height FORD GRANADA 1985 Service Repair Manual

[x] Cancel search | Manufacturer: FORD, Model Year: 1985, Model line: GRANADA, Model: FORD GRANADA 1985Pages: 255, PDF Size: 14.98 MB

Page 29 of 255

14Take the weight of the engine and remove

the two engine bearer-to-mounting nuts.

15Lift the engine/transmission, at the same

time lowering the trolley jack. Draw the unit

forwards and lift it out of the engine bay.

16Temporarily refit the anti-roll bar if the

vehicle is to be moved.

1With the engine and gearbox on the bench,

remove the starter motor.

2Remove the bolt from the engine adapter plate.

3Remove the bracing strap and the

remaining engine-to-bellhousing bolts.

4With the aid of an assistant draw the

gearbox off the engine. Do not allow the weight

of the gearbox to hang on the input shaft.

1It is best to mount the engine on a

dismantling stand, but if this is not available,

stand the engine on a strong bench at a

comfortable working height. Failing this, it will

have to be stripped down on the floor.

2Cleanliness is most important, and if the

engine is dirty, it should be cleaned with

paraffin while keeping it in an upright position.

3Avoid working with the engine on a concrete

floor, as grit can be a real source of trouble.

4As parts are removed, clean them in paraffin.

However, do not immerse parts with internal

oilways in paraffin as it is difficult to remove,

usually requiring a high pressure hose.

5It is advisable to have suitable containers to

hold small items according to their use, as this

will help when reassembling the engine and

also prevent possible losses.

6Always obtain complete sets of gaskets

when the engine is being dismantled, but

retain the old gaskets with a view of using

them as a pattern to make a replacement if a

new one is not available.7When possible, refit nuts, bolts and washers

in their location after being removed, as this

helps protect the threads and will also be

helpful when reassembling the engine.

8Retain unserviceable components in order

to compare them with the new parts supplied.

9A Torx key, size T55, will be needed for

dealing with the cylinder head bolts. A 12-

spline key (to fit bolt size M8) will be needed

for the oil pump bolts. Other Torx and 12-

spline bolts may be encountered; sets of the

keys required to deal with them are available

from most motor accessory shops and tool

factors.

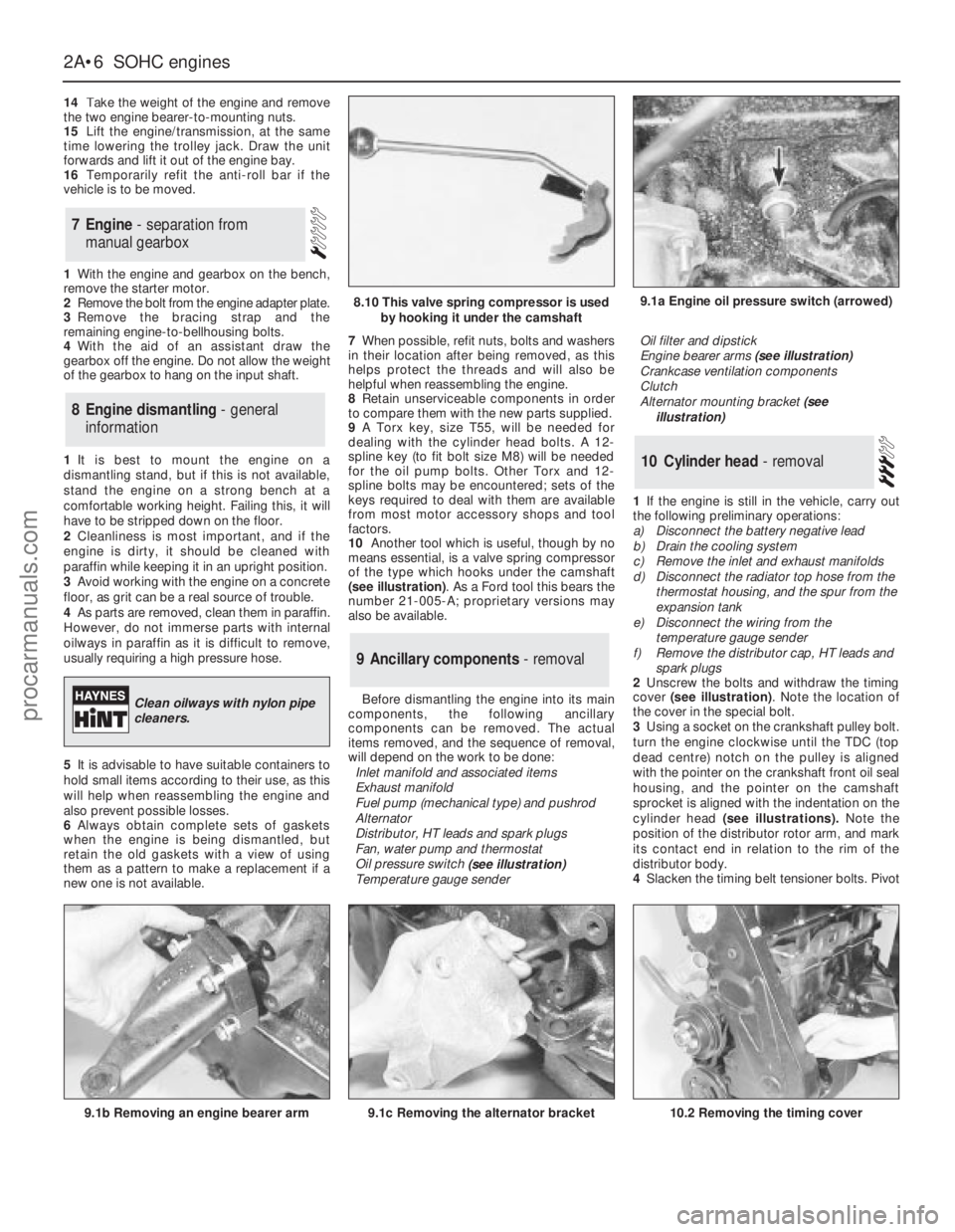

10Another tool which is useful, though by no

means essential, is a valve spring compressor

of the type which hooks under the camshaft

(see illustration). As a Ford tool this bears the

number 21-005-A; proprietary versions may

also be available.

Before dismantling the engine into its main

components, the following ancillary

components can be removed. The actual

items removed, and the sequence of removal,

will depend on the work to be done:

Inlet manifold and associated items

Exhaust manifold

Fuel pump (mechanical type) and pushrod

Alternator

Distributor, HT leads and spark plugs

Fan, water pump and thermostat

Oil pressure switch

(see illustration)

Temperature gauge senderOil filter and dipstick

Engine bearer arms (see illustration)

Crankcase ventilation components

Clutch

Alternator mounting bracket (see

illustration)

1If the engine is still in the vehicle, carry out

the following preliminary operations:

a)Disconnect the battery negative lead

b)Drain the cooling system

c)Remove the inlet and exhaust manifolds

d)Disconnect the radiator top hose from the

thermostat housing, and the spur from the

expansion tank

e)Disconnect the wiring from the

temperature gauge sender

f)Remove the distributor cap, HT leads and

spark plugs

2Unscrew the bolts and withdraw the timing

cover (see illustration). Note the location of

the cover in the special bolt.

3Using a socket on the crankshaft pulley bolt.

turn the engine clockwise until the TDC (top

dead centre) notch on the pulley is aligned

with the pointer on the crankshaft front oil seal

housing, and the pointer on the camshaft

sprocket is aligned with the indentation on the

cylinder head (see illustrations).Note the

position of the distributor rotor arm, and mark

its contact end in relation to the rim of the

distributor body.

4Slacken the timing belt tensioner bolts. Pivot

10Cylinder head - removal

9Ancillary components - removal

8Engine dismantling - general

information

7Engine - separation from

manual gearbox

2A•6SOHCengines

9.1a Engine oil pressure switch (arrowed)

9.1b Removing an engine bearer arm9.1c Removing the alternator bracket

8.10 This valve spring compressor is used

by hooking it under the camshaft

Clean oilways with nylon pipe

cleaners.

