diagram HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 36 of 1139

\.

Engine Electrical

Engine Electrical

SpecialTools

Starting System

Comoonent Location Index ...............

Circuit Diagram

Starter Circu it Troubleshooting

Clutch Interlock Switch Test

Starter Solenoid Test ..............

Sta rter Performance Test

Starter Reolacement ...............

Starter Overhaul .......................

lgnition System

Component Location Index ...............

Circuit Diagram

lgnition Timing Inspection

lgnition Coil Removal/1nsta11ation .......................

Spark Plug Inspection

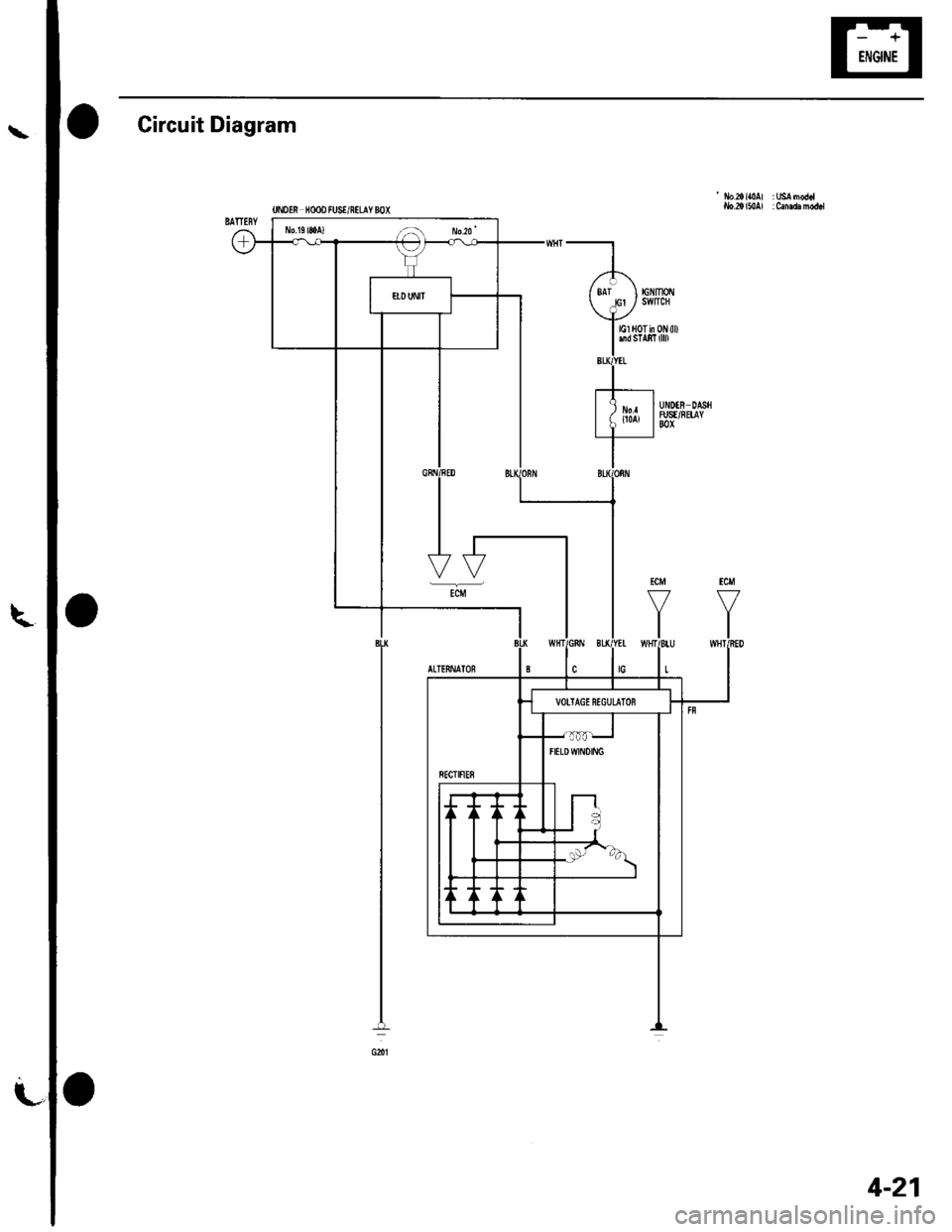

Charging System

Component Location Index .................................. 4-2O

