change wheel FORD MUSTANG 1969 Volume One Chassis

[x] Cancel search | Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 19 of 413

02-01-08

Brakes

02-01-08

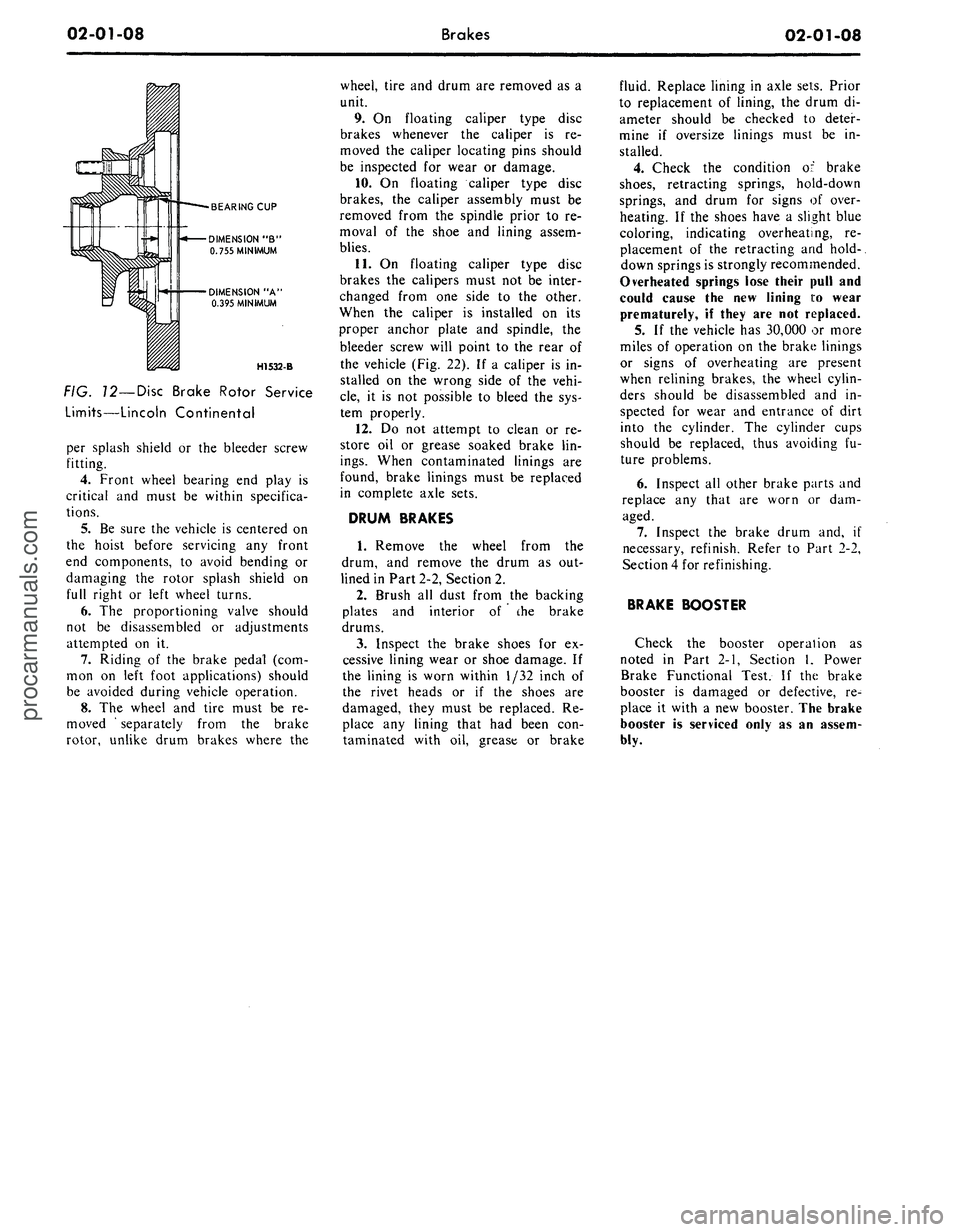

BEARING CUP

DIMENSION "B"

0.755 MINIMUM

DIMENSION "A'

0.395 MINIMUM

H1532-B

FIG. 12—Disc Brake Rotor Service

Limits—Lincoln Continental

per splash shield or the bleeder screw

fitting.

4.

Front wheel bearing end play is

critical and must be within specifica-

tions.

5.

Be sure the vehicle is centered on

the hoist before servicing any front

end components, to avoid bending or

damaging the rotor splash shield on

full right or left wheel turns.

6. The proportioning valve should

not be disassembled or adjustments

attempted on it.

7.

Riding of the brake pedal (com-

mon on left foot applications) should

be avoided during vehicle operation.

8. The wheel and tire must be re-

moved ' separately from the brake

rotor, unlike drum brakes where the

wheel, tire and drum are removed as a

unit.

9. On floating caliper type disc

brakes whenever the caliper is re-

moved the caliper locating pins should

be inspected for wear or damage.

10.

On floating caliper type disc

brakes, the caliper assembly must be

removed from the spindle prior to re-

moval of the shoe and lining assem-

blies.

11.

On floating caliper type disc

brakes the calipers must not be inter-

changed from one side to the other.

When the caliper is installed on its

proper anchor plate and spindle, the

bleeder screw will point to the rear of

the vehicle (Fig. 22). If a caliper is in-

stalled on the wrong side of the vehi-

cle,

it is not possible to bleed the sys-

tem properly.

12.

Do not attempt to clean or re-

store oil or grease soaked brake lin-

ings.

When contaminated linings are

found, brake linings must be replaced

in complete axle sets.

DRUM BRAKES

1.

Remove the wheel from the

drum, and remove the drum as out-

lined in Part 2-2, Section 2.

2.

Brush all dust from the backing

plates and interior of the brake

drums.

3.

Inspect the brake shoes for ex-

cessive lining wear or shoe damage. If

the lining is worn within 1/32 inch of

the rivet heads or if the shoes are

damaged, they must be replaced. Re-

place any lining that had been con-

taminated with oil, grease or brake

fluid. Replace lining in axle sets. Prior

to replacement of lining, the drum di-

ameter should be checked to deter-

mine if oversize linings must be in-

stalled.

4.

Check the condition of brake

shoes,

retracting springs, hold-down

springs, and drum for signs of over-

heating. If the shoes have a slight blue

coloring, indicating overheating, re-

placement of the retracting and hold-.

down springs is strongly recommended.

Overheated springs lose their pull and

could cause the new lining i:o wear

prematurely, if they are not replaced.

5. If the vehicle has 30,000 or more

miles of operation on the brake linings

or signs of overheating are present

when relining brakes, the wheel cylin-

ders should be disassembled and in-

spected for wear and entrance of dirt

into the cylinder. The cylinder cups

should be replaced, thus avoiding fu-

ture problems.

6. Inspect all other brake parts and

replace any that are worn or dam-

aged.

7.

Inspect the brake drum and, if

necessary, refinish. Refer to Part 2-2,

Section 4 for refinishing.

BRAKE BOOSTER

Check the booster operation as

noted in Part 2-1, Section 1, Power

Brake Functional Test. If the brake

booster is damaged or defective, re-

place it with a new booster. The brake

booster is serviced only as an assem-

bly.procarmanuals.com

Page 25 of 413

02-02-06

Brake

System

02-02-06

SHOE GUIDE (ANCHOR

PIN)

PLATE

SHOE GUIDE (ANCHOR

PIN)

PLATE

WASHER

PRIMARY SHOE

-TC

-ANCHOR

SPRING

PARKING

BRAKE LEVER

RETAINING

CLIP

SECONDARY

SHOE

PRIMARY

SHOE

CABLE HOOK

PARKING

BRAKE CABLE

AND HOUSING

PIVOT

NUT

AUTOMATIC

ADJUSTER

SPRING

H

1649-

A

FIG. 8—Self-Adjusting Brake Assemblies—Typical

BRAKE BOOSTER SYSTEM

This diaphragm-type brake booster

is

a

self-contained vacuum-hydraulic

braking unit mounted

on the

engine

side

of the

dash panel.

The brake booster

is of the

vacuum

suspended-type which utilizes engine

intake manifold vacuum

and

atmos-

pheric pressure

for its

power.

Adjustment

of the

push

rod and re-

placement

of the

check valve

and

grommet

are the

only services permit-

ted

on the

brake booster.

The

booster

unit

is to be

exchanged when

it is in-

spected, checked

and

found

to be de-

fective.

PARKING BRAKE

An independent foot-operated park-

ing brake control actuates

the

rear

wheel brake shoes through

a

cable

linkage.

On all

models except Ford,

Mercury, Meteor, Thunderbird

and

Continental Mark

III, the

operating

cable

is

routed from

the

parking brake

control assembly

to the

equalizer.

On

Ford, Mercury, Meteor, Thunderbird,

and Continental Mark

III, the

operat-

ing cable

is

routed from

the

parking

brake control assembly

to the

actuator

assembly.

An

intermediate cable

con-

nects

the

actuator

to the

equalizer.

