check engine FORD KUGA 2011 1.G User Guide

[x] Cancel search | Manufacturer: FORD, Model Year: 2011, Model line: KUGA, Model: FORD KUGA 2011 1.GPages: 2057

Page 87 of 2057

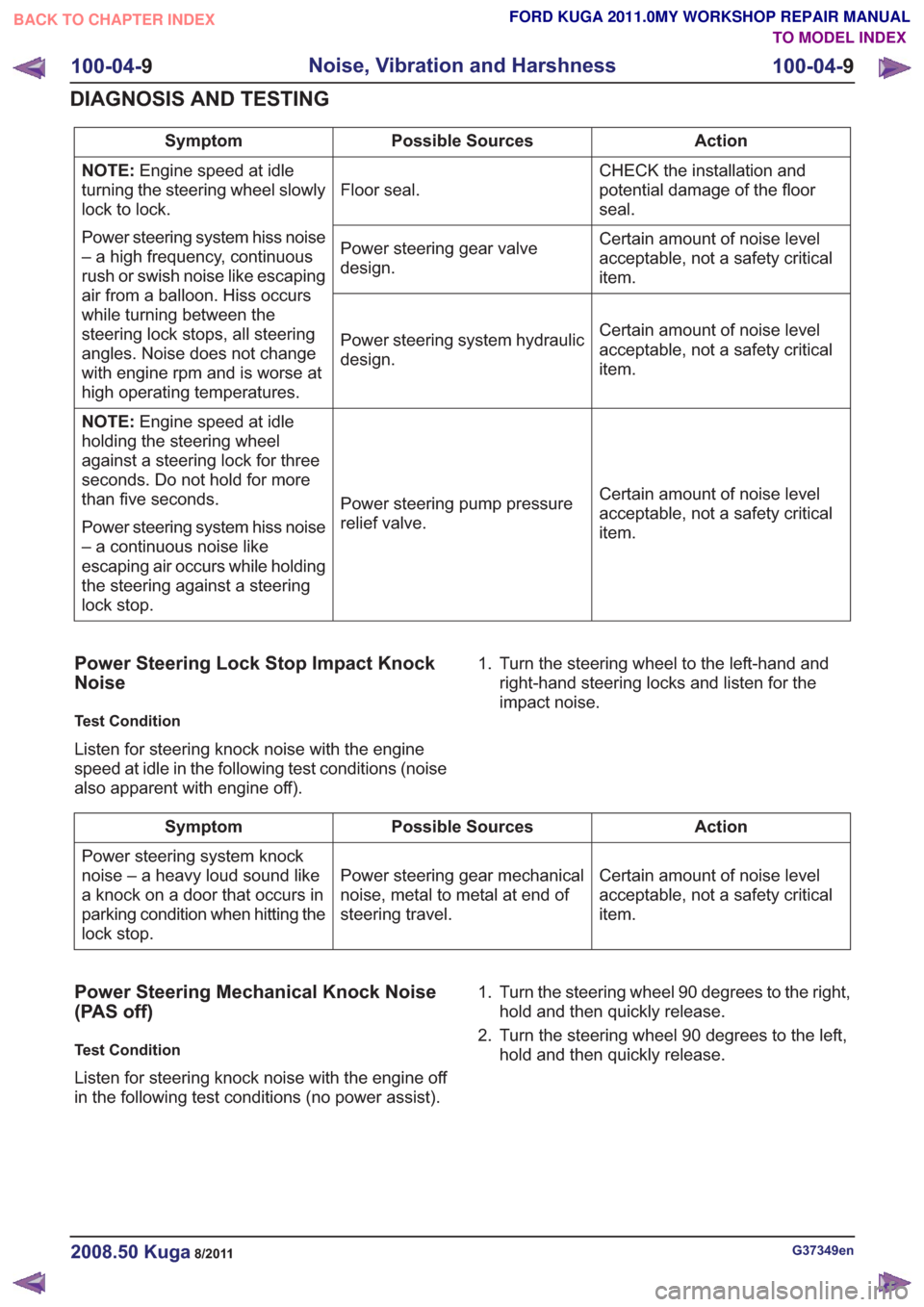

Action

Possible Sources

Symptom

CHECK the installation and

potential damage of the floor

seal.

Floor seal.

NOTE:

Engine speed at idle

turning the steering wheel slowly

lock to lock.

Power steering system hiss noise

– a high frequency, continuous

rush or swish noise like escaping

air from a balloon. Hiss occurs

while turning between the

steering lock stops, all steering

angles. Noise does not change

with engine rpm and is worse at

high operating temperatures. Certain amount of noise level

acceptable, not a safety critical

item.

Power steering gear valve

design.

Certain amount of noise level

acceptable, not a safety critical

item.

Power steering system hydraulic

design.

Certain amount of noise level

acceptable, not a safety critical

item.

Power steering pump pressure

relief valve.

NOTE:

Engine speed at idle

holding the steering wheel

against a steering lock for three

seconds. Do not hold for more

than five seconds.

Power steering system hiss noise

– a continuous noise like

escaping air occurs while holding

the steering against a steering

lock stop.

Power Steering Lock Stop Impact Knock

Noise

Test Condition

Listen for steering knock noise with the engine

speed at idle in the following test conditions (noise

also apparent with engine off). 1. Turn the steering wheel to the left-hand and

right-hand steering locks and listen for the

impact noise.

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

Power steering gear mechanical

noise, metal to metal at end of

steering travel.

Power steering system knock

noise – a heavy loud sound like

a knock on a door that occurs in

parking condition when hitting the

lock stop.