Circuit Diagram ........................... 4-21

Charging Circuit Troubleshooting ....................... 4-22

Drive Belt Inspection ................... 4-26

Drive Beft Replacement .............. 4-26

Drive BeftAuto-tensioner Inspection .................. 4-27

Drive Beft Auto-tensioner Replacement .............. 4-28

Alternator Reolacement ............. 4-29

Alternator Overhaul ................ .... 4-30

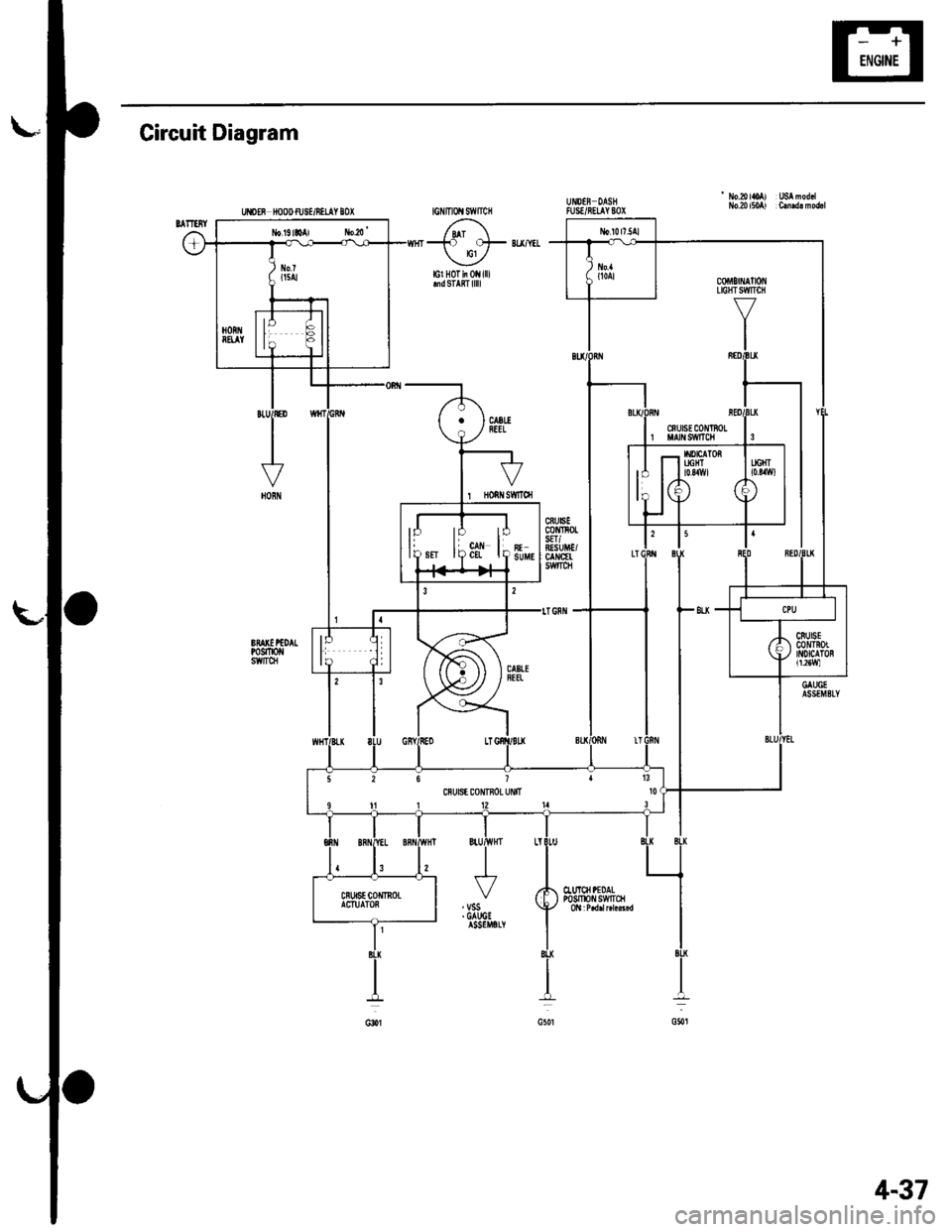

Cruise Control

Component Location Index .................................. 4-36

Circuit Diagram ........................... 4-37

Symptom Troubleshooting Index ....................... 4-38

