four wheel drive FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 115 of 413

03-05-02

Steering Columns

And

Linkage

03-05-02

which also will shear away during

im-

pact.

TILT STEERING COLUMNS

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed.

The tilt column features nine driv-

ing positions (four

up and

four down

from

a

center position).

The

.column

also features

a

turn signal switch with

a lane-changer position turn indicating

position

and

emergency warning flash-

er control.

TILT-AWAY STEERING COLUMNS

The tilt-away steering column

fea-

tures nine driving positions (four

up

and four down from

a

center position)

and

a

tilt-away position that

is

auto-

matically accomplished

on

Mustang

and Cougar models when

the

ignition

key

is

turned

to the

OFF

position

and

the left door

is

opened.

On

Thunder-

bird models,

the

tilt-away occurs when

the shift lever

is

placed

in

PARK

and

the driverns door

is

opened.

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed along with mounting

brackets which will also shear away

during impact.

IN-VEHICLE ADJUSTMENTS

AND

REPAIRS

STEERING WHEEL SPOKE

POSITION ADJUSTMENT

When

the

steering gear

is on the

high point,

the

front wheels should

be

in

the

straight-ahead position

and the

steering wheel spokes should

be in

their normal position with

the

Pitman

arm pointing directly forward.

If the

spokes

are not in

their normal posi-

tion, they

can be

adjusted without

dis-

turbing

the

toe-in adjustment (Part

3-1).

STEERING WHEEL

REPLACEMENT

1.

Disconnect

the

negative cable

from

the

battery.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

crash

pad

attaching screws. Lift

the

crash

pad

from

the

wheel.

(On

Conti-

nental Mark

III

models,

pry out the

crash

pad

insert

and

remove

the two

screws that secure

the

crash

pad. Re-

move

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

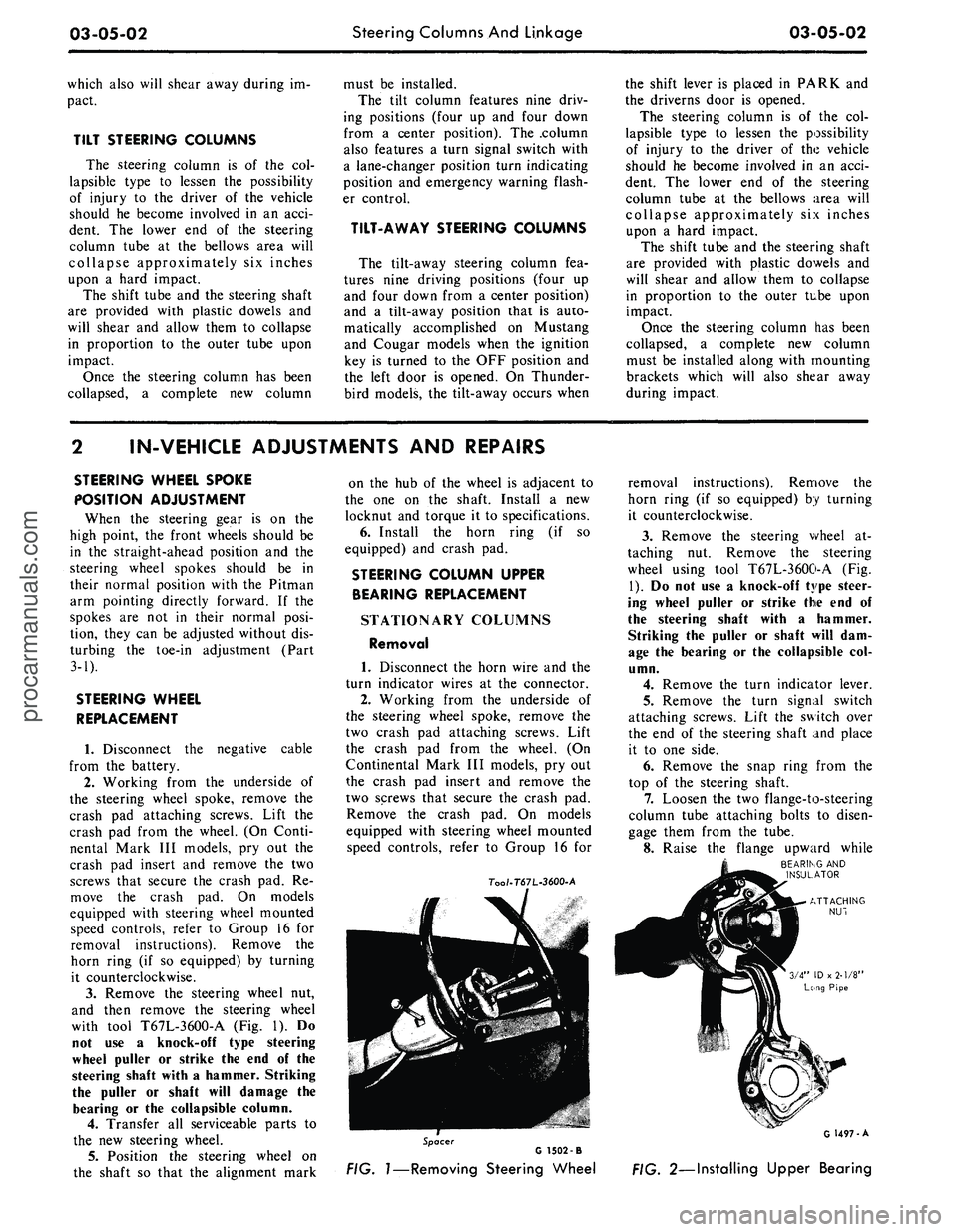

3.

Remove

the

steering wheel

nut,

and then remove

the

steering wheel

with tool T67L-3600-A

(Fig. 1). Do

not

use a

knock-off type steering

wheel puller

or

strike

the end of the

steering shaft with

a

hammer. Striking

the puller

or

shaft will damage

the

bearing

or the

collapsible column.

4.

Transfer

all

serviceable parts

to

the

new

steering wheel.

5.

Position

the

steering wheel

on

the shaft

so

that

the

alignment mark

on

the hub of the

wheel

is

adjacent

to

the

one on the

shaft. Install

a new

locknut

and

torque

it to

specifications.

6. Install

the

horn ring

(if so

equipped)

and

crash

pad.

STEERING COLUMN UPPER

BEARING REPLACEMENT

STATIONARY COLUMNS

Removal

1. Disconnect

the

horn wire

and the

turn indicator wires

at the

connector.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

two crash

pad

attaching screws. Lift

the crash

pad

from

the

wheel.

(On

Continental Mark

III

models,

pry out

the crash

pad

insert

and

remove

the

two screws that secure

the

crash

pad.

Remove

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

7oo/-T67L-3600-A

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

3.

Remove

the

steering wheel

at-

taching

nut.

Remove

the

steering

wheel using tool T67L-3600-A

(Fig.

1).

Do not use a

knock-off type steer-

ing wheel puller

or

strike

the end of

the steering shaft with

a

hammer.

Striking

the

puller

or

shaft will

dam-

age

the

bearing

or the

collapsible

col-

umn.

4.

Remove

the

turn indicator lever.

5.

Remove

the

turn signal switch

attaching screws. Lift

the

switch over

the

end of the

steering shaft

and

place

it

to one

side.

6. Remove

the

snap ring from

the

top

of the

steering shaft.

7.

Loosen

the two

flange-to-steering

column tube attaching bolts

to

disen-

gage them from

the

tube.

8. Raise

the

flange upward while

BEARING

AND

INSULATOR

Spacer

G 1502 -B

FIG.

1—Removing

Steering Wheel

G 1497-A

FIG. 2—Installing Upper Bearingprocarmanuals.com

Page 120 of 413

03-05-07

Steering Columns And Linkage

03-05-07

the steering column

(F in Fig. 8).

7.

Disconnect

the

transmission shift

rod

at the

shift tube.

