lock HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 571 of 1139

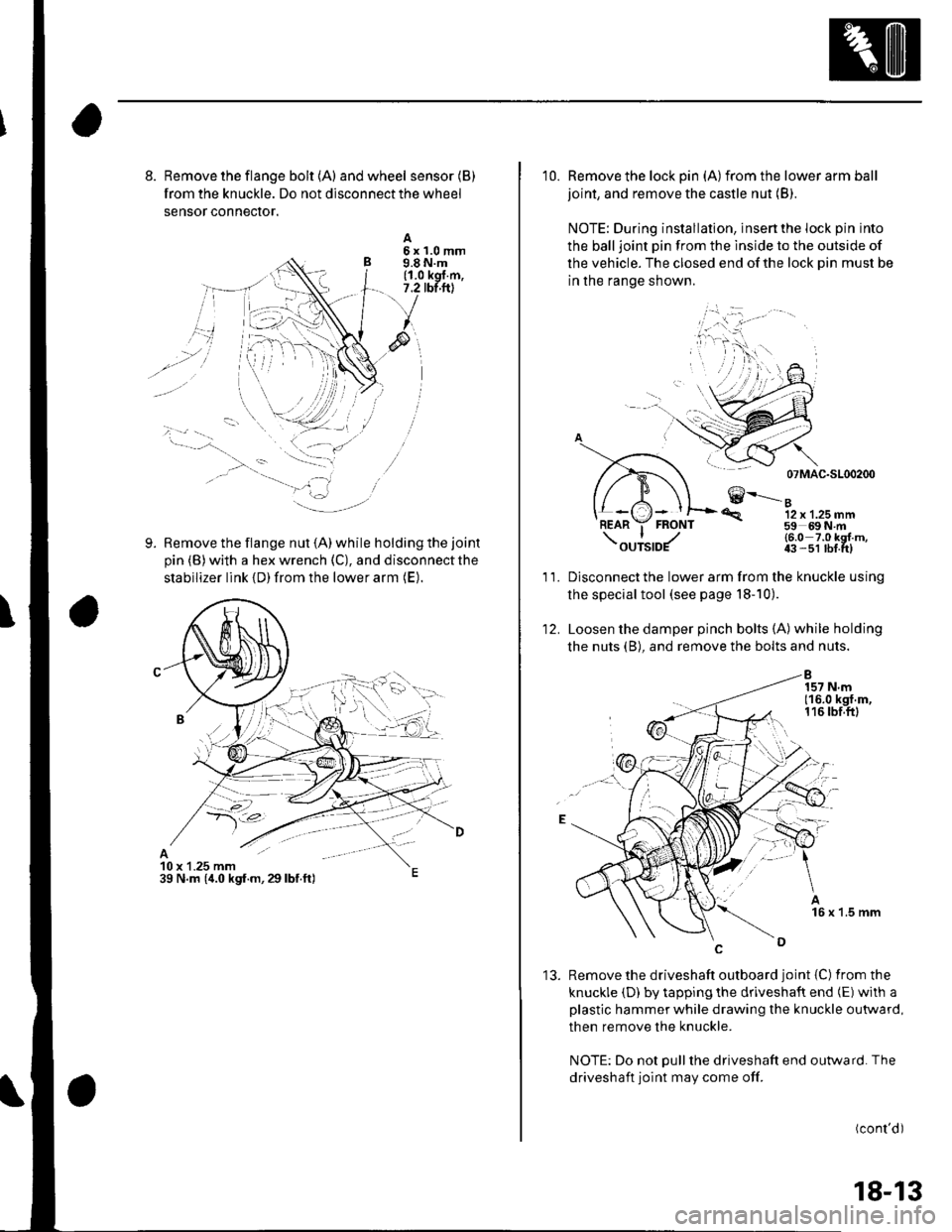

8. Remove the flange bolt {A) andwheel sensor(B)

from the knuckle. Do not disconnect the wheel

sensor conneclor.

Remove the flange nut (A) while holding the joint

pin (B) with a hex wrench (C), and disconnect the

stabilizer link {D) from the lower arm (E).

A5x1.0mm9.8 N.m(1.0 kgl.m,7.2 tbt.ftl

9.

10 x 1.25 mm39 N.m (,1.0 kgf.m,29lbf.ft)

10. Remove the lock pin (A)from the lower arm ball

joint, and remove the castle nut (B).

NOTE: During installation, insert the lock pin into

the balljoint pin from the lnside to the outside of

the vehicle. The closed end of the lock Din must be

in the range shown.

07 MAC-SL00200

€--....-"12 x 1.25 mm59 69N m

'R.

11.

12.

(6.0 7.0 kgl m,43 -51 lbf tt)

Disconnect the lower arm from the knuckle using

the special tool (see page l8-10).

Loosen the damper pinch bolts (A) while holding

the nuts (B), and remove the bolts and nuts.

'13. Remove the driveshaft outboard joint {C) fromthe

knuckle (D) by tapping the driveshaft end (E) with a

plastic hammer while drawing the knuckle outward,

then remove the knuckle.

NOTE: Do not Dull the driveshaft end outward. The

driveshaft joint may come off.

(cont'd)

