brake GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 319 of 425

Brake-32

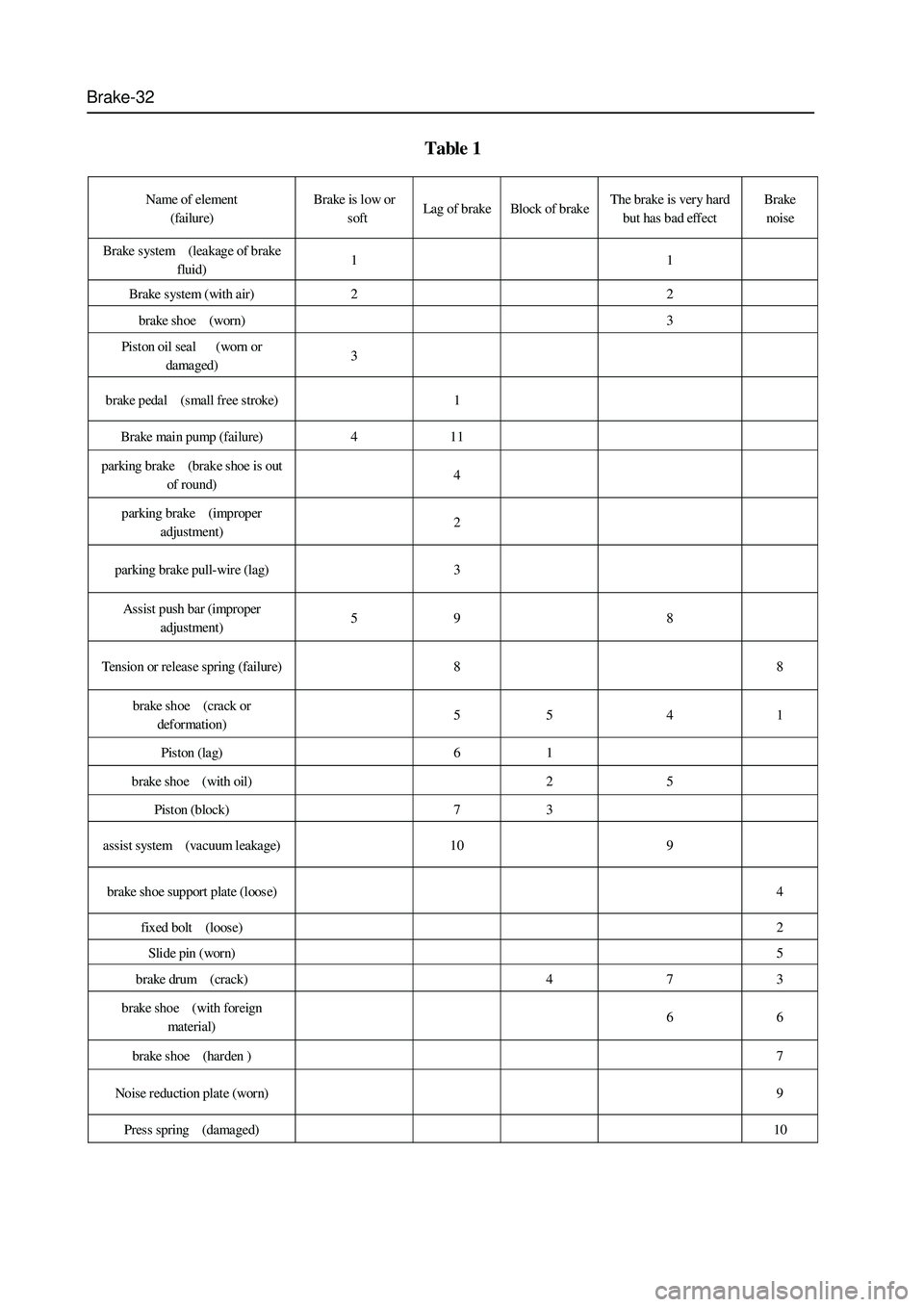

Table 1

Name of element

(failure) Brake is low or

soft Lag of brake Block of brake The brake is very hard

but has bad eff ect Brake

noise

Brake system (leakage of brake

fluid) 1 1

Brake system (with air) 2 2

brake shoe (worn) 3

Piston oil seal (worn or

damaged) 3

brake pedal (small free stroke) 1

Brake mai n p ump (fai lur e) 4 1 1

parking brake (brake shoe is out

of round) 4

parking brake (improper

adjustment) 2

parking brake pull-wire (lag) 3

Assist push bar (improper

adjustment) 5 9 8

Tension or release spring (failure) 8 8