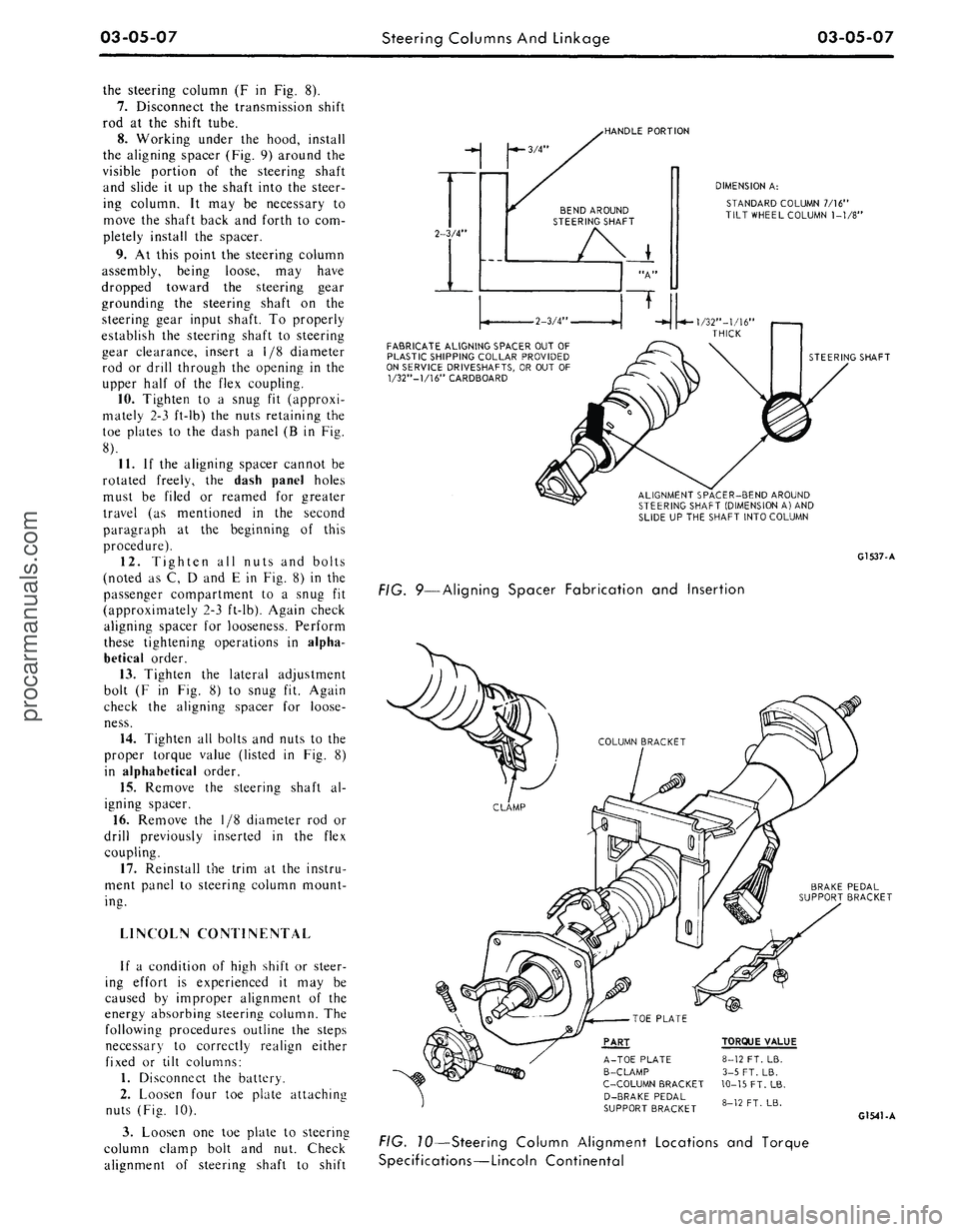

8. Working under

the

hood, install

the aligning spacer (Fig.

9)

around

the

visible portion

of the

steering shaft

and slide

it up the

shaft into

the

steer-

ing column.

It may be

necessary

to

move

the

shaft back

and

forth

to

com-

pletely install

the

spacer.

9.

At

this point

the

steering column

assembly, being loose,

may

have

dropped toward

the

steering gear

grounding

the

steering shaft

on the

steering gear input shaft.

To

properly

establish

the

steering shaft

to

steering

gear clearance, insert

a 1/8

diameter

rod

or

drill through

the

opening

in the

upper half

of the

flex coupling.

10.

Tighten

to a

snug

fit

(approxi-

mately

2-3

ft-lb)

the

nuts retaining

the

toe plates

to the

dash panel

(B in Fig.

8).

11.

If the

aligning spacer cannot

be

rotated freely,

the

dash panel holes

must

be

filed

or

reamed

for

greater

travel

(as

mentioned

in the

second

paragraph

at the

beginning

of

this

procedure).

12.

Tighten

all

nuts

and

bolts

(noted

as C, D and E in

Fig.

8) in the

passenger compartment

to a

snug

fit

(approximately 2-3 ft-lb). Again check

aligning spacer

for

looseness. Perform

these tightening operations

in

alpha-

betical order.

13.

Tighten

the

lateral adjustment

bolt

(F in Fig. 8) to

snug

fit.

Again

check

the

aligning spacer

for

loose-

ness.

14.

Tighten

all

bolts and nuts

to the

proper torque value (listed

in Fig. 8)

in alphabetical order.

15.

Remove

the

steering shaft

al-

igning spacer.

16.

Remove

the 1/8

diameter

rod or

drill previously inserted

in the

flex

coupling.

17.

Reinstall

the

trim

at the

instru-

ment panel

to

steering column mount-

ing.

LINCOLN CONTINENTAL

If

a

condition

of

high shift

or

steer-

ing effort

is

experienced

it may be

caused

by

improper alignment

of the

energy absorbing steering column.

The

following procedures outline

the

steps

necessary

to

correctly realign either

fixed

or

tilt columns:

1.

Disconnect

the

battery.

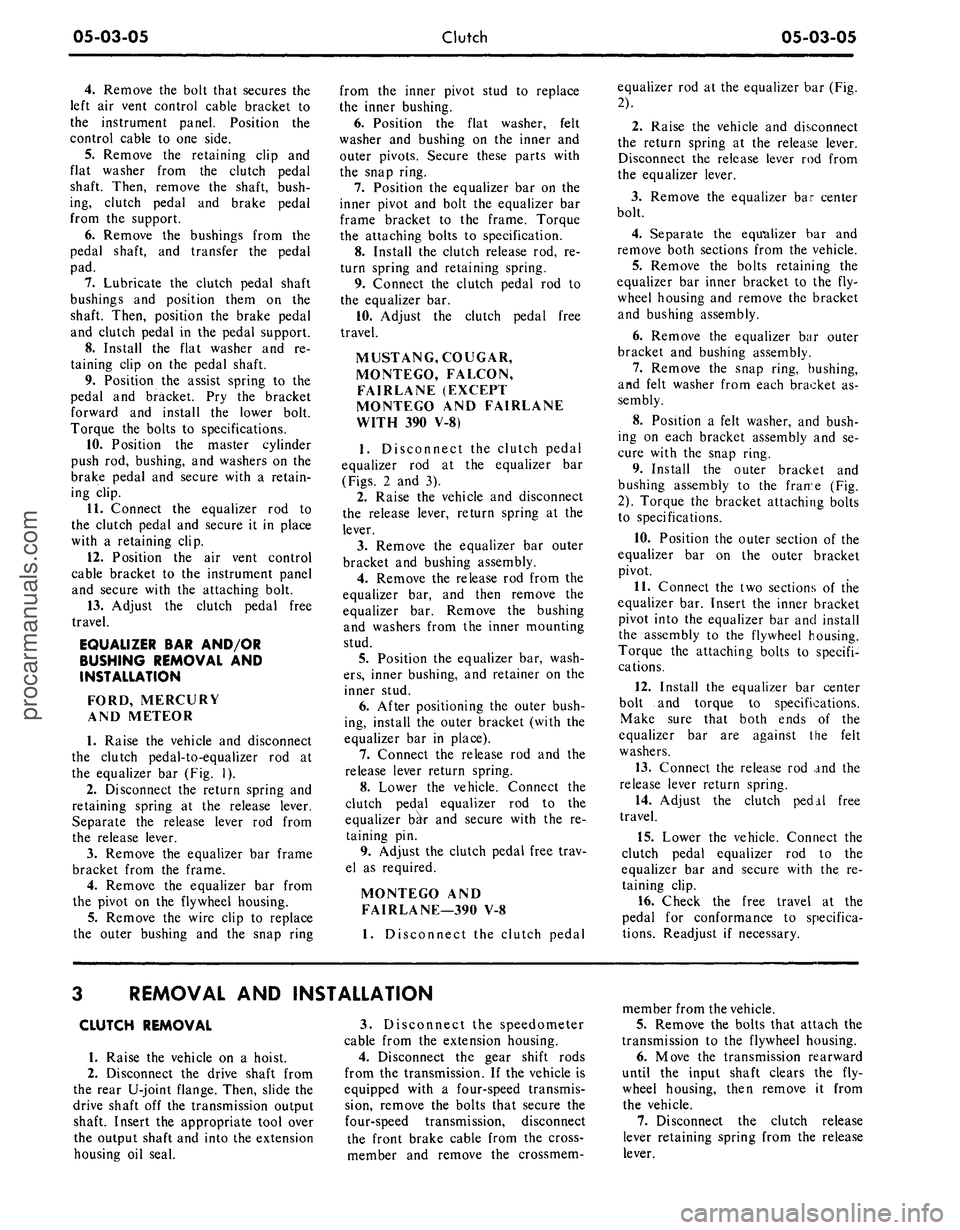

2.

Loosen four

toe

plate attaching

nuts (Fig.

10).

3.

Loosen

one toe

plate

to

steering

column clamp bolt

and nut.

Check

alignment

of

steering shaft

to

shift

-HANDLE PORTION

2-3/4"

-*- 3/4"

BEND AROUND

STEERING SHAFT

DIMENSION

A:

STANDARD COLUMN 7/16"

TILT WHEEL COLUMN

1-1/8"

•2-3/4

FABRICATE ALIGNING SPACER OUT OF

PLASTIC SHIPPING COLLAR PROVIDED

ON SERVICE DRIVESHAFTS, OR OUT

OF

1/32"—1/16" CARDBOARD

STEERING SHAFT

ALIGNMENT SPACER-BEND AROUND

STEERING SHAFT (DIMENSION

A)

AND

SLIDE UP THE SHAFT INTO COLUMN

G1537-A

FIG. 9—Aligning Spacer Fabrication

and

Insertion

BRAKE PEDAL

SUPPORT BRACKET

PART

A-TOE PLATE

B-CLAMP

C-C0LUMN BRACKET

D-BRAKE PEDAL

SUPPORT BRACKET

TORQUE VALUE

8-12 FT. LB.