18-13

Page 575 of 1139

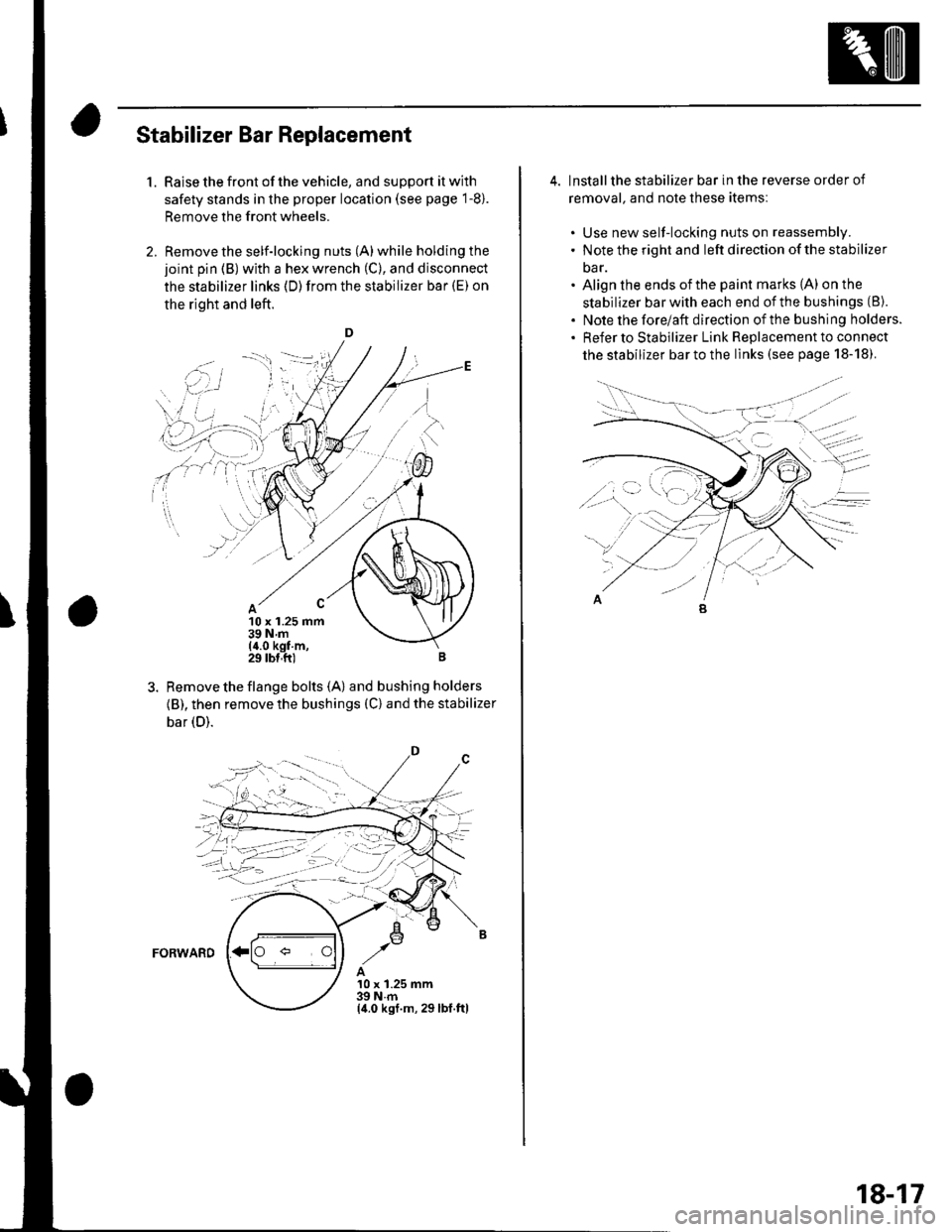

Stabilizer Bar Replacement

1.Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

Remove the self-locking nuts (A) while holding the

joint pin (B) with a hex wrench (C), and disconnect

the stabilizer links (D)from the stabilizer bar (E) on

the right and left.

D

10 x 1.25 mm39Nm(4.0 kgf m,29 tbl,ft)

Remove the flange bolts {A) and bushing holders

{B), then remove the bushings (C) and the stabilizer

bar (D).

FORWARD

A10 x 1.25 mm39Nm(4.0 ksf.m, 29lbl.ftl

,.'i i

''i]

. i.',.:-l I

\' ,r' ,' i :..r'j-- r-'1 _: i'

i-ii::;i

;4-llt,-'j--;

4. lnstallthe stabilizer bar in the reverse order of

removal. and note these itemsl

. Use new self-locking nuts on reassembly.. Note the right and left direction of the stabilizer

oar.. Align the ends ofthe paint marks (A) on the

stabilizer bar with each end of the bushings (8).

. Note the forelaft direction ofthe bushing holders.. Refer to stabilizer Link Replacement to connect

the stabilizer bar to the links (see page 18-18).