The rear brake cables connect

the

equalizer assembly

to the

parking

brake lever

at

each rear secondary

shoe

(Fig. 8).

Two types

of

brake pedal control

are used.

The

automatic (vacuum)

re-

lease type

(Fig. 9) is

used

on the Mer-

cury, Ford

LTD,

Meteor LeMoyne,

Thunderbird, Continental Mark

III

and Lincoln Continental models.

All

other models

use the

manual release-

type

(Fig. 10).

On

the

automatic-type,

the

vacuum

PISTON

ROD

VACUUM POWER UNIT

RELEASE LEVER

PEDAL

H 1635-A

FIG. 9—Parking Brake Control Assembly

With Automatic Release—Typicalprocarmanuals.com

Page 26 of 413

02-02-07

Brake System

02-02-07

ANTI-SKID CONTROL SYSTEM

RELEASE PAWL CAM PIN

RELEASE PAWL CAM LEVER

RELEASE CABLE

H

1636-

A

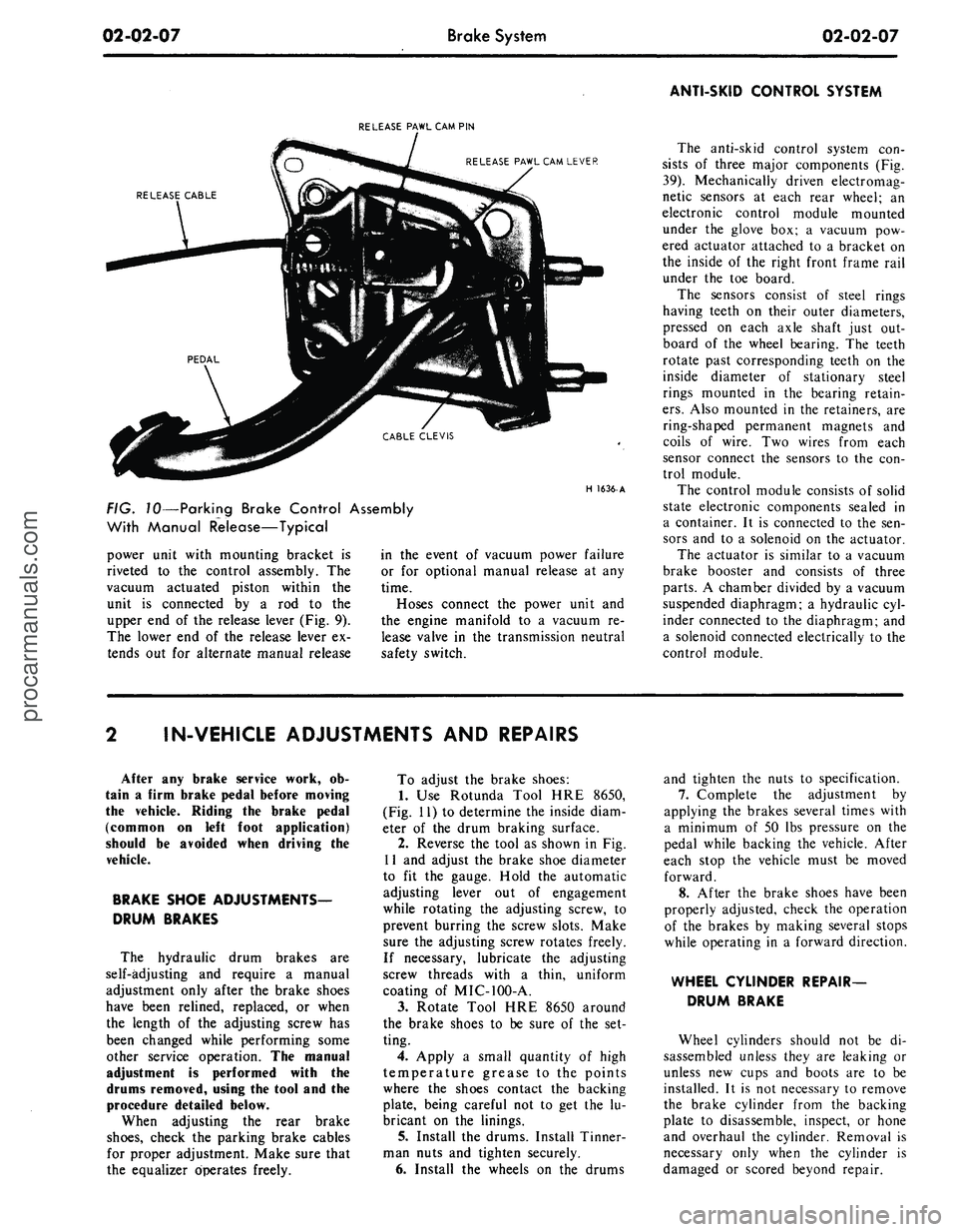

FIG. 10—Parking Brake Control Assembly

With Manual Release—Typical

power unit with mounting bracket is

riveted to the control assembly. The

vacuum actuated piston within the

unit is connected by a rod to the

upper end of the release lever (Fig. 9).

The lower end of the release lever ex-

tends out for alternate manual release

in the event of vacuum power failure

or for optional manual release at any

time.

Hoses connect the power unit and

the engine manifold to a vacuum re-

lease valve in the transmission neutral

safety switch.

The anti-skid control system con-

sists of three major components (Fig.

39).

Mechanically driven electromag-

netic sensors at each rear wheel; an

electronic control module mounted

under the glove box; a vacuum pow-

ered actuator attached to a bracket on

the inside of the right front frame rail

under the toe board.

The sensors consist of steel rings

having teeth on their outer diameters,

pressed on each axle shaft just out-

board of the wheel bearing. The teeth

rotate past corresponding teeth on the

inside diameter of stationary steel

rings mounted in the bearing retain-

ers.

Also mounted in the retainers, are

ring-shaped permanent magnets and

coils of wire. Two wires from each

sensor connect the sensors to the con-

trol module.

The control module consists of solid

state electronic components sealed in

a container. It is connected to the sen-

sors and to a solenoid on the actuator.

The actuator is similar to a vacuum

brake booster and consists of three

parts.

A chamber divided by a vacuum

suspended diaphragm; a hydraulic cyl-

inder connected to the diaphragm; and

a solenoid connected electrically to the

control module.

IN-VEHICLE ADJUSTMENTS AND REPAIRS

After any brake service work, ob-

tain a firm brake pedal before moving

the vehicle. Riding the brake pedal

(common on left foot application)

should be avoided when driving the

vehicle.

BRAKE SHOE ADJUSTMENTS—

DRUM BRAKES

The hydraulic drum brakes are

self-adjusting and require a manual

adjustment only after the brake shoes

have been relined, replaced, or when

the length of the adjusting screw has

been changed while performing some

other service operation. The manual

adjustment is performed with the

drums removed, using the tool and the

procedure detailed below.

When adjusting the rear brake

shoes,

check the parking brake cables

for proper adjustment. Make sure that

the equalizer operates freely.

To adjust the brake shoes:

1.

Use Rotunda Tool HRE 8650,

(Fig. 11) to determine the inside diam-

eter of the drum braking surface.

2.

Reverse the tool as shown in Fig.

11 and adjust the brake shoe diameter

to fit the gauge. Hold the automatic

adjusting lever out of engagement

while rotating the adjusting screw, to

prevent burring the screw slots. Make

sure the adjusting screw rotates freely.

If necessary, lubricate the adjusting

screw threads with a thin, uniform

coating of MIC-100-A.

3.

Rotate Tool HRE 8650 around

the brake shoes to be sure of the set-

ting.

4.

Apply a small quantity of high

temperature grease to the points

where the shoes contact the backing

plate, being careful not to get the lu-

bricant on the linings.

5. Install the drums. Install Tinner-

man nuts and tighten securely.

6. Install the wheels on the drums

and tighten the nuts to specification.

7.

Complete the adjustment by

applying the brakes several times with

a minimum of 50 lbs pressure on the

pedal while backing the vehicle. After

each stop the vehicle must be moved

forward.

8. After the brake shoes have been

properly adjusted, check the operation

of the brakes by making several stops

while operating in a forward direction.

WHEEL CYLINDER REPAIR-

DRUM BRAKE

Wheel cylinders should not be di-

sassembled unless they are leaking or

unless new cups and boots are to be

installed. It is not necessary to remove

the brake cylinder from the backing

plate to disassemble, inspect, or hone

and overhaul the cylinder. Removal is

necessary only when the cylinder is

damaged or scored beyond repair.procarmanuals.com

Page 70 of 413

03-01-05

Suspension — Steering, Wheels And Tires — General Service

03-01-05

type of equipment is used, follow the

installation and inspection instructions

provided by the equipment manufactu-

rer.

