section 18 FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 238 of 413

04-04-07

Rear Axle — Ford Light-Duty (WER)

04-04-07

RUNOUT CHECK

E 1573-A

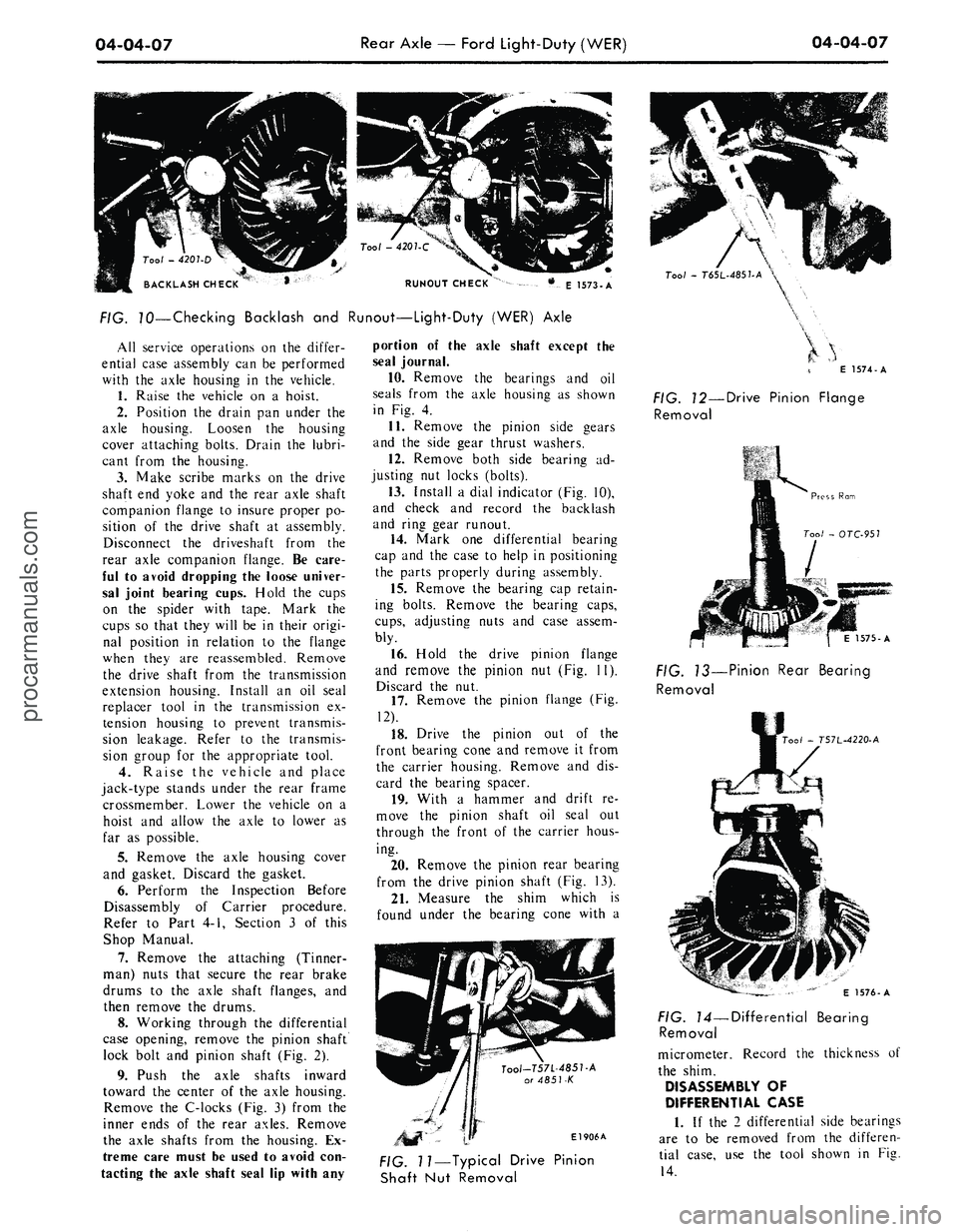

FIG. 70—Checking Backlash and Runout—Light-Duty (WER) Axle

All service operations on the differ-

ential case assembly can be performed

with the axle housing in the vehicle.

1.

Raise the vehicle on a hoist.

2.

Position the drain pan under the

axle housing. Loosen the housing

cover attaching bolts. Drain the lubri-

cant from the housing.

3.

Make scribe marks on the drive

shaft end yoke and the rear axle shaft

companion flange to insure proper po-

sition of the drive shaft at assembly.

Disconnect the driveshaft from the

rear axle companion flange. Be care-

ful to avoid dropping the loose univer-

sal joint bearing cups. Hold the cups

on the spider with tape. Mark the

cups so that they will be in their origi-

nal position in relation to the flange

when they are reassembled. Remove

the drive shaft from the transmission

extension housing. Install an oil seal

replacer tool in the transmission ex-

tension housing to prevent transmis-

sion leakage. Refer to the transmis-

sion group for the appropriate tool.

4.

Raise the vehicle and place

jack-type stands under the rear frame

crossmember. Lower the vehicle on a

hoist and allow the axle to lower as

far as possible.

5.

Remove the axle housing cover

and gasket. Discard the gasket.

6. Perform the Inspection Before

Disassembly of Carrier procedure.

Refer to Part 4-1, Section 3 of this

Shop Manual.

7.

Remove the attaching (Tinner-

man) nuts that secure the rear brake

drums to the axle shaft flanges, and

then remove the drums.

8. Working through the differential

case opening, remove the pinion shaft

lock bolt and pinion shaft (Fig. 2).

9. Push the axle shafts inward

toward the center of the axle housing.

Remove the C-locks (Fig. 3) from the

inner ends of the rear axles. Remove

the axle shafts from the housing. Ex-

treme care must be used to avoid con-

tacting the axle shaft seal lip with any

portion of the axle shaft except the

seal journal.

10.

Remove the bearings and oil

seals from the axle housing as shown

in Fig. 4.

11.

Remove the pinion side gears

and the side gear thrust washers.

12.

Remove both side bearing ad-

justing nut locks (bolts).

13.

Install a dial indicator (Fig. 10),

and check and record the backlash

and ring gear runout.

14.

Mark one differential bearing

cap and the case to help in positioning

the parts properly during assembly.

15.

Remove the bearing cap retain-

ing bolts. Remove the bearing caps,

cups,

adjusting nuts and case assem-

bly.

16.

Hold the drive pinion flange

and remove the pinion nut (Fig. 11).

Discard the nut.

17.

Remove the pinion flange (Fig.

12).

18.

Drive the pinion out of the

front bearing cone and remove it from

the carrier housing. Remove and dis-

card the bearing spacer.

19.

With a hammer and drift re-

move the pinion shaft oil seal out

through the front of the carrier hous-

ing.

20.

Remove the pinion rear bearing

from the drive pinion shaft (Fig. 13).

21.

Measure the shim which is

found under the bearing cone with a

Tool-T57L-485T-A

or 4851-K

El 906A

Tool

-

T6SL-485UA

\

E 1574-A

FIG. 12—Drive Pinion Flange

Removal

1575-A

FIG. 13—Pinion Rear Bearing

Removal

00/

- T57L-4220-A

FIG. 11—Typical Drive Pinion

Shaft Nut Removal

E 1576-A

FIG. 14—Differential Bearing

Removal

micrometer. Record the thickness of

the shim.

DISASSEMBLY OF

DIFFERENTIAL CASE

1.

If the 2 differential side bearings

are to be removed from the differen-

tial case, use the tool shown in Fig.

14.procarmanuals.com

Page 239 of 413

04-04-08

Rear Axle — Ford Light-Duty (WER)

04-04-08

E 1577-A

75—Pinion Bearing

Cup

Installation—Typical

2.

Remove

the

bolts that attach

the

ring gear

to the

differential case. Press

the ring gear from

the

case

or tap it

off with

a

soft-faced hammer.

PARTS REPAIR

OR

REPLACEMENT

Clean

and

inspect

all the

parts

as

outlined

in

Cleaning

and

Inspection,

Part 4-1, Section

3 of

this Shop

Man-

ual.

Before assembling

the

carrier,

re-

pair

or

replace

all

parts

as

indicated

by

the

inspection.

The

principle

re-

placement operations

are

covered

in

the following procedures.