18-17

Page 576 of 1139

Front Suspension

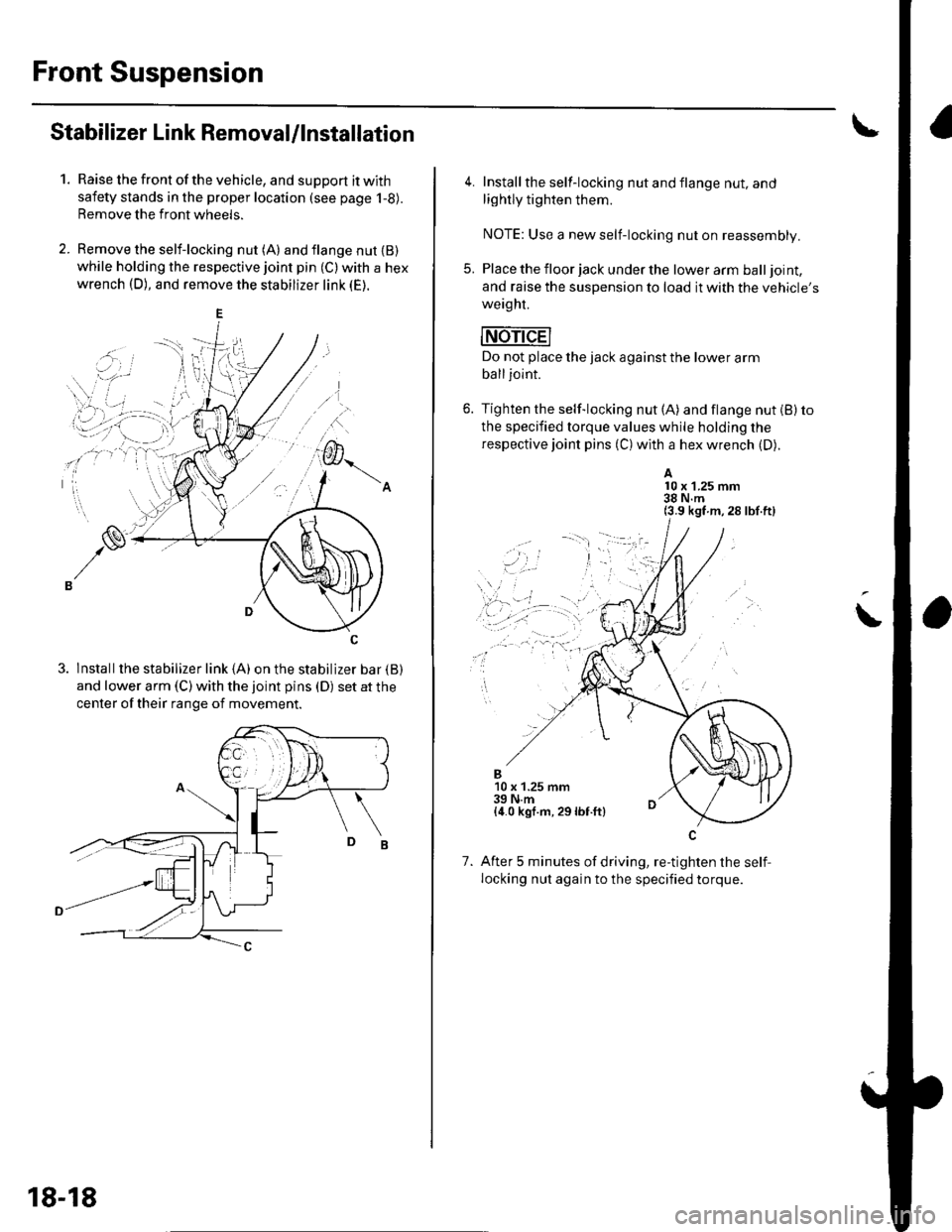

Stabilizer Link Removal/lnstallation

1.Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

Remove the self-locking nut (A) and flange nut {B)while holding the respective joint pin (C) with a hex

wrench (D), and remove the stabilizer link (E).

3. lnstallthe stabilizer link (A) on the stabilizer bar {B)

and lower arm (C) with the joint pins (D) set at the

center of their range of movement.

18-18

4. Install the self-locking nut and flange nut, and

lightly tighten them.

NOTE: Use a new self-locking nut on reassembly.

5. Place the floor jack under the lower arm balljoint,

and raise the suspension to load it with the vehicle's

weaght.

mri-dEl

Do not place the jack against the lower arm

balljoint.

6. Tighten the self-locking nut (A) and flange nut (B) to

the specified torque values while holding the

respective joint pins (C) with a hex wrench (D).

A10 x 1.25 mm38 N.m(3.9 kgf m,28 lbf.ft)

\

..,

1.

B10 x 1.25 mm39 N.m{4.0 kgf.m, 29lbf.ft}

After 5 minutes of driving, re-tighten the self,

locking nut again to the specified torque.

Page 577 of 1139

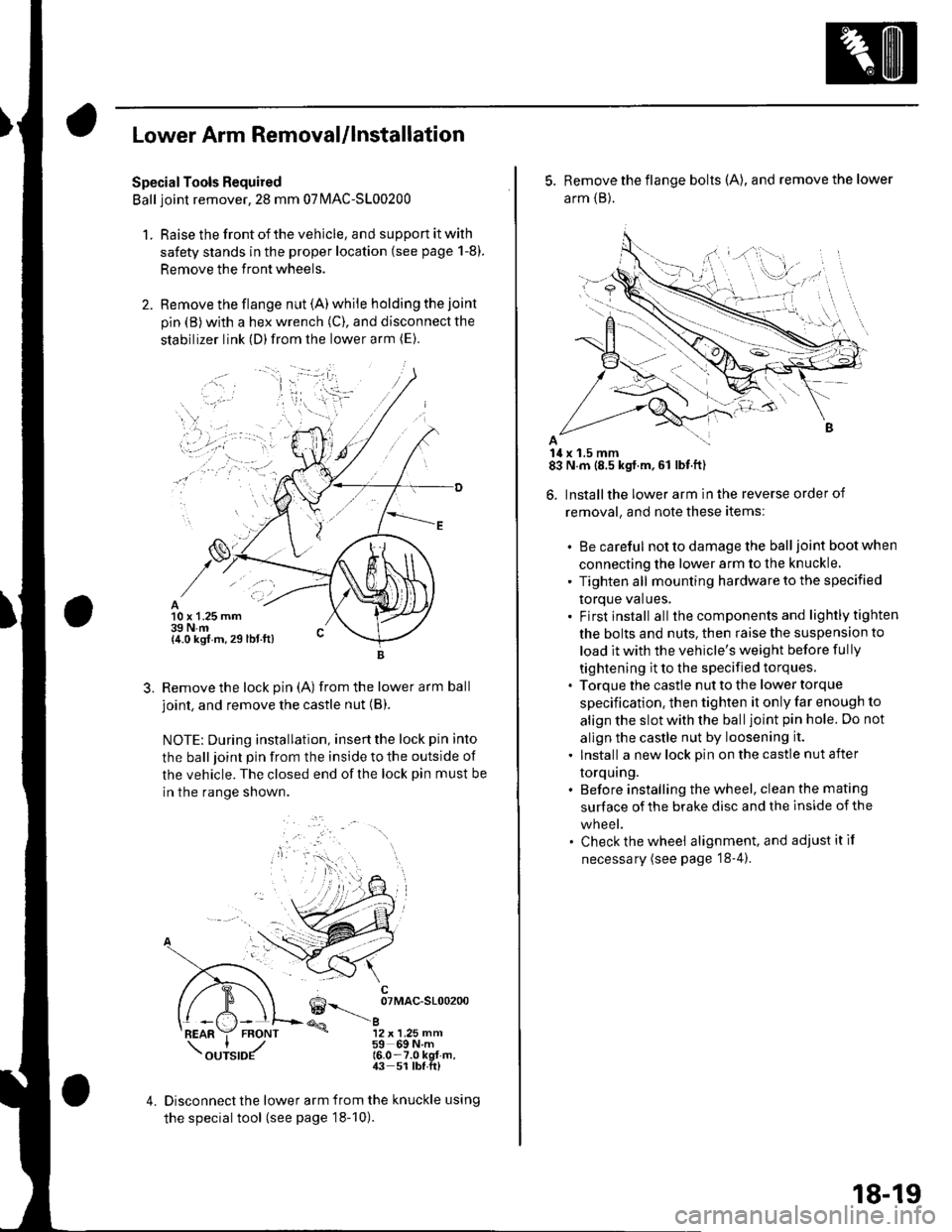

Lower Arm Removal/lnstallation

SpecialTools Required

Ball joint remover,2S mm 07|MAC-S100200

1. Raise the front of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the front wheels.

Remove the flange nut (A) while holding the joint

pin {B) with a hex wrench (C), and disconnect the

stabilizer link (D)from the lower arm (E).