10.2 Removing the timing cover

procarmanuals.com

Page 59 of 255

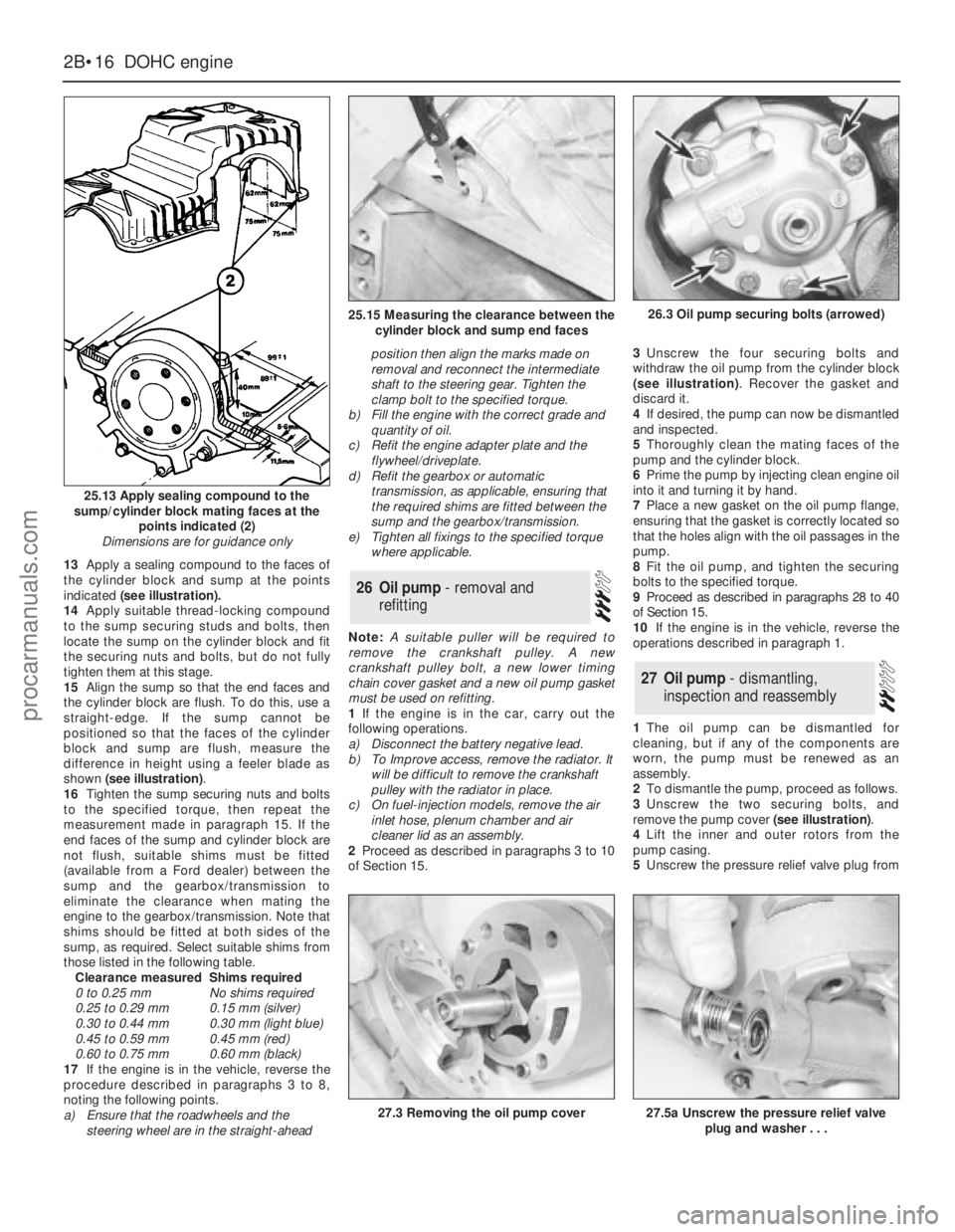

13Apply a sealing compound to the faces of

the cylinder block and sump at the points

indicated(see illustration).

14Apply suitable thread-locking compound

to the sump securing studs and bolts, then

locate the sump on the cylinder block and fit

the securing nuts and bolts, but do not fully

tighten them at this stage.

15Align the sump so that the end faces and

the cylinder block are flush. To do this, use a

straight-edge. If the sump cannot be

positioned so that the faces of the cylinder

block and sump are flush, measure the

difference in height using a feeler blade as

shown (see illustration).

16Tighten the sump securing nuts and bolts

to the specified torque, then repeat the

measurement made in paragraph 15. If the

end faces of the sump and cylinder block are

not flush, suitable shims must be fitted

(available from a Ford dealer) between the

sump and the gearbox/transmission to

eliminate the clearance when mating the

engine to the gearbox/transmission. Note that

shims should be fitted at both sides of the

sump, as required. Select suitable shims from

those listed in the following table.

Clearance measuredShims required

0 to 0.25 mmNo shims required

0.25 to 0.29 mm0.15 mm (silver)

0.30 to 0.44 mm0.30 mm (light blue)

0.45 to 0.59 mm0.45 mm (red)

0.60 to 0.75 mm0.60 mm (black)

17If the engine is in the vehicle, reverse the

procedure described in paragraphs 3 to 8,

noting the following points.

a)Ensure that the roadwheels and the

steering wheel are in the straight-aheadposition then align the marks made on

removal and reconnect the intermediate

shaft to the steering gear. Tighten the

clamp bolt to the specified torque.

b)Fill the engine with the correct grade and

quantity of oil.

c)Refit the engine adapter plate and the

flywheel/driveplate.

d)Refit the gearbox or automatic

transmission, as applicable, ensuring that

the required shims are fitted between the

sump and the gearbox/transmission.

e)Tighten all fixings to the specified torque

where applicable.

Note: A suitable puller will be required to

remove the crankshaft pulley. A new

crankshaft pulley bolt, a new lower timing

chain cover gasket and a new oil pump gasket

must be used on refitting.

1If the engine is in the car, carry out the

following operations.

a)Disconnect the battery negative lead.

b)To Improve access, remove the radiator. It

will be difficult to remove the crankshaft

pulley with the radiator in place.

c)On fuel-injection models, remove the air

inlet hose, plenum chamber and air

cleaner lid as an assembly.

2Proceed as described in paragraphs 3 to 10

of Section 15.3Unscrew the four securing bolts and

withdraw the oil pump from the cylinder block

(see illustration). Recover the gasket and

discard it.

4If desired, the pump can now be dismantled

and inspected.

5Thoroughly clean the mating faces of the

pump and the cylinder block.

6Prime the pump by injecting clean engine oil

into it and turning it by hand.

7Place a new gasket on the oil pump flange,

ensuring that the gasket is correctly located so

that the holes align with the oil passages in the

pump.

8Fit the oil pump, and tighten the securing

bolts to the specified torque.

9Proceed as described in paragraphs 28 to 40

of Section 15.

10If the engine is in the vehicle, reverse the

operations described in paragraph 1.

1The oil pump can be dismantled for

cleaning, but if any of the components are

worn, the pump must be renewed as an

assembly.

2To dismantle the pump, proceed as follows.

3Unscrew the two securing bolts, and

remove the pump cover (see illustration).

4Lift the inner and outer rotors from the

pump casing.

5Unscrew the pressure relief valve plug from

27Oil pump - dismantling,

inspection and reassembly

26Oil pump - removal and

refitting

2B•16DOHCengine

25.13 Apply sealing compound to the

sump/cylinder block mating faces at the

points indicated (2)

Dimensions are for guidance only

27.3 Removing the oil pump cover27.5a Unscrew the pressure relief valve

plug and washer . . .

25.15 Measuring the clearance between the

cylinder block and sump end faces26.3 Oil pump securing bolts (arrowed)

procarmanuals.com

Page 66 of 255

V6 engines 2C•5

2C

Crankshaft

Thrustwasher thickness:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.28 to 2.33 mm

Oversize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2.48 to 2.53 mm

Crankshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.08to 0.32 mm

Permitted undersize for main and big-end bearing journals . . . . . . . . . .0.254 mm

Camshaft

Camshaft drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Chain

Cam lift (inlet and exhaust) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.72 mm

Cam lobe height (inlet and exhaust) . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.08 to 36.25 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.065 to 0.165 mm

Thrust plate thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.02 to 4.05 mm

Valves

Valve timing:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24°BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64°ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66°BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22°ATDC

Head diameter:

Inlet valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39.67 to 40.06 mm

Exhaust valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33.83 to 34.21 mm

Length:

Inlet valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.2 to 106.9 mm

Exhaust valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.1 to 107.1 mm

Valve spring free length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55.12 mm

Torque wrench settingsNmlbf ft

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 to 6844 to 50

Camshaft thrust plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Timing chain guide to block bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 to 127 to 9

Timing chain tensioner to block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 117 to 8

Oil inlet pipe to oil pump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 to 137 to 10

Oil pump to block bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 to 2113 to 15

Sump drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 to 2815to 21

Crankshaft pulley to vibration damper bolts . . . . . . . . . . . . . . . . . . . . . .27 to 3320 to 24

Crankshaft vibration damper bolt:

Stage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 5030 to 37

Stage 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tighten further 80°to 90°Tighten further 80°to 90°

2.9 litre engine

Note: Unless otherwise stated, the specifications and torque wrench settings for the 2.9 litre engine are as given for the 2.8 litre engine.

