service HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 1021 of 1139

sRs

Precautions and Procedures

General Precautions

Please read the following precautions carefully beforeperforming airbag system service. Observe theinstructions described in this manual. or the airbags

could accidentally deploy and cause damage or injuries.

. Except when performing electrical inspections.

always turn the ignition switch OFF, disconnect the

negative cable from the battery, and wait at least 3minutes before beginning work.

NOTE: The memory is not erased even if the ignition

switch is turned OFF or the battery cables are

disconnected from the battery.. Use replacement pans which are manufactured to the

same standards and quality as the original parts. Do

not install used SRS parts from another vehicle. Useonly new pans when making SRS repairs.. Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being

dropped or improperly handled, such as dents, cracks,

or deformation.

. Before removing any SRS parts (including the

disconnection of connectors), always disconnect the

SRS connector.. Use only a digital multimeter to check the system. lf itis not a Honda multimeter, make sure its outout is 10mA (0.01A) or less when switched to the lowest value

in the ohmmeter range. A tester with a higher output

could cause accidental deployment and possible

injury.. Do not put objects on the front passenger's airbag.. The original radio has a coded theft protection circuit.

Be sure to get the customer's radio code and write

down the frequencies for the radio's preset stations

before disconnecting the battery cable.. Before returning the vehicle to the customer, enter

the radio code. then enter the customer's radio

station presets, and set the clock. Do the engine

control module (ECM) idle learn procedure (see page

11-139).

23-14

c

Steering-related Plecautions

Cable Reel Alignment

. Misalignment of the cable reel could cause an open in

the wiring, making the SRS system and the horns

inoperative. Center the cable reel whenever the

following is performed (see step 6 on page 23-121).

- Installation of the steering wheel- Installation of the cable reel- Installation ofthe steering column- Other steering-related adjustment or installation

. Do not disassemble the cable reel.

. Do not apply grease to the cable reel.

. lf the cable reel shows any signs of damage or

contamination. replace it with a new one. For

example, it does not rotate smoothly.

Page 1022 of 1139

Airbag Handling and Storage

Do not disassemble an airbag, lt has no serviceable

parts. Once an airbag has been deployed, it cannot be

repaired or reused.

For temporary storage of an airbag during service,

observe the following precautions.