10 x 1.25 mm39 N.m{4.0 kgf m, 29 lbt.ft)

3.Remove the lock pin (A) from the lower arm ball

joint, and remove the castle nut (B).

NOTE: During installation, insertthe lock pin into

the ball joint pin from the inside to the outside of

the vehicle. The closed end of the lock pin must be

in the range shown.

6--__ oTMAc-sloo2oo

@a12 x 1.25 mm59 69Nm16.0-7.0 kgt-m,43 51 lbf.ft)

4.Disconnect the lower arm from the knuckle using

the special tool (see page 18-10).

5. Remove the flange bolts (A), and remove the lower

arm {B}.

14 x 1.5 mm83 N.m (8.5 kgf.m,61 lbf.ft)

6. Installthe lower arm in the reverse order of

removal, and note these items:

. Be careful not to damage the ball joint boot when

connecting the lower arm to the knuckle.

' Tighten all mounting hardware to the specified

torque values,. Firstinstall all the components and lightlytighten

the bolts and nuts. then raise the suspension to

load it with the vehicle's weight before fully

tightening it to the specified torques.. Torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the ball joint pin hole. Do not

allgn the castle nut by loosening it.

. Install a new lock pin on the castle nut after

torquing.. Before installing the wheel, clean the mating

surface of the brake disc and the inside of the

wneet.. Check the wheel alignment, and adjustitif

necessary (see page '18-4).

18-19

Page 578 of 1139

Front Suspension

Damper/Spring Replacement

Exploded View

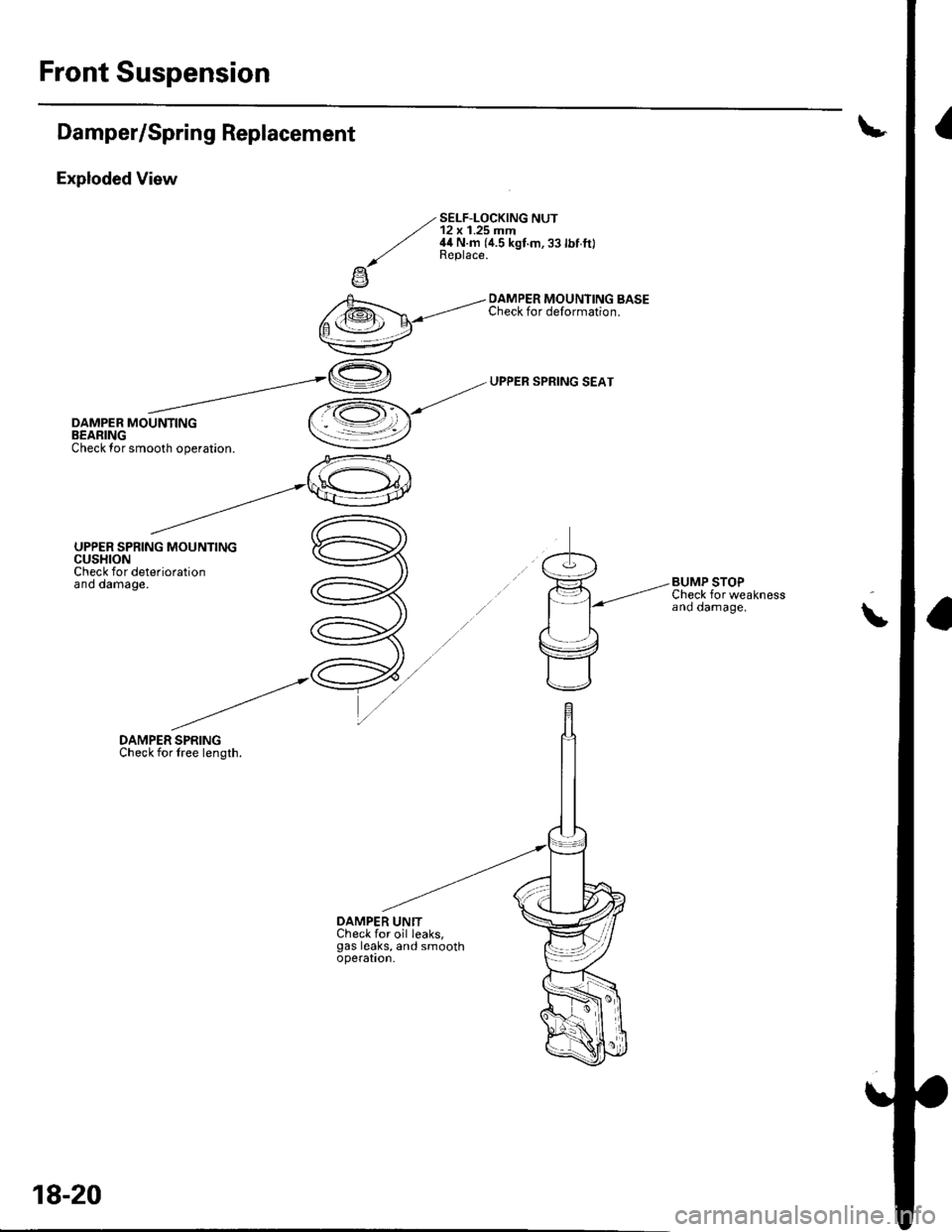

DAMPER MOUNTINGBEARING

UPPER SPRING MOUNTINGCUSHIONCheck for deteriorationano oamage,

DAMPER SPRINGCheck for lree length.