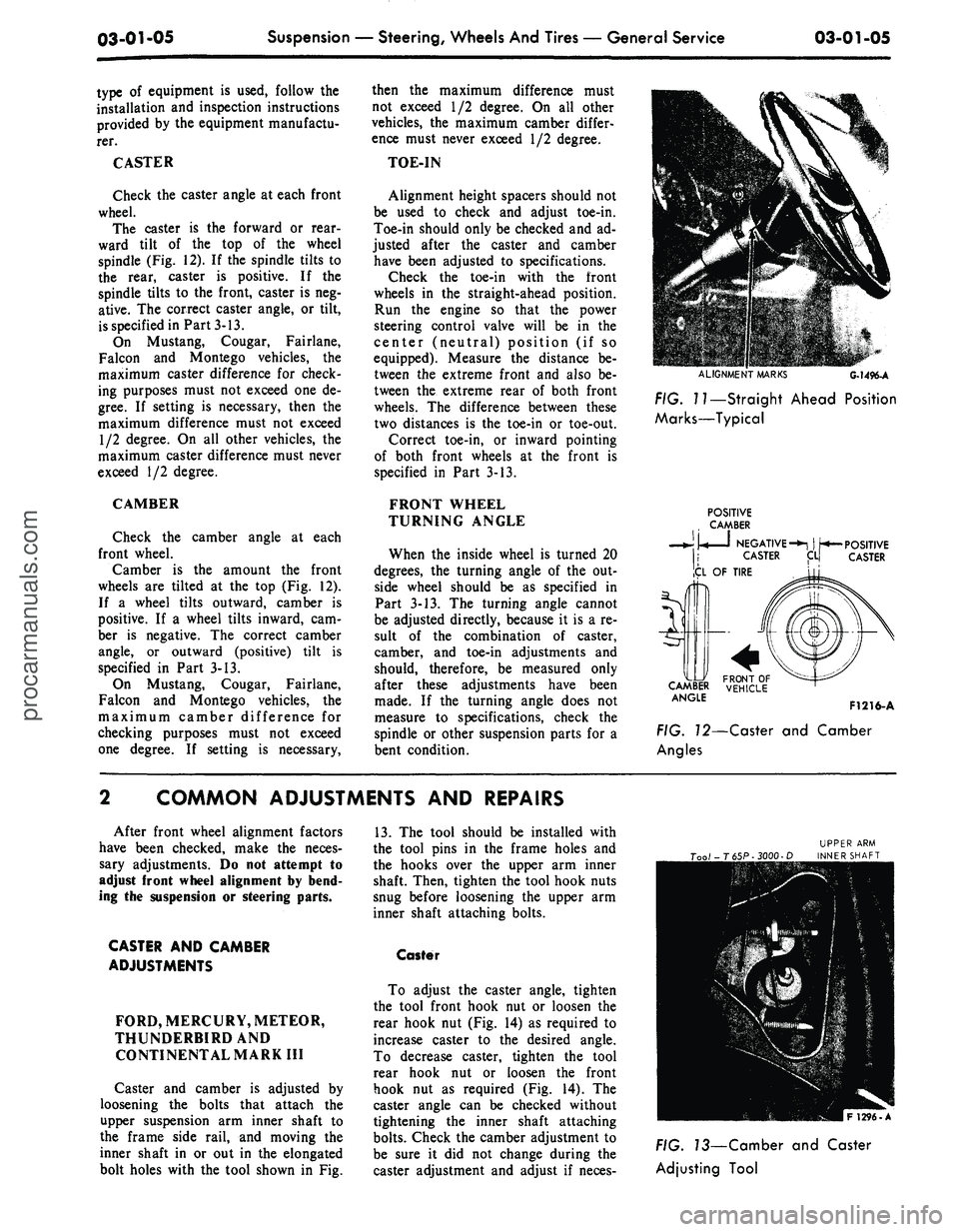

CASTER

Check the caster angle at each front

wheel.

The caster is the forward or rear-

ward tilt of the top of the wheel

spindle (Fig. 12). If the spindle tilts to

the rear, caster is positive. If the

spindle tilts to the front, caster is neg-

ative. The correct caster angle, or tilt,

is specified in Part 3-13.

On Mustang, Cougar, Fairlane,

Falcon and Montego vehicles, the

maximum caster difference for check-

ing purposes must not exceed one de-

gree.

If setting is necessary, then the

maximum difference must not exceed

1/2 degree. On all other vehicles, the

maximum caster difference must never

exceed 1/2 degree.

CAMBER

Check the camber angle at each

front wheel.

Camber is the amount the front

wheels are tilted at the top (Fig. 12).

If a wheel tilts outward, camber is

positive. If a wheel tilts inward, cam-

ber is negative. The correct camber

angle, or outward (positive) tilt is

specified in Part 3-13.

On Mustang, Cougar, Fairlane,

Falcon and Montego vehicles, the

maximum camber difference for

checking purposes must not exceed

one degree. If setting is necessary,

then the maximum difference must

not exceed 1/2 degree. On all other

vehicles, the maximum camber differ-

ence must never exceed 1/2 degree.

TOE-IN

Alignment height spacers should not

be used to check and adjust toe-in.

Toe-in should only be checked and ad-

justed after the caster and camber

have been adjusted to specifications.

Check the toe-in with the front

wheels in the straight-ahead position.

Run the engine so that the power

steering control valve will be in the

center (neutral) position (if so

equipped). Measure the distance be-

tween the extreme front and also be-

tween the extreme rear of both front

wheels. The difference between these

two distances is the toe-in or toe-out.

Correct toe-in, or inward pointing

of both front wheels at the front is

specified in Part 3-13.

FRONT WHEEL

TURNING ANGLE

When the inside wheel is turned 20

degrees, the turning angle of the out-

side wheel should be as specified in

Part 3-13. The turning angle cannot

be adjusted directly, because it is a re-

sult of the combination of caster,

camber, and toe-in adjustments and

should, therefore, be measured only

after these adjustments have been

made. If the turning angle does not

measure to specifications, check the

spindle or other suspension parts for a

bent condition.

ALIGNMENT

MARKS

G-1496-A

FIG. I?—Straight Ahead Position

Marks—Typical

POSITIVE

CAMBER

• •

NEGATIVE-*!

| ^*—

CASTER

ICL

OF TIRE

POSITIVE

CASTER

5r\

CA&U

ANGlE

F1216-A

FIG. 72—Caster and Camber

Angles

COMMON ADJUSTMENTS AND REPAIRS

After front wheel alignment factors

have been checked, make the neces-

sary adjustments. Do not attempt to

adjust front wheel alignment by bend-

ing the suspension or steering parts.

CASTER AND CAMBER

ADJUSTMENTS

FORD, MERCURY, METEOR,

THUNDERBIRDAND

CONTINENTAL MARK III

Caster and camber is adjusted by

loosening the bolts that attach the

upper suspension arm inner shaft to

the frame side rail, and moving the

inner shaft in or out in the elongated

bolt holes with the tool shown in Fig.

13.

The tool should be installed with

the tool pins in the frame holes and

the hooks over the upper arm inner

shaft. Then, tighten the tool hook nuts

snug before loosening the upper arm

inner shaft attaching bolts.

Caster

To adjust the caster angle, tighten

the tool front hook nut or loosen the

rear hook nut (Fig. 14) as required to

increase caster to the desired angle.

To decrease caster, tighten the tool

rear hook nut or loosen the front

hook nut as required (Fig. 14). The

caster angle can be checked without

tightening the inner shaft attaching

bolts.

