lock HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 745 of 1139

7.

Tighten each bolt and nut securely.

Check that the hatch opens properly and locks

securery.

Reinstall the support struts securely.

Reinstall all remaining removed parts.

Apply multipurpose grease to the pivot portion of

the hatch hinges {A) as indicated by the arrows.

9.

10.

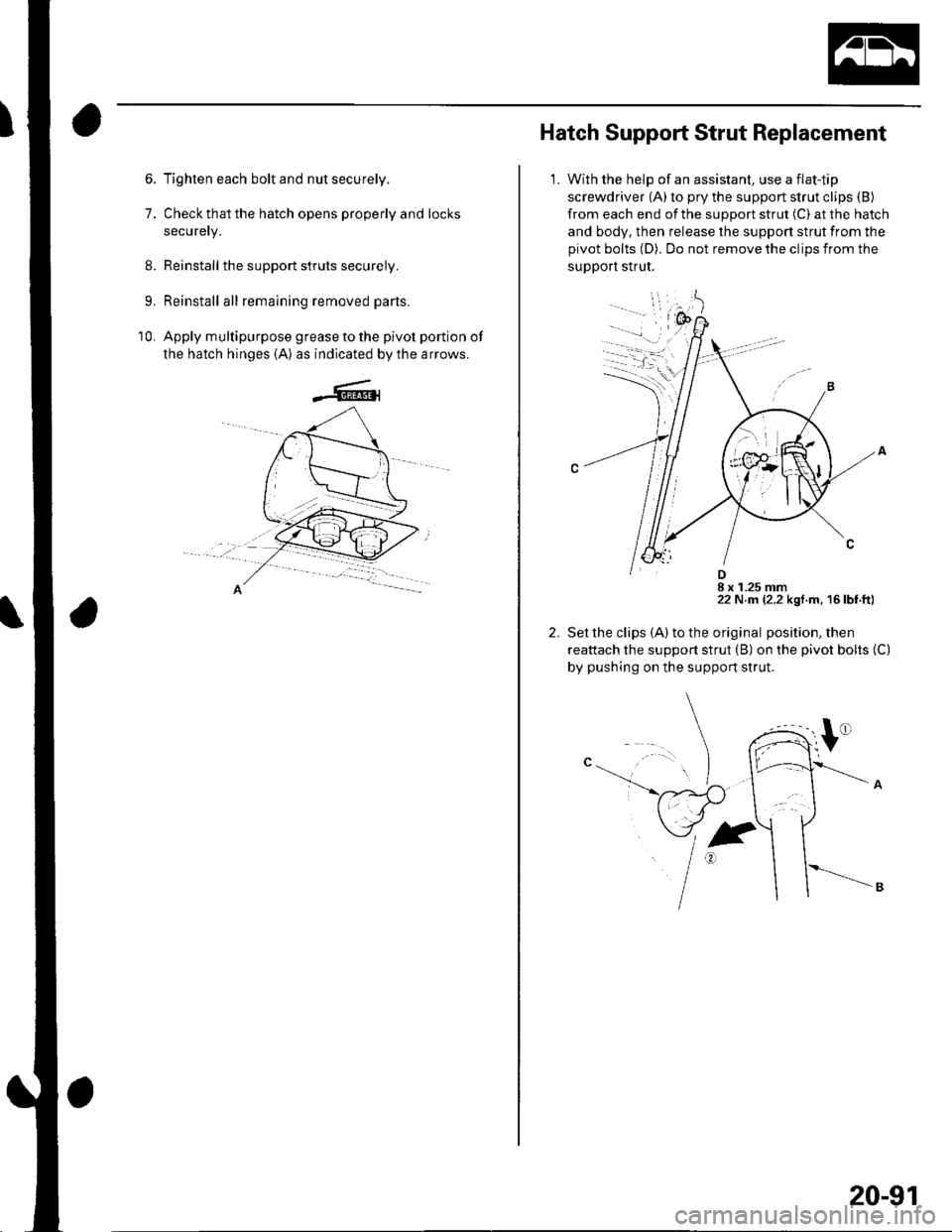

Hatch Support Strut Replacement

1.With the help of an assistant, use a flat-tip

screwdriver (A)to pry the support strut clips (B)

from each end of the support strut (C) at the hatch

and body, then release the support strut from the

pivot bolts (D). Do not remove the clips from the

support strut.

Set the clips (A) to the original position, then

reattach the support strut (B) on the pivot bolts (C)

by pushing on the support strut.

2.

D8 x 1.25 mm22 N.m (2.2 kgf.m, 16 lbf ft)

