ECU FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 158 of 413

03-09-06

Saginaw Design Integral Power Steering Gear

03-09-06

ADJUSTER

PLUG

DUST

SEAL

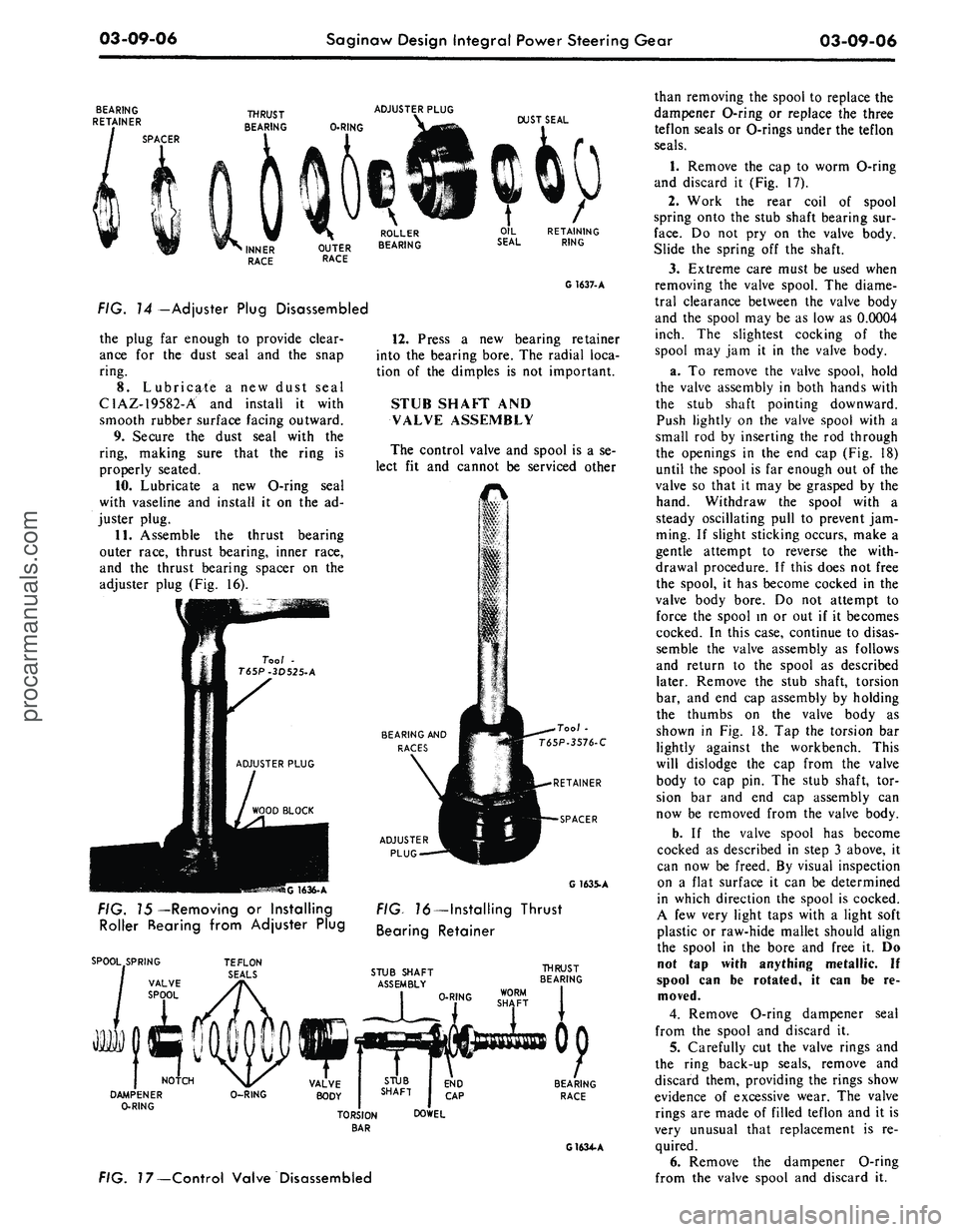

FIG. 14 —Adjuster Plug Disassembled

the plug far enough to provide clear-

ance for the dust seal and the snap

ring.

8. Lubricate a new dust seal

C1AZ-19582-A and install it with

smooth rubber surface facing outward.

9. Secure the dust seal with the

ring, making sure that the ring is

properly seated.

10.

Lubricate a new O-ring seal

with vaseline and install it on the ad-

juster plug.

11.

Assemble the thrust bearing

outer race, thrust bearing, inner race,

and the thrust bearing spacer on the

adjuster plug (Fig. 16).

OIL

RETAINING

SEAL

RING

G

1637-A

12.

Press a new bearing retainer

into the bearing bore. The radial loca-

tion of the dimples is not important.

STUB SHAFT AND

VALVE ASSEMBLY

The control valve and spool is a se-

lect fit and cannot be serviced other

BEARING

AND

RACES

1636-A

FIG. 15 —Removing or Installing

Roller Rearing from Adjuster Plug

G

1635-A

FIG.

76

—Installing Thrust

Bearing Retainer

SPOOL

SPRING

DOWEL

BEARING

RACE

G1634-A

FIG. 77—Control Valve Disassembled

than removing the spool to replace the

dampener O-ring or replace the three

teflon seals or O-rings under the teflon

seals.

1.

Remove the cap to worm O-ring

and discard it (Fig. 17).

2.

Work the rear coil of spool

spring onto the stub shaft bearing sur-

face.

Do not pry on the valve body.

Slide the spring off the shaft.

3.

Extreme care must be used when

removing the valve spool. The diame-

tral clearance between the valve body

and the spool may be as low as 0.0004

inch. The slightest cocking of the

spool may jam it in the valve body.

a. To remove the valve spool, hold

the valve assembly in both hands with

the stub shaft pointing downward.

Push lightly on the valve spool with a

small rod by inserting the rod through

the openings in the end cap (Fig. 18)

until the spool is far enough out of the

valve so that it may be grasped by the

hand. Withdraw the spool with a

steady oscillating pull to prevent jam-

ming. If slight sticking occurs, make a

gentle attempt to reverse the with-

drawal procedure. If this does not free

the spool, it has become cocked in the

valve body bore. Do not attempt to

force the spool in or out if it becomes

cocked. In this case, continue to disas-

semble the valve assembly as follows

and return to the spool as described

later. Remove the stub shaft, torsion

bar, and end cap assembly by holding

the thumbs on the valve body as

shown in Fig. 18. Tap the torsion bar

lightly against the workbench. This

will dislodge the cap from the valve

body to cap pin. The stub shaft, tor-

sion bar and end cap assembly can

now be removed from the valve body.

b.

If the valve spool has become

cocked as described in step 3 above, it

can now be freed. By visual inspection

on a flat surface it can be determined

in which direction the spool is cocked.

A few very light taps with a light soft

plastic or raw-hide mallet should align

the spool in the bore and free it. Do

not tap with anything metallic. If

spool can be rotated, it can be re-

moved.

4.

Remove O-ring dampener seal

from the spool and discard it.

5.

Carefully cut the valve rings and

the ring back-up seals, remove and

discard them, providing the rings show

evidence of excessive wear. The valve

rings are made of filled teflon and it is

very unusual that replacement is re-

quired.

6. Remove the dampener O-ring

from the valve spool and discard it.procarmanuals.com

Page 160 of 413

03-09-08

Saginaw Design Integral Power Steering Gear

03-09-08

Code

Size

6

7

8

9

10

11

Diameter

Mean

0.28117

0.28125

0.28133

0.28141

0.28149

0.28157

Size Range of Ball

(Inch)