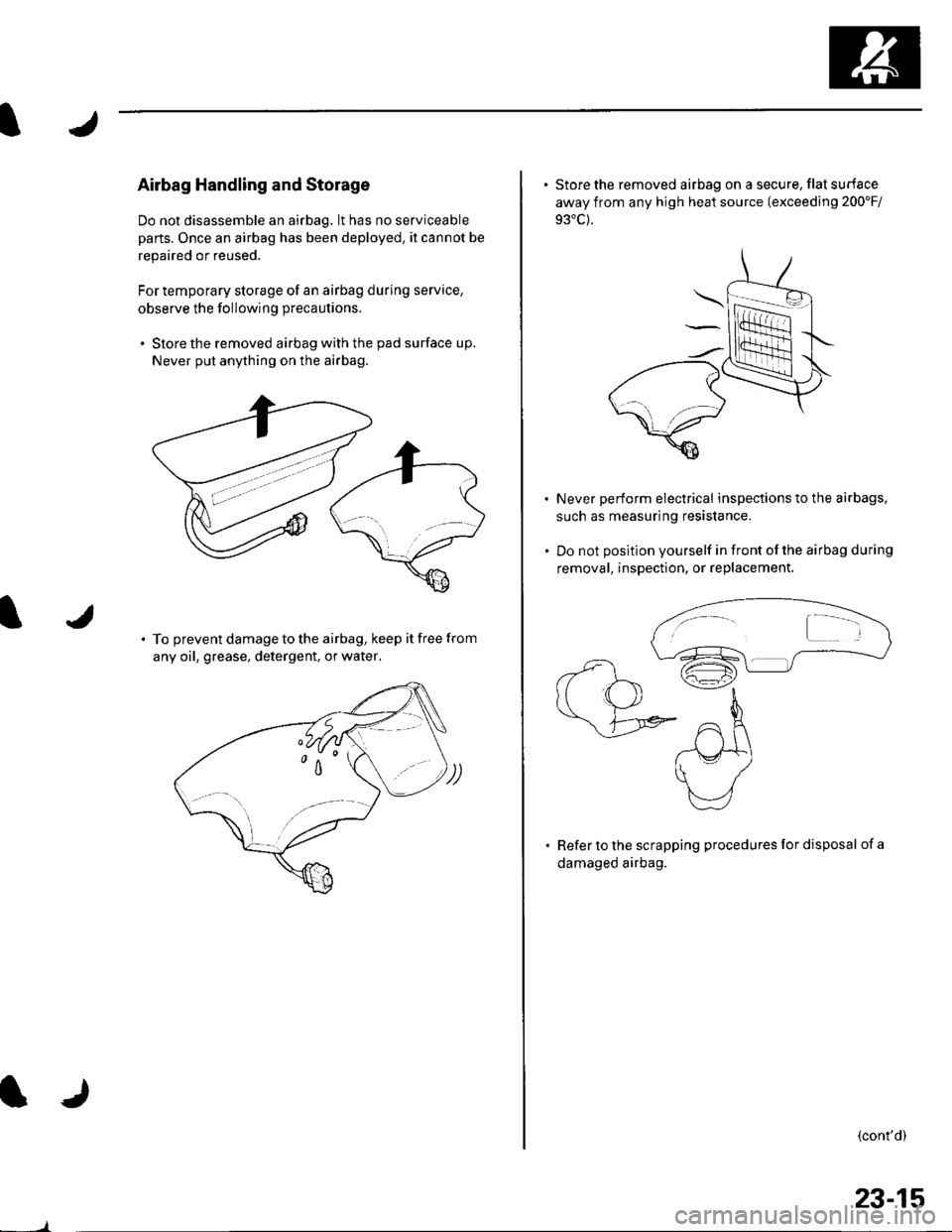

. Store the removed airbag with the pad surface up.

Never put anything on the airbag.

To prevent damage to the airbag, keep it free from

any oil, grease, detergent, or water,

23-15

. Store the removed airbag on a secure, flat surface

away from any high heat source (exceeding 200'Fi

Never perform electrical inspections to the airbags,

such as measuring resistance.

Do not position yourself in front of the airbag during

removal, inspection, or replacement.

Refer to the scrapping procedures for disposal of a

damaged airbag.

(cont'd)

Page 1024 of 1139

I

J

Wiring Precautions

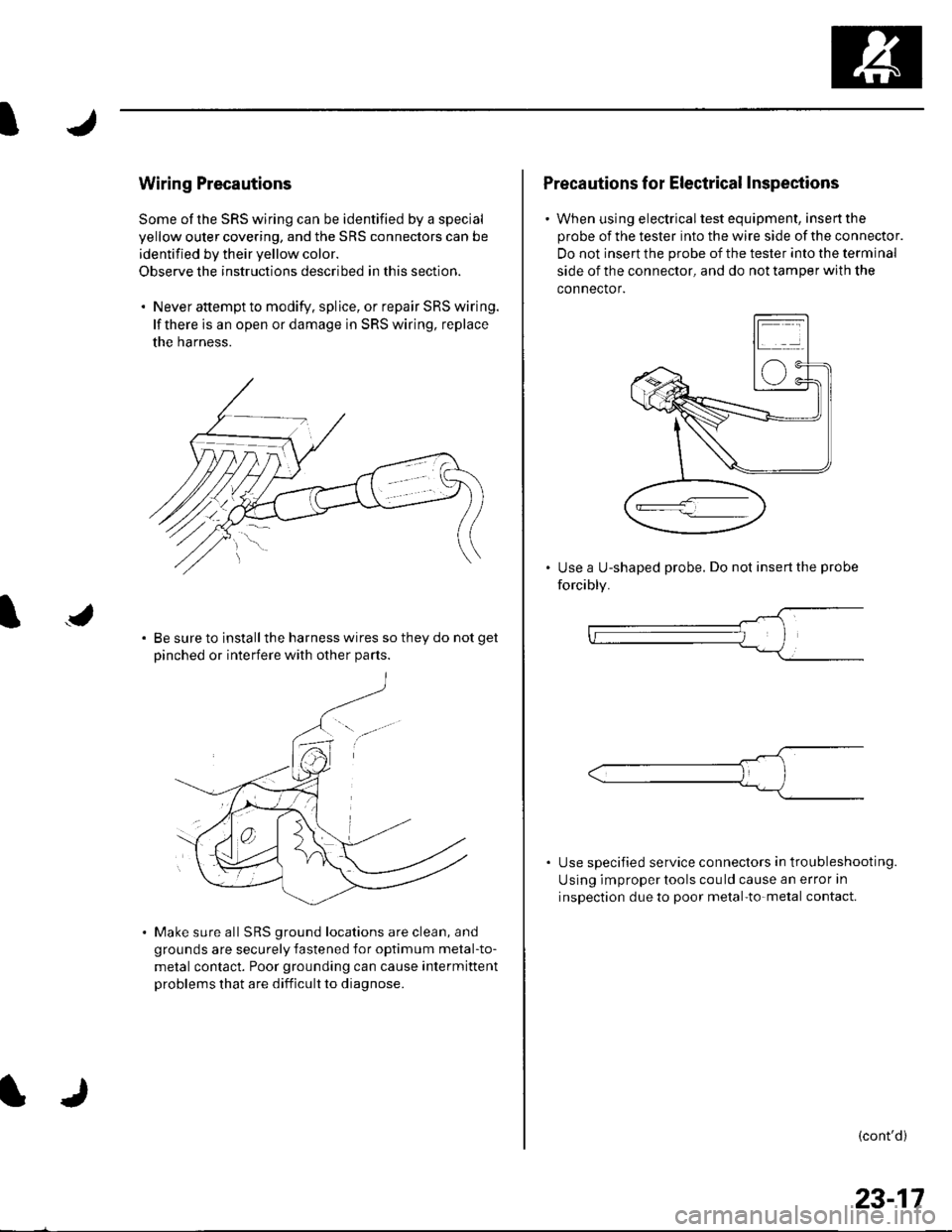

Some of the SRS wiring can be identified by a special

yellow outer covering, and the SRS connectors can be

identified by their yellow color.