20-91

Page 747 of 1139

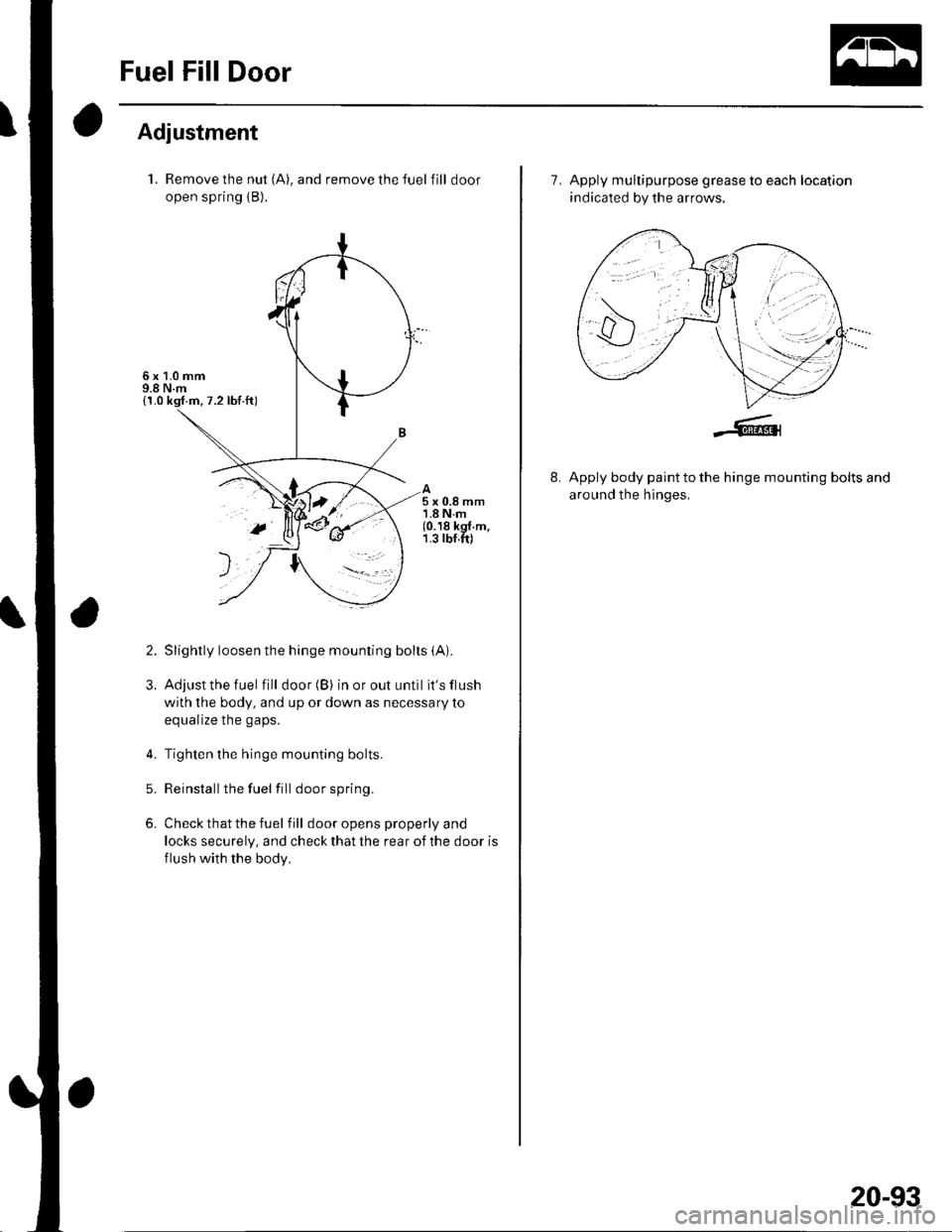

Fuel Fill Door

Adjustment

1. Remove the nut (A), and remove the fuel fill door

open spring {B).

Slightly loosen the hinge mounting bolts (A).

Adjust the fuel fill door (B) in or out until it's flush

with the body, and up or down as necessary toa^rr.li7a tha n.nc

Tighten the hinge mounting bolts.

Reinstallthe fuel fill door spring.

Check that the fuel f ill door opens properly and

locks securely, and check that the rear of the door is

flush with the body.

5x0.8mm1.8Nm(0.18 kgf.m,1.3 rbf.ft)

2.

3.

5.

6.

>t=- r'

7. Apply multipurpose grease to each location

indicated by the arrows.