All

other

re-

pair

or

replacement operations

are

performed during

the

Cleaning

and

Inspection, Part 4-1, Section

3

opera-

tions noted above,

or

during

the as-

sembly

in

this section.

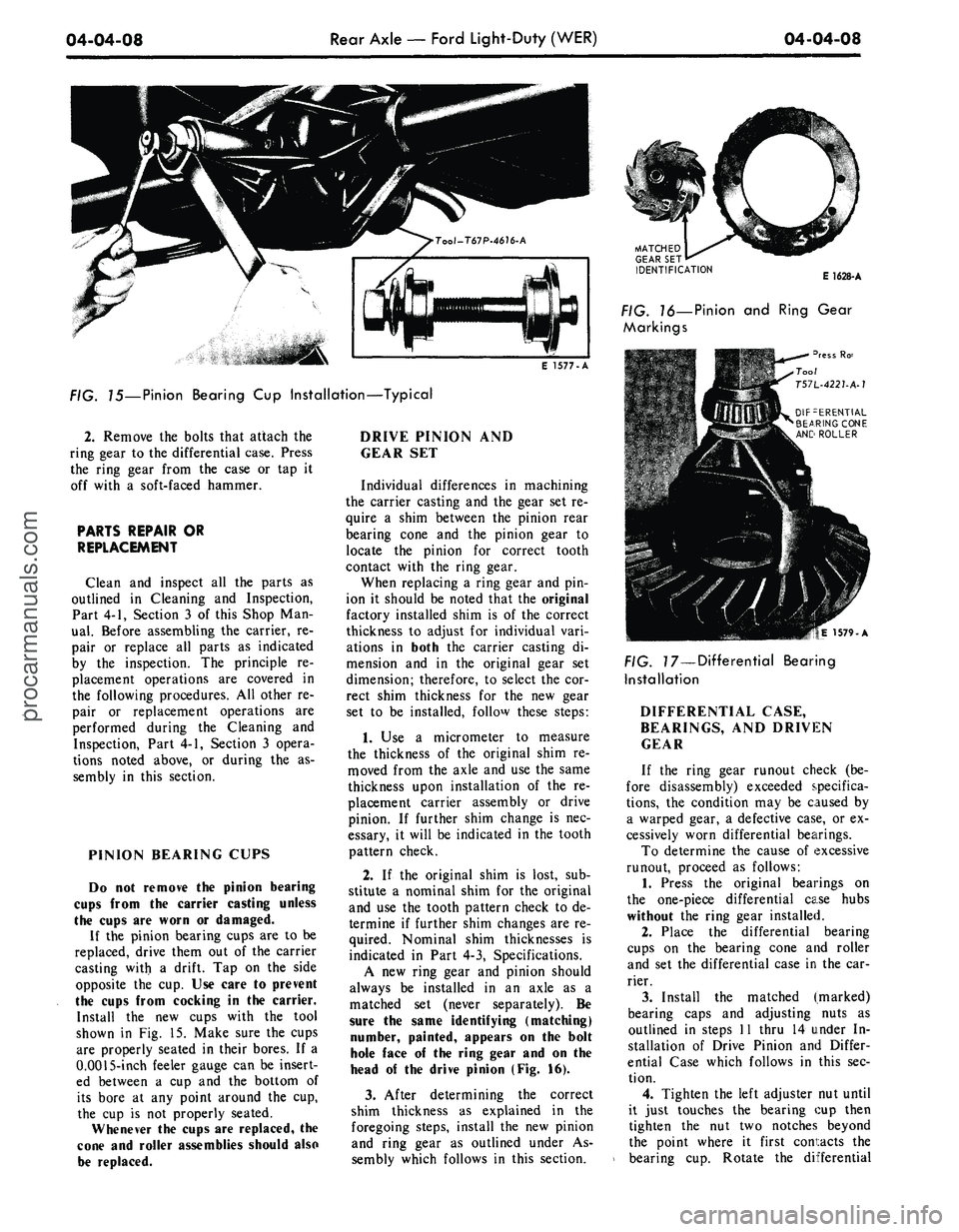

PINION BEARING CUPS

Do

not

remove

the

pinion bearing

cups from

the

carrier casting unless

the cups

are

worn

or

damaged.

If

the

pinion bearing cups

are to be

replaced, drive them

out of the

carrier

casting with

a

drift.

Tap on the

side

opposite

the cup. Use

care

to

prevent

the cups from cocking

in the

carrier.

Install

the new

cups with

the

tool

shown

in Fig. 15.

Make sure

the

cups

are properly seated

in

their bores.

If a

0.0015-inch feeler gauge

can be

insert-

ed between

a cup and the

bottom

of

its bore

at any

point around

the cup,

the

cup is not

properly seated.

Whenever

the

cups

are

replaced,

the

cone

and

roller assemblies should also

be replaced.

DRIVE PINION

AND

GEAR

SET

Individual differences

in

machining

the carrier casting

and the

gear

set re-

quire

a

shim between

the

pinion rear

bearing cone

and the

pinion gear

to

locate

the

pinion

for

correct tooth

contact with

the

ring gear.

When replacing

a

ring gear

and pin-

ion

it

should

be

noted that

the

original

factory installed shim

is of the

correct

thickness

to

adjust

for

individual vari-

ations

in

both

the

carrier casting

di-

mension

and in the

original gear

set

dimension; therefore,

to

select

the cor-

rect shim thickness

for the new

gear

set

to be

installed, follow these steps:

1.

Use a

micrometer

to

measure

the thickness

of the

original shim

re-

moved from

the

axle

and use the

same

thickness upon installation

of the re-

placement carrier assembly

or

drive

pinion.

If

further shim change

is nec-

essary,

it

will

be

indicated

in the

tooth

pattern check.

2.

If the

original shim

is

lost,

sub-

stitute

a

nominal shim

for the

original

and

use the

tooth pattern check

to de-

termine

if

further shim changes

are re-

quired. Nominal shim thicknesses

is

indicated

in

Part

4-3,

Specifications.

A

new

ring gear

and

pinion should

always

be

installed

in an

axle

as a

matched

set

(never separately).

Be

sure

the

same identifying (matching)

number, painted, appears

on the

bolt

hole face

of the

ring gear

and on the

head

of the

drive pinion

(Fig. 16).

3.

After determining

the

correct

shim thickness

as

explained

in the

foregoing steps, install

the new

pinion

and ring gear

as

outlined under

As-

sembly which follows

in

this section.

MATCHED

GEAR

SET

IDENTIFICATION

E 1628-A

. ?6—Pinion

and

Ring Gear

Markings

3ress

Ro-

Tool

T57L-4221-A-1

DIFFERENTIAL

BEARING CONE

ANC ROLLER

|E 1579-A

PIG. 77—Differential Bearing

Installation

DIFFERENTIAL CASE,

BEARINGS,

AND

DRIVEN

GEAR

If

the

ring gear runout check

(be-

fore disassembly) exceeded specifica-

tions,

the

condition

may be

caused

by

a warped gear,

a

defective case,

or ex-

cessively worn differential bearings.

To determine

the

cause

of

excessive

runout, proceed

as

follows:

1.

Press

the

original bearings

on

the one-piece differential case hubs

without

the

ring gear installed.

2.

Place

the

differential bearing

cups

on the

bearing cone

and

roller

and

set the

differential case

in the car-

rier.

3.

Install

the

matched (marked)

bearing caps

and

adjusting nuts

as

outlined

in

steps

11

thru

14

under

In-

stallation

of

Drive Pinion

and

Differ-

ential Case which follows

in

this

sec-

tion.

4.

Tighten

the

left adjuster

nut

until

it just touches

the

bearing

cup

then

tighten

the nut two

notches beyond

the point where

it

first contacts

the

bearing

cup.

Rotate

the

differentialprocarmanuals.com

Page 241 of 413

04-04-10

Rear Axle — Ford Light-Duty (WER)

04-04-10

the differential case and ring gear as-

sembly in the carrier without regard

to the matching of any particular gear

teeth.

12.

Slide the case assembly along

the bores until a slight amount of

backlash is felt between the gear teeth.

Hold the differential case in place.

13.

Set the adjusting nuts in the

bores so that they just contact the

bearing cups.

14.

Carefully position the bearing

caps on the carrier casting. Match the

marks made when the caps were re-

moved (Fig. 21).

15.