Cruise Control Unit lnDut Test ............................. 4-40

Main Switch TesVReolacement ........................... 4-42

SeVResume/Cancel Switch TesVReplacement .. 4-42

Cruise Control Actuator Test ...... 4-43

Cruise Control Actuator/Cable Replacement ...... 4-44

Actuator Cable Adjustment .................................. 4-45

Clutch Pedal Position Switch Test ....................... 4-45

4-2

4-J

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-15

4-16

4-17

4-18

4- 19

-+

ENGINE

Page 39 of 1139

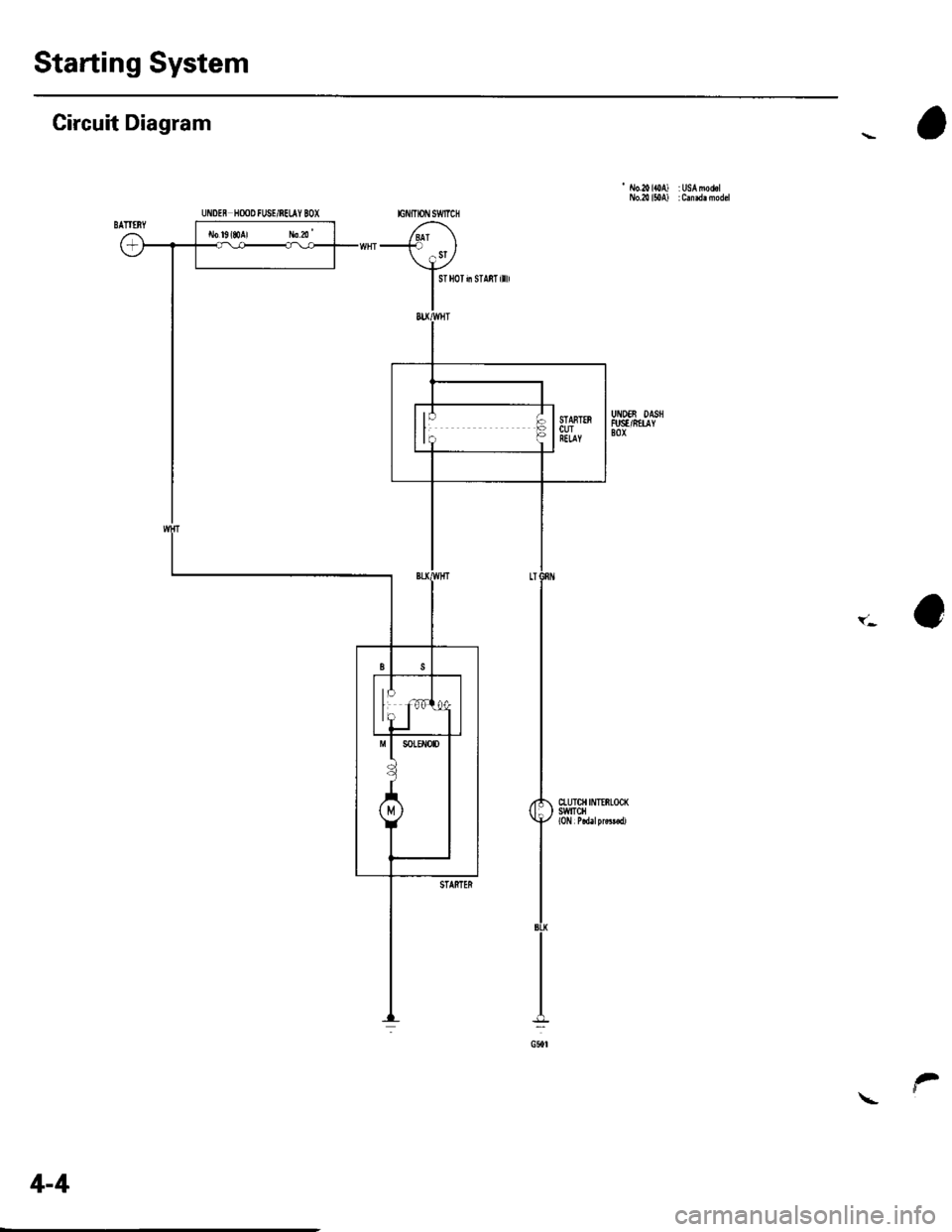

Starting System

Circuit Diagram

- ilo.20lOA) :USA motklNo.2! l50A) : C.nid. model

UiIOEN H@D fUSE/REI.IY BOX

UNDEi OASTIFUST/ifLAY80x

Y.