8.Apply body paint to the hinge mounting bolts and

around the hinges,

20-93

Page 752 of 1139

Exterior Trim

\

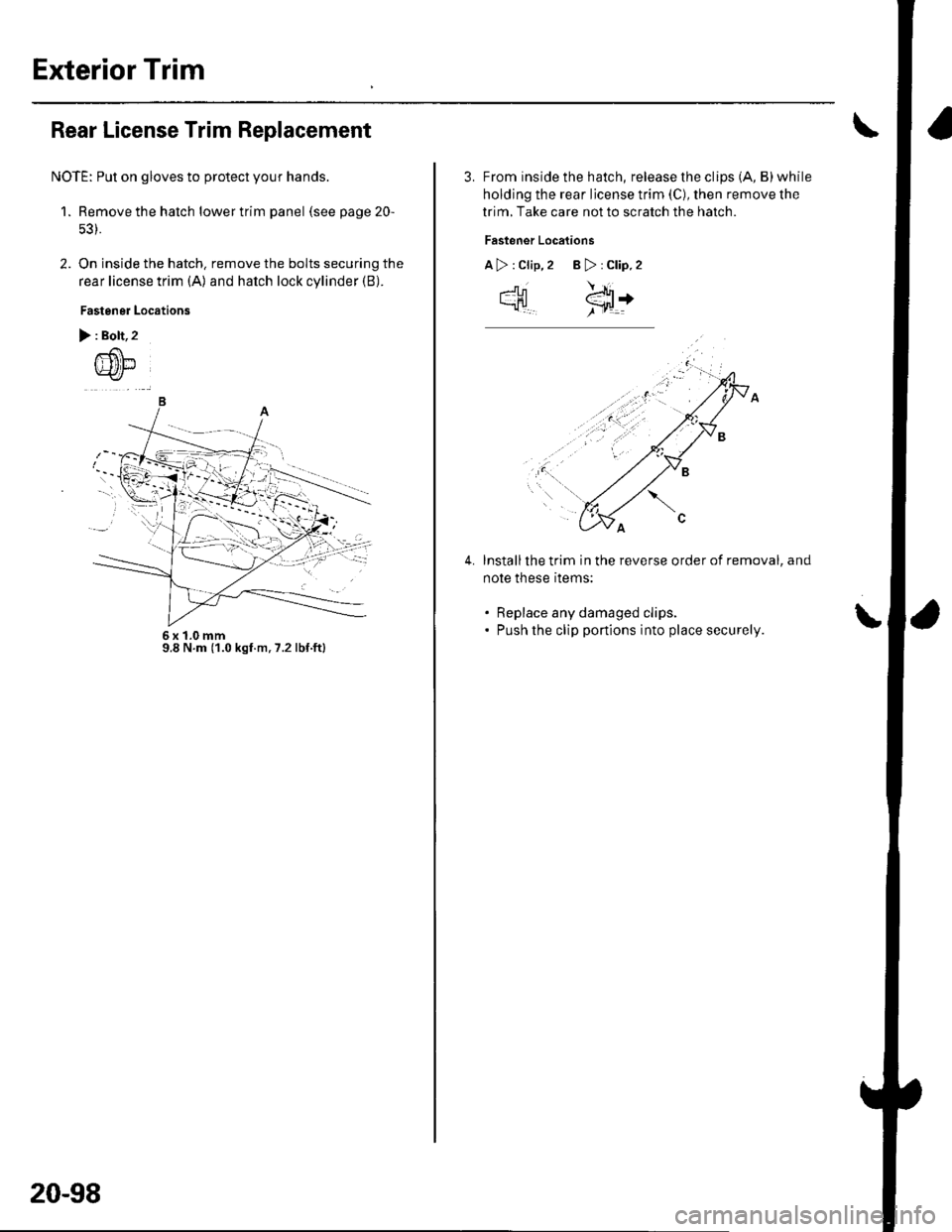

Rear License Trim Replacement

NOTE: Put on gloves to protect your hands.

1. Remove the hatch lower trim panel (see page 20-

2. On inside the hatch. remove the bolts securing the

rear license trim (A) and hatch lock cylinder (B).

Fastener Locations

> : Bolt,2

-)

6x1.0mm9.8 N.m (1.0 kgf.m,7.2lbf.ftl

20-98

3. From inside the hatch, release the clips (A, B)while

holding the rear license trim (C), then remove lhe

trim, Take care not to scratch the hatch.

Fastener Locations

A>:Clip,2 B>:Clip.2

\!-

cHl €:t+

Installthe trim in the reverse order of removal, and

note these rtems:

. Replace any damaged clips.. Push the clip portions into place securely.

4.