Install the bearing cap bolts

and lockwashers. As the bolts are

tightened, turn the adjusting nut with

the tool shown in Fig. 21.

16.

If the adjusting nuts do not turn

freely as the cap bolts are tightened,

remove the bearing caps and again in-

spect for damaged threads or incor-

rectly positioned caps. Tightening the

bolts to the specified torque is done to

be sure that the cups and adjusting

.BEARING CAP IDENTIFICATION-j

MARKS

A

T57L-4067-A

E 1583-A

27—Bearing Cap Installation

nuts are seated. Loosen the cap bolts,

and torque them to only 5 ft-)bs be-

fore making adjustments. Refer to

part 4-1, Section 2 of this shop manu-

al for backlash and bearing preload

adjustment procedures.

17.

Clean the marking compound

from the gear teeth.

18.

Install both side bearing adjust-

ing nut locks (bolts) and torque them

to specification.

19.

Install the differential pinion

side gears and thrust washers.

20.

Install the rear wheel bearings

seals,

rear axle shafts, wheels and tires

and the axle carrier cover as outlined

under Part 4-3, Section 2, Rear Axle

Shaft, Wheel Bearing and Oil Seal

Replacement, Steps 10 through 19.

21.

Raise the axle all the way up.

Rdnove the safety support stands.

22.

Connect the track bar to the

mounting stud. Install the washer and

retaining nut, and torque the nut to

specification.

23.

Remove the oil seal replacer

tool from the transmission extension

housing. Install the front end of the

drive shaft on the transmission.output

shaft. Align the scribe marks on the

cups,

flange and drive shaft and con-

nect the rear end of the drive shaft to

the axle U-joint flange. Torque the re-

taining bolts to specification.

24.

Lower the vehicle.procarmanuals.com

Page 263 of 413

05-03-05

Clutch

05-03-05

4.

Remove the bolt that secures the

left air vent control cable bracket to

the instrument panel. Position the

control cable to one side.

5.

Remove the retaining clip and

flat washer from the clutch pedal

shaft. Then, remove the shaft, bush-

ing, clutch pedal and brake pedal

from the support.

6. Remove the bushings from the

pedal shaft, and transfer the pedal

pad.

7.

Lubricate the clutch pedal shaft

bushings and position them on the

shaft. Then, position the brake pedal

and clutch pedal in the pedal support.

8. Install the flat washer and re-

taining clip on the pedal shaft.

9. Position the assist spring to the

pedal and bracket. Pry the bracket

forward and install the lower bolt.

Torque the bolts to specifications.

10.

Position the master cylinder

push rod, bushing, and washers on the

brake pedal and secure with a retain-

ing clip.

11.

Connect the equalizer rod to

the clutch pedal and secure it in place

with a retaining clip.

12.

Position the air vent control

cable bracket to the instrument panel

and secure with the attaching bolt.

13.

Adjust the clutch pedal free

travel.

EQUALIZER BAR AND/OR

BUSHING REMOVAL AND

INSTALLATION

FORD, MERCURY

AND METEOR

1.

Raise the vehicle and disconnect

the clutch pedal-to-equalizer rod at

the equalizer bar (Fig. 1).

2.

Disconnect the return spring and

retaining spring at the release lever.

Separate the release lever rod from

the release lever.

3.

Remove the equalizer bar frame

bracket from the frame.

4.

Remove the equalizer bar from

the pivot on the flywheel housing.

5.

Remove the wire clip to replace

the outer bushing and the snap ring

from the inner pivot stud to replace

the inner bushing.

6. Position the flat washer, felt

washer and bushing on the inner and

outer pivots. Secure these parts with

the snap ring.

7.

Position the equalizer bar on the

inner pivot and bolt the equalizer bar

frame bracket to the frame. Torque

the attaching bolts to specification.

8. Install the clutch release rod, re-

turn spring and retaining spring.

9. Connect the clutch pedal rod to

the equalizer bar.

10.

Adjust the clutch pedal free

travel.

MUSTANG, COUGAR,

MONTEGO, FALCON,

FAIRLANE (EXCEPT

MONTEGO AND FAIRLANE

WITH 390 V-8)

1.

Disconnect the clutch pedal

equalizer rod at the equalizer bar

(Figs.

2 and 3).

2.

Raise the vehicle and disconnect

the release lever, return spring at the

lever.

3.

Remove the equalizer bar outer

bracket and bushing assembly.

4.

Remove the release rod from the

equalizer bar, and then remove the

equalizer bar. Remove the bushing

and washers from the inner mounting

stud.

5.

Position the equalizer bar, wash-

ers,

inner bushing, and retainer on the

inner stud.

6. After positioning the outer bush-

ing, install the outer bracket (with the

equalizer bar in place).

7.

Connect the release rod and the

release lever return spring.

8. Lower the vehicle. Connect the

clutch pedal equalizer rod to the

equalizer baY and secure with the re-

taining pin.

9. Adjust the clutch pedal free trav-

el as required.

MONTEGO AND

FAIRLANE—390 V-8

1.

Disconnect the clutch pedal

equalizer rod at the equalizer bar (Fig.

2).

2.

Raise the vehicle and disconnect

the return spring at the release lever.

Disconnect the release lever rod from

the equalizer lever.

3.

Remove the equalizer bar center

bolt.

4.

Separate the equalizer bar and

remove both sections from the vehicle.

5.

Remove the bolts retaining the

equalizer bar inner bracket to the fly-

wheel housing and remove the bracket

and bushing assembly.

6. Remove the equalizer bar outer

bracket and bushing assembly.

7.

Remove the snap ring, bushing,

and felt washer from each bracket as-

sembly.

8. Position a felt washer, and bush-

ing on each bracket assembly and se-

cure with the snap ring.

9. Install the outer bracket and

bushing assembly to the frame (Fig.

2).

Torque the bracket attaching bolts

to specifications.

10.

Position the outer section of the

equalizer bar on the outer bracket

pivot.

11.

Connect the two sections of the

equalizer bar. Insert the inner bracket

pivot into the equalizer bar and install

the assembly to the flywheel housing.

Torque the attaching bolts to specifi-

cations.

12.

Install the equalizer bar center

bolt and torque to specifications.

Make sure that both ends of the

equalizer bar are against the felt

washers.

13.

Connect the release rod and the

release lever return spring.

14.

Adjust the clutch pedal free

travel.

15.

Lower the vehicle. Connect the

clutch pedal equalizer rod to the

equalizer bar and secure with the re-

taining clip.

16.

Check the free travel at the

pedal for conformance to specifica-

tions.

Readjust if necessary.

REMOVAL AND INSTALLATION

CLUTCH REMOVAL

1.

Raise the vehicle on a hoist.

2.

Disconnect the drive shaft from

the rear U-joint flange. Then, slide the

drive shaft off the transmission output

shaft. Insert the appropriate tool over

the output shaft and into the extension

housing oil seal.

3.

Disconnect the speedometer

cable from the extension housing.

4.

Disconnect the gear shift rods

from the transmission. If the vehicle is

equipped with a four-speed transmis-

sion, remove the bolts that secure the

four-speed transmission, disconnect

the front brake cable from the cross-

member and remove the crossmem-

member from the vehicle.

5.

Remove the bolts that attach the

transmission to the flywheel housing.

6. Move the transmission rearward

until the input shaft clears the fly-

wheel housing, then remove it from

the vehicle.

7.

