section 18 FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 68 of 413

03-01-03

Suspension — Steering, Wheels And Tires — General Service

03-01-03

4.

Connect a tachometer, start the

engine and operate it at idle speed

until the reservoir fluid temperature

reaches 165 to 175. This temperature

must be maintained throughout the

test. Valve B may be partially closed

to create a back pressure up to 350

psi to hasten the temperature rise. The

reservoir fluid must be at the proper

level.

5.

With the engine operating at rec-

ommended idle rpm and fluid temper-

ature noted in Step 4, close the manu-

al valve B. The minimum acceptable

pressure reading is 620 psi.

6. If the pressure gauge reading is

below the minimum specification, the

pump is at fault and should be re-

paired with necessary parts.

7.

If the reading is at or above the

minimum specification, the pump flow

is normal. Open manual valve B and

proceed to the Pump Fluid Pressure

Test.

PUMP FLUID

PRESSURE TEST

1.

Keep the lines and tools con-

nected as in the Pump Flow Test.

2.

With manual valves A and B

opened fully, operate the engine at

recommended idle speed (Fig. 2).

Close manual valve A, then manual

valve B. Do not keep both valves

closed for more than 5 seconds as this

would abnormally increase the fluid

temperature and cause undue pump

and/or gear wear.

3.

With the valves fully closed, the

pressure gauge should read 1000 psi

minimum for Ford, Mercury, Meteor

or Thunderbird and 750 psi minimum

for Cougar, Fairlane, Falcon, Monte-

go or Mustang.

4.

If the pressure gauge reading is

below the minimum specification, the

pump is at fault and should be re-

paired with necessary parts.

5.

If the pressure gauge reading is

at or above the minimum specifica-

tions,

the pump is normal and the

power steering gear or power assist

control valve is at fault.

FLUID PRESSURE TEST-

LINCOLN CONTINENTAL AND

CONTINENTAL MARK III

The pressure testing gauge set, tool

T56L-33610-D, requires modification

to make it adaptable for installation

in the power steering hydraulic sys-

tem. The parts required and the modi-

fication procedure are as follows:

OWER STEERING

PRESSURE LINE

INVERTED FLARE

CONNECTOR

%* TUBE x VA" PIPE

FLARED FEMALE COUPW

%' TUBE x VA" PIPE

G1544.A

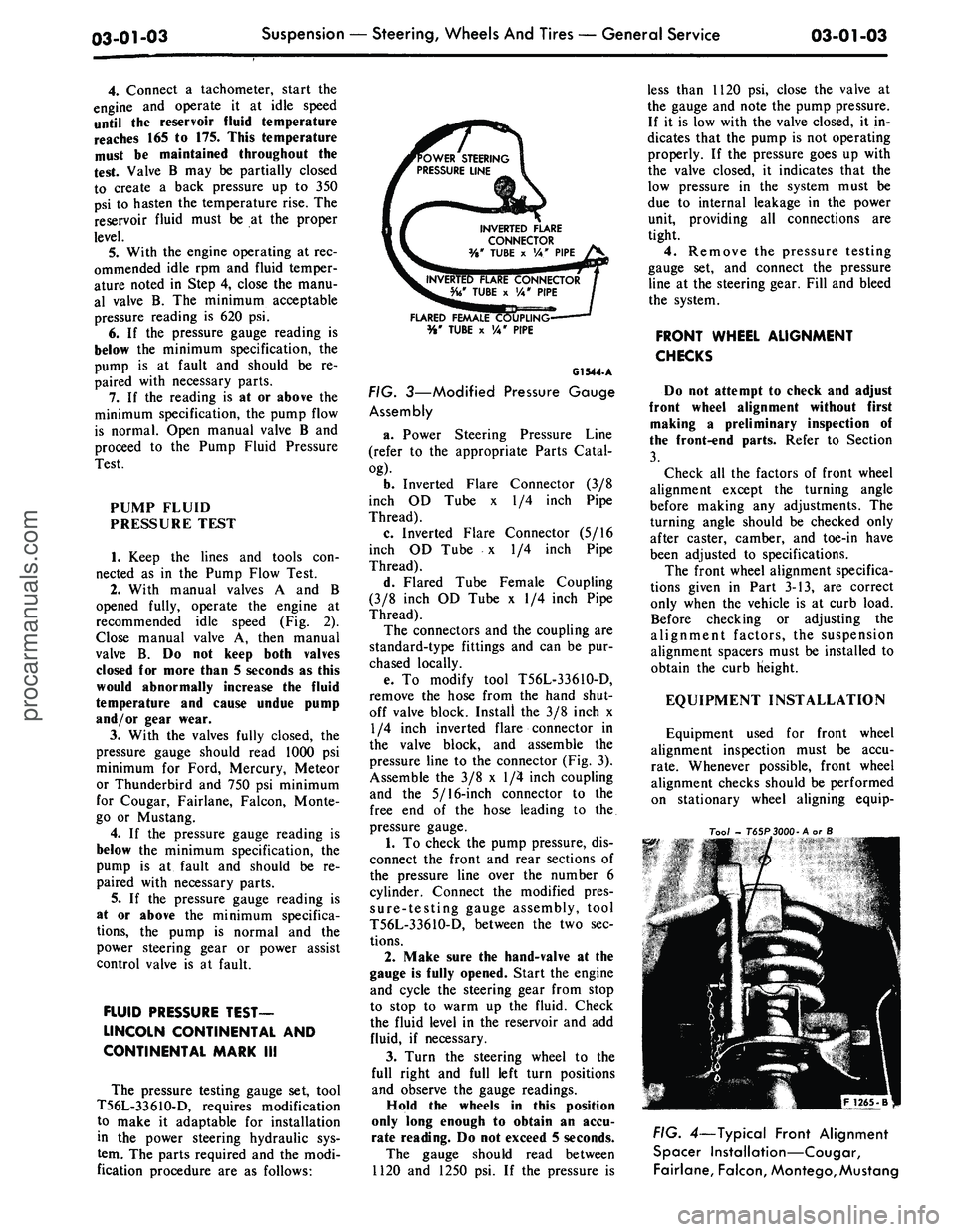

FIG. 3—Modified Pressure Gauge

Assembly

a. Power Steering Pressure Line

(refer to the appropriate Parts Catal-

og).

b.

Inverted Flare Connector (3/8

inch OD Tube x 1/4 inch Pipe

Thread).

c. Inverted Flare Connector (5/16

inch OD Tube x 1/4 inch Pipe

Thread).

d. Flared Tube Female Coupling

(3/8 inch OD Tube x 1/4 inch Pipe

Thread).

The connectors and the coupling are

standard-type fittings and can be pur-

chased locally.

e. To modify tool T56L-33610-D,

remove the hose from the hand shut-

off valve block. Install the 3/8 inch x

1/4 inch inverted flare connector in

the valve block, and assemble the

pressure line to the connector (Fig. 3).

Assemble the 3/8 x 1/4 inch coupling

and the 5/16-inch connector to the

free end of the hose leading to the.

pressure gauge.

1.

To check the pump pressure, dis-

connect the front and rear sections of

the pressure line over the number 6

cylinder. Connect the modified pres-

sure-testing gauge assembly, tool

T56L-3361O-D, between the two sec-

tions.

2.

Make sure the hand-valve at the

gauge is fully opened. Start the engine

and cycle the steering gear from stop

to stop to warm up the fluid. Check

the fluid level in the reservoir and add

fluid, if necessary.

3.

Turn the steering wheel to the

full right and full left turn positions

and observe the gauge readings.

Hold the wheels in this position

only long enough to obtain an accu-

rate reading. Do not exceed 5 seconds.

The gauge should read between

1120 and 1250 psi. If the pressure is

less than 1120 psi, close the valve at

the gauge and note the pump pressure.

If it is low with the valve closed, it in-

dicates that the pump is not operating

properly. If the pressure goes up with

the valve closed, it indicates that the

low pressure in the system must be

due to internal leakage in the power

unit, providing all connections are

tight.

4.

Remove the pressure testing

gauge set, and connect the pressure

line at the steering gear. Fill and bleed

the system.

FRONT WHEEL ALIGNMENT

CHECKS

Do not attempt to check and adjust

front wheel alignment without first

making a preliminary inspection of

the front-end parts. Refer to Section

3.

Check all the factors of front wheel

alignment except the turning angle

before making any adjustments. The

turning angle should be checked only

after caster, camber, and toe-in have

been adjusted to specifications.

The front wheel alignment specifica-

tions given in Part 3-13, are correct

only when the vehicle is at curb load.

Before checking or adjusting the

alignment factors, the suspension

alignment spacers must be installed to

obtain the curb Height.