brake shoe (crack or

deformation) 5 5 4 1

Piston (lag) 6 1

brake shoe (with oil) 2 5

Piston (block) 7 3

assist system (vacuum leakage) 10 9

brake shoe support plate (loose) 4

fixed bolt (loose) 2

Slide pin (worn) 5

brake drum (crack) 4 7 3

brake shoe (with foreign

mater ial) 6 6

brake shoe (harden ) 7

Noise reduction plate (worn) 9

Press spring (damaged) 10

Page 409 of 425

Appendix A-3

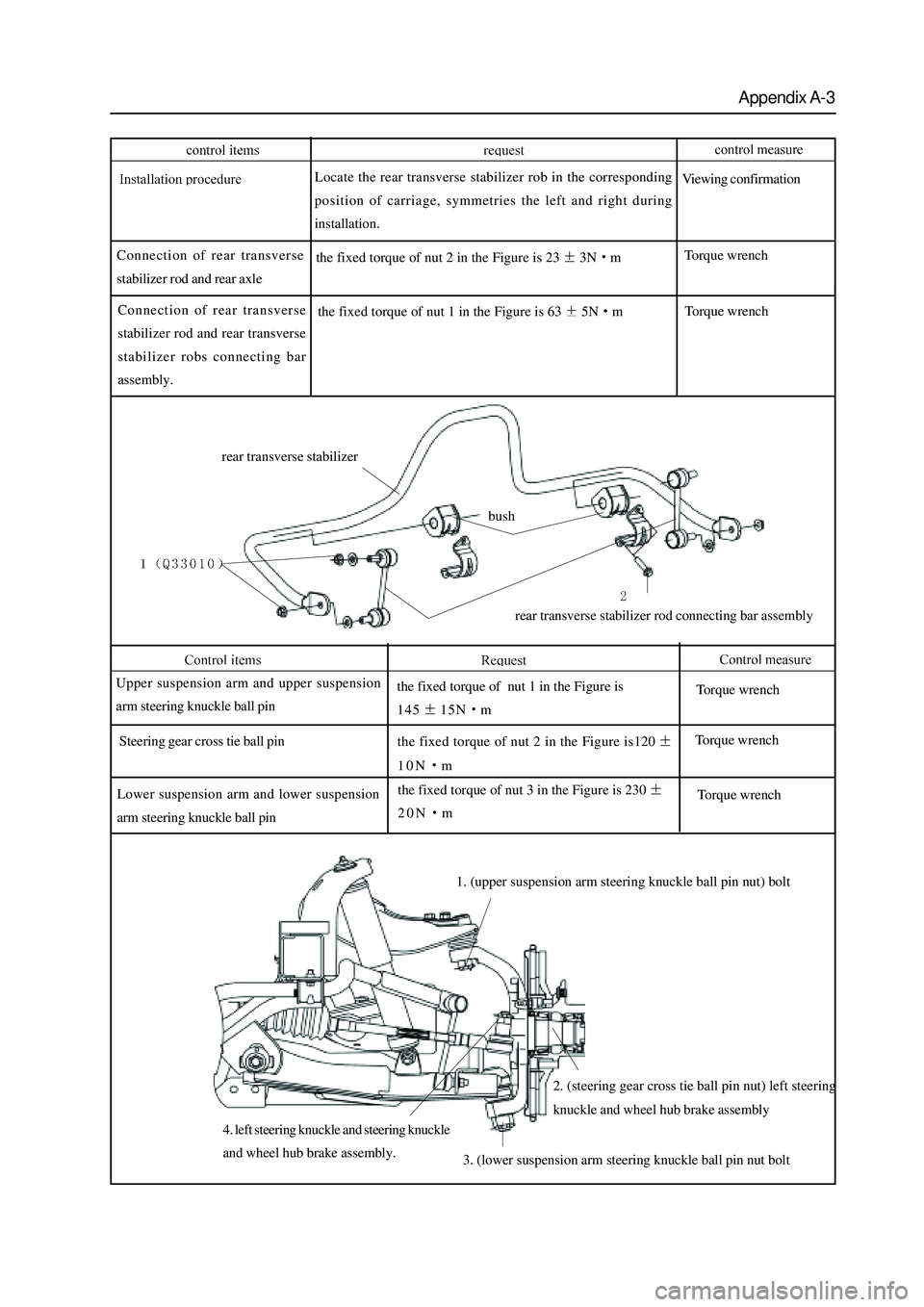

1. (upper suspension arm steering knuckle ball pin nut) bolt

Locate the rear transverse stabilizer rob in the corresponding

position of carriage, symmetries the left and right during

installation.