Power Steering Mechanical Knock Noise

(PAS off)

Test Condition

Listen for steering knock noise with the engine off

in the following test conditions (no power assist). 1. Turn the steering wheel 90 degrees to the right,

hold and then quickly release.

2. Turn the steering wheel 90 degrees to the left, hold and then quickly release.

G37349en2008.50 Kuga8/2011

100-04- 9

Noise, Vibration and Harshness

100-04- 9

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 89 of 2057

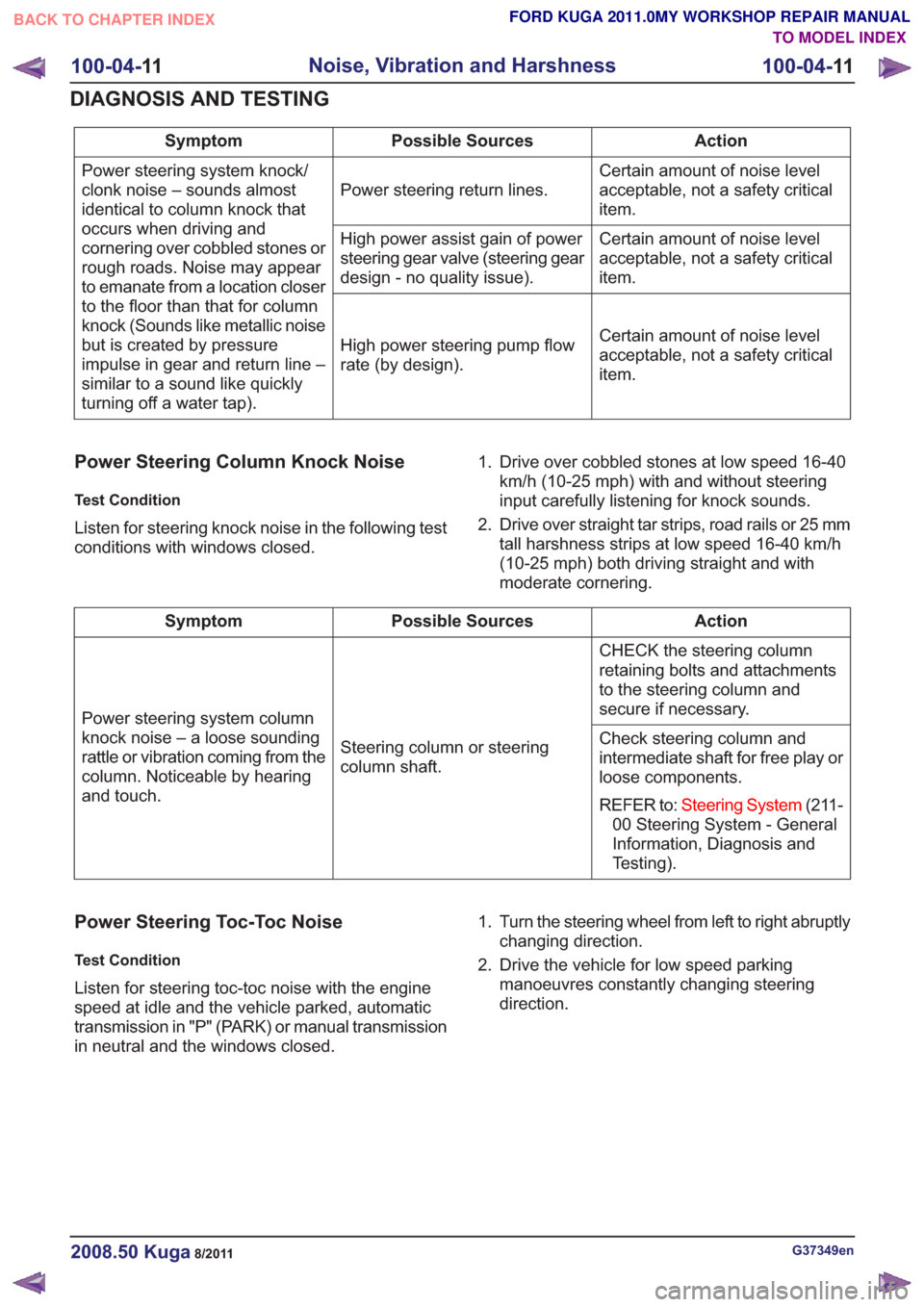

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

Power steering return lines.

Power steering system knock/

clonk noise – sounds almost

identical to column knock that

occurs when driving and

cornering over cobbled stones or

rough roads. Noise may appear

to emanate from a location closer

to the floor than that for column

knock (Sounds like metallic noise

but is created by pressure

impulse in gear and return line –

similar to a sound like quickly

turning off a water tap). Certain amount of noise level

acceptable, not a safety critical

item.

High power assist gain of power

steering gear valve (steering gear

design - no quality issue).

Certain amount of noise level

acceptable, not a safety critical

item.

High power steering pump flow

rate (by design).

Power Steering Column Knock Noise

Test Condition

Listen for steering knock noise in the following test

conditions with windows closed. 1. Drive over cobbled stones at low speed 16-40

km/h (10-25 mph) with and without steering

input carefully listening for knock sounds.

2. Drive over straight tar strips, road rails or 25 mm tall harshness strips at low speed 16-40 km/h

(10-25 mph) both driving straight and with

moderate cornering.

Action

Possible Sources

Symptom

CHECK the steering column

retaining bolts and attachments

to the steering column and

secure if necessary.

Steering column or steering

column shaft.

Power steering system column

knock noise – a loose sounding

rattle or vibration coming from the

column. Noticeable by hearing

and touch. Check steering column and

intermediate shaft for free play or

loose components.

