ABS FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 85 of 413

03-02-09

Suspension

03-02-09

WOOD BLOCK

F

1287-A

FIG. 9—Upper

Arm

Support—

Montego, Falcon

and

Fairlane

Tool-T62F-3006-A

ARM SUPPORT

LOWER BALL JOINT

SLEEVE

Too/-T57P-3006-A

F 1157-C

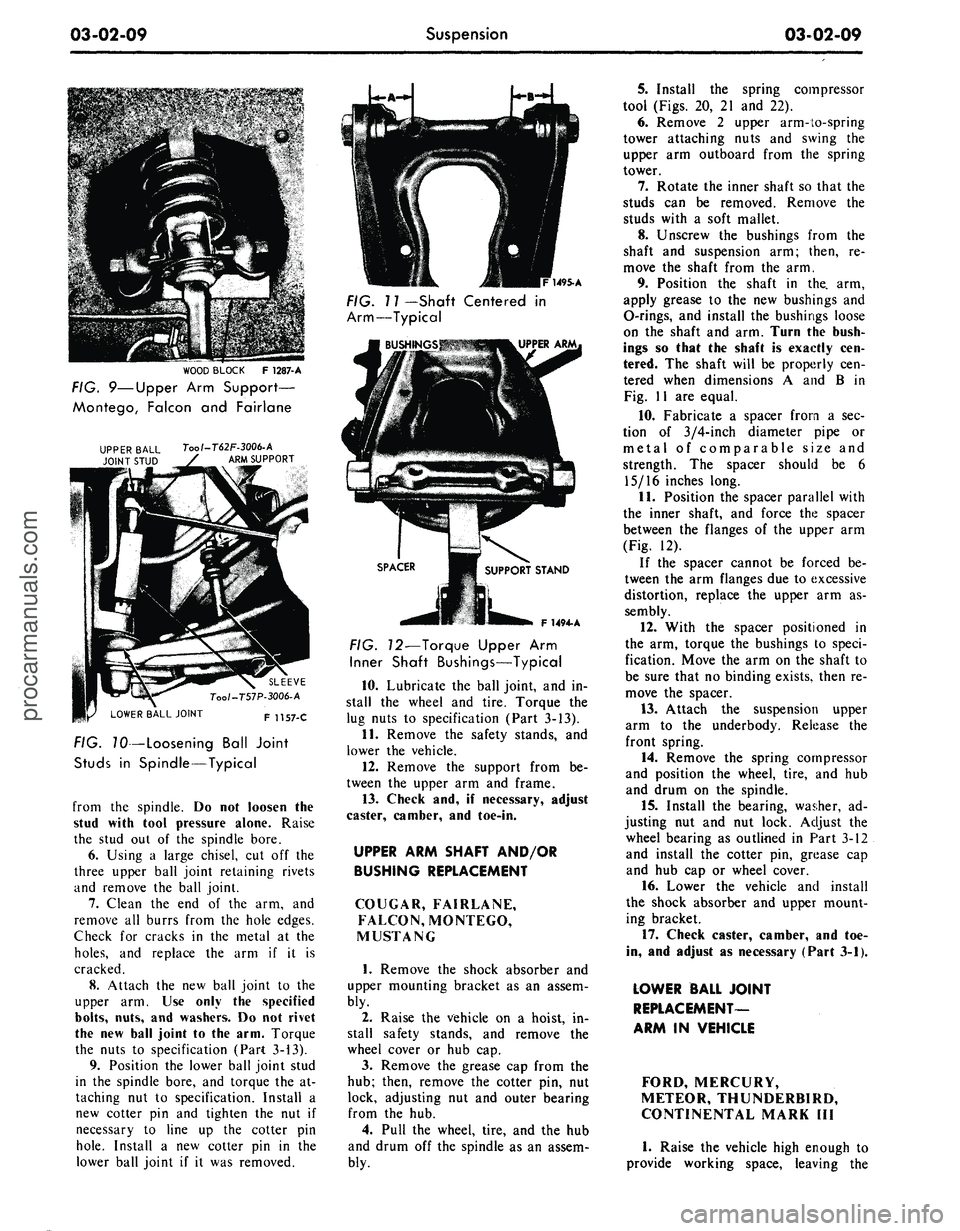

FIG. TO—Loosening Ball Joint

Studs

in

Spindle—Typical

from

the

spindle.

Do not

loosen

the

stud with tool pressure alone. Raise

the stud

out of the

spindle bore.

6. Using

a

large chisel,

cut off the

three upper ball joint retaining rivets

and remove

the

ball joint.

7.

Clean

the end of the arm, and

remove

all

burrs from

the

hole edges.

Check

for

cracks

in the

metal

at the

holes,

and

replace

the arm if it is

cracked.

8. Attach

the new

ball joint

to the

upper

arm. Use

only

the

specified

bolts,

nuts,

and

washers.

Do not

rivet

the

new

ball joint

to the

arm. Torque

the nuts

to

specification (Part 3-13).

9. Position

the

lower ball joint stud

in

the

spindle bore,

and

torque

the at-

taching

nut to

specification. Install

a

new cotter

pin and

tighten

the nut if

necessary

to

line

up the

cotter

pin

hole.

Install

a new

cotter

pin in the

lower ball joint

if it was

removed.

1495-A

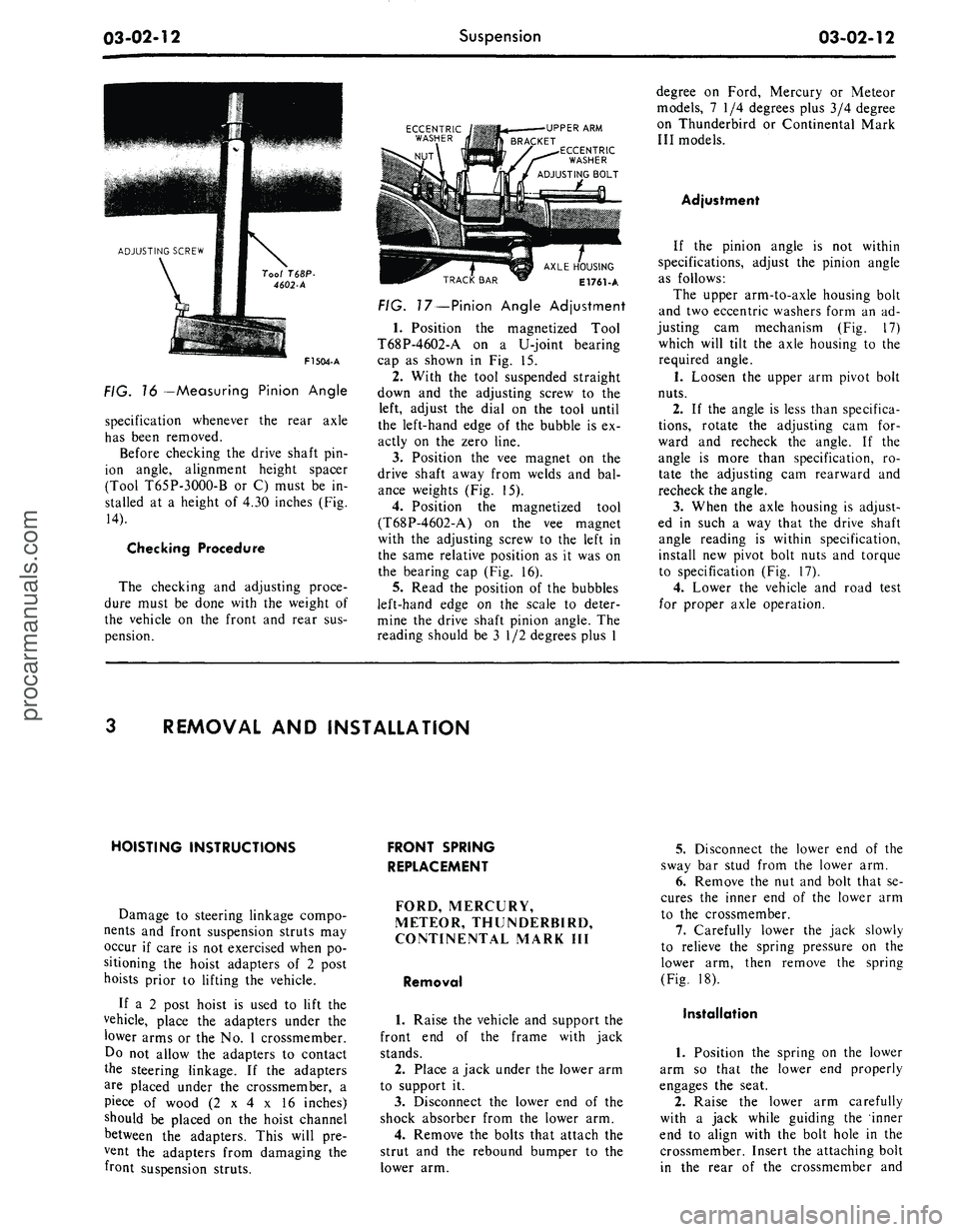

FIG. 11 —Shaft Centered

in

Arm—Typical

F 1494- A

FIG. 12—Torque Upper

Arm

Inner Shaft Bushings—Typical

10.

Lubricate

the

ball joint,

and in-

stall

the

wheel

and

tire. Torque

the

lug nuts

to

specification (Part 3-13).

11.

Remove

the

safety stands,

and

lower

the

vehicle.

12.

Remove

the

support from

be-

tween

the

upper

arm and

frame.

13.

Check

and, if

necessary, adjust

caster, camber,

and

toe-in.