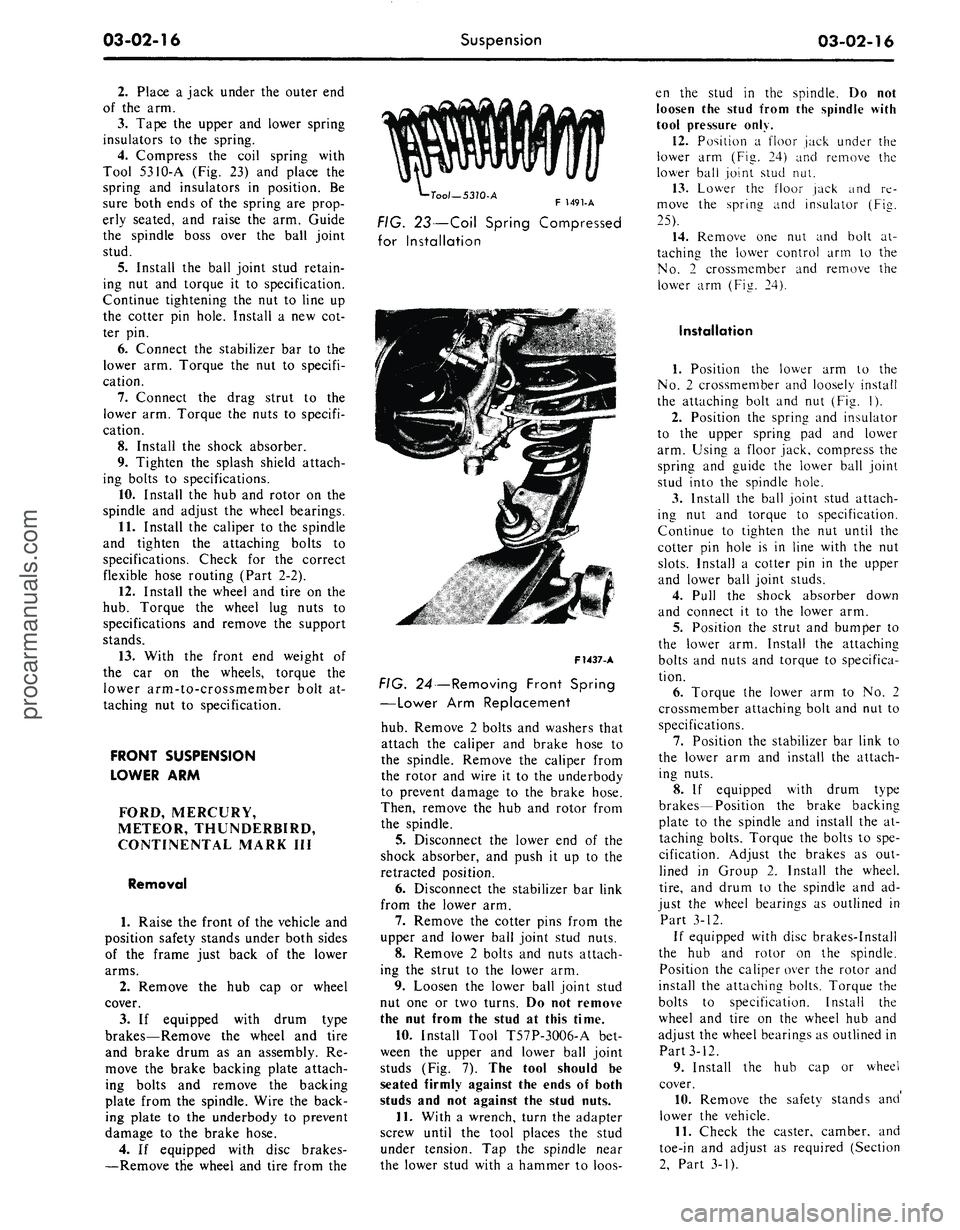

EQUIPMENT INSTALLATION

Equipment used for front wheel

alignment inspection must be accu-

rate.

Whenever possible, front wheel

alignment checks should be performed

on stationary wheel aligning equip-

Too/

- T65P3000-A or S

FIG. 4—Typical Front Alignment

Spacer Installation—Cougar,

Fairlane, Falcon,

Montego,

Mustangprocarmanuals.com

Page 92 of 413

03-02-16

Suspension

03-02-16

2.

Place a jack under the outer end

of the arm.

3.

Tape the upper and lower spring

insulators to the spring.

4.

Compress the coil spring with

Tool 5310-A (Fig. 23) and place the

spring and insulators in position. Be

sure both ends of the spring are prop-

erly seated, and raise the arm. Guide

the spindle boss over the ball joint

stud.

5.

Install the ball joint stud retain-

ing nut and torque it to specification.

Continue tightening the nut to line up

the cotter pin hole. Install a new cot-

ter pin.

6. Connect the stabilizer bar to the

lower arm. Torque the nut to specifi-

cation.

7.

Connect the drag strut to the

lower arm. Torque the nuts to specifi-

cation.

8. Install the shock absorber.

9. Tighten the splash shield attach-

ing bolts to specifications.

10.

Install the hub and rotor on the

spindle and adjust the wheel bearings.

11.

Install the caliper to the spindle

and tighten the attaching bolts to

specifications. Check for the correct

flexible hose routing (Part 2-2).

12.

Install the wheel and tire on the

hub.

Torque the wheel lug nuts to

specifications and remove the support

stands.

13.

With the front end weight of

the car on the wheels, torque the

lower arm-to-crossmember bolt at-

taching nut to specification.

FRONT SUSPENSION

LOWER ARM

FORD, MERCURY,

METEOR, THUNDERBIRD,

CONTINENTAL MARK III

Removal

1.

Raise the front of the vehicle and

position safety stands under both sides

of the frame just back of the lower

arms.

2.

Remove the hub cap or wheel

cover.

3.

If equipped with drum type

brakes—Remove the wheel and tire

and brake drum as an assembly. Re-

move the brake backing plate attach-

ing bolts and remove the backing

plate from the spindle. Wire the back-

ing plate to the underbody to prevent

damage to the brake hose.

4.

If equipped with disc brakes-

—Remove the wheel and tire from the

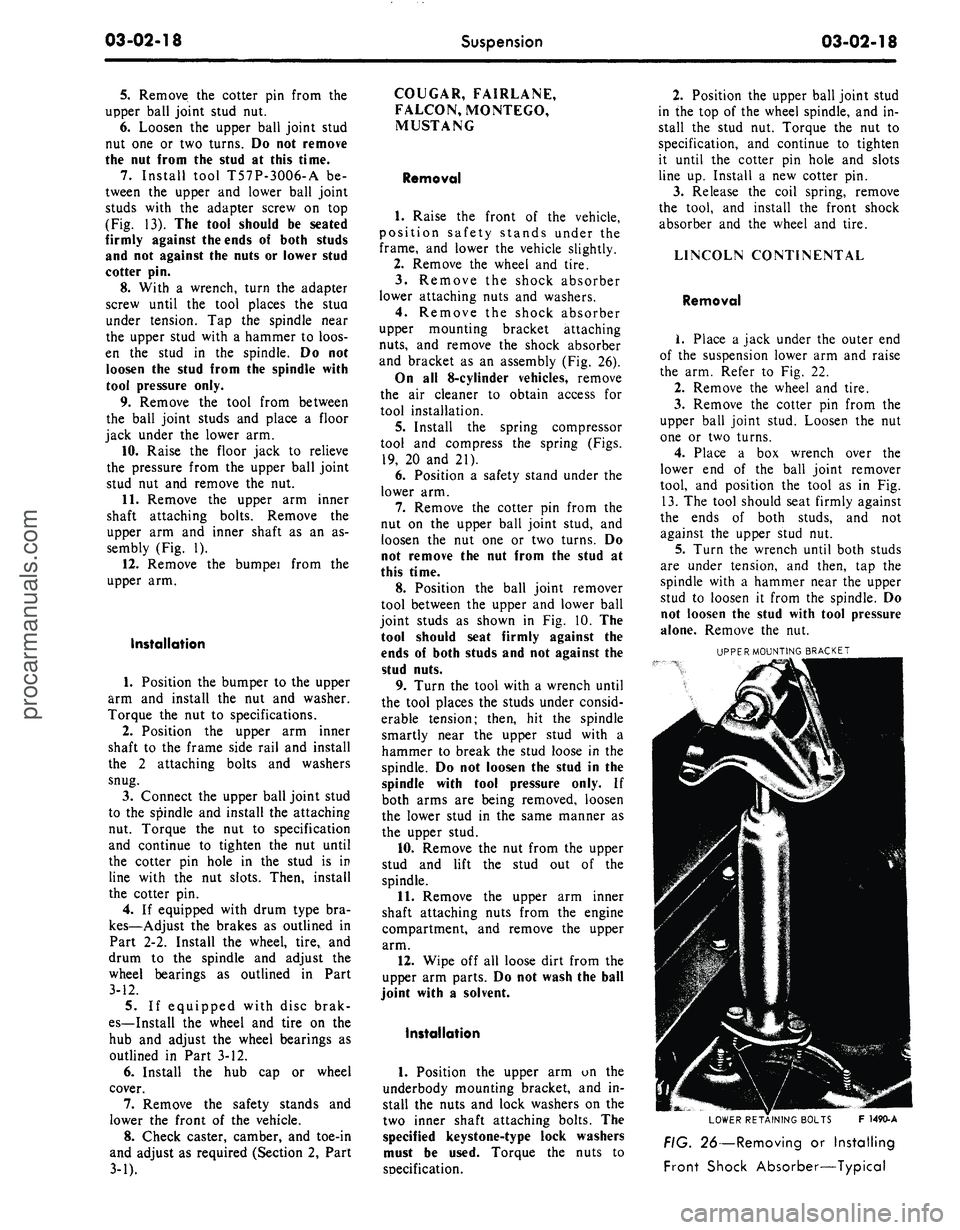

•Tool—5310-A

F 1491-A

FIG. 23—Coil Spring Compressed

for Installation

F1437-A

FIG. 24—Removing Front Spring

—Lower Arm Replacement

hub.

Remove 2 bolts and washers that

attach the caliper and brake hose to

the spindle. Remove the caliper from

the rotor and wire it to the underbody

to prevent damage to the brake hose.

Then, remove the hub and rotor from

the spindle.

5.

Disconnect the lower end of the

shock absorber, and push it up to the

retracted position.

6. Disconnect the stabilizer bar link

from the lower arm.

7.

Remove the cotter pins from the

upper and lower ball joint stud nuts.

8. Remove 2 bolts and nuts attach-

ing the strut to the lower arm.

9. Loosen the lower ball joint stud

nut one or two turns. Do not remove

the nut from the stud at this time.

10.

Install Tool T57P-3OO6-A bet-

ween the upper and lower ball joint

studs (Fig. 7). The tool should be

seated firmly against the ends of both

studs and not against the stud nuts.