./ SELF-LOCK|NG NUT/.' 12 x 1.25inm

,,/ 44 N.m {4.5 kgt.m, 33lbf.ftl,/ neDtace.^atae9

-€.- - DAMPER MOUNTING BASE

1, @-:'\--""' check for delormation

lF \-:-./ - ,

E9-

DAMPER UNITCheck for oil leaks,gas leaks, and smoothoperatron.

\

18-20

Page 580 of 1139

Front Suspension

Damper/Spring Replacement (cont'd)

Disassembly/lnspection

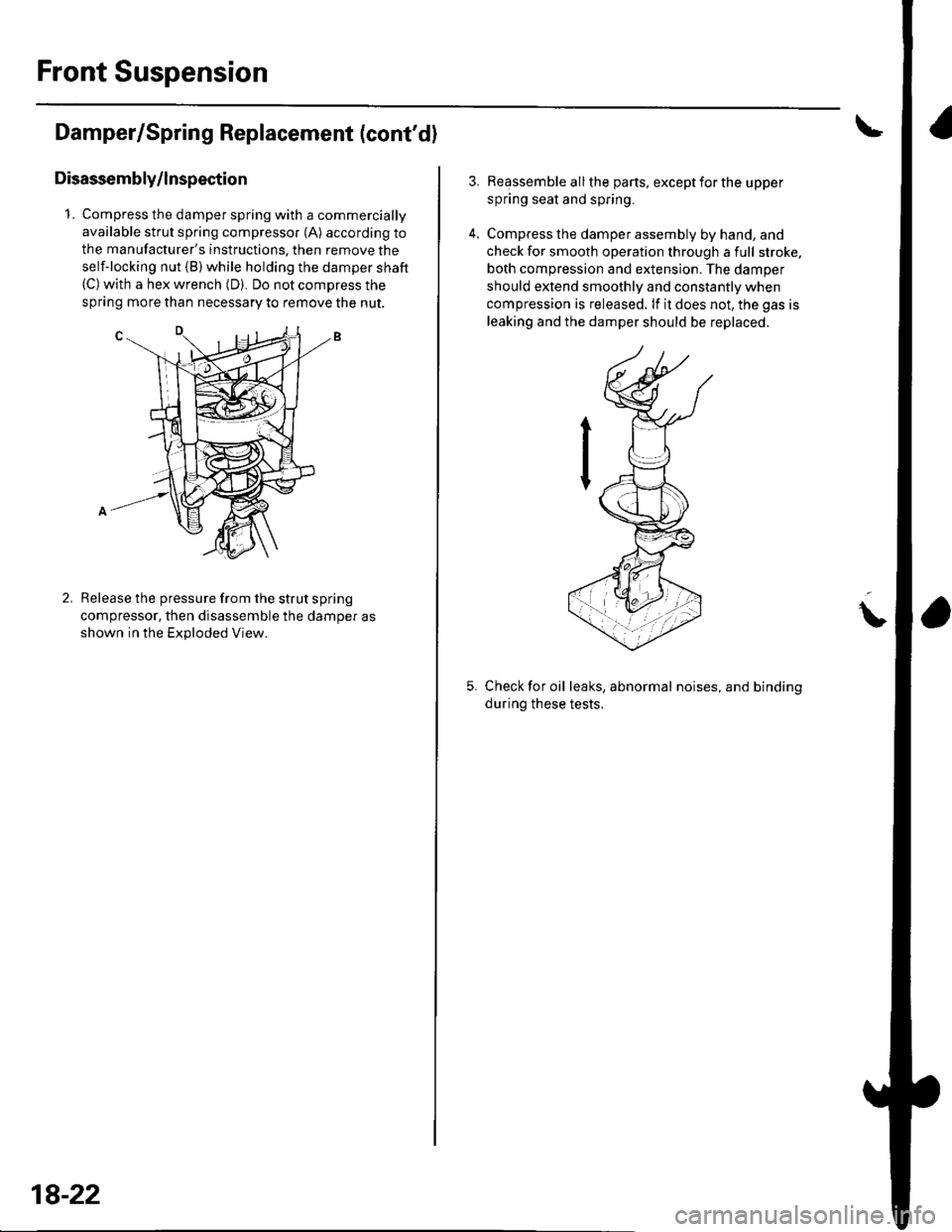

1. Compress the damper spring with a commercially

available strut spring compressor (A) according to

the manufacturer's instructions. then remove the

self-locking nut (B)while holding the damper shaft(C) with a hex wrench (D). Do not compress the

spring more than necessary to remove the nut,

Release the pressure from the strut spring

compressor, then disassemble the damper as

shown in the Exploded View.

18-22

4.

Reassemble all the pans, except for the upper

spring seat and spring.

Compress the damper assembly by hand, and

check for smooth operation through a full stroke.

both compression and extension. The damper

should extend smoothly and constantly when

compression is released. lf it does not, the gas is

leaking and the damper should be replaced.

Check for oil leaks, abnormal noises, and binding

during these tests.