Connection of rear transverse

stabilizer rod and rear axleViewing confirmation

the fixed torque of nut 2 in the Figure is 23

3NmTorque wrench

Connection of rear transverse

stabilizer rod and rear transverse

stabilizer robs connecting bar

assembly.the fixed torque of nut 1 in the Figure is 63

5NmTorque wrench

rear transverse stabilizer

rear transverse stabilizer rod connecting bar assembly bush

Upper suspension arm and upper suspension

arm steering knuckle ball pin

Steering gear cross tie ball pin

Lower suspension arm and lower suspension

arm steering knuckle ball pinthe fixed torque of nut 1 in the Figure is

145

15Nm

the fixed torque of nut 2 in the Figure is120

10Nm

the fixed torque of nut 3 in the Figure is 230

20Nm

Torque wrench

Torque wrench

Torque wrench

2. (steering gear cross tie ball pin nut) left steering

knuckle and wheel hub brake assembly

3. (lower suspension arm steering knuckle ball pin nut bolt 4. left steering knuckle and steering knuckle

and wheel hub brake assembly.

Page 417 of 425

Appendix A-11

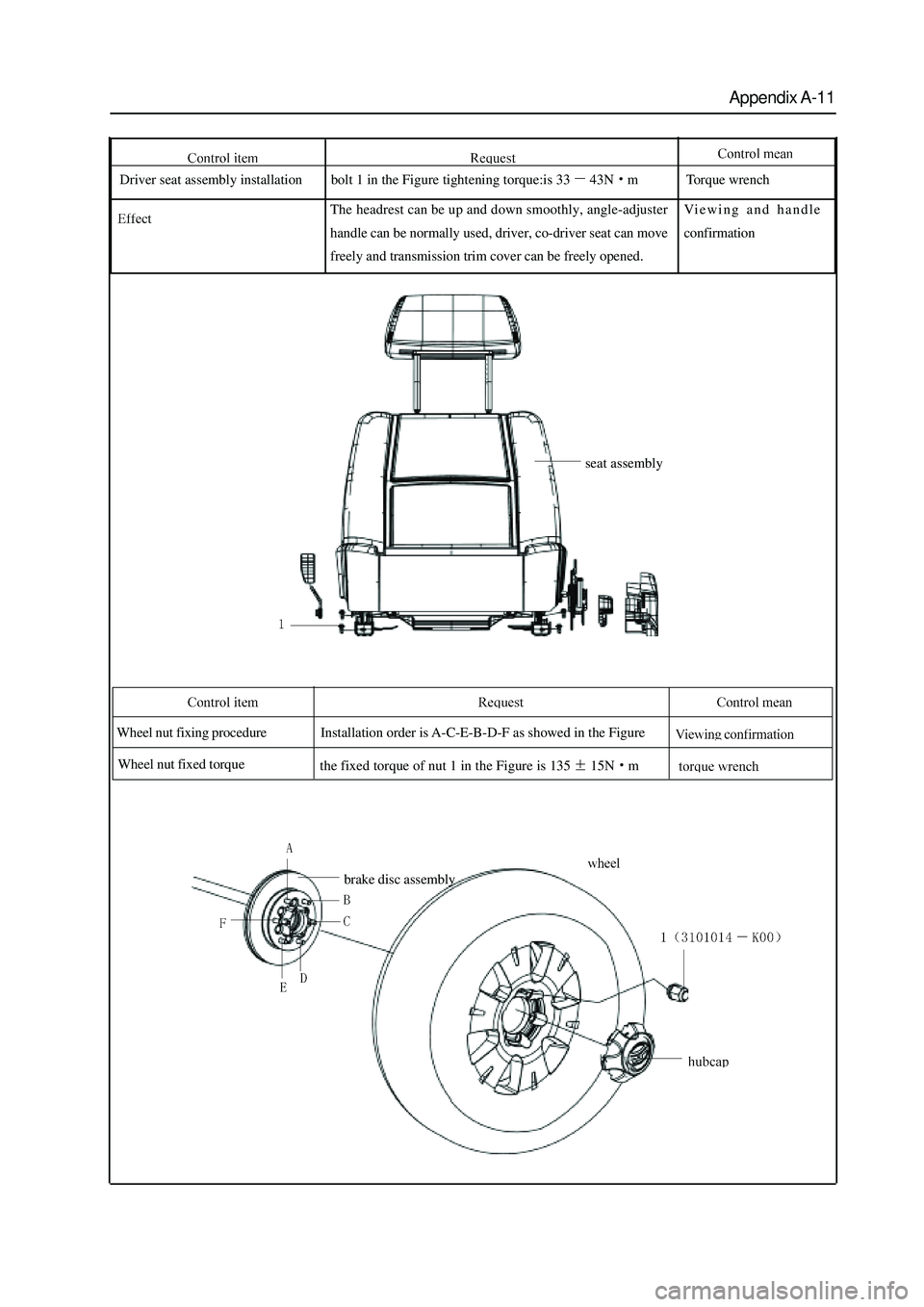

Driver seat assembly installationbolt 1 in the Figure tightening torque:is 3343Nm

Wheel nut fixing procedure

Wheel nut fixed torqueInstallation order is A-C-E-B-D-F as showed in the Figure

Torque wrench

Viewing and handle

confirmation The headrest can be up and down smoothly, angle-adjuster

handle can be normally used, driver, co-driver seat can move

freely and transmission trim cover can be freely opened.