Check the camber adjustment to

be sure it did not change during the

caster adjustment and adjust if neces-

FIG. 73—Camber and Caster

Adjusting Toolprocarmanuals.com

Page 71 of 413

03-01-06

Suspension — Steering, Wheels And Tires — General Service

03-01-06

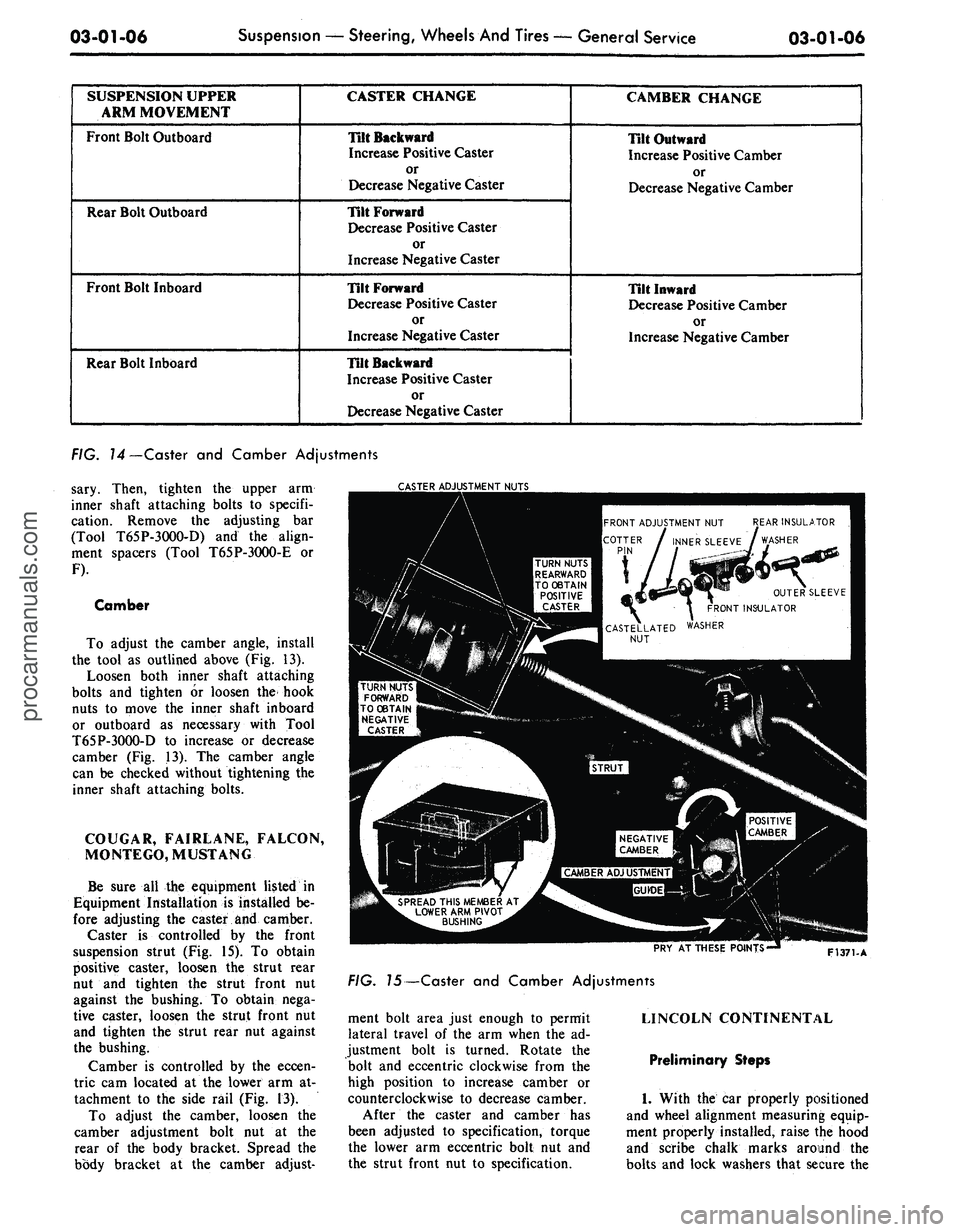

SUSPENSION UPPER

ARM MOVEMENT

Front Bolt Outboard

Rear Bolt Outboard

Front Bolt Inboard

Rear Bolt Inboard

CASTER CHANGE

Tilt Backward

Increase Positive Caster

or

Decrease Negative Caster

Tilt Forward

Decrease Positive Caster

or

Increase Negative Caster

Tilt Forward

Decrease Positive Caster

or

Increase Negative Caster

Tilt Backward

Increase Positive Caster

or

Decrease Negative Caster

CAMBER CHANGE

Tilt Outward

Increase Positive Camber

or

Decrease Negative Camber

Tilt Inward

Decrease Positive Camber

or

Increase Negative Camber

FIG. 14—Caster and Camber Adjustments

sary. Then, tighten the upper arm

inner shaft attaching bolts to specifi-

cation. Remove the adjusting bar

(Tool T65P-3OOO-D) and the align-

ment spacers (Tool T65P-3O00-E or

F).

Camber

To adjust the camber angle, install

the tool as outlined above (Fig. 13).

Loosen both inner shaft attaching

bolts and tighten or loosen the hook

nuts to move the inner shaft inboard

or outboard as necessary with Tool

T65P-3OOO-D to increase or decrease

camber (Fig. 13). The camber angle

can be checked without tightening the

inner shaft attaching bolts.

COUGAR, FAIRLANE, FALCON,

MONTEGO, MUSTANG

Be sure all the equipment listed in

Equipment Installation is installed be-

fore adjusting the caster and camber.

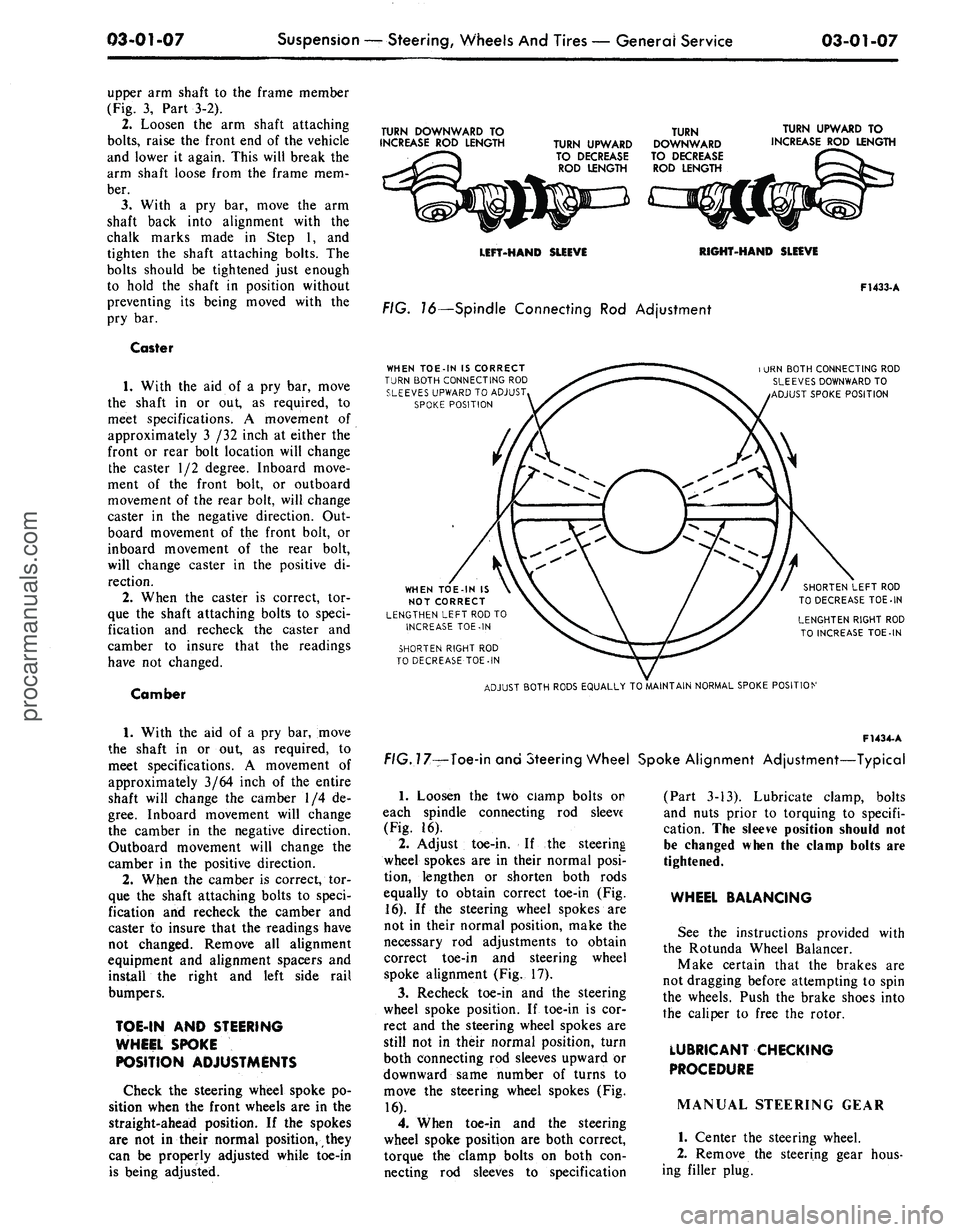

Caster is controlled by the front

suspension strut (Fig. 15). To obtain

positive caster, loosen the strut rear

nut and tighten the strut front nut

against the bushing. To obtain nega-

tive caster, loosen the strut front nut

and tighten the strut rear nut against

the bushing.

Camber is controlled by the eccen-

tric cam located at the lower arm at-

tachment to the side rail (Fig. 13).

To adjust the camber, loosen the

camber adjustment bolt nut at the

rear of the body bracket. Spread the

body bracket at the camber adjust-

TER ADJUSTMENT NUTS

EAR INSULATOR

WASHER

FRONT ADJUSTMENT NUT

INNER SLEEVE

TURN NUTS

REARWARD

TO OBTAIN

POSITIVE

CASTER

OUTER SLEEVE

RONT INSULATOR

WASHER

CASTELLATED

NUT

TURN NUTS

FORWARD

TO OBTAIN

NEGATIVE

CASTER

NEGATIVE

CAMBER

SPREAD THIS MEMBER AT

LOWER ARM PIVOT

BUSHING

PRY AT THESE POINTS'

F1371-A

FIG. J5—Caster and Camber Adjustments

ment bolt area just enough to permit

lateral travel of the arm when the ad-

justment bolt is turned. Rotate the

bolt and eccentric clockwise from the

high position to increase camber or

counterclockwise to decrease camber.

