key FORD FIESTA 2007 Workshop Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 2007, Model line: FIESTA, Model: FORD FIESTA 2007Pages: 1226, PDF Size: 61.26 MB

Page 35 of 1226

100-00-1 9 General Information 100-00-1 9

DESCRIPTION AND OPERATION

Standard Workshop Practices

Vehicle in Workshop

When working on a vehicle in the workshop always

make sure that:

- the parking brake is applied or the wheels are

securely chocked to prevent the vehicle moving

forwards or backwards.

- the key is removed from key operated hood

locks before any work is carried out around the

front of the vehicle.

- if the engine is to be run, there is adequate

ventilation, or an extraction hose to remove

exhaust fumes.

- there is adequate room to raise the vehicle and

remove the wheels, if necessary.

- fender covers are always fitted if any work is to

be carried out in the engine compartment.

- the battery is disconnected if working on the

engine, underneath the vehicle, or if the vehicle

is raised.

Alternative Fuel - Dons

- Do work on the vehicle in a designated area,

that is well ventilated and with access restricted

to qualified personnel only.

- Install new warning labels to their original

locations.

- If possible always isolate the alternative fuel

tank, and run the vehicle on the alternative fuel

until it automatically switches to its normal fuel

prior to taking the vehicle into the workshop

service area.

- Only use tested and approved components and

pipes when repairing or servicing

LPG and CNG

systems.

Alternative Fuel - Do Nots

- Do not vent off LPG fuel.

- Do not use shop air pressure to force LPG fuel

from the fuel tank.

( A CAUTION:When electric arc welding on a - Do not use paint drying ovens above 40°C for vehicle, always disconnect the generator any alternative fuel vehicle. LPG and CNG fuel wiring to prevent the possibility of a surge tanks must be removed from the vehicle prior of current causing damage to the internal to being put into paint drying ovens above 40°C. components of the generator. - Do not modify the system or install new - if using welding equipment on the vehicle, a

components that are not designed for gas

suitable fire extinguisher is readily available.

vehicles.

Alternative Fuel

A WARNING:When servicing the fuel system

always follow the recommended

procedures. Failure to follow these

instructions may result in personal injury.

If the odor of liquefied petroleum gas (LPG) or

compressed natural gas

(CNG) is present in the

air in the workshop, warn all persons in the area

to:

- extinguish all flames and lighted tobacco.

- shut off electrical and air powered equipment.

- evacuate the area.

- ventilate the area.

- contact the fire control authorities.

- remove the vehicle to a dedicated, ventilated

area.

- Do not evacuate fuel tanks unless there is repair

that requires the removal of the fuel tank.

- Do not work on the fuel lines or system

components unless the alternative fuel has been

evacuated and the pressure in the system

reduced to atmospheric or less.

- Do not use anything other than the specified

leak detector fluid to trace fuel leaks.

Be aware of situations that may cause the

LPG or I

CNG fuel system to vent off fuel, such as: I

- extremely hot days.

- parking by a space heater.

- hoisting a vehicle up near a ceiling heater.

Only fully trained personnel, who are conversant

with local standards, are to work on alternative fuel

vehicles.

2006.0 Fiesta 1212006 GI 7373en

procarmanuals.com

Page 107 of 1226

204-01 -9 Front Suspension 204-0 I -9

REMOVAL AND INSTALLATION

Front Stabilizer Bar(l4 752 0)

i , Special Tool(s1

General Equipment

205524

I Transmission jack 1

Alignment Pins, Subframe

205-524 (1 5-1 22)