seat assembly

the fixed torque of nut 1 in the Figure is 135

15Nm

brake disc assembly

Page 418 of 425

Appendix B-12

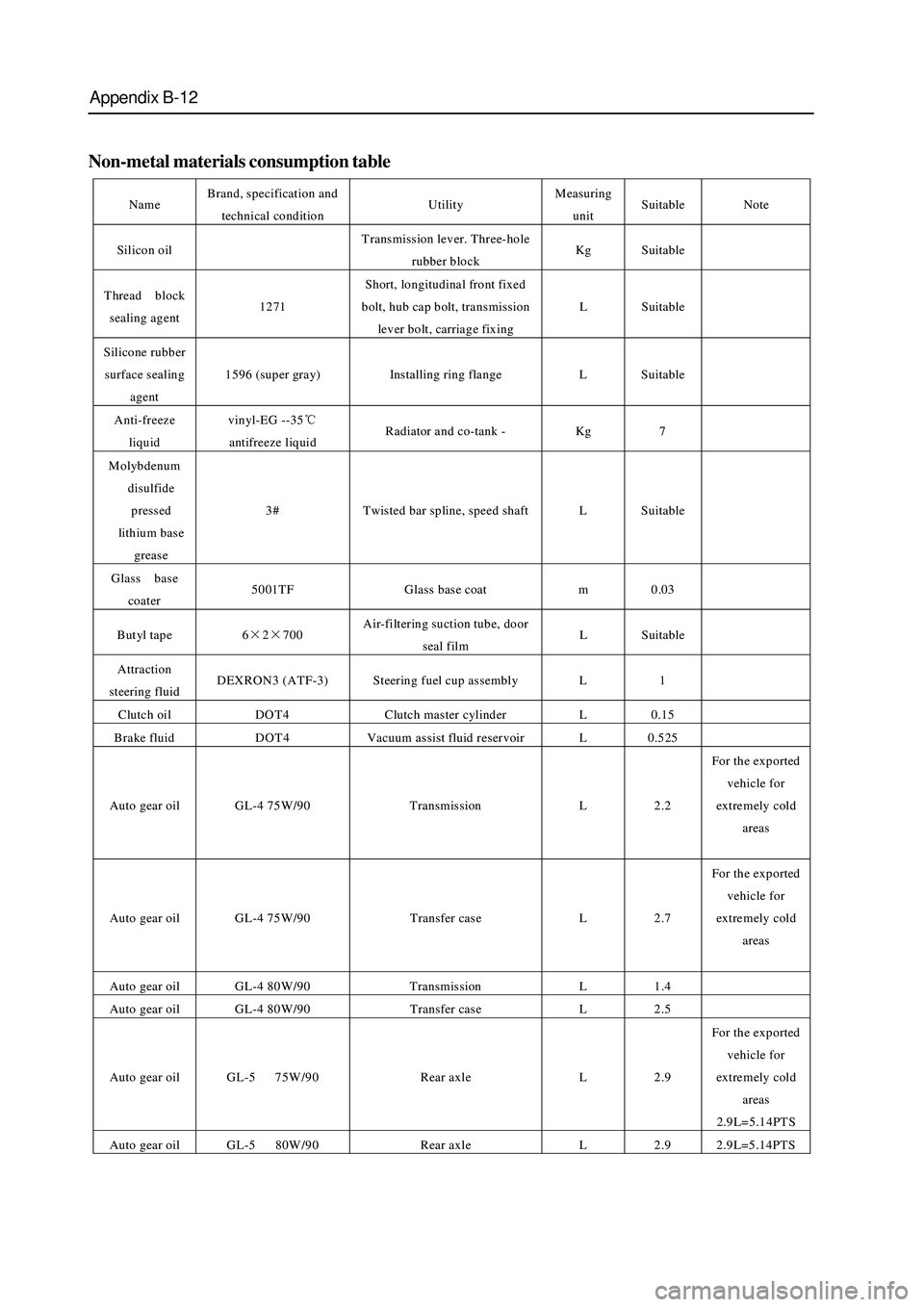

Non-metal materials consumption table

Name Brand, specification and

technical condition Utility Measuring

unit Suitable Note

Silicon oil Transmission lever. Three-hole

rubber block Kg Suitable

Thread block

sealing agent 1271 Short, longitudinal front fixed

bolt, hub cap bolt, transmission

lever bolt, carriage fixing L Suitable

Silicone rubber

surface sealing

agent 1596 (super gray) Installing ring flange L Suitable

Anti-freeze

liquid vinyl-EG --35℃

antifreeze liquid Radiator and co-tank - Kg 7

Molybdenum

disulfide

pressed

lithium base

grease 3# Twisted bar spline, speed shaft L Suitable

Glass base

coat er 5001TF Glass base coat m 0.03

Butyl tape 6×2×700 Air-filtering suction tube, door

seal film L Suitable

Attraction