REFER to:

Steering System (211-

00 Steering System - General

Information, Diagnosis and

Testing).

Power Steering Toc-Toc Noise

Test Condition

Listen for steering toc-toc noise with the engine

speed at idle and the vehicle parked, automatic

transmission in "P" (PARK) or manual transmission

in neutral and the windows closed. 1. Turn the steering wheel from left to right abruptly

changing direction.

2. Drive the vehicle for low speed parking manoeuvres constantly changing steering

direction.

G37349en2008.50 Kuga8/2011

100-04- 11

Noise, Vibration and Harshness

100-04- 11

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 91 of 2057

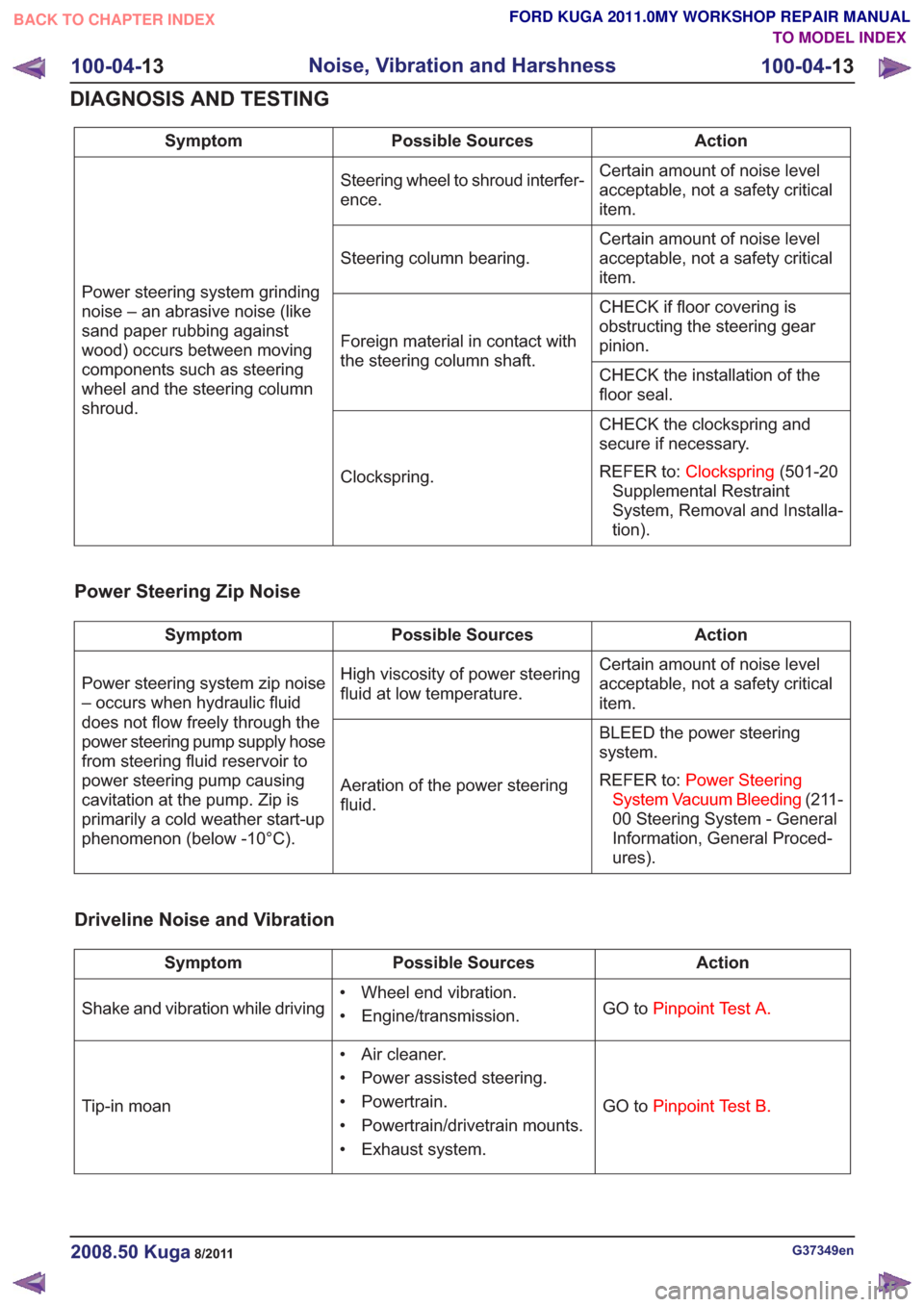

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

Steering wheel to shroud interfer-

ence.

Power steering system grinding

noise – an abrasive noise (like

sand paper rubbing against

wood) occurs between moving

components such as steering

wheel and the steering column

shroud. Certain amount of noise level

acceptable, not a safety critical

item.

Steering column bearing.

CHECK if floor covering is

obstructing the steering gear

pinion.

Foreign material in contact with

the steering column shaft.

CHECK the installation of the

floor seal.

CHECK the clockspring and

secure if necessary.

REFER to:Clockspring (501-20

Supplemental Restraint

System, Removal and Installa-

tion).

Clockspring.

Power Steering Zip Noise

Action

Possible Sources

Symptom

Certain amount of noise level

acceptable, not a safety critical

item.

High viscosity of power steering

fluid at low temperature.

Power steering system zip noise

– occurs when hydraulic fluid

does not flow freely through the

power steering pump supply hose

from steering fluid reservoir to

power steering pump causing

cavitation at the pump. Zip is

primarily a cold weather start-up

phenomenon (below -10°C). BLEED the power steering

system.

REFER to:

Power Steering

System Vacuum Bleeding (211-

00 Steering System - General

Information, General Proced-

ures).