After the caster and camber has

been adjusted to specification, torque

the lower arm eccentric bolt nut and

the strut front nut to specification.

LINCOLN CONTINENTAL

Preliminary Steps

1.

With the car properly positioned

and wheel alignment measuring equip-

ment properly installed, raise the hood

and scribe chalk marks around the

bolts and lock washers that secure theprocarmanuals.com

Page 72 of 413

03-01-07

Suspension — Steering, Wheels And Tires — General Service

03-01-07

upper arm shaft to the frame member

(Fig. 3, Part 3-2).

2.

Loosen the arm shaft attaching

bolts,

raise the front end of the vehicle

and lower it again. This will break the

arm shaft loose from the frame mem-

ber.

3.

With a pry bar, move the arm

shaft back into alignment with the

chalk marks made in Step 1, and

tighten the shaft attaching bolts. The

bolts should be tightened just enough

to hold the shaft in position without

preventing its being moved with the

pry bar.

Caster

1.

With the aid of a pry bar, move

the shaft in or out, as required, to

meet specifications. A movement of

approximately 3 /32 inch at either the

front or rear bolt location will change

the caster 1/2 degree. Inboard move-

ment of the front bolt, or outboard

movement of the rear bolt, will change

caster in the negative direction. Out-

board movement of the front bolt, or

inboard movement of the rear bolt,

will change caster in the positive di-

rection.

2.

When the caster is correct, tor-

que the shaft attaching bolts to speci-

fication and recheck the caster and

camber to insure that the readings

have not changed.

Camber

TURN DOWNWARD TO

INCREASE ROD LENGTH

TURN UPWARD

TO DECREASE

ROD LENGTH

TURN

DOWNWARD

TO DECREASE

ROD LENGTH

TURN UPWARD TO

INCREASE ROD LENGTH

LEFT-HAND SLEEVE

RIGHT-HAND SLEEVE

FIG. 16—Spindle Connecting Rod Adjustment

WHEN TOE-IN IS CORRECT

TURN BOTH CONNECTING ROD

SLEEVES UPWARD TO ADJUST

SPOKE POSITION

F1433-A

i URN BOTH CONNECTING ROD

SLEEVES DOWNWARD TO

ADJUST SPOKE POSITION

WHEN TOE-IN IS

NOT CORRECT

LENGTHEN LEFT ROD TO

INCREASE TOE-IN

SHORTEN RIGHT ROD

TO DECREASE TOE-IN

SHORTEN LEFT ROD

TO DECREASE TOE-IN

LENGHTEN RIGHT ROD

TO INCREASE TOE-IN

ADJUST BOTH RODS EQUALLY TO MAINTAIN NORMAL SPOKE POSITION

1.

With the aid of a pry bar, move

the shaft in or out, as required, to

meet specifications. A movement of

approximately 3/64 inch of the entire

shaft will change the camber 1/4 de-

gree.

Inboard movement will change

the camber in the negative direction.

Outboard movement will change the

camber in the positive direction.

2.

When the camber is correct, tor-

que the shaft attaching bolts to speci-

fication and recheck the camber and

caster to insure that the readings have

not changed. Remove all alignment

equipment and alignment spacers and

install the right and left side rail

bumpers.

TOE-IN AND STEERING

WHEEL SPOKE

POSITION ADJUSTMENTS

Check the steering wheel spoke po-

sition when the front wheels are in the

straight-ahead position. If the spokes

are not in their normal position, they

can be properly adjusted while toe-in

is being adjusted.

F1434-

A

f/G.77—Toe-in and Steering Wheel Spoke Alignment Adjustment—Typical

1.

Loosen the two ciamp bolts or

each spindle connecting rod sleeve

(Fig. 16).

2.

Adjust toe-in. If the steering

wheel spokes are in their normal posi-

tion, lengthen or shorten both rods

equally to obtain correct toe-in (Fig.

16).

If the steering wheel spokes are

not in their normal position, make the

necessary rod adjustments to obtain

correct toe-in and steering wheel

spoke alignment (Fig. 17).

3.

Recheck toe-in and the steering

wheel spoke position. If toe-in is cor-

rect and the steering wheel spokes are

still not in their normal position, turn

both connecting rod sleeves upward or

downward same number of turns to

move the steering wheel spokes (Fig.

16).

4.

When toe-in and the steering

wheel spoke position are both correct,

torque the clamp bolts on both con-

necting rod sleeves to specification

(Part 3-13). Lubricate clamp, bolts

and nuts prior to torquing to specifi-

cation. The sleeve position should not

be changed when the clamp bolts are

tightened.

WHEEL BALANCING

See the instructions provided with

the Rotunda Wheel Balancer.

Make certain that the brakes are

not dragging before attempting to spin

the wheels. Push the brake shoes into

the caliper to free the rotor.

LUBRICANT CHECKING

PROCEDURE

MANUAL STEERING GEAR

1.

Center the steering wheel.

2.

Remove the steering gear hous-

ing filler plug.procarmanuals.com

Page 115 of 413

03-05-02

Steering Columns

And

Linkage

03-05-02

which also will shear away during

im-

pact.

TILT STEERING COLUMNS

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed.

The tilt column features nine driv-

ing positions (four

up and

four down

from

a

center position).

The

.column

also features

a

turn signal switch with

a lane-changer position turn indicating

position

and

emergency warning flash-

er control.

TILT-AWAY STEERING COLUMNS

The tilt-away steering column

fea-

tures nine driving positions (four

up

and four down from

a

center position)

and

a

tilt-away position that

is

auto-

matically accomplished

on

Mustang

and Cougar models when

the

ignition

key

is

turned

to the

OFF

position

and

the left door

is

opened.

On

Thunder-

bird models,

the

tilt-away occurs when

the shift lever

is

placed

in

PARK

and

the driverns door

is

opened.

The steering column

is of the col-

lapsible type

to

lessen

the

possibility

of injury

to the

driver

of the

vehicle

should

he

become involved

in an

acci-

dent.

The

lower

end of the

steering

column tube

at the

bellows area will

collapse approximately

six

inches

upon

a

hard impact.

The shift tube

and the

steering shaft

are provided with plastic dowels

and

will shear

and

allow them

to

collapse

in proportion

to the

outer tube upon

impact.

Once

the

steering column

has

been

collapsed,

a

complete

new

column

must

be

installed along with mounting

brackets which will also shear away

during impact.

IN-VEHICLE ADJUSTMENTS

AND

REPAIRS

STEERING WHEEL SPOKE

POSITION ADJUSTMENT

When

the

steering gear

is on the

high point,

the

front wheels should

be

in

the

straight-ahead position

and the

steering wheel spokes should

be in

their normal position with

the

Pitman

arm pointing directly forward.

If the

spokes

are not in

their normal posi-

tion, they

can be

adjusted without

dis-

turbing

the

toe-in adjustment (Part

3-1).