Observe the instructions described in this section.

. Never attempt to modify. splice, or repair SRS wiring.

lf there is an open or damage in SRS wiring, replace

the harness.

Be sure to install the harness wires so they do not get

Dinched or interfere with other Darts.

Make sure all SRS ground locations are clean, and

grounds are securely fastened for optimum metal-to-

metal contact. Poor grounding can cause intermittent

problems that are difficult to diagnose.

Precautions for Electrical Inspections

. When using electricaltest equipment, insertthe

probe of the tester into the wire side of the connector.

Do not insert the probe of the tester into the terminal

side of the connector, and do not tamper with the

connector.

Use a U-shaped probe. Do not insert the probe

forcibly.

Use specified service connectors in tro u bleshooting.

Using improper tools cou ld cause an error in

inspection due to poor metal-to-metal contact.

(cont'd)

23-17

Page 1033 of 1139

sRs

General Troubleshooting Information (cont'dl

Erasing the DTG Memory

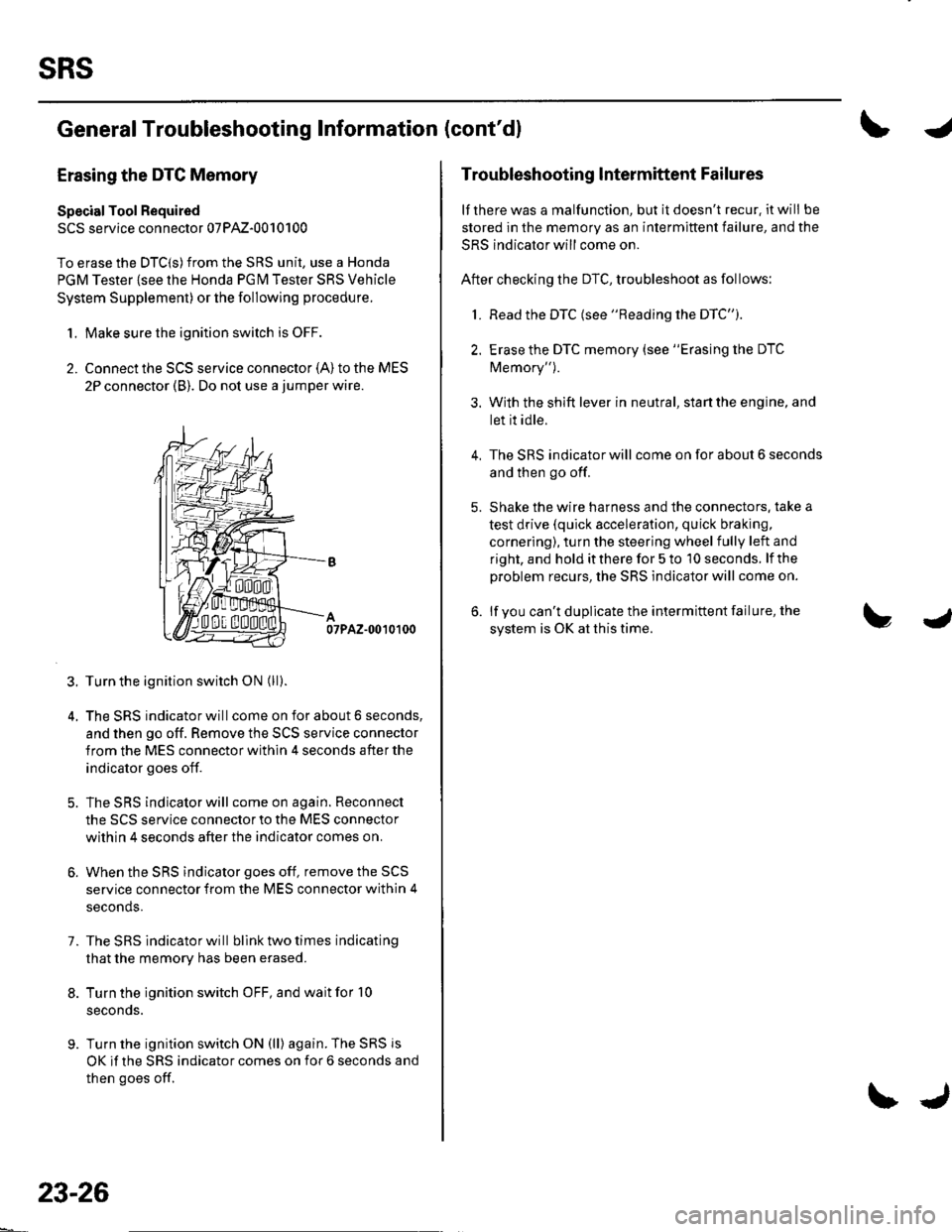

Specisl Tool Required

SCS service connector 07PAz-0010100

To erase the DTC(S)from the SRS unit, use a Honda

PGM Tester {see lhe Honda PGfM Tester SRS Vehicle

System Supplement) or the following procedure.

1. Make sure the ignition switch is OFF.

2. Connect the SCS service connector {A) to the MES

2P connector (B). Do not use a jumper wire.