Aeration of the power steering

fluid.

Driveline Noise and Vibration

Action

Possible Sources

Symptom

GO toPinpoint Test A.

• Wheel end vibration.

• Engine/transmission.

Shake and vibration while driving

GO toPinpoint Test B.

• Air cleaner.

• Power assisted steering.

• Powertrain.

• Powertrain/drivetrain mounts.

• Exhaust system.

Tip-in moan

G37349en2008.50 Kuga8/2011

100-04-

13

Noise, Vibration and Harshness

100-04- 13

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 94 of 2057

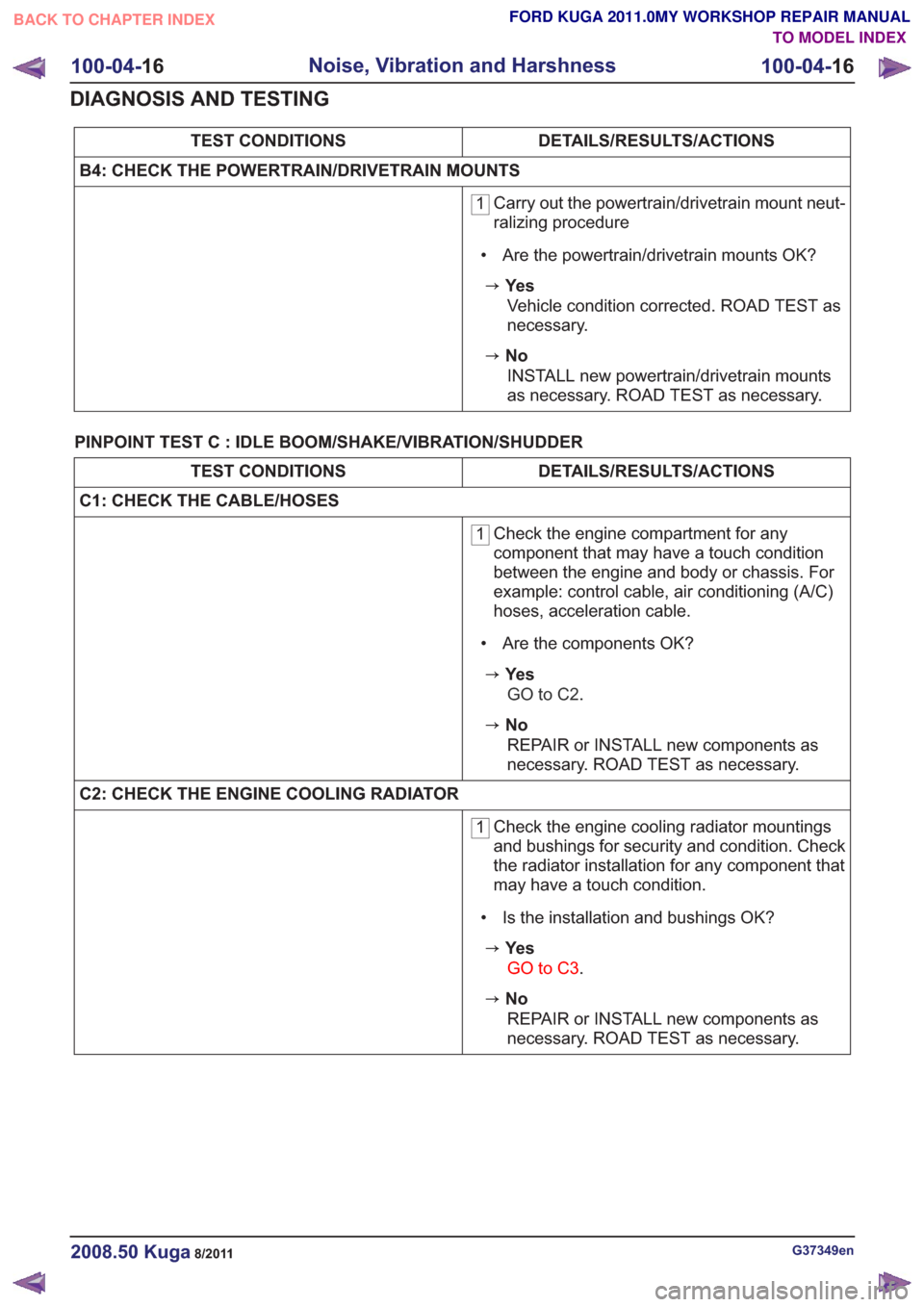

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

B4: CHECK THE POWERTRAIN/DRIVETRAIN MOUNTS

1 Carry out the powertrain/drivetrain mount neut-

ralizing procedure

• Are the powertrain/drivetrain mounts OK?

zYe s Vehicle condition corrected. ROAD TEST as

necessary.

zNoINSTALL new powertrain/drivetrain mounts

as necessary. ROAD TEST as necessary.

PINPOINT TEST C : IDLE BOOM/SHAKE/VIBRATION/SHUDDER

DETAILS/RESULTS/ACTIONS

TEST CONDITIONS

C1: CHECK THE CABLE/HOSES

1 Check the engine compartment for any

component that may have a touch condition

between the engine and body or chassis. For

example: control cable, air conditioning (A/C)

hoses, acceleration cable.

• Are the components OK?

zYe s GO to C2 .

zNo

REPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

C2: CHECK THE ENGINE COOLING RADIATOR

1 Check the engine cooling radiator mountings

and bushings for security and condition. Check

the radiator installation for any component that

may have a touch condition.

• Is the installation and bushings OK?

zYe s GO to C3 .

zNo

REPAIR or INSTALL new components as

necessary. ROAD TEST as necessary.

