lock HONDA CIVIC 2002 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 44 of 1139

Starter Replacement

1. Make sure you have the anti-theft code for the radio.

then write down the frequencies for the radio's

preset buttons.

2. Disconnect the negative cable from the battery first,

then disconnect the positive cable.

3. Disconnect the knock sensor connector.

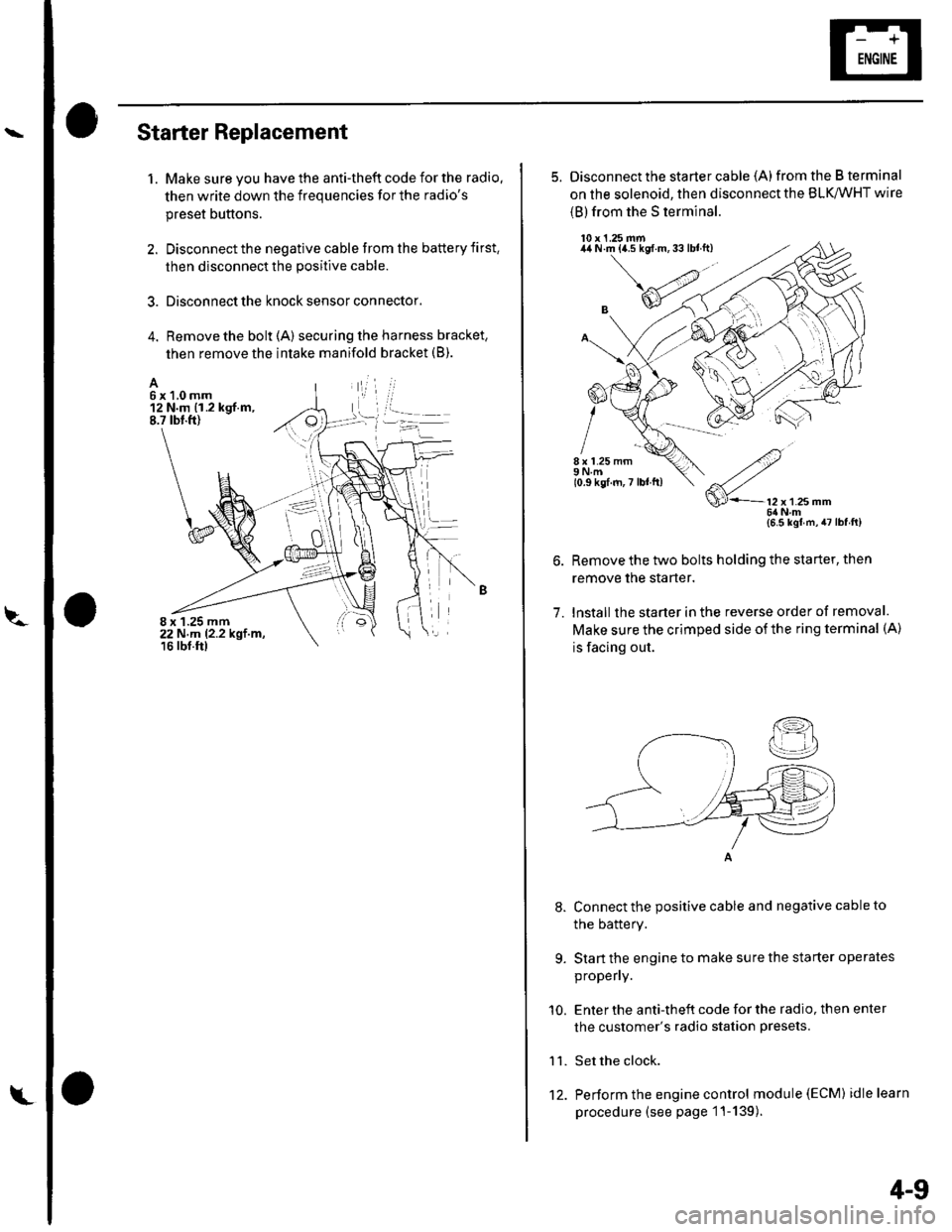

4. Remove the bolt (A) securing the harness bracket,

then remove the intake manifold bracket (B).

A6x1,0mm12 N.m {1.2 kgf.m,8.7 tbt.ft)

8 x 1.25 mm22 N,m 12.2 kgt.m,16 rbf.ftl

L't2.

4-9

5. Disconnect the starter cable (A)from the B terminal

on the solenoid, then disconnect the BLK,/WHT wire

{B) from the S terminal.

10 x 1.25 mm44 N.m {a.5 kgf.m,33lblft)

8 x 1.25 mm9Nm10.9 kgf.m,7 lbl ft)

7.

9.

'10.

11.

2

S'-12x12smm6ilNm{6.5 kgl m,47lbfft)

Remove the two bolts holding the starter, then

remove the starter.

lnstall the starter in the reverse order of removal.

Make sure the crimped side of the ring terminal (A)

is facing out.

Connect the positive cable and negative cable to

the batterY.

Start the engine to make sure the starter operates

propeny.

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Set the clock.

Perform the engine control module (EcM) idle learn

procedure (see page 1 '1- 139 ).