I Wooden block I

Removal

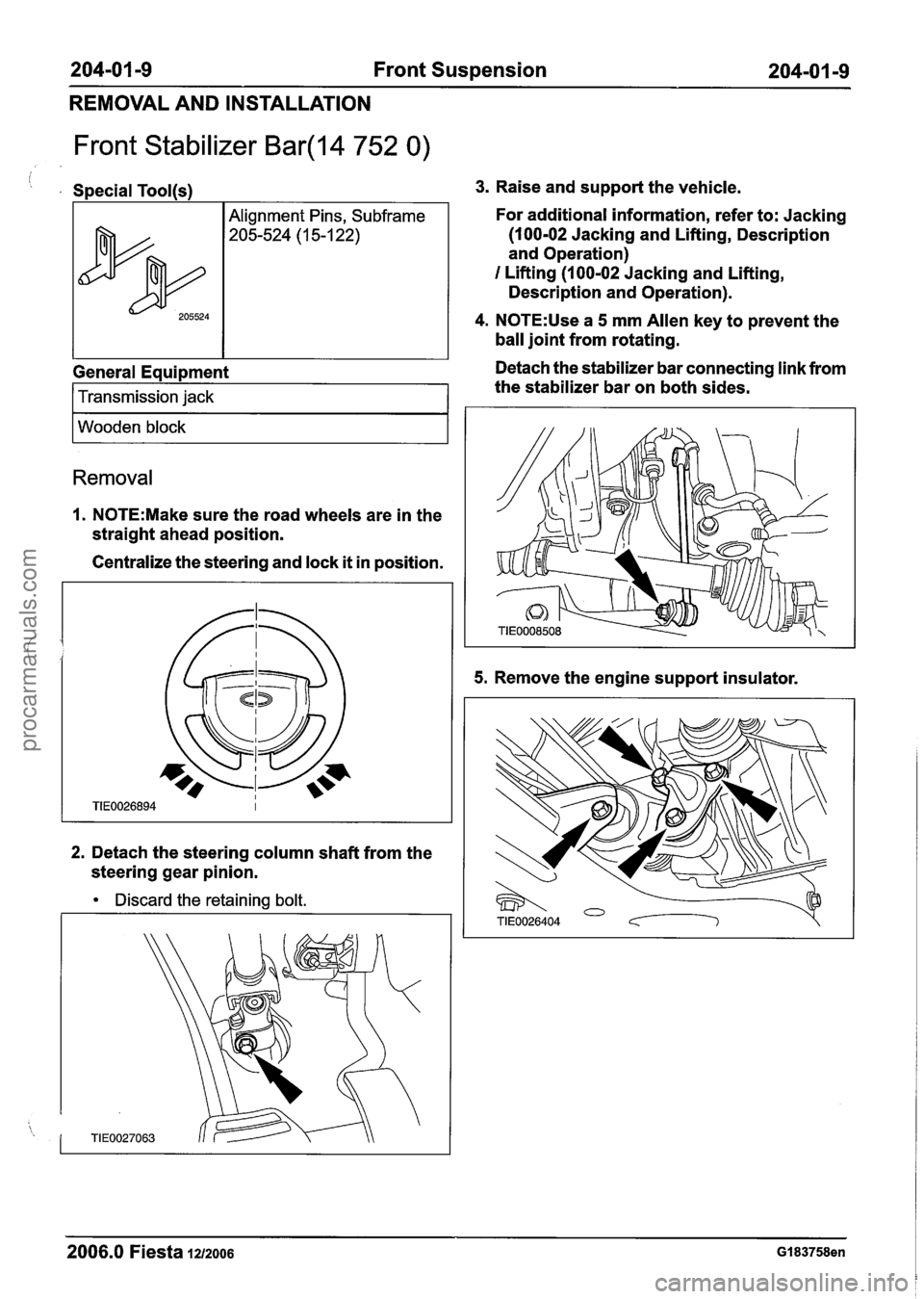

1. N0TE:Make sure the road wheels are in the

straight ahead position.

Centralize the steering and lock

it in position.

2. Detach the steering column shaft from the

steering gear pinion.

Discard the retaining bolt.

3. Raise and support the vehicle.

For additional information, refer to: Jacking

(100-02 Jacking and Lifting, Description

and Operation)

I Lifting (1 00-02 Jacking and Lifting,

Description and Operation).

4. N0TE:Use a 5 mm Allen key to prevent the

ball joint from rotating.

Detach the stabilizer bar connecting link from

the stabilizer bar on both sides.

5. Remove the engine support insulator.

2006.0 Fiesta 1212006 GI 83758en

procarmanuals.com

Page 110 of 1226

204-01 -1 2 Front Suspension 204-01 -1 2 ---- - -

REMOVAL AND INSTALLATION

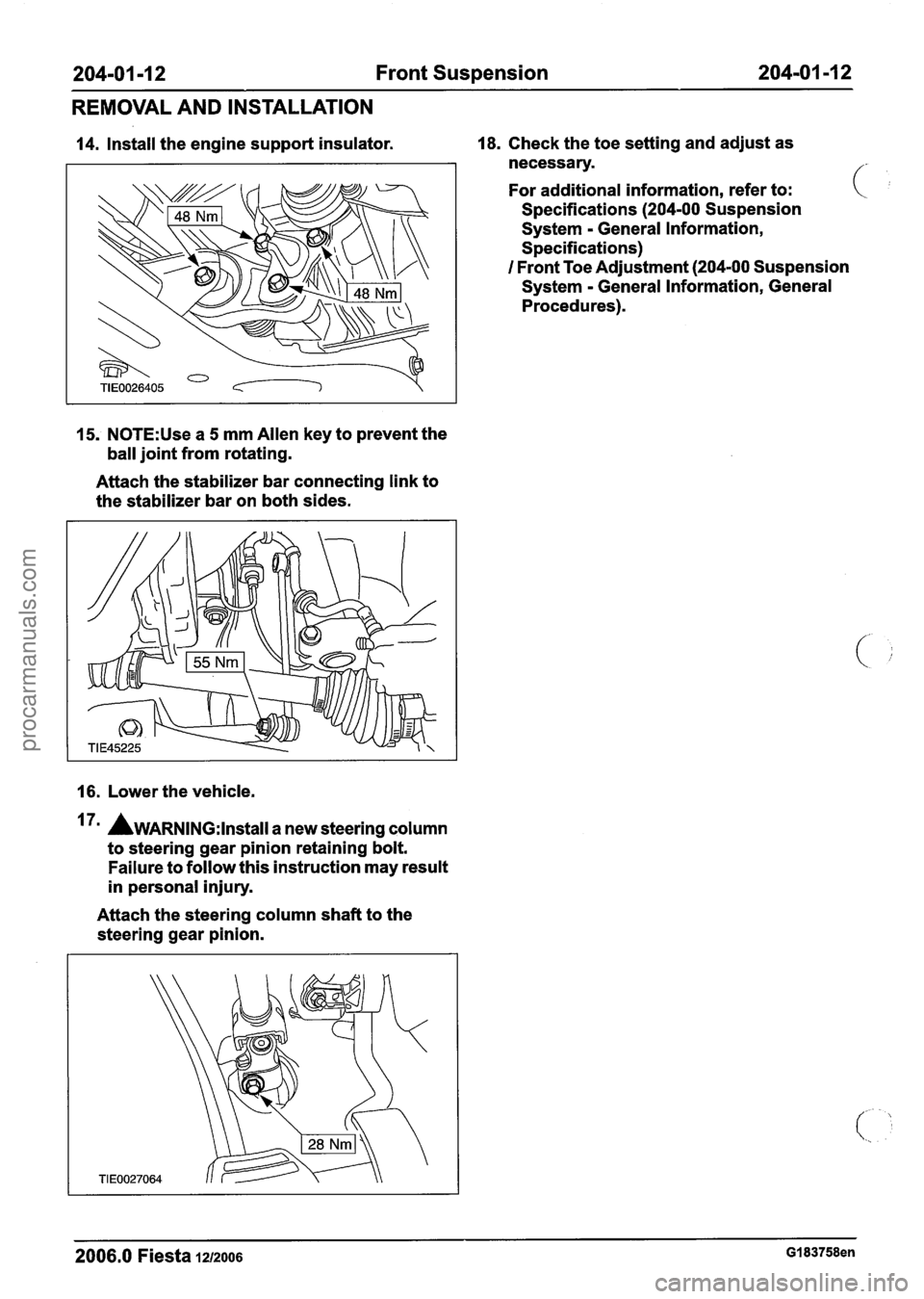

14. Install the engine support insulator. 18. Check the toe setting and adjust as

necessary.