0.28112-0.28122

0.28120-0.28130

0.28128-0.28138

0.28136-0.28146

0.28144-0.28154

0.28152-0.28162

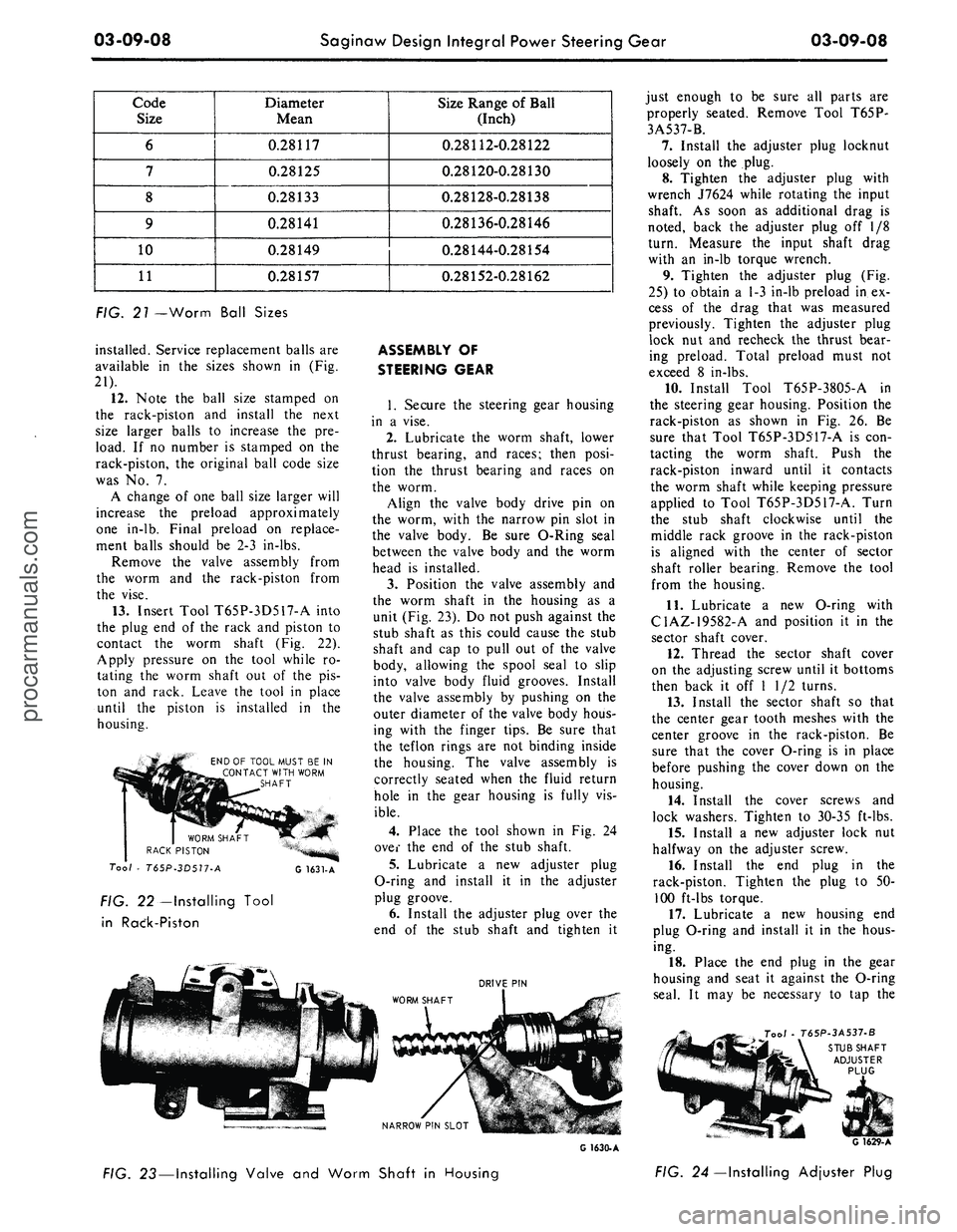

FIG. 21 —Worm Ball Sizes

installed. Service replacement balls are

available in the sizes shown in (Fig.

21).

12.

Note the ball size stamped on

the rack-piston and install the next

size larger balls to increase the pre-

load. If no number is stamped on the

rack-piston, the original ball code size

was No. 7.

A change of one ball size larger will

increase the preload approximately

one in-lb. Final preload on replace-

ment balls should be 2-3 in-lbs.

Remove the valve assembly from

the worm and the rack-piston from

the vise.

13.

Insert Tool T65P-3D517-A into

the plug end of the rack and piston to

contact the worm shaft (Fig. 22).

Apply pressure on the tool while ro-

tating the worm shaft out of the pis-

ton and rack. Leave the tool in place

until the piston is installed in the

housing.

END OF TOOL MUST BE IN

CONTACT WITH WORM

SHAFT

Tool * T65P-3D517-A

FIG. 22—Installing Tool

in Raek-Piston

G 1631-A

ASSEMBLY OF

STEERING GEAR

1.

Secure the steering gear housing

in a vise.

2.

Lubricate the worm shaft, lower

thrust bearing, and races; then posi-

tion the thrust bearing and races on

the worm.

Align the valve body drive pin on

the worm, with the narrow pin slot in

the valve body. Be sure O-Ring seal

between the valve body and the worm

head is installed.

3.

Position the valve assembly and

the worm shaft in the housing as a

unit (Fig. 23). Do not push against the

stub shaft as this could cause the stub

shaft and cap to pull out of the valve

body, allowing the spool seal to slip

into valve body fluid grooves. Install

the valve assembly by pushing on the

outer diameter of the valve body hous-

ing with the finger tips. Be sure that

the teflon rings are not binding inside

the housing. The valve assembly is

correctly seated when the fluid return

hole in the gear housing is fully vis-

ible.

4.

Place the tool shown in Fig. 24

over the end of the stub shaft.

5.

Lubricate a new adjuster plug

O-ring and install it in the adjuster

plug groove.

6. Install the adjuster plug over the

end of the stub shaft and tighten it

DRIVE PIN

just enough to be sure all parts are

properly seated. Remove Tool T65P-

3A537-B.

7.

Install the adjuster plug locknut

loosely on the plug.

8. Tighten the adjuster plug with

wrench J7624 while rotating the input

shaft. As soon as additional drag is

noted, back the adjuster plug off 1/8

turn. Measure the input shaft drag

with an in-lb torque wrench.

9. Tighten the adjuster plug (Fig.

25) to obtain a 1-3 in-lb preload in ex-

cess of the drag that was measured

previously. Tighten the adjuster plug

lock nut and recheck the thrust bear-

ing preload. Total preload must not

exceed 8 in-lbs.

10.

Install Tool T65P-3805-A in

the steering gear housing. Position the

rack-piston as shown in Fig. 26. Be

sure that Tool T65P-3D517-A is con-

tacting the worm shaft. Push the

rack-piston inward until it contacts

the worm shaft while keeping pressure

applied to Tool T65P-3D517-A. Turn

the stub shaft clockwise until the

middle rack groove in the rack-piston

is aligned with the center of sector

shaft roller bearing. Remove the tool

from the housing.

11.

Lubricate a new O-ring with

C1AZ-19582-A and position it in the

sector shaft cover.

12.

Thread the sector shaft cover

on the adjusting screw until it bottoms

then back it off 1 1/2 turns.

13.

Install the sector shaft so that

the center gear tooth meshes with the

center groove in the rack-piston. Be

sure that the cover O-ring is in place

before pushing the cover down on the

housing.

14.

Install the cover screws and

lock washers. Tighten to 30-35 ft-lbs.

15.

Install a new adjuster lock nut

halfway on the adjuster screw.

16.

Install the end plug in the

rack-piston. Tighten the plug to 50-

100 ft-lbs torque.

17.

Lubricate a new housing end

plug O-ring and install it in the hous-

ing.

18.

Place the end plug in the gear

housing and seat it against the O-ring

seal. It may be necessary to tap the

Tool

T65P-3A537-B

STUB SHAFT

ADJUSTER

PLUG

G 1630-A

FIG. 23—Installing Valve and Worm Shaft in Housing

G 1629-A

FIG. 24 —Installing Adjuster Plugprocarmanuals.com

Page 161 of 413

03-09-09

Saginaw Design Integral Power Steering Gear

03-09-09

Tool • T65P-3D517-A

LOCK NUT

ADJUSTER PLUG

G1628-A

FIG. 25

—

Adjusting Thrust Preload

end plug lightly with

a

soft-faced mal-

let

to

seat

it

properly.

19.

Snap

the

retainer ring

in

place

with

the

fingers.

Tap

lightly

on the

ring

to be

sure

the

ring

is

bottomed

securely

in the

housing.

20.

Turn

the

input shaft

to the

full

left

or

right position then turn

it

back

approximately

1 3/4

turns

to

center

the worm.

RACK PISTON

Tool - T65P.3805-A

FIG. 26—Installing Rack-Piston

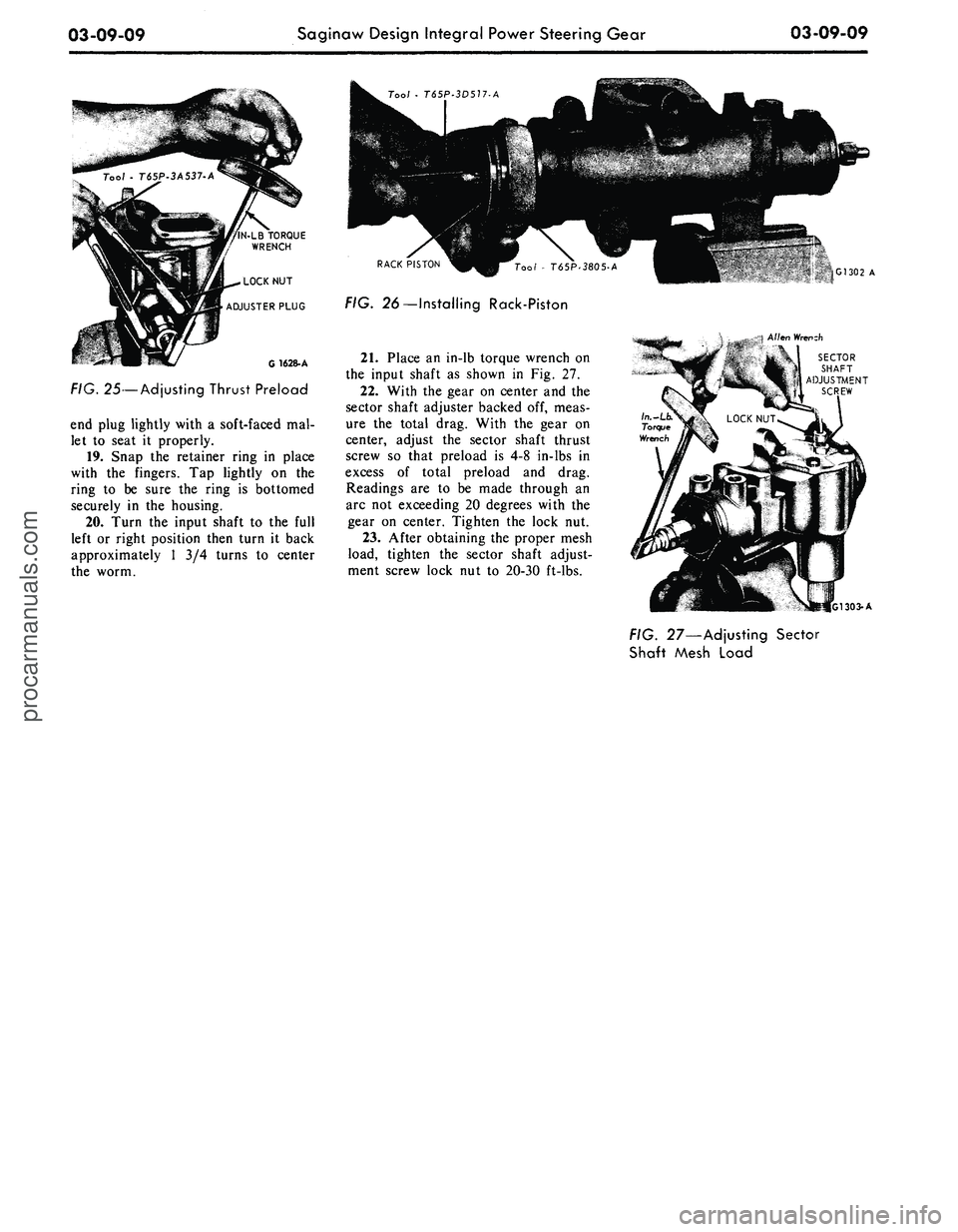

21.

