lock HONDA CIVIC 2002 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 83 of 1139

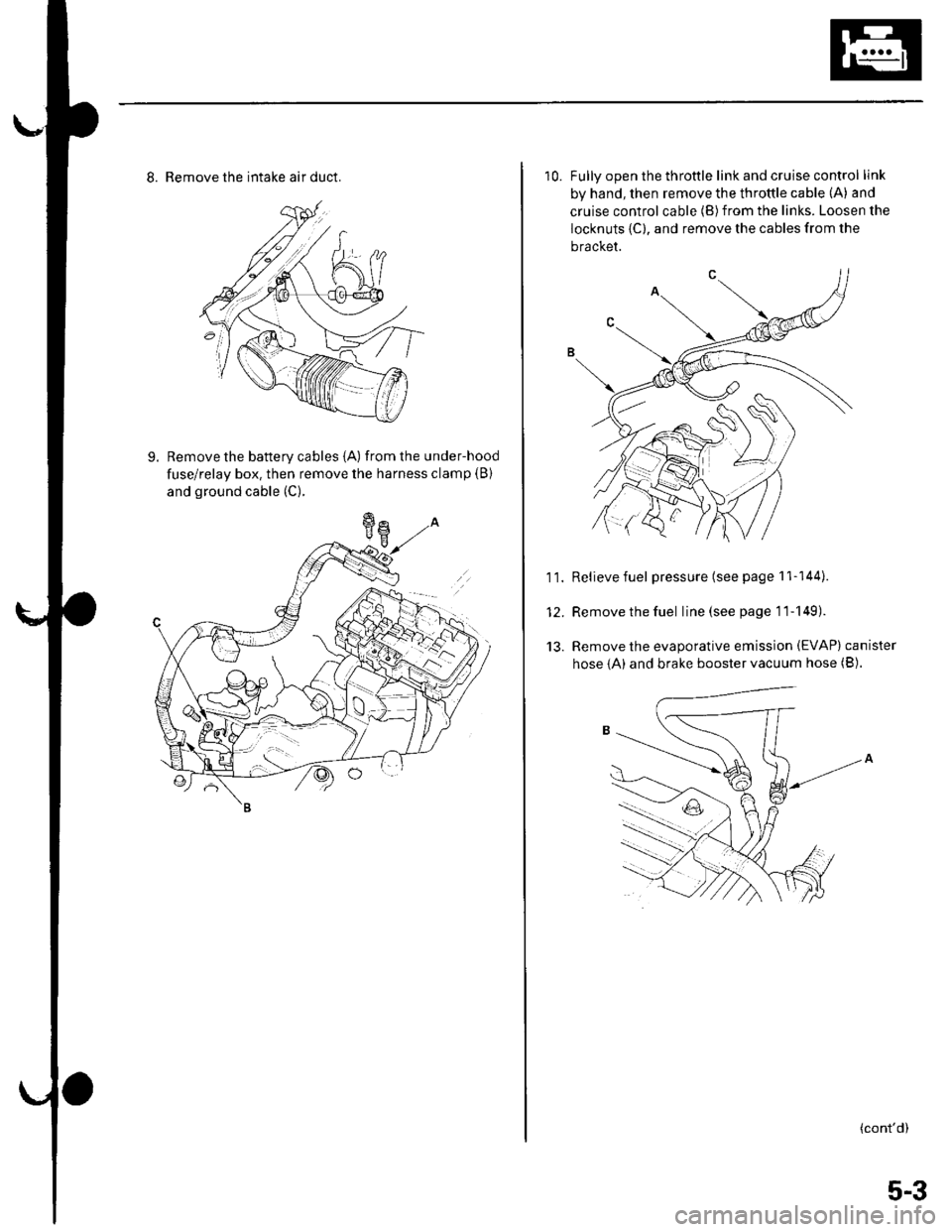

8. Remove the intake air duct.

9. Remove the battery cables {A) fromthe under-hood

fuse/relay box. then remove the harness clamp (B)

and ground cable (C).