For additional information, refer to:

Specifications

(204-00 Suspension

System

- General Information,

Specifications)

I Front Toe Adjustment (204-00 Suspension

System

- General Information, General

Procedures).

15. N0TE:Use a 5 mm Allen key to prevent the

ball joint from rotating.

Attach the stabilizer bar connecting link to

the stabilizer bar on both sides.

16. Lower the vehicle.

7m AWARNING:I~~~~II a new steering column

to steering gear pinion retaining bolt.

Failure to follow this instruction may result

in personal injury.

Attach the steering column shaft to the

steering gear pinion.

2006.0 Fiesta 1212006 GI 83758en

procarmanuals.com

Page 112 of 1226

204-01 -1 4 Front Suspension 204-01 -1 4

REMOVAL AND INSTALLATION

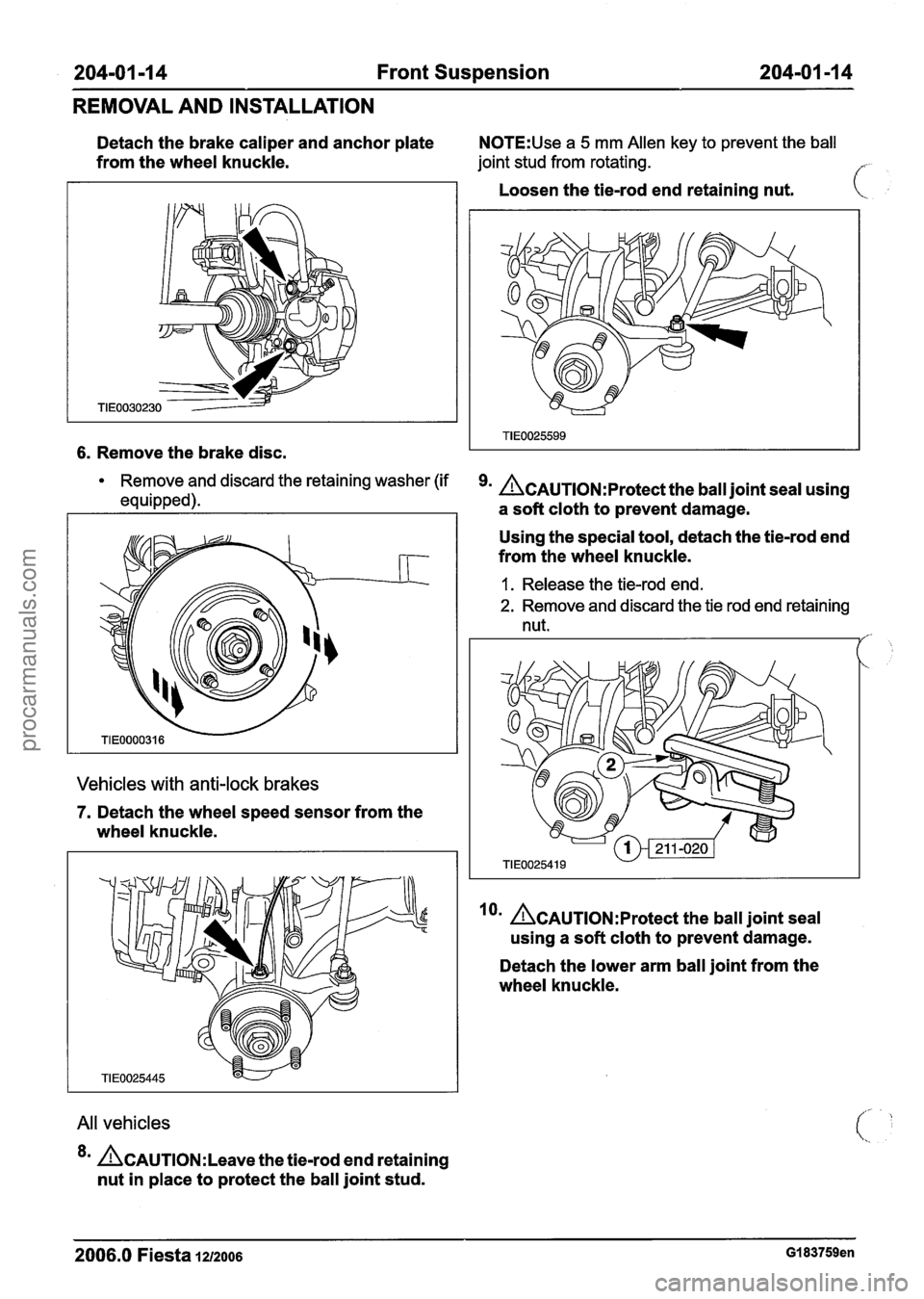

Detach the brake caliper and anchor plate N0TE:Use a 5 mm Allen key to prevent the ball

from the wheel knuckle. joint stud from rotating. f

6. Remove the brake disc.

Remove and discard the retaining washer (if

equipped).

Vehicles with anti-lock brakes

7. Detach the wheel speed sensor from the

wheel knuckle.

All vehicles

*= &AUTION:L~~~~ the tie-rod end retaining

nut in place to protect the ball joint stud. Loosen

the tie-rod end retaining nut.

k

&AuTl~N:~rotect the ball joint seal using

a soft cloth to prevent damage.

Using the special tool, detach the tie-rod end

from the wheel knuckle.

1. Release the tie-rod end.

2. Remove and discard the tie rod end retaining

nut.

/'-

lorn A~AuT10N:~rotect the ball joint seal

using a soft cloth to prevent damage.

Detach the lower arm ball joint from the

wheel knuckle.