\

Page 587 of 1139

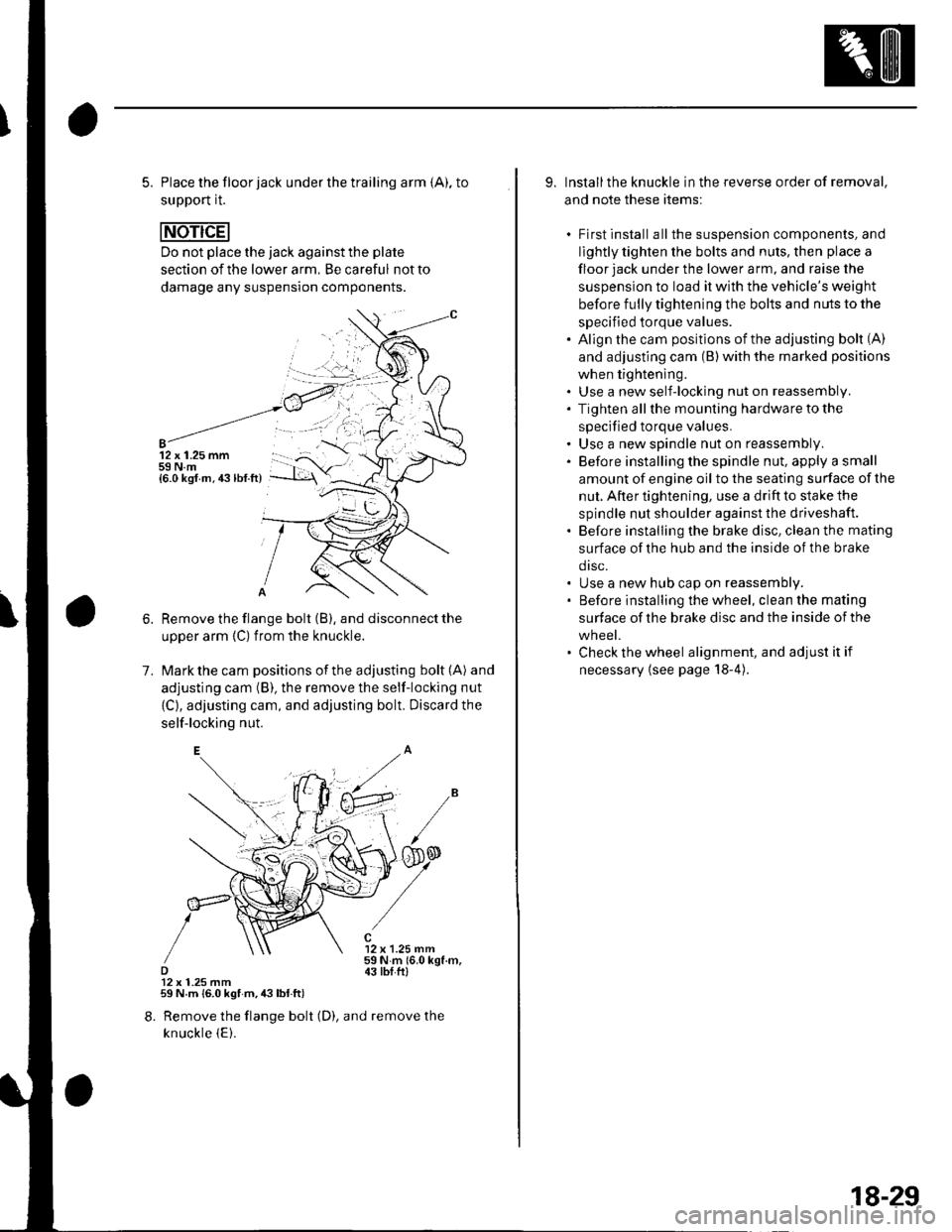

5. Place the floor jack under the trailing arm {A), to

support it.

Do not place the jack against the plate

section of the lower arm, Be careful not to

damage any suspension components.

12 x 1.25 mm59 N.m{6.0 ksf.m.43lbf.ft)

1.

Remove the flange bolt (B), and disconnect the

upper arm {C) from the knuckle.

Mark the cam positions of the adjusting bolt (A) and

adjusting cam (B), the remove the self-locking nut

{C}, adjusting cam, and adjusting bolt. Discard the

self-locking nut.

12 x 1.25 mm59Nm(6.0kgf.m,43 tbI.ftl12 x 1.25 mm59 N.m {6.0 kgf m,43lbl.ft)

8. Remove the flange bolt (D), and remove the

knuckle {E).

9. Installthe knuckle in the reverse order of removal,

and note these items:

. First install all the suspension components, and

lightly tighten the bolts and nuls, then place a

floor jack under the lower a rm, and raise the

suspension to load it with the vehicle's weight

before fully tightening the bolts and nuts to the

specified torque values.. Align the cam positions of the adjusting bolt (A)

and adjusting cam (B) with the marked positions

when tightening.. Use a new self-locking nut on reassembly.. Tighten allthe mounting hardware to the

specified torque values.. Use a new spindle nut on reassembly.. Before installing the spindle nut, apply a small

amount of engine oil to the seating surface of the

nut. After tightening, use a drift to stake the

spindle nut shoulder against the driveshaft.. Before installing the brake disc, clean the mating

surface of the hub and the inside of the brake

drsc.. Use a new hub cap on reassembly.. Before installing the wheel, clean the mating

surface of the brake disc and the inside of the

wheel.. Check the wheel alignment, and adjust it if

necessary {see page 18-4).

18-29

Page 588 of 1139

Rear Suspension

1.