07PAZ-0010100

3. Turn the ignition switch ON (ll).

4. The SRS indicator will come on for about 6 seconds,

and then go off. Remove the SCS service connector

from the MES connector within 4 seconds after the

indicator goes off.

5. The SRS indicator will come on again. Reconnect

the SCS service connector to the MES connector

within 4 seconds after the indicator comes on.

6. When the SRS indicator goes off, remove the SCS

service connector from the MES connector within 4

seconds.

7. The SRS indicator will bllnk two times indicating

that the memory has been erased.

8. Turn the ignition switch OFF, and wait for '10

seconds.

9. Turn the ignition switch ON (ll) again. The SRS js

OK if the SRS indicator comes on for 6 seconds and

then goes off.

23-26

\J

Troubleshooting lntermittent Failures

lf there was a malfunction, but it doesn't recur. it will be

stored in the memory as an intermittent failure, and the

SRS indicator will come on.

After checking the DTC, troubleshoot as follows:

1. Read the DTC (see "Reading the DTC").

2. Erase the DTC memory (see "Erasing the DTC

Memory").

3. With the shift lever in neutral, start the engine, and

let it idle.

The SRS indicator will come on for about 6 seconds

and then go off.

Shake the wire harness and the connectors. take a

test drive (quick acceleration, quick braking,

cornering), turn the steering wheel fully left and

right, and hold it there for 5 to '10 seconds. lf the

problem recurs, the SRS indicator will come on.

lf you can't duplicate the intermittent failure, the

system is OK at this time.

4.

Page 1034 of 1139

I

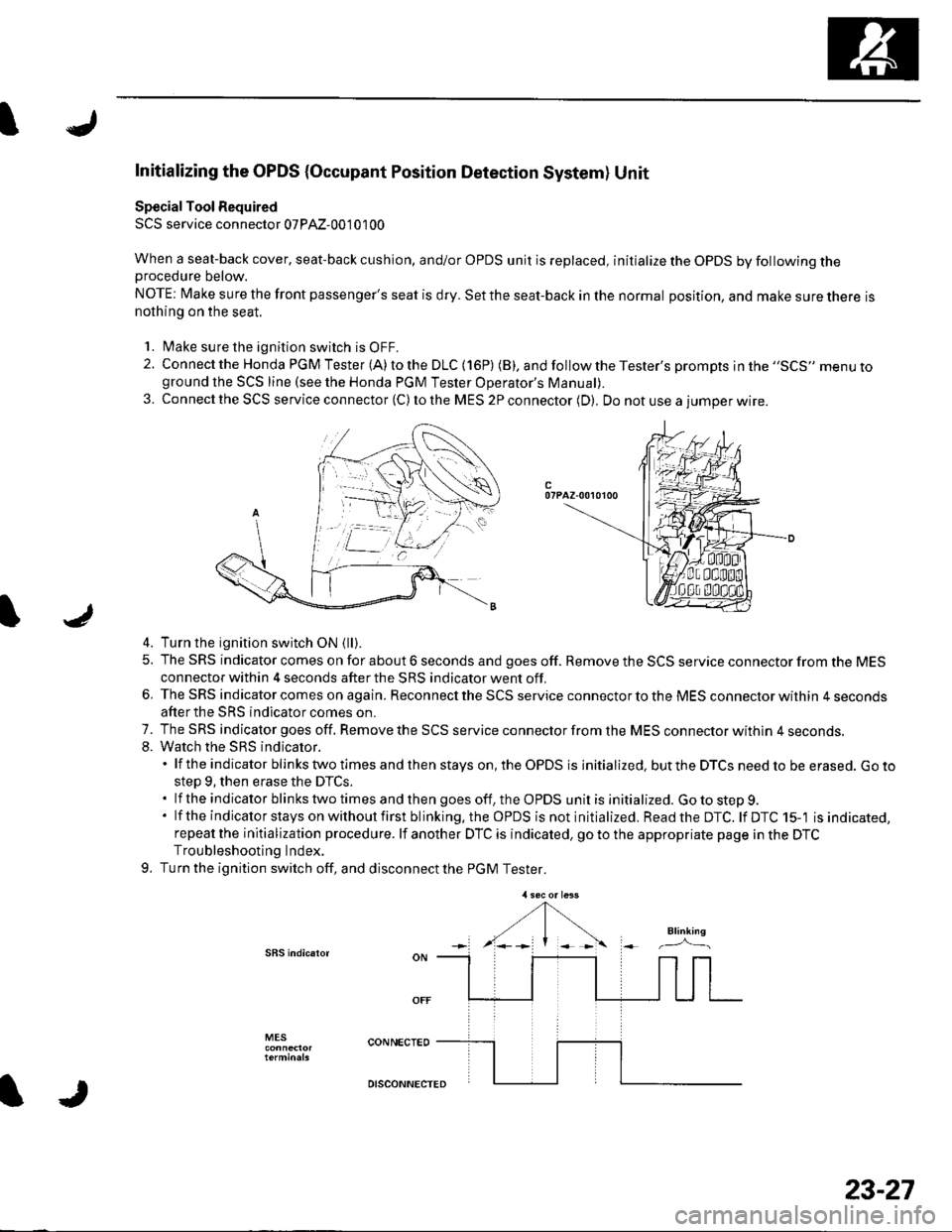

Initializing the OPDS {Occupant Position Detection System} Unit

Special Tool Required

SCS service connector 07PAz-00'1 01 00

When a seat-back cover, seat-back cushion, and/or OPDS unit is replaced, initialize the OPDS by following theprocedure below.