Disconnect the clutch release

lever retaining spring from the release

lever.procarmanuals.com

Page 271 of 413

06-02-02

Ford Design Three Speed Transmission

06-02-02

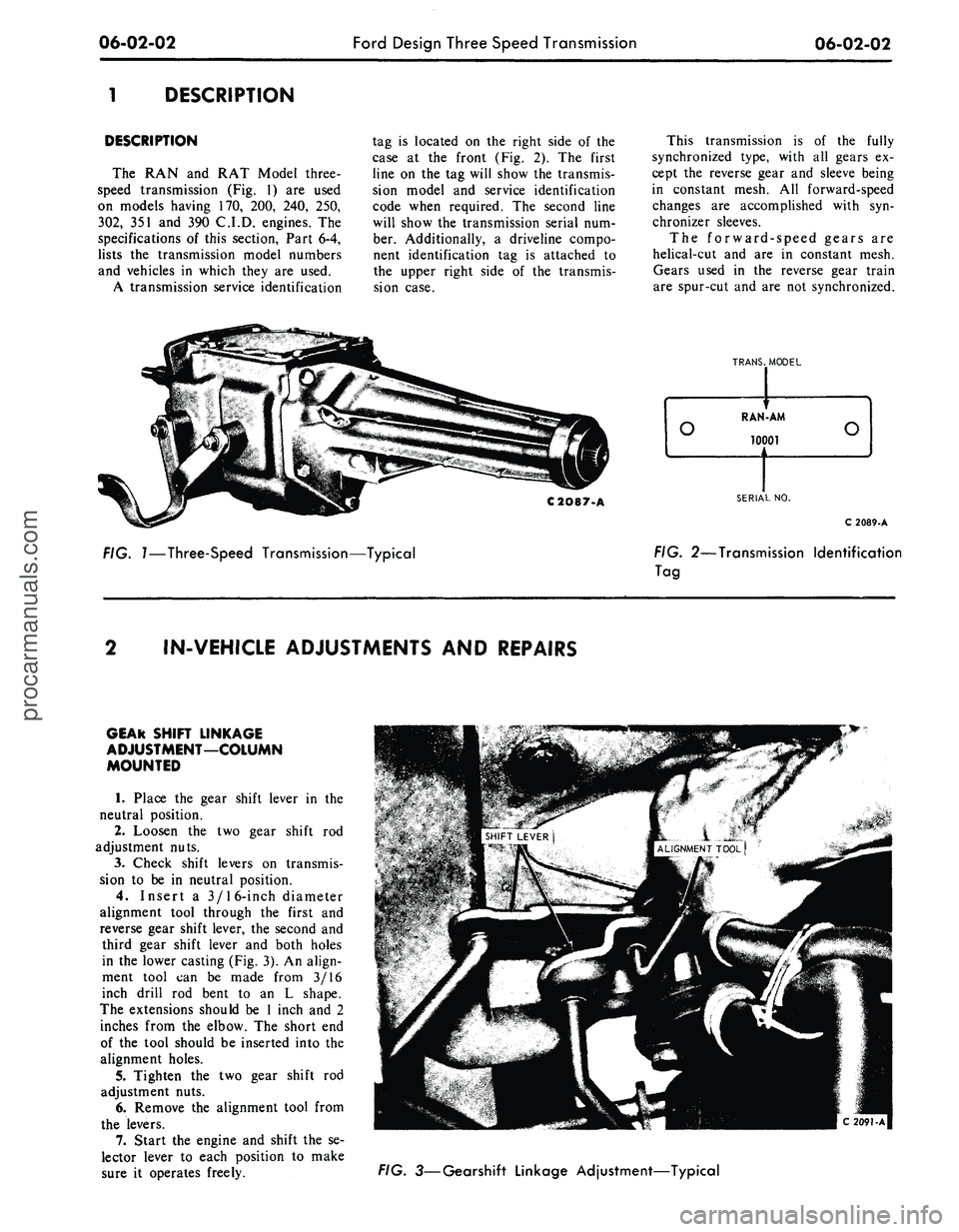

DESCRIPTION

DESCRIPTION

The RAN and RAT Model three-

speed transmission (Fig. 1) are used

on models having 170, 200, 240, 250,

302,

351 and 390 C.I.D. engines. The

specifications of this section, Part 6-4,

lists the transmission model numbers

and vehicles in which they are used.

A transmission service identification

tag is located on the right side of the

case at the front (Fig. 2). The first

line on the tag will show the transmis-

sion model and service identification

code when required. The second line

will show the transmission serial num-

ber. Additionally, a driveline compo-

nent identification tag is attached to

the upper right side of the transmis-

sion case.

This transmission is of the fully

synchronized type, with all gears ex-

cept the reverse gear and sleeve being

in constant mesh. All forward-speed

changes are accomplished with syn-

chronizer sleeves.

The forward-speed gears are

helical-cut and are in constant mesh.

Gears used in the reverse gear train

are spur-cut and are not synchronized.

C2O87-A

FIG.

1—Three-Speed

Transmission—Typical

TRANS.

MODEL

SERIAL

NO.

C 2089-A

FIG.

2—Transmission

Identification

Tag

IN-VEHICLE ADJUSTMENTS

AND

REPAIRS

GEAR SHIFT LINKAGE

ADJUSTMENT—COLUMN

MOUNTED

1. Place the gear shift lever in the

neutral position.

2.

Loosen the two gear shift rod

adjustment nuts.

3.

Check shift levers on transmis-

sion to be in neutral position.

4.

Insert a 3/16-inch diameter

alignment tool through the first and

reverse gear shift lever, the second and

third gear shift lever and both holes

in the lower casting (Fig. 3). An align-

ment tool can be made from 3/16

inch drill rod bent to an L shape.

The extensions should be 1 inch and 2

inches from the elbow. The short end

of the tool should be inserted into the

alignment holes.

5.

Tighten the two gear shift rod

adjustment nuts.

6. Remove the alignment tool from

the levers.

7.

Start the engine and shift the se-

lector lever to each position to make

sure it operates freely.

FIG.

3—Gearshift

Linkage Adjustment—Typicalprocarmanuals.com

Page 281 of 413

06-03-02

Ford Design Four-Speed Transmission

06-03-02

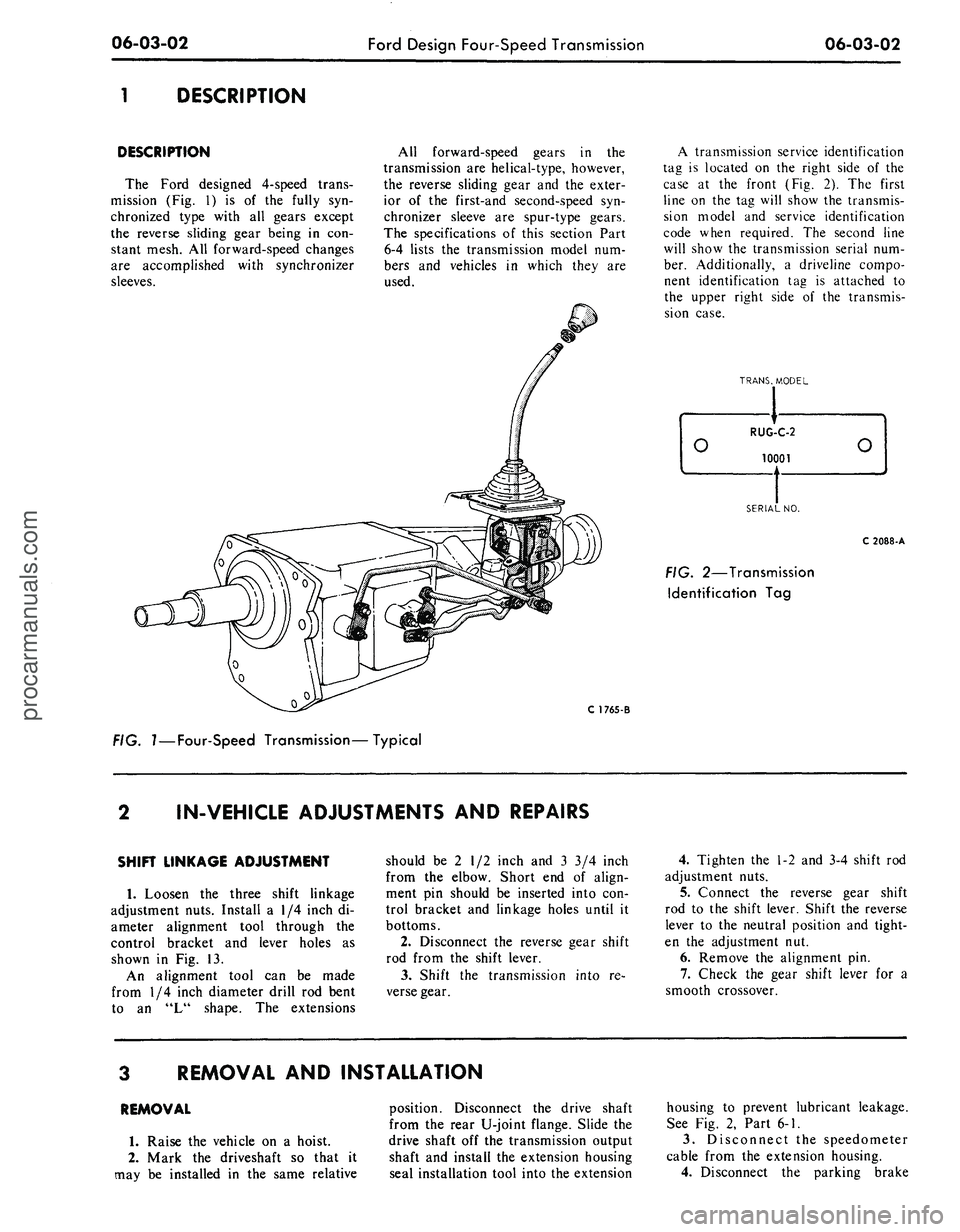

1 DESCRIPTION

DESCRIPTION

The Ford designed 4-speed trans-

mission

(Fig. 1) is of the

fully

syn-

chronized type with

all

gears except

the reverse sliding gear being

in con-

stant mesh.