General

Manufacturer’s code:

Models without catalytic converter . . . . . . . . . . . . . . . . . . . . . . . . . . .BRC

Models equipped with type N manual gearbox or automatic

transmission and a catalytic converter . . . . . . . . . . . . . . . . . . . . . .BRD

Models equipped with MT75 manual gearbox and catalytic converter . .BRE

Stroke - mm (in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72.0 (2.835)

Cubic capacity - cc (cu in) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2936 (179.2)

Compression ratio:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.5:1

BRD and BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.0:1

Maximum power (DIN, kW @ rpm):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110 @ 5700

BRD and BRE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107 @ 5500

Maximum torque (DIN, Nm @ rpm):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233 @ 3000

BRD engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .222 @ 3000

BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .226 @ 3000

Cylinder block

Identification mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F

Pistons

Clearance in bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.028 to 0.048 mm

Piston ring end gaps:

Top and centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.30 to 0.50 mm

procarmanuals.com

Page 67 of 255

The V6 engine fitted to the Granada is only

available in fuel-injected form. Mechanically,

the design of the engine is well-established,

and it is improved by the latest fuel, ignition and

engine management systems (see illustration).

The combined crankcase and cylinder block

is made of cast iron, and houses the pistons,

crankshaft and camshaft. The sump is

attached to the bottom of the crankcase and

the cylinder heads to the top.

The cylinder heads are of the crossflow

design, the inlet manifold being located

between them and the exhaust manifolds

being on the outboard sides. The overhead

valves are operated by tappets, pushrods and

rockers from the centrally located camshaft.

Camshaft drive is by gears (2.8 litre) or chain

(2.4 & 2.9 litre).

The crankshaft runs in four main bearings.

Endfloat is controlled by thrust flanges on the

No 3 bearing shells. The connecting rods are

selected so that all are in the same weight class.

Aluminium alloy pistons are used. The

gudgeon pins are an interference fit in their

connecting rods.The lubrication system is of the usual wet

sump, pressure fed type, with a full-flow

disposable canister oil filter. The oil pump is

driven by a shaft which engages in the bottom

of the distributor drivegear.

The following operations can be carried out

without removing the engine, although some

work will be easier and quicker with the engine

removed.

a)Removal and refitting of the cylinder

heads

b)Removal and refitting of the sump and oil

pump

c)Removal and refitting of the timing gears

d)Removal and refitting of the pistons,

connecting rods and big-end bearings

e)Renewal of the engine mountings

f)Removal and refitting of the flywheel

g)Renewal of the crankshaft front and rear

oil seals

h)Removal and refitting of the camshaft

(after removal of the cylinder heads,

tappets and timing gears)The engine must be removed for the

following operations:

a)Renewal of the crankshaft main bearings

b)Removal and refitting of the crankshaft

The engine is removed from above, without

the transmission. Removal with the

transmission is not recommended because of

the weight and unwieldiness of the combined

units.

2.8 litre engine

1Disconnect the battery negative lead.

2Remove the bonnet.

3Remove the throttle valve cover, which is

retained by three screws.

4Remove the air cleaner cover, valve airflow

5Engine - removal

4Methods of engine removal

3Major operations requiring

engine removal

2Major operations possible with

the engine in the vehicle

1General information

2C•6V6 engines

Cylinder head

Identification mark:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F

BRD and BRE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .K

Crankshaft

Crankshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.08 to 0.24 mm

Permitted undersize for main and big-end bearing journals . . . . . . . . . .0.254 mm

Camshaft

Cam lift (inlet and exhaust):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.72mm

BRD and BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6.54 mm

Cam lobe height (inlet and exhaust):

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.08 to 36.25 mm

BRD and BRE engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36.22 to 36.41 mm

Camshaft endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0.065 to 0.165 mm

Thrust plate thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.02 to 4.05 mm

Valves

Valve timing:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .As 2.4 litre V6

BRD and BRE engines:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30°BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66°ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76°BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20°ATDC

Length:

BRC engine:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.2 to 106.9 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106.8 to 107.8 mm

BRD and BRE engine:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104.7 to 105.4 mm

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104.6 to 105.6 mm

Valve spring free length:

BRC engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55.12 mm

BRD and BRE engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53.00 mm

procarmanuals.com

Page 131 of 255

Models covered in this Manual have disc

brakes fitted all round. The footbrake operates

hydraulically on all four wheels, and the

handbrake operates mechanically on the rear

wheels. Both footbrake and handbrake are

self-adjusting in use.

Ford’s anti-lock braking system (ABS) is

fitted to all models. The system monitors the

rotational speed of each roadwheel. When a

wheel begins to lock under heavy braking, the

ABS reduces the hydraulic pressure to that

wheel, so preventing it from locking. When this

happens a pulsating effect will be noticed at

the brake pedal. On some road surfaces the

tyres may squeal when braking hard even

though the wheels are not locked.

The main components of the system are the

hydraulic unit, the calipers, pads and discs,

the wheel sensors and the “brain” or control

module. The hydraulic unit contains the

elements of a traditional master cylinder, plus

an electric motor and pump, a pressure

accumulator and control valves. The pump is

the source of pressure for the system and

does away with the need for a vacuum servo.

The hydraulic circuit is split front and rear,

as is normal practice with rear-wheel drive

vehicles. In the event that the hydraulic pump

fails, unassisted braking effort is still available

on the front calipers only.

Warning lights inform the driver of low brake

fluid level, ABS failure and (on some models)

brake pad wear. The low fluid level light

doubles as a “handbrake on” light; if it

illuminates at the same time as the ABS

warning light, it warns of low hydraulic

pressure.

ABS cannot overturn the laws of physics:

stopping distances will inevitably be greater on

loose or slippery surfaces. However, the system

should allow even inexperienced drivers to

retain directional control under panic braking.

From August 1986 the following

modifications were made to the braking

system.

a)The relays differ from earlier versions.b)The hydraulic pump is constructed of iron

rather than alloy.

c)A new pressure warning switch is used.

d)The earlier high pressure rubber hose is

replaced by a steel pipe.

To overcome the problem of excessive rear

brake pad wear, Ford introduced a differential

valve which is screwed into the ABS valve

block.The valve limits the pressure applied to

the rear brake calipers and so reduces brake

pad wear. From 1988 onwards, the valve has

been fitted during production. The differential

valve can also be fitted to earlier models. Refer

to your Ford dealer for further information.

From April 1992 onwards, the models

covered in this Manual were equipped with a

new Teves MK IV anti-lock braking system

instead of the Teves MK II system fitted to the

earlier models.

The Teves MK IV system differs from the

earlier MK II system in the following ways.

a)The source of hydraulic pressure for the

system is a conventional master cylinder

and vacuum servo assembly.

b)A valve block and pump assembly is used

instead of the hydraulic control unit. The

block contains the inlet and outlet

solenoid valves that control the hydraulic

system. There are three pairs of valves,

one for each brake circuit (paragraph c).

c)The hydraulic braking system consists of

three separate circuits; one for each front

brake (which are totally independent of

each other), and a joint circuit which

operates both rear brakes.

d)A G (gravity) switch is incorporated in the

system. This is an inertia type switch and

informs the control module when the

vehicle is decelerating rapidly.

e)A Pedal Travel Sensor (PTS) is fitted to the

vacuum servo unit. The PTS informs the

control module of the position of the brake

pedal when the anti-lock sequence starts

and ensures that a constant pedal height

is maintained during the sequence.

The MK IV system operates as follows.