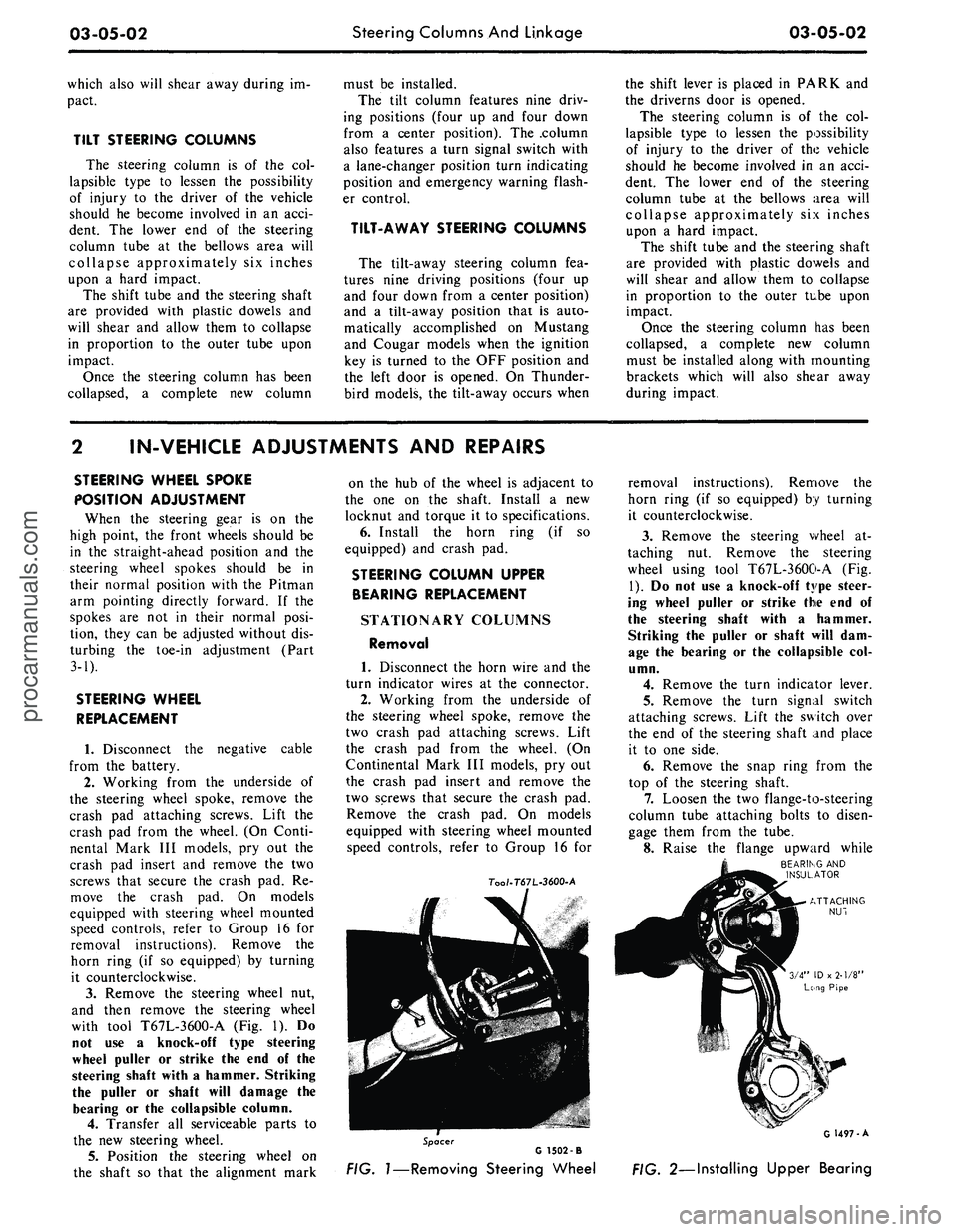

STEERING WHEEL

REPLACEMENT

1.

Disconnect

the

negative cable

from

the

battery.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

crash

pad

attaching screws. Lift

the

crash

pad

from

the

wheel.

(On

Conti-

nental Mark

III

models,

pry out the

crash

pad

insert

and

remove

the two

screws that secure

the

crash

pad. Re-

move

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

3.

Remove

the

steering wheel

nut,

and then remove

the

steering wheel

with tool T67L-3600-A

(Fig. 1). Do

not

use a

knock-off type steering

wheel puller

or

strike

the end of the

steering shaft with

a

hammer. Striking

the puller

or

shaft will damage

the

bearing

or the

collapsible column.

4.

Transfer

all

serviceable parts

to

the

new

steering wheel.

5.

Position

the

steering wheel

on

the shaft

so

that

the

alignment mark

on

the hub of the

wheel

is

adjacent

to

the

one on the

shaft. Install

a new

locknut

and

torque

it to

specifications.

6. Install

the

horn ring

(if so

equipped)

and

crash

pad.

STEERING COLUMN UPPER

BEARING REPLACEMENT

STATIONARY COLUMNS

Removal

1. Disconnect

the

horn wire

and the

turn indicator wires

at the

connector.

2.

Working from

the

underside

of

the steering wheel spoke, remove

the

two crash

pad

attaching screws. Lift

the crash

pad

from

the

wheel.

(On

Continental Mark

III

models,

pry out

the crash

pad

insert

and

remove

the

two screws that secure

the

crash

pad.

Remove

the

crash

pad. On

models

equipped with steering wheel mounted

speed controls, refer

to

Group

16 for

7oo/-T67L-3600-A

removal instructions). Remove

the

horn ring

(if so

equipped)

by

turning

it counterclockwise.

3.

Remove

the

steering wheel

at-

taching

nut.

Remove

the

steering

wheel using tool T67L-3600-A

(Fig.

1).

Do not use a

knock-off type steer-

ing wheel puller

or

strike

the end of

the steering shaft with

a

hammer.

Striking

the

puller

or

shaft will

dam-

age

the

bearing

or the

collapsible

col-

umn.

4.

Remove

the

turn indicator lever.

5.

Remove

the

turn signal switch

attaching screws. Lift

the

switch over

the

end of the

steering shaft

and

place

it

to one

side.

6. Remove

the

snap ring from

the

top

of the

steering shaft.

7.

Loosen

the two

flange-to-steering

column tube attaching bolts

to

disen-

gage them from

the

tube.

8. Raise

the

flange upward while

BEARING

AND

INSULATOR

Spacer

G 1502 -B

FIG.

1—Removing

Steering Wheel

G 1497-A

FIG. 2—Installing Upper Bearingprocarmanuals.com

Page 145 of 413

03-08-01

Ford Design Integral Power Steering Gear

03-08-01

PART

3-8

Ford Design Integral Power

Steering Gear

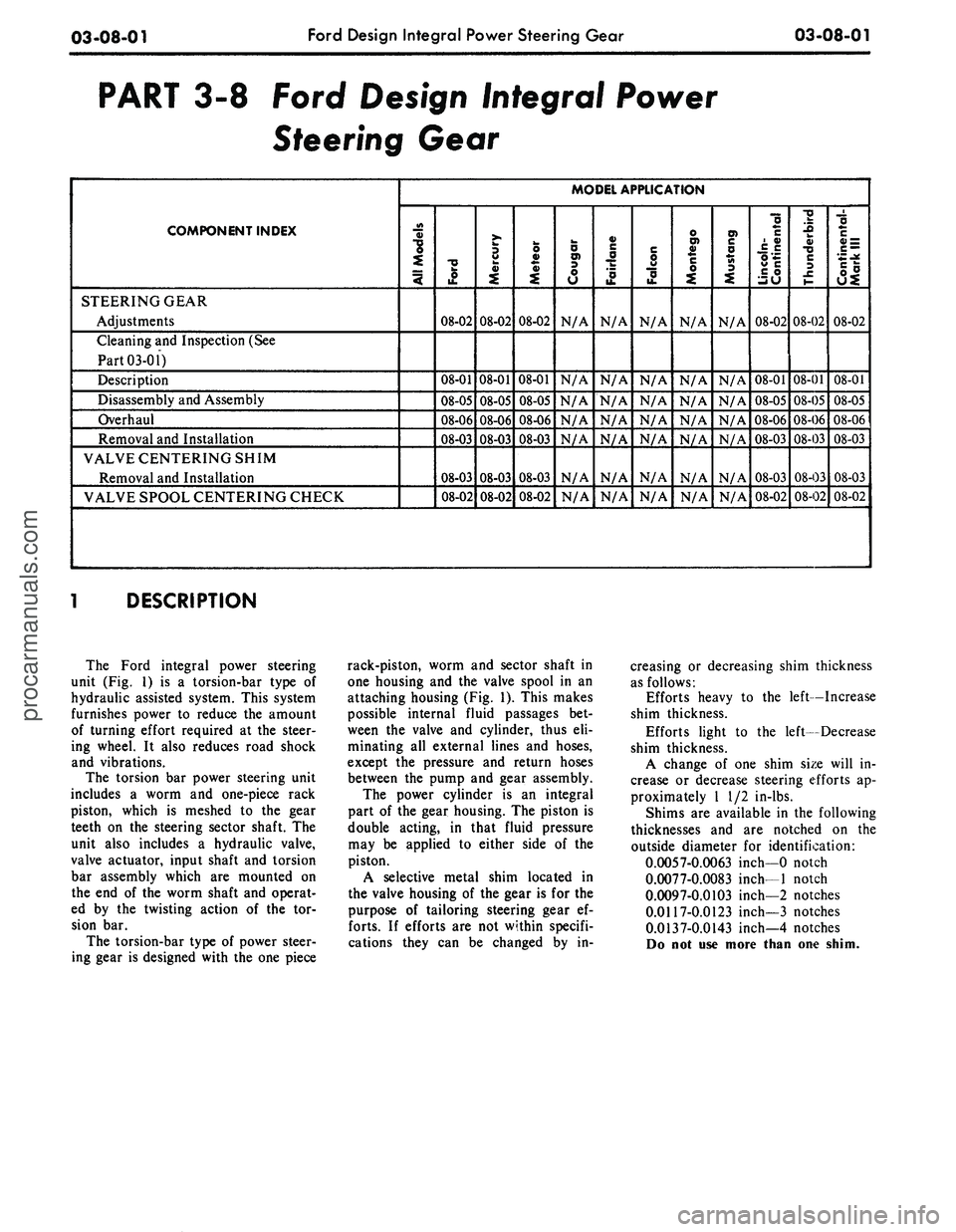

COMPONENT INDEX

STEERING GEAR

Adjustments

Cleaning

and

Inspection

(See

Part 03-01)

Description

Disassembly

and

Assembly

Overhaul

Removal

and

Installation

VALVE CENTERING SHIM

Removal

and

Installation

VALVE SPOOL CENTERING CHECK

MODEL APPLICATION

All Models

Ford

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Mercury

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Meteor

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Cougar

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Fairlane

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Falcon

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Montego

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Mustang

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Lincoln-

Continental

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Thunderbird

08-02

08-01

08-05

08-06

08-03

08-03

08-02

Continental-

Mark

III

08-02

08-01

08-05

08-06

08-03

08-03

08-02

DESCRIPTION

The Ford integral power steering

unit

(Fig. 1) is a

torsion-bar type

of

hydraulic assisted system. This system

furnishes power

to

reduce

the

amount

of turning effort required

at the

steer-

ing wheel.