G37349en2008.50 Kuga8/2011

100-04- 16

Noise, Vibration and Harshness

100-04- 16

DIAGNOSIS AND TESTING

TO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 166 of 2057

Description

Item

Glow plug

1

Combustion Air Blower

2

Fuel pump

3

Fuel-fired heater on

4

Fuel-fired heater - large regulating step

5

Fuel-fired heater - small regulating step

6 Description

Item

Fuel-fired heater off

7

Blower motor on

8

Flame detection

9

Blower motor off

10

Large regulating step

11

Small regulating step

12

Boost heat mode

When the engine is running, the booster heater

helps the engine to heat the passenger

compartment at low ambient temperatures.

When the coolant temperature reaches 30 °C, the

control unit transmits a switch-on signal for the

passenger compartment blower via the CAN bus.

When the coolant temperature drops, the blower

remains on until the temperature reaches 20 °C

whereupon it is deactivated.

The fuel tank must be filled to at least 14% for the

system to be switched on. If the fuel level drops

below 8% then the system is switched off.

In boost mode, the fuel fired booster heater is only

switched on if all of the following criteria are met:

• Engine speed above 500 rpm. The fuel fired booster heater is not allowed to start up while

the engine is being cranked; this prevents a

shut-down due to low voltage if the battery

charge is low.

• Ambient temperature below 5 °C.

• Fuel level above 14% of total capacity.

• Function is active on the trip computer menu.

One of the following conditions is sufficient to

switch off the booster heater in boost heat mode:

• Engine speed below 500 rpm.

• Ambient temperature above 11 °C.

• Function is active on the trip computer menu.

• Fuel level below 8% of total capacity.

Programmable fuel fired booster heater

The programmable fuel fired booster heater has

two operating modes:

• Instant start

• Programmed start

The heater status is displayed on the instrument

cluster display. The parking heater mode is controlled via a menu in the message centre. The

fuel fired booster heater can be activated and

deactivated via the message centre. (If set to 'Auto'

the system is activated, if set to 'Off' the system is

completely deactivated)

Immediate start-up of the booster

heater

This function enables the fuel-fired booster heater

to be switched on manually when the engine is not

running. This function is activated via the menu on

the driver information system.

The ignition key must be in the II" position before

this menu can be accessed. The timer function of

the booster heater remains active when the ignition

key is in position "0".

After an immediate start-up of the booster heater

it is switched off again after 30 minutes (or if the

fuel level in the fuel tank drops below 8%). The

booster heater stops within 2 minutes of the engine

starting. This leaves enough time to check whether

the switch-on conditions for boost heat mode have

been met, thus preventing the booster heater from

having to switch off and switch back on again. The

heater can be switched off manually at any time

from the menu.

Programmed start-up of the booster

heater

The driver can use a menu to adjust the time at

which the vehicle is to be pre-heated. The following

options are available:

• Time setting. One or two times can be

programmed for each day of the week. It is

possible to program days either individually or

together in groups (Mon-Sun/Mon-Sat/Mon-Fri).

• Time and data setting

With the first option, the fuel-fired booster heater

will start repeatedly without needing to be G1066982en

2008.50 Kuga 8/2011 412-02-13

Auxiliary Climate Control

412-02-13

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 167 of 2057

reprogrammed. However, if the engine hasn't been

run since the last programmed start, the fuel-fired

booster heater will not start up the second time so

as to prevent the battery from being discharged.

The length of time required to pre-heat the vehicle

is calculated in the control unit of the fuel-fired

booster heater and is based on two temperature

values:

• Ambient air temperature: this message is taken

from the GEM via the CAN bus.

• Coolant temperature: this is determined via an internal sensor in the fuel-fired booster heater.

The maximum heating time is 30 minutes at an

outside air temperature of -10 °C or lower. The

heating time decreases proportionally with

increasing ambient temperature until the ambient

temperature is between +15 °C and +20 °C. Then

the minimum heating time is 10 minutes. The

parking heater is deactivated at temperatures

above +20 °C.

The sequence for a programmed start of the

booster heater is as follows:

• Two minutes before the start of the maximum heating time the driver information

system/instrument cluster sends an activation

message to the fuel-fired booster heater via the

CAN bus.

• The fuel-fired booster heater calculates the required heating time and, if necessary, sends

a delay request on the CAN bus.

• At the calculated time, the fuel-fired booster heater starts up. The conditions for start-up are:

engine not running and amount of fuel in the

fuel tank is above 14% of maximum.

• When the coolant temperature reaches +30 °C, the control unit of the fuel-fired booster heater

sends a request to switch on the passenger

compartment blower.

• Eight minutes after the programmed switch-off time, the booster heater stops heating mode

and starts a run-on operation to clean the

system's spark plugs.

• Ten minutes after the switch-off time, the post-cleaning operation is complete. The

additional ten minutes run-on time provides

some leeway in case the driver is late arriving.

After a programmed start-up of the booster heater

it is switched off again after the heating time has

elapsed (or if the fuel level in the fuel tank drops

below 8%). The booster heater stops within 2 minutes of the engine starting. This leaves enough

time to check whether the switch-on conditions for

boost heat mode have been met, thus preventing

the booster heater from having to switch off and

switch back on again. The heater can be switched

off manually at any time from the menu.

Whilst the fuel-fired booster heater is in additional

heating mode and/or parking heating mode, the

instrument cluster receives a fuel consumption

signal; this is used to re-calculate the vehicle's

remaining range and fuel consumption data.

Emergency shutoff

In the event of an accident in which the airbags

are deployed, the control unit of the fuel-fired

booster heater receives a message on the CAN

bus from the restraints control module (RCM).