UPPER ARM SHAFT AND/OR

BUSHING REPLACEMENT

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

1.

Remove

the

shock absorber

and

upper mounting bracket

as an

assem-

bly.

2.

Raise

the

vehicle

on a

hoist,

in-

stall safety stands,

and

remove

the

wheel cover

or hub cap.

3.

Remove

the

grease

cap

from

the

hub;

then, remove

the

cotter

pin, nut

lock, adjusting

nut and

outer bearing

from

the hub.

4.

Pull

the

wheel, tire,

and the hub

and drum

off the

spindle

as an

assem-

bly.

5.

Install

the

spring compressor

tool (Figs.

20, 21 and 22).

6. Remove

2

upper arm-to-spring

tower attaching nuts

and

swing

the

upper

arm

outboard from

the

spring

tower.

7.

Rotate

the

inner shaft

so

that

the

studs

can be

removed. Remove

the

studs with

a

soft mallet.

8. Unscrew

the

bushings from

the

shaft

and

suspension

arm;

then,

re-

move

the

shaft from

the arm.

9. Position

the

shaft

in the. arm,

apply grease

to the new

bushings

and

O-rings,

and

install

the

bushings loose

on

the

shaft

and

arm. Turn

the

bush-

ings

so

that

the

shaft

is

exactly

cen-

tered.

The

shaft will

be

properly

cen-

tered when dimensions

A and B in

Fig.

11 are

equal.

10.

Fabricate

a

spacer from

a sec-

tion

of

3/4-inch diameter pipe

or

metal

of

comparable size

and

strength.

The

spacer should

be 6

15/16 inches long.

11.

Position

the

spacer parallel with

the inner shaft,

and

force

the

spacer

between

the

flanges

of the

upper

arm

(Fig.

12).

If

the

spacer cannot

be

forced

be-

tween

the arm

flanges due

to

excessive

distortion, replace

the

upper

arm as-

sembly.

12.

With

the

spacer positioned

in

the

arm,

torque

the

bushings

to

speci-

fication. Move

the arm on the

shaft

to

be sure that

no

binding exists, then

re-

move

the

spacer.

13.

Attach

the

suspension upper

arm

to the

underbody. Release

the

front spring.

14.

Remove

the

spring compressor

and position

the

wheel, tire,

and hub

and drum

on the

spindle.

15.

Install

the

bearing, washer,

ad-

justing

nut and nut

lock. Adjust

the

wheel bearing

as

outlined

in

Part

3-12

and install

the

cotter

pin,

grease

cap

and

hub cap or

wheel cover.

16.

Lower

the

vehicle

and

install

the shock absorber

and

upper mount-

ing bracket.

17.

Check caster, camber,

and toe-

in,

and

adjust

as

necessary (Part 3-1).

LOWER BALL JOINT

REPLACEMENT-

ARM

IN

VEHICLE

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK

III

1.

Raise

the

vehicle high enough

to

provide working space, leaving

theprocarmanuals.com

Page 88 of 413

03-02-12

Suspension

03-02-12

ECCENTRIC

WASHER

F1504-A

FIG. 76 —Measuring Pinion Angle

specification whenever the rear axle

has been removed.

Before checking the drive shaft pin-

ion angle, alignment height spacer

(Tool T65P-3OOO-B or C) must be in-

stalled at a height of 4.30 inches (Fig.

14).

Checking Procedure

The checking and adjusting proce-

dure must be done with the weight of

the vehicle on the front and rear sus-

pension.

UPPER ARM

KET

ECCENTRIC

WASHER

AXLE HOUSING

E1761-A

FIG.

17

—

Pinion

Angle Adjustment

1.

Position the magnetized Tool

T68P-4602-A on a U-joint bearing

cap as shown in Fig. 15.

2.

With the tool suspended straight

down and the adjusting screw to the

left, adjust the dial on the tool until

the left-hand edge of the bubble is ex-

actly on the zero line.

3.

Position the vee magnet on the

drive shaft away from welds and bal-

ance weights (Fig. 15).

4.

Position the magnetized tool

(T68P-4602-A) on the vee magnet

with the adjusting screw to the left in

the same relative position as it was on

the bearing cap (Fig. 16).

5.

Read the position of the bubbles

left-hand edge on the scale to deter-

mine the drive shaft pinion angle. The

reading should be 3 1/2 degrees plus 1

degree on Ford, Mercury or Meteor

models, 7 1/4 degrees plus 3/4 degree

on Thunderbird or Continental Mark

III models.

Adjustment

If the pinion angle is not within

specifications, adjust the pinion angle

as follows:

The upper arm-to-axle housing bolt

and two eccentric washers form an ad-

justing cam mechanism (Fig. 17)

which will tilt the axle housing to the

required angle.

1.

Loosen the upper arm pivot bolt

nuts.

2.

If the angle is less than specifica-

tions,

rotate the adjusting cam for-

ward and recheck the angle. If the

angle is more than specification, ro-

tate the adjusting cam rearward and

recheck the angle.

3.

When the axle housing is adjust-

ed in such a way that the drive shaft

angle reading is within specification,

install new pivot bolt nuts and torque

to specification (Fig. 17).

4.

Lower the vehicle and road test

for proper axle operation.

REMOVAL AND INSTALLATION

HOISTING INSTRUCTIONS

Damage to steering linkage compo-

nents and front suspension struts may

occur if care is not exercised when po-

sitioning the hoist adapters of 2 post

hoists prior to lifting the vehicle.

If a 2 post hoist is used to lift the

vehicle, place the adapters under the

lower arms or the No. 1 crossmember.

Do not allow the adapters to contact

the steering linkage. If the adapters

are placed under the crossmember, a

piece of wood (2 x 4 x 16 inches)

should be placed on the hoist channel

between the adapters. This will pre-

vent the adapters from damaging the

front suspension struts.

FRONT SPRING

REPLACEMENT

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK HI

Removal

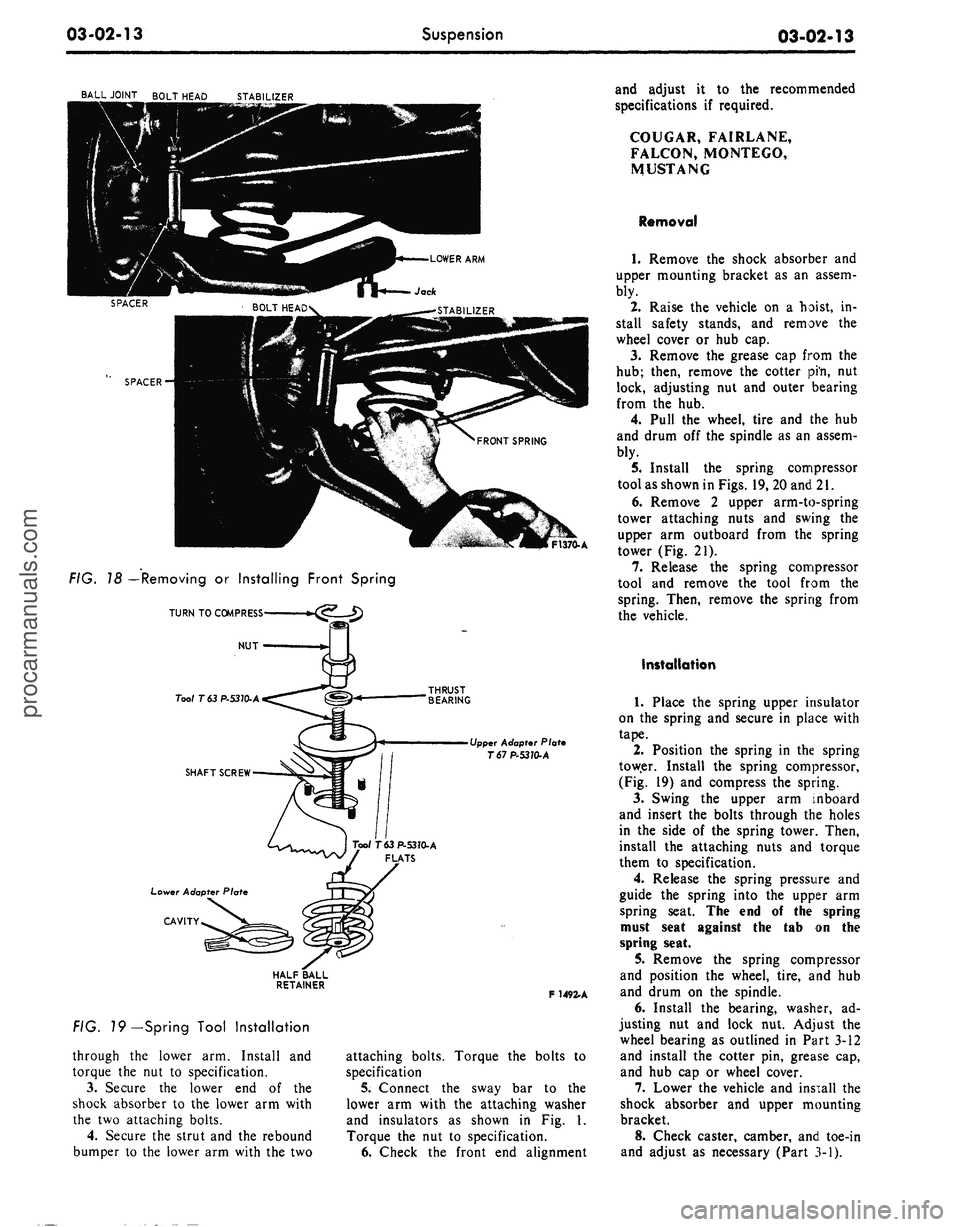

1.

