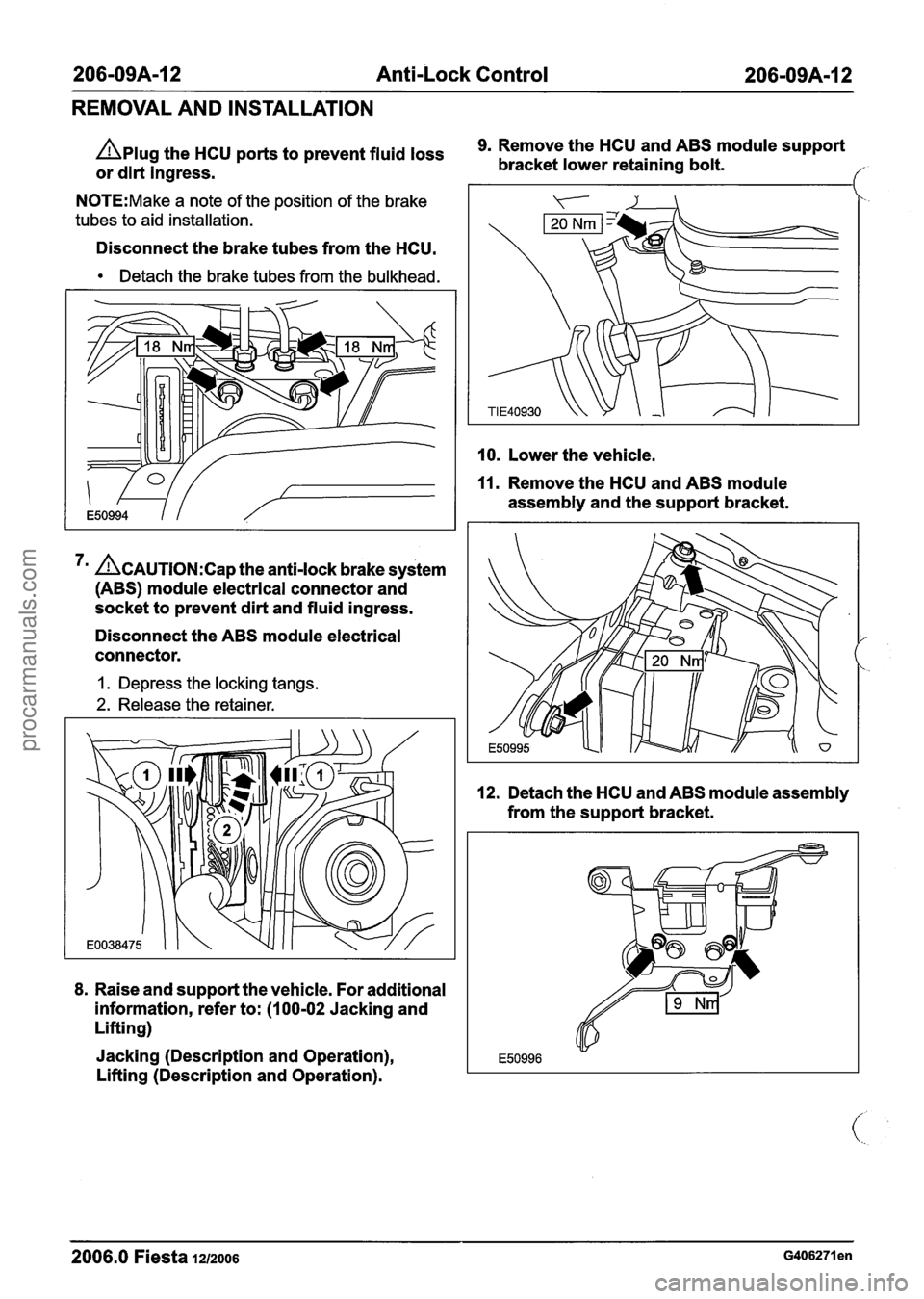

206-09A-I 2 Anti-Lock Control 206-0949-12

REMOVAL AND INSTALLATION

Aplug the HCU ports to prevent fluid loss

or dirt ingress.

N0TE:Make a note of the position of the brake

tubes to aid installation.

Disconnect the brake tubes from the HCU.

Detach the brake tubes from the bulkhead.

7m &AUTION:C~~ the anti-lock brake system

(ABS) module electrical connector and

socket to prevent dirt and fluid ingress.

Disconnect the ABS module electrical

connector.

I. Depress the locking tangs.

2. Release the retainer.

8.

Raise and support the vehicle. For additional

information, refer to: (100-02 Jacking and

Lifting)

Jacking (Description and Operation),

Lifting (Description and Operation).

9. Remove the HCU and ABS module support

bracket lower retaining bolt.

f

10. Lower the vehicle.

11. Remove the HCU and ABS module

assembly and the support bracket.