It

also reduces road shock

and vibrations.

The torsion

bar

power steering unit

includes

a

worm

and

one-piece rack

piston, which

is

meshed

to the

gear

teeth

on the

steering sector shaft.

The

unit also includes

a

hydraulic valve,

valve actuator, input shaft

and

torsion

bar assembly which

are

mounted

on

the

end of the

worm shaft

and

operat-

ed

by the

twisting action

of the tor-

sion

bar.

The torsion-bar type

of

power steer-

ing gear

is

designed with

the one

piece

rack-piston, worm

and

sector shaft

in

one housing

and the

valve spool

in an

attaching housing

(Fig. 1).

This makes

possible internal fluid passages

bet-

ween

the

valve

and

cylinder, thus

eli-

minating

all

external lines

and

hoses,

except

the

pressure

and

return hoses

between

the

pump

and

gear assembly.

The power cylinder

is an

integral

part

of the

gear housing.

The

piston

is

double acting,

in

that fluid pressure

may

be

applied

to

either side

of the

piston.

A selective metal shim located

in

the valve housing

of the

gear

is for the

purpose

of

tailoring steering gear

ef-

forts.

If

efforts

are not

within specifi-

cations they

can be

changed

by in-

creasing

or

decreasing shim thickness

as follows:

Efforts heavy

to the

left—Increase

shim thickness.

Efforts light

to the

left—Decrease

shim thickness.

A change

of one

shim size will

in-

crease

or

decrease steering efforts

ap-

proximately

1 1/2

in-lbs.

Shims

are

available

in the

following

thicknesses

and are

notched

on the

outside diameter

for

identification:

0.0057-0.0063 inch—0 notch

0.0077-0.0083 inch—1 notch

0.0097-0.0103 inch—2 notches

0.0117-0.0123 inch—3 notches

0.0137-0.0143 inch—4 notches

Do

not use

more than

one

shim.

procarmanuals.com

Page 147 of 413

03-08-03

Ford Design Integral Power Steering Gear

03-08-03

factory adjustments will change. These

changes in adjustment do not neces-

sarily affect the satisfactory operation

of the steering gear assembly, and

therefore ordinarily do not require

readjustment unless there is excessive

lash or other malfunctioning.

ADJUSTMENT IN

VEHICLE

The only adjustment which can be

performed is the total over center

position load, to eliminate excessive

lash between the sector and rack

teeth.

1.

Disconnect the pitman arm from

the sector shaft.

2.

Disconnect the fluid return line

at the reservoir, at the same time cap

the reservoir return line pipe.

3.

Place the end of the return line

in a clean container and cycle the

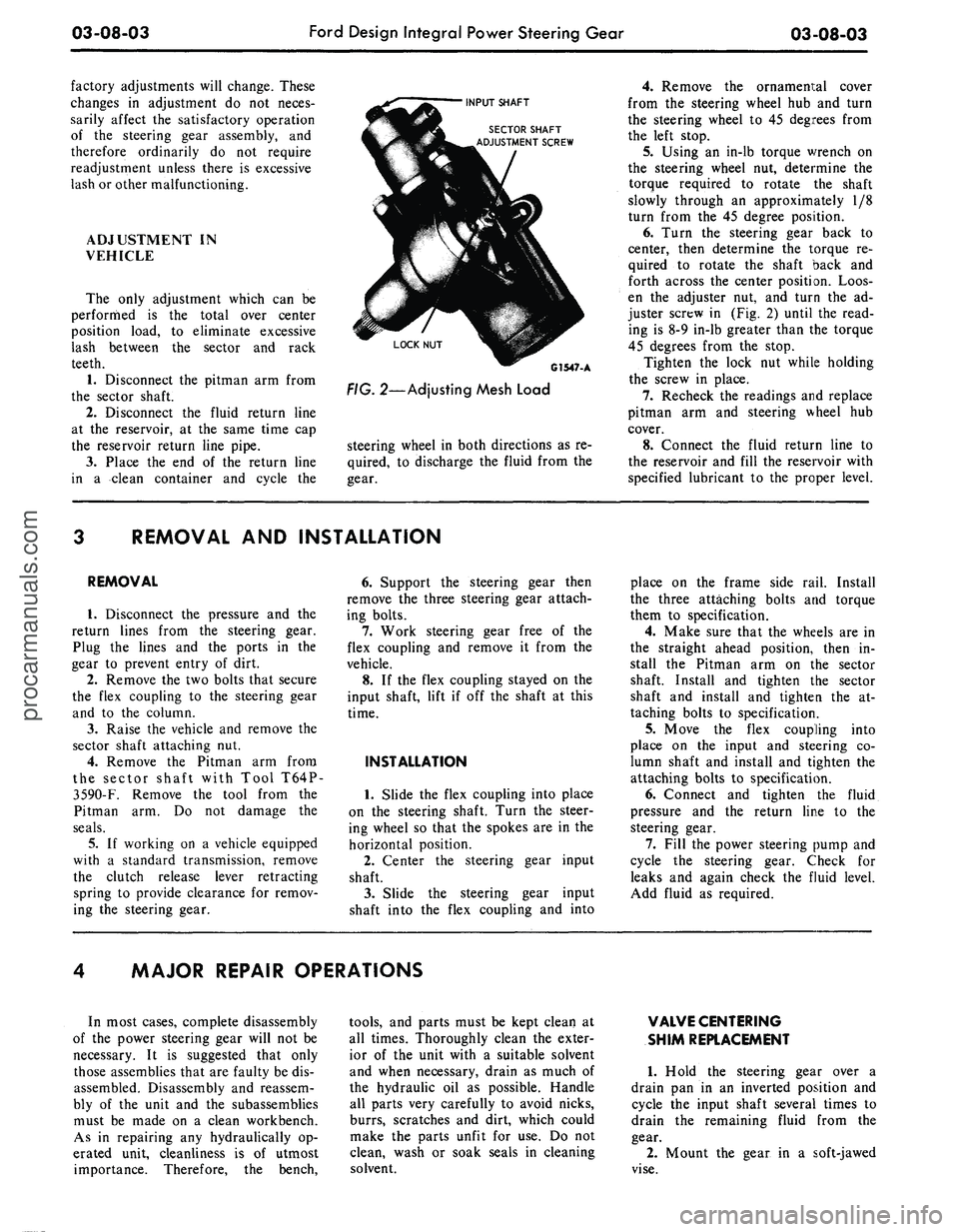

INPUT SHAFT

SECTOR SHAFT

ADJUSTMENT SCREW

C1547- A

FIG.

2—Adjusting Mesh Load

steering wheel in both directions as re-

quired, to discharge the fluid from the

gear.

4.

Remove the ornamental cover

from the steering wheel hub and turn

the steering wheel to 45 degrees from

the left stop.

5.

Using an in-lb torque wrench on

the steering wheel nut, determine the

torque required to rotate the shaft

slowly through an approximately 1/8

turn from the 45 degree position.

6. Turn the steering gear back to

center, then determine the torque re-

quired to rotate the shaft back and

forth across the center position. Loos-

en the adjuster nut, and turn the ad-

juster screw in (Fig. 2) until the read-

ing is 8-9 in-lb greater than the torque

45 degrees from the stop.

Tighten the lock nut while holding

the screw in place.

7.

Recheck the readings and replace

pitman arm and steering wheel hub

cover.

8. Connect the fluid return line to

the reservoir and fill the reservoir with

specified lubricant to the proper level.

REMOVAL AND INSTALLATION

REMOVAL

1.

Disconnect the pressure and the

return lines from the steering gear.

Plug the lines and the ports in the

gear to prevent entry of dirt.

2.

Remove the two bolts that secure

the flex coupling to the steering gear

and to the column.

3.

Raise the vehicle and remove the

sector shaft attaching nut.

4.

Remove the Pitman arm from

the sector shaft with Tool T64P-

3590-F.

Remove the tool from the

Pitman arm. Do not damage the

seals.

5.

If working on a vehicle equipped

with a standard transmission, remove

the clutch release lever retracting

spring to provide clearance for remov-

ing the steering gear.

6. Support the steering gear then

remove the three steering gear attach-

ing bolts.

7.

Work steering gear free of the

flex coupling and remove it from the

vehicle.

8. If the flex coupling stayed on the

input shaft, lift if off the shaft at this

time.

INSTALLATION

1.

Slide the flex coupling into place

on the steering shaft. Turn the steer-

ing wheel so that the spokes are in the

horizontal position.

2.

Center the steering gear input

shaft.

3.

Slide the steering gear input

shaft into the flex coupling and into

place on the frame side rail. Install

the three attaching bolts and torque

them to specification.

4.

Make sure that the wheels are in

the straight ahead position, then in-

stall the Pitman arm on the sector

shaft. Install and tighten the sector

shaft and install and tighten the at-

taching bolts to specification.