Raise the vehicle and support the

front end of the frame with jack

stands.

2.

Place a jack under the lower arm

to support it.

3.

Disconnect the lower end of the

shock absorber from the lower arm.

4.

Remove the bolts that attach the

strut and the rebound bumper to the

lower arm.

5.

Disconnect the lower end of the

sway bar stud from the lower arm.

6. Remove the nut and bolt that se-

cures the inner end of the lower arm

to the crossmember.

7.

Carefully lower the jack slowly

to relieve the spring pressure on the

lower arm, then remove the spring

(Fig. 18).

Installation

1.

Position the spring on the lower

arm so that the lower end properly

engages the seat.

2.

Raise the lower arm carefully

with a jack while guiding the inner

end to align with the bolt hole in the

crossmember. Insert the attaching bolt

in the rear of the crossmember andprocarmanuals.com

Page 89 of 413

03-02-13

Suspension

03-02-13

BALL JOINT BOLT HEAD

STABILIZER

F1370-A

FIG. 18 —Removing or Installing Front Spring

TURN TO COMPRESS

NUT

•

Tool T 63 P-53J0-A

SHAFT SCREW

Lower Adapter Plate

CAVITY

Upper Adapter Plate

T67P-5370-A

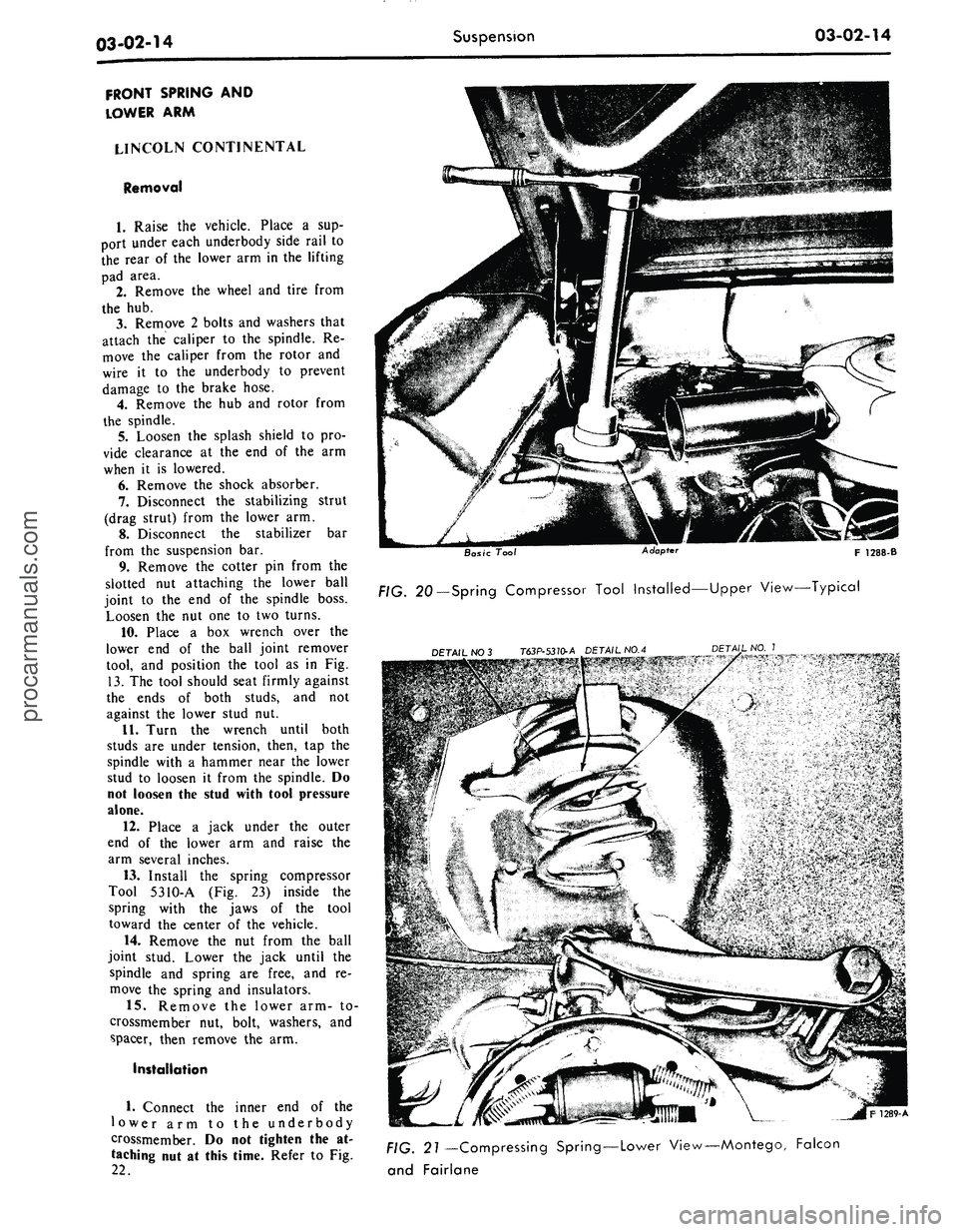

FIG. 79—Spring Tool Installation

through the lower arm. Install and

torque the nut to specification.

3.

Secure the lower end of the

shock absorber to the lower arm with

the two attaching bolts.

4.

Secure the strut and the rebound

bumper to the lower arm with the two

F

1492.

A

attaching bolts. Torque the bolts to

specification

5.

Connect the sway bar to the

lower arm with the attaching washer

and insulators as shown in Fig. 1.

Torque the nut to specification.

6. Check the front end alignment

and adjust it to the recommended

specifications if required.

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1.

Remove the shock absorber and

upper mounting bracket as an assem-

bly.

2.

Raise the vehicle on a hoist, in-

stall safety stands, and remove the

wheel cover or hub cap.

3.

Remove the grease cap from the

hub;

then, remove the cotter pin, nut

lock, adjusting nut and outer bearing

from the hub.

4.

Pull the wheel, tire and the hub

and drum off the spindle as an assem-

bly.

5.

Install the spring compressor

tool as shown in Figs. 19, 20 and 21.

6. Remove 2 upper arm-to-spring

tower attaching nuts and swing the

upper arm outboard from the spring

tower (Fig. 21).

7.

Release the spring compressor

tool and remove the tool from the

spring. Then, remove the spring from

the vehicle.

Installation

1.

Place the spring upper insulator

on the spring and secure in place with

tape.

2.

Position the spring in the spring

tower. Install the spring compressor,

(Fig. 19) and compress the spring.

3.

Swing the upper arm inboard

and insert the bolts through the holes

in the side of the spring tower. Then,

install the attaching nuts and torque

them to specification.

4.

Release the spring pressure and

guide the spring into the upper arm

spring seat. The end o! the spring

must seat against the tab on the

spring seat.

5. Remove the spring compressor

and position the wheel, tire, and hub

and drum on the spindle.

6. Install the bearing, washer, ad-

justing nut and lock nut. Adjust the

wheel bearing as outlined in Part 3-12

and install the cotter pin, grease cap,

and hub cap or wheel cover.

7.

Lower the vehicle and install the

shock absorber and upper mounting

bracket.

8. Check caster, camber, and toe-in

and adjust as necessary (Part 3-1).procarmanuals.com

Page 90 of 413

03-02-14

Suspension

03-02-14

FRONT SPRING AND

LOWER ARM

LINCOLN CONTINENTAL

Removal

1.

Raise the vehicle. Place a sup-

port under each underbody side rail to

the rear of the lower arm in the lifting

pad area.

2.

Remove the wheel and tire from

the hub.

3.

Remove 2 bolts and washers that

attach the caliper to the spindle. Re-

move the caliper from the rotor and

wire it to the underbody to prevent

damage to the brake hose.

4.

Remove the hub and rotor from

the spindle.

5.

Loosen the splash shield to pro-

vide clearance at the end of the arm

when it is lowered.

6. Remove the shock absorber.

7.

Disconnect the stabilizing strut

(drag strut) from the lower arm.

8. Disconnect the stabilizer bar

from the suspension bar.

9. Remove the cotter pin from the

slotted nut attaching the lower ball

joint to the end of the spindle boss.

Loosen the nut one to two turns.

10.

Place a box wrench over the

lower end of the ball joint remover

tool, and position the tool as in Fig.

13.

The tool should seat firmly against

the ends of both studs, and not

against the lower stud nut.

11.

Turn the wrench until both

studs are under tension, then, tap the

spindle with a hammer near the lower

stud to loosen it from the spindle. Do

not loosen the stud with tool pressure

alone.

12.

Place a jack under the outer

end of the lower arm and raise the

arm several inches.

13.

Install the spring compressor

Tool 5310-A (Fig. 23) inside the

spring with the jaws of the tool

toward the center of the vehicle.

14.

Remove the nut from the ball

joint stud. Lower the jack until the

spindle and spring are free, and re-

move the spring and insulators.

15.

Remove the lower arm- to-

crossmember nut, bolt, washers, and

spacer, then remove the arm.

Installation

1.

Connect the inner end of the

lower arm to the underbody

crossmember. Do not tighten the at-

taching nut at this time. Refer to Fig.

22.

Basic Tool Adapter F 1288-B

FIG. 20—Spring Compressor Tool Installed—Upper View—Typical

DETAIL NO 3 T63P-5310-A DETAIL NO.4

DETAIL

NO.