Page 759 of 1139

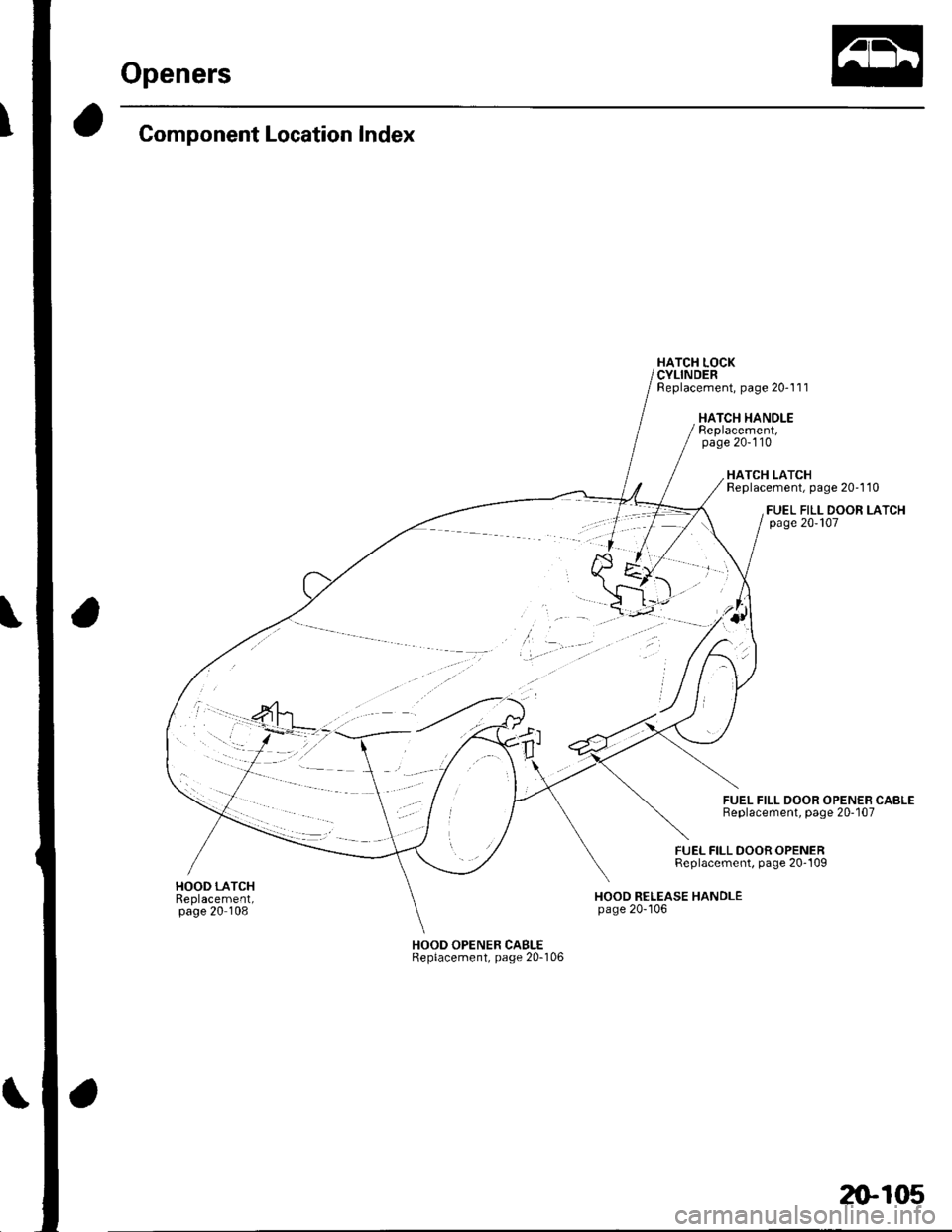

Openers

Component Location Index

HATCH LOCKCYLINDERReplacement, page 20-1'l 1

HATCH HANDLEReplacement,page 20-110

FUEL FILL DOOR OPENERReplacement, page 20-109

HATCH LATCHReplacement, page 20'1 10

FUEL FILL DOOR LATCHpage 20-107

FUEL FILL DOOR OPENEB CABLEReplacement, page 20-107

I{OOD RELEASE HANDLEpage 20-'106

HOOD OPENER CABLEReplacement, page 20-106

z)-105

Page 762 of 1139

Openers

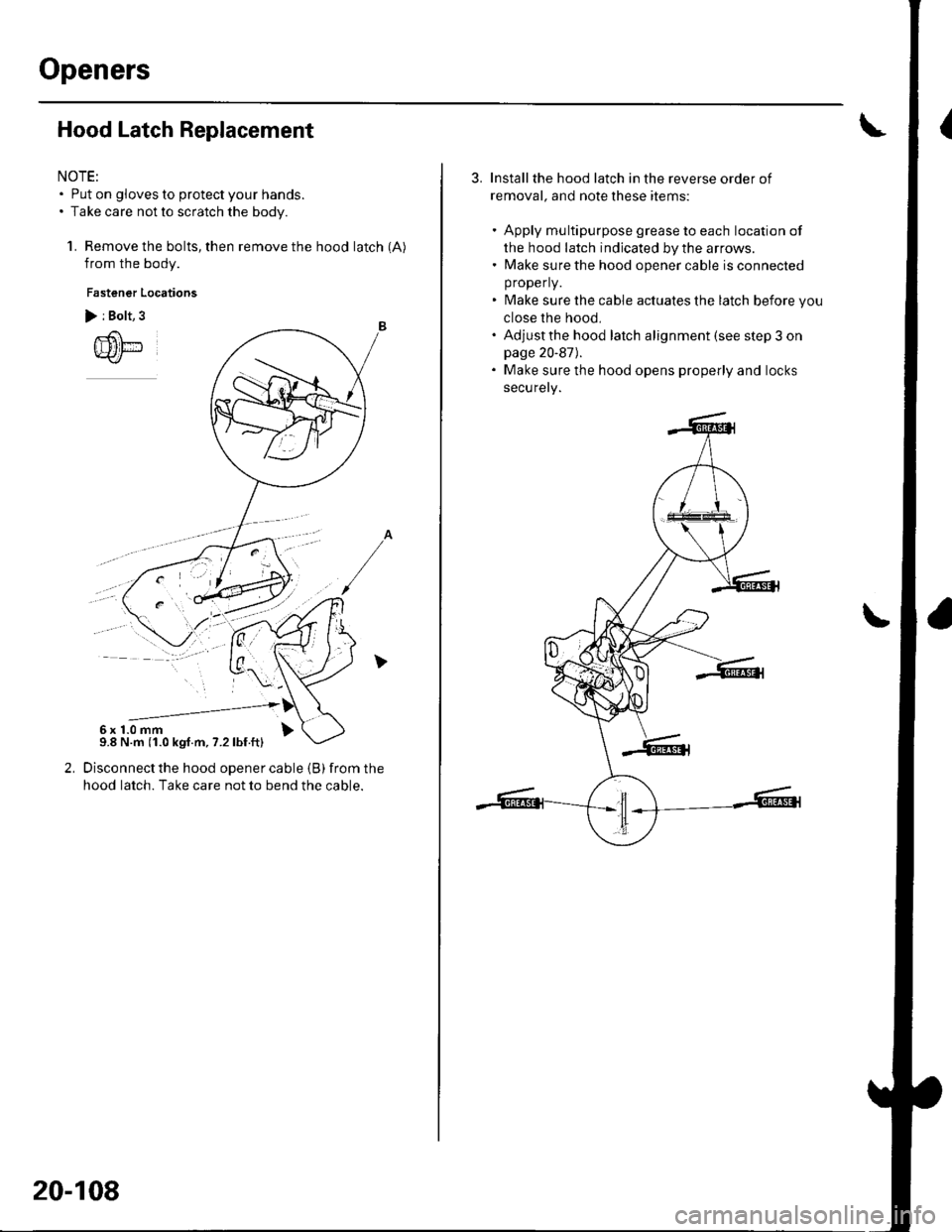

Hood Latch Replacement

NOTE:. Put on gloves to protect your hands.. Take care not to scratch the body.

1. Remove the bolts, then remove the hood latch (A)

from the body.

Fastener Locations

> i Bolt, 3

Disconnect the hood opener cable (B) from the

hood latch. Take care not to bend the cable.

--------------'6x1.0mm9.8 N.m (1.0 kgf.m, 7.2lbf.ft)

20-108

Installthe hood latch in the reverse order of

removal, and note these items:

. Apply multipurpose grease to each location of

the hood latch indicated by the arrows.. Make sure the hood opener cable is connected

properly.

. Make sure the cable actuates the latch before you

close the hood,. Adjustthe hood latch alignment (see step 3 onpage 20-87).. Make sure the hood opens properly and locks

securely.