Place

an

in-lb torque wrench

on

the input shaft

as

shown

in Fig. 27.

22.

With

the

gear

on

center

and the

sector shaft adjuster backed

off,

meas-

ure

the

total drag. With

the

gear

on

center, adjust

the

sector shaft thrust

screw

so

that preload

is 4-8

in-lbs

in

excess

of

total preload

and

drag.

Readings

are to be

made through

an

arc

not

exceeding

20

degrees with

the

gear

on

center. Tighten

the

lock

nut.

23.

After obtaining

the

proper mesh

load, tighten

the

sector shaft adjust-

ment screw lock

nut to

20-30 ft-lbs.

jG1302

A

G1303-A

FIG. 27—Adjusting Sector

Shaft Mesh Loadprocarmanuals.com

Page 189 of 413

04-01-02

General Axle Service

04-01-02

COMPONENT INDEX

MODEL APPLICATION

o

3

I

i

Ji

LUBRICANT LEVEL CHECK

01-10

PINION RETAINER

01-10

Cleaning and Inspection

01-10

SHIM AND BACKLASH CHANGES

01-03

Integral Carrier

Removable Carrier

01-04

N/A

01-04

01-04

01-04

01-04

01-04

01-04

N/A

N/A

N/A

U-JOINT FLANGE

01-10

Cleaning and Inspection

01-10

A page number indicates that the item is for the vehicle listed at the head of the column.

N/A indicates that the item is not applicable to the vehicle listed.

1

COMMON ADJUSTMENTS

AND

REPAIRS

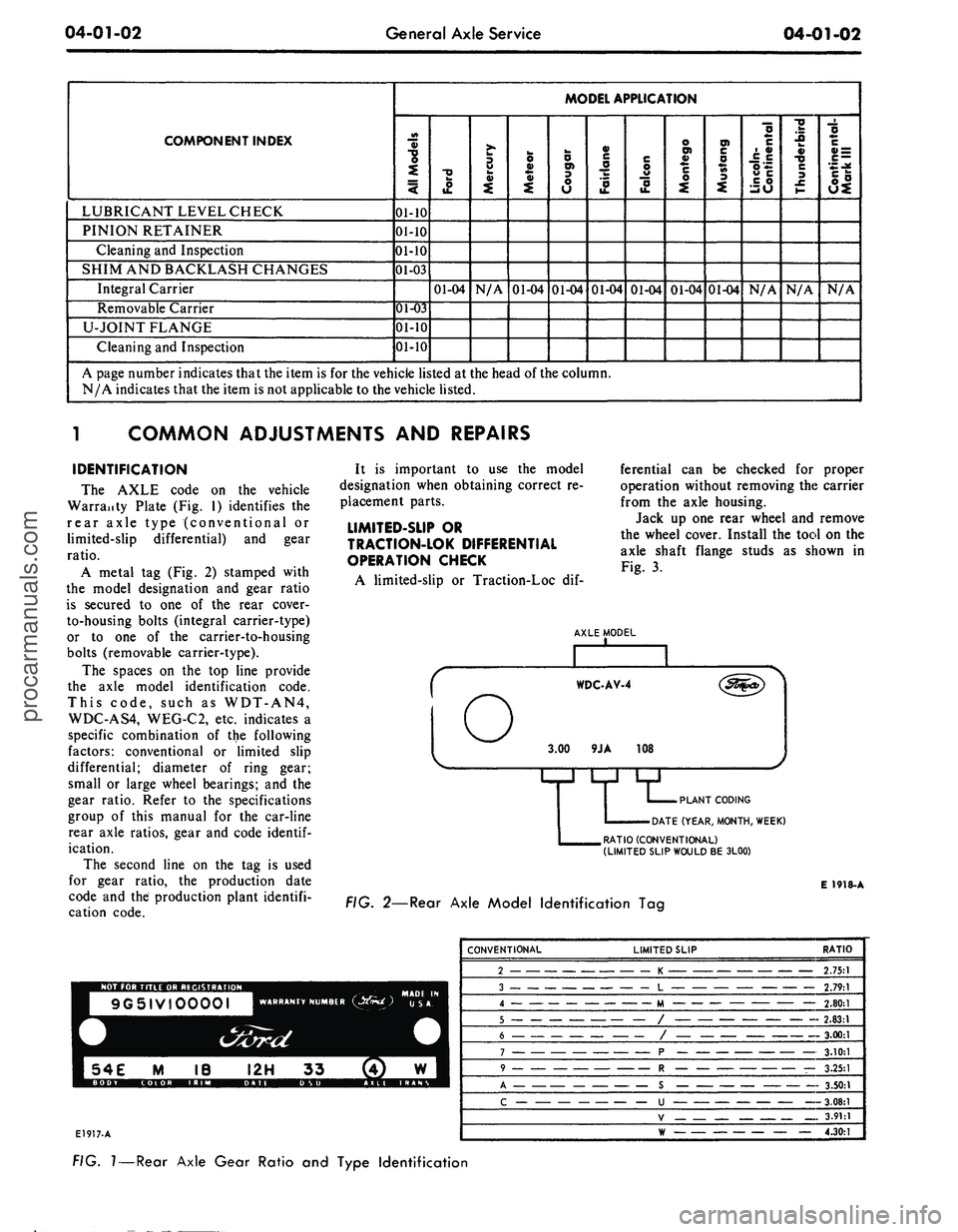

IDENTIFICATION

The AXLE code on the vehicle

Warranty Plate (Fig. 1) identifies the

rear axle type (conventional or

limited-slip differential) and gear

ratio.

A metal tag (Fig. 2) stamped with

the model designation and gear ratio

is secured to one of the rear cover-

to-housing bolts (integral carrier-type)

or to one of the carrier-to-housing

bolts (removable carrier-type).

The spaces on the top line provide

the axle model identification code.

This code, such as WDT-AN4,

WDC-AS4, WEG-C2, etc. indicates a

specific combination of the following

factors: conventional or limited slip

differential; diameter of ring gear;

small or large wheel bearings; and the

gear ratio. Refer to the specifications

group of this manual for the car-line

rear axle ratios, gear and code

identif-

ication.

The second line on the tag is used

for gear ratio, the production date

code and the production plant identifi-

cation code.

It is important to use the model

designation when obtaining correct re-

placement parts.

LIMITED-SUP

OR

TRACTION-LOK DIFFERENTIAL

OPERATION CHECK

A limited-slip or Traction-Loc dif-

ferential can be checked for proper

operation without removing the carrier

from the axle housing.

Jack up one rear wheel and remove

the wheel cover. Install the tool on the

axle shaft flange studs as shown in

Fig. 3.

AXLE MODEL

PLANT CODING

DATE (YEAR, MONTH, WEEK)

RATIO (CONVENTIONAL)

(LIMITED SLIP WOULD

BE

3L00)

E 1918-A

FIG.

2—Rear

Axle Model Identification

Tag

NOT

FOR

TITLE

OR

REGISTRATION

9G5IVI0000I

WARRANTY NUMBER

E1917-A

CONVENTIONAL

2

3

4

.

5

6

7

A

c

LIMITED SLIP

K

L

M

/

/

p

_ —

R

— —

c

—

u

V

RATIO

2.75:1

2.79:1

— 2.80:1

2.83:1

-

3.00:1

3.10:1

—

3.25:1

3.50:1

3.08:1

3.91:1

— 4.30:1

FIG.

1

— Rear Axle Gear Ratio

and

Type Identificationprocarmanuals.com

Page 194 of 413

04-01-07

General Axle Service

04-01-07

Tool-4201-

C

Tool-6565 USED WITH BRACKET

FROM Too/^*207-C

FLANGE

E1743-A

procedure under Backlash and Differ-

ential Bearing Preload Adjustments.

If the tooth pattern indicates a change

in shim thickness, follow the proce-

dure under Pinion Location.