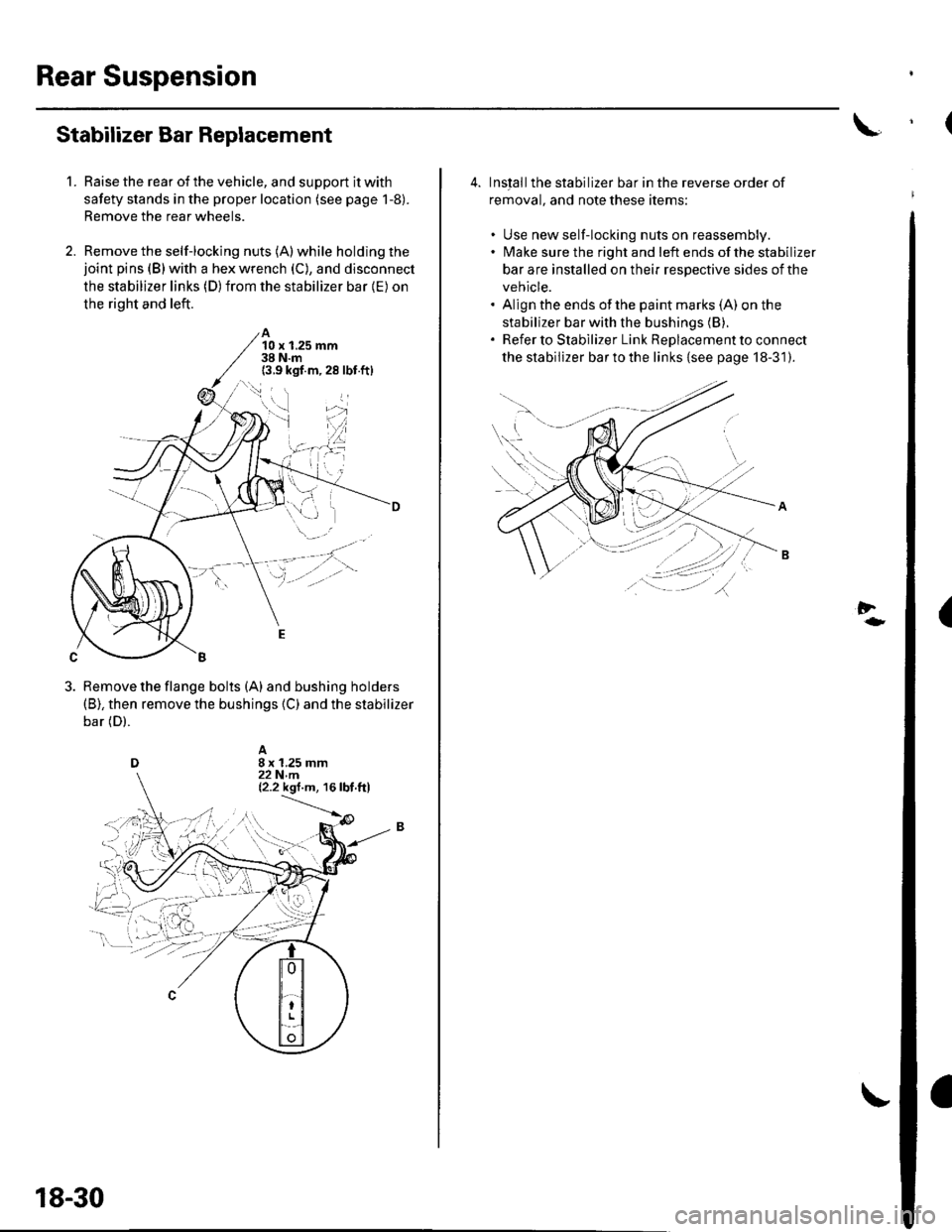

Stabilizer Bar Replacement

Raise the rear of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the rear wheels.

Remove the self-locking nuts (A) while holding thejoint pins (B) with a hex wrench (C), and disconnect

the stabilizer links (D) from the stabilizer bar {E) on

the right and left.

A10 x 1.25 mm38 N.m(3.9 kgf.m,28 lbf.ft)

Remove the flange bolts (A) and bushing holders(B), then remove the bushings {C) and the stabilizer

bar (D).

18-30

4. Inslallthe stabilizer bar in the reverse order of

removal, and note these items:

. Use new self-locking nuts on reassembly.. lMake sure the right and left ends of the stabilizer

bar are installed on their respective sides of the

vehicle.. Align the ends of the paint marks (A) on the

stabilizer bar with the bushings (B).

. Refer to Stabilizer Link ReDlacement to connect

the stabilizer bar to the links {see page 18-31).

Al\.... '..: .

.----'';-r'--\---r-

-tt'.,'t),

(

Page 589 of 1139

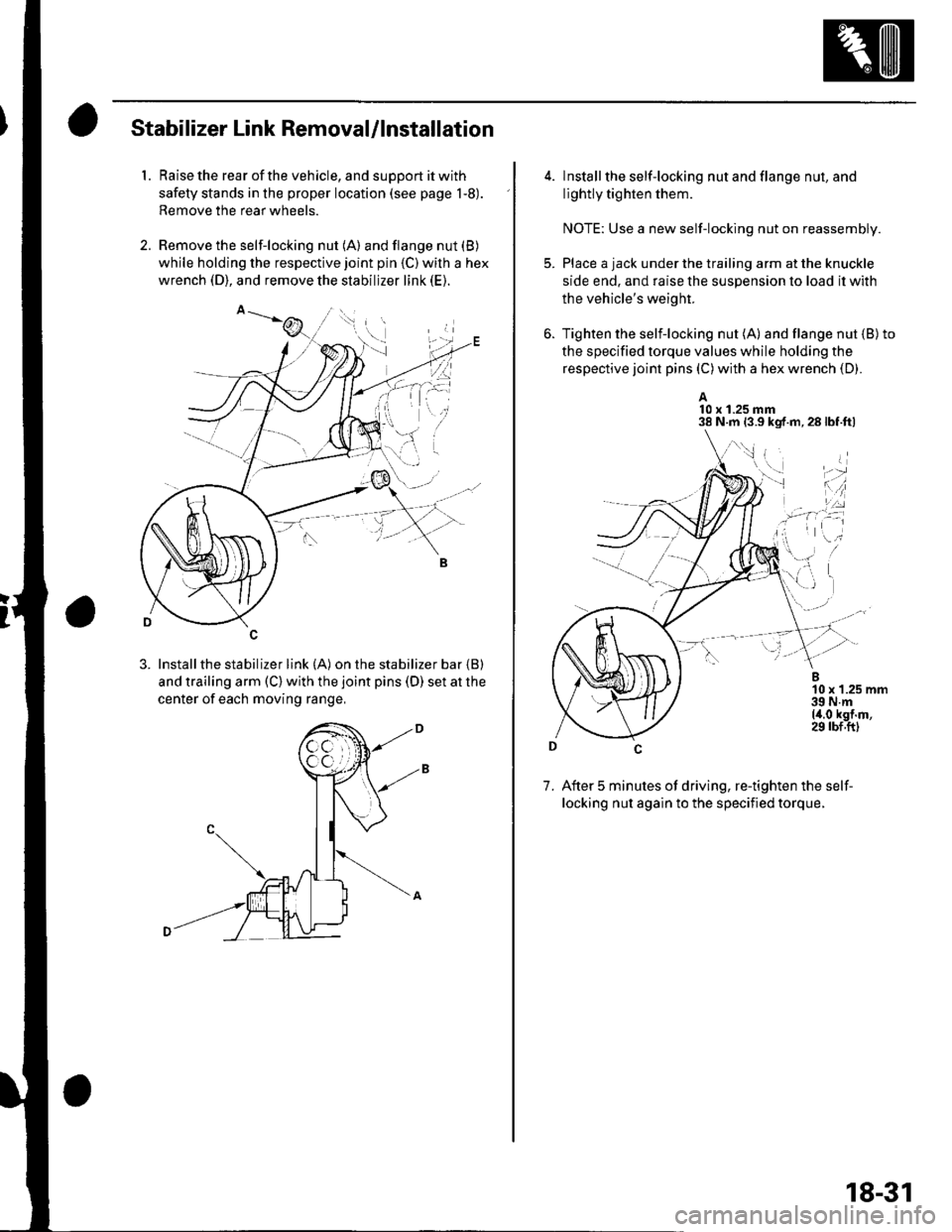

Stabilizer Link Removal/lnstallation

1. Raise the rear of the vehicle, and support it with

safety stands in the proper location (see page 1-8).