During normal operation the system

functions in the same way as a non-ABS

system would. During this time the three inlet

valves in the valve block are open and theoutlet valves are closed, allowing full hydraulic

pressure present in the master cylinder to act

on the main braking circuit. If the control

module receives a signal from one of the

wheel sensors and senses that a wheel is

about to lock, it closes the relevant inlet valve

in the valve block which then isolates the

brake caliper on the wheel which is about to

lock from the master cylinder, effectively

sealing in the hydraulic pressure. If the speed

of rotation of the wheel continues to decrease

at an abnormal rate, the control module will

then open the relevant outlet valve in the valve

block; this allows the fluid from the relevant

hydraulic circuit to return to the master

cylinder reservoir, releasing pressure on the

brake caliper so that the brake is released. The

pump in the valve block also operates to assist

in the quick release of pressure. Once the

speed of rotation of the wheel returns to an

acceptable rate the pump stops, the outlet

valve closes and the inlet valve is opened,

allowing the hydraulic master cylinder

pressure to return to the caliper which then

reapplies the brake. This cycle can be carried

many times a second. The solenoid valves

connected to the front calipers operate

independently, but the valve connected to the

rear calipers operates both calipers

simultaneously.

The operation of the ABS system is entirely

dependent on electrical signals. To prevent

the system responding to any inaccurate

signals, a built-in safety circuit monitors all

signals received by the control module. If an

inaccurate signal or low battery voltage is

detected, the ABS system is automatically

shut down and the warning lamp on the

instrument cluster is illuminated to inform the

driver that the ABS system is not operational.

Whilst in this state the system functions in the

same way as a non-ABS system would. If a

fault does develop in the ABS system, the car

must be taken to a Ford dealer for fault

diagnosis and repair. The system is equipped

with a diagnostic plug into which a special

diagnostic (STAR) tester can be plugged. This

allows faults to be easily traced.

1General information

10•2Braking system

Torque wrench settingsNmlbf ft

Front caliper:

To stub axle carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 to 6138 to 45

Slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Rear caliper:

Bracket to carrier plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 to 6138 to 45

Slide bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 to 3523 to 26

Hydraulic unit to bulkhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Accumulator to pump body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Pump mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 to 95 to 7

High pressure hose banjo bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 to 2412 to 18

Reservoir mounting bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 to 63 to 4

Wheel sensor fixing bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 to 116 to 8

Vacuum servo unit retaining nuts (Teves MK IV) . . . . . . . . . . . . . . . . . .35 to 4526 to 33

Master cylinder retaining nuts (Teves MK IV) . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Valve block and pump assembly mounting nuts (Teves MK IV) . . . . . . .21 to 2815 to 21

procarmanuals.com

Page 144 of 255

Chapter 11

Steering and suspension

Front anti-roll bar - removal and refitting . . . . . . . . . . . . . . . . . . . . .19

Front anti-roll bar bushes - renewal . . . . . . . . . . . . . . . . . . . . . . . . .20

Front stub axle carrier - removal and refitting . . . . . . . . . . . . . . . . .16

Front suspension crossmember - removal and refitting . . . . . . . . .15

Front suspension lower arm - removal, overhaul and refitting . . . . .18

Front suspension strut - dismantling and reassembly . . . . . . . . . . .22

Front suspension strut - removal and refitting . . . . . . . . . . . . . . . . .21

Front wheel alignment - checking and adjusting . . . . . . . . . . . . . . .14

Front wheel bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Power steering fluid - level check and bleeding . . . . . . . . . . . . . . . . .2

Power steering hoses - removal and refitting . . . . . . . . . . . . . . . . . .12

Power steering pump - removal and refitting . . . . . . . . . . . . . . . . . .11

Power steering pump drivebelt - removal, refitting and tensioning .10

Rear anti-roll bar - removal and refitting . . . . . . . . . . . . . . . . . . . . .30

Rear crossmember insulator - removal and refitting . . . . . . . . . . . .28

Rear hub - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Rear shock absorber - removal and refitting . . . . . . . . . . . . . . . . . .31Rear spring - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . .27

Rear suspension and final drive assembly - removal and refitting . .23

Rear suspension lower arm - removal and refitting . . . . . . . . . . . . .29

Rear wheel bearings - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Ride height control compressor - removal and refitting . . . . . . . . . .33

Ride height control sensor - removal and refitting . . . . . . . . . . . . . .34

Ride height control system - general information . . . . . . . . . . . . . .32

Steering column - removal and refitting . . . . . . . . . . . . . . . . . . . . . . .7

Steering column lock - removal and refitting . . . . . . . . . . . . . . . . . . .8

Steering gear - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . .3

Steering intermediate shaft and flexible coupling - removal and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Steering rack bellows - renewal in vehicle . . . . . . . . . . . . . . . . . . . . .4

Steering wheel - centralising . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Steering wheel - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .5

Track rod end - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . .13

Wheel stud - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

General

Suspension type:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Independent, MacPherson struts and anti-roll bar

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Independent, semi-trailing arms and anti-roll bar; ride height

control optionally available

Steering type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Rack and pinion, power-assisted on some models

Front wheel alignment

Toe:

Setting value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 ± 1 mm (0.08 ± 0.04 in) toe-in

Tolerance in service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 mm (0.02 in) toe-out to 4.5 mm (0.18 in) toe-in

Castor :

SOHC and 2.8 litre models:

Standard, without ride height control . . . . . . . . . . . . . . . . . . . . . . . + 1°51’ ± 1°00’

Standard, with ride height control . . . . . . . . . . . . . . . . . . . . . . . . . . + 1°58’ ± 1°00’

Heavy duty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 1°46’ ± 1°00’

DOHC carburettor and low series fuel-injection models . . . . . . . . . . + 2°27’ ± 1°00’

DOHC high series models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 2°26’± 1°00’

2.4 litre:

low series models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 2°17’ ± 1°00’

high series models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 2°50’ ± 1°00’

2.9 litre models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . + 2°22’ ± 1°00’

11•1

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanicDifficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert

DIY or professional

Degrees of difficulty

Specifications Contents

11

procarmanuals.com

Page 146 of 255

The steering gear is of rack-and-pinion type.

Power assistance is standard on V6 models

and optional on others. The power-assisted

steering gear has a “variable ratio” effect

which increases the steering ratio about the

straight-ahead position: this provides quick

lock-to-lock action without the penalty of

over-responsiveness in open road driving.

The steering wheel is adjustable both up-

and-down and fore-and-aft. Both steering

column and shaft are designed to collapse

under impact. The steering shaft is connected

to the pinion by an intermediate shaft, which

has a universal joint at its upper end and a

flexible coupling at the lower end.

Front suspension is independent, of the

MacPherson strut type, with coil springs and

concentric telescopic shock absorbers. The

struts are attached to the tops of the stub axle

carriers, which are located at their lower ends

by balljoints incorporated in the lower

suspension arms. The lower suspension arms

pivot at their inner ends, where they are

attached to a central crossmember. The anti-

roll bar is attached to the rear of the arms and

serves to control fore-and-aft movement as

well as reducing roll.

Suspension geometry has been designed to

give good steering “feel”, resistance to pulling

caused by uneven braking effort or tyre

deflation, and (in the case of manual steering)

acceptably low steering wheel effort at parking

speeds. Only toe is adjustable in service.

The rear suspension is also independent. It

is of the semi-trailing arm type, with coil

springs and separate telescopic shock

absorbers. An optionally-available ride height

control system keeps the rear suspension

height constant, regardless of vehicle load.

Both front and rear wheel bearings are of a

special taper-roller type and require no

periodic adjustment in service.1Refer to Chapter 1, Section 35, to check the

power steering fluid level.

2If the fluid level falls so low that air enters

the pump, or after component renewal, the

system must be bled as follows.

3Remove the reservoir filler cap. Top-up with

clean fluid to the appropriate “cold” level. It is

important that the fluid is free of air bubbles,

so do not shake the container when topping-

up, and pour the fluid slowly.

4Disconnect the negative LT lead from the

ignition coil. Have an assistant crank the

engine on the starter in two second bursts, at

the same time turning the steering wheel from

lock to lock. Keep the reservoir topped up

whilst this is going on.

5When air bubbles no longer appear in the

fluid, stop the cranking. Reconnect the coil

negative lead and run the engine for a few

seconds, then stop it and check the level

again. Refit the filler cap.