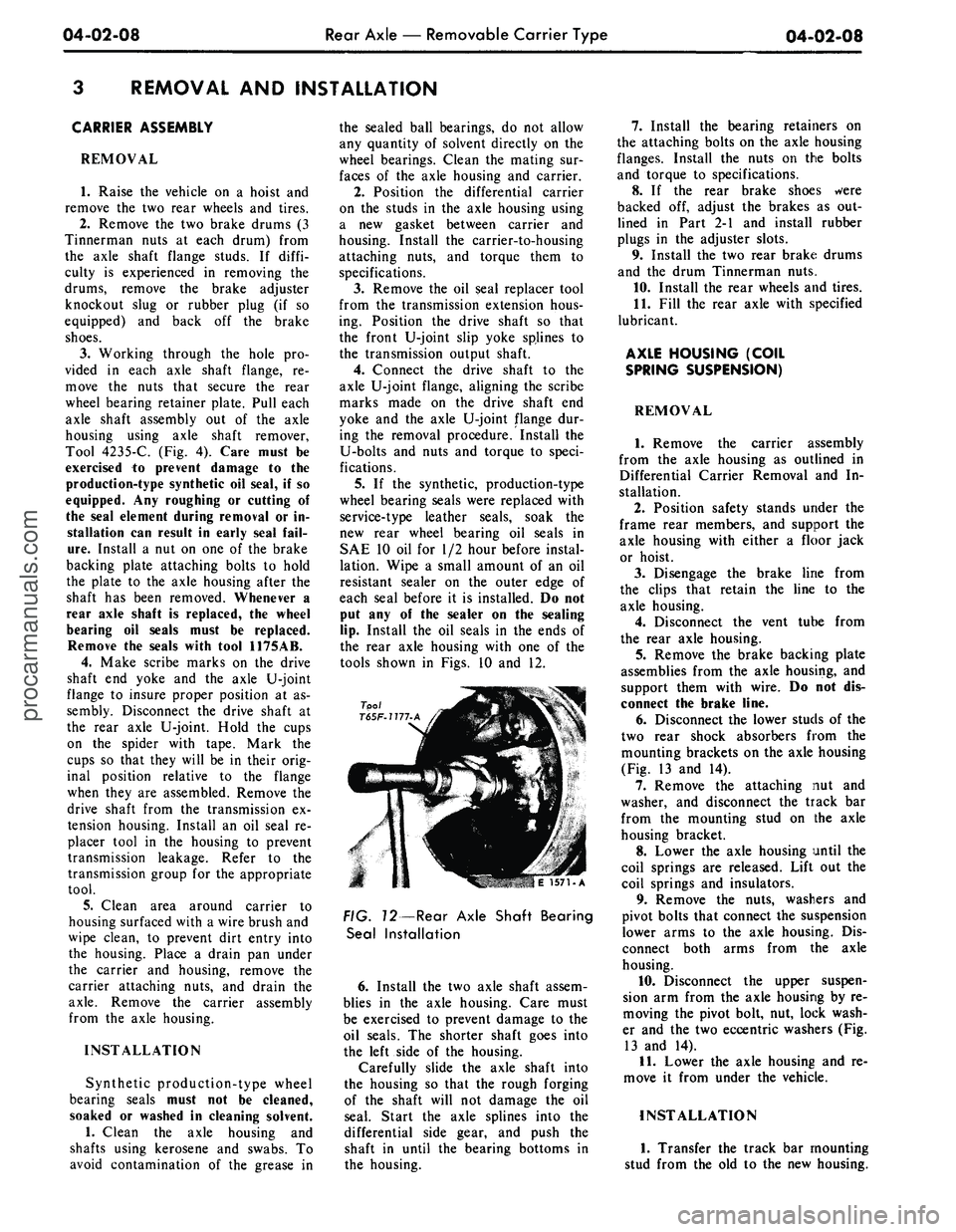

REMOVABLE CARRIER

TYPE AXLE

The shim location for the removable

carrier type axle is between the pinion

retainer and the carrier (Fig. 13).

When adjusting this type carrier re-

ducing shim thickness will move the

pinion toward the ring gear; increas-

ing shim thickness will move the pi-

nion away from the ring gear (Fig.

13).

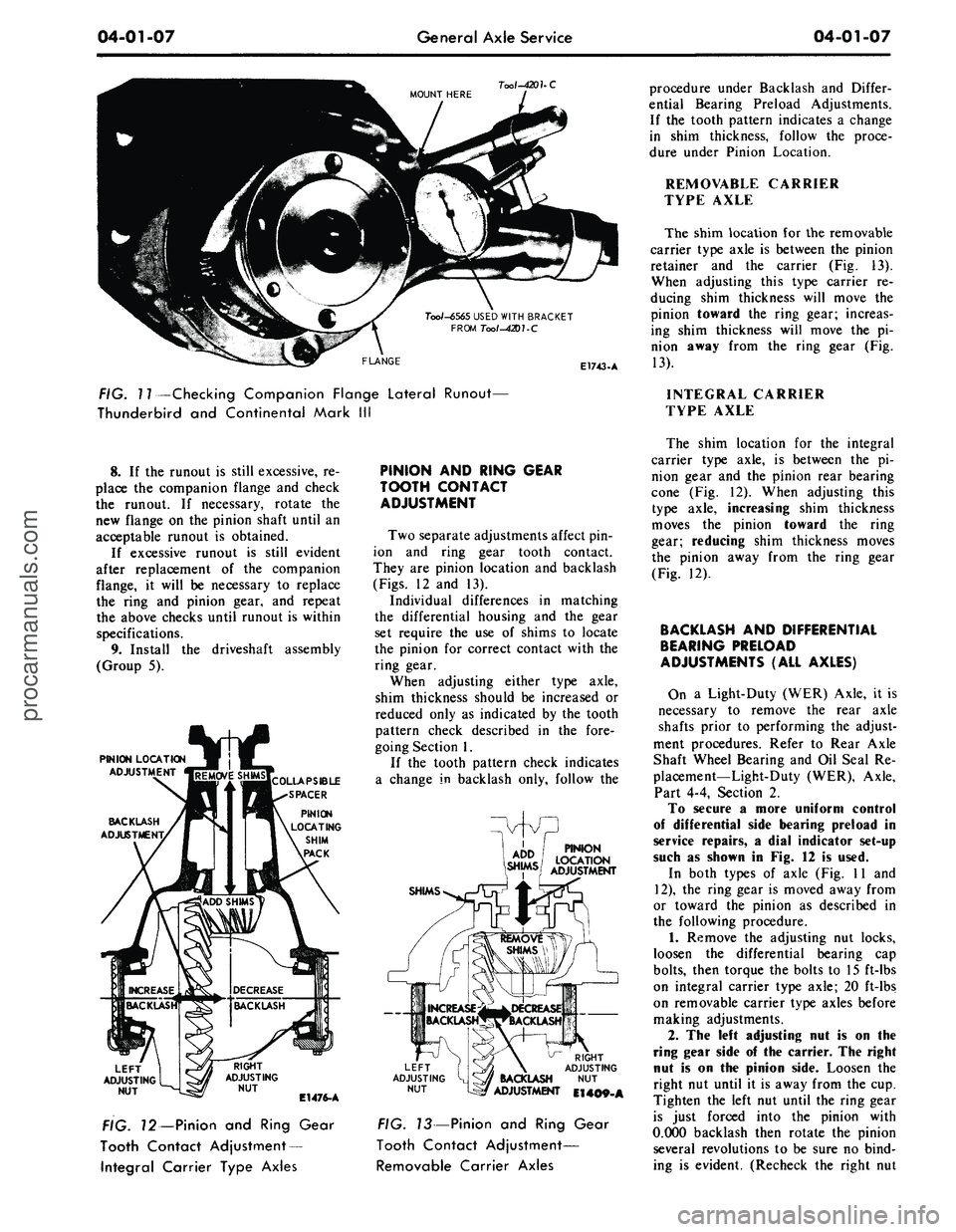

FIG. 11—Checking Companion Flange Lateral Runout—

Thunderbird and Continental Mark III

INTEGRAL CARRIER

TYPE AXLE

8. If the runout is still excessive, re-

place the companion flange and check

the runout. If necessary, rotate the

new flange on the pinion shaft until an

acceptable runout is obtained.

If excessive runout is still evident

after replacement of the companion

flange, it will be necessary to replace

the ring and pinion gear, and repeat

the above checks until runout is within

specifications.

9. Install the driveshaft assembly

(Group 5).