I

21 —Compressing Spring—Lower View—Montego, Falcon

and Fairlaneprocarmanuals.com

Page 92 of 413

03-02-16

Suspension

03-02-16

2.

Place a jack under the outer end

of the arm.

3.

Tape the upper and lower spring

insulators to the spring.

4.

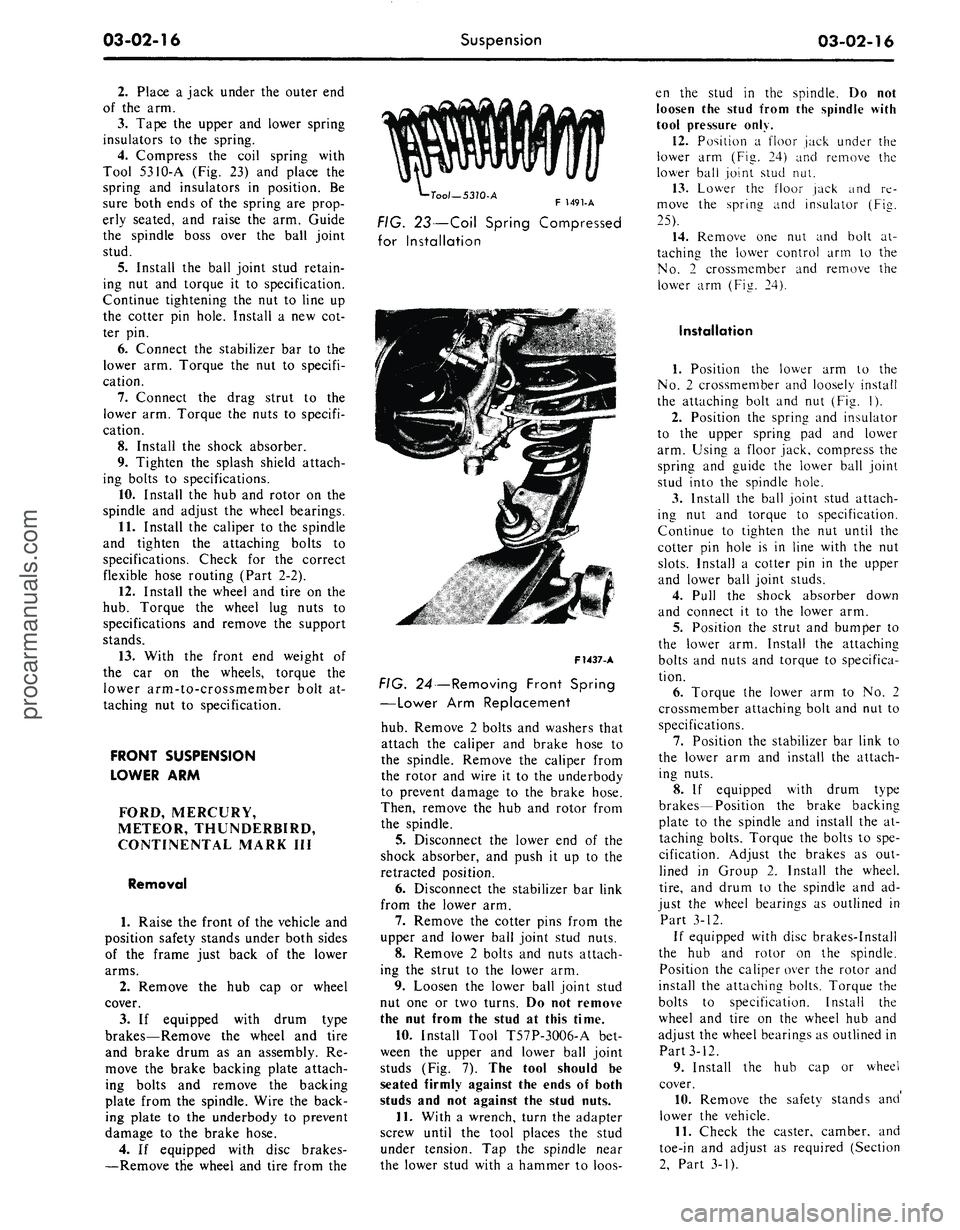

Compress the coil spring with

Tool 5310-A (Fig. 23) and place the

spring and insulators in position. Be

sure both ends of the spring are prop-

erly seated, and raise the arm. Guide

the spindle boss over the ball joint

stud.

5.

Install the ball joint stud retain-

ing nut and torque it to specification.

Continue tightening the nut to line up

the cotter pin hole. Install a new cot-

ter pin.

6. Connect the stabilizer bar to the

lower arm. Torque the nut to specifi-

cation.

7.

Connect the drag strut to the

lower arm. Torque the nuts to specifi-

cation.

8. Install the shock absorber.

9. Tighten the splash shield attach-

ing bolts to specifications.

10.

Install the hub and rotor on the

spindle and adjust the wheel bearings.

11.

Install the caliper to the spindle

and tighten the attaching bolts to

specifications. Check for the correct

flexible hose routing (Part 2-2).

12.

Install the wheel and tire on the

hub.

Torque the wheel lug nuts to

specifications and remove the support

stands.

13.

With the front end weight of

the car on the wheels, torque the

lower arm-to-crossmember bolt at-

taching nut to specification.

FRONT SUSPENSION

LOWER ARM

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

Removal

1.

Raise the front of the vehicle and

position safety stands under both sides

of the frame just back of the lower

arms.

2.

Remove the hub cap or wheel

cover.

3.

If equipped with drum type

brakes—Remove the wheel and tire

and brake drum as an assembly. Re-

move the brake backing plate attach-

ing bolts and remove the backing

plate from the spindle. Wire the back-

ing plate to the underbody to prevent

damage to the brake hose.

4.

If equipped with disc brakes-

—Remove the wheel and tire from the

•Tool—5310-A

F 1491-A

FIG. 23—Coil Spring Compressed

for Installation

F1437-A

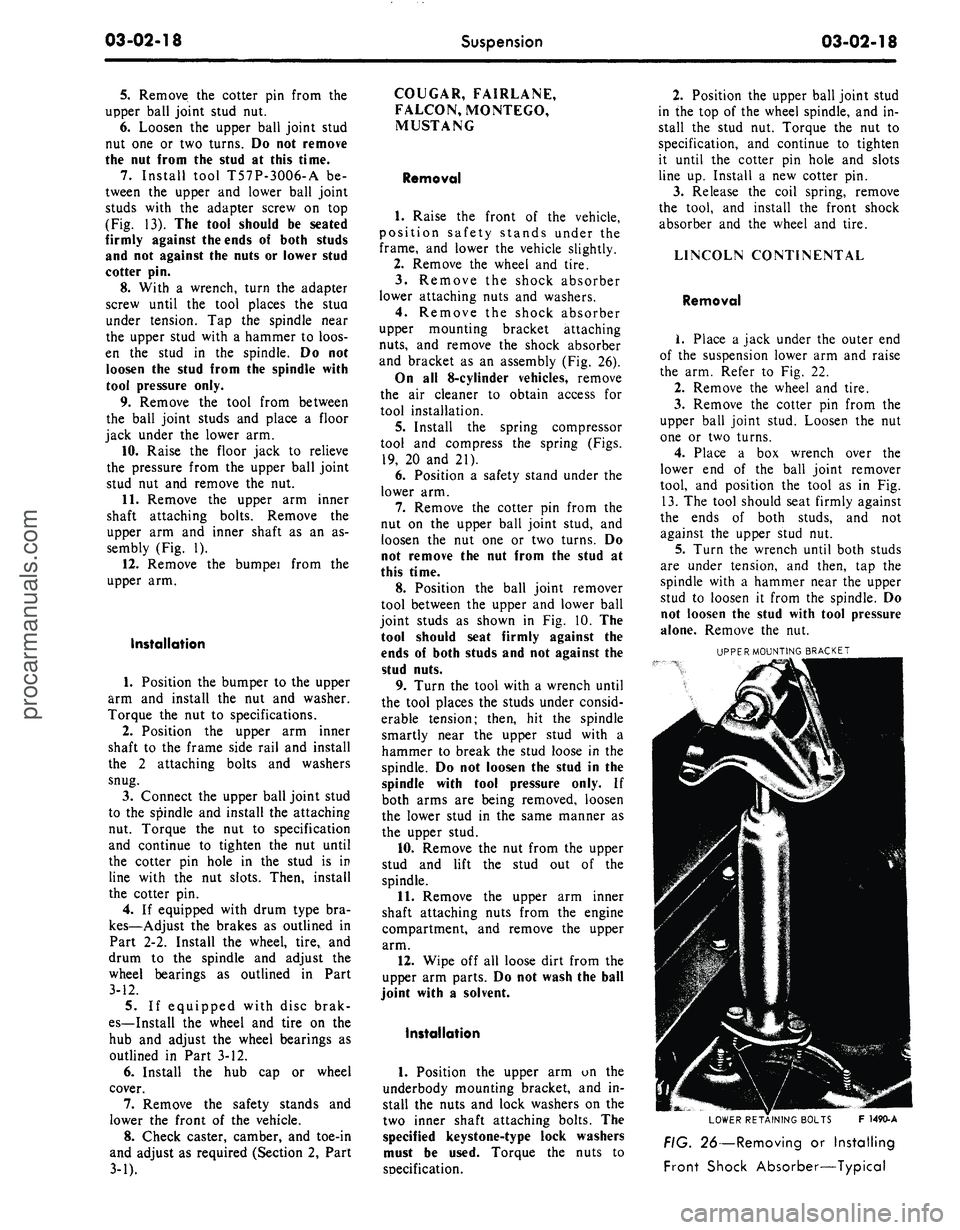

FIG. 24—Removing Front Spring

—Lower Arm Replacement

hub.