ST HOT in STA8T illl

cLuTot [{Tr8LocKswtlcH

4-4

a

Page 43 of 1139

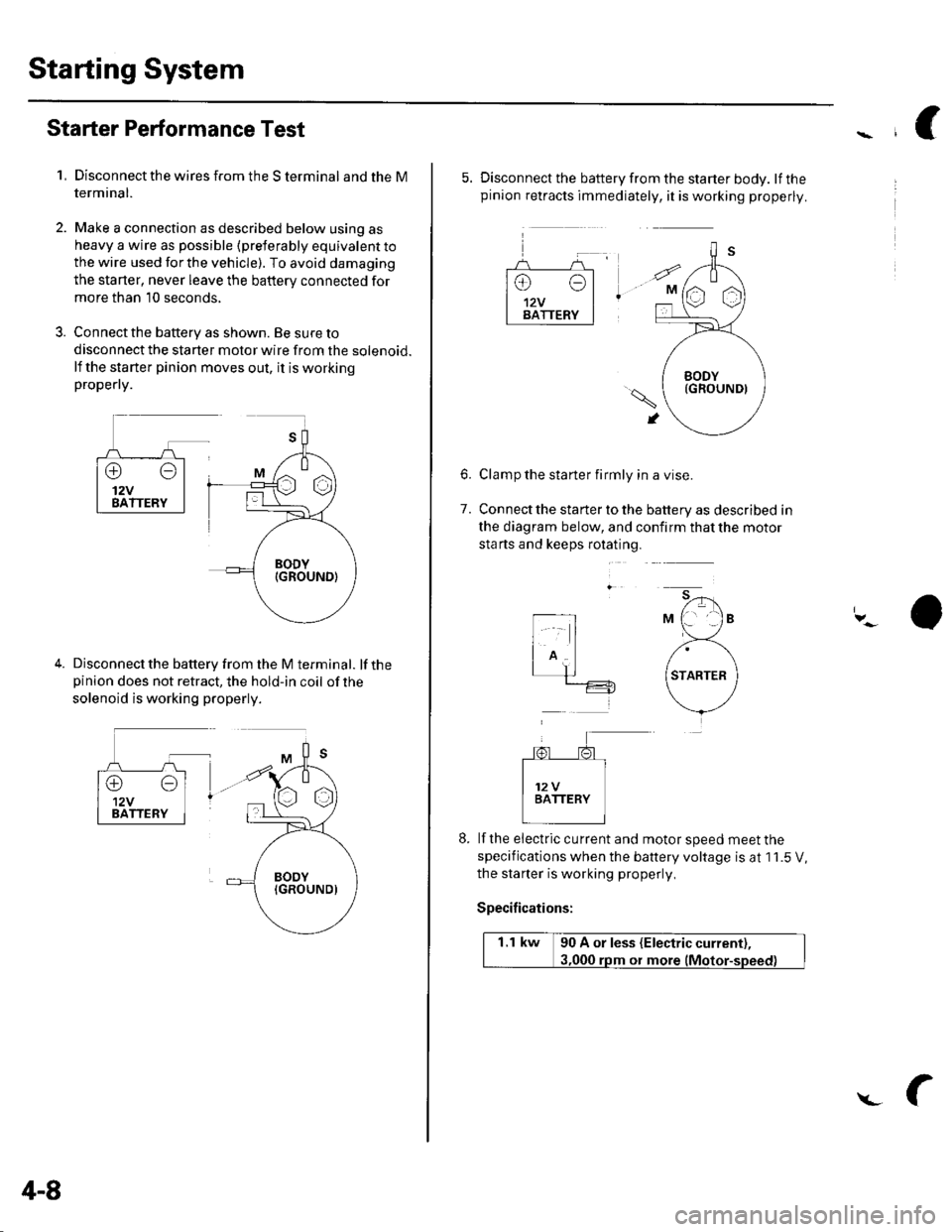

Starting System

Starter Performance Test

1,Disconnect the wires from the S terminal and the M

termrnal.

Make a connection as described below using as

heavy a wire as possible (preterably equivalent to

the wire used for the vehicle). To avoid damaging

the starter, never leave the battery connected for

more than 10 seconds,

Connect the battery as shown. Be sure to

disconnect the starter motor wire from the solenoid.

lf the starter pinion moves out, it is workingpropefly.

Disconnect the battery from the M terminal. lf thepinion does not retract, the hold-in coil of the

solenoid is working properly.

4-8

L

5. Disconnect the battery from the starter body. lfthepinion retracts immediately, it is working properly.

Clamp the starter firmly in a vise.

Connect the starter to the battery as described in

the diagram below, and confirm that the motor

sta rts and keeps rotating.

6.

7.

lf the eiectric cu rrent and motor speed meet the

specifications when the battery voltage is at 1 1.5 V,

the staner is working properly,

Specifications:

1.1 kw 90 A or less (Electric current),

ot more

Page 51 of 1139

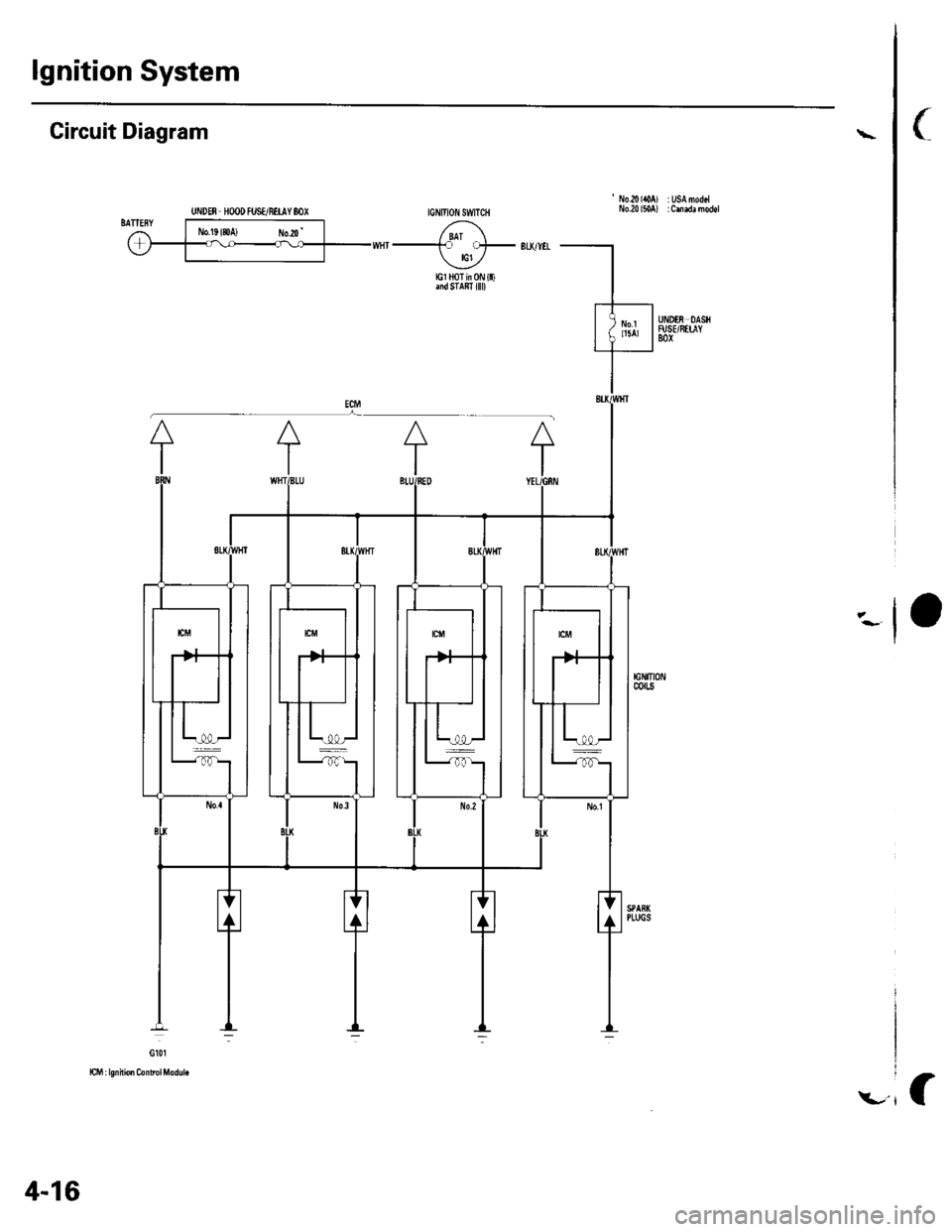

lgnition System

Gircuit Diagram

'No.20lOA) :USAmo&lNo.A l50A) :Cmrda model

(

UNDEB HOOD FUST/8TIAY M)(

lG1 tioT in 0N {ll)rd SIARI illl)

4-16

Page 56 of 1139

\

L

Circuit Diagram

'flo. {l0Al :uSA hod.lilo.20l50Al :C.n.d.mod.lUNDTR XOOD FUSI/RILAY MX

+--,

I fm lil*t"t'