11.

With a wrench, turn the adapter

screw until the tool places the stud

under tension. Tap the spindle near

the lower stud with a hammer to loos-

en the stud in the spindle. Do not

loosen the stud from the spindle with

tool pressure only.

12.

Position a floor jack under the

lower arm (Fig. 24) and remove the

lower ball joint stud nut.

13.

Lower the floor jack and re-

move the sprina and insulator (Fie.

25).

14.

Remove one nut and bolt at-

taching the lower control arm to the

No.

2 crossmember and remove the

lower arm (Fig. 24).

Installation

1.

Position the lower arm to the

No.

2 crossmember and loosely install

the attaching bolt and nut (Fig. 1).

2.

Position the spring and insulator

to the upper spring pad and lower

arm. Using a floor jack, compress the

spring and guide the lower ball joint

stud into the spindle hole.

3.

Install the ball joint stud attach-

ing nut and torque to specification.

Continue to tighten the nut until the

cotter pin hole is in line with the nut

slots.

Install a cotter pin in the upper

and lower ball joint studs.

4.

Pull the shock absorber down

and connect it to the lower arm.

5.

Position the strut and bumper to

the lower arm. Install the attaching

bolts and nuts and torque to specifica-

tion.

6. Torque the lower arm to No. 2

crossmember attaching bolt and nut to

specifications.

7.

Position the stabilizer bar link to

the lower arm and install the attach-

ing nuts.

8. If equipped with drum type

brakes—Position the brake backing

plate to the spindle and install the at-

taching bolts. Torque the bolts to spe-

cification. Adjust the brakes as out-

lined in Group 2. Install the wheel,

tire,

and drum to the spindle and ad-

just the wheel bearings as outlined in

Part 3-12.

If equipped with disc brakes-Install

the hub and rotor on the spindle.

Position the caliper over the rotor and

install the attaching bolts. Torque the

bolts to specification. Install the

wheel and tire on the wheel hub and

adjust the wheel bearings as outlined in

Part 3-12.

9. Install the hub cap or wheel

cover.

10.

Remove the safety stands and'

lower the vehicle.

11.

Check the caster, camber, and

toe-in and adjust as required (Section

2,

Part 3-1).procarmanuals.com

Page 94 of 413

03-02-18

Suspension

03-02-18

5.

Remove the cotter pin from the

upper ball joint stud nut.

6. Loosen the upper ball joint stud

nut one or two turns. Do not remove

the nut from the stud at this time.

7.

Install tool T57P-3006-A be-

tween the upper and lower ball joint

studs with the adapter screw on top

(Fig. 13). The tool should be seated

firmly against the ends of both studs

and not against the nuts or lower stud

cotter pin.

8. With a wrench, turn the adapter

screw until the tool places the stua

under tension. Tap the spindle near

the upper stud with a hammer to loos-

en the stud in the spindle. Do not

loosen the stud from the spindle with

tool pressure only.

9. Remove the tool from between

the ball joint studs and place a floor

jack under the lower arm.

10.

Raise the floor jack to relieve

the pressure from the upper ball joint

stud nut and remove the nut.

11.

Remove the upper arm inner

shaft attaching bolts. Remove the

upper arm and inner shaft as an as-

sembly (Fig. 1).

12.

Remove the bumpei from the

upper arm.

Installation

1.

Position the bumper to the upper

arm and install the nut and washer.

Torque the nut to specifications.

2.

Position the upper arm inner

shaft to the frame side rail and install

the 2 attaching bolts and washers

snug.

3.

Connect the upper ball joint stud

to the spindle and install the attaching

nut. Torque the nut to specification

and continue to tighten the nut until

the cotter pin hole in the stud is in

line with the nut slots. Then, install

the cotter pin.

4.

If equipped with drum type bra-

kes—Adjust the brakes as outlined in

Part 2-2. Install the wheel, tire, and

drum to the spindle and adjust the

wheel bearings as outlined in Part

3-12.

5.

If equipped with disc brak-

es—Install the wheel and tire on the

hub and adjust the wheel bearings as

outlined in Part 3-12.

6. Install the hub cap or wheel

cover.

7.

Remove the safety stands and

lower the front of the vehicle.

8. Check caster, camber, and toe-in

and adjust as required (Section 2, Part

3-D.

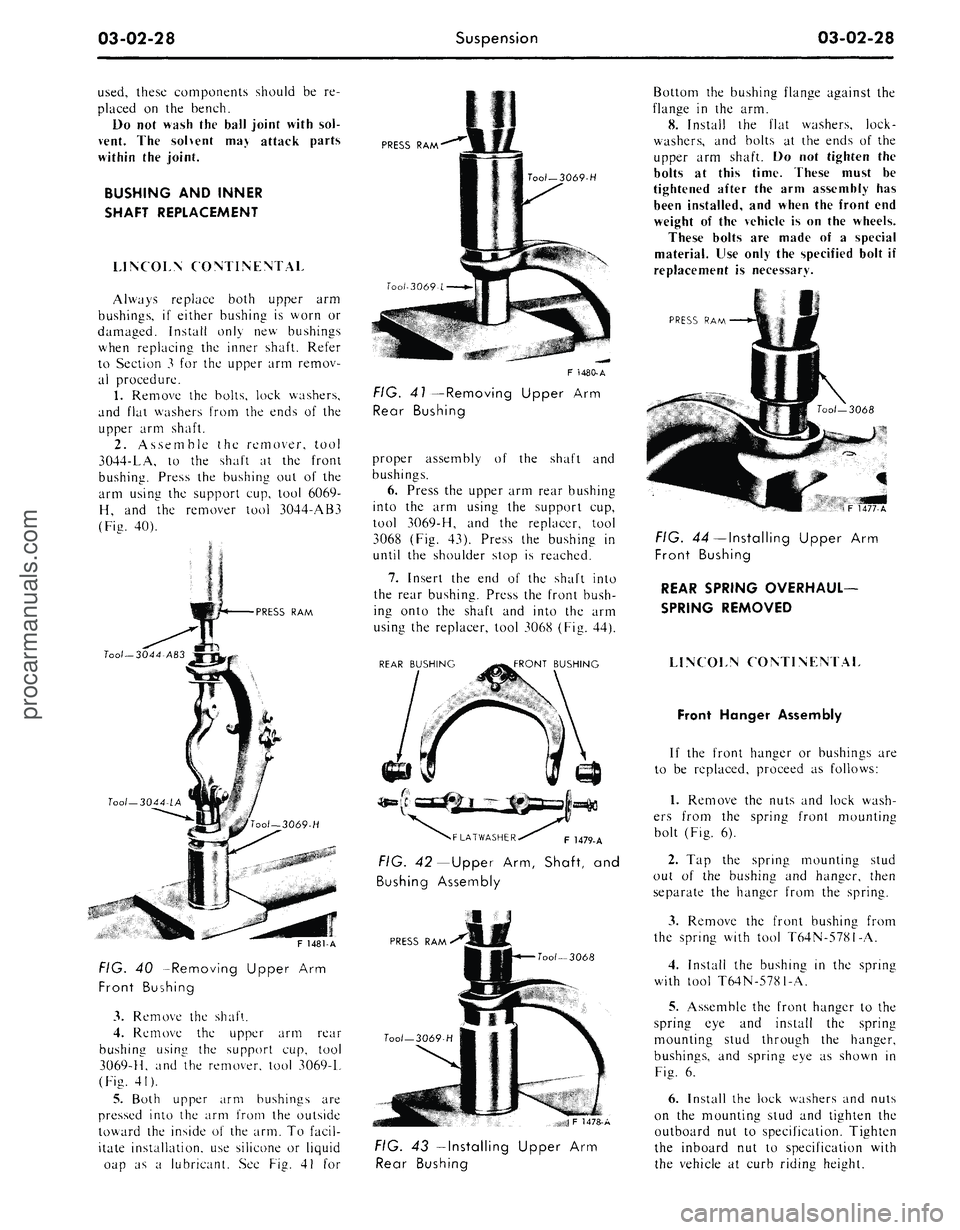

COUGAR, FAIRLANE,

FALCON, MONTEGO,

MUSTANG

Removal

1.

Raise the front of the vehicle,

position safety stands under the

frame, and lower the vehicle slightly.

2.

Remove the wheel and tire.

3.

Remove the shock absorber

lower attaching nuts and washers.

4.

Remove the shock absorber

upper mounting bracket attaching

nuts,

and remove the shock absorber

and bracket as an assembly (Fig. 26).

On all 8-cylinder vehicles, remove

the air cleaner to obtain access for

tool installation.

5.

Install the spring compressor

tool and compress the spring (Figs.

19,

20 and 21).

6. Position a safety stand under the

lower arm.

7.

Remove the cotter pin from the

nut on the upper ball joint stud, and

loosen the nut one or two turns. Do

not remove the nut from the stud at

this time.

8. Position the ball joint remover

tool between the upper and lower ball

joint studs as shown in Fig. 10. The

tool should seat firmly against the

ends of both studs and not against the

stud nuts.

9. Turn the tool with a wrench until

the tool places the studs under consid-

erable tension; then, hit the spindle

smartly near the upper stud with a

hammer to break the stud loose in the

spindle. Do not loosen the stud in the

spindle with tool pressure only. If

both arms are being removed, loosen

the lower stud in the same manner as

the upper stud.

10.

Remove the nut from the upper

stud and lift the stud out of the

spindle.

11.

Remove the upper arm inner

shaft attaching nuts from the engine

compartment, and remove the upper

arm.

12.

Wipe off all loose dirt from the

upper arm parts. Do not wash the ball

joint with a solvent.

Installation

1.

Position the upper arm on the

underbody mounting bracket, and in-

stall the nuts and lock washers on the

two inner shaft attaching bolts. The

specified keystone-type lock washers

must be used. Torque the nuts to

soecification.