steering fluid DEXRON3 (ATF-3) Steering fuel cup assembly L 1

Clutch oil DOT4 Clutch master cylinder L 0.15

Brake fluid DOT4 Vacuum assist fluid reservoir L 0.525

Auto gear oil GL-4 75W/90 Transmission L 2.2 For the exported

vehicle for

extremely cold

areas

Auto gear oil GL-4 75W/90 Transfer case L 2.7 For the exported

vehicle for

extremely cold

areas

Auto gear oil GL-4 80W/90 Transmission L 1.4

Auto gear oil GL-4 80W/90 Transfer case L 2.5

Auto gear oil GL-5 75W/90 Rear axle L 2.9 For the exported

vehicle for

extremely cold

areas

2.9L=5.14PTS

Auto gear oil GL-5 80W/90 Rear axle L 2.9 2.9L=5.14PTS

Page 424 of 425

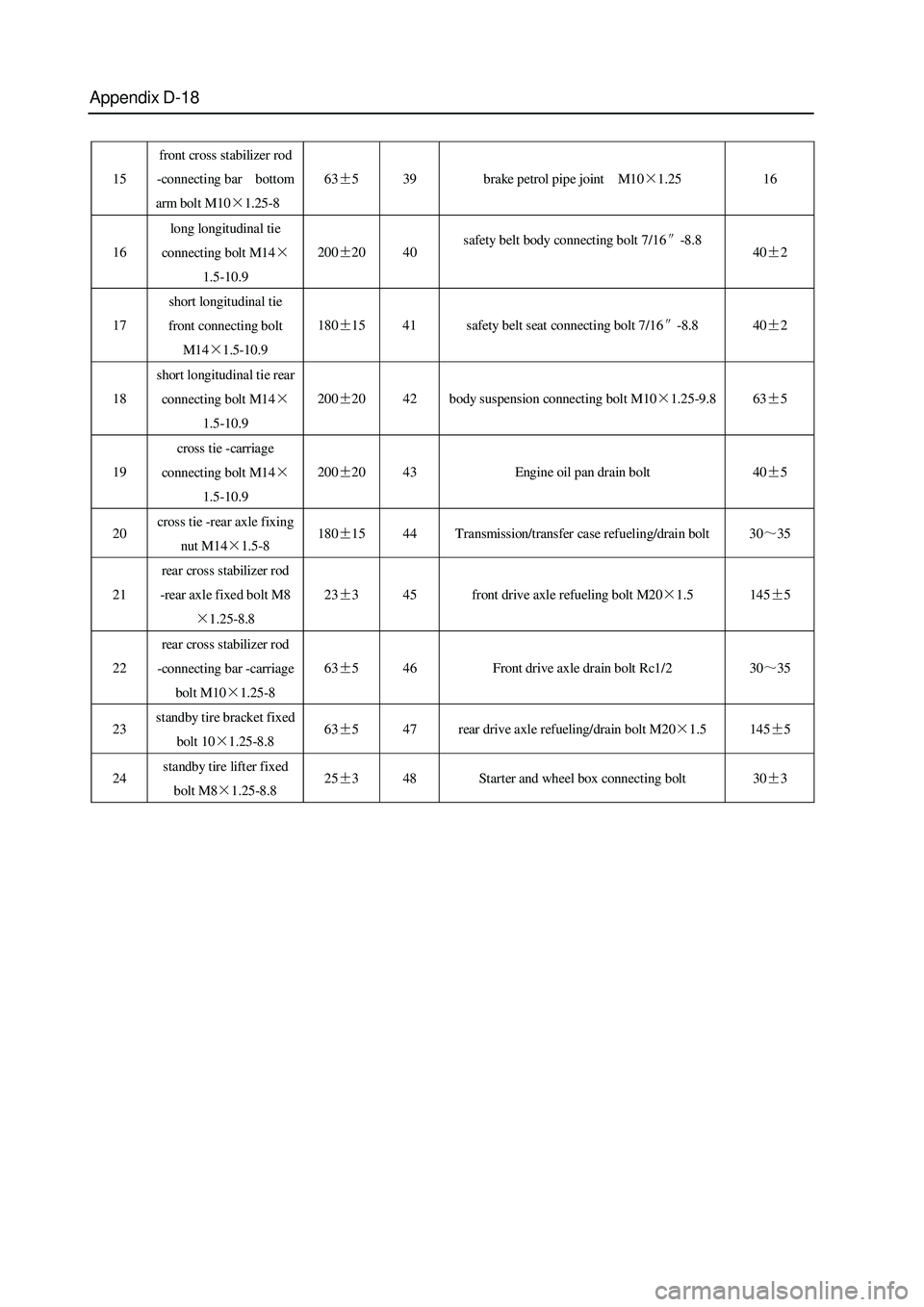

Appendix D-18

15 front cross stabilizer rod

-connecting bar bottom

arm bolt M10×1.25-8 63±5 39 brake petrol pipe joint M10×1.25 16

16 long longitudinal tie

connecting bolt M14×

1.5-10.9 200±20 40 safety belt body connecting bolt 7/16″-8.8

40±2

17 short longitudinal tie

front connecting bolt

M14×1.5-10.9 180±15 41 safety belt seat connecting bolt 7/16″-8.8 40±2

18 short longitudinal tie rear

connecting bolt M14×

1.5-10.9 200±20 42 body suspension connecting bolt M10×1.25-9.8 63±5

19 cross tie -carriage

connecting bolt M14×

1.5-10.9 200±20 43 Engine oil pan drain bolt 40±5

20 cross tie -rear axle fixing

nut M14×1.5-8 180±15 44 Transmission/transfer case refueling/drain bolt 30~35

21 rear cross stabilizer rod

-rear axle fixed bolt M8

×1.25-8.8 23±3 45 front drive axle refueling bolt M20×1.5 145±5

22 rear cross stabilizer rod

-connecting bar -carriage

bolt M10×1.25-8 63±5 46 Front drive axle drain bolt Rc1/2 30~35

23 standby tire bracket fixed

bolt 10×1.25-8.8 63±5 47 rear drive axle refueling/drain bolt M20×1.5 145±5

24 standby tire lifter fixed

bolt M8×1.25-8.8 25±3 48 Starter and wheel box connecting bolt 30±3