I

Page 49 of 1139

Starting System

Starter Overhaul (cont'dl

Planetary Gear Inspection

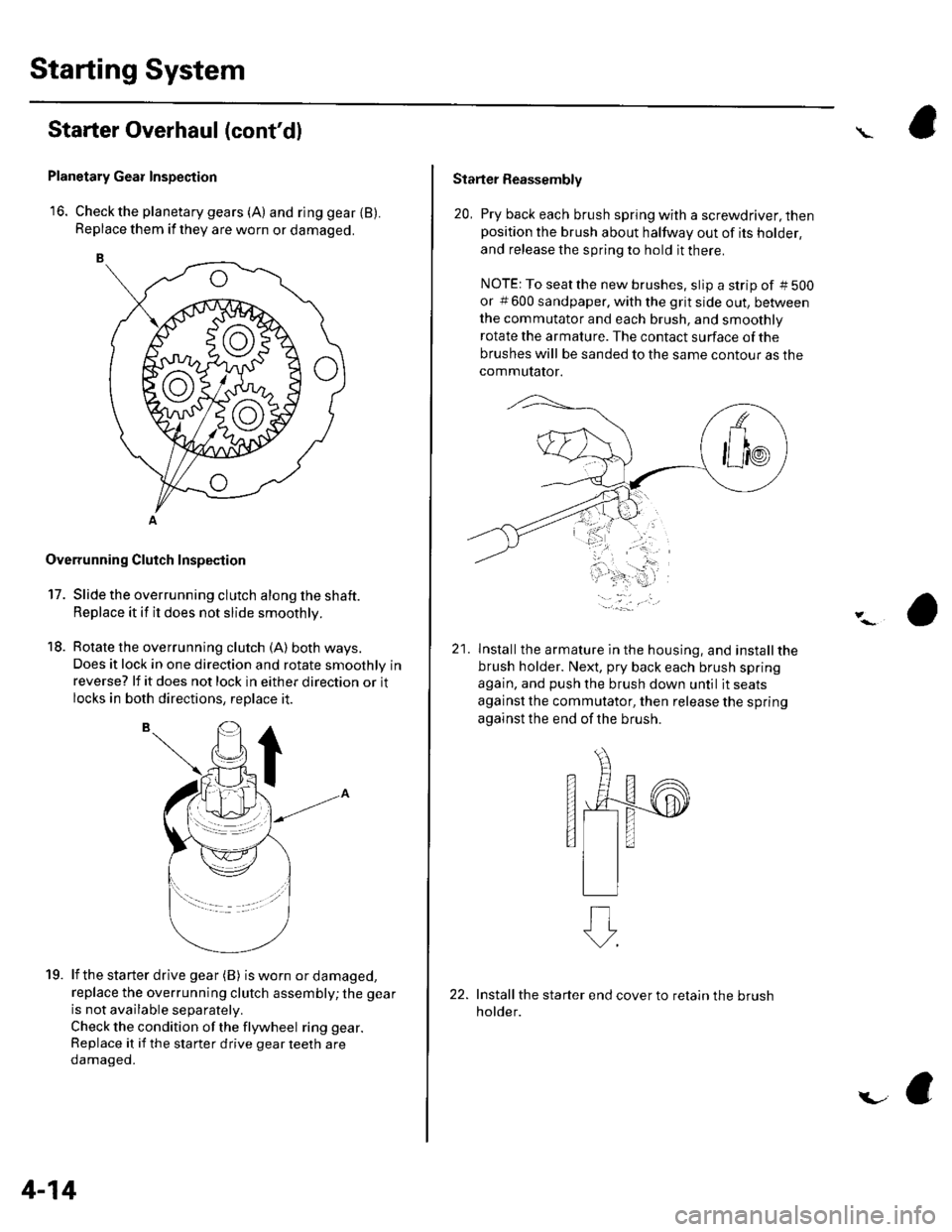

16. Check the planetary gears (A) and ring gear {B).Replace them if they are worn or damaged.

Overrunning Cluich Inspection

17. Slide the overrunning clutch along the shaft.

Replace it if it does not slide smoothly.

18. Rotate the overrunning clutch (A) both ways.

Does it lock in one direction and rotate smoothly inreverse? lf it does not lock in either direction or it

locks in both directions, replace it.

lf the starter drive gear (B) is worn or damaged,

replace the overrunning clutch assembly; the gear

is not available separately.

Check the condition of the flywheel ring gear.

Replace it if the starter drive gear teeth are

oamageo.

19.

4-14

i.-

Starter Reassembly

20, Pry back each brush spring with a screwdriver, thenposition the brush about halfway out of its holder,

and release the spring to hold it there.

NOTE: To seatthe new brushes. slip a strip of #5OO

or # 600 sandpaper. with the grit side out, be&veen

the commutator and each brush, and smoothly

rotate the armature. The contact surface of the

brushes will be sanded to the same contour as the

commutator.

21lnstallthe armature in the housing, and installthe

brush holder. Next, pry back each brush spring

again, and push the brush down until it seats

against the commutator, then release the spring

against the end of the brush.

s

Install the starter end cover to retain the brush

holder.