Remove 2 bolts and washers that

attach the caliper and brake hose to

the spindle. Remove the caliper from

the rotor and wire it to the underbody

to prevent damage to the brake hose.

Then, remove the hub and rotor from

the spindle.

5.

Disconnect the lower end of the

shock absorber, and push it up to the

retracted position.

6. Disconnect the stabilizer bar link

from the lower arm.

7.

Remove the cotter pins from the

upper and lower ball joint stud nuts.

8. Remove 2 bolts and nuts attach-

ing the strut to the lower arm.

9. Loosen the lower ball joint stud

nut one or two turns. Do not remove

the nut from the stud at this time.

10.

Install Tool T57P-3OO6-A bet-

ween the upper and lower ball joint

studs (Fig. 7). The tool should be

seated firmly against the ends of both

studs and not against the stud nuts.

11.

With a wrench, turn the adapter

screw until the tool places the stud

under tension. Tap the spindle near

the lower stud with a hammer to loos-

en the stud in the spindle. Do not

loosen the stud from the spindle with

tool pressure only.

12.

Position a floor jack under the

lower arm (Fig. 24) and remove the

lower ball joint stud nut.

13.

Lower the floor jack and re-

move the sprina and insulator (Fie.

25).

14.

Remove one nut and bolt at-

taching the lower control arm to the

No.

2 crossmember and remove the

lower arm (Fig. 24).

Installation

1.

Position the lower arm to the

No.

2 crossmember and loosely install

the attaching bolt and nut (Fig. 1).

2.

Position the spring and insulator

to the upper spring pad and lower

arm. Using a floor jack, compress the

spring and guide the lower ball joint

stud into the spindle hole.

3.

Install the ball joint stud attach-

ing nut and torque to specification.

Continue to tighten the nut until the

cotter pin hole is in line with the nut

slots.

Install a cotter pin in the upper

and lower ball joint studs.

4.

Pull the shock absorber down

and connect it to the lower arm.

5.

Position the strut and bumper to

the lower arm. Install the attaching

bolts and nuts and torque to specifica-

tion.

6. Torque the lower arm to No. 2

crossmember attaching bolt and nut to

specifications.

7.

Position the stabilizer bar link to

the lower arm and install the attach-

ing nuts.

8. If equipped with drum type

brakes—Position the brake backing

plate to the spindle and install the at-

taching bolts. Torque the bolts to spe-

cification. Adjust the brakes as out-

lined in Group 2. Install the wheel,

tire,

and drum to the spindle and ad-

just the wheel bearings as outlined in

Part 3-12.

If equipped with disc brakes-Install

the hub and rotor on the spindle.

Position the caliper over the rotor and

install the attaching bolts. Torque the

bolts to specification. Install the

wheel and tire on the wheel hub and

adjust the wheel bearings as outlined in

Part 3-12.

9. Install the hub cap or wheel

cover.

10.

Remove the safety stands and'

lower the vehicle.

11.

Check the caster, camber, and

toe-in and adjust as required (Section

2,

Part 3-1).procarmanuals.com

Page 94 of 413

03-02-18

Suspension

03-02-18

5.

Remove the cotter pin from the

upper ball joint stud nut.

6. Loosen the upper ball joint stud

nut one or two turns. Do not remove

the nut from the stud at this time.

7.

Install tool T57P-3006-A be-

tween the upper and lower ball joint

studs with the adapter screw on top

(Fig. 13). The tool should be seated

firmly against the ends of both studs

and not against the nuts or lower stud

cotter pin.

8. With a wrench, turn the adapter

screw until the tool places the stua

under tension. Tap the spindle near

the upper stud with a hammer to loos-

en the stud in the spindle. Do not

loosen the stud from the spindle with

tool pressure only.

9. Remove the tool from between

the ball joint studs and place a floor

jack under the lower arm.

10.

Raise the floor jack to relieve

the pressure from the upper ball joint

stud nut and remove the nut.

11.

Remove the upper arm inner

shaft attaching bolts. Remove the

upper arm and inner shaft as an as-

sembly (Fig. 1).

12.

Remove the bumpei from the

upper arm.

Installation

1.

Position the bumper to the upper

arm and install the nut and washer.

Torque the nut to specifications.

2.

Position the upper arm inner

shaft to the frame side rail and install

the 2 attaching bolts and washers

snug.

3.

Connect the upper ball joint stud

to the spindle and install the attaching

nut. Torque the nut to specification

and continue to tighten the nut until

the cotter pin hole in the stud is in

line with the nut slots. Then, install

the cotter pin.

4.

If equipped with drum type bra-

kes—Adjust the brakes as outlined in

Part 2-2. Install the wheel, tire, and

drum to the spindle and adjust the

wheel bearings as outlined in Part

3-12.

5.

If equipped with disc brak-

es—Install the wheel and tire on the

hub and adjust the wheel bearings as

outlined in Part 3-12.

6. Install the hub cap or wheel

cover.

7.

Remove the safety stands and

lower the front of the vehicle.

8. Check caster, camber, and toe-in

and adjust as required (Section 2, Part

3-D.

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1.

Raise the front of the vehicle,

position safety stands under the

frame, and lower the vehicle slightly.

2.

Remove the wheel and tire.

3.

Remove the shock absorber

lower attaching nuts and washers.

4.

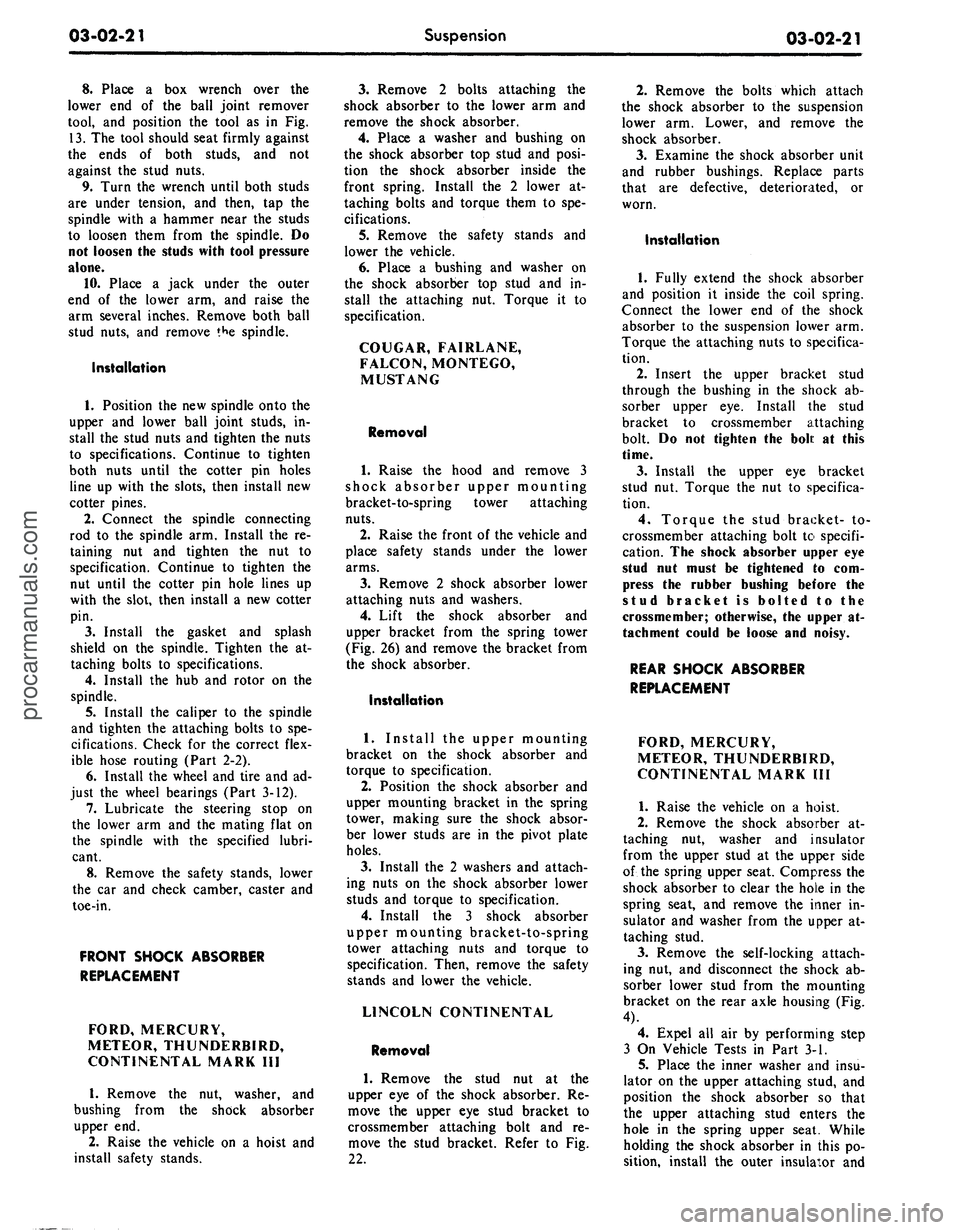

Remove the shock absorber

upper mounting bracket attaching

nuts,

and remove the shock absorber

and bracket as an assembly (Fig. 26).

On all 8-cylinder vehicles, remove

the air cleaner to obtain access for

tool installation.

5.

Install the spring compressor

tool and compress the spring (Figs.

19,

20 and 21).

6. Position a safety stand under the

lower arm.