2006.0 Fiesta 1212006 GI 83759en

procarmanuals.com

Page 114 of 1226

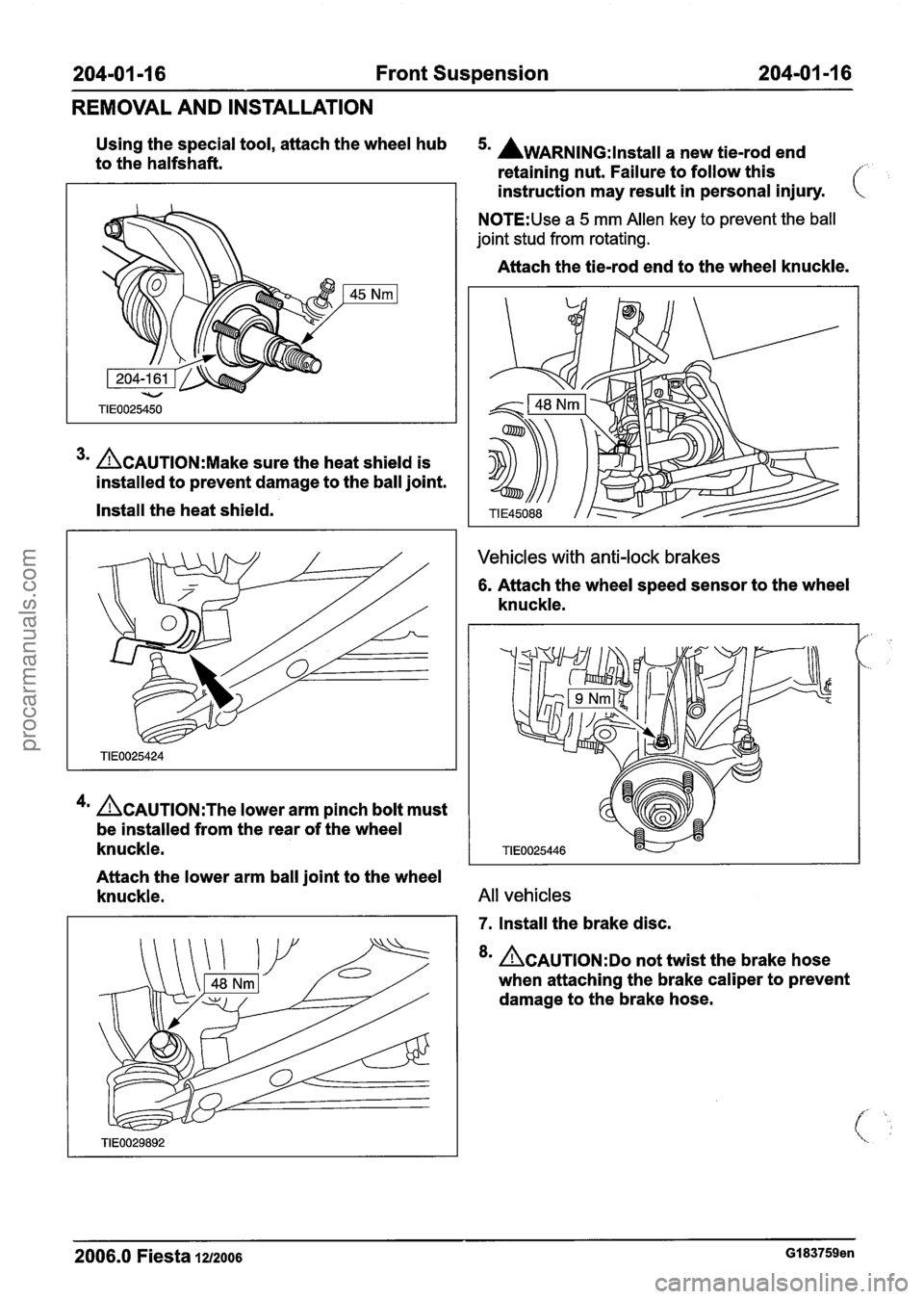

204-01 -1 6 Front Suspension 204-01 -1 6

REMOVAL AND INSTALLATION

Using the special tool, attach the wheel hub 5. AWARNING:lnstall a new tie-rod end to the halfshaft.

retaining nut. Failure to follow this f

3m ACAUTION:M~~~ sure the heat shield is

installed to prevent damage to the ball joint.

Install the heat shield.

4m &AUTION:T~~ lower arm pinch bolt must

be installed from the rear of the wheel

knuckle. instruction

may result in personal injury.

N0TE:Use a 5 mm Allen key to prevent the ball

joint stud from rotating.

Attach the tie-rod end to the wheel knuckle.

Vehicles with anti-lock brakes

6. Attach the wheel speed sensor to the wheel

knuckle.

Attach the lower arm ball joint to the wheel

knuckle.

All vehicles

7. Install the brake disc.

8m &AUTION:DO not twist the brake hose

when attaching the brake caliper to prevent

damage to the brake hose.