PINION LOCATION

ADJUSTMENT

BACKLASH

ADJUSTMENT,

LEFT

ADJUSTING

NUT

E1476-A

FIG. 12—Pinion and Ring Gear

Tooth Contact Adjustment

—

Integral Carrier Type Axles

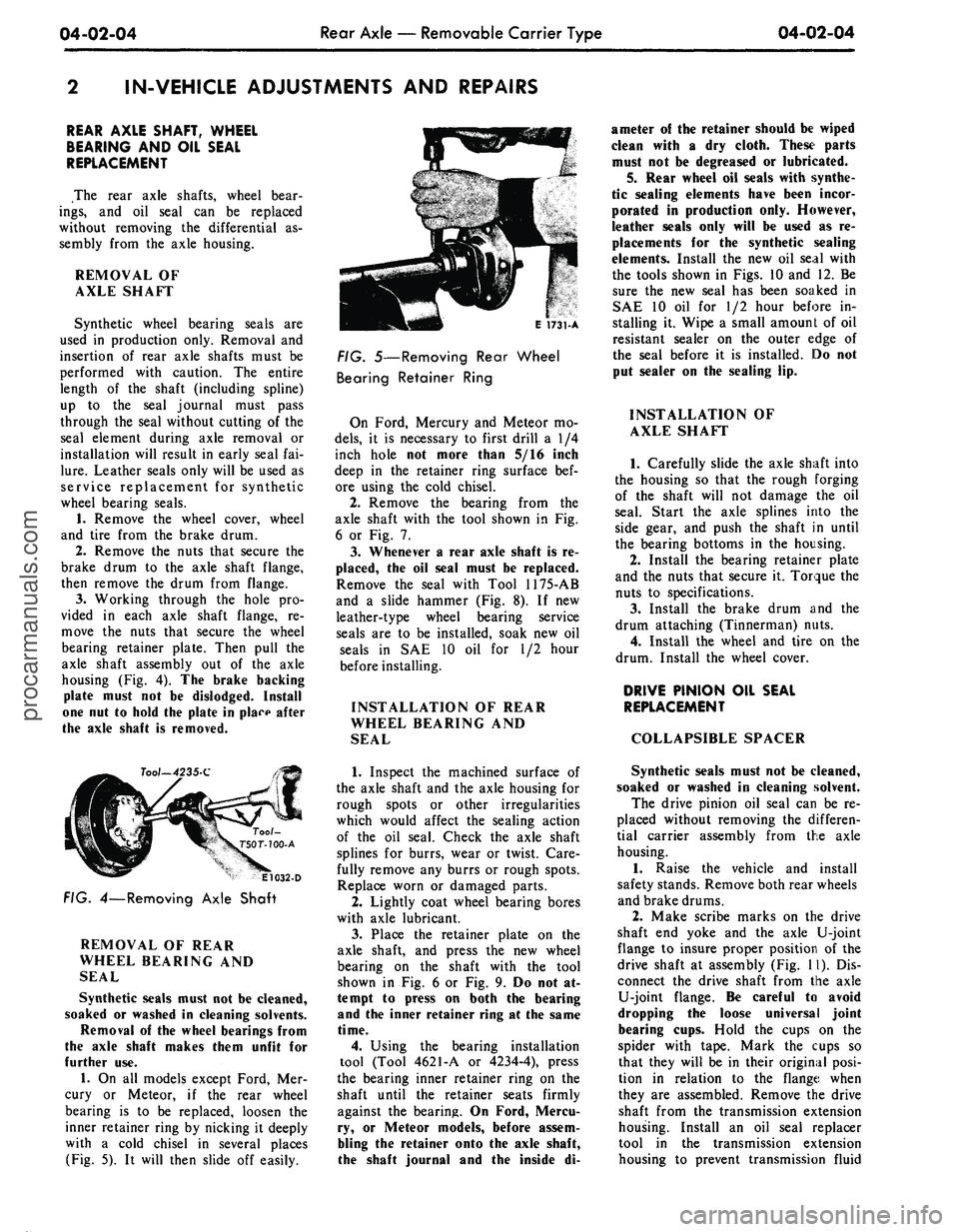

PINION AND RING GEAR

TOOTH CONTACT

ADJUSTMENT

Two separate adjustments affect pin-

ion and ring gear tooth contact.

They are pinion location and backlash

(Figs.

12 and 13).

Individual differences in matching

the differential housing and the gear

set require the use of shims to locate

the pinion for correct contact with the

ring gear.

When adjusting either type axle,

shim thickness should be increased or

reduced only as indicated by the tooth

pattern check described in the fore-

going Section 1.

If the tooth pattern check indicates

a change in backlash only, follow the

PINION

LOCATION

ADJUSTMENT

SHIMS

LEFT

ADJUSTING

NUT

RIGHT

ADJUSTING

BACKLASH NUT

ADJUSTMENT El 409-A

FIG. 13—Pinion and Ring Gear

Tooth Contact Adjustment—

Removable Carrier Axles

The shim location for the integral

carrier type axle, is between the pi-

nion gear and the pinion rear bearing

cone (Fig. 12). When adjusting this

type axle, increasing shim thickness

moves the pinion toward the ring

gear; reducing shim thickness moves

the pinion away from the ring gear

(Fig. 12).

BACKLASH AND DIFFERENTIAL

BEARING PRELOAD

ADJUSTMENTS (ALL AXLES)

On a Light-Duty (WER) Axle, it is

necessary to remove the rear axle

shafts prior to performing the adjust-

ment procedures. Refer to Rear Axle

Shaft Wheel Bearing and Oil Seal Re-

placement—Light-Duty (WER), Axle,

Part 4-4, Section 2.

To secure a more uniform control

of differential side bearing preload in

service repairs, a dial indicator set-up

such as shown in Fig. 12 is used.

In both types of axle (Fig. 11 and

12),

the ring gear is moved away from

or toward the pinion as described in

the following procedure.

1.

Remove the adjusting nut locks,

loosen the differential bearing cap

bolts,

then torque the bolts to 15 ft-lbs

on integral carrier type axle; 20 ft-lbs

on removable carrier type axles before

making adjustments.

2.

The left adjusting nut is on the

ring gear side of the carrier. The right

nut is on the pinion side. Loosen the

right nut until it is away from the cup.

Tighten the left nut until the ring gear

is just forced into the pinion with

0.000 backlash then rotate the pinion

several revolutions to be sure no bind-

ing is evident. (Recheck the right nutprocarmanuals.com

Page 201 of 413

04-02-04

Rear Axle — Removable Carrier Type

04-02-04

IN-VEHICLE ADJUSTMENTS AND REPAIRS

REAR AXLE SHAFT, WHEEL

BEARING AND OIL SEAL

REPLACEMENT

The rear axle shafts, wheel bear-

ings,

and oil seal can be replaced

without removing the differential as-

sembly from the axle housing.

REMOVAL OF

AXLE SHAFT

Synthetic wheel bearing seals are

used in production only. Removal and

insertion of rear axle shafts must be

performed with caution. The entire

length of the shaft (including spline)

up to the seal journal must pass

through the seal without cutting of the

seal element during axle removal or

installation will result in early seal fai-

lure.

Leather seals only will be used as

service replacement for synthetic

wheel bearing seals.

1.

Remove the wheel cover, wheel

and tire from the brake drum.

2.

Remove the nuts that secure the

brake drum to the axle shaft flange,

then remove the drum from flange.

3.

Working through the hole pro-

vided in each axle shaft flange, re-

move the nuts that secure the wheel

bearing retainer plate. Then pull the

axle shaft assembly out of the axle

housing (Fig. 4). The brake backing

plate must not be dislodged. Install

one nut to hold the plate in place after

the axle shaft is removed.

Too/-4235-C

E1032-D

FIG. 4—Removing Axle Shaft

REMOVAL OF REAR

WHEEL BEARING AND

SEAL

Synthetic seals must not be cleaned,

soaked or washed in cleaning solvents.

Removal of the wheel bearings from

the axle shaft makes them unfit for

further use.

1.

On all models except Ford, Mer-

cury or Meteor, if the rear wheel

bearing is to be replaced, loosen the

inner retainer ring by nicking it deeply

with a cold chisel in several places

(Fig. 5). It will then slide off easily.

E 1731-A

FIG. 5—Removing Rear Wheel

Bearing Retainer Ring

On Ford, Mercury and Meteor mo-

dels,

it is necessary to first drill a 1/4

inch hole not more than 5/16 inch

deep in the retainer ring surface bef-

ore using the cold chisel.

2.

Remove the bearing from the

axle shaft with the tool shown in Fig.

6 or Fig. 7.

3.

Whenever a rear axle shaft is re-

placed, the oil seal must be replaced.

Remove the seal with Tool 1175-AB

and a slide hammer (Fig. 8). If new

leather-type wheel bearing service

seals are to be installed, soak new oil

seals in SAE 10 oil for 1/2 hour

before installing.

INSTALLATION OF REAR

WHEEL BEARING AND

SEAL

1.

Inspect the machined surface of

the axle shaft and the axle housing for

rough spots or other irregularities

which would affect the sealing action

of the oil seal. Check the axle shaft

splines for burrs, wear or twist. Care-

fully remove any burrs or rough spots.

Replace worn or damaged parts.

2.

Lightly coat wheel bearing bores

with axle lubricant.

3.

Place the retainer plate on the

axle shaft, and press the new wheel

bearing on the shaft with the tool

shown in Fig. 6 or Fig. 9. Do not at-

tempt to press on both the bearing

and the inner retainer ring at the same

time.

4.

Using the bearing installation

tool (Tool 4621-A or 4234-4), press

the bearing inner retainer ring on the

shaft until the retainer seats firmly

against the bearing. On Ford, Mercu-

ry, or Meteor models, before assem-

bling the retainer onto the axle shaft,

the shaft journal and the inside di-

ameter of the retainer should be wiped

clean with a dry cloth. These parts

must not be degreased or lubricated.

5. Rear wheel oil seals with synthe-

tic sealing elements have been incor-

porated in production only. However,

leather seals only will be used as re-

placements for the synthetic sealing

elements. Install the new oil seal with

the tools shown in Figs. 10 and 12. Be

sure the new seal has been soaked in

SAE 10 oil for 1/2 hour before in-

stalling it. Wipe a small amount of oil

resistant sealer on the outer edge of

the seal before it is installed. Do not

put sealer on the sealing lip.

INSTALLATION OF

AXLE SHAFT

1.

Carefully slide the axle shaft into

the housing so that the rough forging

of the shaft will not damage the oil

seal. Start the axle splines into the

side gear, and push the shaft in until

the bearing bottoms in the housing.

2.

Install the bearing retainer plate

and the nuts that secure it. Torque the

nuts to specifications.

3.

Install the brake drum and the

drum attaching (Tinnerman) nuts.

4.

Install the wheel and tire on the

drum. Install the wheel cover.

DRIVE PINION OIL SEAL

REPLACEMENT

COLLAPSIBLE SPACER

Synthetic seals must not be cleaned,

soaked or washed in cleaning solvent.

The drive pinion oil seal can be re-

placed without removing the differen-

tial carrier assembly from the axle

housing.

1.

Raise the vehicle and install

safety stands. Remove both rear wheels

and brake drums.

2.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position of the

drive shaft at assembly (Fig. 11). Dis-

connect the drive shaft from the axle

U-joint flange. Be careful to avoid

dropping the loose universal joint

bearing cups. Hold the cups on the

spider with tape. Mark the cups so

that they will be in their original posi-

tion in relation to the flange when

they are assembled. Remove the drive

shaft from the transmission extension

housing. Install an oil seal replacer

tool in the transmission extension

housing to prevent transmission fluidprocarmanuals.com

Page 205 of 413

04-02-08

Rear Axle — Removable Carrier Type

04-02-08

REMOVAL AND INSTALLATION

CARRIER ASSEMBLY

REMOVAL

1.