T-

+ilt

=l

4-21

Page 72 of 1139

Circuit Diagram

' No.aloAl USAnod.lNo.20 itoAl C.md! modrlUISEF NOOD fUS'/iILAY IOX

-to ots BU/YIL

lcl H0Tii0llilllmdSTARTlllll

1 Honilsffroi

CTuICII PEDALP0sm0 swtrct

26 1113cnu6E coNTnoL uNtT l0

4-37

Page 191 of 1139

Engine Cooling

Cooling System

Component Location Index ......................................... 10-2

Radiator Cap Test ..................... .......... 10-3

RadiatorTest ............. 10-3

Fan Motor Test .......... l0-4

Thermostat Test ...................... ........... 10-4

Water Pump Inspection ..................... 10-5

Water Pump Replacement ................. 10-5

Coolant Check .............. ....................... 10-6

Coolant Replacement ......................... 10-6

Thermostat Replacement .................. 10-8

Water Passage Installation ................ 10-9

Water Outlet Installation .................... 10-9

Radiator and Fan Replacement ................................... 10-10

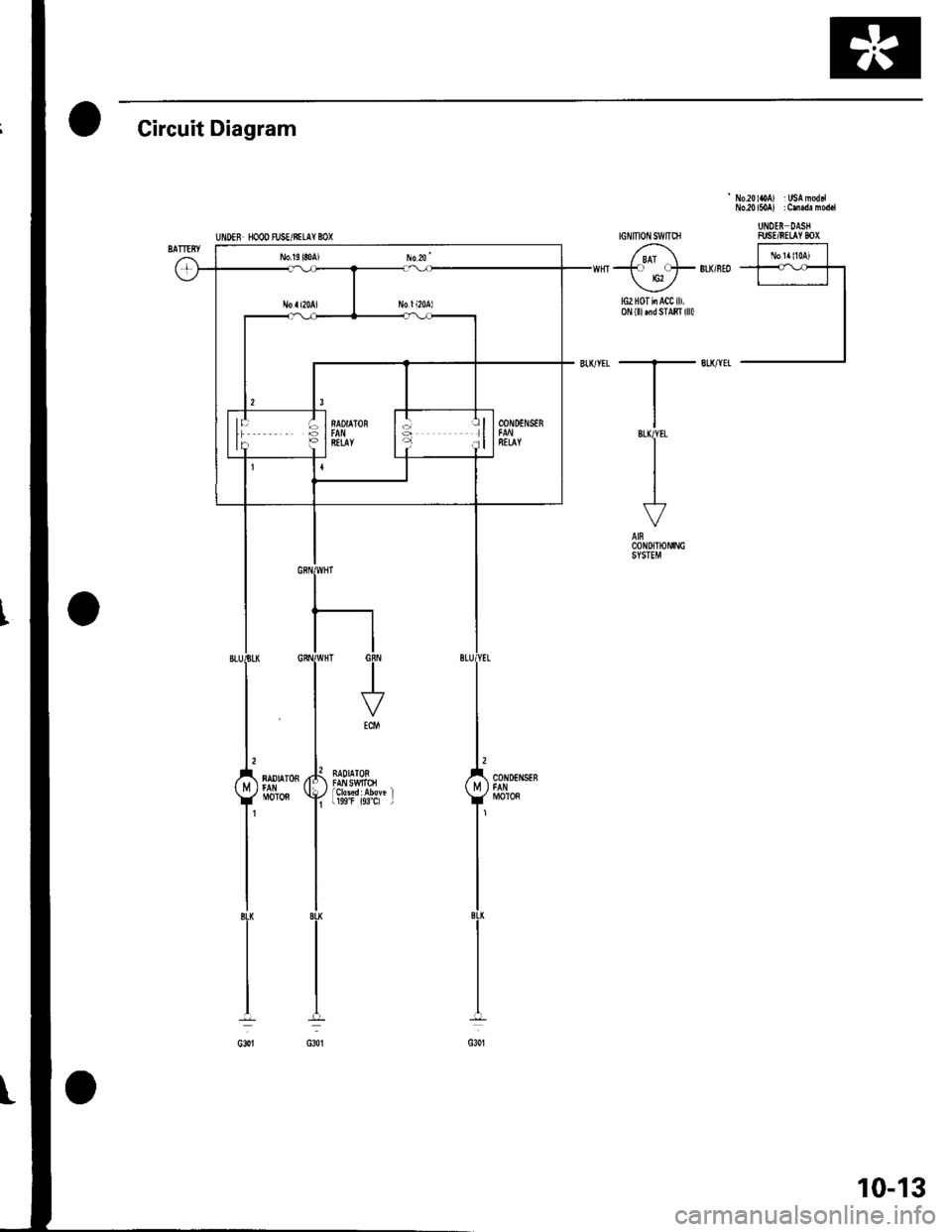

Fan Controls

Component Location Index ......................................... 10-11

Symptom Troubleshooting Index ............................... 10-12

Circuit Diagram ......... 10-13

Radiator Fan CircuitTroubleshooting ........................ 10-14

Radiator Fan Switch Circuit Troubleshooting

(Open) ............ ........ 10-16

Radiator Fan Switch Circuit Troubleshooting

(Short) ............ ........ 10-16

Radiator Fan Switch Test ................... 10-17

Radiator Fan Switch Reolacement .............................. 10-17

Page 203 of 1139

oCircuit Diagram

UIIDEF HOOD FJSE/NILAY BOX

' No.20loA) : USA moddNo.20l50A) : Cm.de mod.l

UNDEN DASXFUSE/RELAY BOX

lG2H0TiiAClill,0N{lllrndSTABI llll)