10. Fullv ooen the throttle link and cruise control link

by hand, then remove the throttle cable (A) and

cruise control cable (B)from the links. Loosen the

locknuts {C), and remove the cables from the

bracket.

11. Relievefuel pressure (see page 11-144).

12. Remove the fuel line(seepagell-149).

13. Remove the evaporative emission (EVAP) canister

hose {A) and brake booster vacuum hose (B).

(cont'd)

5-3

Page 92 of 1139

Engine Assembly

18.

Engine Installation {cont'dl

10 x 1.25 mm33 N.m {3.i1kgf.m,25 tbt.ftl

19.

20.

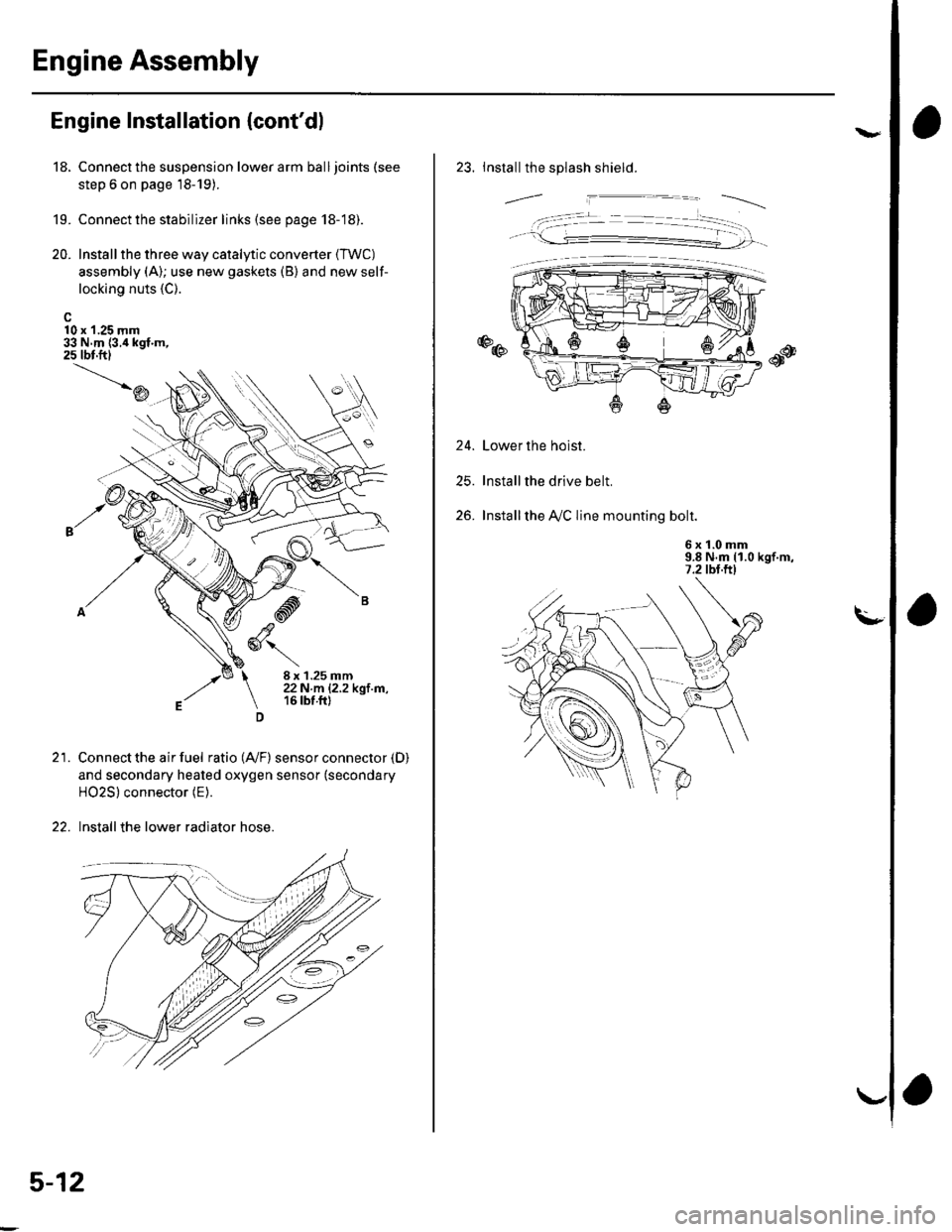

Connect the suspension lower arm ball joints (see

step 6 on page 18-19).