7.

Remove the cotter pin from the

nut on the upper ball joint stud, and

loosen the nut one or two turns. Do

not remove the nut from the stud at

this time.

8. Position the ball joint remover

tool between the upper and lower ball

joint studs as shown in Fig. 10. The

tool should seat firmly against the

ends of both studs and not against the

stud nuts.

9. Turn the tool with a wrench until

the tool places the studs under consid-

erable tension; then, hit the spindle

smartly near the upper stud with a

hammer to break the stud loose in the

spindle. Do not loosen the stud in the

spindle with tool pressure only. If

both arms are being removed, loosen

the lower stud in the same manner as

the upper stud.

10.

Remove the nut from the upper

stud and lift the stud out of the

spindle.

11.

Remove the upper arm inner

shaft attaching nuts from the engine

compartment, and remove the upper

arm.

12.

Wipe off all loose dirt from the

upper arm parts. Do not wash the ball

joint with a solvent.

Installation

1.

Position the upper arm on the

underbody mounting bracket, and in-

stall the nuts and lock washers on the

two inner shaft attaching bolts. The

specified keystone-type lock washers

must be used. Torque the nuts to

soecification.

2.

Position the upper ball joint stud

in the top of the wheel spindle, and in-

stall the stud nut. Torque the nut to

specification, and continue to tighten

it until the cotter pin hole and slots

line up. Install a new cotter pin.

3.

Release the coil spring, remove

the tool, and install the front shock

absorber and the wheel and tire.

LINCOLN CONTINENTAL

Removal

1.

Place a jack under the outer end

of the suspension lower arm and raise

the arm. Refer to Fig. 22.

2.

Remove the wheel and tire.

3.

Remove the cotter pin from the

upper ball joint stud. Loosen the nut

one or two turns.

4.

Place a box wrench over the

lower end of the ball joint remover

tool, and position the tool as in Fig.

13.

The tool should seat firmly against

the ends of both studs, and not

against the upper stud nut.

5.

Turn the wrench until both studs

are under tension, and then, tap the

spindle with a hammer near the upper

stud to loosen it from the spindle. Do

not loosen the stud with tool pressure

alone. Remove the nut.

UPPER MOUNTING BRACKET

LOWER RETAINING BOLTS F 1490-A

FIG. 26—Removing or Installing

Front Shock Absorber—Typicalprocarmanuals.com

Page 97 of 413

03-02-21

Suspension

03-02-21

8. Place a box wrench over the

lower end of the ball joint remover

tool, and position the tool as in Fig.

13.

The tool should seat firmly against

the ends of both studs, and not

against the stud nuts.

9. Turn the wrench until both studs

are under tension, and then, tap the

spindle with a hammer near the studs

to loosen them from the spindle. Do

not loosen

the

studs with tool pressure

alone.

10.

Place a jack under the outer

end of the lower arm, and raise the

arm several inches. Remove both ball

stud nuts, and remove t^e spindle.

Installation

1.

Position the new spindle onto the

upper and lower ball joint studs, in-

stall the stud nuts and tighten the nuts

to specifications. Continue to tighten

both nuts until the cotter pin holes

line up with the slots, then install new

cotter pines.

2.

Connect the spindle connecting

rod to the spindle arm. Install the re-

taining nut and tighten the nut to

specification. Continue to tighten the

nut until the cotter pin hole lines up

with the slot, then install a new cotter

pin.

3.

Install the gasket and splash

shield on the spindle. Tighten the at-

taching bolts to specifications.

4.

Install the hub and rotor on the

spindle.

5.

Install the caliper to the spindle

and tighten the attaching bolts to spe-

cifications. Check for the correct flex-

ible hose routing (Part 2-2).

6. Install the wheel and tire and ad-

just the wheel bearings (Part 3-12).

7.

Lubricate the steering stop on

the lower arm and the mating flat on

the spindle with the specified lubri-

cant.

8. Remove the safety stands, lower

the car and check camber, caster and

toe-in.

FRONT SHOCK ABSORBER

REPLACEMENT

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

1.

Remove the nut, washer, and

bushing from the shock absorber

upper end.

2.

Raise the vehicle on a hoist and

install safety stands.

3.

Remove 2 bolts attaching the

shock absorber to the lower arm and

remove the shock absorber.

4.

Place a washer and bushing on

the shock absorber top stud and posi-

tion the shock absorber inside the

front spring. Install the 2 lower at-

taching bolts and torque them to spe-

cifications.

5.

Remove the safety stands and

lower the vehicle.

6. Place a bushing and washer on

the shock absorber top stud and in-

stall the attaching nut. Torque it to

specification.

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1. Raise the hood and remove 3

shock absorber upper mounting

bracket-to-spring tower attaching

nuts.

2.

Raise the front of the vehicle and

place safety stands under the lower

arms.

3.

Remove 2 shock absorber lower

attaching nuts and washers.

4.

Lift the shock absorber and

upper bracket from the spring tower

(Fig. 26) and remove the bracket from

the shock absorber.

Installation

1. Install the upper mounting

bracket on the shock absorber and

torque to specification.

2.

Position the shock absorber and

upper mounting bracket in the spring

tower, making sure the shock absor-

ber lower studs are in the pivot plate

holes.

3.

Install the 2 washers and attach-

ing nuts on the shock absorber lower

studs and torque to specification.

4.

Install the 3 shock absorber

upper mounting bracket-to-spring

tower attaching nuts and torque to

specification. Then, remove the safety

stands and lower the vehicle.

LINCOLN CONTINENTAL

Removal

1.

Remove the stud nut at the

upper eye of the shock absorber. Re-

move the upper eye stud bracket to

crossmember attaching bolt and re-

move the stud bracket. Refer to Fig.

22.

2.

Remove the bolts which attach

the shock absorber to the suspension

lower arm. Lower, and remove the

shock absorber.

3.

Examine the shock absorber unit

and rubber bushings. Replace parts

that are defective, deteriorated, or

worn.

Installation

1. Fully extend the shock absorber

and position it inside the coil spring.

Connect the lower end of the shock

absorber to the suspension lower arm.

Torque the attaching nuts to specifica-

tion.

2.

Insert the upper bracket stud

through the bushing in the shock ab-

sorber upper eye. Install the stud

bracket to crossmember attaching

bolt. Do not tighten the bolt: at this

time.

3.

Install the upper eye bracket

stud nut. Torque the nut to specifica-

tion.

4.

Torque the stud bracket- to-

crossmember attaching bolt to specifi-

cation.

The

shock absorber upper

eye

stud

nut

must

be

tightened

to com-

press

the

rubber bushing before

the

stud bracket

is

bolted

to the

crossmember;

otherwise,

the

upper

at-

tachment could

be

loose

and

noisy.

REAR SHOCK ABSORBER

REPLACEMENT

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK 1(11

1.

Raise the vehicle on a hoist.

2.

Remove the shock absorber at-

taching nut, washer and insulator

from the upper stud at the upper side

of the spring upper seat. Compress the

shock absorber to clear the hole in the

spring seat, and remove the inner in-

sulator and washer from the upper at-

taching stud.

3.

Remove the self-locking attach-

ing nut, and disconnect the shock ab-

sorber lower stud from the mounting

bracket on the rear axle housing (Fig.

4).

4.

Expel all air by performing step

3 On Vehicle Tests in Part 3-1.

5.

Place the inner washer and insu-

lator on the upper attaching stud, and

position the shock absorber so that

the upper attaching stud enters the

hole in the spring upper seat. While

holding the shock absorber in this po-

sition, install the outer insulator andprocarmanuals.com

Page 98 of 413

03-02-22

Suspension

03-02-22

washer and the nut on the upper stud

from the upper side of the spring

upper seat. Torque the nut to specifi-

cations.

6. Extend the shock absorber and

locate the lower stud in the hole in

mounting bracket on the rear axle

housing. Install a new self-locking at-

taching nut and torque to specifica-

tion.