2006.0 Fiesta 1212006 GI 83759en

procarmanuals.com

Page 117 of 1226

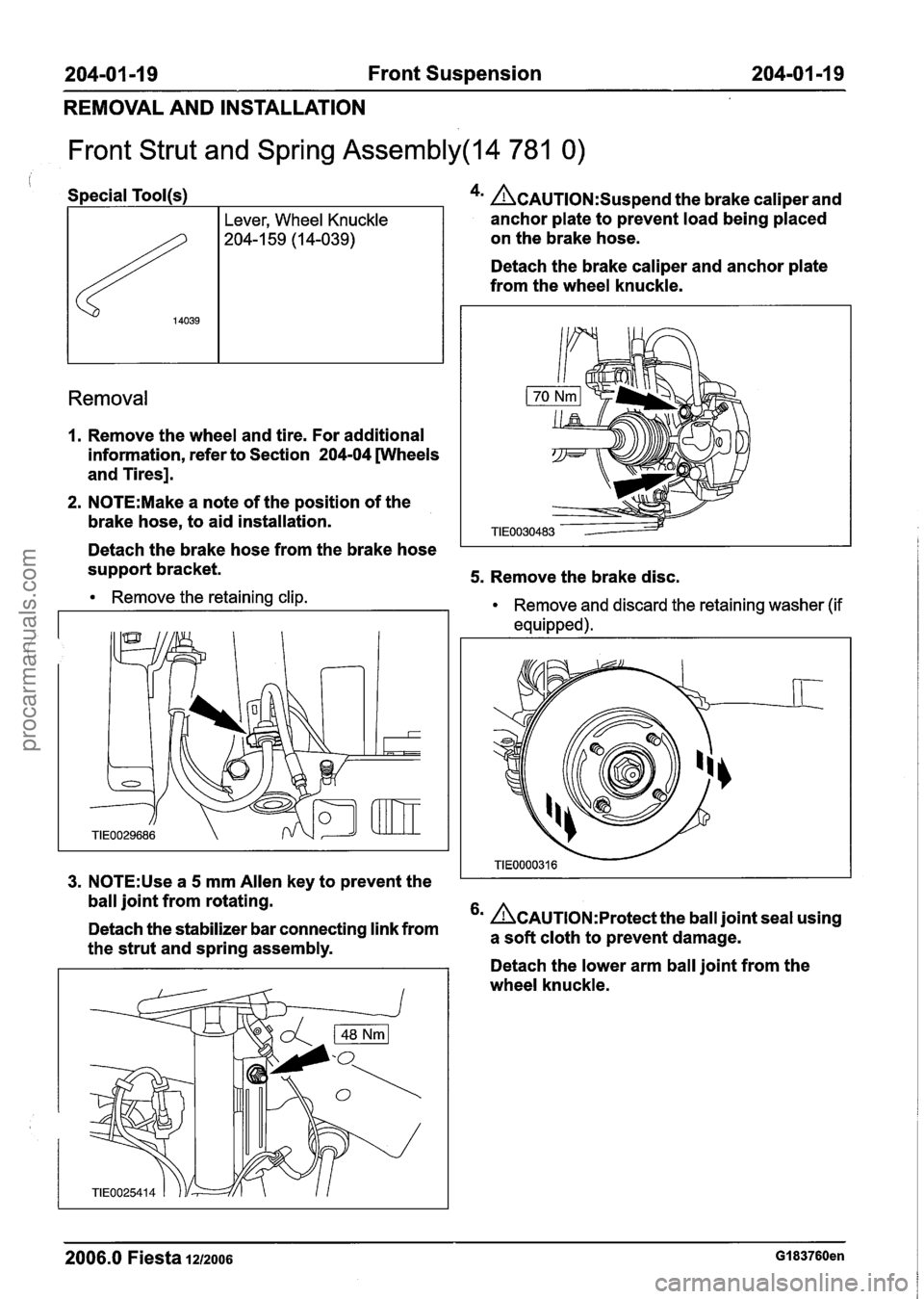

204-01 -1 9 Front Suspension 204-01 -1 9

REMOVAL AND INSTALLATION

Front Strut and Spring Assembly(l4 781 0)

, Special Tool(s)

I Lever, Wheel Knuckle

- 4m &AUTION:S~~~~~~ the brake caliper and

anchor plate to prevent load being placed

on the brake hose.

Detach the brake caliper and anchor plate

from the wheel knuckle.

Removal

1. Remove the wheel and tire. For additional

information, refer to Section

204-04 wheels

and Tires].

2. N0TE:Make a note of the position of the

brake hose, to aid installation.

Detach the brake hose from the brake hose

support bracket.

5. Remove the brake disc.

Remove the retaining clip.

Remove and discard the retaining washer (if

equipped).

I

3. N0TE:Use a 5 mm Allen key to prevent the I I

ball joint from rotating.

6m &~u~l~N:~rotect the ball joint seal using

Detach the stabilizer bar connecting link from a cloth to prevent damage. the strut and spring assembly. . - - Detach the lower arm ball joint from the

wheel knuckle.