All

forward-speed changes

are accomplished with synchronizer

sleeves.

All forward-speed gears

in the

transmission

are

helical-type, however,

the reverse sliding gear

and the

exter-

ior

of the

first-and second-speed

syn-

chronizer sleeve

are

spur-type gears.

The specifications

of

this section Part

6-4 lists

the

transmission model

num-

bers

and

vehicles

in

which they

are

used.

C 1765-B

FIG. 7—Four-Speed Transmission—Typical

A transmission service identification

tag

is

located

on the

right side

of the

case

at the

front

(Fig. 2). The

first

line

on the tag

will show

the

transmis-

sion model

and

service identification

code when required.

The

second line

will show

the

transmission serial

num-

ber. Additionally,

a

driveline compo-

nent identification

tag is

attached

to

the upper right side

of the

transmis-

sion case.

TRANS.

MODEL

O

RUG-C-2

10001

O

SERIAL NO.

C 2088-A

FIG. 2—Transmission

Identification

Tag

IN-VEHICLE ADJUSTMENTS

AND

REPAIRS

SHIFT LINKAGE ADJUSTMENT

1.

Loosen

the

three shift linkage

adjustment nuts. Install

a 1/4

inch

di-

ameter alignment tool through

the

control bracket

and

lever holes

as

shown

in Fig. 13.

An alignment tool

can be

made

from

1/4

inch diameter drill

rod

bent

to

an "L"

shape.

The

extensions

should

be 2 1/2

inch

and 3 3/4

inch

from

the

elbow. Short

end of

align-

ment

pin

should

be

inserted into

con-

trol bracket

and

linkage holes until

it

bottoms.

2.

Disconnect

the

reverse gear shift

rod from

the

shift lever.

3.

Shift

the

transmission into

re-

verse gear.

4.

Tighten

the 1-2 and 3-4

shift

rod

adjustment nuts.

5.

Connect

the

reverse gear shift

rod

to the

shift lever. Shift

the

reverse

lever

to the

neutral position

and

tight-

en

the

adjustment

nut.

6. Remove

the

alignment

pin.

7.

Check

the

gear shift lever

for a

smooth crossover.

REMOVAL

AND

INSTALLATION

REMOVAL

1.

Raise

the

vehicle

on a

hoist.

2.

Mark

the

driveshaft

so

that

it

may

be

installed

in the

same relative

position. Disconnect

the

drive shaft

from

the

rear U-joint flange. Slide

the

drive shaft

off the

transmission output

shaft

and

install

the

extension housing

seal installation tool into the extension

housing

to

prevent lubricant leakage.

See

Fig. 2,

Part

6-1.

3.

Disconnect

the

speedometer

cable from

the

extension housing.

4.

Disconnect

the

parking brakeprocarmanuals.com

Page 285 of 413

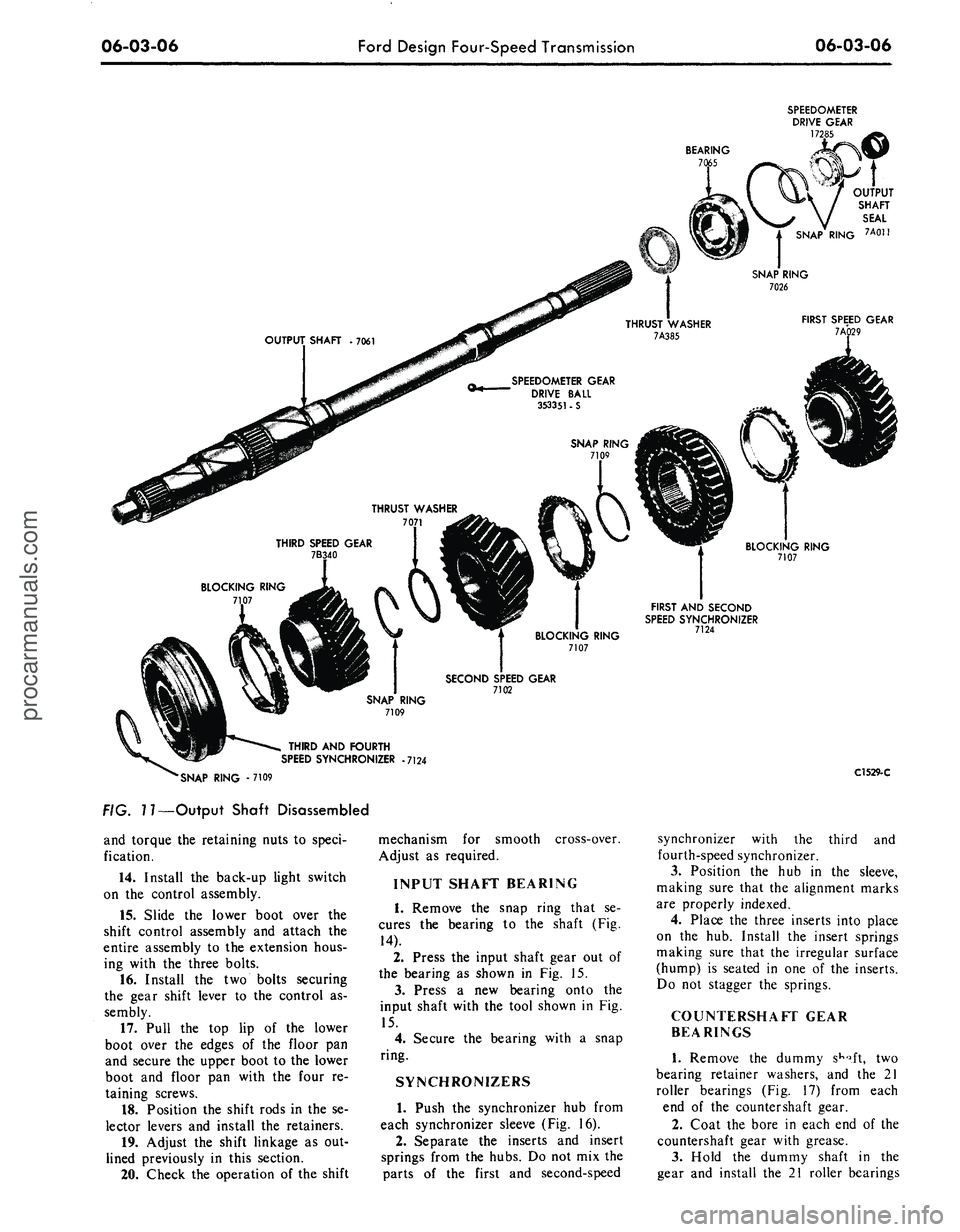

06-03-06

Ford Design Four-Speed Transmission

06-03-06

BEARING

7C

SPEEDOMETER

DRIVE GEAR

172

OUTPUT

SHAFT

SEAL

SNAP RING 7Aon

SPEEDOMETER GEAR

DRIVE BALL

353351•S

BLOCKING RING

7107

FIRST AND SECOND

SPEED SYNCHRONIZER

7124

SECOND SPEED GEAR

7102

THIRD AND FOURTH

SPEED SYNCHRONIZER

•7124

SNAP RING - 7109

FIG.

7

7—Output Shaft Disassembled

and torque the retaining nuts to speci-

fication.

14.

Install the back-up light switch

on the control assembly.

15.

Slide the lower boot over the

shift control assembly and attach the

entire assembly to the extension hous-

ing with the three bolts.

16.

Install the two bolts securing

the gear shift lever to the control as-

sembly.

17.