When this message is received, the booster heater

system switches off immediately.

The booster heater control module deactivates the

system and does not respond to further messages

on the CAN bus. The booster heater control module

needs to be activated with WDS.

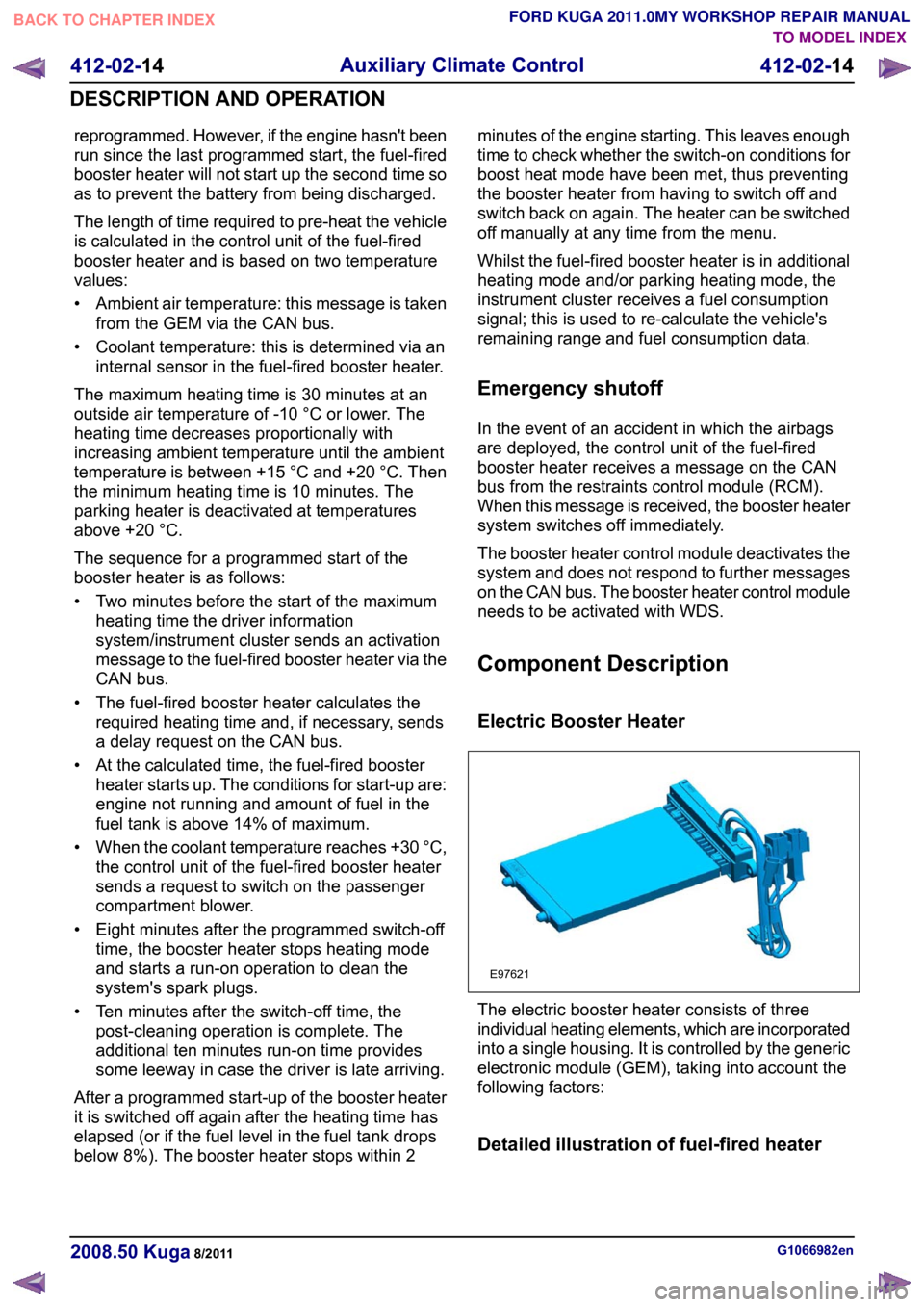

Component Description

Electric Booster Heater

The electric booster heater consists of three

individual heating elements, which are incorporated

into a single housing. It is controlled by the generic

electronic module (GEM), taking into account the

following factors:

Detailed illustration of fuel-fired heater

G1066982en

2008.50 Kuga 8/2011 412-02-14

Auxiliary Climate Control

412-02-14

DESCRIPTION AND OPERATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE97621