NOTE: Make sure the front passenger's seat is dry. Set the seat-back in the normal position, and make sure there isnothing on the seat.

'1. l\4ake sure the ignition switch is OFF.

2. Connect the Honda PGM Tester (A) to the DLC (16P) (B), andfollowtheTester's prompts jn the ,,SCS,, menu toground the SCS line (see the Honda PGM Tester Operator's ManuaD.

3. Connect the SCS service connector (C) to the MES 2P connector (D). Do not use a iumoer wire.

c07PAZ-00r0100

4. Turn the ignition switch ON {ll).

5. The SRS indicator comes on for about 6 seconds and goes off. Remove the SCS service connector from the MESconnector within 4 seconds after the SRS indicator went off.

6. The SRS indicator comes on again. Reconnect the SCS service connector to the MES connector within 4 secondsafter the SRS indicator comes on.

7. The SRS indicator goes off. Remove the SCS service connector from the MES connector withln 4 seconds.8. Watch the sRS indicator.'lftheindicatorblinkstwotimesandthenstayson,theOPDSisinitialized.buttheDTCSneedtobeerased.Goto

step 9, then erase the DTCS..lftheindicatorblinkstwotimesandthengoesoff,theOPDSunitisinitialized.Gotostep9.

' lf the indicator stays on without first blinking.the OPDS is not initialized. Readthe DTC. lf DTC 15-'l is indicated,repeat the initialization procedure. lf another DTC is indicated, go to the appropriate page in the DTCTroubleshooting Index.

9. Turn the ignition switch off, and disconnect the PGM Tester.

SBS indic.ror

MES

IJ

DISCONNECTED

23-27

Page 1040 of 1139

Self-diagnosis System

A self-diagnosis circuit is built into the SRS uniU when the ignition switch is turned ON (ll), the SRS indicator comes onand goes off after about 6 seconds if the SRS is operating normally.

lf the indicator does not come on, or does not go off after 6 seconds. or if il comes on while driving, it indicates anabnormality in the SRS. The SRS must be inspected and repaired as soon as possible.

For better serviceability, the SRS unit memory stores a DTC that relates to the cause of the malfunction, and the unit isconnected to the data link circuit. This information can be read with the Honda PGM Tester when it is connected to thedata link connector (DLc) (see page 23-23).