3-5 FT. LB.

10-15

FT.

LB.

8-12 FT. LB.

G1541-A

FIG. 10—Steering Column Alignment Locations

and

Torque

Specifications—Lincoln Continentalprocarmanuals.com

Page 263 of 413

05-03-05

Clutch

05-03-05

4.

Remove the bolt that secures the

left air vent control cable bracket to

the instrument panel. Position the

control cable to one side.

5.

Remove the retaining clip and

flat washer from the clutch pedal

shaft. Then, remove the shaft, bush-

ing, clutch pedal and brake pedal

from the support.

6. Remove the bushings from the

pedal shaft, and transfer the pedal

pad.

7.

Lubricate the clutch pedal shaft

bushings and position them on the

shaft. Then, position the brake pedal

and clutch pedal in the pedal support.

8. Install the flat washer and re-

taining clip on the pedal shaft.

9. Position the assist spring to the

pedal and bracket. Pry the bracket

forward and install the lower bolt.

Torque the bolts to specifications.

10.

Position the master cylinder

push rod, bushing, and washers on the

brake pedal and secure with a retain-

ing clip.

11.

Connect the equalizer rod to

the clutch pedal and secure it in place

with a retaining clip.

12.

Position the air vent control

cable bracket to the instrument panel

and secure with the attaching bolt.

13.

Adjust the clutch pedal free

travel.

EQUALIZER BAR AND/OR

BUSHING REMOVAL AND

INSTALLATION

FORD, MERCURY

AND METEOR

1.

Raise the vehicle and disconnect

the clutch pedal-to-equalizer rod at

the equalizer bar (Fig. 1).

2.

Disconnect the return spring and

retaining spring at the release lever.

Separate the release lever rod from

the release lever.

3.

Remove the equalizer bar frame

bracket from the frame.

4.

Remove the equalizer bar from

the pivot on the flywheel housing.

5.

Remove the wire clip to replace

the outer bushing and the snap ring

from the inner pivot stud to replace

the inner bushing.

6. Position the flat washer, felt

washer and bushing on the inner and

outer pivots. Secure these parts with

the snap ring.

7.

Position the equalizer bar on the

inner pivot and bolt the equalizer bar

frame bracket to the frame. Torque

the attaching bolts to specification.

8. Install the clutch release rod, re-

turn spring and retaining spring.

9. Connect the clutch pedal rod to

the equalizer bar.

10.

Adjust the clutch pedal free

travel.

MUSTANG, COUGAR,

MONTEGO, FALCON,

FAIRLANE (EXCEPT

MONTEGO AND FAIRLANE

WITH 390 V-8)

1.

Disconnect the clutch pedal

equalizer rod at the equalizer bar

(Figs.

2 and 3).

2.

Raise the vehicle and disconnect

the release lever, return spring at the

lever.

3.

Remove the equalizer bar outer

bracket and bushing assembly.

4.

Remove the release rod from the

equalizer bar, and then remove the

equalizer bar. Remove the bushing

and washers from the inner mounting

stud.

5.

Position the equalizer bar, wash-

ers,

inner bushing, and retainer on the

inner stud.

6. After positioning the outer bush-

ing, install the outer bracket (with the

equalizer bar in place).

7.

Connect the release rod and the

release lever return spring.

8. Lower the vehicle. Connect the

clutch pedal equalizer rod to the

equalizer baY and secure with the re-

taining pin.

9. Adjust the clutch pedal free trav-

el as required.

MONTEGO AND

FAIRLANE—390 V-8

1.

Disconnect the clutch pedal

equalizer rod at the equalizer bar (Fig.

2).

2.

Raise the vehicle and disconnect

the return spring at the release lever.

Disconnect the release lever rod from

the equalizer lever.

3.

Remove the equalizer bar center

bolt.

4.

Separate the equalizer bar and

remove both sections from the vehicle.

5.

Remove the bolts retaining the

equalizer bar inner bracket to the fly-

wheel housing and remove the bracket

and bushing assembly.

6. Remove the equalizer bar outer

bracket and bushing assembly.

7.

Remove the snap ring, bushing,

and felt washer from each bracket as-

sembly.

8. Position a felt washer, and bush-

ing on each bracket assembly and se-

cure with the snap ring.

9. Install the outer bracket and

bushing assembly to the frame (Fig.

2).

Torque the bracket attaching bolts

to specifications.

10.

Position the outer section of the

equalizer bar on the outer bracket

pivot.

11.

Connect the two sections of the

equalizer bar. Insert the inner bracket

pivot into the equalizer bar and install

the assembly to the flywheel housing.

Torque the attaching bolts to specifi-

cations.

12.

Install the equalizer bar center

bolt and torque to specifications.

Make sure that both ends of the

equalizer bar are against the felt

washers.

13.

Connect the release rod and the

release lever return spring.

14.

Adjust the clutch pedal free

travel.

15.

Lower the vehicle. Connect the

clutch pedal equalizer rod to the

equalizer bar and secure with the re-

taining clip.

16.

Check the free travel at the

pedal for conformance to specifica-

tions.

Readjust if necessary.

REMOVAL AND INSTALLATION

CLUTCH REMOVAL

1.

Raise the vehicle on a hoist.

2.

Disconnect the drive shaft from

the rear U-joint flange. Then, slide the

drive shaft off the transmission output

shaft. Insert the appropriate tool over

the output shaft and into the extension

housing oil seal.

3.

Disconnect the speedometer

cable from the extension housing.

4.

Disconnect the gear shift rods

from the transmission. If the vehicle is

equipped with a four-speed transmis-

sion, remove the bolts that secure the

four-speed transmission, disconnect

the front brake cable from the cross-

member and remove the crossmem-

member from the vehicle.

5.

Remove the bolts that attach the

transmission to the flywheel housing.

6. Move the transmission rearward

until the input shaft clears the fly-

wheel housing, then remove it from

the vehicle.

7.

Disconnect the clutch release

lever retaining spring from the release

lever.procarmanuals.com

Page 264 of 413

05-03-06

Clutch

05-03-06

8. Remove the starter cable then

remove the starter motor from the fly-

wheel housing.

9. Remove the bolts that secure the

engine rear plate to the front lower

part of the flywheel housing.

10.

Remove the flywheel housing

lower cover (390 CID housing only).

11.

Remove the bolts that attach

the housing to the cylinder block.

12.

Move the housing back just far

enough to clear the pressure plate,

then move it to the right to free the

pivot from the clutch equalizer bar. Be

careful not to disturb the linkage and

assist spring.

13.

Loosen the six pressure plate

cover attaching bolts evenly to release

the spring tension. If the same pres-

sure plate and cover is to be installed

after the clutch is overhauled, mark

the cover and flywheel so that the

pressure plate can be installed in the

same position.

14.

Remove the pressure plate and

the clutch disc from the flywheel.

CLUTCH INSTALLATION

1.

Install the clutch release lever if

it was removed.

2.

Place the clutch disc, and pres-

sure plate assembly in position on the

flywheel. Start the cover attaching

bolts to hold the pieces in place, but

do not tighten them. Avoid touching

the clutch disc facing, dropping the

parts or contaminating them with oil

or grease as clutch chatter may result.