Raise the vehicle on a hoist and

remove the two rear wheels and tires.

2.

Remove the two brake drums (3

Tinnerman nuts at each drum) from

the axle shaft flange studs. If diffi-

culty is experienced in removing the

drums, remove the brake adjuster

knockout slug or rubber plug (if so

equipped) and back off the brake

shoes.

3.

Working through the hole pro-

vided in each axle shaft flange, re-

move the nuts that secure the rear

wheel bearing retainer plate. Pull each

axle shaft assembly out of the axle

housing using axle shaft remover,

Tool 4235-C. (Fig. 4). Care must be

exercised to prevent damage to the

production-type synthetic oil seal, if so

equipped. Any roughing or cutting of

the seal element during removal or in-

stallation can result in early seal fail-

ure.

Install a nut on one of the brake

backing plate attaching bolts to hold

the plate to the axle housing after the

shaft has been removed. Whenever a

rear axle shaft is replaced, the wheel

bearing oil seals must be replaced.

Remove the seals with tool 1175AB.

4.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position at as-

sembly. Disconnect the drive shaft at

the rear axle U-joint. Hold the cups

on the spider with tape. Mark the

cups so that they will be in their orig-

inal position relative to the flange

when they are assembled. Remove the

drive shaft from the transmission ex-

tension housing. Install an oil seal re-

placer tool in the housing to prevent

transmission leakage. Refer to the

transmission group for the appropriate

tool.

5.

Clean area around carrier to

housing surfaced with a wire brush and

wipe clean, to prevent dirt entry into

the housing. Place a drain pan under

the carrier and housing, remove the

carrier attaching nuts, and drain the

axle.

Remove the carrier assembly

from the axle housing.

INSTALLATION

Synthetic production-type wheel

bearing seals must not be cleaned,

soaked or washed in cleaning solvent.

1.

Clean the axle housing and

shafts using kerosene and swabs. To

avoid contamination of the grease in

the sealed ball bearings, do not allow

any quantity of solvent directly on the

wheel bearings. Clean the mating sur-

faces of the axle housing and carrier.

2.

Position the differential carrier

on the studs in the axle housing using

a new gasket between carrier and

housing. Install the carrier-to-housing

attaching nuts, and torque them to

specifications.

3.

Remove the oil seal replacer tool

from the transmission extension hous-

ing. Position the drive shaft so that

the front U-joint slip yoke splines to

the transmission output shaft.

4.

Connect the drive shaft to the

axle U-joint flange, aligning the scribe

marks made on the drive shaft end

yoke and the axle U-joint flange dur-

ing the removal procedure. Install the

U-bolts and nuts and torque to speci-

fications.

5.

If the synthetic, production-type

wheel bearing seals were replaced with

service-type leather seals, soak the

new rear wheel bearing oil seals in

SAE 10 oil for 1/2 hour before instal-

lation. Wipe a small amount of an oil

resistant sealer on the outer edge of

each seal before it is installed. Do not

put any of the sealer on the sealing

lip.

Install the oil seals in the ends of

the rear axle housing with one of the

tools shown in Figs. 10 and 12.

Tool

T65F-1177.A

E 1571-A

FIG. 12—Rear Axle Shaft Bearing

Seal Installation

6. Install the two axle shaft assem-

blies in the axle housing. Care must

be exercised to prevent damage to the

oil seals. The shorter shaft goes into

the left side of the housing.

Carefully slide the axle shaft into

the housing so that the rough forging

of the shaft will not damage the oil

seal. Start the axle splines into the

differential side gear, and push the

shaft in until the bearing bottoms in

the housing.

7.

Install the bearing retainers on

the attaching bolts on the axle housing

flanges. Install the nuts on the bolts

and torque to specifications.

8. If the rear brake shoes were

backed off, adjust the brakes as out-

lined in Part 2-1 and install rubber

plugs in the adjuster slots.

9. Install the two rear brake drums

and the drum Tinnerman nuts.

10.

Install the rear wheels and tires.

11.

Fill the rear axle with specified

lubricant.

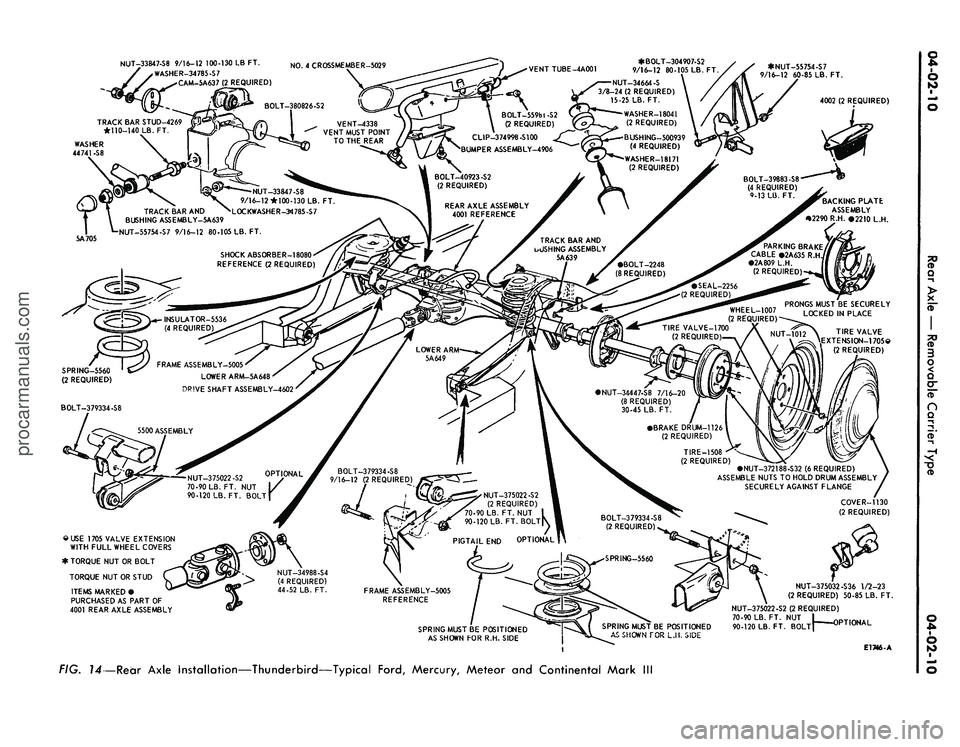

AXLE HOUSING (COIL

SPRING SUSPENSION)

REMOVAL

1.

Remove the carrier assembly

from the axle housing as outlined in

Differential Carrier Removal and In-

stallation.

2.

Position safety stands under the

frame rear members, and support the

axle housing with either a floor jack

or hoist.

3.

Disengage the brake line from

the clips that retain the line to the

axle housing.

4.

Disconnect the vent tube from

the rear axle housing.

5.

Remove the brake backing plate

assemblies from the axle housing, and

support them with wire. Do not dis-

connect the brake line.

6. Disconnect the lower studs of the

two rear shock absorbers from the

mounting brackets on the axle housing

(Fig. 13 and 14).

7.

Remove the attaching nut and

washer, and disconnect the track bar

from the mounting stud on the axle

housing bracket.

8. Lower the axle housing until the

coil springs are released. Lift out the

coil springs and insulators.

9. Remove the nuts, washers and

pivot bolts that connect the suspension

lower arms to the axle housing. Dis-

connect both arms from the axle

housing.

10.

Disconnect the upper suspen-

sion arm from the axle housing by re-

moving the pivot bolt, nut, lock wash-

er and the two eccentric washers (Fig.

13 and 14).

11.

Lower the axle housing and re-

move it from under the vehicle.

INSTALLATION

1.

Transfer the track bar mounting

stud from the old to the new housing.procarmanuals.com

Page 207 of 413

NUT-33847-S8

9/16-12

100-130 LB FT.

*-34785-S7

-CAM-5A637 (2 REQUIRED)

• NUT-55754-S7

9/16-12

60-85 LB. FT.

4002 (2 REQUIRED)

• BOLT-304907-S2

9/16-12

80-105 LB. FT.

NO.

4 CROSSMEMBER-5029

VENT TUBE-4A001

NUT-34664-S

3/8-24

(2 REQUIRED)

15-25 LB. FT.

WASHER-18041

(2 REQUIRED)

BOLT-559bl-S2

(2 REQUIRED)

TRACK BAR STUD-4269

•110-140 LB. FT.

VENT-4338

VENT MUST POINT

TO THE REAR

CLIP-374998-S100

BUMPER ASSEMBLY-4906

BUSHING-500939

(4 REQUIRED)

WASHER-18171

(2 REQUIRED)

BOLT-40923-S2

(2 REQUIRED)

BOLT-39883-S8

(4 REQUIRED)

9-13 LB. FT.

NUT-33847-

9/16-12*100-130

LB. FT

L

OC

KWASHE R -34

785

-S 7

BACKING PLATE

ASSEMBLY

*2290 R.H. #2210 L.H.

REAR AXLE ASSEMBLY

4001 REFERENCE

TRACK BAR AND

BUSHING ASSEMBLY-5A639

NUT-55754-S7

9/16-12

80-105 LB. FT.

TRACK BAR AND

oJSHfNG ASSEMBLY

5A639

PARKING BRAKE

CABLE »2A635 R.H

•2A809 L.H.