2.

Position the upper ball joint stud

in the top of the wheel spindle, and in-

stall the stud nut. Torque the nut to

specification, and continue to tighten

it until the cotter pin hole and slots

line up. Install a new cotter pin.

3.

Release the coil spring, remove

the tool, and install the front shock

absorber and the wheel and tire.

LINCOLN CONTINENTAL

Removal

1.

Place a jack under the outer end

of the suspension lower arm and raise

the arm. Refer to Fig. 22.

2.

Remove the wheel and tire.

3.

Remove the cotter pin from the

upper ball joint stud. Loosen the nut

one or two turns.

4.

Place a box wrench over the

lower end of the ball joint remover

tool, and position the tool as in Fig.

13.

The tool should seat firmly against

the ends of both studs, and not

against the upper stud nut.

5.

Turn the wrench until both studs

are under tension, and then, tap the

spindle with a hammer near the upper

stud to loosen it from the spindle. Do

not loosen the stud with tool pressure

alone. Remove the nut.

UPPER MOUNTING BRACKET

LOWER RETAINING BOLTS F 1490-A

FIG. 26—Removing or Installing

Front Shock Absorber—Typicalprocarmanuals.com

Page 104 of 413

03-02-28

Suspension

03-02-28

used, these components should

be re-

placed

on the

bench.

Do not wash the ball joint with sol-

vent.

The

solvent

may

attack parts

within the joint.

BUSHING AND INNER

SHAFT REPLACEMENT

LINCOLN CONTINENTAL

Always replace both upper

arm

bushings,

if

either bushing

is

worn

or

damaged. Install only

new

bushings

when replacing

the

inner shaft. Refer

to Section

3 for

the upper arm remov-

al procedure.

1.

Remove

the

bolts, lock washers,

and flat washers from the ends

of

the

upper arm shaft.

2.

Assemble

the

remover, tool

3044-LA,

to the

shaft

at the

front

bushing. Press

the

bushing

out of the

arm using

the

support cup, tool 6069-

H,

and the

remover tool 3044-AB3

(Fig. 40).

PRESS RAM

FIG.

40

—Removing Upper

Arm

Front Bushing

3.

Remove

the

shaft.

4.

Remove

the

upper

arm

rear

bushing using

the

support

cup,

tool

3069-H, and

the

remover, tool 3069-L

(Fig. 41).

5.

Both upper

arm

bushings

are

pressed into the arm from the outside

toward the inside

of

the arm. To facil-

itate installation, use silicone

or

liquid

oap

as a

lubricant.

See

Fig.

41 for

PRESS RAM

Tool-3069-H

F 1480-A

FIG. 41—Removing Upper

Arm

Rear Bushing

proper assembly

of the

shaft

and

bushings.

6. Press the upper arm rear bushing

into

the arm

using

the

support cup,

tool 3069-H,

and the

replacer, tool

3068 (Fig. 43). Press

the

bushing

in

until

the

shoulder stop

is

reached.

7.

Insert

the end of the

shaft into

the rear bushing. Press the front bush-

ing onto

the

shaft

and

into

the arm

using the replacer, tool 3068 (Fig. 44).

REAR BUSHING

FRONT BUSHING

F 1479-A

FIG. 42— Upper Arm, Shaft,

and

Bushing Assembly

PRESS RAM

Tool— 3068

JF 1478-A

Bottom the bushing flange against the

flange

in the

arm.

8. Install

the

flat washers, lock-

washers,

and

bolts

at

the ends

of

the

upper

arm

shaft.

Do not

tighten

the

bolts

at

this time. These must

be

tightened after

the

arm assembly

has

been installed, and when the front end

weight

of

the vehicle

is

on the wheels.

These bolts

are

made

of a

special

material. Use only the specified bolt

if

replacement

is

necessary.

PRESS

RAM

FIG. 43—Installing Upper

Arm

Rear Bushing

FIG. 44—Installing Upper

Arm

Front Bushing

REAR SPRING OVERHAUL-

SPRING REMOVED

LINCOLN CONTINENTAL

Front Hanger Assembly

If

the

front hanger

or

bushings

are

to

be

replaced, proceed

as

follows:

1.

Remove

the

nuts and lock wash-

ers from

the

spring front mounting

bolt (Fig.

6).

2.

Tap the

spring mounting stud

out

of the

bushing

and

hanger, then

separate

the

hanger from

the

spring.

3.

Remove

the

front bushing from

the spring with tool T64N-5781-A.

4.

Install

the

bushing

in the

spring

with tool T64N-5781-A.

5.

Assemble the front hanger

to

the

spring

eye and

install

the

spring

mounting stud through

the

hanger,

bushings,

and

spring eye

as

shown

in

Fig.

6.

6. Install the lock washers and nuts

on

the

mounting stud

and

tighten

the

outboard

nut to

specification. Tighten

the inboard

nut to

specification with

the vehicle

at

curb riding height.procarmanuals.com

Page 112 of 413

03-04-03

Automatic Air Leveling System — Lincoln Continental

03-04-03

outlet lines to their respective parts.

3.

Adjust the trim height as de-

tailed in Section 4.

4.

Connect the link to the arm.

5.

Remove the jack stands and

lower the vehicle.

SUPER LIFT SHOCK ABSORBER

REMOVAL

1.

Raise the vehicle and place jack

stands under the axle to compress the

super lift.

2.

Loosen the air line or lines (right

super lift) slowly to release the air

from the system. Then, disconnect the

line or lines.

3.

Remove the three mounting plate

attaching screws from the upper end

of the super lift.

4.

Remove the attaching nut and

washer from the lower end of the

super lift and remove it from the vehi-

cle.

5.

Remove the nut, outer washer

and the insulator that attach the super

lift to the mounting plate. Remove the

plate, remaining insulator and washer.

INSTALLATION

1.

Position a washer, insulator,

mounting plate, insulator, washer and

nut on the stud at the upper end of

the super lift. Torque the nut to speci-

fication.

2.

Install the mounting plate, outer

insulator, washer and nut on the stud.

Torque the nut to specification.

3.

Attach the mounting plate and

shock absorber to the crossmember

with the attaching screws to specifica-

tions.

4.

Connect the lower end of the

super lift to the mounting stud with

the washers and attaching nut. Torque

the nut to specification.

5.

Connect the air line or lines

(right super lift) to the super lift.

6. Start the engine and check for

leaks.

3 IN-VEHICLE ADJUSTMENTS AND REPAIRS

REGULATOR ADJUSTMENT HEIGHT CONTROL VALVE

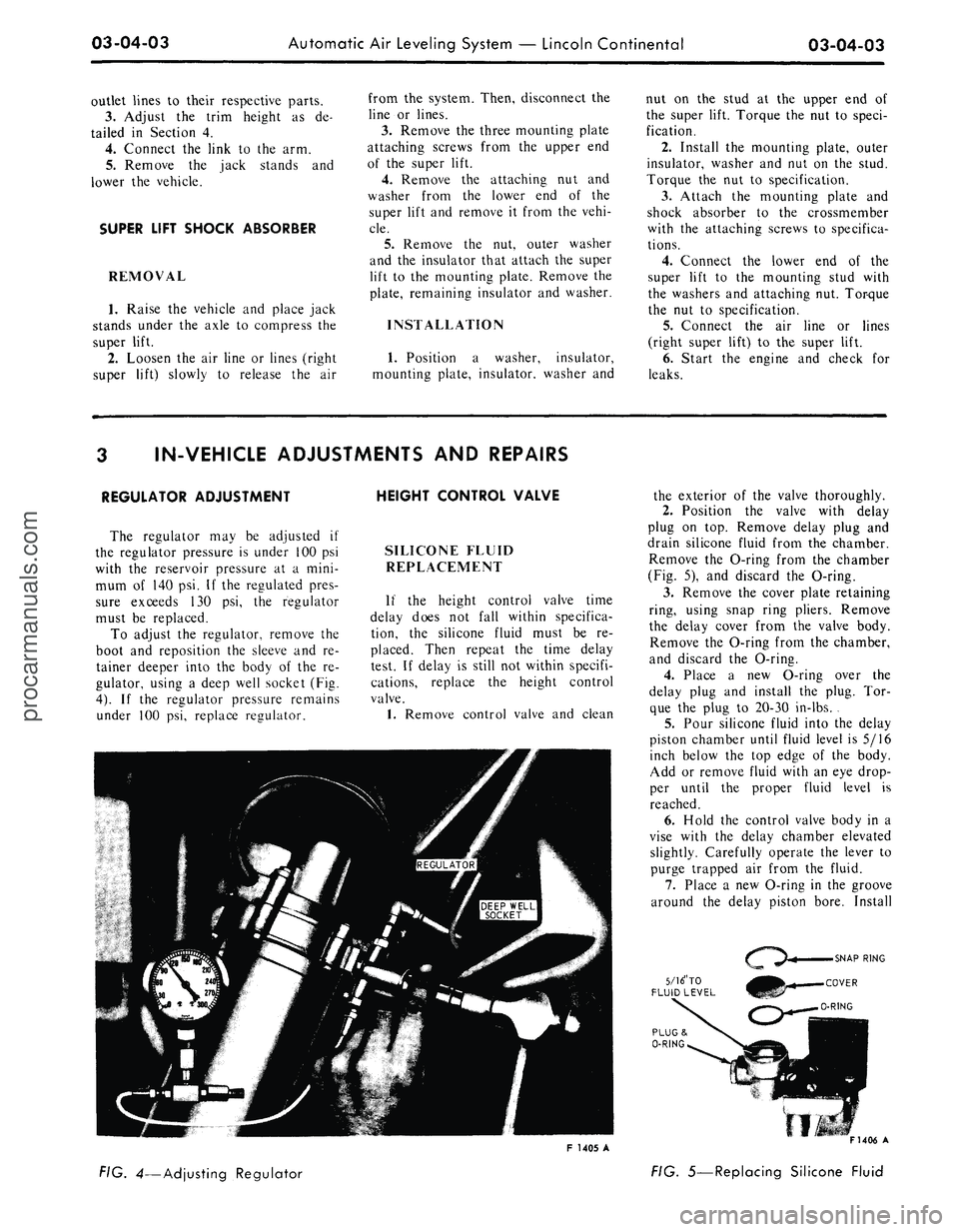

The regulator may be adjusted if

the regulator pressure is under 100 psi

with the reservoir pressure at a mini-

mum of 140 psi. If the regulated pres-

sure exceeds 130 psi, the regulator

must be replaced.