10-13

Page 238 of 1139

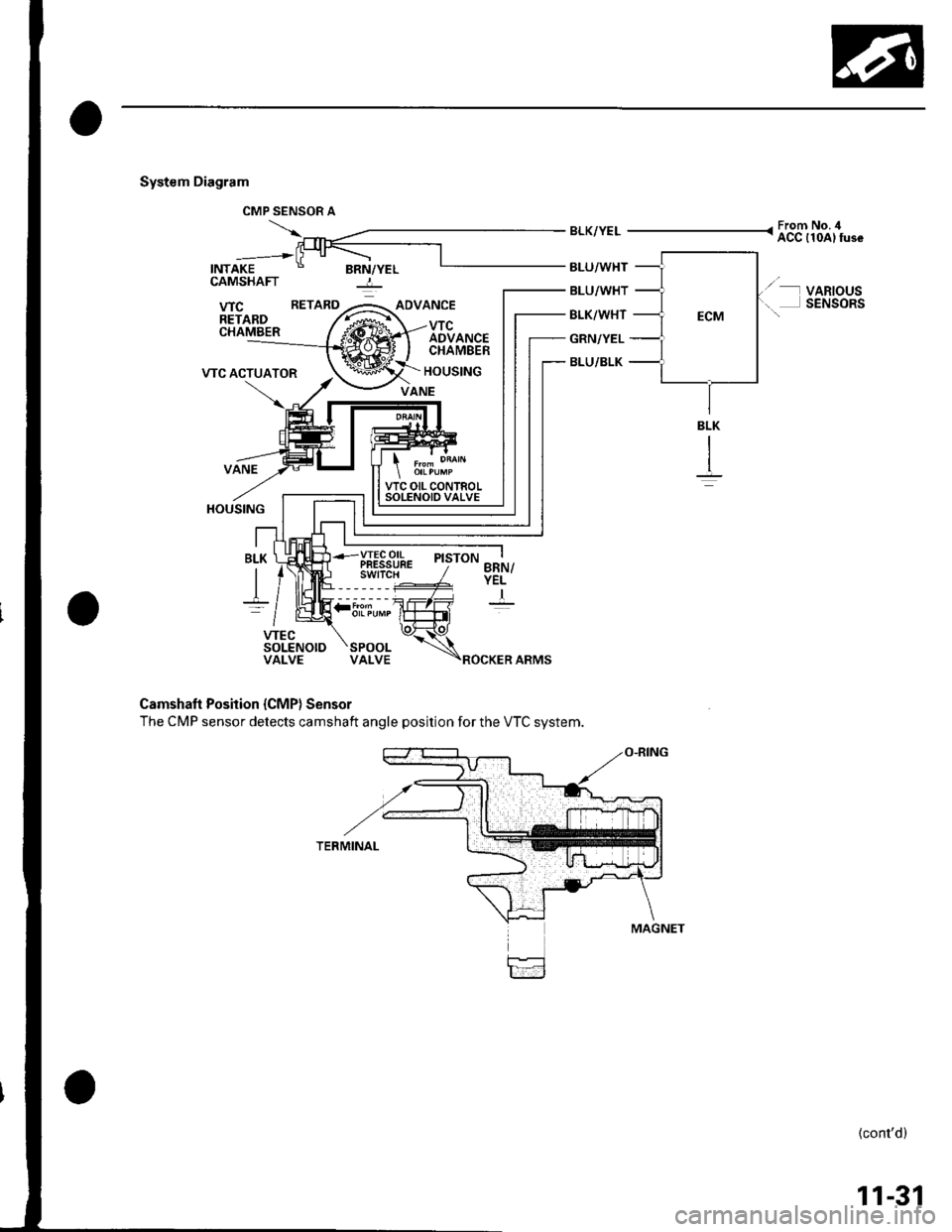

System Diagram

INTAKE

CMP SENSOR A

BRN/YELBLU/WHT

BLU/WHT

BLK/WHT

GRN/YEL

BLU/BLK

From No. ilACC {10A) fuse

VARIOUSSENSORS

CAMSHAFT -:-

BLK

It

Camshaft Position {CMP} Sensor

The CMP sensor detects camshaft angle position for the VTC system.

{cont'd}

11-31

:5i.T,""

Page 239 of 1139

Fuel and Emissions Systems

(

{

System Descriptions (cont'd)

ldle Control System

When the engine is cold, the Ay'C compressor is on, the

transmission is in gear, the brake pedal is pressed. thepower steering load is high, or the alternator is

charging, the ECIM controls current to the ldle Air

Control (lAC) valve to maintain the correct idle speed.

Refer to the System Diagram to see the functional

layout of the system.

Brake Pedal Position Switch

The brake pedal position switch signals the ECM when

the brake pedal is oressed.

Electrical Power Steering (EPS) Senser

The EPS sensor signals the ECM when the power

steering load is high.