5.

Move the flex coupling into

place on the input and steering co-

lumn shaft and install and tighten the

attaching bolts to specification.

6. Connect and tighten the fluid

pressure and the return line to the

steering gear.

7.

Fill the power steering pump and

cycle the steering gear. Check for

leaks and again check the fluid level.

Add fluid as required.

MAJOR REPAIR OPERATIONS

In most cases, complete disassembly

of the power steering gear will not be

necessary. It is suggested that only

those assemblies that are faulty be dis-

assembled. Disassembly and reassem-

bly of the unit and the subassemblies

must be made on a clean workbench.

As in repairing any hydraulically op-

erated unit, cleanliness is of utmost

importance. Therefore, the bench,

tools,

and parts must be kept clean at

all times. Thoroughly clean the exter-

ior of the unit with a suitable solvent

and when necessary, drain as much of

the hydraulic oil as possible. Handle

all parts very carefully to avoid nicks,

burrs,

scratches and dirt, which could

make the parts unfit for use. Do not

clean, wash or soak seals in cleaning

solvent.

VALVE CENTERING

SHIM REPLACEMENT

1.

Hold the steering gear over a

drain pan in an inverted position and

cycle the input shaft several times to

drain the remaining fluid from the

gear.

2.

Mount the gear in a soft-jawed

vise.procarmanuals.com

Page 153 of 413

03-09-01

Saginaw Design Integral Power Steering Gear

03-09-01

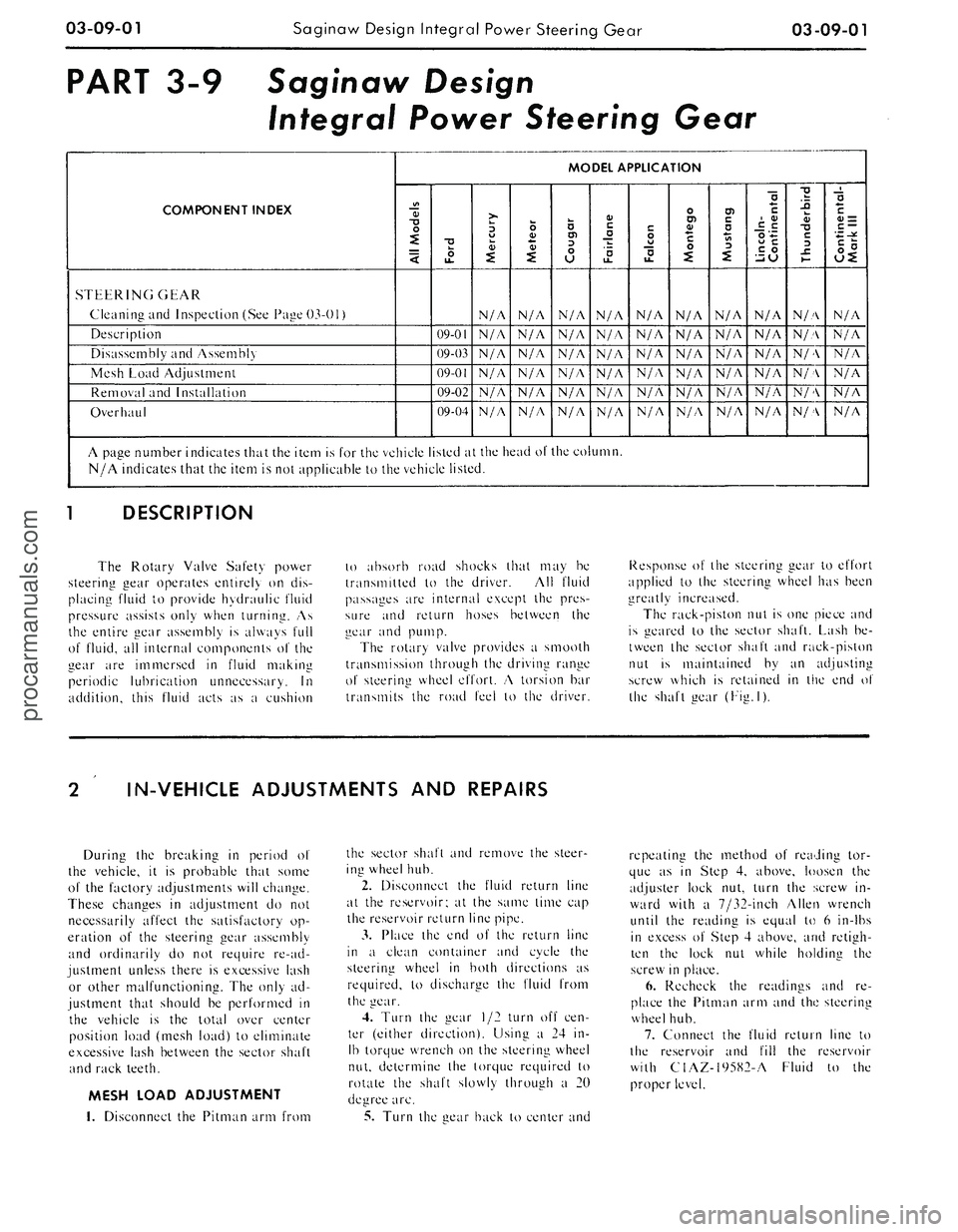

PART 3-9 Saginaw Design

Integral Power Steering Gear

COMPONENT INDEX

STEERING GEAR

Cleaning and Inspection (See Page 03-01)

Description

Disassembly and Assembly

Mesh Load Adjustment

Removal and Installation

Overhaul

MODEL APPLICATION

All

Models

Ford

09-01

09-03

09-01

09-02

09-04

Mercury

N/A

N/A

N/A

N/A

N/A

N/A

Meteor

N/A

N/A

N/A

N/A

N/A

N/A

Cougar

N/A

N/A

N/A

N/A

N/A

N/A

Fairlane

N/A

N/A

N/A

N/A

N/A

N/A

Falcon

N/A

N/A

N/A

N/A

N/A

N/A

Montego

N/A

N/A

N/A

N/A

N/A

N/A

Mustang

N/A

N/A

N/A

N/A

N/A

N/A

Lincoln-

Continental

N/A

N/A

N/A

N/A

N/A

N/A

Thunderbird

N/A

N/A

N/A

N/A

N/\

N/A

Continental-

Mark III

N/A

N/A

N/A

N/A

N/A

N/A

A page number indicates that the item is for the vehicle listed at the head of the column.

N/A indicates that the item is not applicable to the vehicle listed.

DESCRIPTION

The Rotary Valve Safety power

steering gear operates entirely on dis-

placing fluid to provide hydraulic fluid

pressure assists only when turning. As

the entire gear assembly is always full

of fluid, all internal components of the

gear are immersed in fluid making

periodic lubrication unnecessary. In

addition, this fluid acts as a cushion

to absorb road shocks that may be

transmitted to the driver. All fluid

passages are internal except the pres-

sure and return hoses between the

gear and pump.

The rotary valve provides a smooth

transmission through the driving range

of steering wheel effort. A torsion bar

transmits the road feel to the driver.

Response of the steering gear to effort

applied to the steering wheel has been

greatly increased.

The rack-piston nut is one piece and

is geared to the sector shaft. Lash be-

tween the sector shaft and rack-piston

nut is maintained by an adjusting

screw which is retained in the end o\'

the shaft uear (Eiiz.l).

IN-VEHICLE ADJUSTMENTS AND REPAIRS

During the breaking in period of

the vehicle, it is probable that some

of the factory adjustments will change.

These changes in adjustment do not

necessarily affect the satisfactory op-

eration of the steering gear assembly

and ordinarily do not require re-ad-

justment unless there is excessive lash

or other malfunctioning. The only ad-

justment that should be performed in

the vehicle is the total over center

position load (mesh load) to eliminate

excessive lash between the sector shaft

and rack teeth.

MESH LOAD ADJUSTMENT

1.

Disconnect the Pitman arm from

the sector shaft and remove the steer-

ing wheel hub.

2.

Disconnect the fluid return line

at the reservoir; at the same time cap

the reservoir return line pipe.

3.

Place the end of the return line

in a clean container and cycle the

steering wheel in both directions as

required, to discharge the fluid from

the gear.

4.

Turn the gear 1/2 turn off cen-

ter (either direction). Using a 24 in-

lb torque wrench on the steering wheel

nut, determine the torque required to

rotate the shaft slowly through a 20

degree arc.

5.

Turn the sear back to center and

repeating the method of reading tor-

que as in Step 4, above, loosen the

adjuster lock nut, turn the screw in-

ward with a 7/32-inch Allen wrench

until the reading is equal to 6 in-lbs

in excess of Step 4 above, and retigh-

ten the lock nut while holding the

screw in place.

6. Recheck the readings and re-

place the Pitman arm and the steering

wheel hub.

7.

Connect the fluid return line to

the reservoir and fill the reservoir

with C1AZ-I9582-A Fluid to the

proper level.

procarmanuals.com