To adjust the regulator, remove the

boot and reposition the sleeve and re-

tainer deeper into the body of the re-

gulator, using a deep well socket (Fig.

4).

If the regulator pressure remains

under 100 psi, replace regulator.

SILICONE FLUID

REPLACEMENT

If the height control valve time

delay does not fall within specifica-

tion, the silicone fluid must be re-

placed. Then repeat the time delay

test. If delay is still not within specifi-

cations, replace the height control

valve.

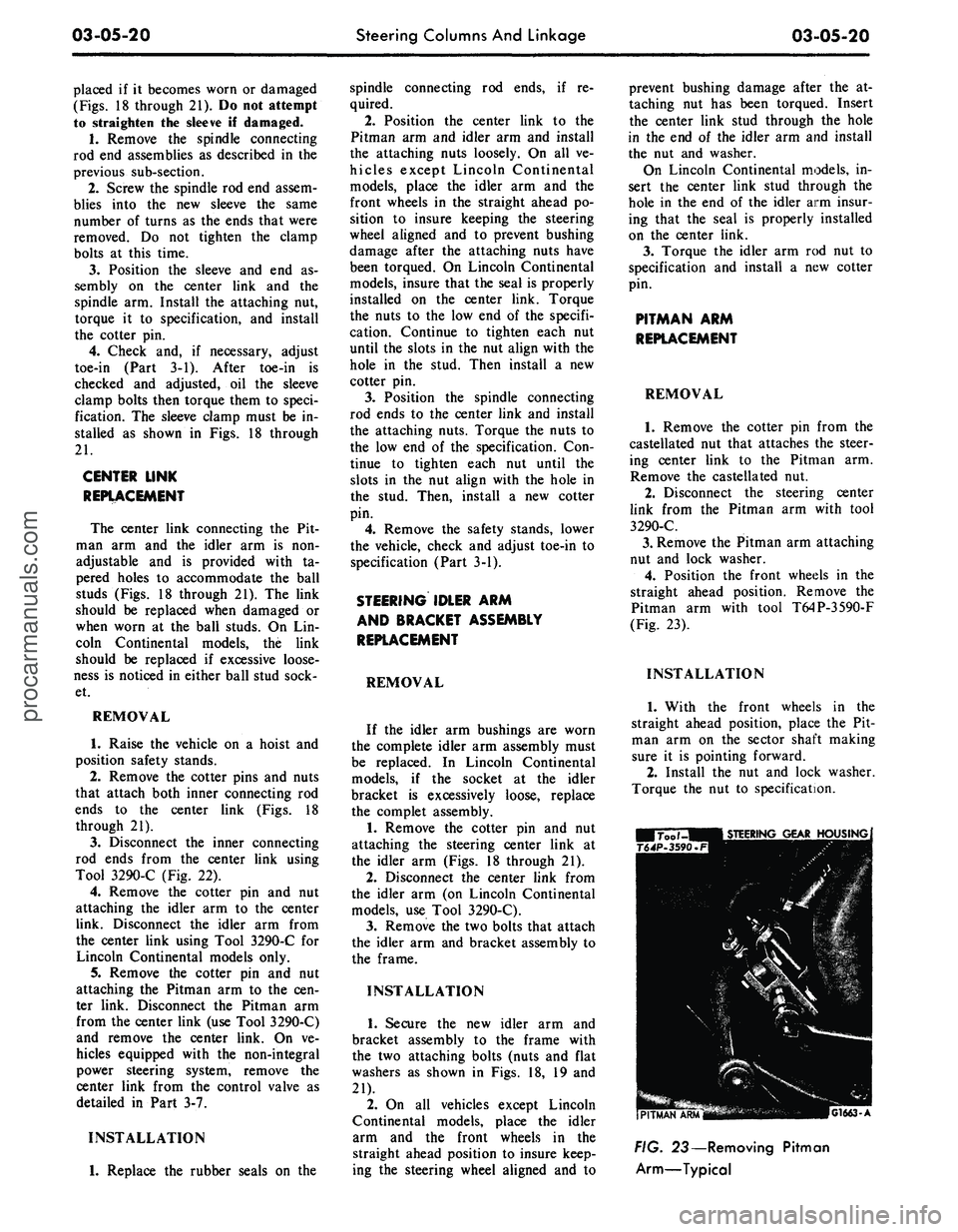

1.

Remove control valve and clean

the exterior of the valve thoroughly.

2.

Position the valve with delay

plug on top. Remove delay plug and

drain silicone fluid from the chamber.

Remove the O-ring from the chamber

(Fig. 5), and discard the O-ring.

3.

Remove the cover plate retaining

ring, using snap ring pliers. Remove

the delay cover from the valve body.

Remove the O-ring from the chamber,

and discard the O-ring.

4.

Place a new O-ring over the

delay plug and install the plug. Tor-

que the plug to 20-30 in-lbs. .

5.

Pour silicone fluid into the delay

piston chamber until fluid level is 5/16

inch below the top edge of the body.

Add or remove fluid with an eye drop-

per until the proper fluid level is

reached.

6. Hold the control valve body in a

vise with the delay chamber elevated

slightly. Carefully operate the lever to

purge trapped air from the fluid.

7.

Place a new O-ring in the groove

around the delay piston bore. Install

5/16" TO

FLUID LEVEL

F 1405 A

FIG. 4—Adjusting Regulator

F1406 A

FIG. 5—Replacing Silicone Fluidprocarmanuals.com

Page 133 of 413

03-05-20

Steering Columns And Linkage

03-05-20

placed if it becomes worn or damaged

(Figs.

18 through 21). Do not attempt

to straighten the sleeve if damaged.

1.

Remove the spindle connecting

rod end assemblies as described in the

previous sub-section.

2.

Screw the spindle rod end assem-

blies into the new sleeve the same

number of turns as the ends that were

removed. Do not tighten the clamp

bolts at this time.

3.

Position the sleeve and end as-

sembly on the center link and the

spindle arm. Install the attaching nut,

torque it to specification, and install

the cotter pin.

4.

Check and, if necessary, adjust

toe-in (Part 3-1). After toe-in is

checked and adjusted, oil the sleeve

clamp bolts then torque them to speci-

fication. The sleeve clamp must be in-

stalled as shown in Figs. 18 through

21.

CENTER LINK

REPLACEMENT

The center link connecting the Pit-

man arm and the idler arm is non-

adjustable and is provided with ta-

pered holes to accommodate the ball

studs (Figs. 18 through 21). The link

should be replaced when damaged or

when worn at the ball studs. On Lin-

coln Continental models, the link

should be replaced if excessive loose-

ness is noticed in either ball stud sock-

et.

REMOVAL

1.

Raise the vehicle on a hoist and

position safety stands.

2.

Remove the cotter pins and nuts

that attach both inner connecting rod

ends to the center link (Figs. 18

through 21).

3.

Disconnect the inner connecting

rod ends from the center link using

Tool 3290-C (Fig. 22).

4.

Remove the cotter pin and nut

attaching the idler arm to the center

link. Disconnect the idler arm from

the center link using Tool 3290-C for

Lincoln Continental models only.

5.

Remove the cotter pin and nut

attaching the Pitman arm to the cen-

ter link. Disconnect the Pitman arm

from the center link (use Tool 3290-C)

and remove the center link. On ve-

hicles equipped with the non-integral

power steering system, remove the

center link from the control valve as

detailed in Part 3-7.

INSTALLATION

1.

Replace the rubber seals on the

spindle connecting rod ends, if re-

quired.

2.

Position the center link to the

Pitman arm and idler arm and install

the attaching nuts loosely. On all ve-

hicles except Lincoln Continental

models, place the idler arm and the

front wheels in the straight ahead po-

sition to insure keeping the steering

wheel aligned and to prevent bushing

damage after the attaching nuts have

been torqued. On Lincoln Continental

models, insure that the seal is properly

installed on the center link. Torque

the nuts to the low end of the specifi-

cation. Continue to tighten each nut

until the slots in the nut align with the

hole in the stud. Then install a new

cotter pin.

3.

Position the spindle connecting

rod ends to the center link and install

the attaching nuts. Torque the nuts to

the low end of the specification. Con-

tinue to tighten each nut until the

slots in the nut align with the hole in

the stud. Then, install a new cotter

pin.

4.

Remove the safety stands, lower

the vehicle, check and adjust toe-in to

specification (Part 3-1).

STEERING IDLER ARM

AND BRACKET ASSEMBLY

REPLACEMENT

REMOVAL

If the idler arm bushings are worn

the complete idler arm assembly must

be replaced. In Lincoln Continental

models, if the socket at the idler

bracket is excessively loose, replace

the complet assembly.

1.

Remove the cotter pin and nut

attaching the steering center link at

the idler arm (Figs. 18 through 21).

2.

Disconnect the center link from

the idler arm (on Lincoln Continental

models, use Tool 3290-C).

3.

Remove the two bolts that attach

the idler arm and bracket assembly to

the frame.