6Run the vehicle for a few miles to warm up

the fluid and expel any remaining air, then stop

the engine and make a final fluid level check.

Manual steering

1Position the steering in the straight-ahead

position, then remove the ignition key so that

the steering is locked.

2Slacken the front wheel nuts. Raise and

support the front of the vehicle and remove

the front wheels.

3Remove the pinch-bolt and nut which

secure the intermediate shaft flexible coupling

to the pinion shaft (see illustration).

4Slacken the track rod end locknuts by half a

turn each (see illustration).

5Remove the split pin from the track rod

balljoint nuts. Unscrew the nuts, break the

balljoint tapers using a separator tool anddisengage the track rod ends from the

steering arms.

6Remove the two bolts which secure the

steering gear to the crossmember. Lift out the

steering gear.

7Mark the positions of the track rod ends on

the track rods, using paint or sticky tape, so

that they can be refitted in approximately the

same positions. Unscrew the track rod ends

and locknuts.

8Commence refitting by screwing on the

locknuts and track rod ends, observing the

previously made position marks when

applicable.

9Bring the rack to the straight-ahead

position. Do this by counting the number of

turns of the pinion needed to go from lock to

lock, then applying half that number of turns

from full lock on one side.

10Offer the steering gear to the vehicle,

engaging the flexible coupling and loosely

fitting the securing bolts. Note that the master

spline on the pinion shaft mates with the

corresponding groove in the flexible coupling.

11Tighten the two steering gear-to-

crossmember bolts to the specified Stage 1

torque. Slacken the bolts and retighten to the

Stage 2 torque. Finally tighten the bolts

through the angle specified for Stage 3.

12Make sure that the flexible coupling and

pinion shaft are properly engaged, then fit the

pinch-bolt and nut. Tighten the pinch-bolt to

the specified torque.

3Steering gear - removal and

refitting

2Power steering fluid - level

check and bleeding1General information

Steering and suspension 11•3

11

3.3 Master spline and groove on pinion

shaft and coupling

Torque wrench settings (continued)Nmlbf ft

Rear suspension

Driveshaft stub axle nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .250 to 290180 to 210

Final drive mounting to floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Final drive mounting to rear cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 to 5030 to 37

Guide plate-to-floor bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41 to 5130 to 38

Guide plate insulator bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69 to 8851 to 65

Lower arm to crossmember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 to 9559 to 70

Brake anchor plate to lower arm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52 to 6438 to 47

Anti-roll bar bracket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 to 2515 to 18

Shock absorber mountings:

Top . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73 to 9754 to 72

Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68 to 9250 to 68

Rear hub bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 to 10059 to 74

Wheels

Wheel nuts (steel or alloy wheels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 to 10052 to 74

procarmanuals.com

Page 148 of 255

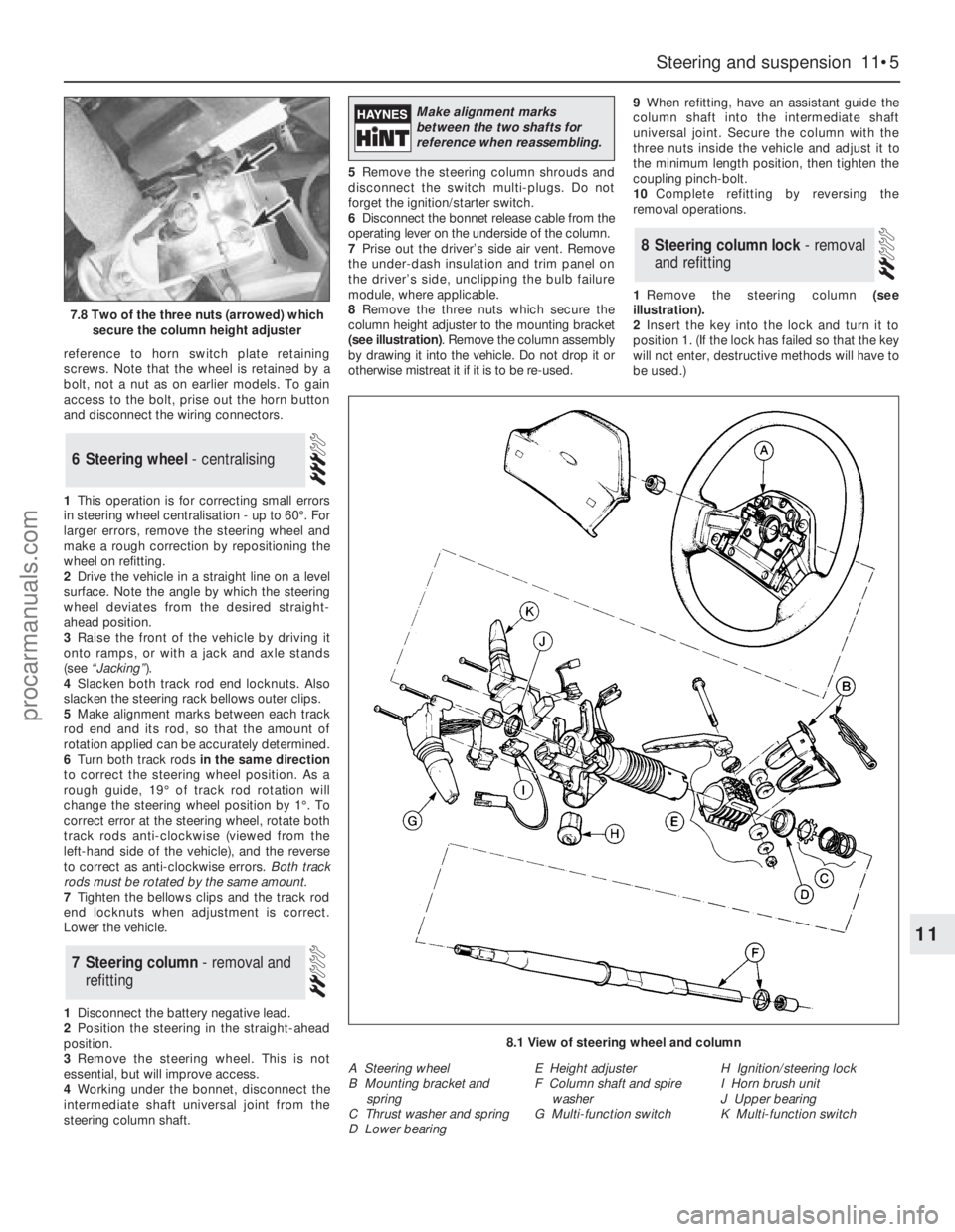

reference to horn switch plate retaining

screws. Note that the wheel is retained by a

bolt, not a nut as on earlier models. To gain

access to the bolt, prise out the horn button

and disconnect the wiring connectors.

1This operation is for correcting small errors

in steering wheel centralisation - up to 60°. For

larger errors, remove the steering wheel and

make a rough correction by repositioning the

wheel on refitting.

2Drive the vehicle in a straight line on a level

surface. Note the angle by which the steering

wheel deviates from the desired straight-

ahead position.

3Raise the front of the vehicle by driving it

onto ramps, or with a jack and axle stands

(see “Jacking”).

4Slacken both track rod end locknuts. Also

slacken the steering rack bellows outer clips.

5Make alignment marks between each track

rod end and its rod, so that the amount of

rotation applied can be accurately determined.

6Turn both track rodsin the same direction

to correct the steering wheel position. As a

rough guide, 19°of track rod rotation will

change the steering wheel position by 1°. To

correct error at the steering wheel, rotate both

track rods anti-clockwise (viewed from the

left-hand side of the vehicle), and the reverse

to correct as anti-clockwise errors. Both track

rods must be rotated by the same amount.

7Tighten the bellows clips and the track rod

end locknuts when adjustment is correct.

Lower the vehicle.

1Disconnect the battery negative lead.

2Position the steering in the straight-ahead

position.

3Remove the steering wheel. This is not

essential, but will improve access.

4Working under the bonnet, disconnect the

intermediate shaft universal joint from the

steering column shaft.5Remove the steering column shrouds and

disconnect the switch multi-plugs. Do not

forget the ignition/starter switch.

6Disconnect the bonnet release cable from the

operating lever on the underside of the column.

7Prise out the driver’s side air vent. Remove

the under-dash insulation and trim panel on

the driver’s side, unclipping the bulb failure

module, where applicable.