Pull the top lip of the lower

boot over the edges of the floor pan

and secure the upper boot to the lower

boot and floor pan with the four re-

taining screws.

18.

Position the shift rods in the se-

lector levers and install the retainers.

19.

Adjust the shift linkage as out-

lined previously in this section.

20.

Check the operation of the shift

mechanism for smooth

Adjust as required.

cross-over.

INPUT SHAFT BEARING

1.

Remove the snap ring that se-

cures the bearing to the shaft (Fig.

14).

2.

Press the input shaft gear out of

the bearing as shown in Fig. 15.

3.

Press a new bearing onto the

input shaft with the tool shown in Fig.

15.

4.

Secure the bearing with a snap

ring.

SYNCHRONIZERS

1.

Push the synchronizer hub from

each synchronizer sleeve (Fig. 16).

2.

Separate the inserts and insert

springs from the hubs. Do not mix the

parts of the first and second-speed

C1529-C

synchronizer with the third and

fourth-speed synchronizer.

3.

Position the hub in the sleeve,

making sure that the alignment marks

are properly indexed.

4.

Place the three inserts into place

on the hub. Install the insert springs

making sure that the irregular surface

(hump) is seated in one of the inserts.

Do not stagger the springs.

COUNTERSHAFT GEAR

BEARINGS

1.

Remove the dummy

sKo.ft,

two

bearing retainer washers, and the 21

roller bearings (Fig. 17) from each

end of the countershaft gear.

2.

Coat the bore in each end of the

countershaft gear with grease.

3.

Hold the dummy shaft in the

gear and install the 21 roller bearingsprocarmanuals.com

Page 288 of 413

06-03-09

Ford Design Four-Speed Transmission

06-03-09

24.

Place a detent plug (Fig. 5) in

the detent bore. Place the reverse shift

rail into neutral position.

25.

Coat the third and fourth-

speed shift rail interlock pin with

grease and position it in the shift rail.

26.

Align the third and fourth-

speed shift fork with the shift rail

bores and slide the shift rail into place

making sure that the three detents are

facing toward the outside of the case.

Place the front synchronizer into

third-speed position and install the set

screw in the third and fourth-speed

shift fork. Move the synchronizer to

the neutral position. Install the third

and fourth-speed shift rail detent plug,

spring and bolt in the left side of the

transmission case (Fig. 5). Place the

interlock plug (tapered ends) in the

detent case.

27.

Align the first and second-

speed shift fork with the case bores

and slide the shift rail into place. Se-

cure the fork with the set screw.

28.

Coat the input gear bore with a

thin film of grease, then install the 15

roller bearings in the bore. A thick

film of grease could plug the lubricant

holes and restrict lubrication of the

bearings.

29.

Position the front blocking ring

in the third and fourth-speed synchro-

nizer.

Place the input shaft gear in the

transmission case making sure that

the output shaft pilot enters the roller

bearings in the input gear.

30.

Place a new gasket on the input

shaft bearing retainer. Dip the attach-

ing bolts in sealer and install and

tighten them to specifications.

31.

Install the output shaft bearing

as shown in Fig. 21. Install the snap

ring to retain the bearing.

32.

On some transmissions, position

the speedometer gear iometer drive

gear retaining clip on the output shaft

with the lower tang in the retaining

hole.

Align the groove in the gear with

the clip and slide the gear forward

until the upper tang on the clip locks

the gear (Fig. 4).

33.

Place the transmission in a ver-

tical position as shown in Fig. 22.

Align the countershaft gear bore and

thrust washers with the bore in the

case.

Install the countershaft.

34.

Use a new gasket and secure

the extension housing to the case with

the attaching screws. Use a sealer on

the extension housing attaching

screws. Torque the screws to specifica-

tions.

35.

Install the filler plug and drain

plug (if so equipped) in the case if

they were removed. Make sure that

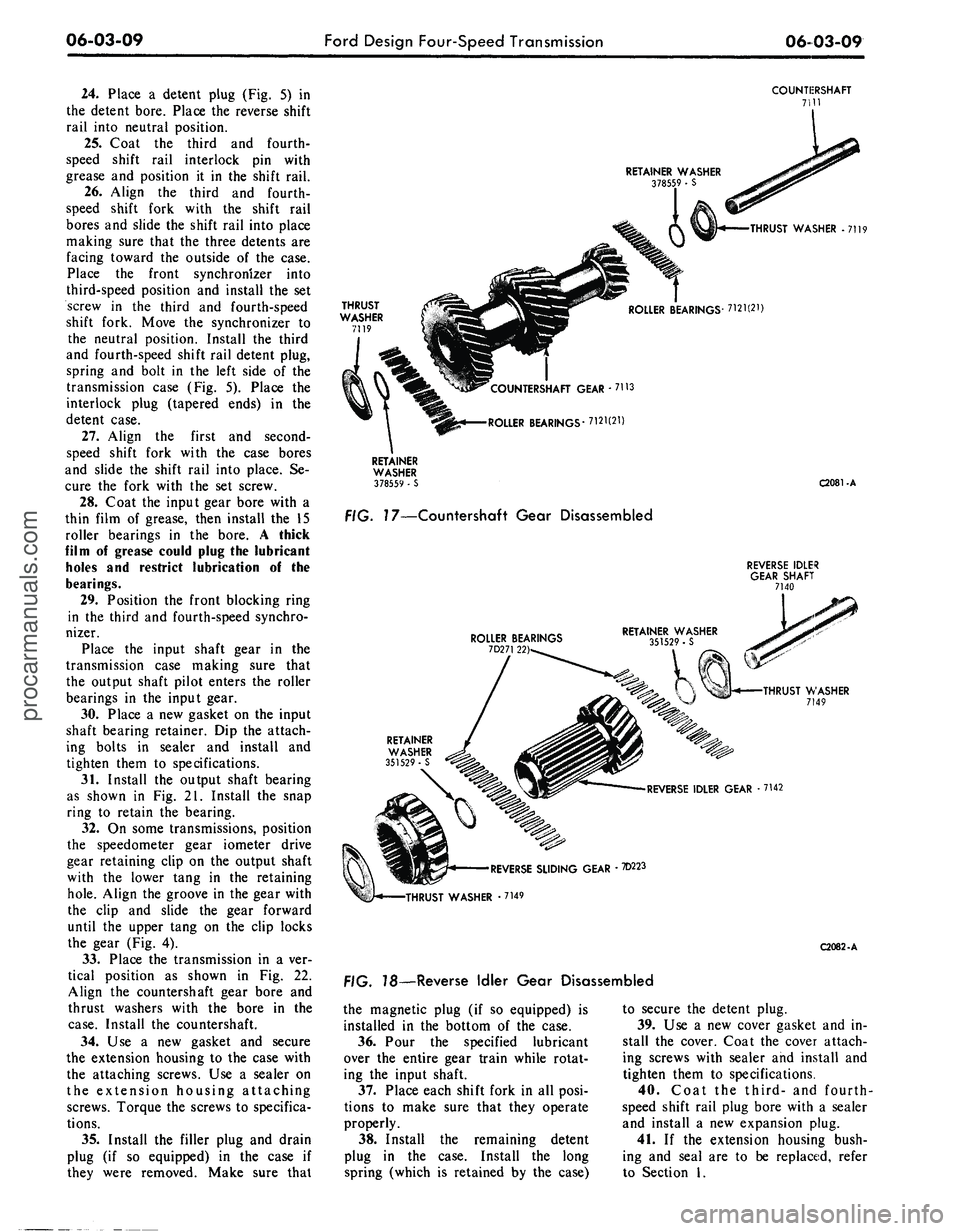

COUNTIERSHAFT

7111

RETAINER WASHER

378559 • S

THRUST WASHER -7119

THRUST

WASHER

7119

ROLLER BEARINGS- 7121(21)

COUNTERSHAFT GEAR - 7113

ROLLER BEARINGS'7121(21)

RETAINER

WASHER

378559 • S

FIG. 17—Countershaft Gear Disassembled

C2081-A

REVERSE IDLER

GEAR SHAFT

7140

ROLLER BEARINGS

7D271 22)

THRUST WASHER

7149

RETAINER

WASHER

351529 - S

REVERSE IDLER GEAR -7142

'REVERSE SLIDING GEAR • 7D223

•THRUST WASHER • 7149

FIG. 78—Reverse Idler Gear Disassembled

C2082-A

the magnetic plug (if so equipped) is

installed in the bottom of the case.