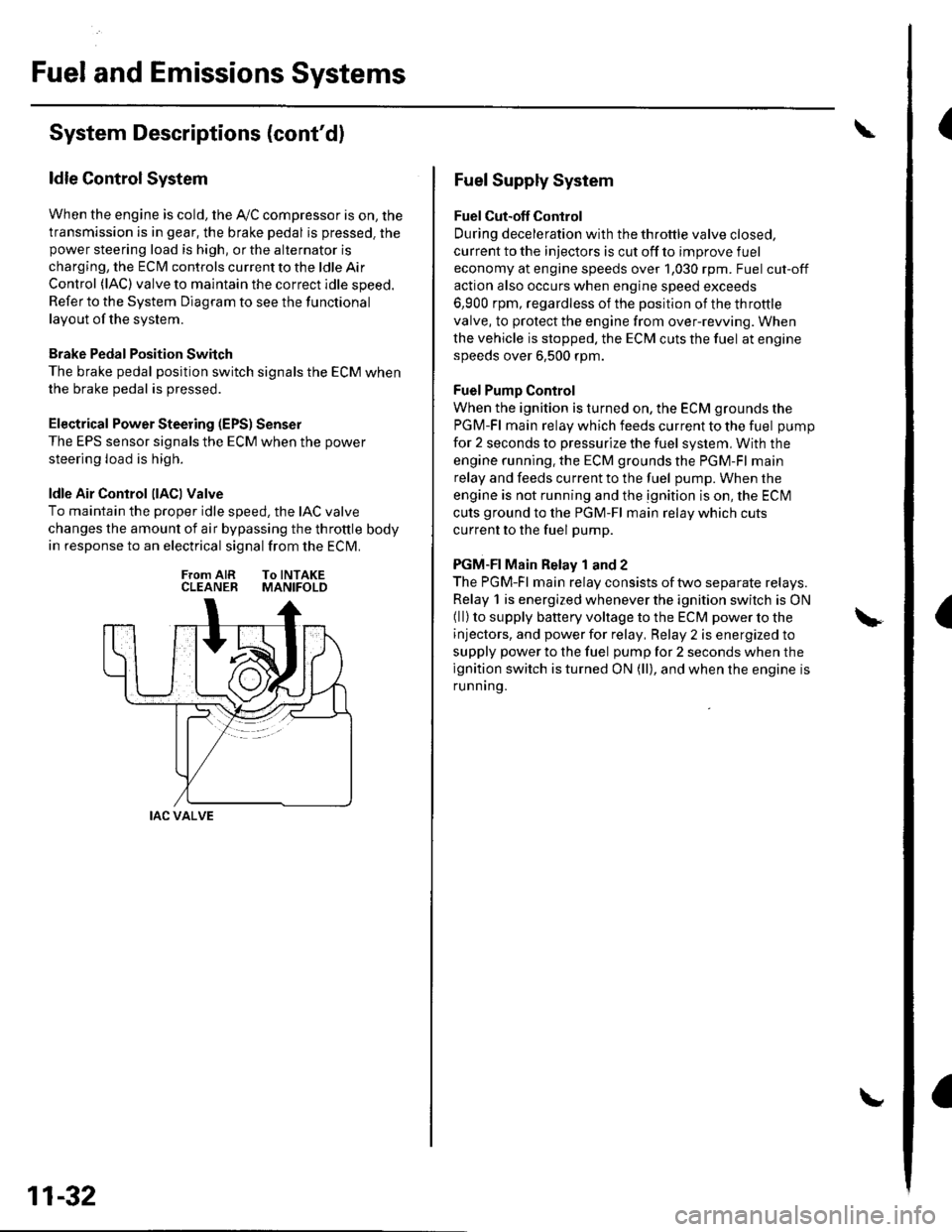

ldle Air Control llACl Valve

To maintain the proper idle speed, the IAC valve

changes the amount of air bypassing the throttle body

in response to an electrical signal from the ECM.

From AIR To INTAKECLEANER MANIFOLD

IAC VALVE

11-32

Fuel Supply System

Fuel Cut-off Control

During deceleration with the throttle valve closed,

current to the injectors is cut off to improve fuel

economy at engine speeds over 1,030 rpm. Fuel cut-off

action also occurs when engine speed exceeds

6,900 rpm, regardless of the position of the throttle

valve, to protect the engine from over-rewing. When

the vehicle is stopped. the ECM cuts the fuel at engine

speeds over 6,500 rpm.

Fuel Pump Control

When the ignition is turned on, the ECM grounds the

PGM-Fl main relay which feeds current to the fuel pump

for 2 seconds to pressurize the fuel system, With the

engine running. the ECM grounds the PGM-Fl main

relay and feeds current to the fuel pump. When the

engine is not running and the ignition is on, the ECI\4

cuts ground to the PGM-Fl main relay which cuts

current to the fuel pump.

PGM-FI Main Relay 1 and 2

The PGM-Fl main relay consists of two separate relays.

Relay 1 is energized whenever the ignition switch is ON(ll) to supply battery voltage to the ECM power to the

injectors, and power for relay, Relay 2 is energized to

supply power to the fuel pump for 2 seconds when the

ignition switch is turned ON (ll), and when the engine is

runnrng.