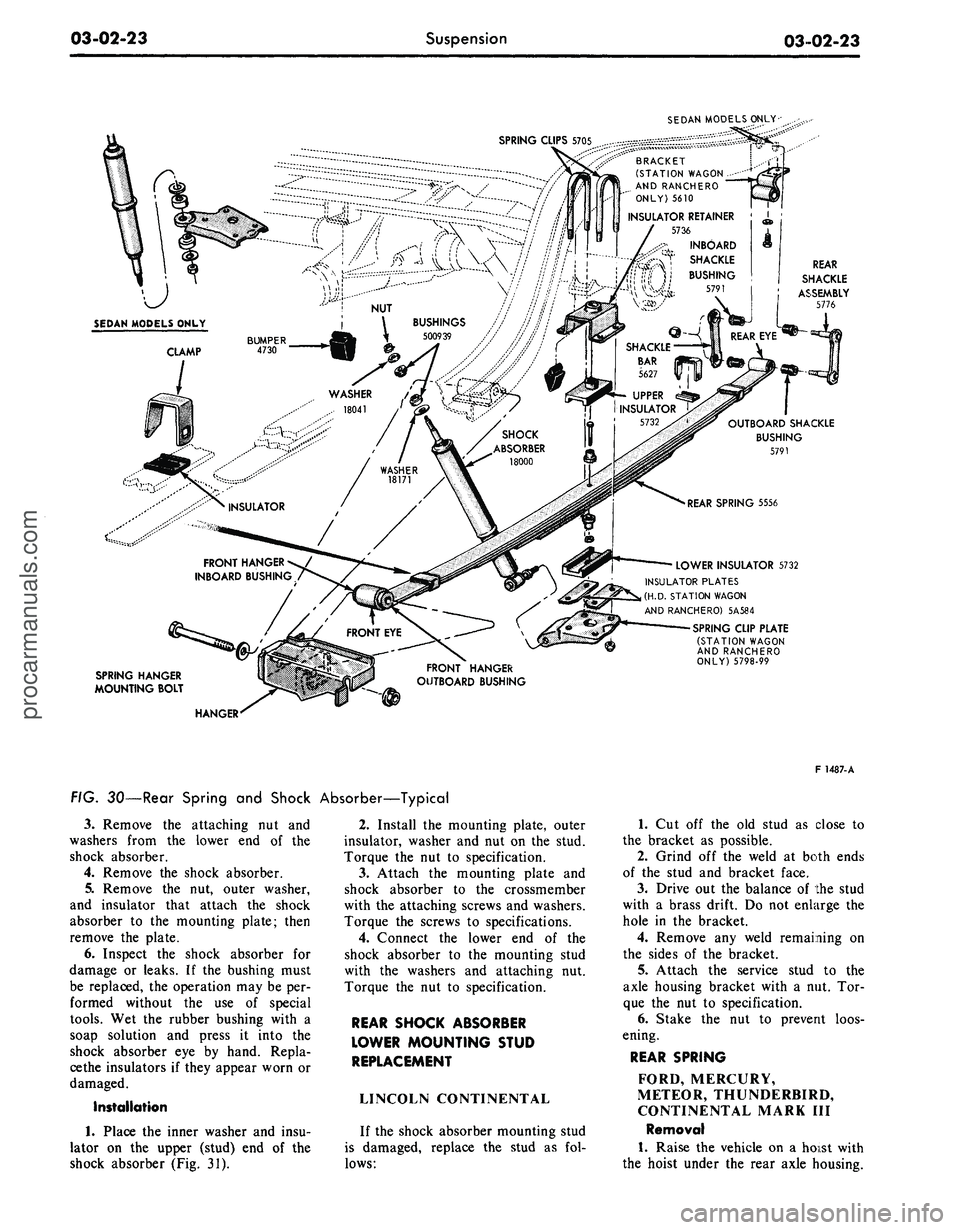

MUSTANG AND COUGAR

Removal

1.

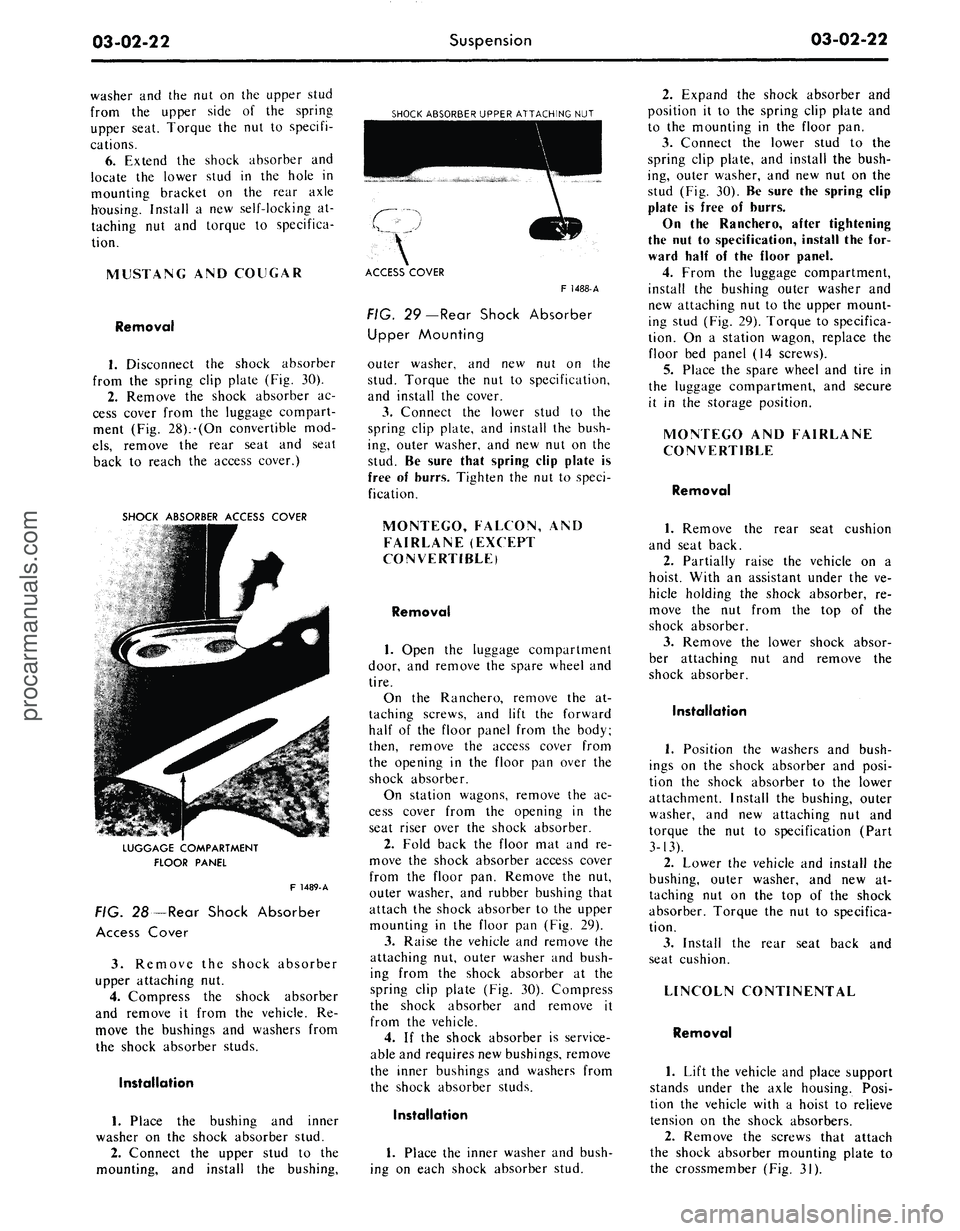

Disconnect the shock absorber

from the spring clip plate (Fig. 30).

2.

Remove the shock absorber ac-

cess cover from the luggage compart-

ment (Fig. 28).-(On convertible mod-

els,

remove the rear seat and seat

back to reach the access cover.)

SHOCK ABSORBER ACCESS COVER

SHOCK ABSORBER UPPER ATTACHING NUT

LUGGAGE COMPARTMENT

FLOOR PANEL

F 1489-A

FIG. 28—Rear Shock Absorber

Access Cover

3.

Remove the shock absorber

upper attaching nut.

4.

Compress the shock absorber

and remove it from the vehicle. Re-

move the bushings and washers from

the shock absorber studs.

Installation

1.

Place the bushing and inner

washer on the shock absorber stud.

2.

Connect the upper stud to the

mounting, and install the bushing,

ACCESS COVER

F 1488-A

FIG. 29—Rear Shock Absorber

Upper Mounting

outer washer, and new nut on the

stud. Torque the nut to specification,

and install the cover.

3.

Connect the lower stud to the

spring clip plate, and install the bush-

ing, outer washer, and new nut on the

stud. Be sure that spring clip plate is

free of burrs. Tighten the nut to speci-

fication.

MONTEGO, FALCON, AND

FAIRLANE (EXCEPT

CONVERTIBLE)

Removal

1.

Open the luggage compartment

door, and remove the spare wheel and

tire.

On the Ranchero, remove the at-

taching screws, and lift the forward

half of the floor panel from the body;

then, remove the access cover from

the opening in the floor pan over the

shock absorber.

On station wagons, remove the ac-

cess cover from the opening in the

seat riser over the shock absorber.

2.

Fold back the floor mat and re-

move the shock absorber access cover

from the floor pan. Remove the nut,

outer washer, and rubber bushing that

attach the shock absorber to the upper

mounting in the floor pan (Fig. 29).

3.

Raise the vehicle and remove the

attaching nut, outer washer and bush-

ing from the shock absorber at the

spring clip plate (Fig. 30). Compress

the shock absorber and remove it

from the vehicle.

4.

If the shock absorber is service-

able and requires new bushings, remove

the inner bushings and washers from

the shock absorber studs.

Installation

1.

Place the inner washer and bush-

ing on each shock absorber stud.

2.

Expand the shock absorber and

position it to the spring clip plate and

to the mounting in the floor pan.

3.

Connect the lower stud to the

spring clip plate, and install the bush-

ing, outer washer, and new nut on the

stud (Fig. 30). Be sure the spring clip

plate is free of burrs.

On the Ranchero, after tightening

the nut to specification, install the for-

ward half of the floor panel.

4.

From the luggage compartment,

install the bushing outer washer and

new attaching nut to the upper mount-

ing stud (Fig. 29). Torque to specifica-

tion. On a station wagon, replace the

floor bed panel (14 screws).

5.

Place the spare wheel and tire in

the luggage compartment, and secure

it in the storage position.

MONTEGO AND FAIRLANE

CONVERTIBLE

Removal

1.

Remove the rear seat cushion

and seat back.

2.

Partially raise the vehicle on a

hoist. With an assistant under the ve-

hicle holding the shock absorber, re-

move the nut from the top of the

shock absorber.

3.

Remove the lower shock absor-

ber attaching nut and remove the

shock absorber.

Installation

1.

Position the washers and bush-

ings on the shock absorber and posi-

tion the shock absorber to the lower

attachment. Install the bushing, outer

washer, and new attaching nut and

torque the nut to specification (Part

3-13).

2.