23-33

Page 1118 of 1139

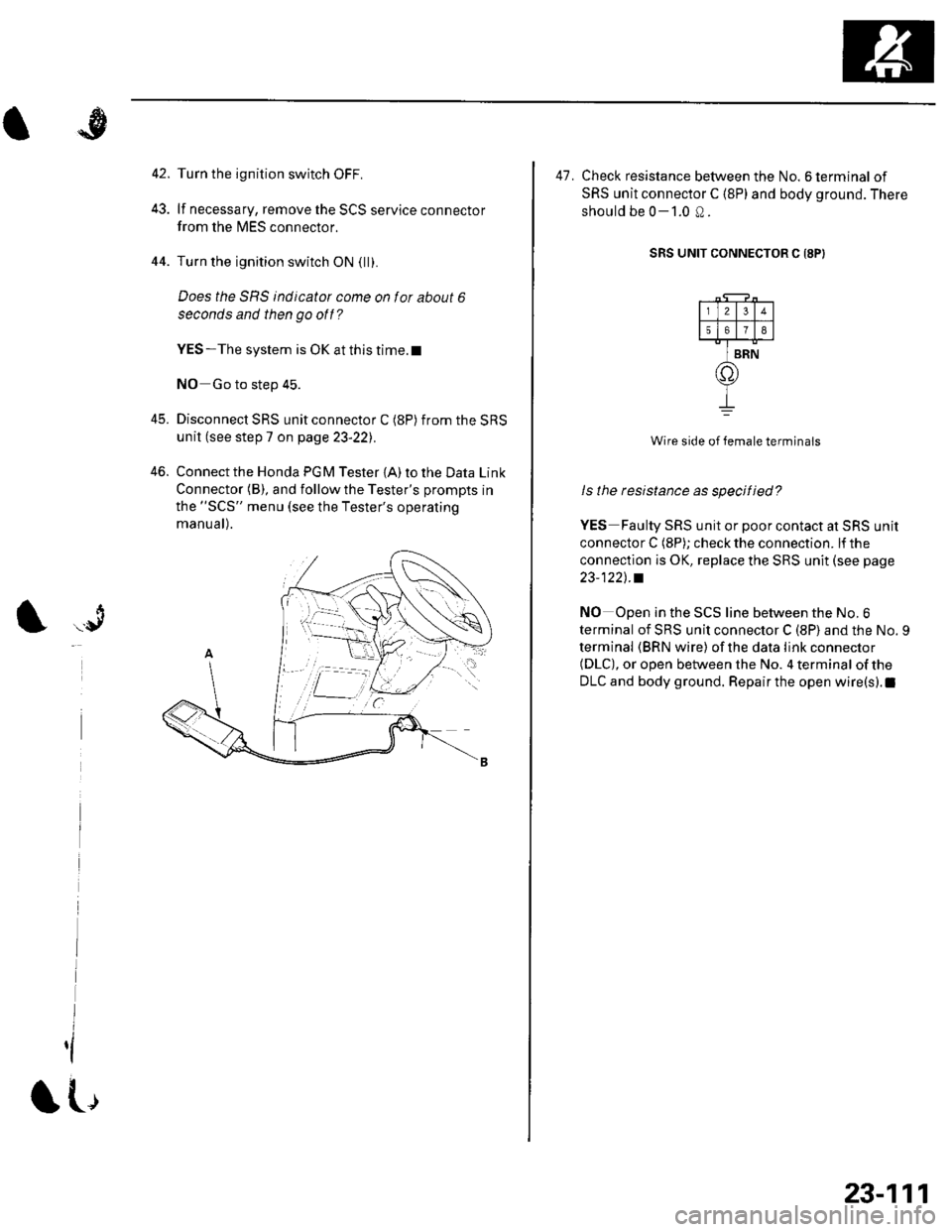

42. Turn the ignition switch OFF.

43. lf necessary, remove the SCS service connector

from the l\4ES connector.

44. Turn the ignition switch ON {ll}.

Does the SBS indicator come on for about 6

seconds and then go off?

YES -The system is OK at this time. t

NO Go to step 45.

45. Disconnect SRS unit connector C (8P) fromtheSRS

unit (see step 7 on page 23-221.

46. Connect the Honda PGM Tester {A) to the Data Link

Connector (B), and follow the Tester's prompts in

the "SCS" menu (see the Tester's operating

manu a l).

t .r9

I

,l

IL,

23-111

47. Check resistance between the No. 6 terminal of

SRS unit connector C (8P) and body ground. There

should be 0-1.0 Q.

SRS UNIT CONNECTOR C I8P)

Wire side of female terminals

ls the resistance as specified?

YES Faulty SRS unit or poor contact at SRS unit

connector C (8P); check the connection. lf the

connection is OK, replace the SRS unit (see page

23-1221..

NO Open in the SCS line between the No.6

terminal of SRS unit connector C (8P) and the No. 9

terminal (BRN wire) ofthe data link connector(DLC), or open between the No. 4 terminal of the