8Remove the three nuts which secure the

column height adjuster to the mounting bracket

(see illustration). Remove the column assembly

by drawing it into the vehicle. Do not drop it or

otherwise mistreat it if it is to be re-used.9When refitting, have an assistant guide the

column shaft into the intermediate shaft

universal joint. Secure the column with the

three nuts inside the vehicle and adjust it to

the minimum length position, then tighten the

coupling pinch-bolt.

10Complete refitting by reversing the

removal operations.

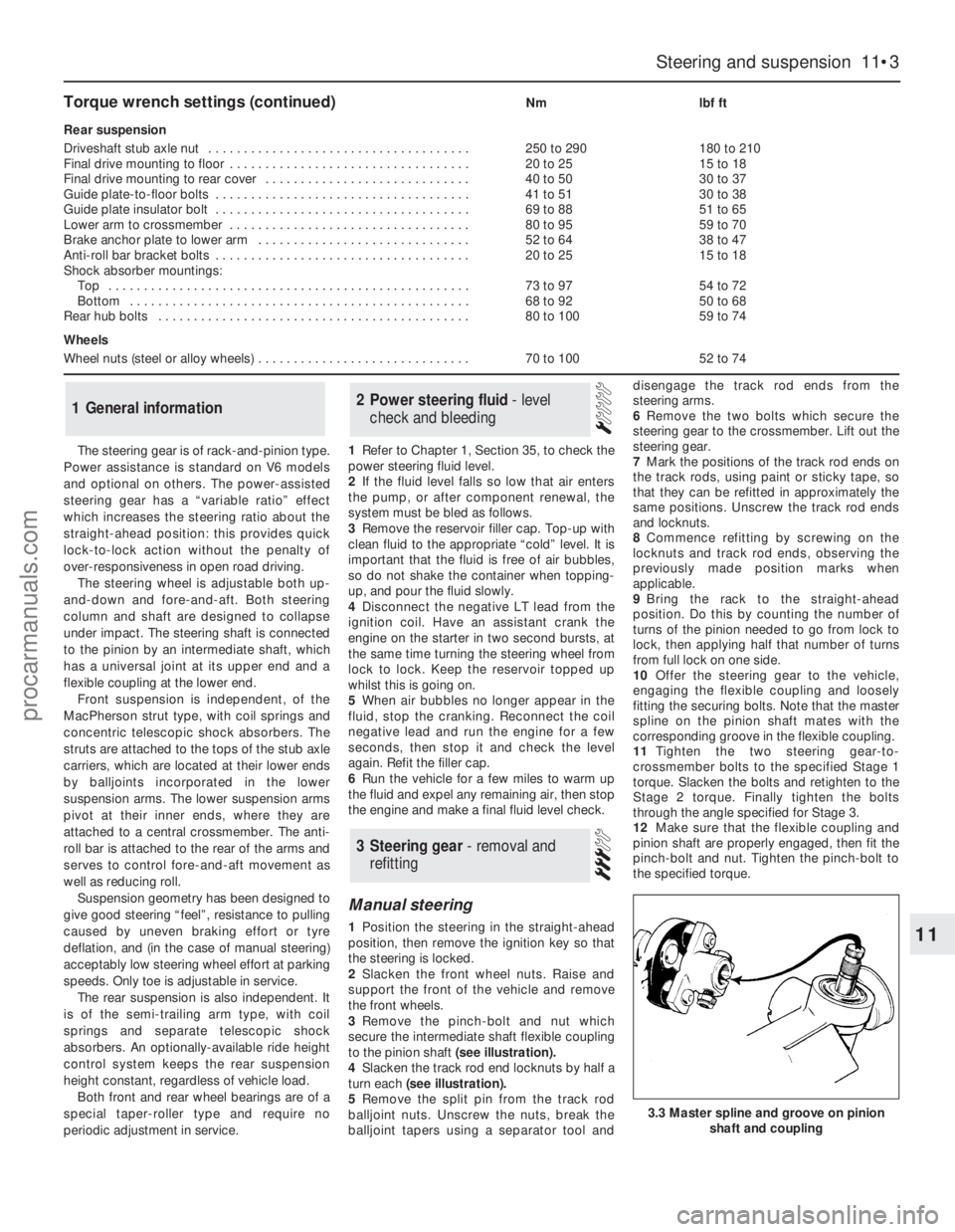

1Remove the steering column (see

illustration).

2Insert the key into the lock and turn it to

position 1. (If the lock has failed so that the key

will not enter, destructive methods will have to

be used.)

8Steering column lock - removal

and refitting

7Steering column - removal and

refitting

6Steering wheel - centralising

Steering and suspension 11•5

11

7.8 Two of the three nuts (arrowed) which

secure the column height adjuster

8.1 View of steering wheel and column

A Steering wheel

B Mounting bracket and

spring

C Thrust washer and spring

D Lower bearingE Height adjuster

F Column shaft and spire

washer

G Multi-function switchH Ignition/steering lock

I Horn brush unit

J Upper bearing

K Multi-function switch

Make alignment marks

between the two shafts for

reference when reassembling.

procarmanuals.com

Page 150 of 255

6When refitting, screw the track rod end onto

the track rod as far as the locknut, then back it

off half a turn.

7Insert the ball-pin into the steering arm.

Tighten the balljoint nut to the specified torque

and secure with a new split pin. Nip up the

track rod end locknut, but do not tighten it fully

yet.

8Refit the roadwheel, lower the vehicle and

tighten the wheel nuts to the specified torque.

9Check the toe setting as described in the

following Section. (This may not be strictly

necessary if the same track rod end has been

refitted, but is certainly advisable if any

components have been renewed.)

10Tighten the track rod end locknut when

toe is correct.