Lower the vehicle and install the

bushing, outer washer, and new at-

taching nut on the top of the shock

absorber. Torque the nut to specifica-

tion.

3.

Install the rear seat back and

seat cushion.

LINCOLN CONTINENTAL

Removal

1.

Lift the vehicle and place support

stands under the axle housing. Posi-

tion the vehicle with a hoist to relieve

tension on the shock absorbers.

2.

Remove the screws that attach

the shock absorber mounting plate to

the crossmember (Fig. 31).procarmanuals.com

Page 99 of 413

03-02-23

Suspension

03-02-23

SEDAN MODELS ONLY-

SPRING CLIPS

5705

,^-::^^^^SSSS^

^CS^.-''' .--'""-.'.'""'"* D D

A

f~

V

C

T

BRACKET

(STATION WAGON-

AND RANCHERO

ONLY) 5610

INSULATOR RETAINER

5736

INBOARD

SHACKLE

BUSHING

5791

... ».IA-

vae.

FRONT HANGER

INBOARD BUSHING

FRONT HANGER

OUTBOARD BUSHING

REAR

SHACKLE

ASSEMBLY

5776

OUTBOARD SHACKLE

BUSHING

5791

LOWER INSULATOR 5732

INSULATOR PLATES

(H.D.

STATION WAGON

AND RANCHERO) 5A584

SPRING CLIP PLATE

(STATION WAGON

AND RANCHERO

ONLY) 5798-99

SPRING HANGER

MOUNTING BOLT

HANGER

FIG. 30—Rear Spring and Shock Absorber—Typical

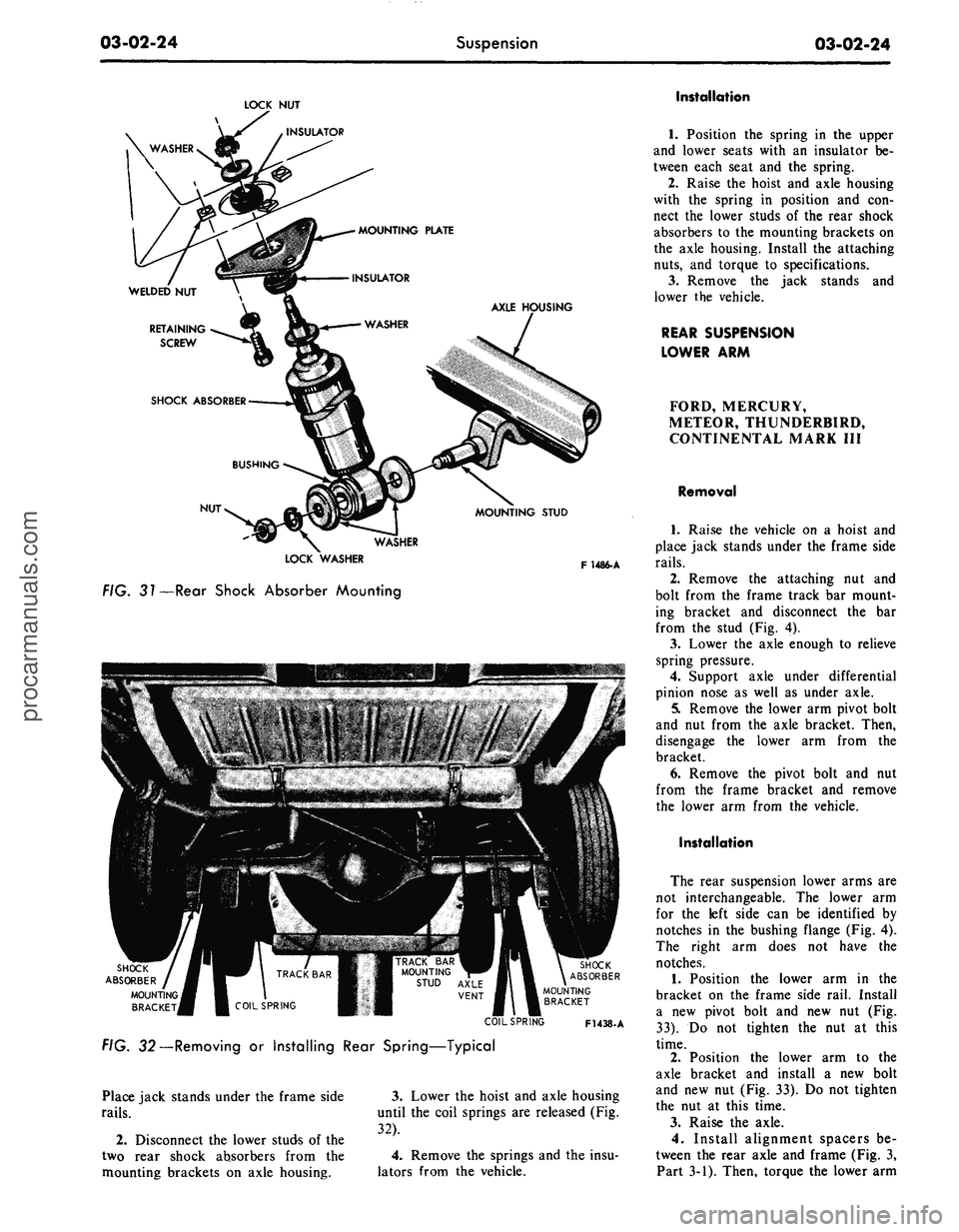

3.

Remove the attaching nut and

washers from the lower end of the

shock absorber.

4.

Remove the shock absorber.

5.

Remove the nut, outer washer,

and insulator that attach the shock

absorber to the mounting plate; then

remove the plate.

6. Inspect the shock absorber for

damage or leaks. If the bushing must

be replaced, the operation may be per-

formed without the use of special

tools.

Wet the rubber bushing with a

soap solution and press it into the

shock absorber eye by hand. Repla-

cethe insulators if they appear worn or

damaged.

Installation

1.

Place the inner washer and insu-

lator on the upper (stud) end of the

shock absorber (Fig. 31).

2.

Install the mounting plate, outer

insulator, washer and nut on the stud.

Torque the nut to specification.

3.

Attach the mounting plate and

shock absorber to the crossmember

with the attaching screws and washers.

Torque the screws to specifications.

4.

Connect the lower end of the

shock absorber to the mounting stud

with the washers and attaching nut.

Torque the nut to specification.

REAR SHOCK ABSORBER

LOWER MOUNTING STUD

REPLACEMENT

LINCOLN CONTINENTAL

If the shock absorber mounting stud

is damaged, replace the stud as fol-

lows:

F 1487-A

1.

Cut off the old stud as close to

the bracket as possible.

2.

Grind off the weld at both ends

of the stud and bracket face.

3.

Drive out the balance of the stud

with a brass drift. Do not enlarge the

hole in the bracket.

4.

Remove any weld remaining on

the sides of the bracket.

5.

Attach the service stud to the

axle housing bracket with a nut. Tor-

que the nut to specification.

6. Stake the nut to prevent loos-

ening.

REAR SPRING

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

Removal

1.

Raise the vehicle on a hoist with

the hoist under the rear axle housing.procarmanuals.com

Page 100 of 413

03-02-24

Suspension

03-02-24

LOCK NUT

INSULATOR

NG

NUT

MOUNTING STUD

WASHER

LOCK WASHER

FIG. 31—Rear Shock Absorber Mounting

F1486-A

TRACK BAR

MOUNTING

STUD AXLE

VENT

SHOCK

ABSORBER

MOUNTING

BRACKET

SHOCK

ABSORBER

MOUNTING

BRACKET

V-V.

FIG. 32—Removing or Installing Rear Spring—Typical

COIL SPRING

F1438-A

Place jack stands under the frame side

rails.

2.

Disconnect the lower studs of the

two rear shock absorbers from the

mounting brackets on axle housing.

3.

Lower the hoist and axle housing

until the coil springs are released (Fig.

32).

4.

Remove the springs and the insu-

lators from the vehicle.

Installation

1.

Position the spring in the upper

and lower seats with an insulator be-

tween each seat and the spring.

2.

Raise the hoist and axle housing

with the spring in position and con-

nect the lower studs of the rear shock

absorbers to the mounting brackets on

the axle housing. Install the attaching

nuts,

and torque to specifications.

3.

Remove the jack stands and

lower the vehicle.

REAR SUSPENSION

LOWER ARM

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

Removal

1.

Raise the vehicle on a hoist and

place jack stands under the frame side

rails.

2.

Remove the attaching nut and

bolt from the frame track bar mount-

ing bracket and disconnect the bar

from the stud (Fig. 4).

3.

Lower the axle enough to relieve

spring pressure.

4.

Support axle under differential

pinion nose as well as under axle.

5.

Remove the lower arm pivot bolt

and nut from the axle bracket. Then,

disengage the lower arm from the

bracket.

6. Remove the pivot bolt and nut

from the frame bracket and remove

the lower arm from the vehicle.

Installation

The rear suspension lower arms are

not interchangeable. The lower arm

for the left side can be identified by

notches in the bushing flange (Fig. 4).

The right arm does not have the

notches.

1.

Position the lower arm in the

bracket on the frame side rail. Install

a new pivot bolt and new nut (Fig.

33).

Do not tighten the nut at this

time.

2.

Position the lower arm to the

axle bracket and install a new bolt

and new nut (Fig. 33). Do not tighten

the nut at this time.

3.

Raise the axle.

4.

Install alignment spacers be-

tween the rear axle and frame (Fig. 3,

Part 3-1). Then, torque the lower armprocarmanuals.com