36.

Pour the specified lubricant

over the entire gear train while rotat-

ing the input shaft.

37.

Place each shift fork in all posi-

tions to make sure that they operate

properly.

38.

Install the remaining detent

plug in the case. Install the long

spring (which is retained by the case)

to secure the detent plug.

39.

Use a new cover gasket and in-

stall the cover. Coat the cover attach-

ing screws with sealer and install and

tighten them to specifications.

40.

Coat the third- and fourth-

speed shift rail plug bore with a sealer

and install a new expansion plug.

41.

If the extension housing bush-

ing and seal are to be replaced, refer

to Section 1.procarmanuals.com

Page 295 of 413

07-01-04

General Transmission Service

07-01-04

taching bolts to the proper torque. If

necessary, replace the gasket.

Check the fluid filler tube connec-

tion at the transmission case or pan.

If leakage is found here, install a new

O-ring or tighten the fitting to the

specified torque.

Check the fluid lines and fittings

between the transmission and the

cooler in the radiator tank for loose-

ness,

wear, or damage. If leakage can-

not be stopped by tightening a fitting,

replace the damaged parts.

Check the engine coolant in the ra-

diator. If transmission fluid is present

in the coolant, the cooler in the radia-

tor is probably leaking.

The cooler can be further checked

for leaks by disconnecting the lines

from the cooler fittings and applying

50-75 psi air pressure to the fittings.

Remove the radiator cap to relieve the

pressure build at the exterior of the oil

cooler tank. If the cooler is leaking

and will not hold this pressure the

cooler must be replaced. Cooler re-

placement is described in the Cooling

System Section of Group 11.

If leakage is found at either the

downshift control lever shaft or the

manual lever shaft, replace either or

both seals.

Inspect the pipe plug on the left

side of the transmission case at the

front. If the plug shows leakage, tor-

que the plug to specifications. If tight-

ening does not stop the leaks, replace

the plug. On a C6 transmission, a TV

pressure plug is also provided on the

right rear side of the case.

When converter drain plugs leak,

remove drain plugs with a six-point

wrench. Coat the threads with FoMo-

Co Perfect Seal Sealing Compound or

its equivalent, and install the plugs.

Torque the drain plugs to specifica-

tion. Fluid leakage from the converter

housing may be caused by engine oil

leaking past the rear main bearing or

from oil gallery plugs, or power steer-

ing oil leakage from steering system.

Be sure to determine the exact cause

of the leak before repair procedures

are started.

Oil-soluble aniline or fluorescent dyes

premixed at the rate of 1/2 teaspoon

of dye powder to 1/2 pint of transmis-

sion fluid have proved helpful in locat-

ing the source of the fluid leakage.

Such dyes may be used to determine

whether an engine oil or transmission

fluid leak is present or if the fluid in

the oil cooler leaks into the engine

coolant system. A black light, how-

ever, must be used with the fluorescent

dye solution.

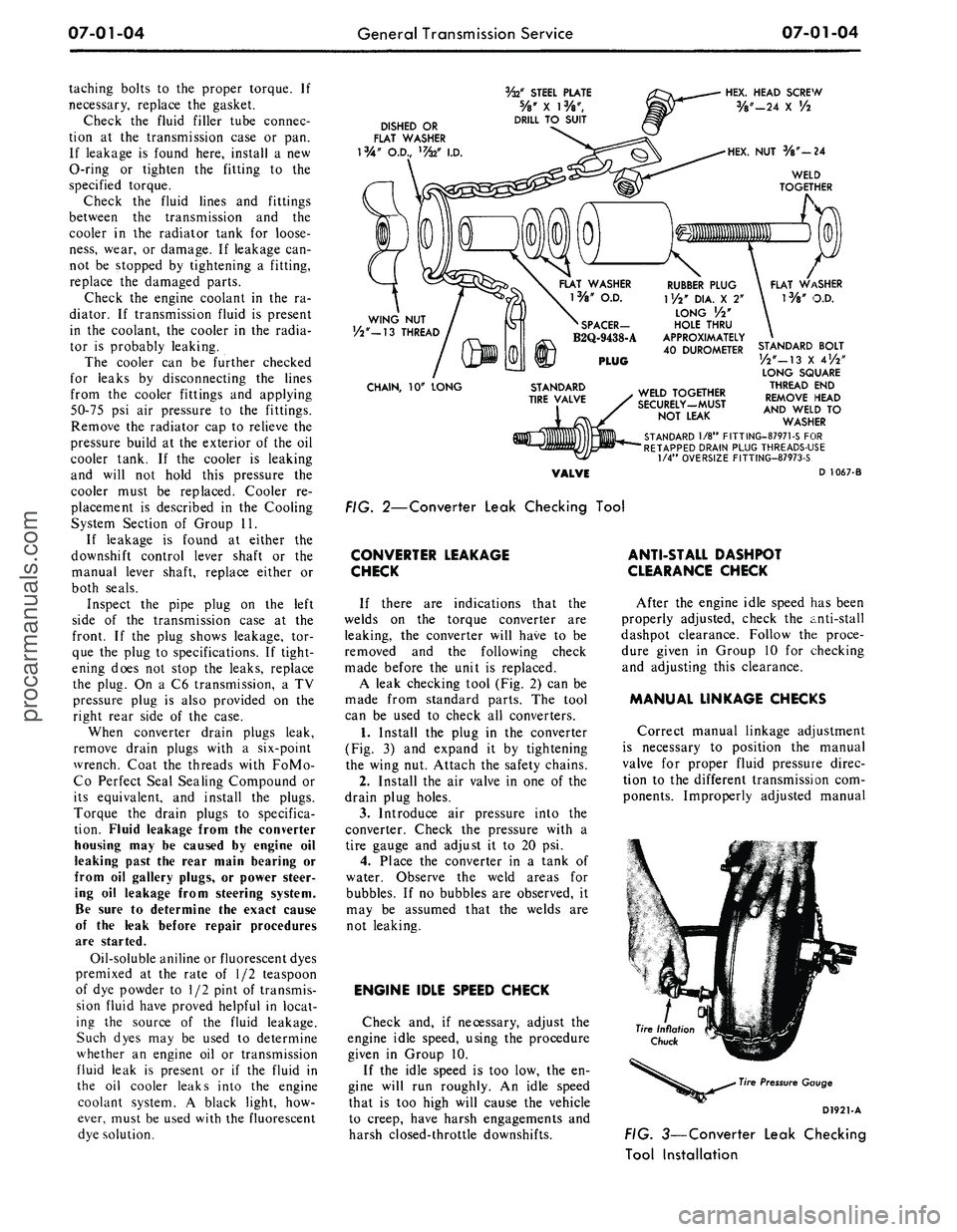

DISHED OR

FLAT WASHER

" O.D.,

a" STEEL PLATE

5/8"X \W,

DRILL TO SUIT

HEX. HEAD SCREW

3/8"-24 X Vl

HEX. NUT W—

24

WELD

TOGETHER

WING

NUT

>/2"_13

THREAD

CHAIN,

10"

LONG

RUBBER PLUG

1

Vi" DIA. X 2"

LONG Vl"

HOLE THRU

APPROXIMATELY

40 DUROMETER

FLAT WASHER

Vs" O.D.

PLUG

VALVE

STANDARD BOLT

W-13

X 4Vl"

LONG SQUARE

THREAD

END

REMOVE HEAD

AND WELD

TO

WASHER

STANDARD 1/8" FITTING-87971-S FOR

RETAPPED DRAIN PLUG THREADS-USE

1/4" OVERSIZE FITTING-87973-S

D 1067-B

WELD TOGETHER

SECURELY—MUST

NOT LEAK

FIG. 2—Converter Leak Checking Tool

CONVERTER LEAKAGE

CHECK

If there are indications that the

welds on the torque converter are

leaking, the converter will have to be

removed and the following check

made before the unit is replaced.

A leak checking tool (Fig. 2) can be

made from standard parts. The tool

can be used to check all converters.

1.

Install the plug in the converter

(Fig. 3) and expand it by tightening

the wing nut. Attach the safety chains.

2.

Install the air valve in one of the

drain plug holes.

3.

Introduce air pressure into the

converter. Check the pressure with a

tire gauge and adjust it to 20 psi.

4.