(2 REQUIRED)

SHOCK ABSORBER-18080'

REFERENCE (2 REQUIRED)

•BOLT-2248

(8 REQUIRED)

• SEAL-2256

(2 REQUIRED)

PRONGS MUST BE SECURELY

LOCKED IN PLACE

WHEEL-1007

(2 REQUIRED)

INSULATOR-5536

(4 REQUIRED)

TIRE VALVE-1700

(2 REQUIRED

TIRE VALVE

XTENSION-1705©

(2 REQUIRED)

FRAME ASSEMBLY-5005

LOWER ARM-5A648

DRIVE SHAFT ASSEMBLY-4602

SPRING-5560

(2 REQUIRED)

• NUT-34447-S8

7/16-20

(8 REQUIRED)

30-45 LB. FT.

•BRAKE DRUM-1126

(2 REQUIRED)

TIRE-1508

(2 REQUIRED)

• NUT-372188-S32 (6 REQUIRED)

ASSEMBLE NUTS TO HOLD DRUM ASSEMBLY

SECURELY AGAINST FLANGE

BOLT-379334-S8

9/16-12

(2 REQUIRED)

NUT-375022-S2

70-90 LB. FT. NUT

90-120 LB. FT. BOLT

NUT-375022-S2

(2 REQUIRED)

-90 LB. FT. NUT

90-120 LB. FT. BOLT

BOLT-3 79334-S8

(2 REQUIRED)

NUT-34988-S4

(4 REQUIRED)

44-52 LB. FT.

FRAME ASSEMBLY-5005

REFERENCE

2

o

i

O

TO

Q

>

X

TO

O

3

n

Q

©USE 1705 VALVE EXTENSION

WITH FULL WHEEL COVERS

* TORQUE NUT OR BOLT

TORQUE NUT OR STUD

ITEMS MARKED •

PURCHASED AS PART OF

4001 REAR AXLE ASSEMBLY

NUT-375032-S36

1/2-23

(2 REQUIRED) 50-85 LB. FT.

SPRING MUST BE POSITIONED

AS SHOWN FOR R.H. SIDE

SPRING MUST BE POSITIONED

AS SHOWN FOR L.H. SiDE

NUT-375022-S2 (2 REQUIRED)

70-90 LB. FT. NUT

90-120 LB. FT. BOLTl

TIONAL

El 746-A

?

6

FIG. 14—Redr Axle Installation—Thunderbird—Typical Ford, Mercury, Meteor and Continental Markprocarmanuals.com

Page 208 of 413

04-02-11

Rear Axle — Removable Carrier Type

04-02-11

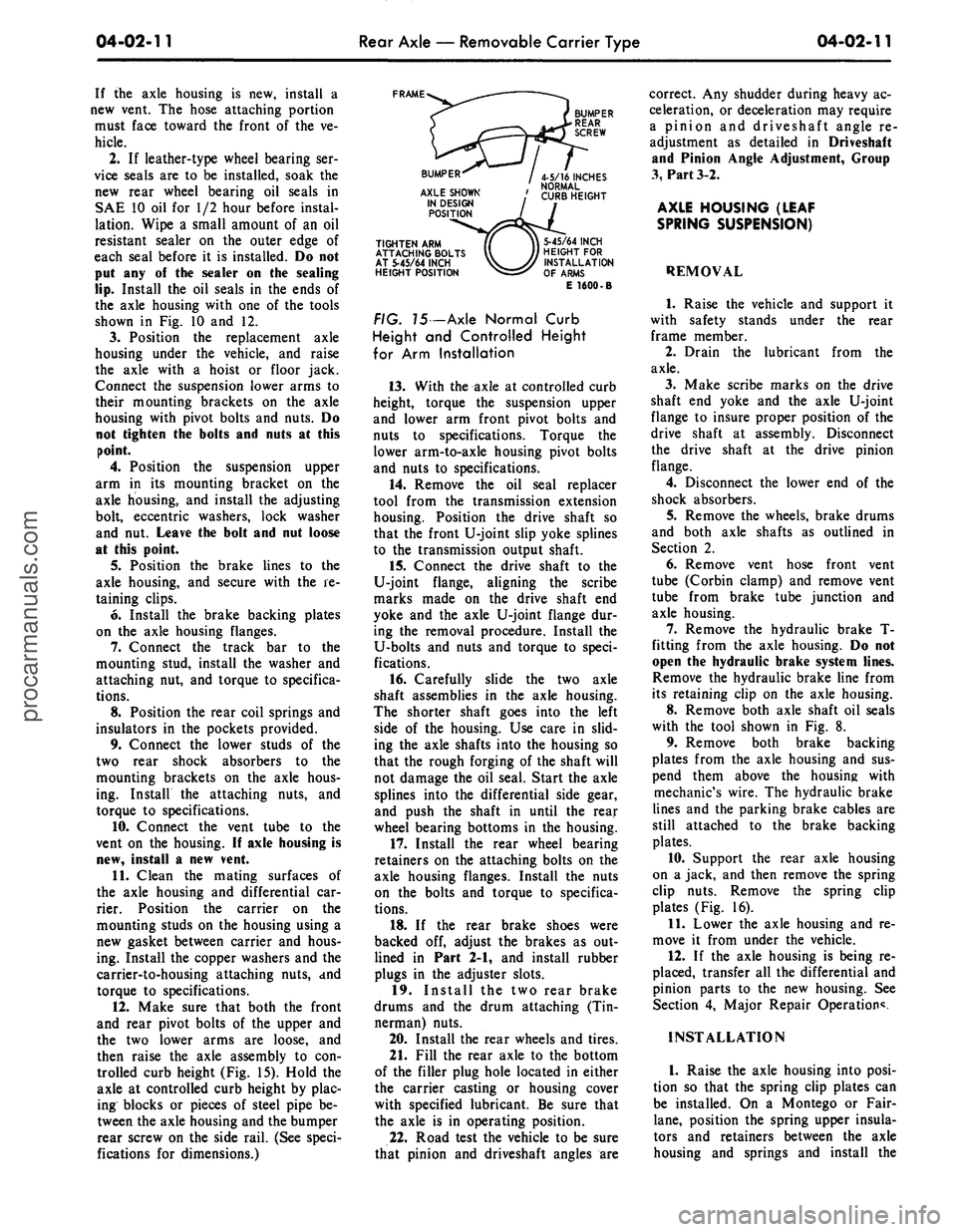

If the axle housing is new, install a

new vent. The hose attaching portion

must face toward the front of the ve-

hicle.

2.

If leather-type wheel bearing ser-

vice seals are to be installed, soak the

new rear wheel bearing oil seals in

SAE 10 oil for 1/2 hour before instal-

lation. Wipe a small amount of an oil

resistant sealer on the outer edge of

each seal before it is installed. Do not

put any of the sealer on the sealing

lip.

Install the oil seals in the ends of

the axle housing with one of the tools

shown in Fig. 10 and 12.

3.

Position the replacement axle

housing under the vehicle, and raise

the axle with a hoist or floor jack.

Connect the suspension lower arms to

their mounting brackets on the axle

housing with pivot bolts and nuts. Do

not tighten the bolts and nuts at this

point.

4.

Position the suspension upper

arm in its mounting bracket on the

axle housing, and install the adjusting

bolt, eccentric washers, lock washer

and nut. Leave the bolt and nut loose

at this point.

5.

Position the brake lines to the

axle housing, and secure with the re-

taining clips.

6. Install the brake backing plates

on the axle housing flanges.

7.

Connect the track bar to the

mounting stud, install the washer and

attaching nut, and torque to specifica-

tions.

8. Position the rear coil springs and

insulators in the pockets provided.

9. Connect the lower studs of the

two rear shock absorbers to the

mounting brackets on the axle hous-

ing. Install the attaching nuts, and

torque to specifications.

10.

Connect the vent tube to the

vent on the housing. If axle housing is

new, install a new vent.

11.

Clean the mating surfaces of

the axle housing and differential car-

rier. Position the carrier on the

mounting studs on the housing using a

new gasket between carrier and hous-

ing. Install the copper washers and the

carrier-to-housing attaching nuts, and

torque to specifications.

12.

Make sure that both the front

and rear pivot bolts of the upper and

the two lower arms are loose, and

then raise the axle assembly to con-

trolled curb height (Fig. 15). Hold the

axle at controlled curb height by plac-

ing blocks or pieces of steel pipe be-

tween the axle housing and the bumper

rear screw on the side rail. (See speci-

fications for dimensions.)

FRAME

TIGHTEN ARM

ATTACHING BOLTS

AT 5-45/64 INCH

HEIGHT POSITION

5-45/64 INCH

HEIGHT FOR

INSTALLATION

OF ARMS

E 1600-B

FIG. 75 -Axle Normal Curb

Height and Controlled Height

for Arm Installation

13.

With the axle at controlled curb

height, torque the suspension upper

and lower arm front pivot bolts and

nuts to specifications. Torque the

lower arm-to-axle housing pivot bolts

and nuts to specifications.

14.

Remove the oil seal replacer

tool from the transmission extension

housing. Position the drive shaft so

that the front U-joint slip yoke splines

to the transmission output shaft.

15.

Connect the drive shaft to the

U-joint flange, aligning the scribe

marks made on the drive shaft end

yoke and the axle U-joint flange dur-

ing the removal procedure. Install the

U-bolts and nuts and torque to speci-

fications.

16.

Carefully slide the two axle

shaft assemblies in the axle housing.

The shorter shaft goes into the left

side of the housing. Use care in slid-

ing the axle shafts into the housing so

that the rough forging of the shaft will

not damage the oil seal. Start the axle

splines into the differential side gear,

and push the shaft in until the rear

wheel bearing bottoms in the housing.

17.

Install the rear wheel bearing

retainers on the attaching bolts on the

axle housing flanges. Install the nuts

on the bolts and torque to specifica-

tions.

18.