INSTALLATION

1.

Secure the new idler arm and

bracket assembly to the frame with

the two attaching bolts (nuts and flat

washers as shown in Figs. 18, 19 and

21).

2.

On all vehicles except Lincoln

Continental models, place the idler

arm and the front wheels in the

straight ahead position to insure keep-

ing the steering wheel aligned and to

prevent bushing damage after the at-

taching nut has been torqued. Insert

the center link stud through the hole

in the end of the idler arm and install

the nut and washer.

On Lincoln Continental models, in-

sert the center link stud through the

hole in the end of the idler arm insur-

ing that the seal is properly installed

on the center link.

3.

Torque the idler arm rod nut to

specification and install a new cotter

pin.

PITMAN ARM

REPLACEMENT

REMOVAL

1.

Remove the cotter pin from the

castellated nut that attaches the steer-

ing center link to the Pitman arm.

Remove the castellated nut.

2.

Disconnect the steering center

link from the Pitman arm with tool

3290-C.

3.

Remove the Pitman arm attaching

nut and lock washer.

4.

Position the front wheels in the

straight ahead position. Remove the

Pitman arm with tool T64P-3590-F

(Fig. 23).

INSTALLATION

1.

With the front wheels in the

straight ahead position, place the Pit-

man arm on the sector shaft making

sure it is pointing forward.

2.

Install the nut and lock washer.

Torque the nut to specification.

G1663-A

FIG. 23— Removing Pitman

Arm—Typicalprocarmanuals.com

Page 141 of 413

03-07-03

Ford Design Non-Integral Power Steering System

03-07-03

5.

Lower the vehicle and disconnect

the fluid return hose from the reser-

voir.

6. Disconnect the fluid pressure

hose from the pump outlet fitting.

7.

Remove 1 bolt attaching the

hoses,

insulator, and the retainer to

the frame side rail and remove the

hoses,

and the insulator and retainer

as an assembly from the vehicle.

8. Remove the pressure and return

hoses from the retainer and insulator.

INSTALLATION

1.

Install the pressure and return

hoses in the insulator and retainer.

Paint stripe on pressure hose must be

aligned with slot in insulator. Paint or

tape band on return hose must be cen-

tered in insulator. Position the assem-

bly to the frame side rail and install

the attaching bolt.

2.

Place a hose clamp on the fluid

return hose and install the hose on the

power steering pump reservoir return

fitting.

3.

Torque the pump outlet fitting to

specification (Part 3-13). Then, con-

nect the pressure hose to the outlet fit-

ting and torque the fitting to specifica-

tion.

4.

Raise the vehicle and connect the

pressure and return lines to the con-

trol valve.

5.

Install the clamp to retain the

hose tubes to the control valve.

6. Lower the vehicle and fill the

power steering pump reservoir with

fluid, C1AZ-19582-A, to the proper

level (Part 3-1).

7.

Start the engine and turn the

steering wheel to each end of its travel

several times to cycle the system.

Then, check for fluid leaks.

8. Stop the engine and again check

the power steering fluid level (Part

3-1). Add fluid as required.

REMOVAL AND INSTALLATION

HOISTING INSTRUCTIONS

Damage to suspension and/or steer-

ing linkage components may occur if

care is not exercised when positioning

the hoist adapters of 2 post hoists

prior to lifting the vehicle.

If a 2 post hoist is used to lift the

vehicle, place the adapters under the

front suspension lower arms. Do not

allow the adapters to contact the

steering linkage.

STEERING GEAR

Refer to Group 3-6, Section 3 for

detailed instructions.

POWER STEERING PUMP

Refer to Group 3-10, Section 3 for

detailed instructions.

POWER STEERING CONTROL

VALVE

REMOVAL

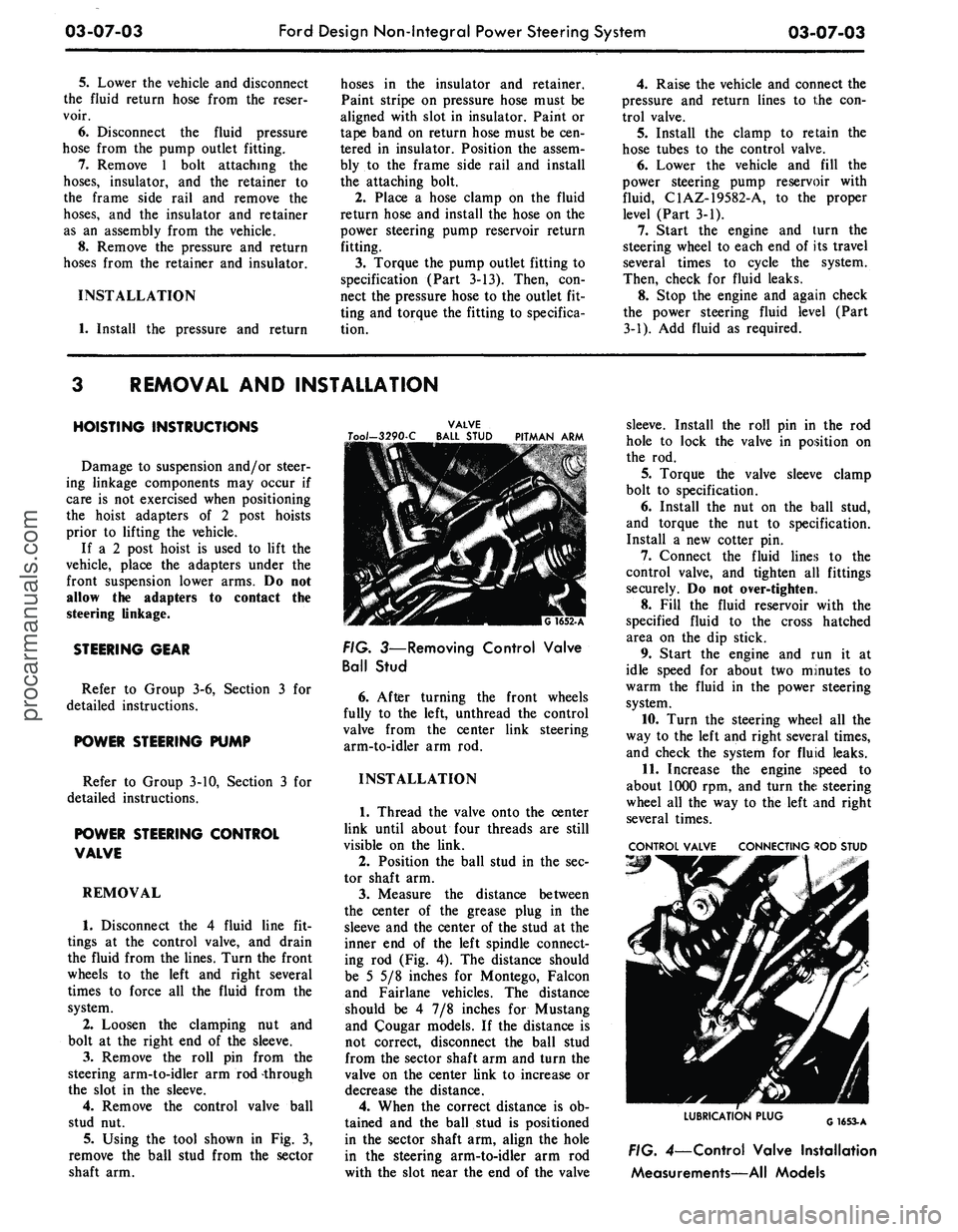

1.

Disconnect the 4 fluid line fit-

tings at the control valve, and drain

the fluid from the lines. Turn the front

wheels to the left and right several

times to force all the fluid from the

system.

2.

Loosen the clamping nut and

bolt at the right end of the sleeve.

3.

Remove the roll pin from the

steering arm-to-idler arm rod -through

the slot in the sleeve.

4.

Remove the control valve ball

stud nut.

5.

Using the tool shown in Fig. 3,

remove the ball stud from the sector

shaft arm.

VALVE

Too/-3290-C BALL STUD PITMAN ARM

FIG. 3—Removing Control Valve

Ball Stud

6. After turning the front wheels

fully to the left, unthread the control

valve from the center link steering

arm-to-idler arm rod.