Page 64 of 1139

l\-Alternator Replacement

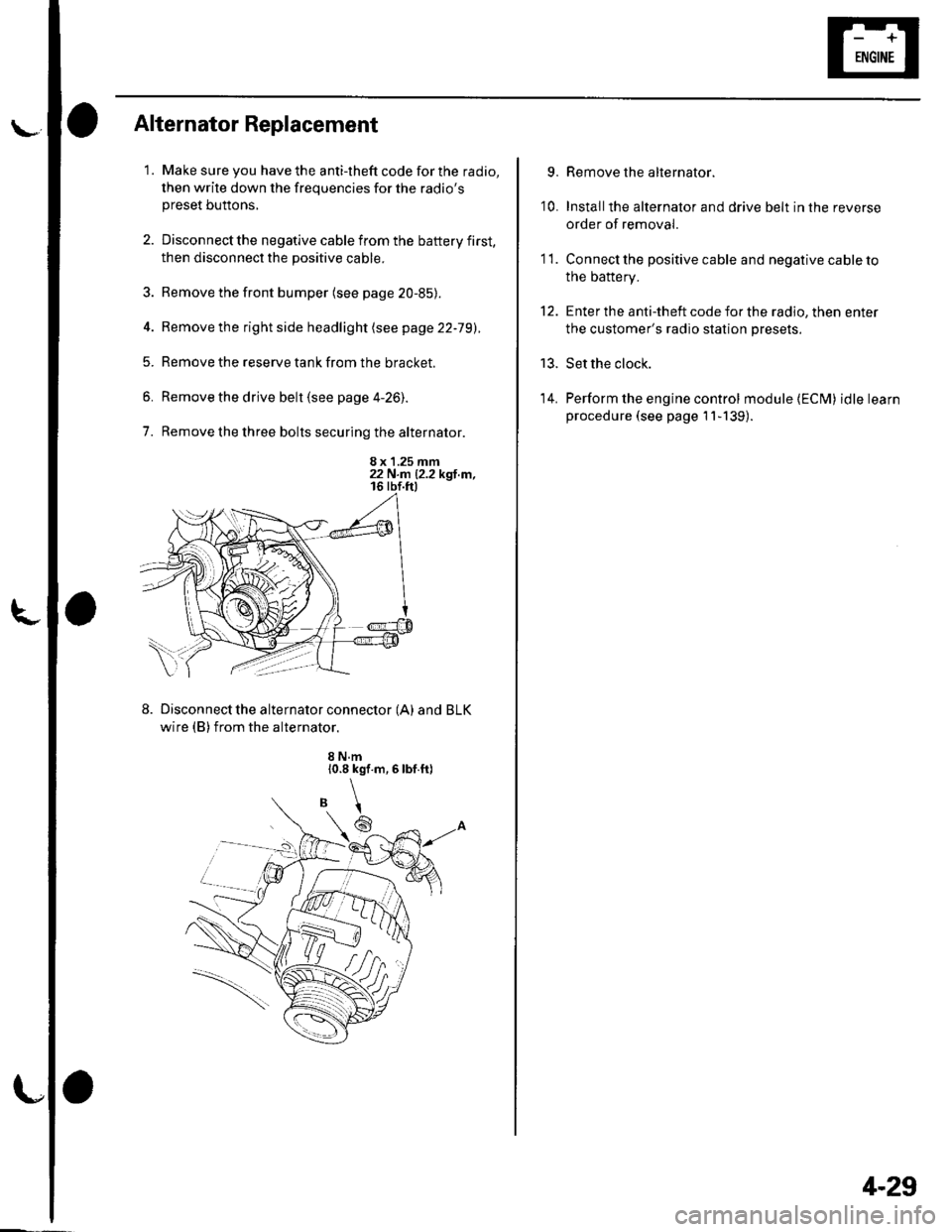

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio'spreset buttons,

2. Disconnect the negative cable from the battery first,

then disconnect the positive cable.

3. Remove the front bumper (see page 20-85).

4. Remove the right side headlight (see page 22-79).

5. Remove the reserve tank from the bracket.

6. Remove the drive belt (see page 4-26).

7. Remove the three bolts securing the alternator.

8 x 1.25 mm22 N.n 12.2 kgl.m,

Disconnect the alternator connector (A) and BLK

wire (B) from the alternator.

8 N.m10.8 kgf.m,6lbf.ft)

\

6

'I 1.

9.

10.

13.

14.

Remove the alternator.

Installthe alternator and drive belt in the reverse

order of removal.

Connect the positive cable and negative cable to

the battery.

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Set the clock.

Perform the engine control module {ECM) idle learn

procedure (see page 11-139).

tt.