Page 763 of 1139

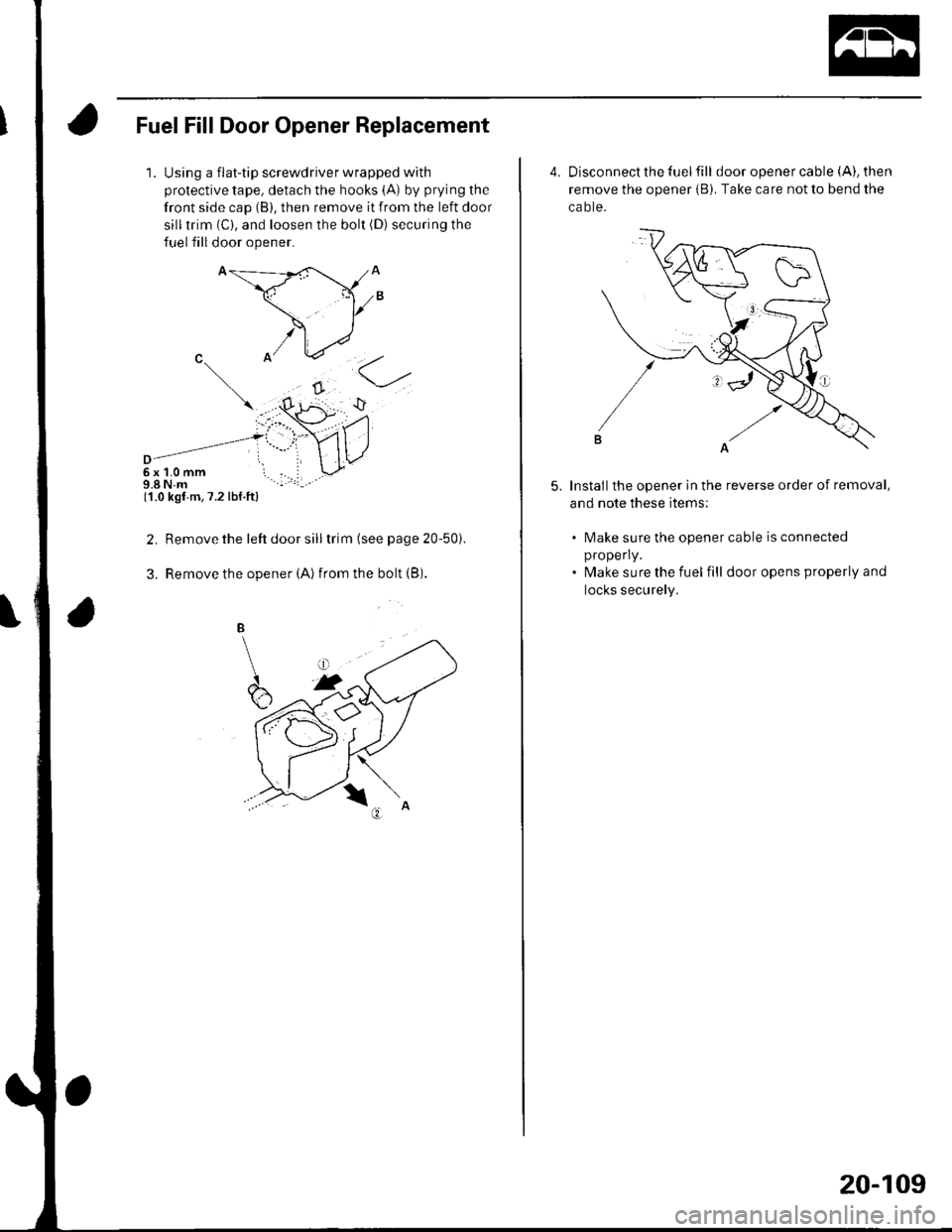

Fuel Fill Door Opener Replacement

1.Using a flat-tip screwdriver wrapped with

protective tape, detach the hooks (A) by prying the

front side cap (B), then remove it from the left door

silltrim (C), and loosen the bolt (D) securing the

fuel fill door opener.

6x1.0mm9.8 N.m11.0 kgf m,7.2 lbf.ft)

Remove the left door sill trim (see page 20-50i.

Remove the opener (Alfrom the bolt {B).

2.

3.

4. Disconnect the fuel fill door opener cable (A), then

remove the opener iB). Take care not to bend the

ca o te.

Installthe opener in the reverse order of removal,

and note these items:

5.

lMake sure the opener cable is connected

properly.

lvlake sure the fuel fill door opens properly and

locks securely.