2006.0 Fiesta 1212006 GI 83760en

procarmanuals.com

Page 121 of 1226

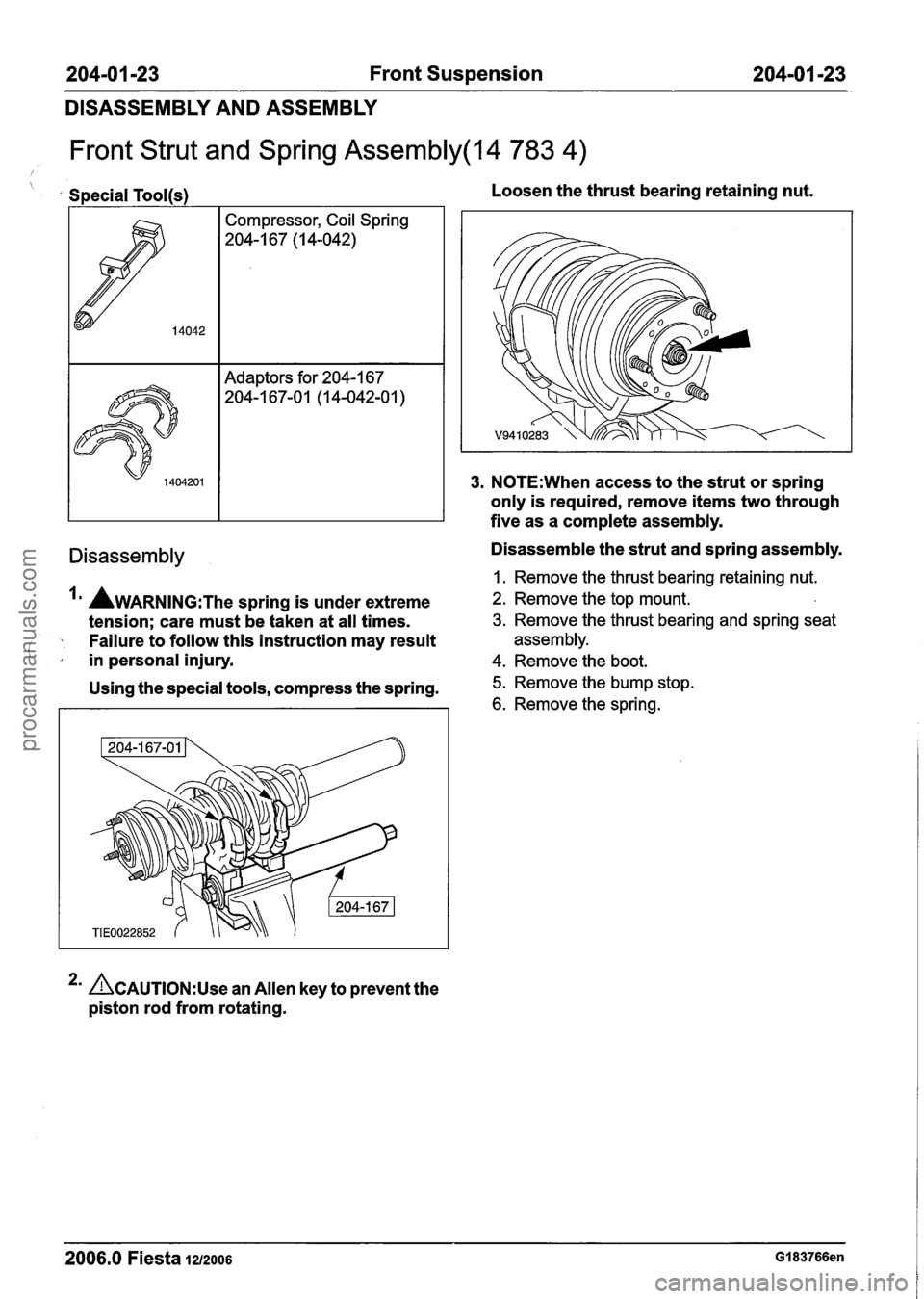

204-01 -23 Front Suspension 204-01 -23

DISASSEMBLY AND ASSEMBLY

Front Strut and Spring Assembly(l4 783 4)

Special Tool(s) I Compressor, Coil Spring

204-1 67 (I 4-042)

Adaptors for 204-1 67

204-1 67-0 1 (1 4-042-0 1

)

Loosen the thrust bearing retaining nut.

3. N0TE:When access to the strut or spring

only is required, remove items two through

five as a complete assembly.

Disassembly Disassemble the strut and spring assembly.

I. Remove the thrust bearing retaining nut.

AWARNING:T~~ spring is under extreme 2. Remove the top mount.

tension; care must be taken at all times. 3. Remove the thrust bearing and spring seat

Failure to follow this instruction may result assembly.

( ,' in personal injury. 4. Remove the boot.

Using the special tools, compress the spring. 5. Remove the bump stop.

6. Remove the spring.

2' &AUTION:U~~ an Allen key to prevent the

piston rod from rotating.