INSTALLATION

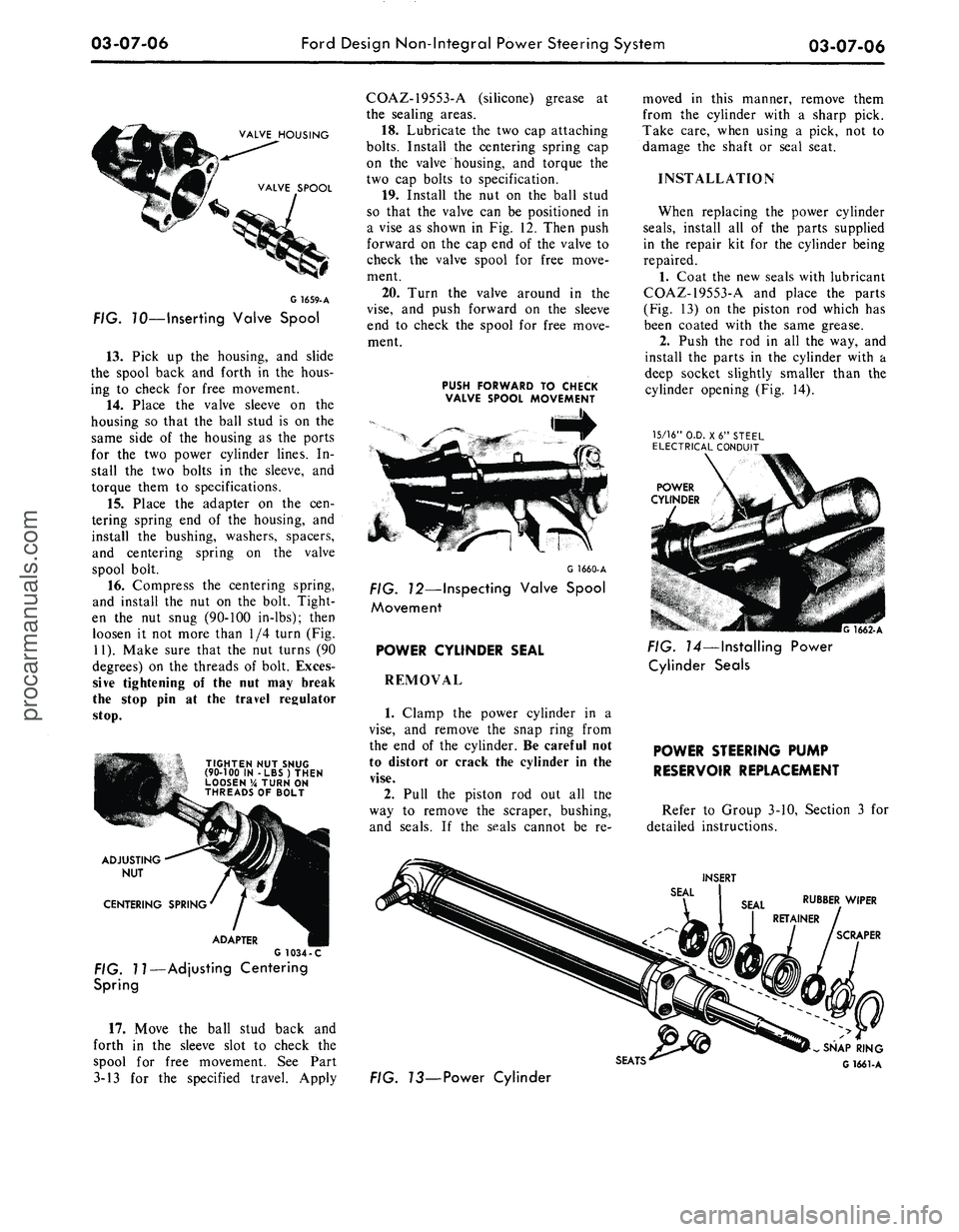

1.

Thread the valve onto the center

link until about four threads are still

visible on the link.

2.

Position the ball stud in the sec-

tor shaft arm.

3.

Measure the distance between

the center of the grease plug in the

sleeve and the center of the stud at the

inner end of the left spindle connect-

ing rod (Fig. 4). The distance should

be 5 5/8 inches for Montego, Falcon

and Fairlane vehicles. The distance

should be 4 7/8 inches for Mustang

and Cougar models. If the distance is

not correct, disconnect the ball stud

from the sector shaft arm and turn the

valve on the center link to increase or

decrease the distance.

4.

When the correct distance is ob-

tained and the ball stud is positioned

in the sector shaft arm, align the hole

in the steering arm-to-idler arm rod

with the slot near the end of the valve

sleeve. Install the roll pin in the rod

hole to lock the valve in position on

the rod.

5.

Torque the valve sleeve clamp

bolt to specification.

6. Install the nut on the ball stud,

and torque the nut to specification.

Install a new cotter pin.

7.

Connect the fluid lines to the

control valve, and tighten all fittings

securely. Do not over-tighten.

8. Fill the fluid reservoir with the

specified fluid to the cross hatched

area on the dip stick.

9. Start the engine and run it at

idle speed for about two minutes to

warm the fluid in the power steering

system.

10.

Turn the steering wheel all the

way to the left and right several times,

and check the system for fluid leaks.

11.

Increase the engine speed to

about 1000 rpm, and turn the steering

wheel all the way to the left and right

several times.

CONTROL VALVE CONNECTING ROD STUD

LUBRICATION PLUG

G1653-A

FIG. 4—Control Valve Installation

Measurements—All Modelsprocarmanuals.com

Page 144 of 413

03-07-06

Ford Design Non-Integral Power Steering System

03-07-06

VALVE HOUSING

VALVE SPOOL

G

1659-

A

FIG. 70—Inserting Valve Spool

13.

Pick up the housing, and slide

the spool back and forth in the hous-

ing to check for free movement.

14.

Place the valve sleeve on the

housing so that the ball stud is on the

same side of the housing as the ports

for the two power cylinder lines. In-

stall the two bolts in the sleeve, and

torque them to specifications.

15.

Place the adapter on the cen-

tering spring end of the housing, and

install the bushing, washers, spacers,

and centering spring on the valve

spool bolt.

16.

Compress the centering spring,

and install the nut on the bolt. Tight-

en the nut snug (90-100 in-lbs); then

loosen it not more than 1/4 turn (Fig.

11).

Make sure that the nut turns (90

degrees) on the threads of bolt. Exces-

sive tightening of the nut may break

the stop pin at the travel regulator

stop.

TIGHTEN NUT SNUG

(90-100 IN -LBS) THEN

LOOSEN % TURN ON

THREADS OF BOLT

ADJUSTING

NUT

CENTERING SPRING

ADAPTER

G 1034 -C

FIG. 11—Adjusting Centering

Spring

17.

Move the ball stud back and

forth in the sleeve slot to check the

spool for free movement. See Part

3-13 for the specified travel. Apply

COAZ-19553-A (silicone) grease at

the sealing areas.

18.

Lubricate the two cap attaching

bolts.

Install the centering spring cap

on the valve housing, and torque the

two cap bolts to specification.

19.

Install the nut on the ball stud

so that the valve can be positioned in

a vise as shown in Fig. 12. Then push

forward on the cap end of the valve to

check the valve spool for free move-

ment.

20.

Turn the valve around in the

vise,

and push forward on the sleeve

end to check the spool for free move-

ment.

PUSH FORWARD TO CHECK

VALVE SPOOL MOVEMENT

G 1660-A

FIG. 12—Inspecting Valve Spool

Movement

POWER CYLINDER SEAL

REMOVAL

1.

Clamp the power cylinder in a

vise,

and remove the snap ring from

the end of the cylinder. Be careful not

to distort or crack the cylinder in the

vise.

2.

Pull the piston rod out all the

way to remove the scraper, bushing,

and seals. If the seals cannot be re-

moved in this manner, remove them

from the cylinder with a sharp pick.

Take care, when using a pick, not to

damage the shaft or seal seat.

INSTALLATION

When replacing the power cylinder

seals,

install all of the parts supplied

in the repair kit for the cylinder being

repaired.

1.

Coat the new seals with lubricant

COAZ-19553-A and place the parts

(Fig. 13) on the piston rod which has

been coated with the same grease.

2.

Push the rod in all the way, and

install the parts in the cylinder with a

deep socket slightly smaller than the

cylinder opening (Fig. 14).

15/16"

O.D. X6" STEEL

ELECTRICAL CONDUIT

POWER

CYLINDER

G 1662-A

FIG. 14—Installing Power

Cylinder Seals

POWER STEERING PUMP

RESERVOIR REPLACEMENT

Refer to Group 3-10, Section 3 for

detailed instructions.

INSERT

RUBBER WIPER

SCRAPER

SEATS'