4-29

Page 65 of 1139

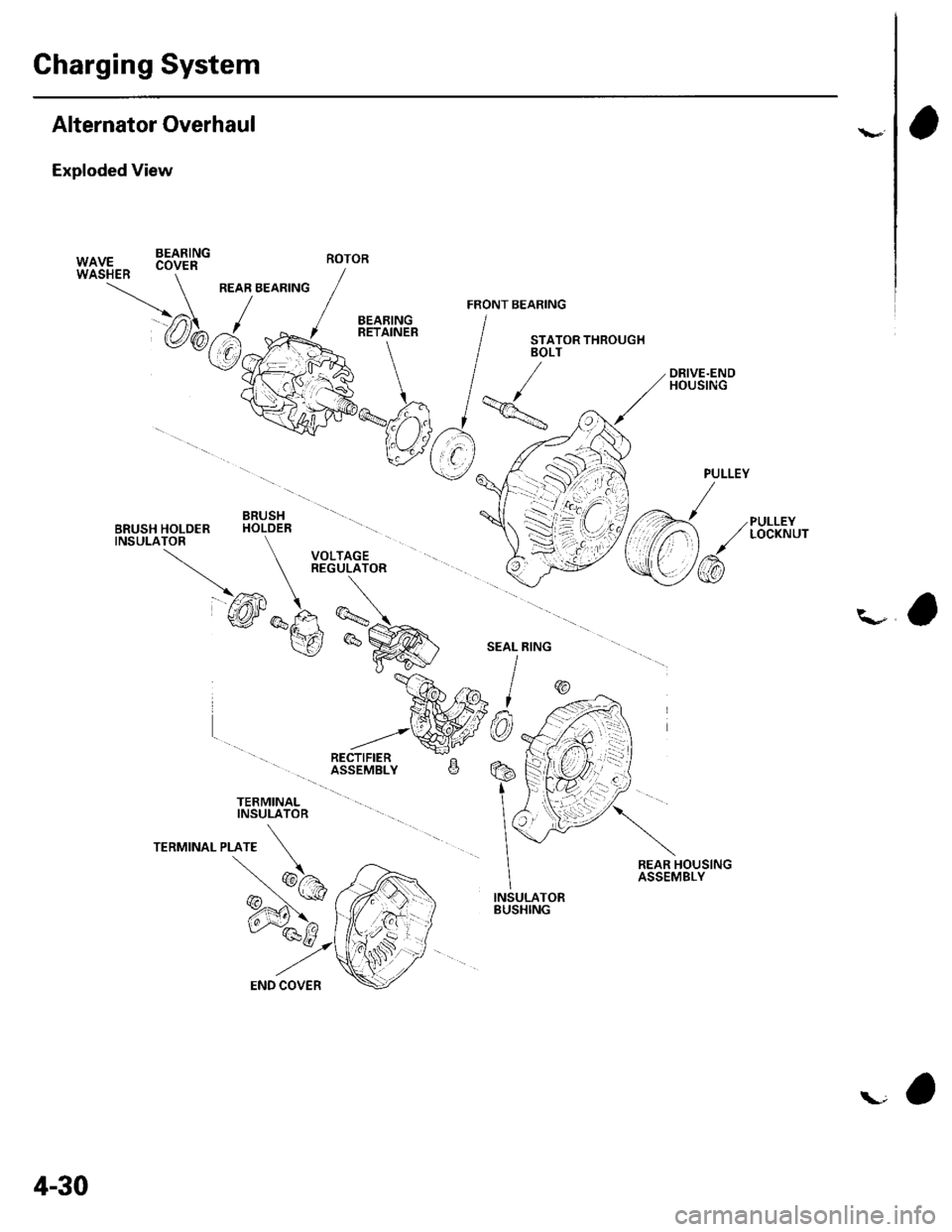

Charging System

Alternator Overhaul

Exploded View

BEARING

PULLEYLOCKNUT

\-a

TERMINALINSULATOR

REAR HOUSINGASSEMBLY

INSULATORBUSHING

PULLEY

/

\/

/@

W|UF., .oy." -

/

REAR BEARING / ,/ ./ FRoNr B

@b.J.y{=RE+LN'"'

IvVFko"-% /

qtr*njlv

V( r),

"V

BRUSH \11BRUSH HOLOER HOLDER -\

TNSULATOR \l VOLTAGE }

\-

REGULATOR (-

@*F, -\:

v_re *^i

\gP^@' I

*ffilw9

ROTOR

4-30

Page 66 of 1139

L

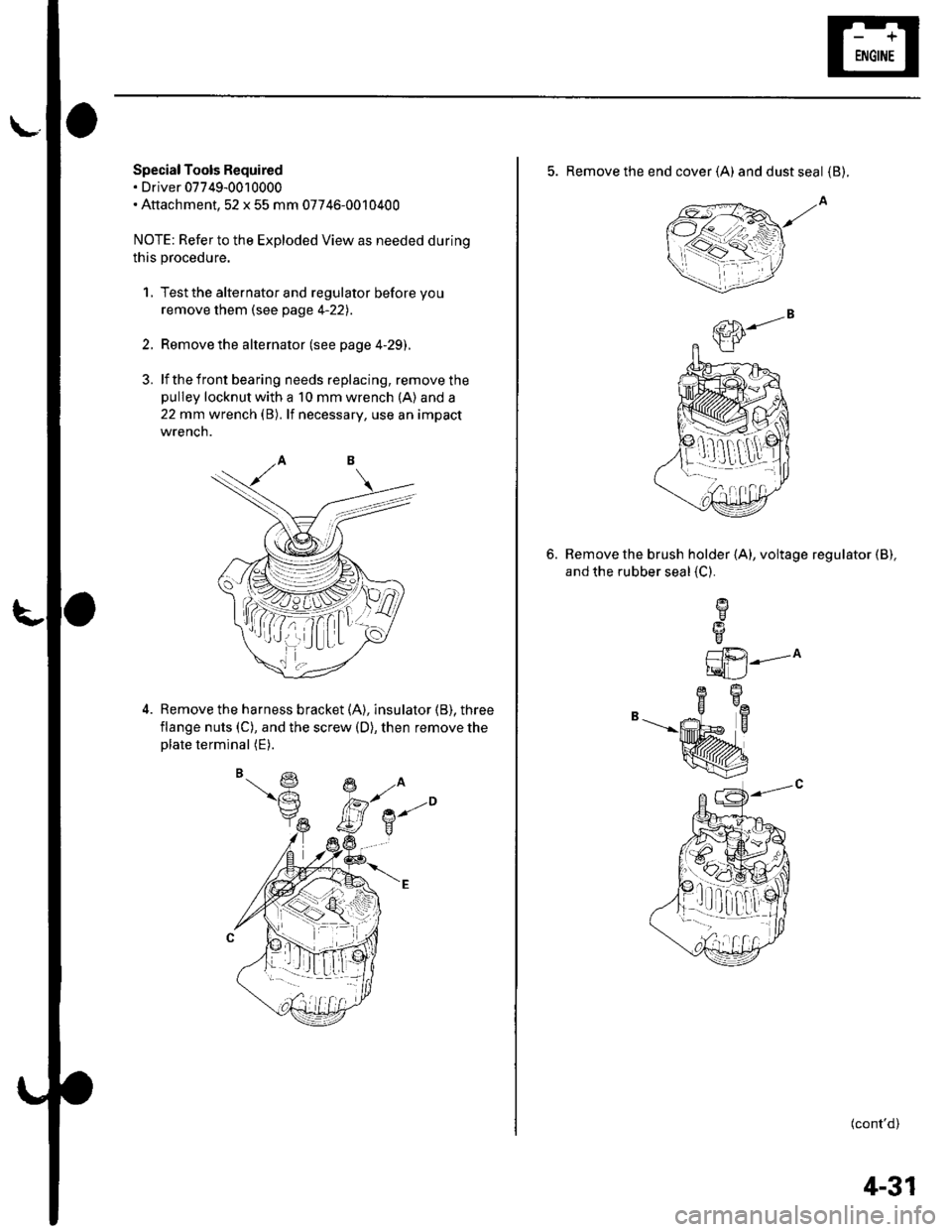

Special Tools Required. Driver 07749-0010000. Attachment,52 x 55 mm 07746-0010400

NOTE: Refer to the Exploded View as needed during

this procedure.

1, Test the alternator and regulator before you

remove them (see page 4-22l,.

2. Remove the alternator (see page 4-29).

3. lf the front bearing needs replacing, remove thepulley locknut with a 10 mm wrench (A) and a

22 mm wrench (B). lf necessary, use an impact

wrencn.

Remove the harness bracket (A), insulator (B). three

flange nuts (C), and the screw (D), then remove theplate terminal (E).

,( ( , tt I;r_ lLt

5. Remove the end cover (A) anddustseal {B).

Remove the brush holder (A), voltage regulator (B),

and the rubber seal {C}.

6.

L1i.21---^

tqLJ

B-"--|.