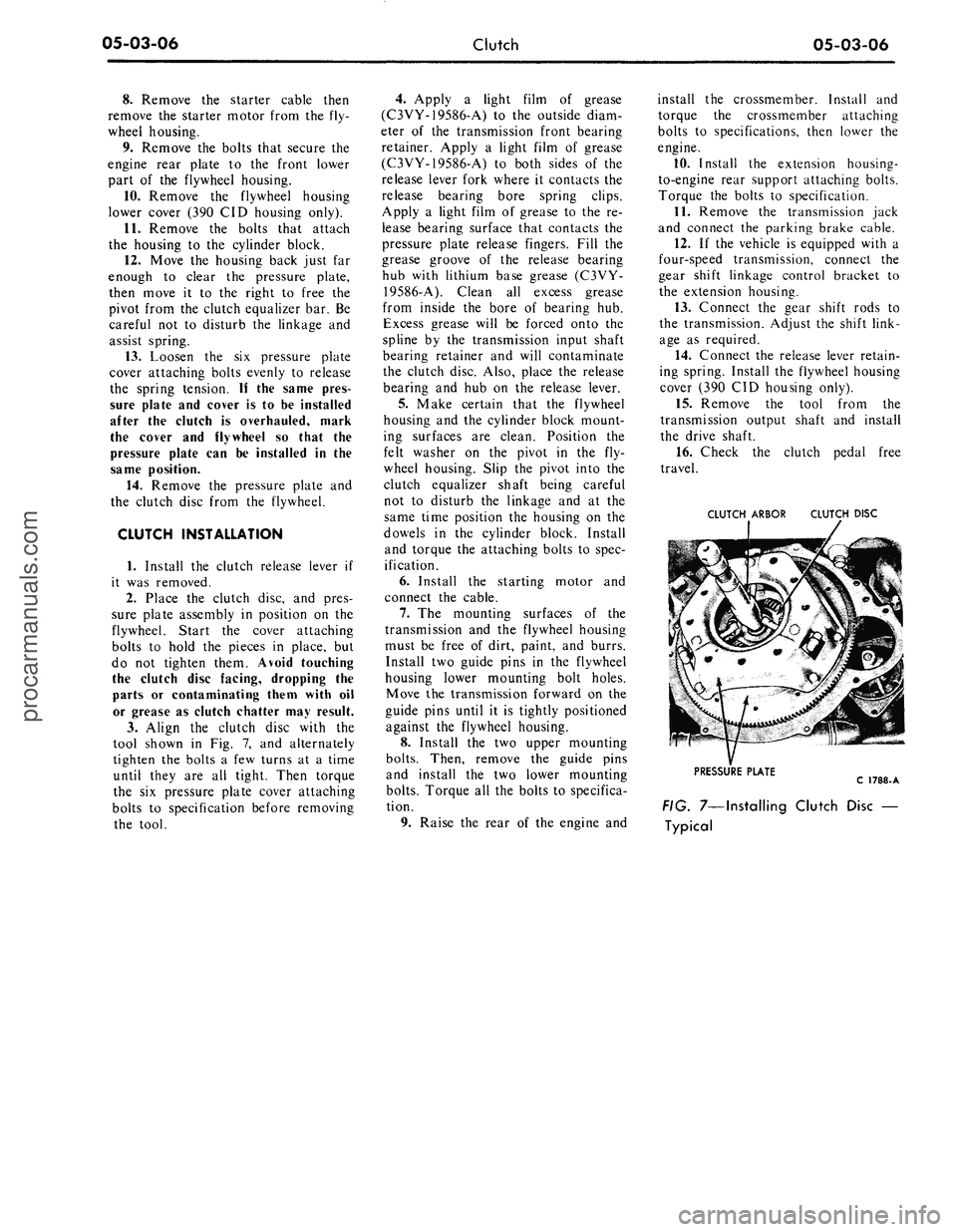

3.

Align the clutch disc with the

tool shown in Fig. 7, and alternately

tighten the bolts a few turns at a time

until they are all tight. Then torque

the six pressure plate cover attaching

bolts to specification before removing

the tool.

4.

Apply a light film of grease

(C3VY-19586-A) to the outside diam-

eter of the transmission front bearing

retainer. Apply a light film of grease

(C3VY-19586-A) to both sides of the

release lever fork where it contacts the

release bearing bore spring clips.

Apply a light film of grease to the re-

lease bearing surface that contacts the

pressure plate release fingers. Fill the

grease groove of the release bearing

hub with lithium base grease (C3VY-

19586-A). Clean all excess grease

from inside the bore of bearing hub.

Excess grease will be forced onto the

spline by the transmission input shaft

bearing retainer and will contaminate

the clutch disc. Also, place the release

bearing and hub on the release lever.

5.

Make certain that the flywheel

housing and the cylinder block mount-

ing surfaces are clean. Position the

felt washer on the pivot in the fly-

wheel housing. Slip the pivot into the

clutch equalizer shaft being careful

not to disturb the linkage and at the

same time position the housing on the

dowels in the cylinder block. Install

and torque the attaching bolts to spec-

ification.

6. Install the starting motor and

connect the cable.

7.

The mounting surfaces of the

transmission and the flywheel housing

must be free of dirt, paint, and burrs.

Install two guide pins in the flywheel

housing lower mounting bolt holes.

Move the transmission forward on the

guide pins until it is tightly positioned

against the flywheel housing.

8. Install the two upper mounting

bolts.

Then, remove the guide pins

and install the two lower mounting

bolts.

Torque all the bolts to specifica-

tion.

9. Raise the rear of the engine and

install the crossmember. Install and

torque the crossmember attaching

bolts to specifications, then lower the

engine.

10.

Install the extension housing-

to-engine rear support attaching bolts.

Torque the bolts to specification.

11.

Remove the transmission jack

and connect the parking brake cable.

12.

If the vehicle is equipped with a

four-speed transmission, connect the

gear shift linkage control bracket to

the extension housing.

13.

Connect the gear shift rods to

the transmission. Adjust the shift link-

age as required.

14.

Connect the release lever retain-

ing spring. Install the flywheel housing

cover (390 CID housing only).

15.

Remove the tool from the

transmission output shaft and install

the drive shaft.

16.

Check the clutch pedal free

travel.

CLUTCH ARBOR CLUTCH DISC

PRESSURE PLATE

C 1788-A

FIG. 7—Installing Clutch Disc —

Typicalprocarmanuals.com

Page 282 of 413

06-03-03

Ford Design Four-Speed Transmission

06-03-03

cable from the equalizer lever and sep-

arate the lever from the crossmember.

5.

Remove the hairpin retainer se-

curing the cable to the transmission

rear support crossmember, and then

pull the cable assembly forward and

out of the crossmember.

6. Remove the retaining clip, flat

washer, and spring washer that se-

cures the shift rods to the shift levers.

7.

Remove the bolts that attach the

shift linkage control bracket to the ex-

tension housing and position the as-

sembly out of the way.

8. Support the engine with a trans-

mission jack and remove the extension

housing-to-engine rear support attach-

ing bolts.

9. Raise the rear of the engine high

enough to remove the weight from the

crossmember. Remove the bolts re-

taining the crossmember to the frame

side supports and remove the

crossmember.

10.

Support the transmission on a

jack and remove the bolts that attach

the transmission to the flywheel hous-

ing.

11.

Move the transmission and jack

rearward until the transmission input

shaft clears the flywheel housing. If

necessary, lower the engine enough to

obtain clearance for transmission re-

moval.

Do not depress the clutch pedal

while the transmission is removed.

INSTALLATION

1.

Make sure that the mounting

surface of the transmission and the

flywheel housing are free of dirt,

paint, and burrs. Install two guide

pins in the flywheel housing lower

mounting bolt holes. Move the trans-

mission forward on the guide pins

until the input shaft splines enter the

clutch hub splines and the case is posi-

tioned against the flywheel housing.

2.

Install the two upper transmis-

sion to flywheel housing, mounting

bolts snug, and then remove the two

guide pins. Install the two lower

mounting bolts. Torque all mounting

bolts to specifications.

3.

Raise the rear of the engine and

install the crossmember. Install and

torque the crossmember attaching

bolts to specifications, then lower the

engine.

4.

With the transmission extension

housing resting on the engine rear

support, install the transmission ex-

tension housing attaching bolts. Tor-

que the bolts to specifications.

5.

Position the shift linkage control

bracket to the extension housing and

install the attaching bolts.

6. Secure each shift rod to its re-

spective lever with the spring washer,

flat washer, and retaining pin.

7.

Guide the parking brake cable

assembly through the hole in the

transmission rear support crossmemb-

er. Secure the cable assembly to the

crossmember with the hair pin retain-

er.

8. Insert the parking brake front

cable in the equalizer and install the

equalizer in the bracket on the

crossmember. Secure the parking

brake rear cable to the equalizer.

9. Connect the speedometer cable

to the extension housing.

10.

Remove the extension housing

installation tool and slide the forward

end of the drive shaft over the trans-

mission output shaft. Connect the

drive shaft to the rear U-joint flange.

11.

Place both forward gear shift

levers and the reverse shift lever in the

neutral position and insert a 1/4 inch

diameter alignment tool in the shift

linkage alignment hole (Fig. 17). It

may be necessary to loosen the adjust-

ment nuts to install the alignment

tool. Adjust the linkage as necessary

and tighten the adjustment nuts to

specifications. Remove the alignment

tool.

12.

Fill the transmission to the

proper level with the specified lubri-

cant.

13.

Lower the car. Check tne shift

and crossover motion for full shift en-

gagement and smooth crossover oper-

ation.

MAJOR REPAIR OPERATIONS

DISASSEMBLY

1.

Mount the transmission in a

holding fixture and drain the lubri-

cant.

2.

Remove the cover attaching

screws from the case. Lift the cover

and gasket from the case.

3.

Remove the long spring that re-

tains the detent plug in the case (Fig.

4).

Remove the detent plug with a

small magnet.

4.

Remove the extension housing

attaching screws and lock washers.

Remove the housing and the gasket.

5.

Remove the input shaft bearing

retainer attaching screws. Slide the re-

tainer off the input shaft.