DLC and body ground. Repair the open wire(s).1

I2

50

BRN

n

Page 1122 of 1139

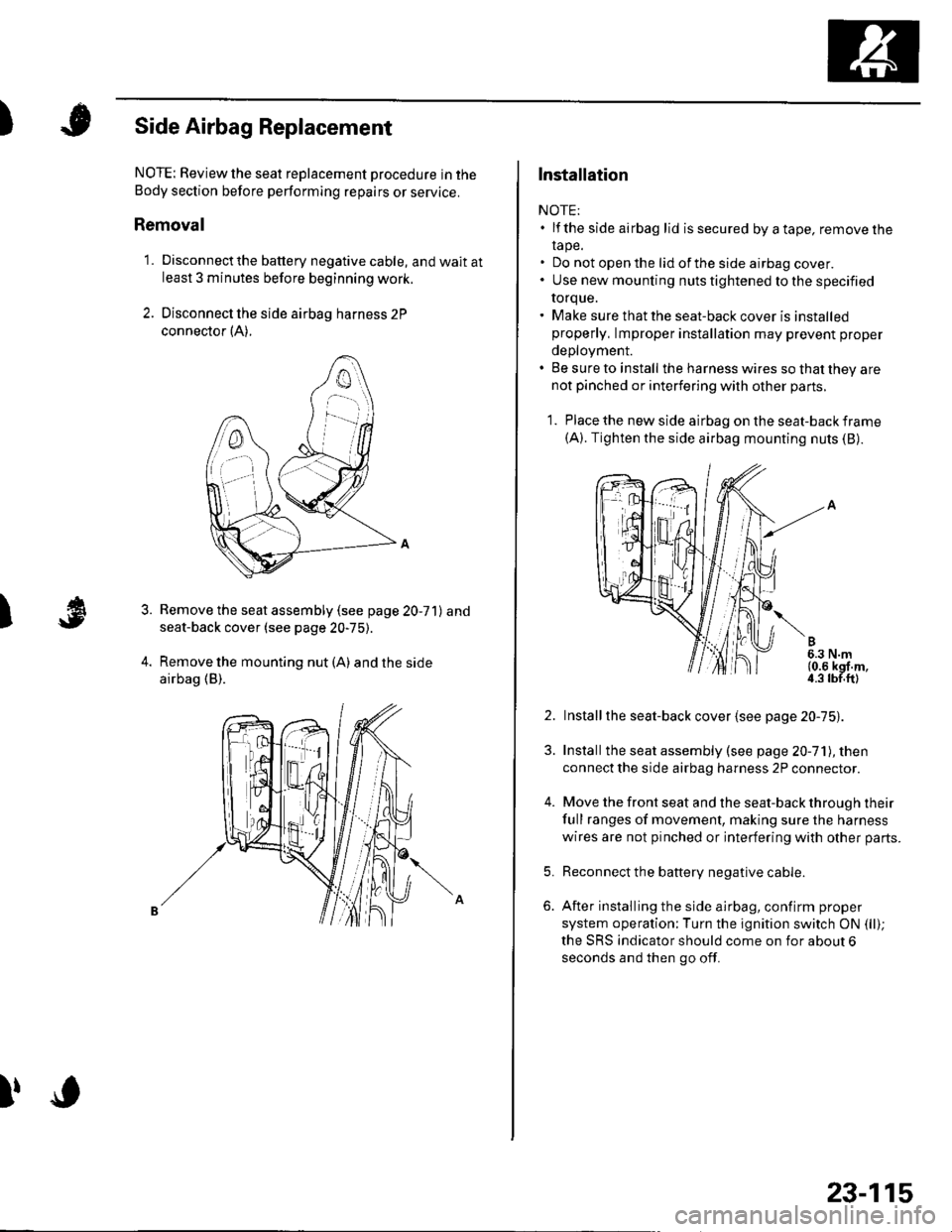

)Side Airbag Replacement

)

NOTE: Review the seat replacement pro6edure in the

Body section before pertorming repairs or service.

Removal

1. Disconnectthe battery negative cable, and wait atleast 3 minutes before beginning work.

2. Disconnect the side airbag harness 2P

connector {A).

Remove the seat assembly (see page 20-71) and

seat-back cover (see page 20-75).

Remove the mounting nut (A) and the side

airbag (B).

3.

l,o

23-115

Installation

NOTE:. lf the side airbag lid issecured byatape, removelhe

rape.. Do not open the lid of the side airbag cover.. Use new mounting nuts tightened to the specified

torque.. Make sure that the seat-back cover is installedproperly, lmproper installation may prevent proper

deployment.. Be sure to install the harness wires so that they arenot pinched or interfering with other parts.

1. Place the new side airbag on the seat-back frame(A). Tighten the side airbag mounting nuts (B).

2. Installthe seat-back cover {see page 20-75).

3. Installthe seat assembly (see page 20-71), then

connect the side airbag harness 2P connector.

4. Move the front seat and the seat-back through their

full ranges of movement, making sure the harness

wires are not pinched or interfering with other parts.

5. Reconnect the battery negative cable.

6. After installing the side airbag, confirm proper

system operation;Turn the ignition switch ON (ll);

the SRS indicator should come on for about 6

seconds and then go off.

Page 1123 of 1139

sRs

Airbag Disposal

Special Tool Required

Deployment tool 07HAz-SG00500

Before scrapping any airbags, side airbags, seat belt

tensioners, or seat belt buckle tensioners (including

those in a whole vehicle to be scrapped), the airbags,

side airbags, seat belt tensioners, or seat belt buckle

tensioners must be deployed. lf the vehicle is still within

the warranty period, the Honda District Service

Manager must give approval and/or special instruction

before deploying the airbags, side airbags, seat belt

tensioners, or seat belt buckle tensioners. Only after the

airbags, side airbags, seat belt tensioners, or seat belt

buckle tensioners have been deployed (as the result of

vehicle collision, for example), can they be scrapped.

lf the airbags, side airbags, seat belt tensioners, and

seat belt buckle tensioners appear intact (not deployed),

treat them with extreme caution. Follow this Drocedure.

Deploying Airbags in the Vehicle

lf an SRS equipped vehicle is to be entirely scrapped, its

airbags, side airbags. seat belt tensioners. and seat belt

buckle tensioners should be deoloved while still in the

vehicle. The airbags, side airbags, seat belttensioners,

and seat belt buckle tensioners should not be

considered as salvageable parts and should never be

installed in another vehicle.

1. Turn the ignition switch OFF, then disconnect the

battery negative cable, and wait at least 3 minutes.

2. Confirm that each airbag, side airbag, or seat belt

tensioner is securely mounted.

3. Conf irm that the specia I tool isfunctioning properly

by following the check procedure on the tool label.

23-116

$J

Driver's Airbag:

4. Remove the access panel f rom the steering wheel,

then disconnect the driver's airbag 4P connector

from the cable reel (see step 2 on page 23-21).

Front Passenger's Airbag:

5. Lowerthe glove box, then disconnectthe front

passenger's airbag 4P connector from dashboard

wire harness B (see step 3 on page 23-211.

Side Airbag:

6. Disconnect the side airbag 2P connectors from the

floor wire harness (see step 4 on page 23-211.

Seat belt tensioner:

7. Disconnect the seat belt tensioner 2P connectors

from the floor wire harness {see step 5 on page 23-

22). Pull the seat belt out all the way, and cut it off.

Seat belt buckle tensioner:

8, Disconnect the seat belt buckle tensioner 4P

connectors from the floor wire harness (see step 6

on page 23-221.