(cont'd)

1!q[-dr,:l

4-31

Page 70 of 1139

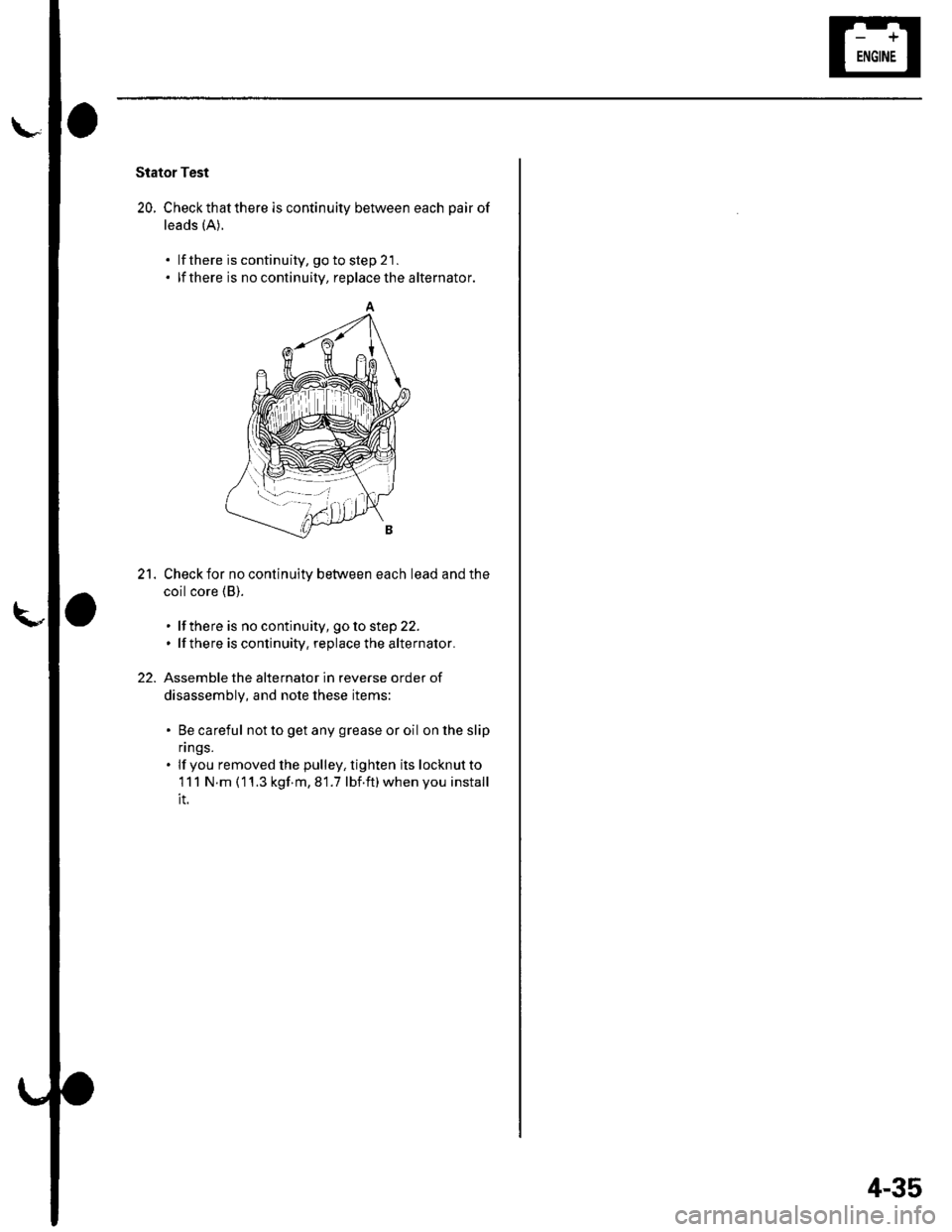

Stator Test

20. Checkthatthere is continuity between each pair of

leads (A).

lf there is continuity, go to step 21 .

lf there is no continuity, replace the alternator.

Check for no continuity between each lead and the

coil core (B).

. lf there is no continuity, goto step 22.. lfthere is continuity, replace the alternator.

Assemble the alternator in reverse order of

disassembly, and note these items:

. Be careful not to get any grease or oil on lhe slip

n ngs.. lf you removed lhe pulley, tighten its locknutto

111 N.m (11.3 kgf m,81.7 lbf.ft)whenyou install

it.

21.

22.