Page 170 of 2057

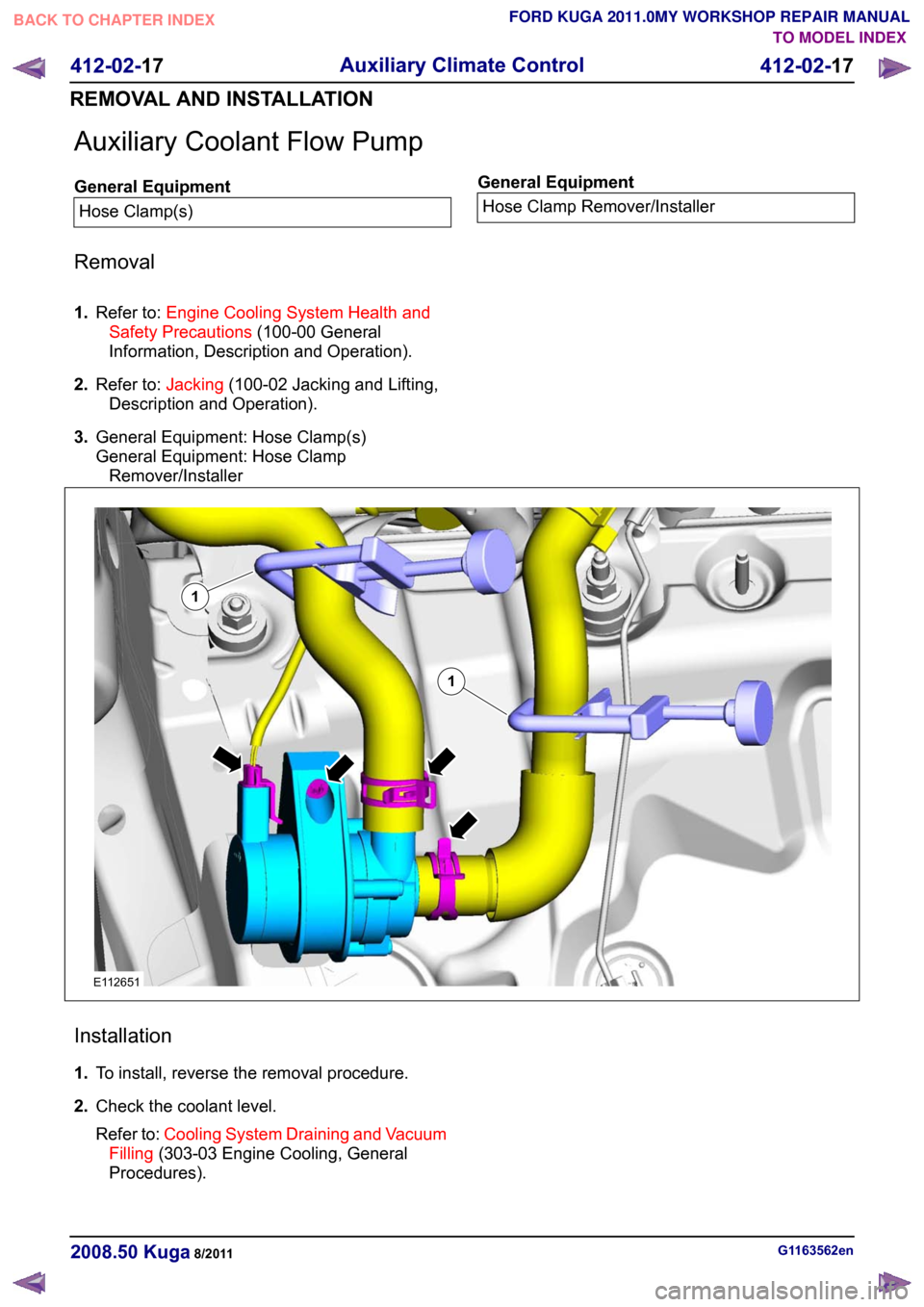

Auxiliary Coolant Flow Pump

General Equipment

Hose Clamp(s) General Equipment

Hose Clamp Remover/Installer

Removal

1. Refer to: Engine Cooling System Health and

Safety Precautions (100-00 General

Information, Description and Operation).

2. Refer to: Jacking(100-02 Jacking and Lifting,

Description and Operation).

3. General Equipment: Hose Clamp(s)

General Equipment: Hose Clamp

Remover/Installer Installation

1.

To install, reverse the removal procedure.

2. Check the coolant level.

Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures). G1163562en

2008.50 Kuga 8/2011 412-02-17

Auxiliary Climate Control

412-02-17

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL11E112651

Page 177 of 2057

7.

Installation

1.

To install, reverse the removal procedure.

2. Check the coolant level.

Refer to: Cooling System Draining and Vacuum

Filling (303-03 Engine Cooling, General

Procedures). G1163563en

2008.50 Kuga 8/2011 412-02-24

Auxiliary Climate Control

412-02-24

REMOVAL AND INSTALLATIONTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUALE112645

Page 199 of 2057

Oil Change Indicator Reset

1.

Turn the ignition key to position II without

cranking the engine.

2. Simultaneously press and hold the accelerator

pedal and the brake pedal for approximately 15

seconds until the oil change reminder indicator

starts to flash or the "Service Oil Reset

Complete" message appears in the information

and message center (if equipped).

3. Release the pedals.

4. Check that the oil change reminder indicator

has turned off or that there is no "Service Oil"

message in the information and message center

(if equipped). If the oil change reminder indicator

is still illuminated or the "Service Oil" message

is still displayed, turn the ignition key to position

0 and repeat the procedure from Step 1. If it has

turned off or the "Service Oil" message has

disappeared, proceed to Step 5.

5. Turn the ignition key to position 0 and leave it

there for at least 2 minutes so that the

powertrain control module (PCM) fully powers

down and updates the non-volatile memory

(NVM) in the PCM.

6. Turn the ignition key to position II without

cranking the engine and check that the oil

change reminder indicator is not illuminated or

that there is no "Service Oil" message displayed.