20-109

Page 764 of 1139

Openers

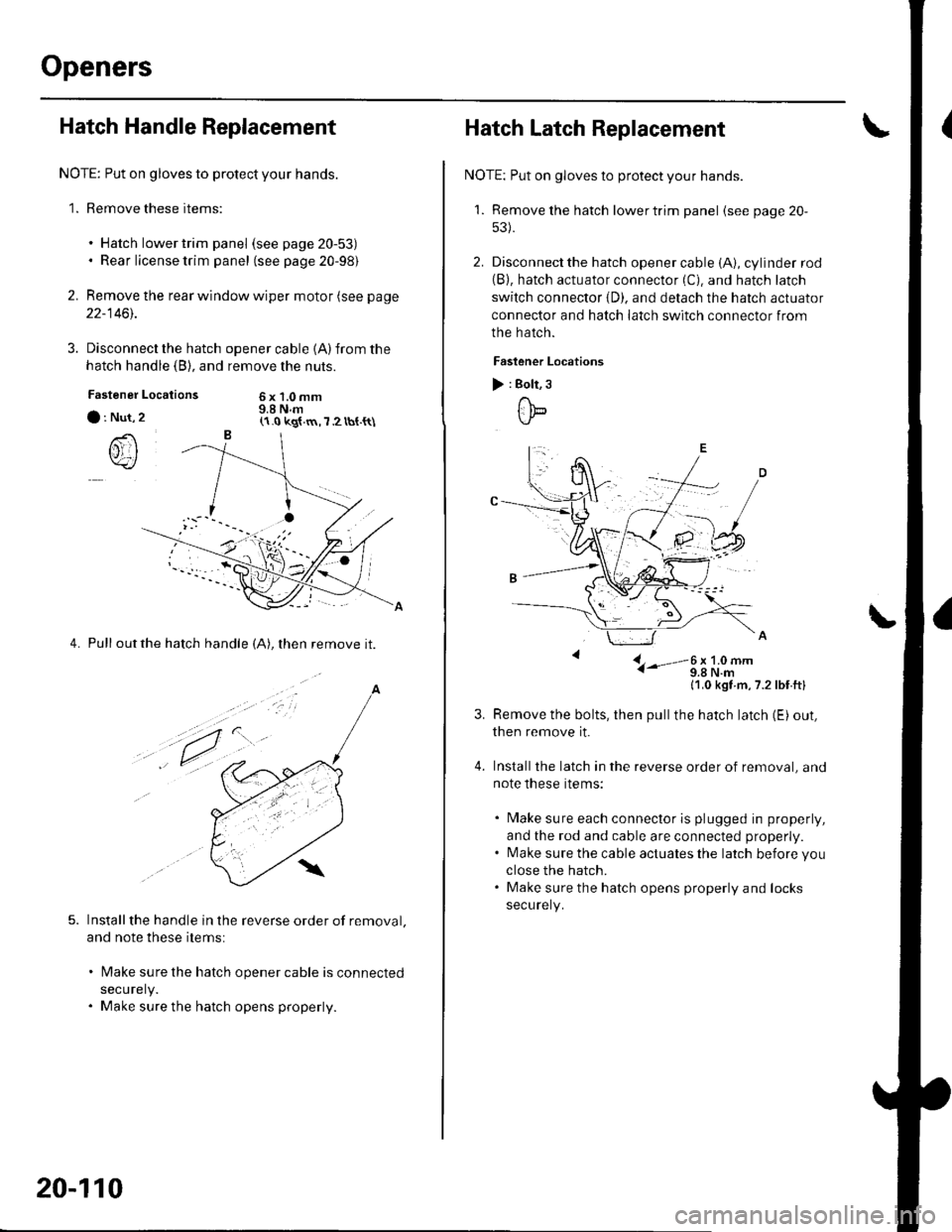

Hatch Handle Replacement

NOTE: Put on gloves to protect your hands.

1. Remove these items:

. Hatch lower trim panel (see page 20-53). Rear license trim panel (see page 20-98)

2. Remove the rear window wiper motor (see page

22-1461.

3. Disconnect the hatch

hatch handle (B), and

Locations

opener cable 1A)from the

remove the nuts.

6x1.0mm9.8 N.mFastener

a : Nut,

()rI

4. Pull outthe hatch handle (A), then remove it.

Installthe handle in the reverse order of removal.

and note these items:

lMake sure the hatch opener cable is connected

securely.

Make sure the hatch opens properly.

(1.0 kg{.m,7 2 tbt.{t\

a

,t.

20-110

Hatch Latch Replacement

NOTE: Put on gloves to protect your hands.

'1. Remove the hatch lowertrim panel (see page 20-

53).

2. Disconnect the hatch opener cable (A), cylinder rod(B). hatch actuator connector (C). and hatch latch

switch connector {D). and detach the hatch actuator

connector and hatch latch switch connector from

the hatch.

Faslener Locations

) : Bolt, 3

ttb

L- i-'-3;li9#-

11,0 kgt m,7.2lbf ftl

Remove the bolts, then pullthe hatch latch (E) out,

then remove it.

Installthe latch in the reverse order of removal, and

note these items:

. Make sure each connector is plugged in properly,

and the rod and cable are connected properly.. l\4ake sure the cable actuates the latch before you

close the hatch.. Make sure the hatch opens properly and locks

securely.

Page 765 of 1139

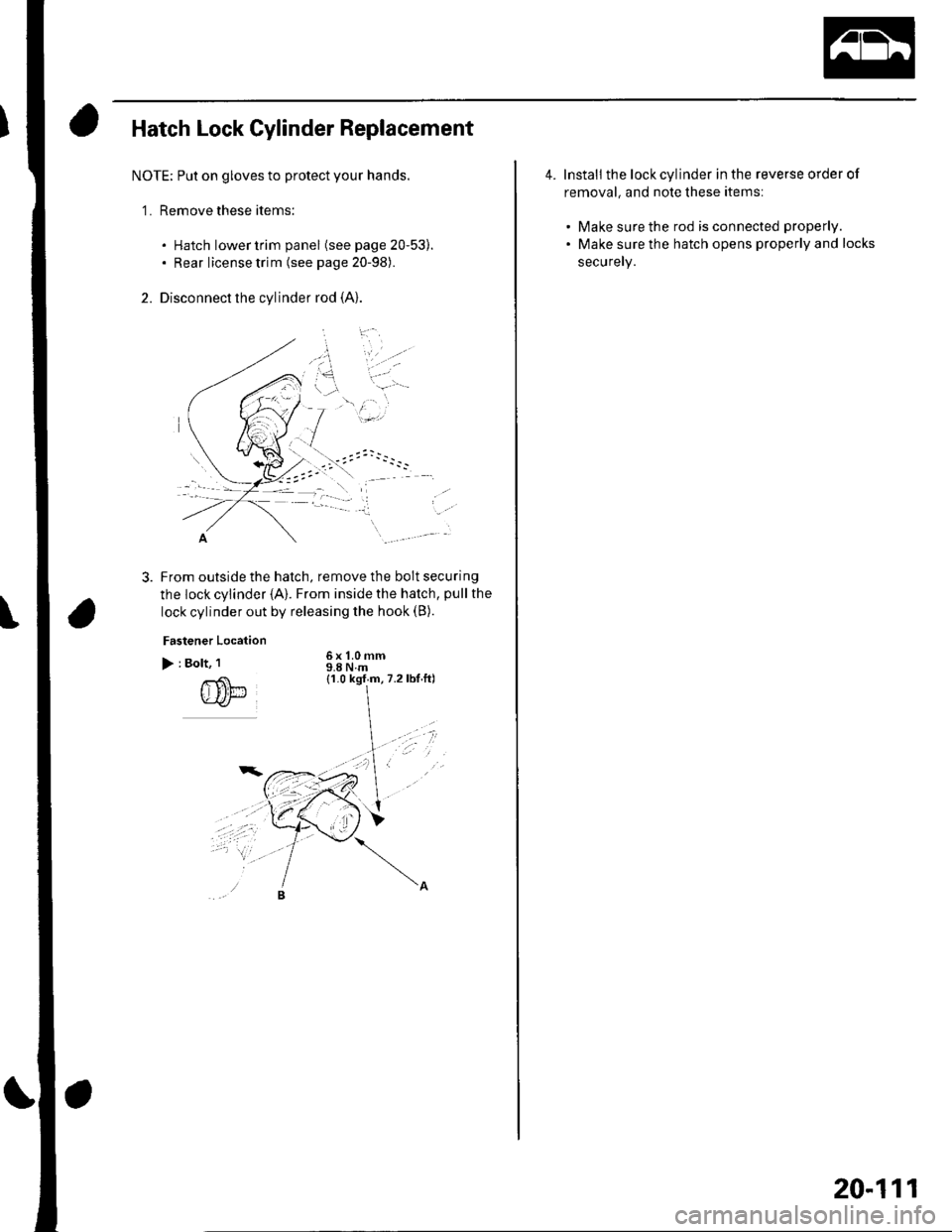

Hatch Lock Cylinder Replacement

NOTE; Put on gloves to protect your hands.