'--l-- --i

4-35

Page 75 of 1139

Cruise Gontrol

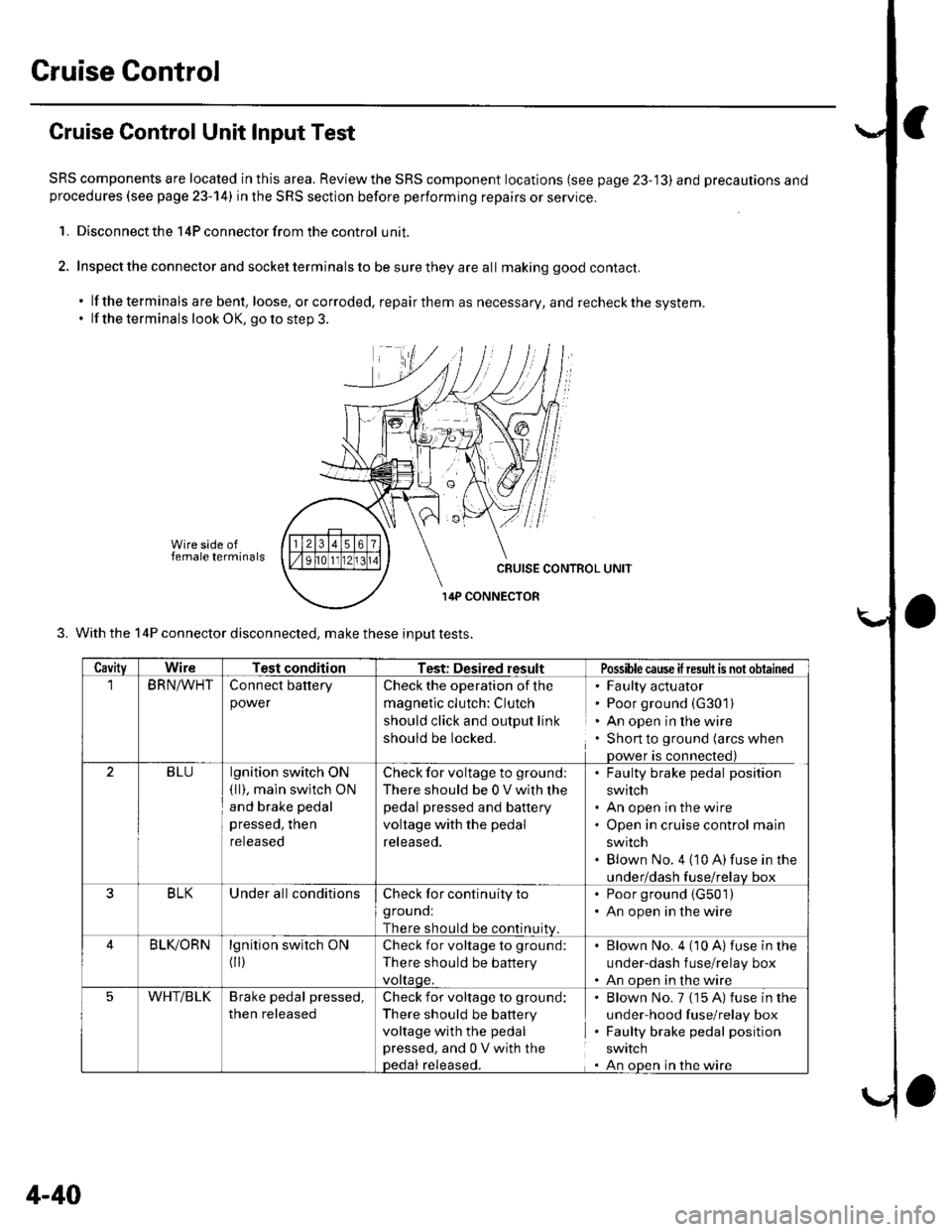

Cruise Control Unit Input Test

SRS components are located in this area. Reviewthe SRS component locations (see page 23-'13) and precautions andprocedures (see page 23-14) in the SRS section before performing repairs or service.

1. Disconnect the 14P connector from the control unit.

2. Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose, orcorroded, repairthem as necessary, and recheckthe system.. lf the terminals look OK, go to step 3.

Wire side offemale terminals

3. With the 14P connector disconnected, make these inDut tests.

CavityWireTest conditionTest: Desired resultPossiblecause ifresuh is not obtained

BRN/WHTConnect battery

power

Check the operation of the

magnetic clutch: Clutch

should click and output link

should be locked.

' Faulty actuator. Poor ground (G301)

. An open in the wire. Shon to ground (arcs when

Dower is connected)

2BLUlgnition switch ON(ll), main swltch ON

and brake pedal

pressed, then

reteaseo

Check for voltage to ground;

There should be 0 V with lhe

pedal pressed and battery

voltage with the pedal

released.

. Faulty brake pedal position

switch. An open in the wire. Open in cruise control main

swrtcn. Blown No. 4 (10 A)fuse in the

under/dash fuse/relav box

3BLKUnder all conditionsCheck for continuity to

grouno:

There should be continuitv

. Poor ground (G501)

. An open in the wire

BLIVORNlgnition switch ON

flr)

Check for voltage to ground:

There should be battery

vottaqe.

Blown No. 4 (10 A)fuse in the

under-dash f use/relay box

An oDen in the wire

5WHT/BLKBrake pedal pressed,

then released

Check for voltage to ground:

There should be battery

voltage with the pedal

pressed, and 0 V with thepedal released.