FIG. 73—Power Cylinder

SNAP RING

G 1661-Aprocarmanuals.com

Page 154 of 413

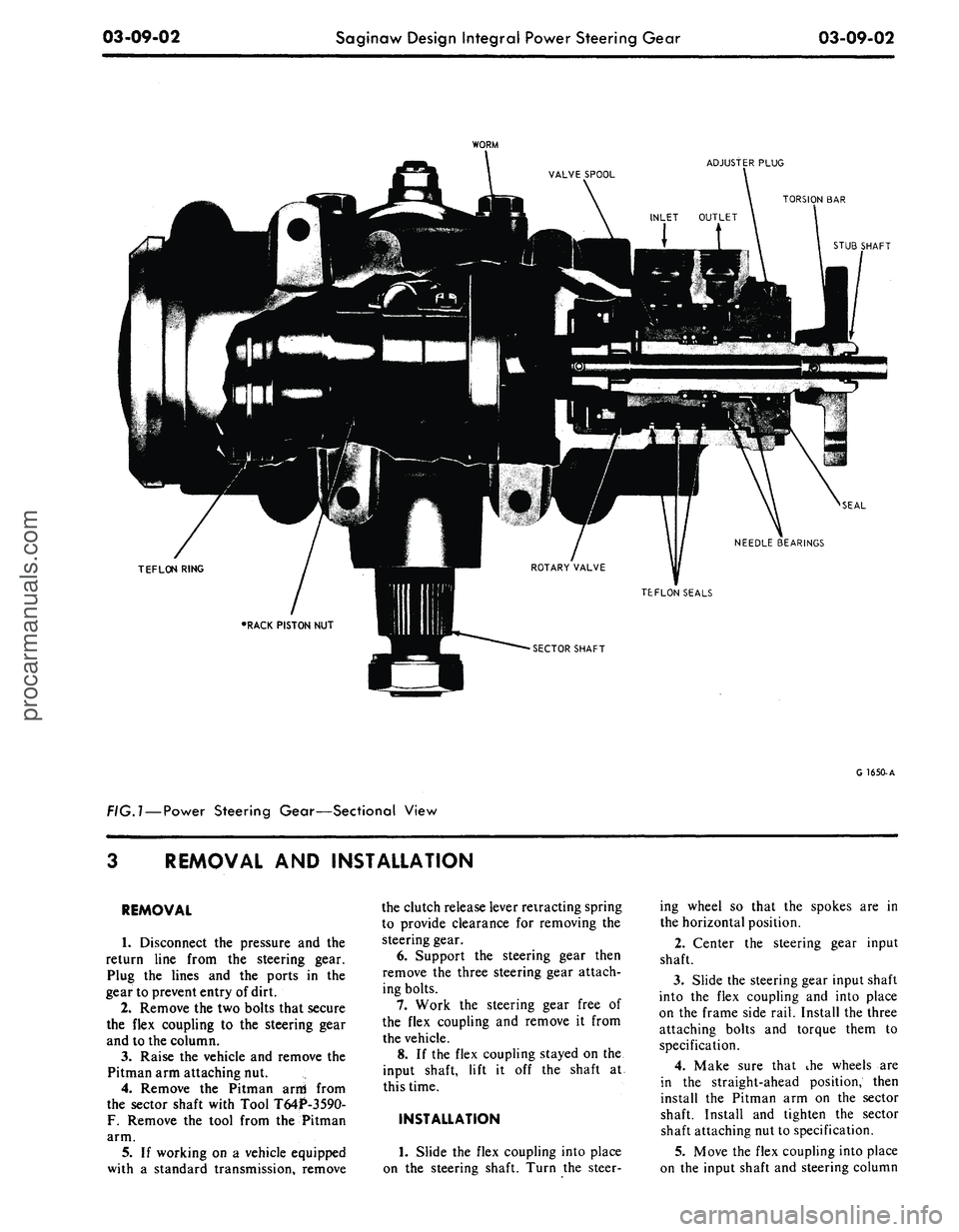

03-09-02

Saginaw Design Integral Power Steering Gear

03-09-02

WORM

ADJUSTER PLUG

TORSION BAR

STUB SHAFT

SEAL

NEEDLE BEARINGS

TEFLON RING

TEFLON SEALS

SECTOR SHAFT

FIG.l —

Power

Steering Gear—Sectional View

G 1650-A

REMOVAL

AND

INSTALLATION

REMOVAL

1.

Disconnect

the

pressure

and the

return line from

the

steering gear.

Plug

the

lines

and the

ports

in the

gear to prevent entry of dirt.

2.

Remove the two bolts that secure

the flex coupling

to the

steering gear

and

to

the column.

3.

Raise

the

vehicle

and

remove

the

Pitman arm attaching nut.

4.

Remove

the

Pitman arni from

the sector shaft with Tool T64P-3590-

F.

Remove

the

tool from

the

Pitman

arm.

5.

If

working

on a

vehicle equipped

with

a

standard transmission, remove

the clutch release lever retracting spring

to provide clearance

for

removing

the

steering gear.

6. Support

the

steering gear then

remove

the

three steering gear attach-

ing bolts.

7.

Work

the

steering gear free

of

the flex coupling

and

remove

it

from

the vehicle.

8.

If

the flex coupling stayed

on the

input shaft, lift

it off the

shaft

at

this time.

INSTALLATION

1.

Slide

the

flex coupling into place

on

the

steering shaft. Turn

the

steer-

ing wheel

so

that

the

spokes

are in

the horizontal position.

2.

Center

the

steering gear input

shaft.

3.

Slide the steering gear input shaft

into

the

flex coupling

and

into place

on

the

frame side rail. Install the three

attaching bolts

and

torque them

to

specification.

4.

Make sure that

ihe

wheels

are

in

the

straight-ahead position, then

install

the

Pitman

arm on the

sector

shaft. Install

and

tighten

the

sector

shaft attaching nut to specification.

5.

Move the flex coupling into place

on

the

input shaft

and

steering columnprocarmanuals.com

Page 162 of 413

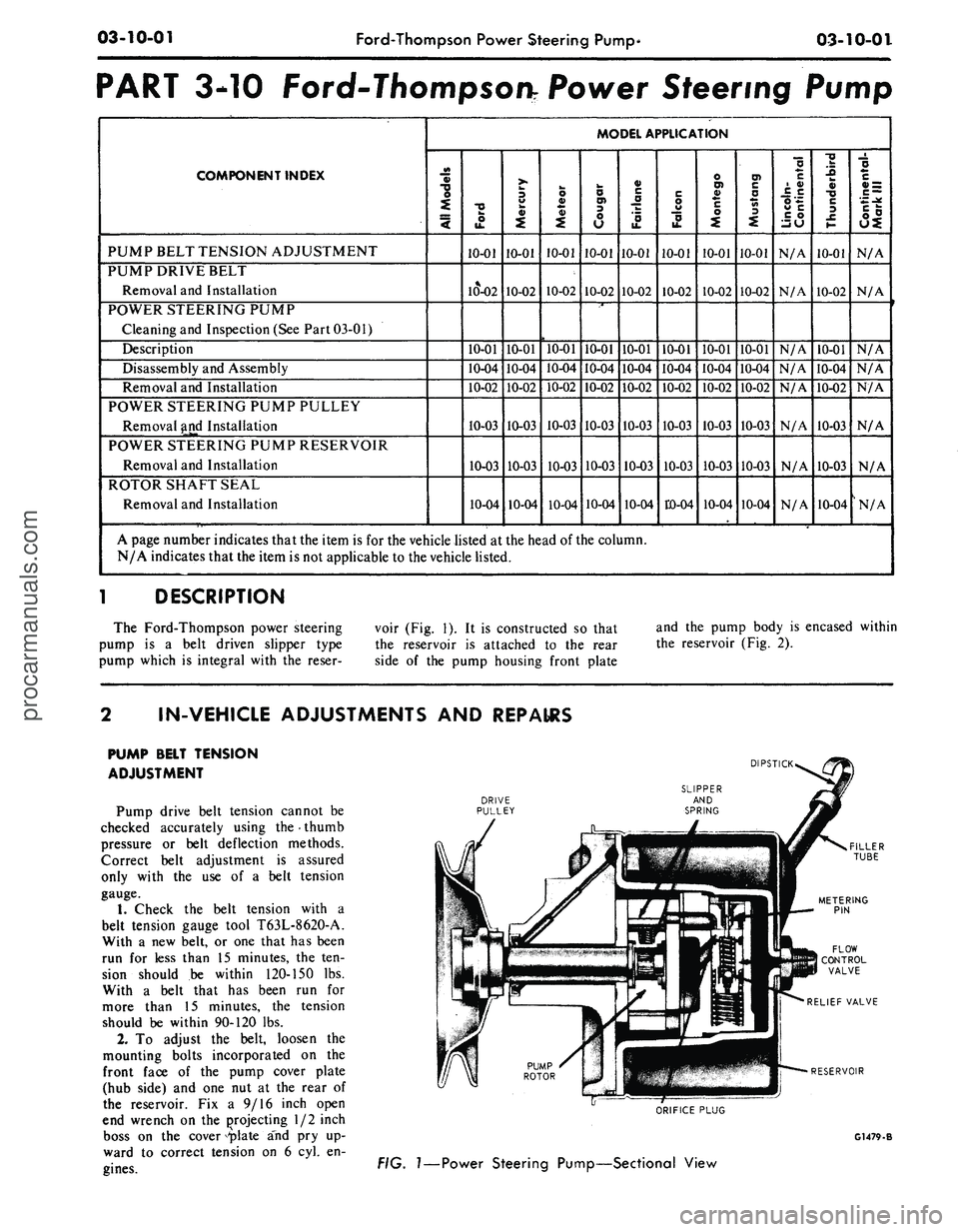

03-10-01

Ford-Thompson Power Steering Pump*

03-10-01

PART 3-10 Ford-Thompsonr Power Steering Pump

COMPONENT INDEX

PUMP BELT TENSION ADJUSTMENT

PUMP DRIVE BELT

Removal and Installation

POWER STEERING PUMP

Cleaning and Inspection (See Part 03-01)

Description

Disassembly and Assembly

Removal and Installation

POWER STEERING PUMP PULLEY

Removal and Installation

POWER STEERING PUMP RESERVOIR

Removal and Installation

ROTOR SHAFT SEAL

Removal and Installation

MODEL APPLICATION

All

Models

Ford

10-01

l5-O2

10-01

10-04

10-02

10-03

10-03

10-04

Mercury

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Meteor

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Cougar

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Fairlane

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Falcon

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Montego

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Mustang

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Lincoln-

Continental

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Thunderbird

10-01

10-02

10-01

10-04

10-02

10-03

10-03

10-04

Continental-

Mark

III

N/A

N/A

N/A

N/A

N/A

N/A

N/A

'N/A

A page number indicates that the item is for the vehicle listed at the head of the column.

N/A indicates that the item is not applicable to the vehicle listed.

1

DESCRIPTION

The Ford-Thompson power steering

pump is a belt driven slipper type

pump which is integral with the reser-

voir (Fig. 1). It is constructed so that

the reservoir is attached to the rear

side of the pump housing front plate

and the pump body is encased within

the reservoir (Fig. 2).

IN-VEHICLE ADJUSTMENTS AND REPAIRS

PUMP BELT TENSION

ADJUSTMENT

Pump drive belt tension cannot be

checked accurately using the

•

thumb

pressure or belt deflection methods.

Correct belt adjustment is assured

only with the use of a belt tension

gauge.

1.

Check the belt tension with a

belt tension gauge tool T63L-8620-A.

With a new belt, or one that has been

run for less than 15 minutes, the ten-

sion should be within 120-150 lbs.

With a belt that has been run for

more than 15 minutes, the tension

should be within 90-120 lbs.

2.

To adjust the belt, loosen the

mounting bolts incorporated on the

front face of the pump cover plate

(hub side) and one nut at the rear of

the reservoir. Fix a 9/16 inch open

end wrench on the nrojecting 1/2 inch

boss on the cover -'plate a"hd pry up-

ward to correct tension on 6 cyl. en-

gines.

DIPSTICK.

DRIVE

PULLEY

RELIEF VALVE

RESERVOIR

ORIFICE PLUG

G1479-B

FIG.

1—Power

Steering Pump—Sectional View

procarmanuals.com