Connect the stabilizer links (see page 18-18).

Install the three way catalytic converter (TWC)

assembly (A); use new gaskets (B) and new self-

locking nuts {C).

\D

21.

-d

,ry6\

8 x 1.25 mm22N.m |.2.2kgl m,16 tbt.ft)

Connect the air fuel ratio (4,/F) sensor connector (D)

and secondary heated oxygen sensor (secondary

HO2S) connector (E).

Install the lower radiator hose.

5-12

va

23. Installthe splash shield.

24.

25.

26.

Lower the hoist.

Installthe drive belt.

Installthe A,/C line mounting bolt.

6 x '!.0 mm9.8 N.m (1.0 kgf.m,7.2 tbt.ftl

. -t- --�- --�--r

Page 95 of 1139

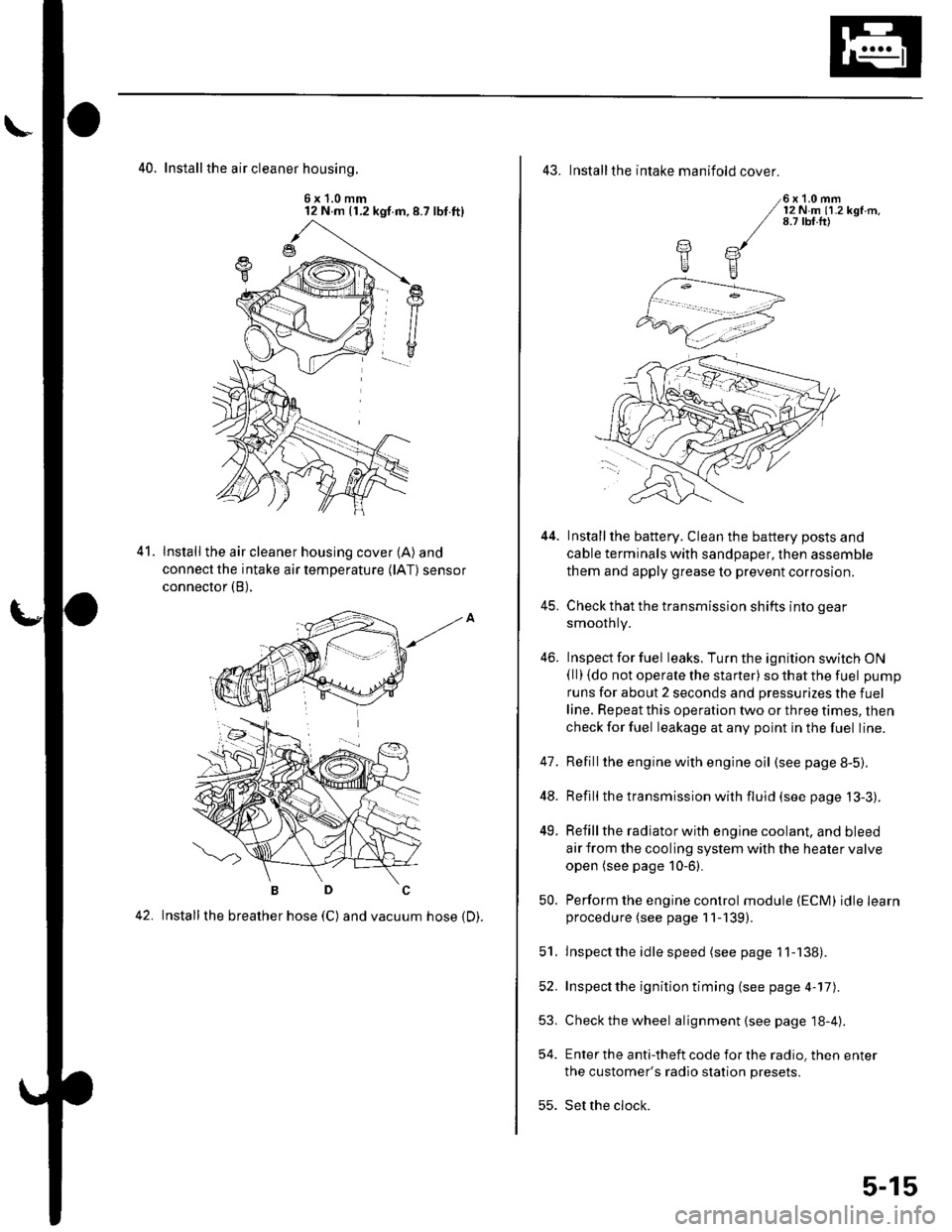

40. Install the air cleaner housinq.

6x1.0mm12 N m (1.2 kgf.m,8.7 lbt.ft)

Install the air cleaner housing cover (A) and

connect the intake air temperature (lAT) sensor

connector (B),

42. Installthe breather hose (C) and vacuum hose 1D).

41.

43. Installthe intake manifold cover.

6x1.0mm12Nm11.2kgf.m.8.7 tbf.ft)

Installthe battery. Clean the battery posts and

cable terminals with sandpaper, then assemble

them and apply grease to prevent corrosion.

Check that the transmission shifts into gear

smoothly.

Inspect for fuel leaks. Turn the ignition switch ON(ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refillthe engine with engine oil (see page 8-5).

Refill the transmission with fluid (see page 13-3).

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

Perform the engine control module (ECM) idle learnprocedure (see page 11-139).

Inspect the idle speed (see page 1 1-138).

Inspect the ignition timing (see page 4-17).

Check the wheel alignment {see page 18-4).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Set the clock.

YE

44.

41.

]tE

46.

48.

49.

52.

53.

54.

50.

51.

55.