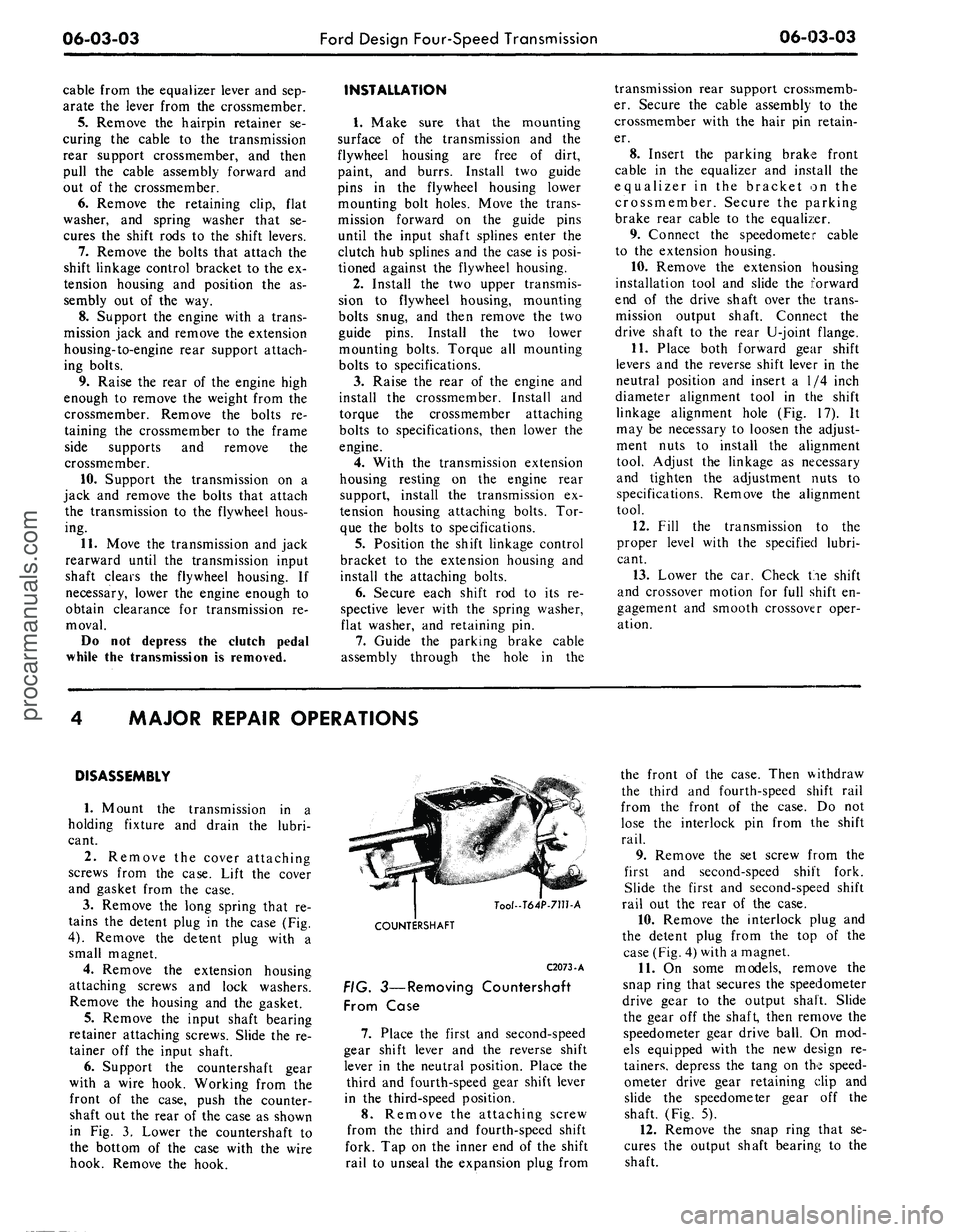

6. Support the countershaft gear

with a wire hook. Working from the

front of the case, push the counter-

shaft out the rear of the case as shown

in Fig. 3. Lower the countershaft to

the bottom of the case with the wire

hook. Remove the hook.

Tool-T64P-711hA

COUNTERSHAFT

C2073-A

FIG. 3—Removing Countershaft

From Case

7.

Place the first and second-speed

gear shift lever and the reverse shift

lever in the neutral position. Place the

third and fourth-speed gear shift lever

in the third-speed position.

8. Remove the attaching screw

from the third and fourth-speed shift

fork. Tap on the inner end of the shift

rail to unseal the expansion plug from

the front of the case. Then withdraw

the third and fourth-speed shift rail

from the front of the case. Do not

lose the interlock pin from the shift

rail.

9. Remove the set screw from the

first and second-speed shift fork.

Slide the first and second-speed shift

rail out the rear of the case.

10.

Remove the interlock plug and

the detent plug from the top of the

case (Fig. 4) with a magnet.

11.

On some models, remove the

snap ring that secures the speedometer

drive gear to the output shaft. Slide

the gear off the shaft, then remove the

speedometer gear drive ball. On mod-

els equipped with the new design re-

tainers, depress the tang on the speed-

ometer drive gear retaining clip and

slide the speedometer gear off the

shaft. (Fig. 5).

12.

Remove the snap ring that se-

cures the output shaft bearing to the

shaft.procarmanuals.com

Page 291 of 413

06-04-02

Specifications

06-04-02

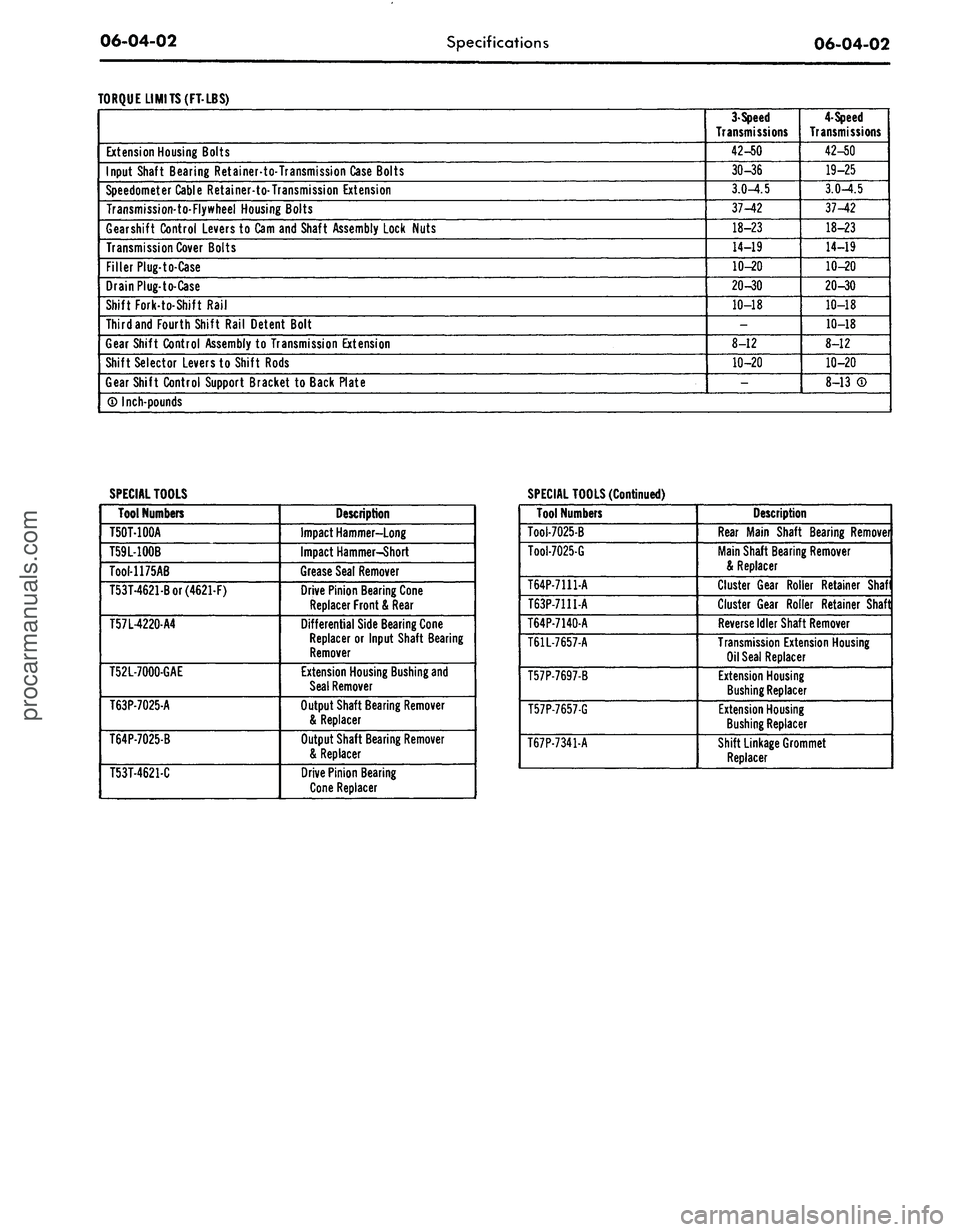

TORQUE LIMITS(FT-LBS)

Extension Housing Bolts

Input Shaft Bearing Retainer-to-Transmission Case Bolts

Speedometer Cable Retainer-to-Transmission Extension

Transmission-to-Flywheel Housing Bolts

Gearshift Control Levers to Cam and Shaft Assembly Lock Nuts

Transmission Cover Bolts

Filler Plug-to-Case

Drain Plug-to-Case

Shift Fork-to-Shift Rail

Third and Fourth Shift Rail Detent Bolt

Gear Shift Control Assembly

to

Transmission Extension

Shift Selector Levers to Shift Rods

Gear Shift Control Support Bracket

to

Back Plate

3-Speed

Transmissions

42-50

30-36

3.0-4.5

37-42

18-23

14-19

10-20

20-30

10-18

-

8-12

10-20

-

4-Speed

Transmissions

42-50

19-25

3.0-4.5

37-42

18-23

14-19

10-20

20-30

10-18

10-18

8-12

10-20

8-13

® Inch-pounds

SPECIAL TOOLS

SPECIAL TOOLS (Continued)