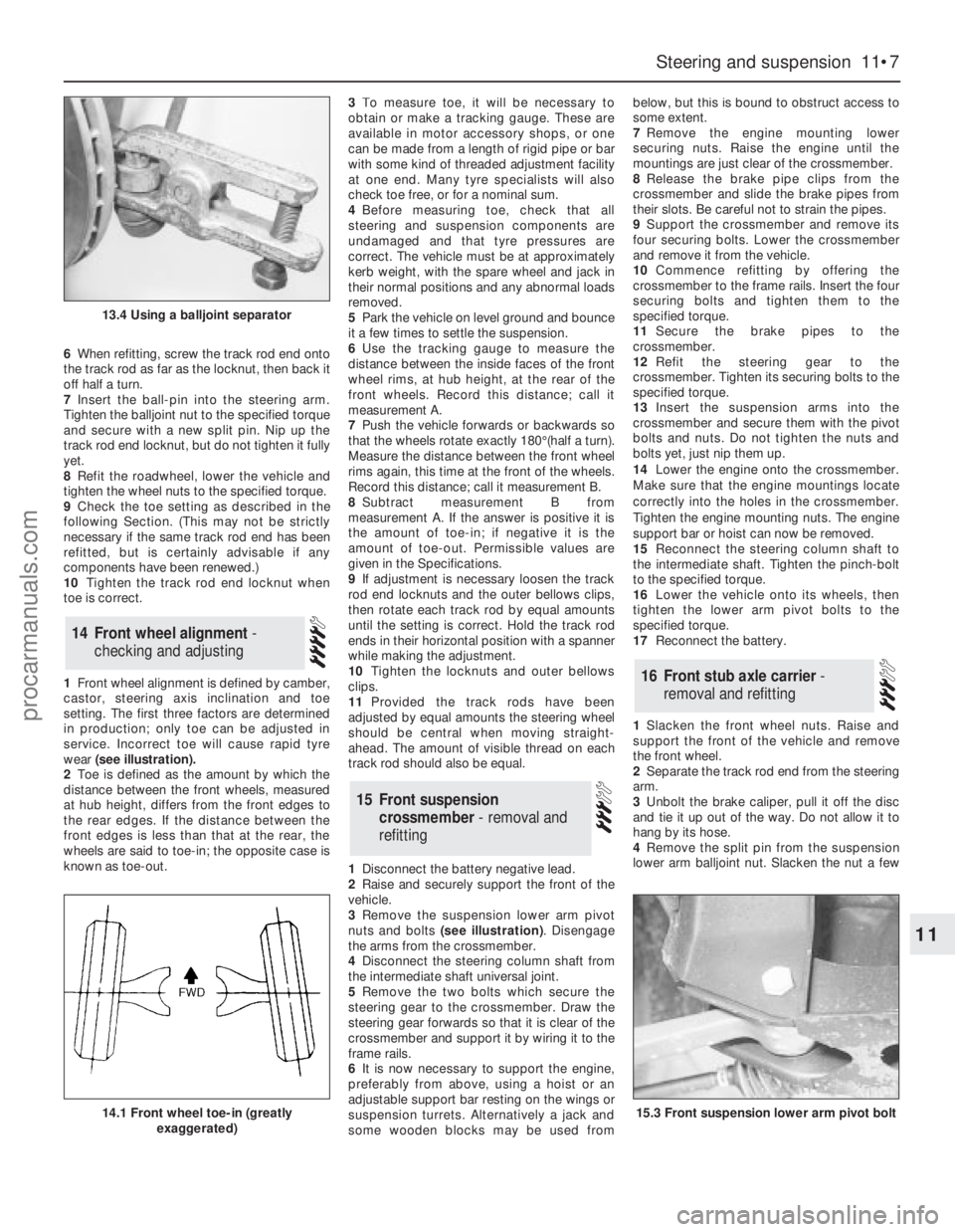

1Front wheel alignment is defined by camber,

castor, steering axis inclination and toe

setting. The first three factors are determined

in production; only toe can be adjusted in

service. Incorrect toe will cause rapid tyre

wear (see illustration).

2Toe is defined as the amount by which the

distance between the front wheels, measured

at hub height, differs from the front edges to

the rear edges. If the distance between the

front edges is less than that at the rear, the

wheels are said to toe-in; the opposite case is

known as toe-out.3To measure toe, it will be necessary to

obtain or make a tracking gauge. These are

available in motor accessory shops, or one

can be made from a length of rigid pipe or bar

with some kind of threaded adjustment facility

at one end. Many tyre specialists will also

check toe free, or for a nominal sum.

4Before measuring toe, check that all

steering and suspension components are

undamaged and that tyre pressures are

correct. The vehicle must be at approximately

kerb weight, with the spare wheel and jack in

their normal positions and any abnormal loads

removed.

5Park the vehicle on level ground and bounce

it a few times to settle the suspension.

6Use the tracking gauge to measure the

distance between the inside faces of the front

wheel rims, at hub height, at the rear of the

front wheels. Record this distance; call it

measurement A.

7Push the vehicle forwards or backwards so

that the wheels rotate exactly 180°(half a turn).

Measure the distance between the front wheel

rims again, this time at the front of the wheels.

Record this distance; call it measurement B.

8Subtract measurement B from

measurement A. If the answer is positive it is

the amount of toe-in; if negative it is the

amount of toe-out. Permissible values are

given in the Specifications.

9If adjustment is necessary loosen the track

rod end locknuts and the outer bellows clips,

then rotate each track rod by equal amounts

until the setting is correct. Hold the track rod

ends in their horizontal position with a spanner

while making the adjustment.

10Tighten the locknuts and outer bellows

clips.

11Provided the track rods have been

adjusted by equal amounts the steering wheel

should be central when moving straight-

ahead. The amount of visible thread on each

track rod should also be equal.

1Disconnect the battery negative lead.

2Raise and securely support the front of the

vehicle.

3Remove the suspension lower arm pivot

nuts and bolts (see illustration). Disengage

the arms from the crossmember.

4Disconnect the steering column shaft from

the intermediate shaft universal joint.

5Remove the two bolts which secure the

steering gear to the crossmember. Draw the

steering gear forwards so that it is clear of the

crossmember and support it by wiring it to the

frame rails.

6It is now necessary to support the engine,

preferably from above, using a hoist or an

adjustable support bar resting on the wings or

suspension turrets. Alternatively a jack and

some wooden blocks may be used frombelow, but this is bound to obstruct access to

some extent.

7Remove the engine mounting lower

securing nuts. Raise the engine until the

mountings are just clear of the crossmember.

8Release the brake pipe clips from the

crossmember and slide the brake pipes from

their slots. Be careful not to strain the pipes.

9Support the crossmember and remove its

four securing bolts. Lower the crossmember

and remove it from the vehicle.

10Commence refitting by offering the

crossmember to the frame rails. Insert the four

securing bolts and tighten them to the

specified torque.

11Secure the brake pipes to the

crossmember.

12Refit the steering gear to the

crossmember. Tighten its securing bolts to the

specified torque.

13Insert the suspension arms into the

crossmember and secure them with the pivot

bolts and nuts. Do not tighten the nuts and

bolts yet, just nip them up.

14Lower the engine onto the crossmember.

Make sure that the engine mountings locate

correctly into the holes in the crossmember.

Tighten the engine mounting nuts. The engine

support bar or hoist can now be removed.

15Reconnect the steering column shaft to

the intermediate shaft. Tighten the pinch-bolt

to the specified torque.

16Lower the vehicle onto its wheels, then

tighten the lower arm pivot bolts to the

specified torque.

17Reconnect the battery.

1Slacken the front wheel nuts. Raise and

support the front of the vehicle and remove

the front wheel.

2Separate the track rod end from the steering

arm.

3Unbolt the brake caliper, pull it off the disc

and tie it up out of the way. Do not allow it to

hang by its hose.