Blown No. 7 {15 A) fuse in the

under-hood fuse/relay box

Faulty brake pedal position

SWIICN

An oDen in the wire

4-40

Page 78 of 1139

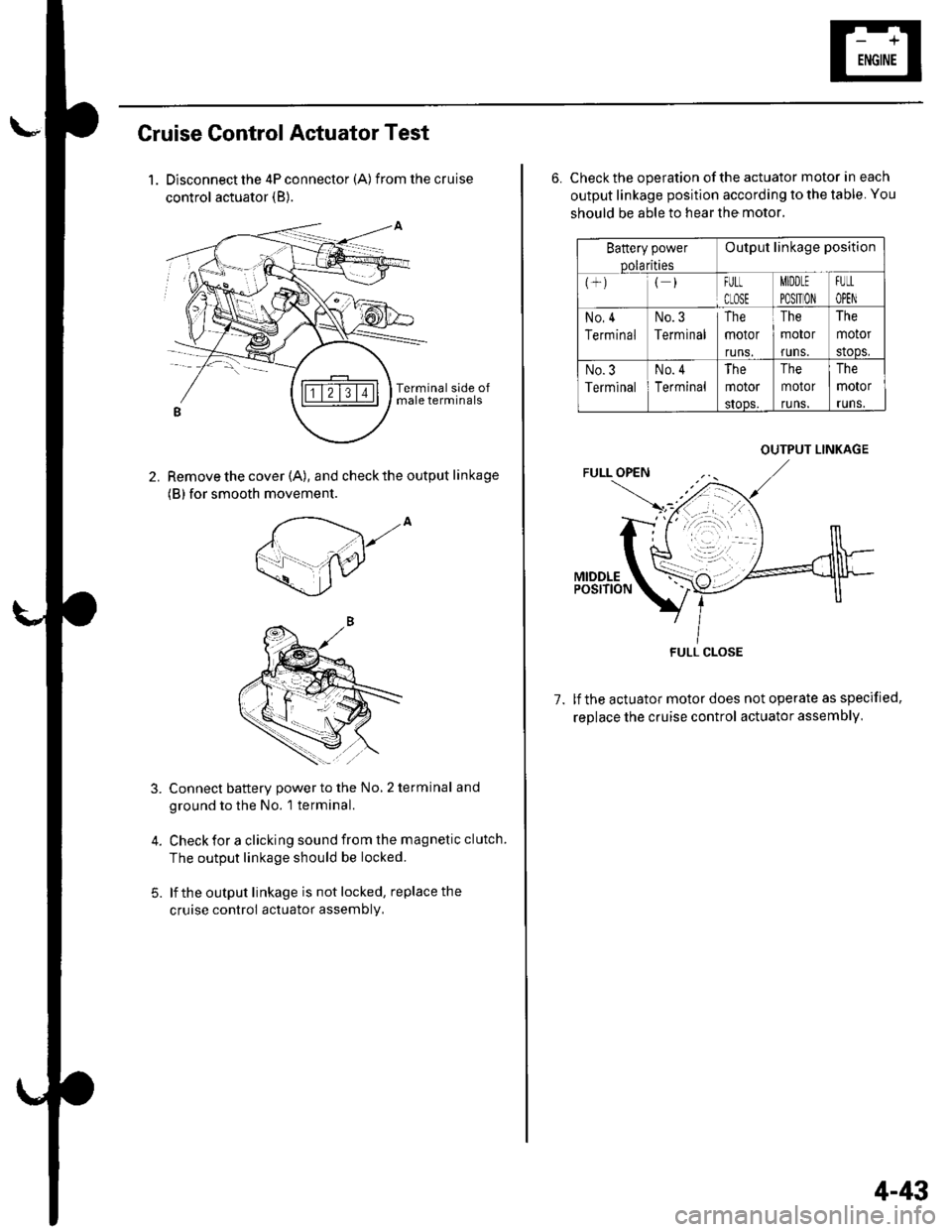

Cruise Control Actuator Test

1. Disconnect the 4P connector (A) from the cruise

control actuator (B).

Remove the cover (A), and check the output linkage

(B) for smooth movement.

2.

,to

5.

Connect battery power to the No, 2 terminal and

ground to the No. 1 terminal.

Check for a clicking sound from the magnetic clutch.

The output linkage should be locked.

lf the output linkage is not locked, replace the

cruise control actuator assembly,

6. Check the operation of the actuator motor in each

output linkage position according to the table. You

should be able to hear the motor.

Battery power

Dolarities

Output linkage position

FULt

CLOSE

MIDDLE

PO$TION

FUtL

OPEN

No,4

Terminal

No.3

Terminal

The

motor

runs.

The

motor

runs.

The

motor

stoDs,

No.3

Terminal

No. 4

Terminal

The

motor

sIoos.

The

motor

runs.

The

motor

runs.

1.lf the actuator motor does not operate as specified,

replace the cruise control actuator assembly,

OUTPUT LINKAGE

FULL CLOSE

4-43

Page 79 of 1139

Cruise Control

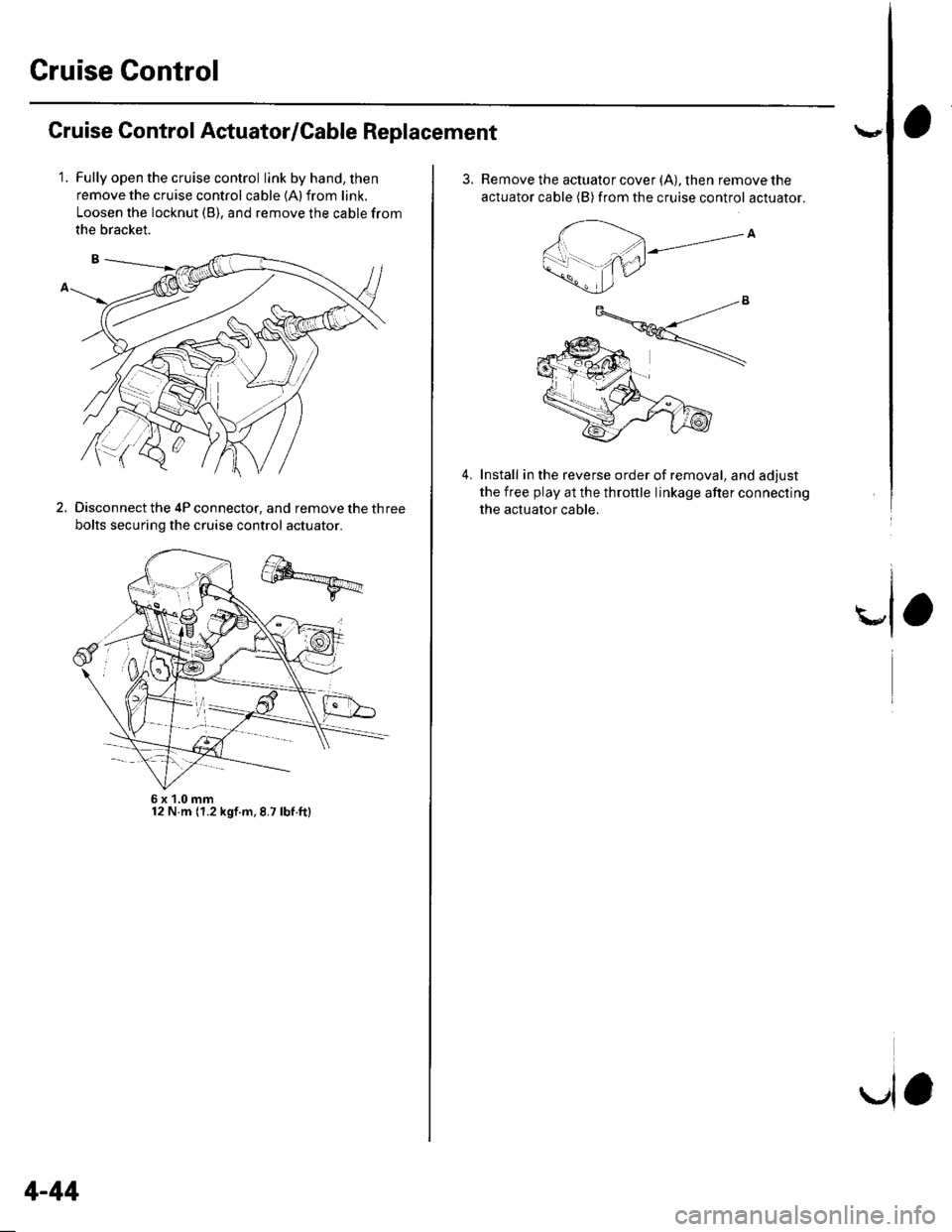

Cruise Control Actuator/Cable Replacement

1.Fully open the cruise control link by hand, then

remove the cruise control cable {A) from link.