If the rear brake shoes were

backed off, adjust the brakes as out-

lined in Part 2-1, and install rubber

plugs in the adjuster slots.

19.

Install the two rear brake

drums and the drum attaching (Tin-

nerman) nuts.

20.

Install the rear wheels and tires.

21.

Fill the rear axle to the bottom

of the filler plug hole located in either

the carrier casting or housing cover

with specified lubricant. Be sure that

the axle is in operating position.

22.

Road test the vehicle to be sure

that pinion and driveshaft angles are

correct. Any shudder during heavy ac-

celeration, or deceleration may require

a pinion and driveshaft angle re-

adjustment as detailed in Driveshaft

and Pinion Angle Adjustment, Group

3,

Part 3-2.

AXLE HOUSING (LEAF

SPRING SUSPENSION)

REMOVAL

1.

Raise the vehicle and support it

with safety stands under the rear

frame member.

2.

Drain the lubricant from the

axle.

3.

Make scribe marks on the drive

shaft end yoke and the axle U-joint

flange to insure proper position of the

drive shaft at assembly. Disconnect

the drive shaft at the drive pinion

flange.

4.

Disconnect the lower end of the

shock absorbers.

5.

Remove the wheels, brake drums

and both axle shafts as outlined in

Section 2.

6. Remove vent hose front vent

tube (Corbin clamp) and remove vent

tube from brake tube junction and

axle housing.

7.

Remove the hydraulic brake T-

fitting from the axle housing. Do not

open the hydraulic brake system lines.

Remove the hydraulic brake line from

its retaining clip on the axle housing.

8. Remove both axle shaft oil seals

with the tool shown in Fig. 8.

9. Remove both brake backing

plates from the axle housing and sus-

pend them above the housing with

mechanic's wire. The hydraulic brake

lines and the parking brake cables are

still attached to the brake backing

plates.

10.

Support the rear axle housing

on a jack, and then remove the spring

clip nuts. Remove the spring clip

plates (Fig. 16).

11.

Lower the axle housing and re-

move it from under the vehicle.

12.

If the axle housing is being re-

placed, transfer all the differential and

pinion parts to the new housing. See

Section 4, Major Repair Operation*.

INSTALLATION

1.

Raise the axle housing into posi-

tion so that the spring clip plates can

be installed. On a Montego or Fair-

lane,

position the spring upper insula-

tors and retainers between the axle

housing and springs and install theprocarmanuals.com

Page 211 of 413

04-02-14

Rear Axle

—

Removable Carrier Type

04-02-14

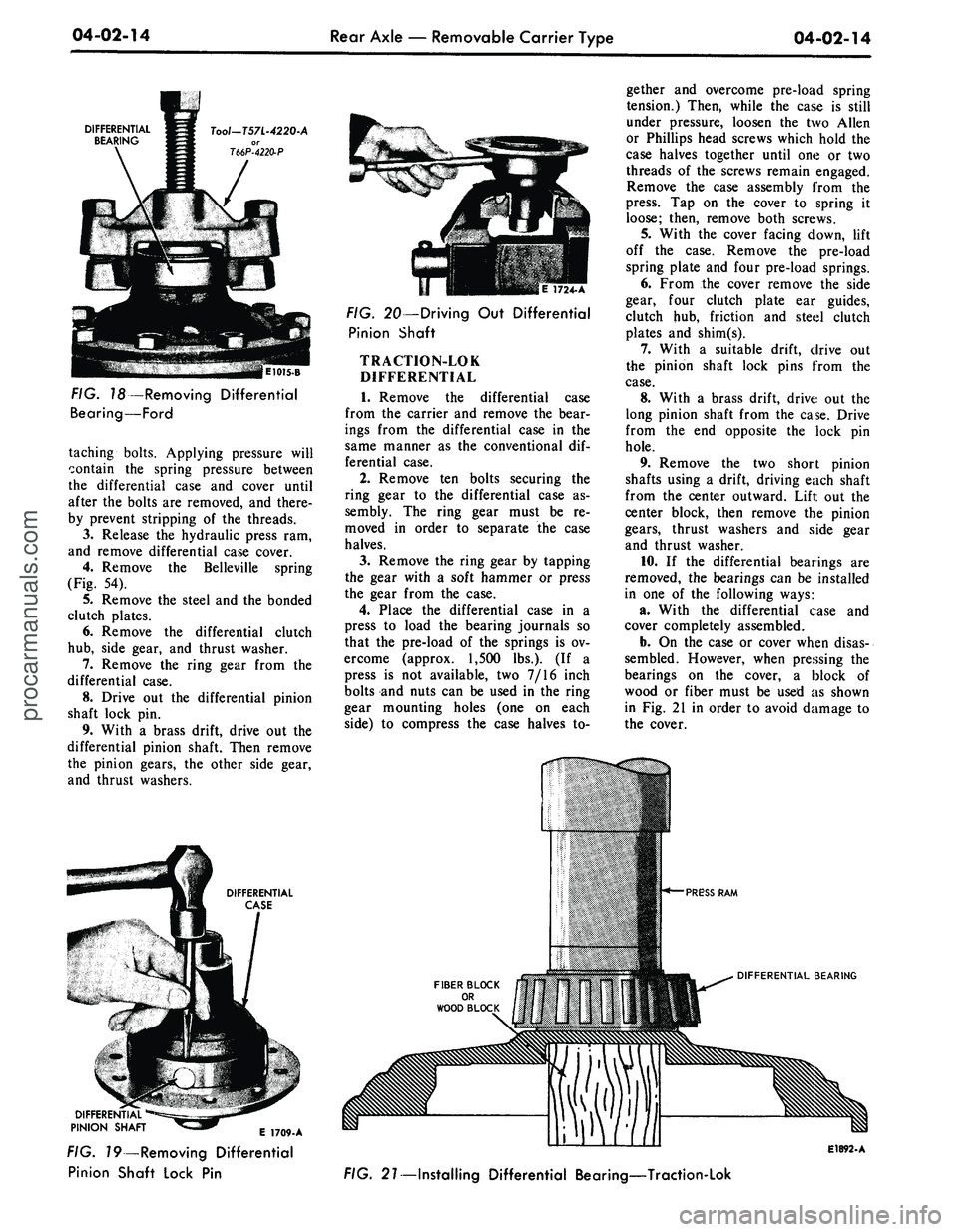

DIFFERENTIAL

BEARING

Tool—

7

571-4220-A

T66P°4220-P

E1015-B

FIG. 18—Removing Differential

Bearing—Ford

taching bolts. Applying pressure will

contain

the

spring pressure between

the differential case

and

cover until

after

the

bolts

are

removed,

and

there-

by prevent stripping

of the

threads.

3.

Release

the

hydraulic press

ram,

and remove differential case cover.

4.

Remove

the

Belleville spring

(Fig.

54).

5.

Remove

the

steel

and the

bonded

clutch plates.

6. Remove

the

differential clutch

hub,

side gear,

and

thrust washer.

7.

Remove

the

ring gear from

the

differential case.

8. Drive

out the

differential pinion

shaft lock

pin.

9. With

a

brass drift, drive

out the

differential pinion shaft. Then remove

the pinion gears,

the

other side gear,

and thrust washers.

E 1724-A

FIG. 20—Driving

Out

Differential

Pinion Shaft

TRACTION-LOK

DIFFERENTIAL

1.

Remove

the

differential case

from

the

carrier

and

remove

the

bear-

ings from

the

differential case

in the

same manner

as the

conventional

dif-

ferential case.

2.

Remove

ten

bolts securing

the

ring gear

to the

differential case

as-

sembly.

The

ring gear must

be re-

moved

in

order

to

separate

the

case

halves.

3.

Remove

the

ring gear

by

tapping

the gear with

a

soft hammer

or

press

the gear from

the

case.

4.

Place

the

differential case

in a

press

to

load

the

bearing journals

so

that

the

pre-load

of the

springs

is ov-

ercome (approx.

1,500

lbs.).

(If a

press

is not

available,

two 7/16

inch

bolts

and

nuts

can be

used

in the

ring

gear mounting holes

(one on

each

side)

to

compress

the

case halves

to-

gether

and

overcome pre-load spring

tension.) Then, while

the

case

is

still

under pressure, loosen

the two

Allen

or Phillips head screws which hold

the

case halves together until

one or two

threads

of the

screws remain engaged.

Remove

the

case assembly from

the

press.

Tap on the

cover

to

spring

it

loose; then, remove both screws.

5.

With

the

cover facing down, lift

off

the

case. Remove

the

pre-load

spring plate

and

four pre-load springs.

6. From

the

cover remove

the

side

gear, four clutch plate

ear

guides,

clutch

hub,

friction

and

steel clutch

plates

and

shim(s).

7.

With

a

suitable drift, drive

out

the pinion shaft lock pins from

the

case.

8. With

a

brass drift, drive

out the

long pinion shaft from

the

case. Drive

from

the end

opposite

the

lock

pin

hole.

9. Remove

the two

short pinion

shafts using

a

drift, driving each shaft

from

the

center outward. Lift

out the

center block, then remove

the

pinion

gears,

thrust washers

and

side gear

and thrust washer.

10.

If the

differential bearings

are

removed,

the

bearings

can be

installed

in

one of the

following ways:

a. With

the

differential case

and

cover completely assembled.

b.

On the

case

or

cover when disas-

sembled. However, when pressing

the

bearings

on the

cover,

a

block

of

wood

or

fiber must

be

used

as

shown

in Fig.

21 in

order

to

avoid damage

to

the cover.

E 1709-A

FIG. 79—Removing Differential

Pinion Shaft Lock

Pin

DIFFERENTIAL BEARING

E1892-A

FIG. 21—Installing Differential Bearing—Traction-Lokprocarmanuals.com