Remove the rear wheels.

2. Remove the self-locking nut (A) and flange nut (B)

while holding the respective joint pin {C) wilh a hex

wrench (D), and remove the stabilizer link (E).

3. Installthe stabilizer link (A) on the stabilizer bar {B)

and trailing arm (C) with the joint pins (D) set at the

center of each moving range,

4. lnstall the self-locking nut and flange nut, and

lightly tighten them.

NOTE: Use a new self-locking nut on reassembly.

Place a jack under the trailing arm at the knuckle

side end. and raise the suspension lo load it with

the vehicle's weight.

Tighten the selflocking nut (A) and flange nut {B)to

the specified torque values while holding the

respective joint pins (C) with a hex wrench (D).

A10 x 1.25 mm38 N.m 13.9 kgf.m,28lbf.ftl

7. After 5 minutes of driving, re-tighten the self-

locking nut again to the specified torque.

\,1 i

i'-r d

*l'',:

18-31

Page 592 of 1139

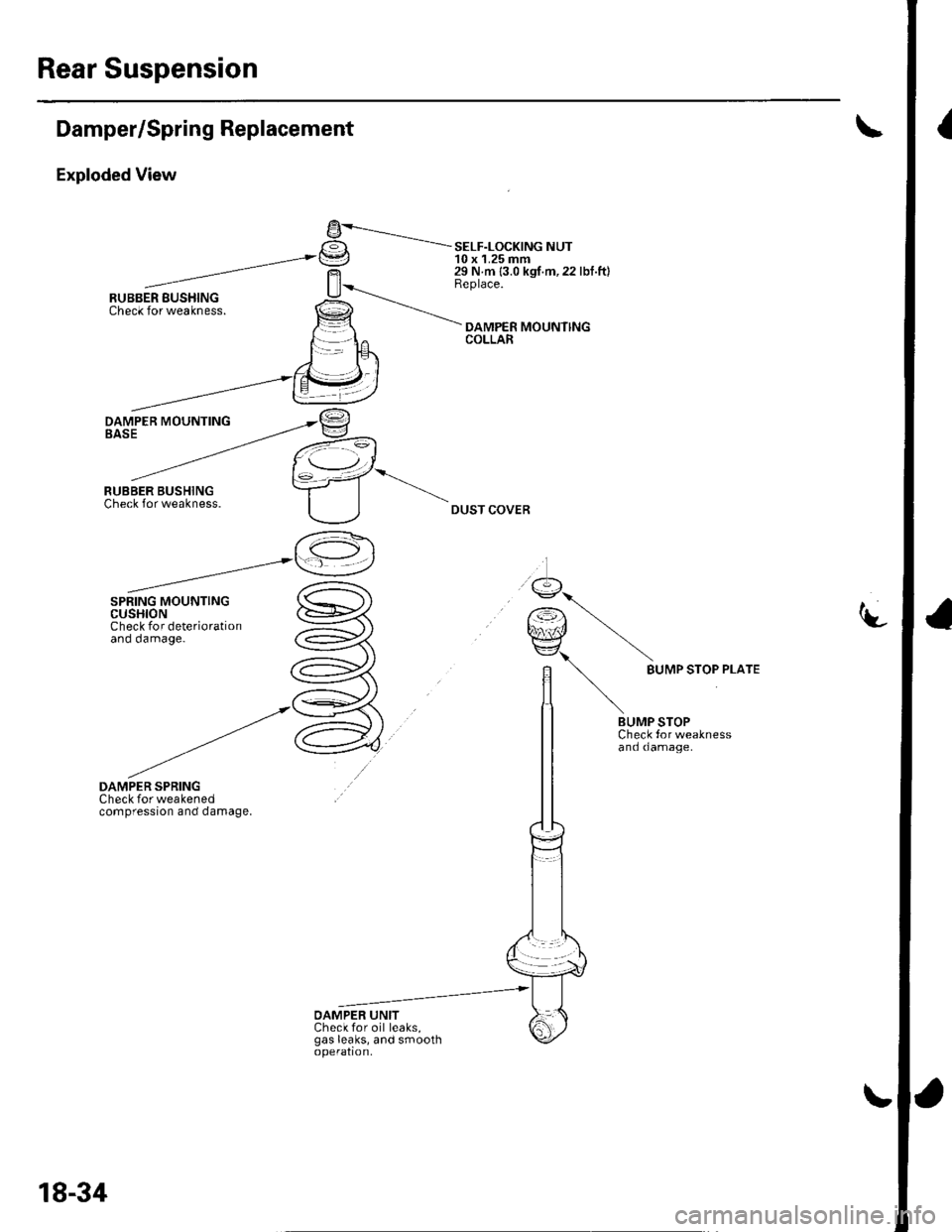

Rear Suspension

IDamper/Spring Replacement

Exploded View

DAMPER SPRINGCheck for weakenedcompression and damage.

9-----.---.-.I€tI -= SELF-LoCK|NG NUTt=J 10 x 1.25 mm29 N m {3.0 kgf.m,22 lbf.ft}Replace.

DAMPER MOUNlINGCOLLAR

DUST COVER

-t-

9...

r€) \qnJ/ \EZ\\

n BUMP sroP PLArE

lt \

/t \BUMP STOPCheck tor weaknessand damage.

OAMPER UNITCheck for oil leaks,gas leaks, and smoothoperation,

18-34