Tool Numbers

T50T-100A

T59L-100B

Tool-1175AB

T53T-4621-Bor(4621-F)

T57L-4220-A4

T52L-7000-GAE

T63P-7025-A

T64P-7025-B

T53T-4621-C

Description

Impact Hammer-Long

Impact Hammer-Short

Grease Seal Remover

Drive Pinion Bearing Cone

Replacer Front

&

Rear

Differential Side Bearing Cone

Replacer

or

Input Shaft Bearing

Remover

Extension Housing Bushing and

Seal Remover

Output Shaft Bearing Remover

& Replacer

Output Shaft Bearing Remover

& Replacer

Drive Pinion Bearing

Cone Replacer

Tool Numbers

Tool-7025-B

Tool-7025-G

T64P-7111-A

T63P-7111-A

T64P-7140-A

T61L-7657-A

T57P-7697-B

T57P-7657-G

T67P-7341-A

Description

Rear Main Shaft Bearing Removei

Main Shaft Bearing Remover

& Replacer

Cluster Gear Roller Retainer Shaf

Cluster Gear Roller Retainer Shaft

Reverse Idler Shaft Remover

Transmission Extension Housing

Oil Seal Replacer

Extension Housing

Bushing Replacer

Extension Housing

Bushing Replacer

Shift Linkage Grommet

Replacerprocarmanuals.com

Page 319 of 413

07-02-11

C4 Automatic Transmission

07-02-11

REMOVAL AND INSTALLATION

An oil impregnated plastic grommet

is incorporated in the end of the man-

ual shift linkage lever arm on all col-

umn shift vehicles. A special tool

T67P-7341-A is required to install the

grommet in the manual lever, and to

install the manual linkage rod into the

grommet. Refer to Part 7-1, Section

2,

for the grommet replacement pro-

cedures.

TRANSMISSION REMOVAL

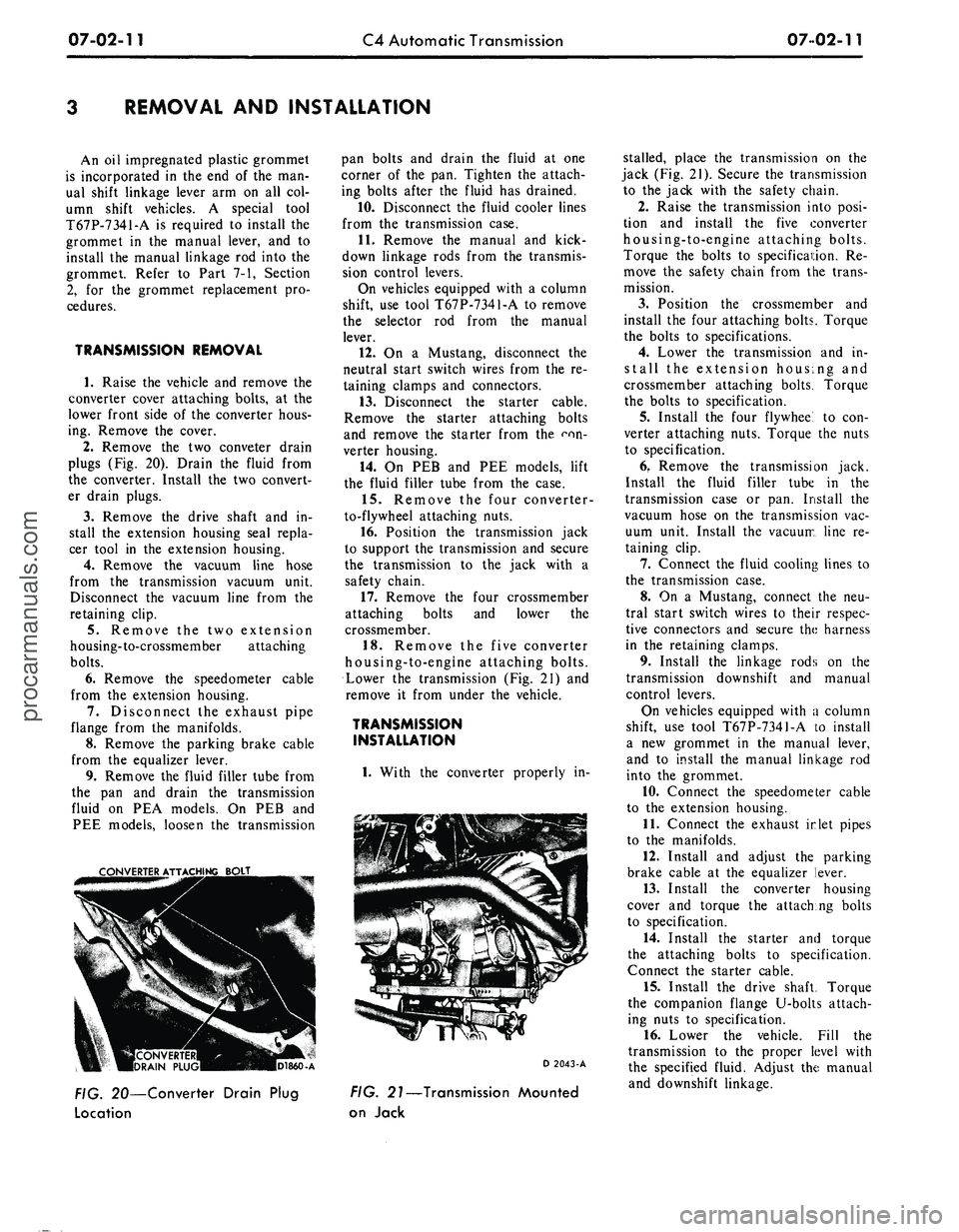

1.

Raise the vehicle and remove the

converter cover attaching bolts, at the

lower front side of the converter hous-

ing. Remove the cover.

2.

Remove the two conveter drain

plugs (Fig. 20). Drain the fluid from

the converter. Install the two convert-

er drain plugs.

3.

Remove the drive shaft and in-

stall the extension housing seal repla-

cer tool in the extension housing.

4.

Remove the vacuum line hose

from the transmission vacuum unit.

Disconnect the vacuum line from the

retaining clip.

5.

Remove the two extension

housing-to-crossmember attaching

bolts.

6. Remove the speedometer cable

from the extension housing.

7.

Disconnect the exhaust pipe

flange from the manifolds.

8. Remove the parking brake cable

from the equalizer lever.

9. Remove the fluid filler tube from

the pan and drain the transmission

fluid on PEA models. On PEB and

PEE models, loosen the transmission

CONVERTER A

ATT,

pan bolts and drain the fluid at one

corner of the pan. Tighten the attach-

ing bolts after the fluid has drained.

10.

Disconnect the fluid cooler lines

from the transmission case.

11.

Remove the manual and kick-

down linkage rods from the transmis-

sion control levers.

On vehicles equipped with a column

shift, use tool T67P-7341-A to remove

the selector rod from the manual

lever.

12.

On a Mustang, disconnect the

neutral start switch wires from the re-

taining clamps and connectors.

13.

Disconnect the starter cable.

Remove the starter attaching bolts

and remove the starter from the con-

verter housing.

14.

On PEB and PEE models, lift

the fluid filler tube from the case.

15.

Remove the four converter-

to-flywheel attaching nuts.

16.

Position the transmission jack

to support the transmission and secure

the transmission to the jack with a

safety chain.

17.

Remove the four crossmember

attaching bolts and lower the

crossmember.

18.

Remove the five converter

housing-to-engine attaching bolts.

Lower the transmission (Fig. 21) and

remove it from under the vehicle.

TRANSMISSION

INSTALLATION

1.

With the converter properly in-

D 2043-A

FIG. 20—Converter Drain Plug

Location

FIG. 21—Transmission Mounted

on Jack

stalled, place the transmission on the

jack (Fig. 21). Secure the transmission

to the jack with the safety chain.

2.

Raise the transmission into posi-

tion and install the five converter

housing-to-engine attaching bolts.

Torque the bolts to specification. Re-

move the safety chain from the trans-

mission.

3.

Position the crossmember and

install the four attaching bolts. Torque

the bolts to specifications.

4.

Lower the transmission and in-

stall the extension housing and

crossmember attaching bolts. Torque

the bolts to specification.

5.

Install the four flywheel to con-

verter attaching nuts. Torque the nuts

to specification.

6. Remove the transmission jack.

Install the fluid filler tube in the

transmission case or pan. Install the

vacuum hose on the transmission vac-

uum unit. Install the vacuum line re-

taining clip.

7.

Connect the fluid cooling lines to

the transmission case.

8. On a Mustang, connect the neu-

tral start switch wires to their respec-

tive connectors and secure the harness

in the retaining clamps.

9. Install the linkage rods on the

transmission downshift and manual

control levers.

On vehicles equipped with a column

shift, use tool T67P-7341-A to install

a new grommet in the manual lever,

and to install the manual linkage rod

into the grommet.

10.

Connect the speedometer cable

to the extension housing.

11.

Connect the exhaust inlet pipes

to the manifolds.

12.

Install and adjust the parking

brake cable at the equalizer lever.

13.

Install the converter housing

cover and torque the attaching bolts

to specification.

14.

Install the starter and torque

the attaching bolts to specification.