12. Detach the HCU and ABS module assembly

from the support bracket.

2006.0 Fiesta 1212006 ~406271 en

procarmanuals.com

Page 289 of 1226

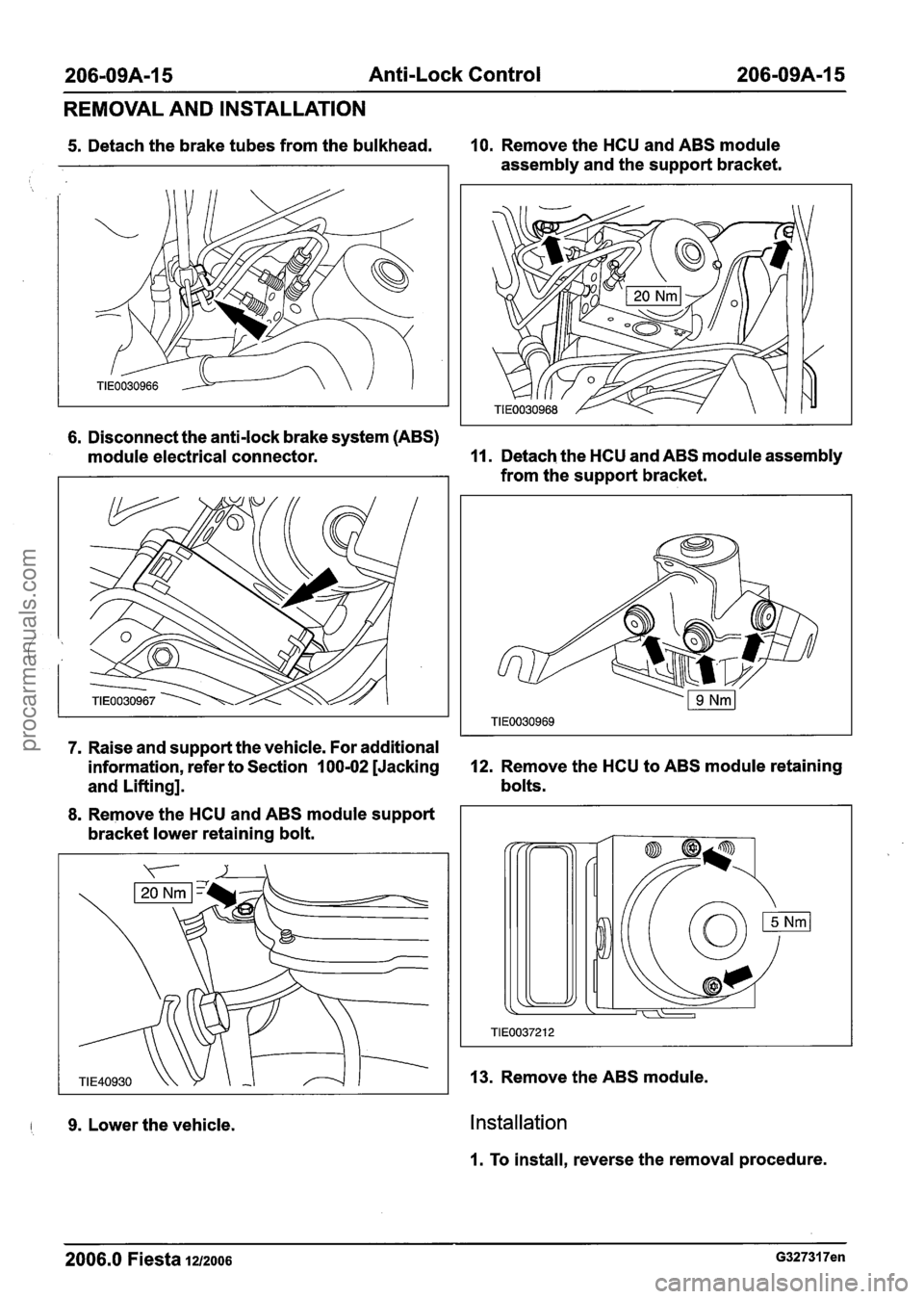

206-09A-I 5 Anti-Lock Control 206-09A-15

REMOVAL AND INSTALLATION

5. Detach the brake tubes from the bulkhead. 10. Remove the HCU and ABS module

assembly and the support bracket.

6. Disconnect the anti-lock brake system (ABS)

module electrical connector.

11. Detach the HCU and ABS module assembly

from the support bracket.

7. Raise and support the vehicle. For additional

information, refer to Section

100-02 [Jacking 12. Remove the HCU to ABS module retaining

and Lifting]. bolts.

8. Remove the HCU and ABS module support

bracket lower retaining bolt.

I 9. Lower the vehicle.

13. Remove the ABS module.

Installation

I. To install, reverse the removal procedure.

2006.0 Fiesta 1212006 G327317en

procarmanuals.com