Loosen the locknut (B), and remove the cable from

the bracket.

Disconnect the 4P connector, and remove the three

bolts securing the cruise control actuator.

2.

6x1,0mm12 N.m (1.2 kgf.m,8.7 lbf.ft)

4-44

la

3.Remove the actuator cover (A), then remove the

actuator cable (B) from the cruise control actuator.

Install in the reverse order of removal, and adjust

the free play at the throttle linkage after connecting

the actuator cable.

4.

Page 80 of 1139

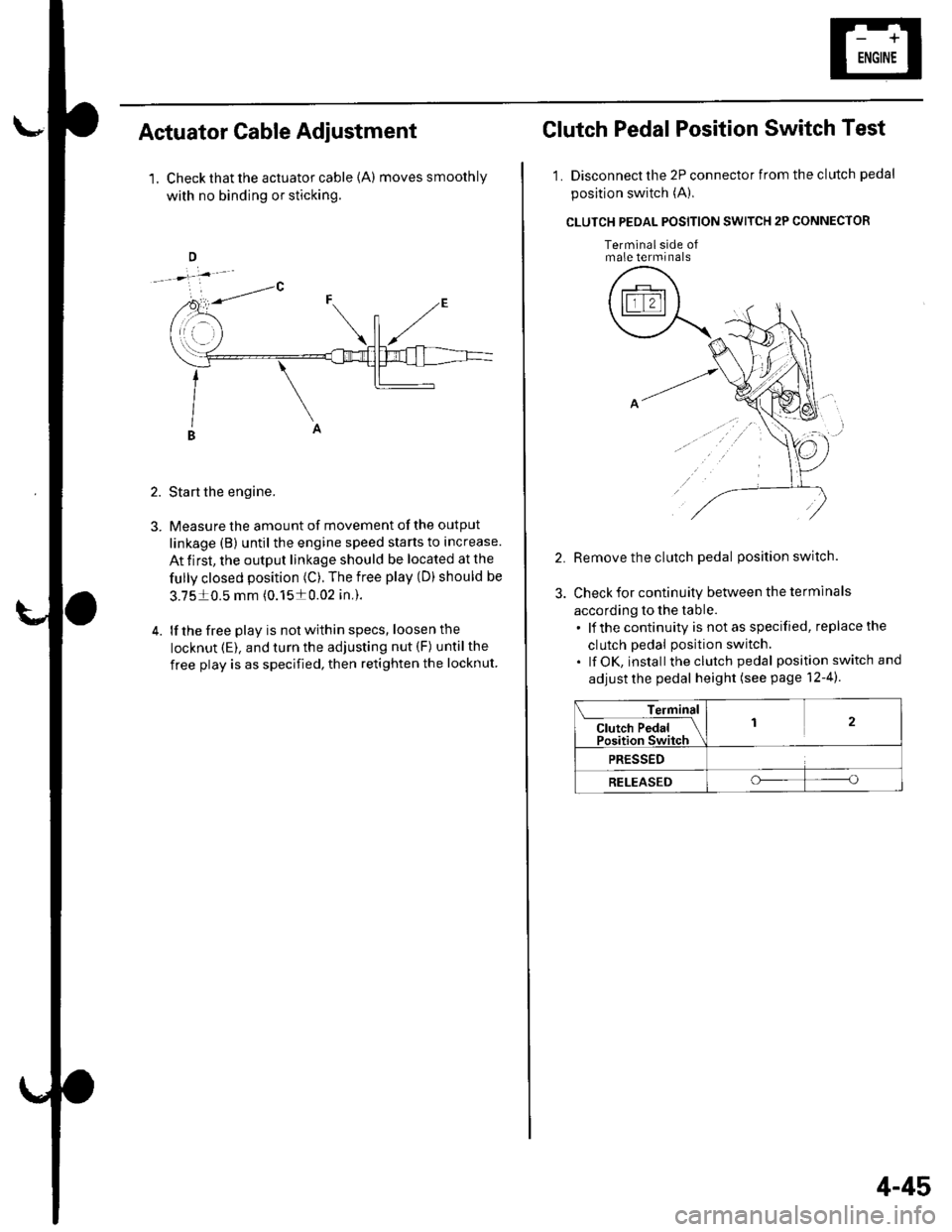

Actuator Cable Adiustment

1. Check that the actuator cable {A) moves smoothly

with no binding or sticking.

2. Start the engine.

3. Measure the amount of movement of the output

linkage (B) until the engine speed starts to increase.

At first, the output linkage should be located at the

fully closed position (C). The free play (D) should be

3.7510.5 mm (0.1510.02 in,).

4. lf the free play is not within specs, loosenthe

locknut (E). and turn the adjusting nut (F) untilthe

free play is as specified, then retighten the locknut

Clutch Pedal Position Switch Test

1. Disconnect the 2P connector from the clutch pedal

position switch (A),

CLUTCH PEOAL POSITION SWITCH 2P CONNECTOR

Terminalside ofmale terminals

Remove the clutch pedal position switch.

Check for continuity between the terminals

according to the table.. lf the continuity is not as specified, replace the

clutch pedal position switch.. lf OK, install theclutch pedal position switch and

adjust the pedal height (see page 12-4).

Terminal

Cl"t"h P"d"l IPosition Switch

12

PRESSED

RELEASEDoo

4-45