Connect the starter cable.

15.

Install the drive shaft. Torque

the companion flange U-bolts attach-

ing nuts to specification.

16.

Lower the vehicle. Fill the

transmission to the proper level with

the specified fluid. Adjust the manual

and downshift linkage.procarmanuals.com

Page 382 of 413

07-04-13

C-6 Automatic Transmission

07-04-13

On a Lincoln Continental, install

the reinforcement plate and secure it

with the attaching bolts.

4.

Lower the vehicle and fill the

transmission to the correct level with

the specified fluid.

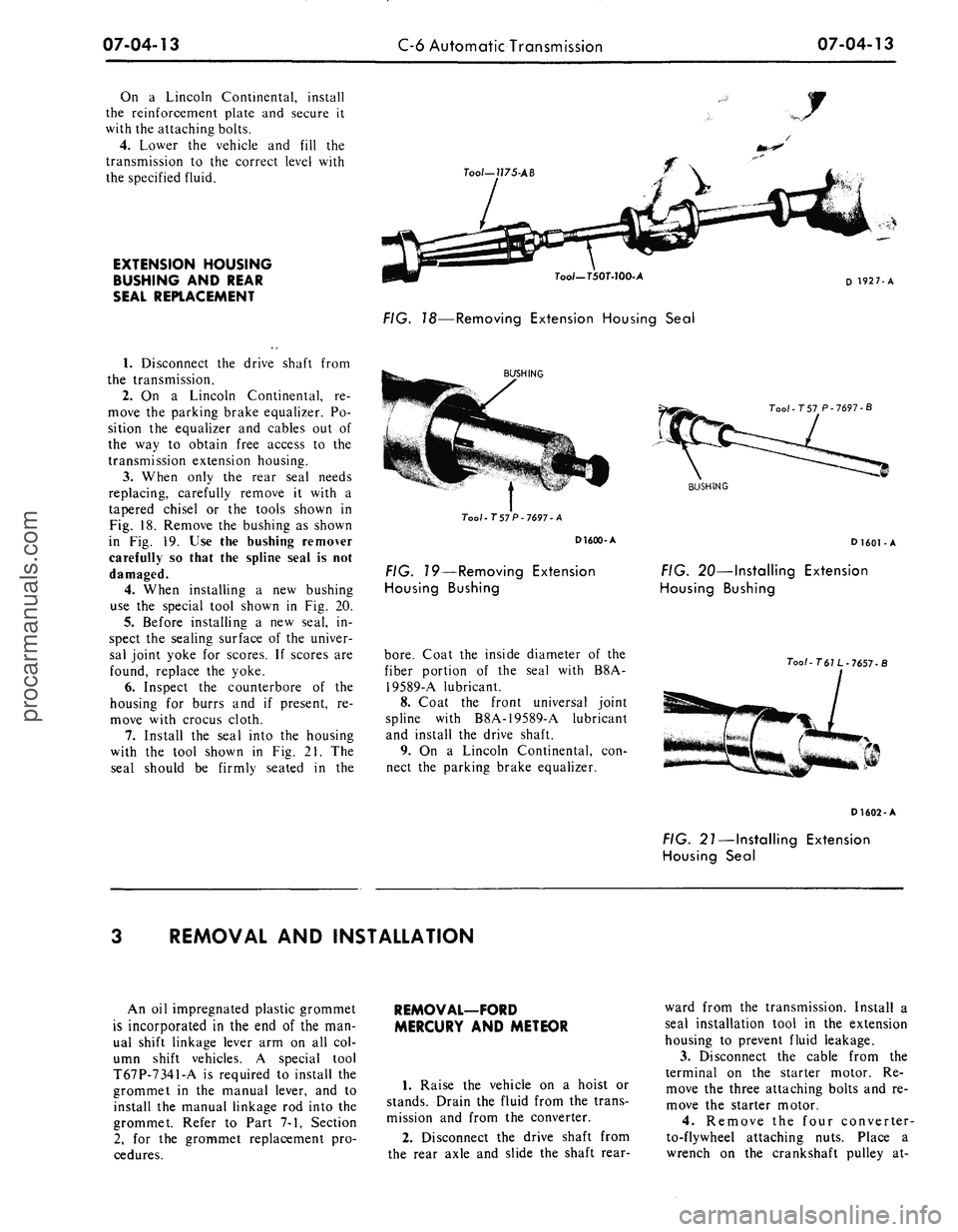

EXTENSION HOUSING

BUSHING AND REAR

SEAL REPLACEMENT

Too/—

1175-AB

Tool—750T-70O-A

D 1927-A

FIG. 18—Removing Extension Housing Seal

1.

Disconnect the drive shaft from

the transmission.

2.

On a Lincoln Continental, re-

move the parking brake equalizer. Po-

sition the equalizer and cables out of

the way to obtain free access to the

transmission extension housing.

3.

When only the rear seal needs

replacing, carefully remove it with a

tapered chisel or the tools shown in

Fig. 18. Remove the bushing as shown

in Fig. 19. Use the bushing remover

carefully so that the spline seal is not

damaged.

4.

When installing a new bushing

use the special tool shown in Fig. 20.

5.

Before installing a new seal, in-

spect the sealing surface of the univer-

sal joint yoke for scores. If scores are

found, replace the yoke.

6. Inspect the counterbore of the

housing for burrs and if present, re-

move with crocus cloth.

7.

Install the seal into the housing

with the tool shown in Fig. 21. The

seal should be firmly seated in the

BUSHING

Too/-757 P-7697-A

D1600-A

FIG. 19—Removing Extension

Housing Bushing

bore.

Coat the inside diameter of the

fiber portion of the seal with B8A-

19589-A lubricant.

8. Coat the front universal joint

spline with B8A-19589-A lubricant

and install the drive shaft.

9. On a Lincoln Continental, con-

nect the parking brake equalizer.

Tool-T 57 P-7697-B

BUSHING

D

1601

-A

FIG. 20—Installing Extension

Housing Bushing

Tool-

T61 L

-

7657-

B

D1602-A

FIG. 21—Installing Extension

Housing Seal

REMOVAL AND INSTALLATION

An oil impregnated plastic grommet

is incorporated in the end of the man-

ual shift linkage lever arm on all col-

umn shift vehicles. A special tool

T67P-7341-A is required to install the

grommet in the manual lever, and to

install the manual linkage rod into the

grommet. Refer to Part 7-1, Section

2,

for the grommet replacement pro-

cedures.

REMOVAL—FORD

MERCURY AND METEOR

1.

Raise the vehicle on a hoist or

stands. Drain the fluid from the trans-

mission and from the converter.

2.

Disconnect the drive shaft from

the rear axle and slide the shaft rear-

ward from the transmission. Install a

seal installation tool in the extension

housing to prevent fluid leakage.

3.

Disconnect the cable from the

terminal on the starter motor. Re-

move the three attaching bolts and re-

move the starter motor.

4.

Remove the four converter-

to-flywheel attaching nuts. Place a

wrench on the crankshaft pulley at-procarmanuals.com

Page 383 of 413

07-04-14

C-6 Automatic Transmission

07-04-14

taching bolt to turn the converter to

gain access to the nuts.

5.

Remove the rear mount to

crossmember attaching bolt.

6. Remove the two crossmember-

to-frame attaching bolts.

7.

Remove the two engine rear

support-to-extension housing attaching

bolts.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the manual linkage

rod from the lever at the transmission.

On a column shift, use tool T67P-

7341-A to remove the rod.

10.

Remove the two bolts securing

the bellcrank bracket to the converter

housing.

11.

Raise the transmission with a

transmission jack to provide clearance

to remove the crossmember.

12.

Remove the rear mount from

the crossmember and remove the

crossmember from the side supports.

13.

Lower the transmission to gain

access to the oil cooler lines.

14.

Disconnect each oil line from

the fittings on the transmission.

15.

Disconnect the vacuum line

from the diaphragm located at the

right rear of the transmission. Remove

the metal line from the retaining clip

on the transmission.

16.

Disconnect the speedometer

cable from the extension housing.

17.

Remove the bolt that secures

the transmission fluid filler tube to the

cylinder block. Lift the filler tube and

the dipstick from the transmission.

18.

Secure the transmission to the

jack with the chain.

19.

Remove the converter housing-

to-cylinder block attaching bolts.

20.

Carefully move the transmission

away from the engine and, at the

same time, lower it to clear the und-

erside of the vehicle.

21.

Remove the converter and

mount the transmission in a holding

fixture.

INSTALLATION—FORD

MERCURY AND METEOR

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission to the

jack with the chain.

4.

Rotate the flywheel to place two

converter mounting stud holes that are

adjacent to the drain plug holes in a

vertical position.

5.

Rotate the converter so that the

studs and drain plugs are in alignment

with those in the flywheel.

6. Move the transmission toward

the cylinder block until they are in

contact. Install and torque the attach-

ing bolts to specification making sure

that the vacuum tube retaining clips

are properly positioned.

7.

Remove the transmission jack

chain from around the transmission.

8. Install a new Oring on the lower

end of the transmission filler tube. In-

sert the tube in the transmission case

and secure the tube to the engine with

the attaching bolt.

9. Connect the speedometer cable

to the extension housing.

10.

Connect the oil cooler lines to

the right side of transmission case.