2006.0 Fiesta 1212006 GI 83766en

procarmanuals.com

Page 269 of 1226

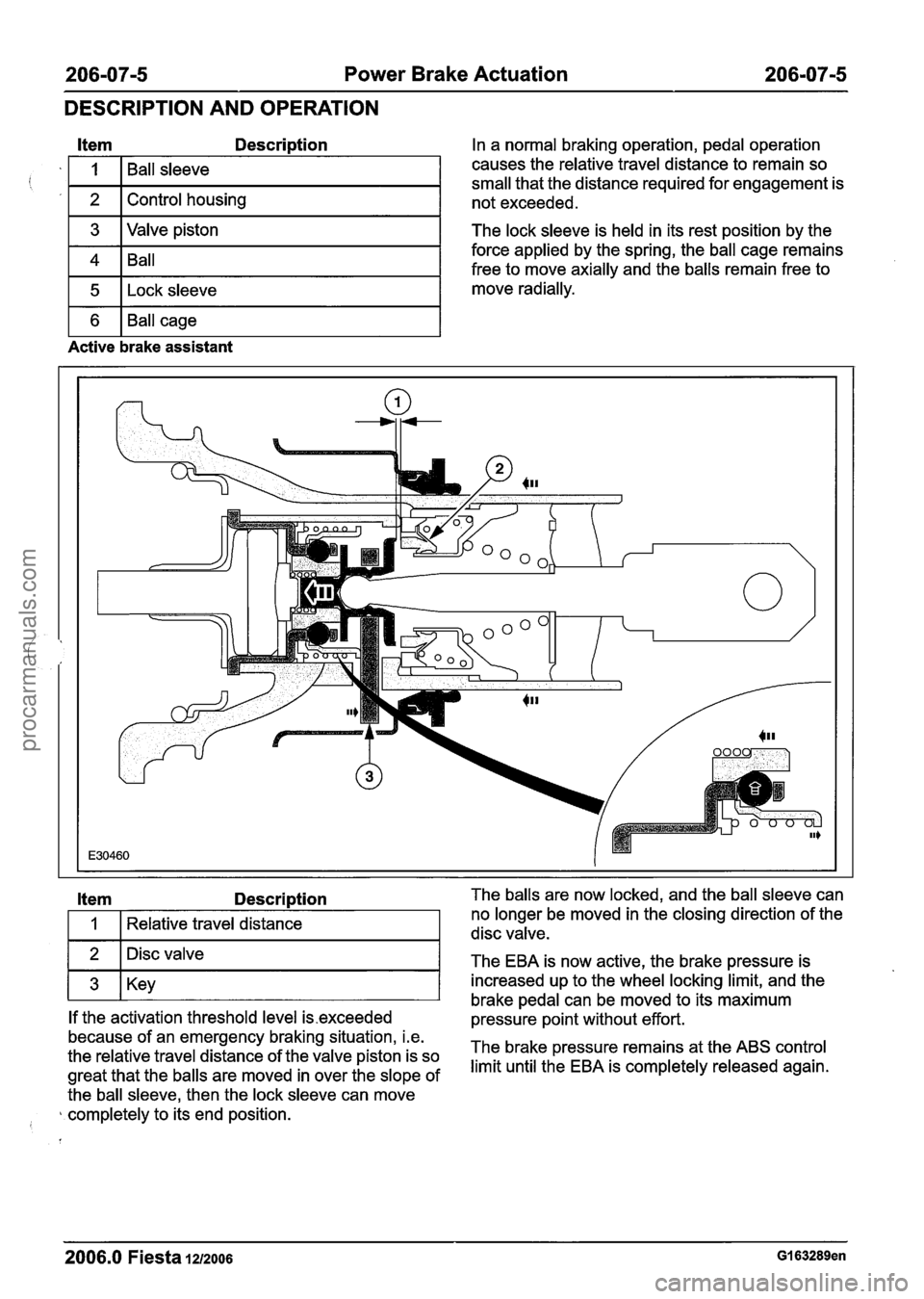

206-07-5 Power Brake Actuation 206-07-5

DESCRIPTION AND OPERATION

Item Description

1 3 I Valve piston I

i '

1 4 1 Ball I

1 5 1 ~ock sleeve I

I

2

1 6 1 Ball cage I

Ball sleeve

Control housing

Active brake assistant

In a normal braking operation, pedal operation

causes the relative travel distance to remain so

small that the distance required for engagement is

not exceeded.

The lock sleeve is held in its rest position by the

force applied by the spring, the ball cage remains

free to move axially and the balls remain free to

move radially.

Item Description

I 1 I Relative travel distance I

1 2 1 Disc valve I -

1 3 1 Key I

If the activation threshold level is.exceeded

because of an emergency braking situation, i.e.

the relative travel distance of the valve piston is so

great that the balls are moved in over the slope of

the ball sleeve, then the lock sleeve can move

completely to its end position.

I

--

The balls are now locked, and the ball sleeve can

no longer be moved in the closing direction of the

disc valve.

The EBA is now active, the brake pressure is

increased up to the wheel locking limit, and the

brake pedal can be moved to its maximum

pressure point without effort.

The brake pressure remains at the ABS control

limit until the EBA is completely released again.

2006.0 Fiesta 1212006 GI 63289en

procarmanuals.com

Page 270 of 1226

206-0716 Power Brake Actuation 206-0716

DESCRIPTION AND OPERATION

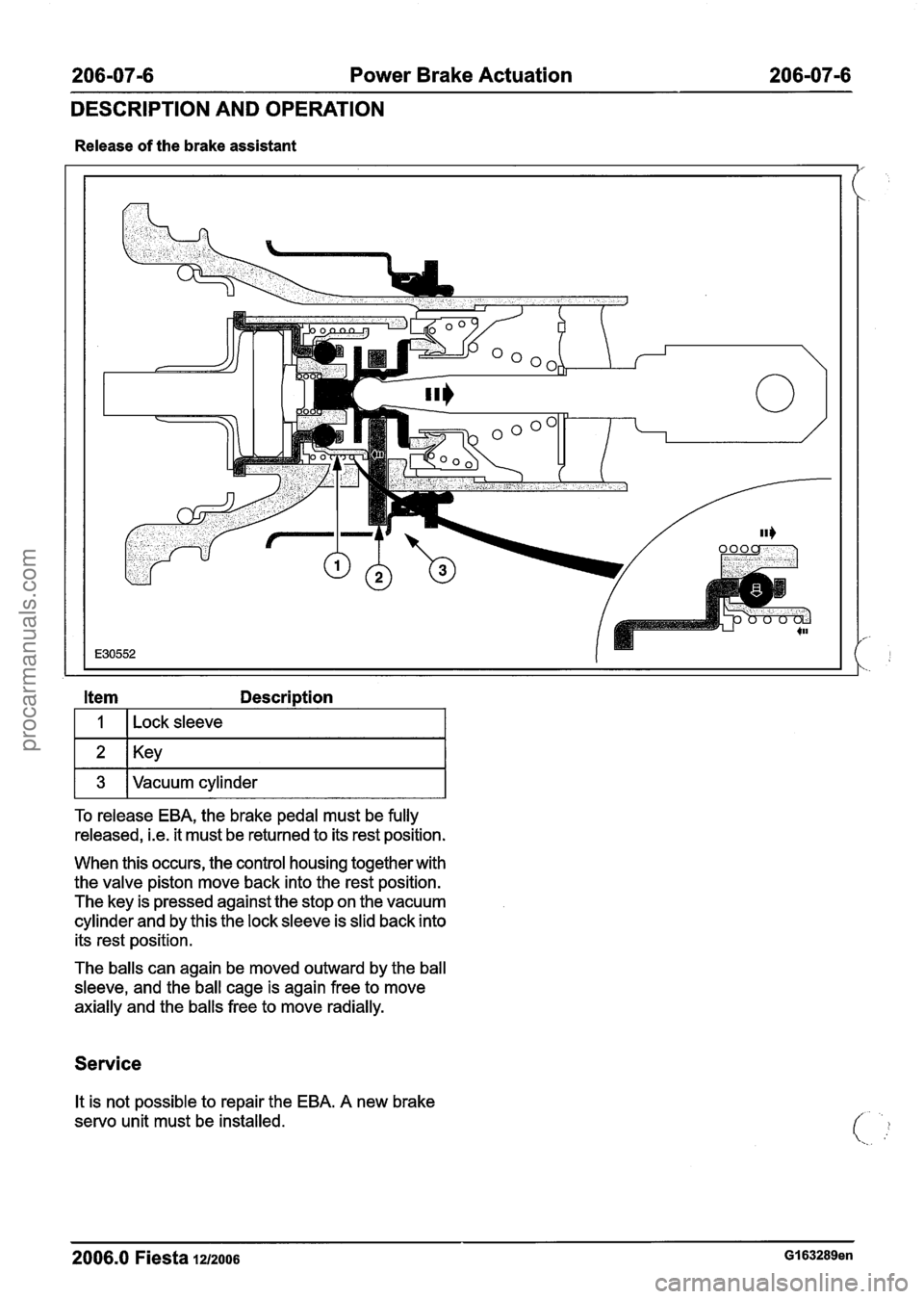

Release of the brake assistant

Item Description

I I I ~ock sleeve I

1 3 IVacuum cylinder I

To release EBA, the brake pedal must be fully

released,

i.e. it must be returned to its rest position.