7. Turn the ignition key to position 0. G898940en

2008.50 Kuga 8/2011 413-09-4

Warning Devices

413-09-4

GENERAL PROCEDURESTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL

Page 263 of 2057

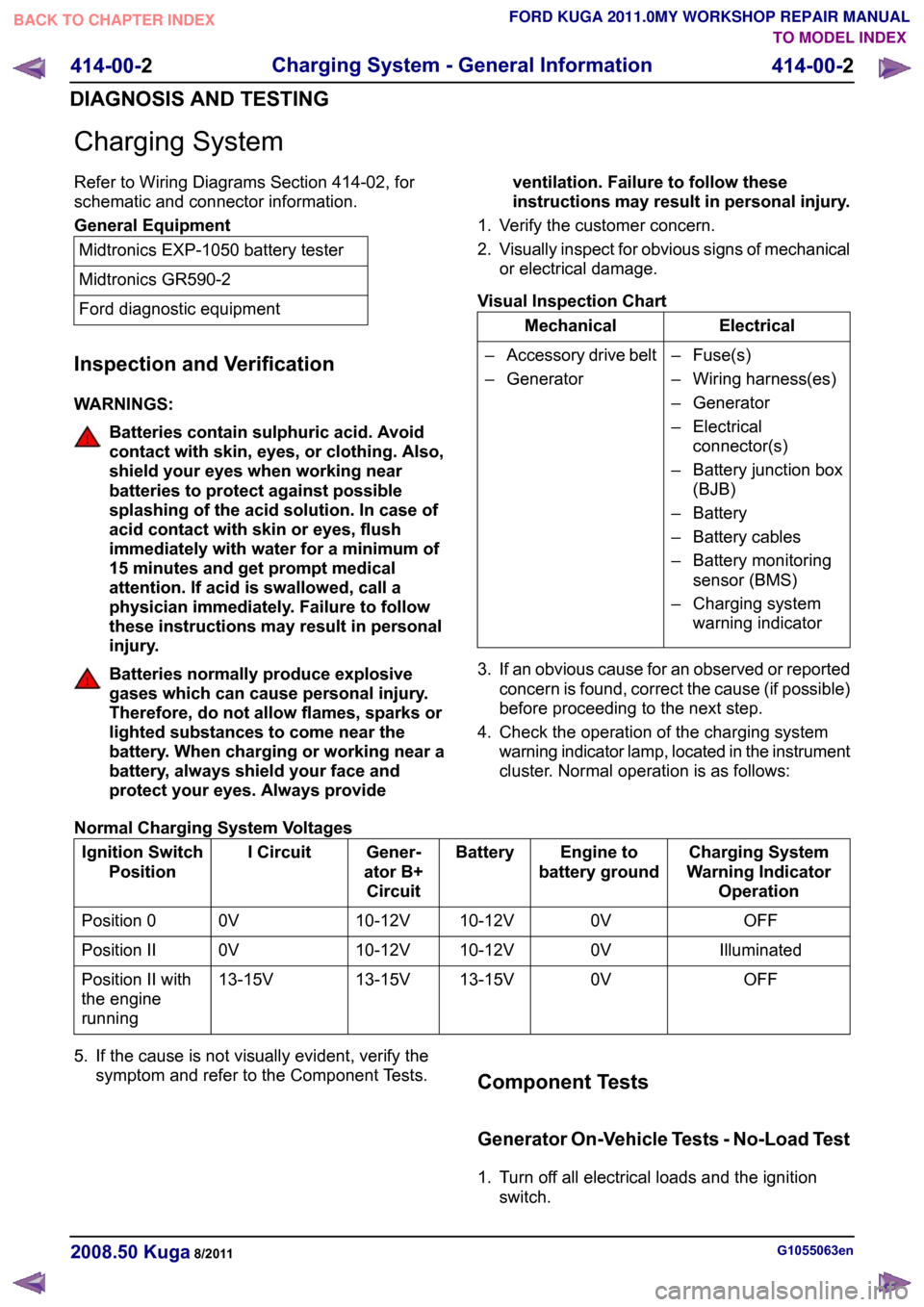

Charging System

Refer to Wiring Diagrams Section 414-02, for

schematic and connector information.

General Equipment

Midtronics EXP-1050 battery tester

Midtronics GR590-2

Ford diagnostic equipment

Inspection and Verification

WARNINGS: Batteries contain sulphuric acid. Avoid

contact with skin, eyes, or clothing. Also,

shield your eyes when working near

batteries to protect against possible

splashing of the acid solution. In case of

acid contact with skin or eyes, flush

immediately with water for a minimum of

15 minutes and get prompt medical

attention. If acid is swallowed, call a

physician immediately. Failure to follow

these instructions may result in personal

injury.

Batteries normally produce explosive

gases which can cause personal injury.

Therefore, do not allow flames, sparks or

lighted substances to come near the

battery. When charging or working near a

battery, always shield your face and

protect your eyes. Always provide

ventilation. Failure to follow these

instructions may result in personal injury.

1. Verify the customer concern.

2. Visually inspect for obvious signs of mechanical

or electrical damage.

Visual Inspection Chart Electrical

Mechanical

– Fuse(s)

– Wiring harness(es)

– Generator

– Electricalconnector(s)

– Battery junction box (BJB)

– Battery

– Battery cables

– Battery monitoring sensor (BMS)

– Charging system warning indicator

–

Accessory drive belt

– Generator

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible)

before proceeding to the next step.

4. Check the operation of the charging system warning indicator lamp, located in the instrument

cluster. Normal operation is as follows:

Normal Charging System Voltages Charging System

Warning Indicator Operation

Engine to

battery ground

Battery

Gener-

ator B+ Circuit

I Circuit

Ignition Switch

Position

OFF

0V

10-12V

10-12V

0V

Position 0

Illuminated

0V

10-12V

10-12V

0V

Position II

OFF

0V

13-15V

13-15V

13-15V

Position II with

the engine

running

5. If the cause is not visually evident, verify the symptom and refer to the Component Tests. Component Tests

Generator On-Vehicle Tests - No-Load Test

1. Turn off all electrical loads and the ignition

switch. G1055063en

2008.50 Kuga 8/2011 414-00-2

Charging System - General Information

414-00-2

DIAGNOSIS AND TESTINGTO MODEL INDEX

BACK TO CHAPTER INDEX

FORD KUGA 2011.0MY WORKSHOP REPAIR MANUAL