Page 1125 of 1139

sRs

Airbag Disposal (cont'dl

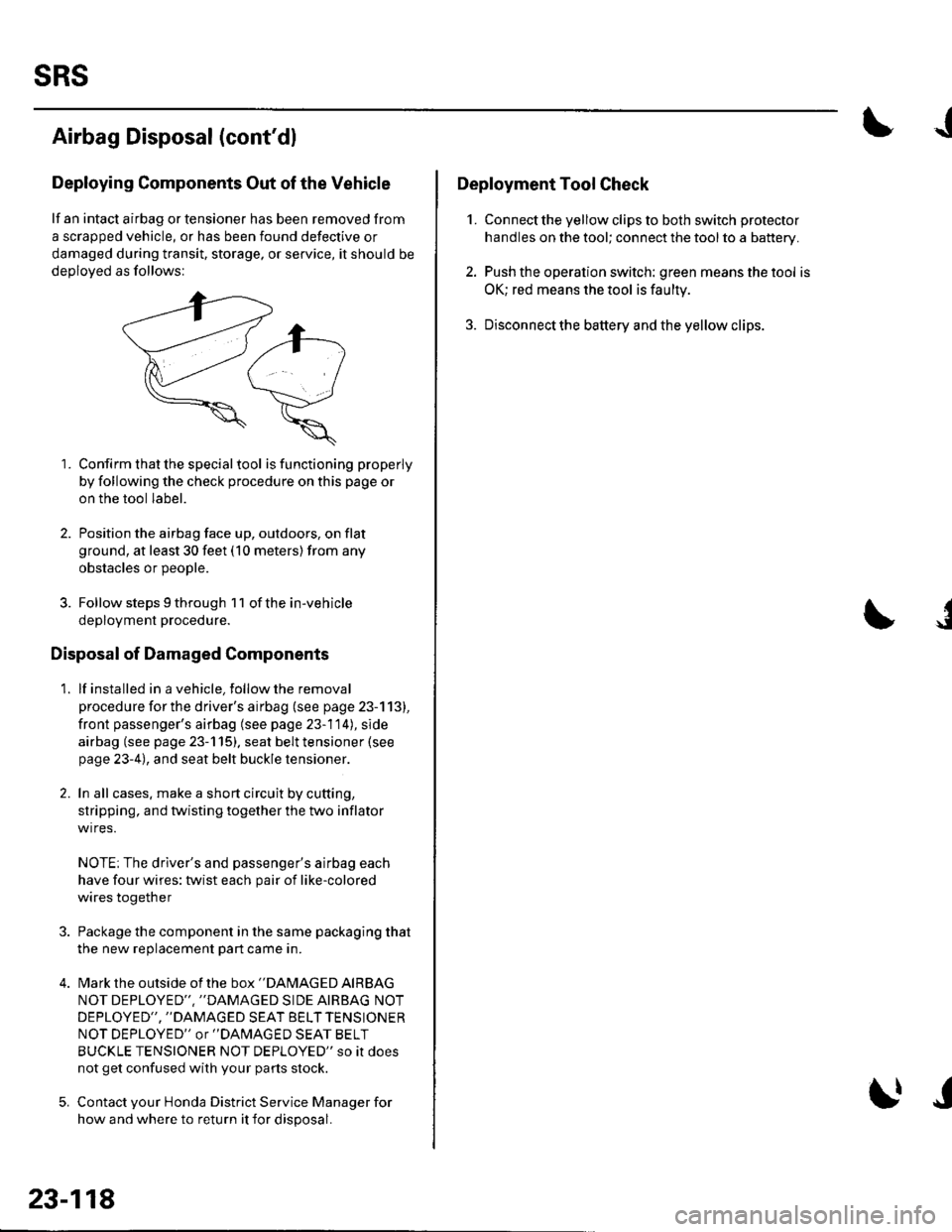

Deploying Components Out of the Vehicle

lf an intact airbag or tensioner has been removed from

a scrapped vehicle, or has been found defective or

damaged during transit, storage, or service, it should be

deoloved as follows:

1. Confirm that the special tool isfunctioning properly

by following the check procedure on this page or

on the tool label.

2. Position the airbag face up, outdoors, on flat

ground, at least 30 feet (10 meters) from any

obstacles or DeoDle.

3. Follow steps 9 through 1 1 of the in-vehicle

deployment procedure.

Disposal of Damaged Components

1. lf installed in a vehicle, follow the removal

procedure for the driver's airbag (see page 23-113),

front passenger's airbag (see page 23-114), side

airbag (see page 23-115). seat belt tensioner (see

page 23-4), and seat belt buckle tensioner.

2. In all cases. make a short circuit by cutting,

stripping, and twisting together the two inflator

wires.

NOTE; The driver's and passenger's airbag each

have four wires: twist each pair of like-colored

wires together

Package the component in the same packaging that

the new reolacement Dart came in.

Mark the outside of the box "DAMAGED AIRBAG

NOT DEPLOYED'" ''DAMAGED SIDE AIRBAG NOT

DEPLOYED", "DAMAGED SEAT BELT TENSIONER

NOT DEPLOYED" or "DAlvlAGED SEAT BELT

BUCKLE TENSIONER NOT DEPLOYED" so it does

not get confused with your parts stock.

Contact your Honda District Service Manager for

how and where to return it for disposal.

23-118

I|J

J

Deployment Tool Check

1. Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

2. Push the operation switch: green means the tool is

OK; red means the tool is faulty

3. Disconnectthe battery and the yellow clips.

J