5-15

Page 103 of 1139

Cylinder Head

WEC Rocker Arms Test (cont'dl

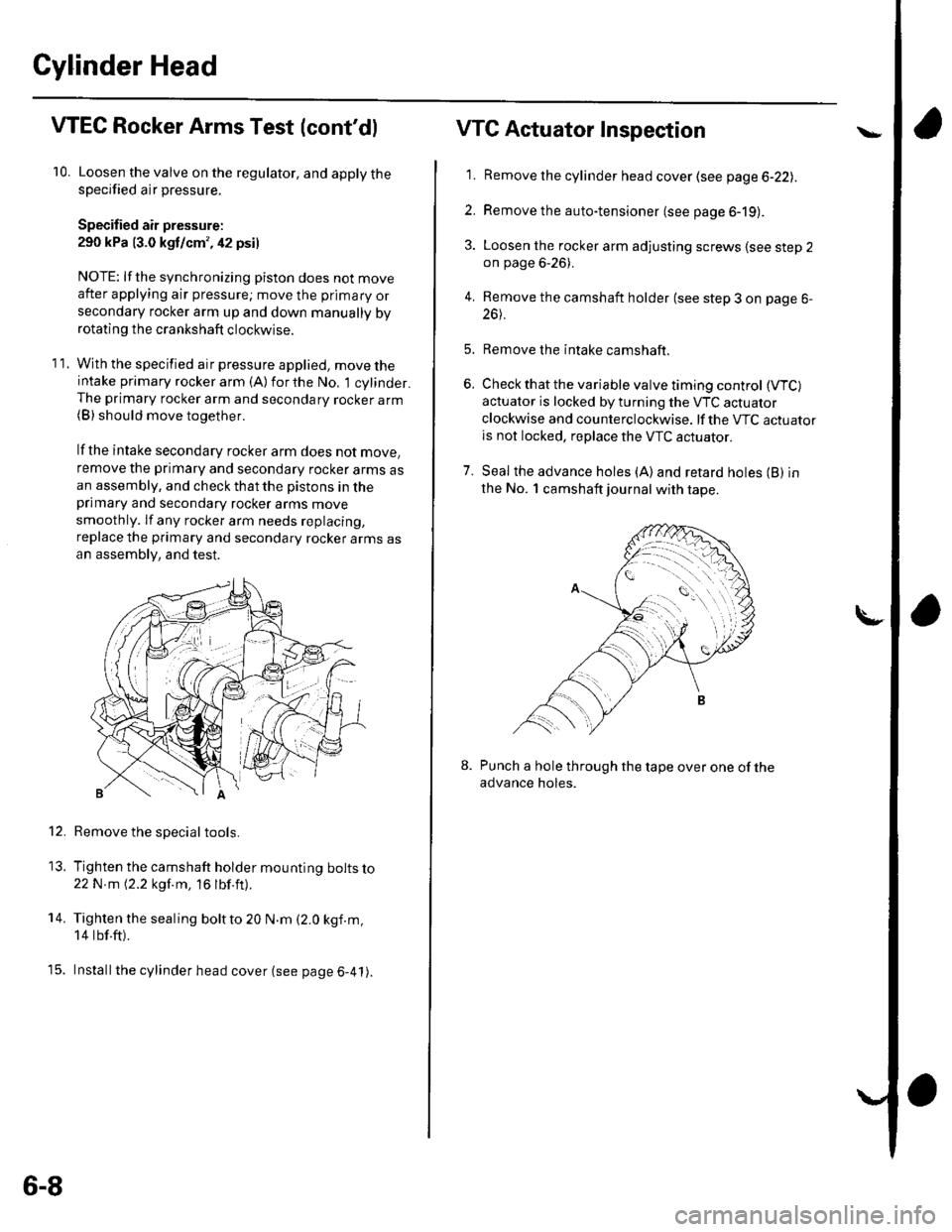

'10. Loosen the valve on the regulator, and apply thespecified air pressure.

Specified air pressure:

290 kPa 13.0 kgt/cm', 42 psi)

NOTE: lf the synchronizing piston does not moveafter applying air pressure; move the primary orsecondary rocker arm up and down manually byrotating the crankshaft clockwise.

11. With the specified air pressure applied, move theintake primary rocker arm (A)forthe No, 1 cylinder.The primary rocker arm and secondary rocker arm(B) should move together.

lf the intake secondary rocker arm does not move,

remove the primary and secondary rocker arms asan assembly, and check that the pistons in theprimary and secondary rocker arms move

smoothly. lf any rocker arm needs replacing,

replace the primary and secondary rocker arms asan assembly, and test.

Remove the special tools.

Tighten the camshaft holder mounting bolts lo22N m 12.2 kgf.m, 16 lbf.ft).

Tighten the sealing boltto 20 N.m (2.0 kgf.m,

14 tbf.ft).

Installthe cylinder head cover (see page 6-41).

12.

13.

14.

t5.

6-8

VTG Actuator Inspection

'11. Remove the cylinder head cover (see page 6-22lr.

2. Remove the auto-tensioner (see page 6-19).

3. Loosen the rocker arm adjusting screws lsee step 2on page 6-26).

4. Remove the camshaft holder (see step 3 on page 6-

26t.

5. Remove the intake camshaft.

6, Check that the variable valve timing control (VTC)

actuator is locked by turning the VTC actuator

clockwise and counterclockwise. lf the VTC actuatoris not locked, replace the VTC actuator.

7. Seal the advance holes (A)and retard holes (B) in

the No. 1 camshaft journal with tape.

Punch a hole through the tape over one of theadvance holes.