11.

Connect the vacuum line to the

vacuum diaphragm making sure that

the metal tube is secured in the retain-

ing clip.

12.

Position the cross member on

the side supports. Position the rear

mount on the crossmember and install

the attaching bolt and nut.

13.

Secure the engine rear support

to the extension housing and torque

the bolts to specification.

14.

Lower the transmission and re-

move the jack.

15.

Secure the crossmember to the

side supports with the attaching bolts

and torque them to specification.

16.

Position the bellcrank bracket

to the converter housing and install

the two attaching bolts.

17.

Connect the downshift rod to

the transmission downshift lever.

18.

Connect the selector rod to the

manual lever at the transmission. On

a column shift, use tool T67P-7341-A

and install a new grommet in the

manual lever. Then, secure the manual

selector rod to the lever.

19.

Secure the converter-to-flywheel

attaching nuts and torque them to

specification. Use a wrench on the

crankshaft pulley attaching nut to ro-

tate the flywheel. Do not use a wrench

on the converter attaching nuts to ro-

tate it.

20.

Install the converter housing

dust shield and secure it with the at-

taching bolts.

21.

Secure the starter motor in

place with the attaching bolts. Con-

nect the cable to the terminal on the

starter.

22.

Install the driveshaft.

23.

Adjust the shift linkage as de-

tailed in Section 2.

24.

Lower the vehicle.

25.

Fill the transmission to the cor-

rect level with the specified lubricant.

Start the engine and shift the trans-

mission to all ranges, then recheck the

fluid level.

REMOVAL—FAIRLANE,

MONTEGO, MUSTANG

AND COUGAR

1.

On Mustang and Cougar, dis-

connect the neutral switch wires from

the harness connector and the retain-

ing clip on the dash.

2.

Remove the bolt that secures the

filler tube to the rear of the right

cylinder head.

3.

Raise the vehicle on a hoist or

jack stands.

4.

Remove the converter drain plug

access cover from the lower end of the

converter housing.

5.

Place a drain pan under nhe con-

verter housing and remove the two

converter drain plugs. Install the plugs

after the fluid has drained.

6. Place the drain pan under the

transmission fluid pan. Starting at the

rear of the pan and working toward

the front, loosen the attaching bolts

and allow the fluid to drain. Finally

remove all of the pan attaching bolts

except two at the front, to allow the

fluid to further drain. After the fluid

has drained, install two bolts on the

rear side of the pan to temporarily

hold it in place.

7.

Disconnect the drive shaft from

the rear axle flange and remove it

from the transmission. Install tool

T61L-7657-A in the rear of the exten-

sion housing to prevent the fluid from

leaking.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the shift rod from the

manual lever. On a column shift, use

tool T67P-7341-A to remove the rod.

10.

Disconnect the speedometer

cable from the extension housing.

11.

Disconnect the rubber hose

from the vacuum diaphragm at the

rear of the transmission. Remove the

vacuum tube from the retaining clip at

the transmission.

12.

Disconnect the starter cable

from the terminal on the starter. Re-

move the starter attaching bolts and

remove it from the housing.

13.

Lift the fluid filler tube from

the transmission case.

14.

Remove the four converter-

to-flywheel attaching nuts.

15.

On a Mustang or Cougar, dis-

connect the complete exhaust system

and allow it to hang on the rear axle.

16.

Remove the two nuts that at-

tach the engine rear support to the

crossmember.

17.

Raise the transmission with a

jack just enough to remove the weight

from the crossmember.

18.

Remove the cotter pins from

the crossmember-to-frame side sup-procarmanuals.com

Page 384 of 413

07-04-15

C-6

Automatic Transmission

07-04-15

port attaching nuts and remove the

nuts.

Lift the crossmember from the

frame side supports.

19.

Remove the bolts that attach

the engine rear support to the exten-

sion housing and remove the support.

20.

Lower the transmission, then

disconnect the fluid cooler lines from

the transmission case.

21.

Secure the transmission to the

jack with a chain.

22.

Remove the six bolts that at-

tach the converter housing to the cyl-

inder block.

23.

Move the jack rearward until

the transmission clears the engine,

then tip it forward to provide clear-

ance. Lower the transmission and re-

move it from under the vehicle.

24.

Remove the converter from the

transmission. Mount the transmission

in a holding fixture if repairs are nec-

essary.

INSTALLATION—FAIRLANE,

MONTEGO,

MUSTANG

AND COUGAR

1. Mount the transmission in a

transmission jack and secure it with a

safety chain.

2.

Install the converter on the front

pump.

3.

Rotate the flywheel so that the

drain plug holes are in a vertical posi-

tion. Rotate the converter so that the

drain plugs are in the same relative

position as the drain plug holes in the

flywheel.

4.

Roll the transmission into posi-

tion under the vehicle and raise it to

alignment with the engine. Move it

forward until the converter housing

contacts the cylinder block. Install

and torque the converter-to-cylinder

block attaching bolts.

5.

Remove the jack safety chain

from the transmission.

6. Connect the two fluid cooler

lines to the fittings in the transmission

case.

7.

Secure the engine rear support to

the extension housing with the attach-

ing bolts. Torque the bolts to specifi-

cation.

8. Position the crossmember on the

frame side supports and install and

tighten the attaching nuts to specifica-

tion. Install cotter Dins to retain the

nuts.

9. Remove the transmission jack

from under the vehicle. Install and

torque the engine rear support-

to-crossmember attaching nuts.

10.

Install the exhaust system on

Mustang and Cougar.

11.

Install the converter-to-flywheel

attaching nuts and torque them to

specifications. Tighten the drain plugs

to specification.

12.

Secure the converter drain plug

access cover to the lower end of the

converter housing with the attaching

bolts.

13.

Install a new O-ring on the

lower end of the fluid filler tube. Dip

the O-ring in clean automatic trans-

mission fluid and insert the filler tube

in the transmission case.

14.

Secure the starter to the con-

verter housing. Connect the cable to

the terminal on the starter.

15.

Connect the speedometer cable

to the extension housing.

16.

Connect the shift rod to the

manual lever at the transmission. On

a column shift, use tool T67P-7341-A

and install a new grommet in the

manual lever. Then, secure the manual

selector rod to the lever.

17.

Connect the downshift rod to

the lever on the transmission. Adjust

the rod.

18.

Remove the tool from the ex-

tension housing and install the drive

shaft.

19.

Lower the vehicle.

20.

Working from the engine com-

partment, secure the fluid filler tube

to the rear of the right cylinder head

with the attaching bolt.

21.

On Mustang and Cougar, con-

nect the neutral switch wires to the

harness. Secure the wires to the dash

with the retaining clip.

22.

Fill the transmission with the

specified lubricant as detailed in Part

7-1.

REMOVAL—THUNDERBIRD

1. Working from the engine com-

partment, remove the fluid filler tube

bracket attaching screw that secures it

to the rear of the right cylinder head.

Lift the tube and dipstick from the

transmission.

2.

Remove the starting motor upper

attaching bolt using a long extension.

3.

Remove the two converter hous-

ing upper attaching bolts.

4.

Raise the vehicle on a hoist or

stands.

5.

Remove the dust shield from the

front lower end of the converter hous-

ing.

6. Crank the engine until one of the

converter drain plugs is accessible.

Then, remove the plug.

7.

Crank the engine until the other

plug is at the bottom. Place a drain

pan to catch the fluid, then remove

the pan and allow the fluid to drain.

8. Remove the drive shaft.

9. Remove the frame side rail sup-

port brace attaching bolts and remove

the brace.

10.

After the fluid has been drained

from the converter, install the plug.

11.

Place the drain pan under the

transmission pan and loosen the at-

taching bolts and allow the fluid to

drain. Finally remove all of the pan

attaching bolts except two, to allow

the oil to further drain. After the fluid

has drained, install two bolts on the

opposite side of the pan to temporari-

ly hold it in place.

12.

Remove the converter-

to-flywheel attaching nuts.

13.

Disconnect the downshift link-

age from the transmission downshift

lever.

14.

Using tool T67P-7341-A, re-

move the selector rod from the manu-

al lever.

15.

Remove the two screws that at-

tach the shift rod bellcrank bracket to

the converter housing and remove the

bracket.

16.

Disconnect the vacuum dia-

phragm hose from the upper end of

the vacuum tube.

17.

Disconnect the speedometer

cable from the extension housing and

place it to one side.

18.

Remove the starting motor two

lower attaching bolts and place the

motor to one side.

19.

Disconnect the two oil cooler

lines from the right side of the trans-

mission.

20.

Disconnect the muffler inlet

pipes at the exhaust manifolds and

allow the pipes to hang.

21.

Remove the vibration absorber

from the extension housing.

22.

Remove the two engine rear

support-to-extension housing attaching

bolts.

23.

Place a transmission jack under

the transmission and raise it just

enough to remove the weight from the

support.

24.

Remove the two support attach-

ing bolts and remove the support.

25.

Lower the jack just enough to

remove the weight.

26.

Remove the four remaining

converter housing-to-cylinder block at-

taching bolts and the accelerator link-

age stop from the left side of the

housing.

27.

Carefully lower the transmis-

sion and remove it from under the ve-

hicle.

28.

Remove the converter and

mount the transmission in a holding

fixture.procarmanuals.com