When this occurs, the control housing together with

the valve piston move back into the rest position.

The key is pressed against the stop on the vacuum

cylinder and by this the lock sleeve is slid back into

its rest position.

The balls can again be moved outward by the ball

sleeve, and the ball cage is again free to move

axially and the balls free to move radially.

Service

It is not possible to repair the EBA. A new brake

servo unit must be installed.

2006.0 Fiesta 12/2006 GI 63289en

procarmanuals.com

Page 373 of 1226

21 1 -02-25 Power Steering 21 1 -02-25

REMOVAL AND INSTALLATION

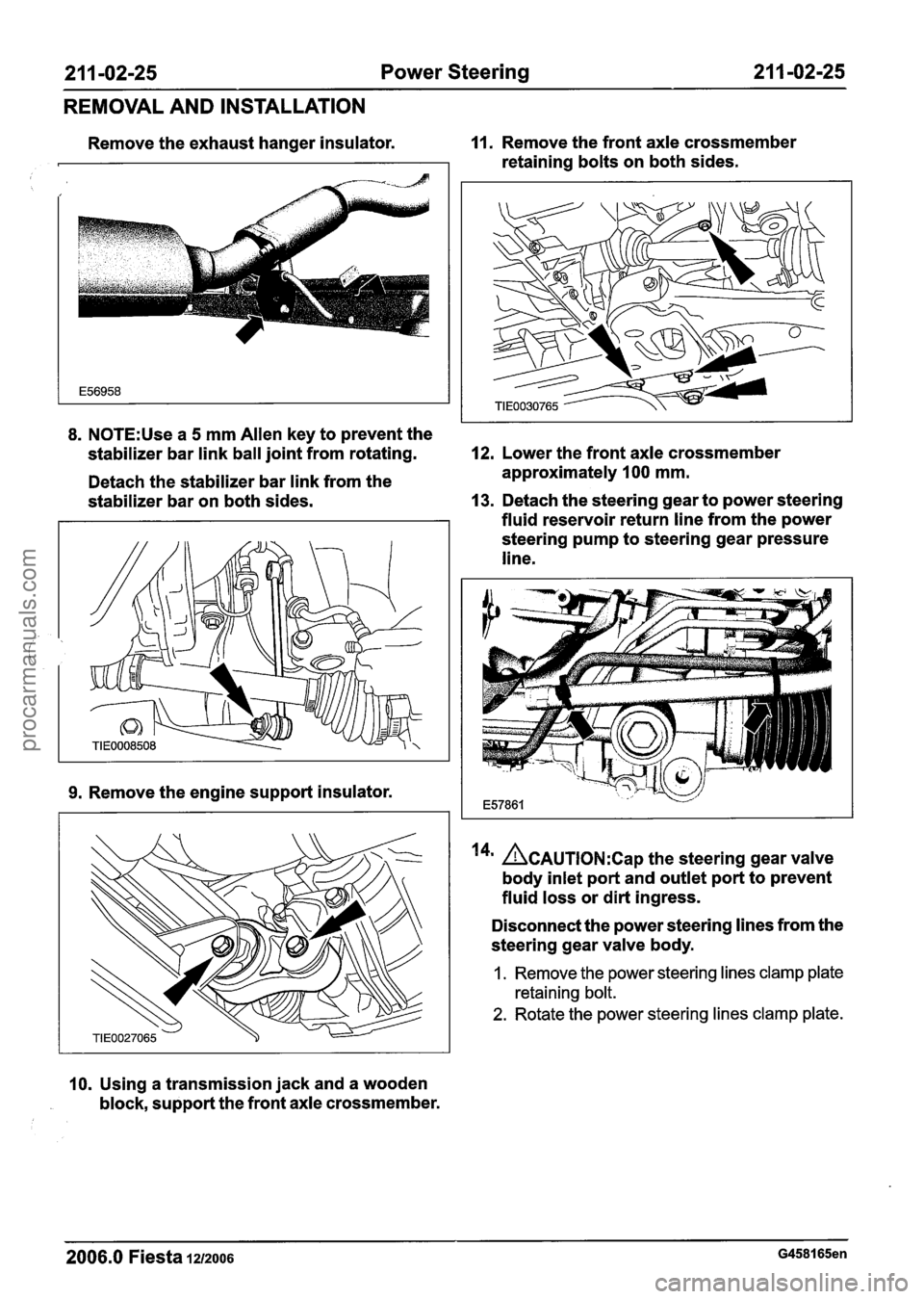

Remove the exhaust hanger insulator. 11. Remove the front axle crossmember

retaining bolts on both sides.

8. N0TE:Use a 5 mm Allen key to prevent the

stabilizer bar link ball joint from rotating.

12. Lower the front axle crossmember

Detach the stabilizer bar link from the approximately

100 mm.

stabilizer bar on both sides.

13. Detach the steering gear to power steering

fluid reservoir return line from the power

steering pump to steering gear pressure

line.

9. Remove the engine support insulator.

10. Using a transmission jack and a wooden

block, support the front axle crossmember.

14' ~CAUTION:C~~ the steering gear valve

body inlet port and outlet port to prevent

fluid loss or dirt ingress.

Disconnect the power steering lines from the

steering gear valve body.

1. Remove the power steering lines clamp plate

retaining bolt.

2. Rotate the power steering lines clamp plate.

2006.0 Fiesta 1212006 G458165en

procarmanuals.com