'1. Remove these items:

. Hatch lower trim panel (see page 20-53).. Rear license trim (see page 20-98).

2. Disconnect the cylinder rod (A)

-..

From outside the hatch, remove the bolt securing

the lock cylinder {A}. From inside the hatch, pull the

lock cylinder out by releasing the hook (B).

Fastener Location

> : Bolt, 1

rS'l-.u-ar

6x 1.0 mm9.8Nm(1.0 kgf m,7.2lbt.ftl

*/t

4. Install the lock cylinder in the reverse order of

removal, and note these items:

. Make sure the rod is connected properly.

. Make sure the hatch opens properly and locks

securely.

20-111

Page 779 of 1139

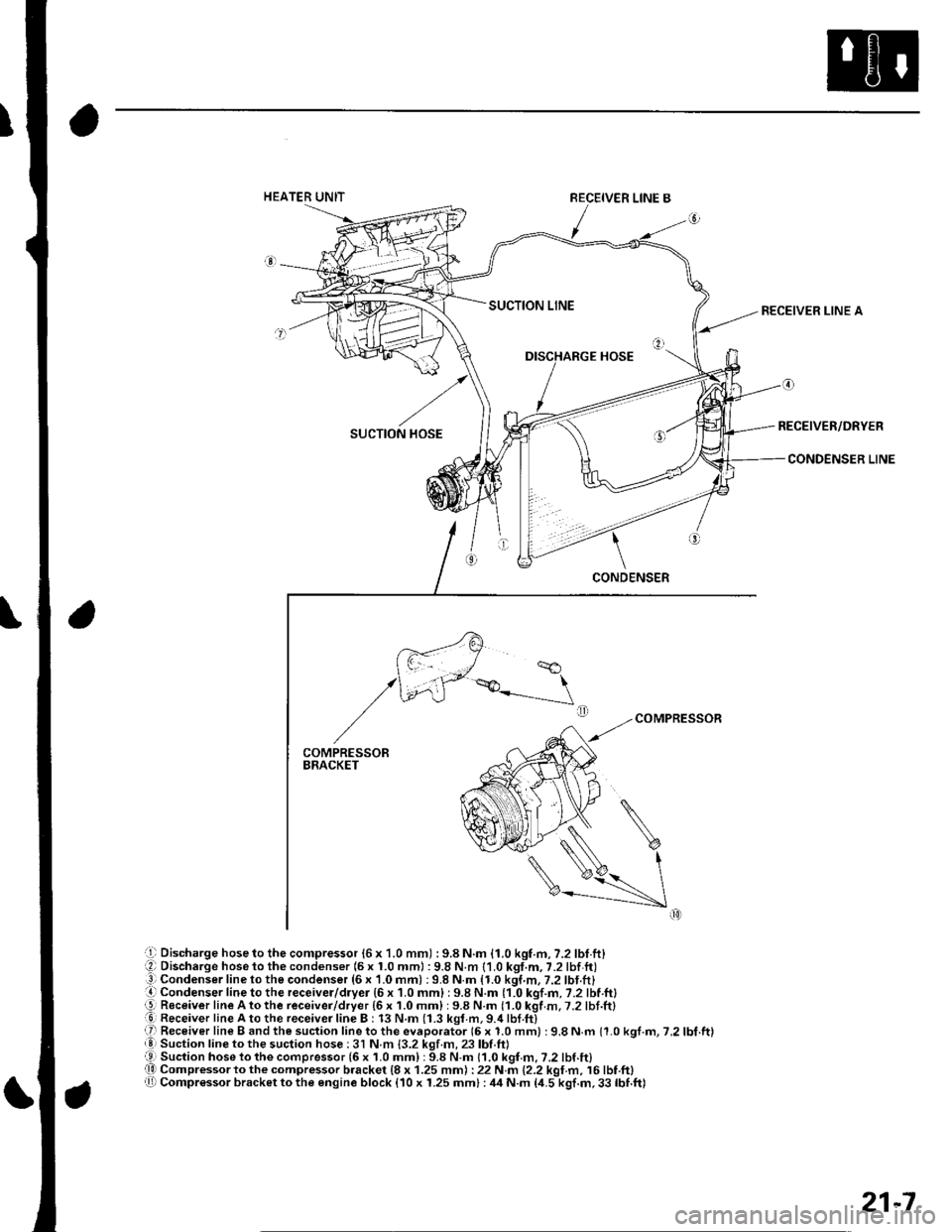

Discharge hose to the compressor {6 x 1.0 mm) : 9.8 N.m {1.0 kgf.m, 7.2 lbl.ft}Discharge hose to the condenser (5 x 1.0 mml : 9.8 N.m {1.0 kgt.m, 7.2 lbf ft)Condenser line to the condenser (6 x 1.0 mm) : 9.8 N.m {1.0 kgf,m, 7.2 lbt.ft}Condenser f ine to the receiver/dryer {6 x 1.0 mm} : 9.8 N.m (1.0 kgt.fi,7.2lbt.ltlReceiver lineAtothe receiver/dryer {6 x 1.0 mm} : 9.8 N.m {1.0 kgf .m. 7.2 lbf .ft}Receiver line A to the receivei line B : 13 N.m (1.3 kgr.m, 9.4 lbf.ft)Receiver line B and the suction line to the evaporator (6 x 1.0 mm) :9.8 N.m 11.0 kgf.m, 7,2 lbf.ft)Suction line to the suction hose : 3l N m {3.2 kgf.m, 23 lbf ftlSuction hose 1o the compressor (6 x 1.0 mm) : 9.8 N.m 11.0 kgf.m. ?.2 lbf.lt)Compressor to the compressor b.acket {8 x 1.25 mm) : 22 N m {2.2 kgt.m, 16 lbf.ft)Compr€ssor bracket to the engine block {10 x 1.25 mm} : ,14 N.m 14.5 kgf.m, 33 lbf.ft)