Place the converter in a tank of

water. Observe the weld areas for

bubbles. If no bubbles are observed, it

may be assumed that the welds are

not leaking.

ENGINE IDLE SPEED CHECK

Check and, if necessary, adjust the

engine idle speed, using the procedure

given in Group 10.

If the idle speed is too low, the en-

gine will run roughly. An idle speed

that is too high will cause the vehicle

to creep, have harsh engagements and

harsh closed-throttle downshifts.

ANTI-STALL DASHPOT

CLEARANCE CHECK

After the engine idle speed has been

properly adjusted, check the anti-stall

dashpot clearance. Follow the proce-

dure given in Group 10 for checking

and adjusting this clearance.

MANUAL LINKAGE CHECKS

Correct manual linkage adjustment

is necessary to position the manual

valve for proper fluid pressure direc-

tion to the different transmission com-

ponents. Improperly adjusted manual

Tire Pressure Gauge

D1921-A

FIG. 3—Converter Leak Checking

Tool Installationprocarmanuals.com

Page 297 of 413

07-01-06

General Transmission Service

07-01-06

MAKE MARK HERE

BELLOWS INTACT

BELLOWS FAILED

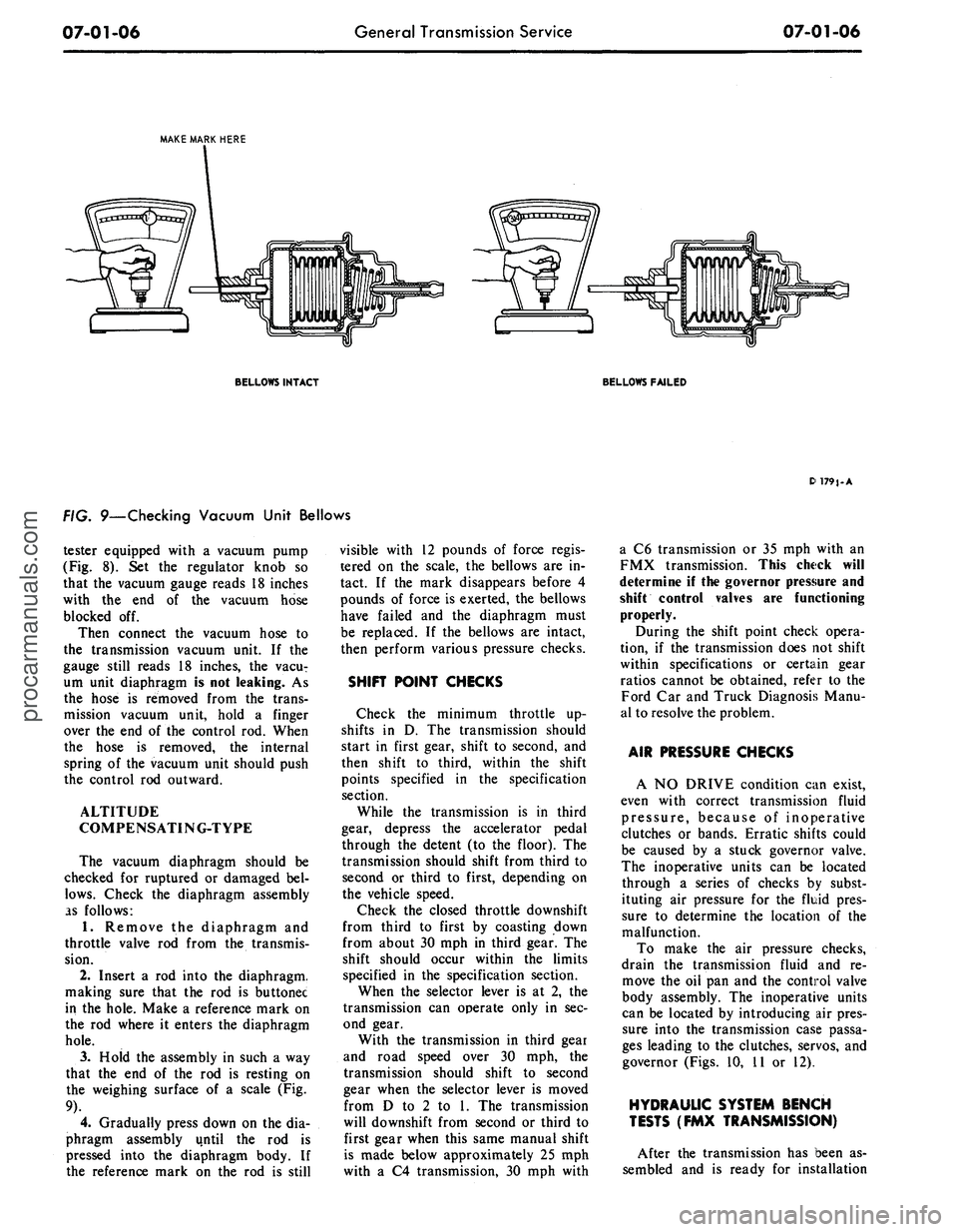

FIG. 9—Checking Vacuum Unit Bellows

tester equipped with a vacuum pump

(Fig. 8). Set the regulator knob so

that the vacuum gauge reads 18 inches

with the end of the vacuum hose

blocked off.

Then connect the vacuum hose to

the transmission vacuum unit. If the

gauge still reads 18 inches, the vacuT

urn unit diaphragm is not leaking. As

the hose is removed from the trans-

mission vacuum unit, hold a finger

over the end of the control rod. When

the hose is removed, the internal

spring of the vacuum unit should push

the control rod outward.

ALTITUDE

COMPENSATING-TYPE

The vacuum diaphragm should be

checked for ruptured or damaged bel-

lows.

Check the diaphragm assembly

as follows:

1.

Remove the diaphragm and

throttle valve rod from the transmis-

sion.

2.

Insert a rod into the diaphragm,

making sure that the rod is buttonec

in the hole. Make a reference mark on

the rod where it enters the diaphragm

hole.

3.

Hold the assembly in such a way

that the end of the rod is resting on

the weighing surface of a scale (Fig.

9).

4.

Gradually press down on the dia-

phragm assembly until the rod is

pressed into the diaphragm body. If

the reference mark on the rod is still

visible with 12 pounds of force regis-

tered on the scale, the bellows are in-

tact. If the mark disappears before 4

pounds of force is exerted, the bellows

have failed and the diaphragm must

be replaced. If the bellows are intact,

then perform various pressure checks.

SHIFT POINT CHECKS

Check the minimum throttle up-

shifts in D. The transmission should

start in first gear, shift to second, and

then shift to third, within the shift

points specified in the specification

section.

While the transmission is in third

gear, depress the accelerator pedal

through the detent (to the floor). The

transmission should shift from third to

second or third to first, depending on

the vehicle speed.

Check the closed throttle downshift

from third to first by coasting down

from about 30 mph in third gear. The

shift should occur within the limits

specified in the specification section.

When the selector lever is at 2, the

transmission can operate only in sec-

ond gear.

With the transmission in third gear

and road speed over 30 mph, the

transmission should shift to second

gear when the selector lever is moved

from D to 2 to 1. The transmission

will downshift from second or third to

first gear when this same manual shift

is made below approximately 25 mph

with a C4 transmission, 30 mph with

D 1791.A

a C6 transmission or 35 mph with an

FMX transmission. This check will

determine if the governor pressure and

shift control valves are functioning

properly.

During the shift point check opera-

tion, if the transmission does not shift

within specifications or certain gear

ratios cannot be obtained, refer to the

Ford Car and Truck Diagnosis Manu-

al to resolve the problem.

AIR PRESSURE CHECKS

A NO DRIVE condition can exist,

even with correct transmission fluid

pressure, because of inoperative

clutches or bands. Erratic shifts could

be caused by a stuck governor valve.

The inoperative units can be located

through a series of checks by subst-

ituting air pressure for the fluid pres-

sure to determine the location of the

malfunction.

To make the air pressure checks,

drain the transmission fluid and re-

move the oil pan and the control valve

body assembly. The inoperative units

can be located by introducing air pres-

sure into the transmission case passa-

ges leading to the clutches, servos, and

governor (Figs. 10, 11 or 12).

HYDRAULIC SYSTEM BENCH

TESTS (FMX TRANSMISSION)

After the transmission has been as-

sembled and is ready for installationprocarmanuals.com