4Remove the split pin from the suspension

lower arm balljoint nut. Slacken the nut a few

16Front stub axle carrier -

removal and refitting

15Front suspension

crossmember - removal and

refitting

14Front wheel alignment -

checking and adjusting

Steering and suspension 11•7

11

13.4 Using a balljoint separator

14.1 Front wheel toe-in (greatly

exaggerated)15.3 Front suspension lower arm pivot bolt

procarmanuals.com

Page 153 of 255

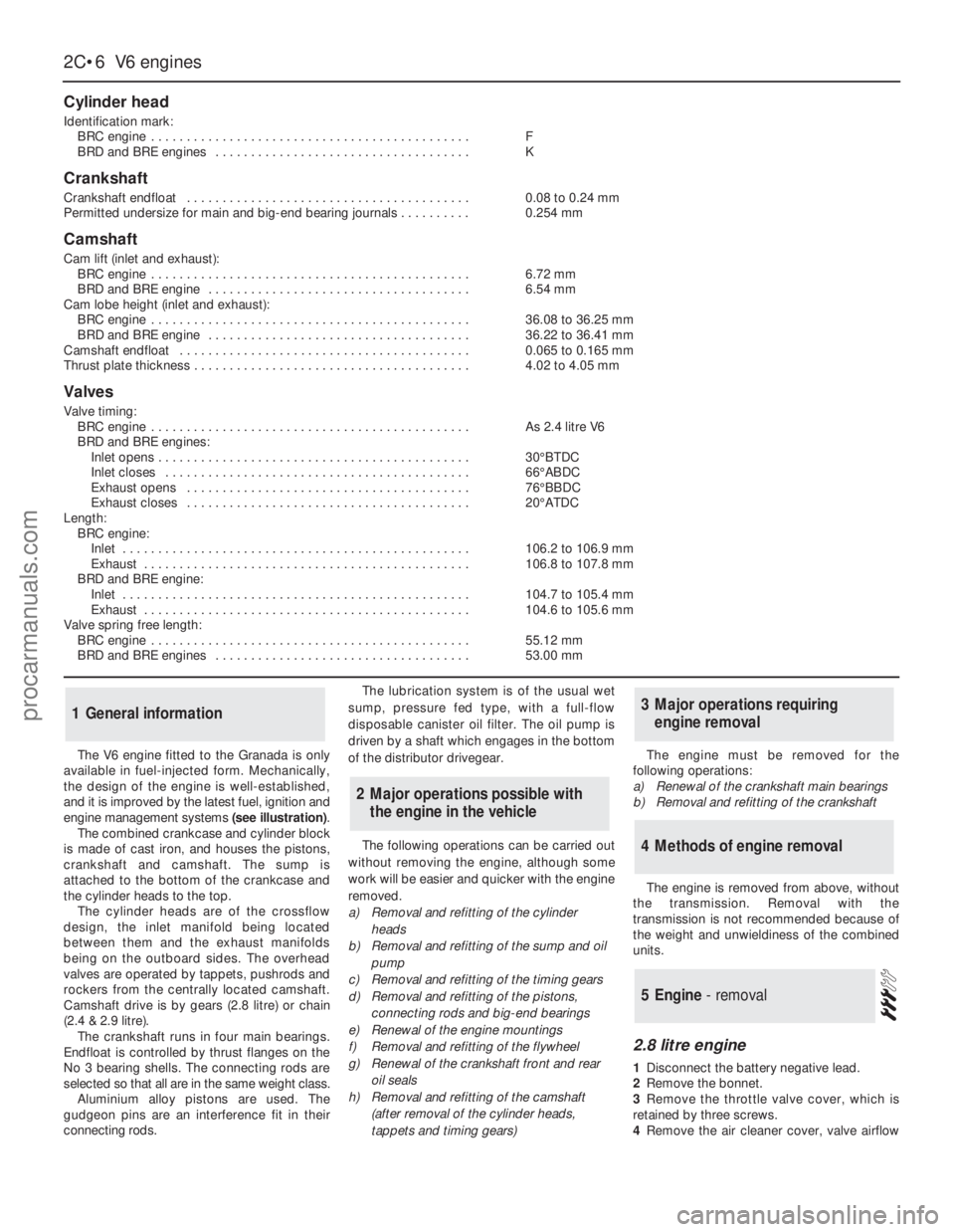

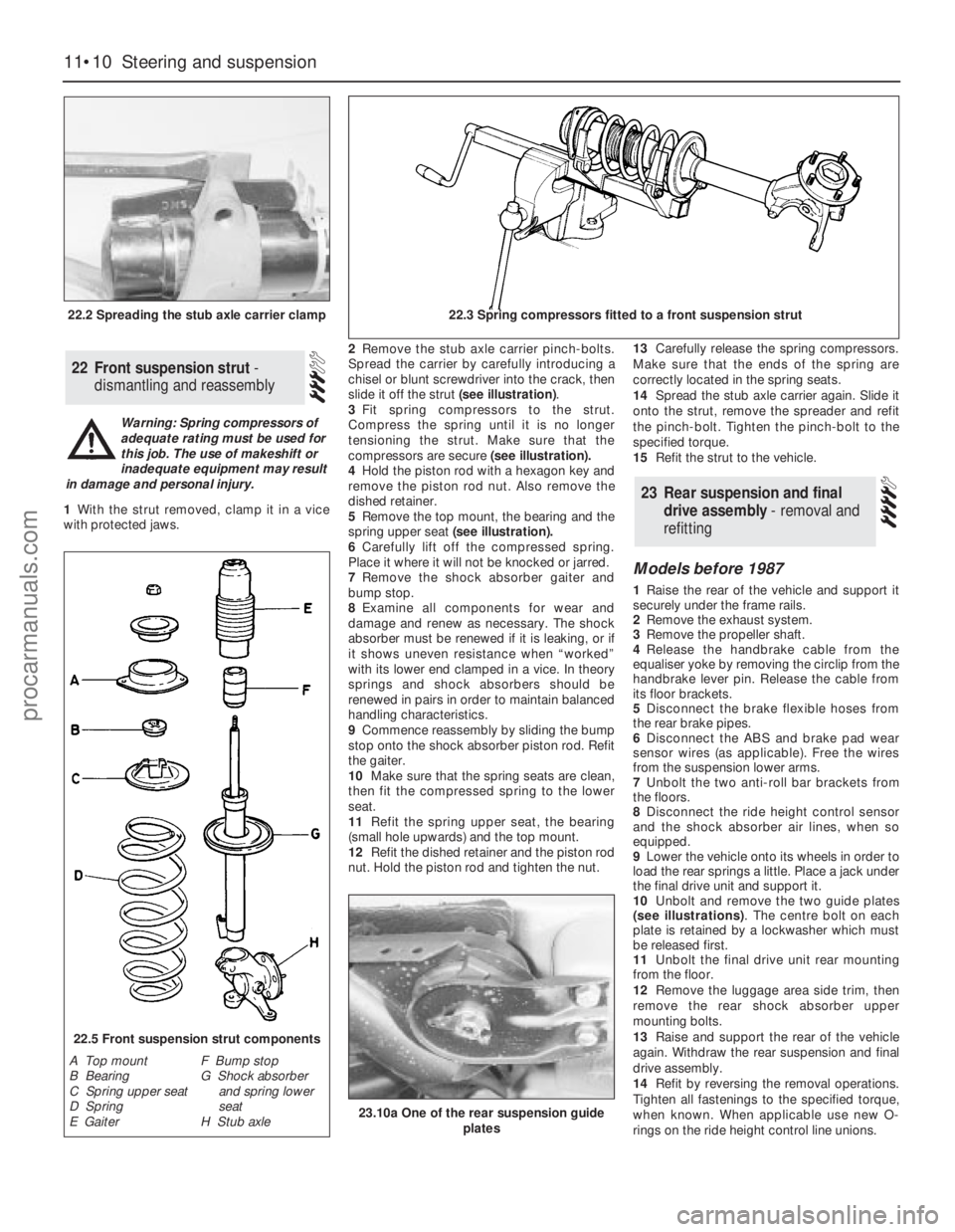

1With the strut removed, clamp it in a vice

with protected jaws.2Remove the stub axle carrier pinch-bolts.

Spread the carrier by carefully introducing a

chisel or blunt screwdriver into the crack, then

slide it off the strut (see illustration).

3Fit spring compressors to the strut.

Compress the spring until it is no longer

tensioning the strut. Make sure that the

compressors are secure (see illustration).

4Hold the piston rod with a hexagon key and

remove the piston rod nut. Also remove the

dished retainer.

5Remove the top mount, the bearing and the

spring upper seat(see illustration).

6Carefully lift off the compressed spring.

Place it where it will not be knocked or jarred.

7Remove the shock absorber gaiter and

bump stop.

8Examine all components for wear and

damage and renew as necessary. The shock

absorber must be renewed if it is leaking, or if

it shows uneven resistance when “worked”

with its lower end clamped in a vice. In theory

springs and shock absorbers should be

renewed in pairs in order to maintain balanced

handling characteristics.

9Commence reassembly by sliding the bump

stop onto the shock absorber piston rod. Refit

the gaiter.

10Make sure that the spring seats are clean,

then fit the compressed spring to the lower

seat.

11Refit the spring upper seat, the bearing

(small hole upwards) and the top mount.

12Refit the dished retainer and the piston rod

nut. Hold the piston rod and tighten the nut.13Carefully release the spring compressors.

Make sure that the ends of the spring are

correctly located in the spring seats.

14Spread the stub axle carrier again. Slide it

onto the strut, remove the spreader and refit

the pinch-bolt. Tighten the pinch-bolt to the

specified torque.

15Refit the strut to the vehicle.

Models before 1987

1Raise the rear of the vehicle and support it

securely under the frame rails.

2Remove the exhaust system.

3Remove the propeller shaft.

4Release the handbrake cable from the

equaliser yoke by removing the circlip from the

handbrake lever pin. Release the cable from

its floor brackets.

5Disconnect the brake flexible hoses from

the rear brake pipes.

6Disconnect the ABS and brake pad wear

sensor wires (as applicable). Free the wires

from the suspension lower arms.

7Unbolt the two anti-roll bar brackets from

the floors.

8Disconnect the ride height control sensor

and the shock absorber air lines, when so

equipped.

9Lower the vehicle onto its wheels in order to

load the rear springs a little. Place a jack under

the final drive unit and support it.

10Unbolt and remove the two guide plates

(see illustrations). The centre bolt on each

plate is retained by a lockwasher which must

be released first.

11Unbolt the final drive unit rear mounting

from the floor.

12Remove the luggage area side trim, then

remove the rear shock absorber upper

mounting bolts.

13Raise and support the rear of the vehicle

again. Withdraw the rear suspension and final

drive assembly.

14Refit by reversing the removal operations.

Tighten all fastenings to the specified torque,

when known. When applicable use new O-

rings on the ride height control line unions.

23Rear suspension and final

drive assembly - removal and

refitting

22Front suspension strut -

dismantling and reassembly

11•10Steering and suspension

22.2 Spreading the stub axle carrier clamp22.3 Spring compressors fitted to a front suspension strut

22.5 Front suspension strut components

A Top mount

B Bearing

C Spring upper seat

D Spring

E GaiterF Bump stop

G Shock absorber

and spring lower

seat

H Stub axle

Warning: Spring compressors of

adequate rating must be used for

this job. The use of makeshift or

inadequate equipment may result

in damage and personal injury.

23.10a One of the rear suspension guide

plates

procarmanuals.com