RECEIVER LINE A

RECEIVER/DRYER

CONDENSER LINE

21-7

Page 809 of 1139

Heating and Air Gonditioning

a

\

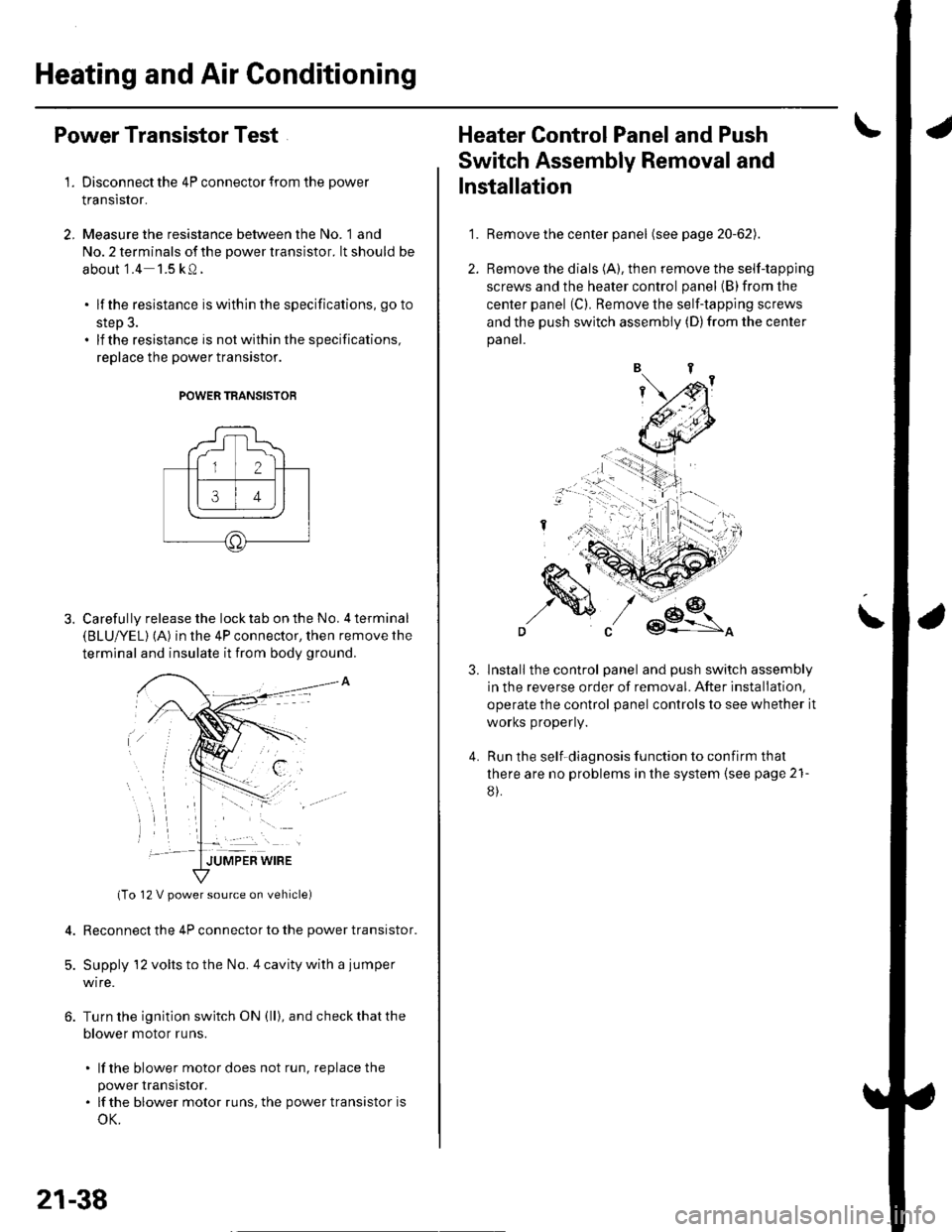

Power Transistor Test

1. Disconnect the 4P connector from the power

Iranslslor.

2, Measure the resistance between the No. 1 and

No. 2 terminals of the power transistor. lt should be

about '1.4 1.5 kQ.

. lf the resistance iswithln the specifications, go to

step 3.. lf the resistance is notwithin the specifications,

replace the power transistor.

POWER TRANSISTOB

Carefully release the lock tab on the No. 4 terminal(BLUI/EL) (A) in the 4P connector, then remove the

terminal and insulate it from body ground.

(To 12 V power source on vehicle)

Reconnect the 4P connector to the power transistor.

Supply 12 volts to the No. 4 cavity with a jumper

wire.

Turn the ignition switch ON (ll), and check that the

blower motor runs.

. lf the blower motor does not run, replace the

power rranstsror.. lf the blower motor runs,the powertransistoris

oK.

12 V power source on vehicle)

21-38

1.

Heater Control Panel and Push

Switch Assembly Removal and

Installation

Remove the center panel (see page 20-62).

Remove the dials (A), then remove the self-tapping

screws and the heater control panel (B)from the

center panel (Cl. Remove the self-tapping screws

and the push switch assembly (D)from the center

panel.

lnstall the control panel and push switch assembly

in the reverse order of removal. After installation,

operate the control panel controls to see whether it

worKs propeny.

Run the self-diagnosis function to confirm that

there are no problems in the system (see page 21-

8).

3.

4.