Page 104 of 1139

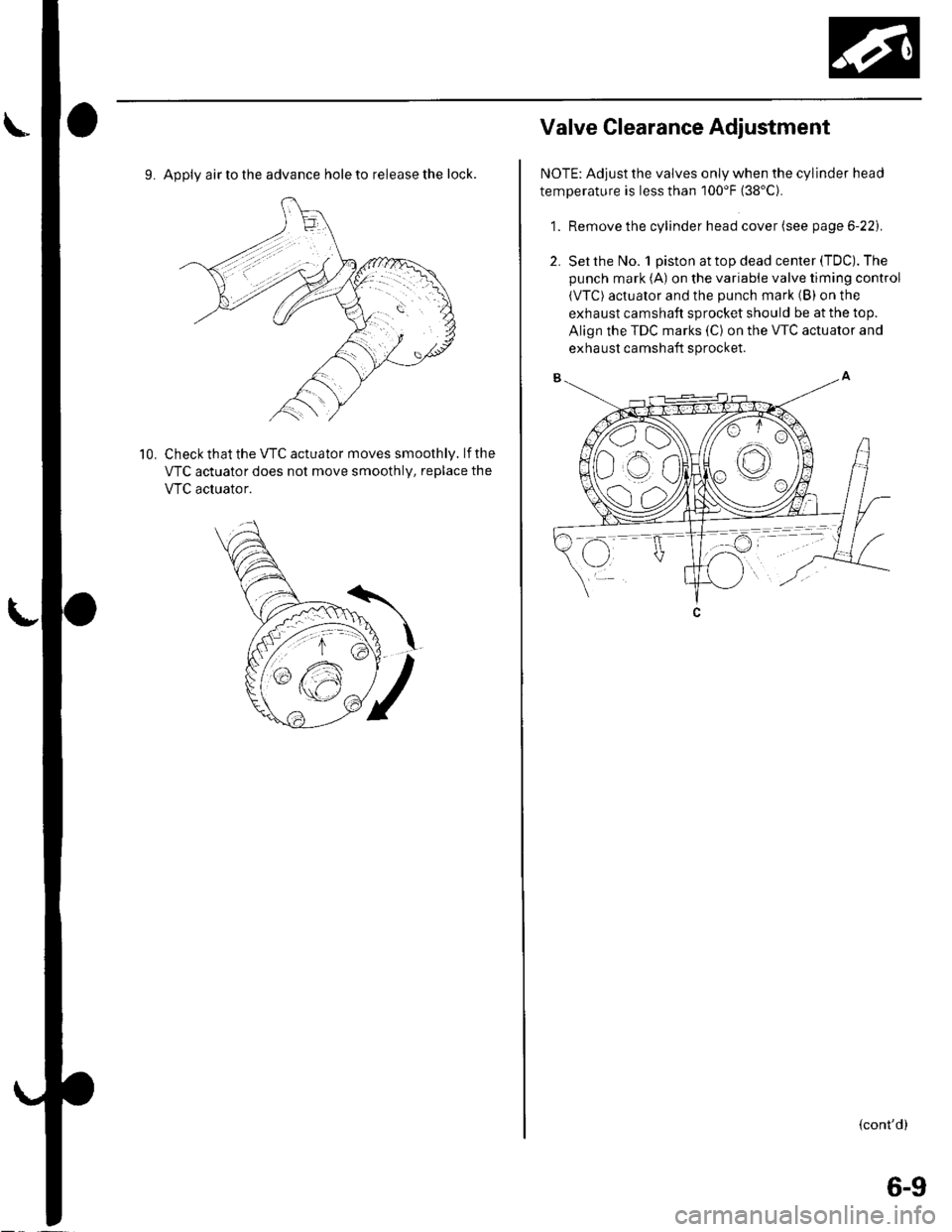

9. Apply air to the advance hole to release the lock.

Check that the VTC actuator moves smoothly. lf the

VTC actuator does not move smoothly, replace the

VTC acluator.

10.

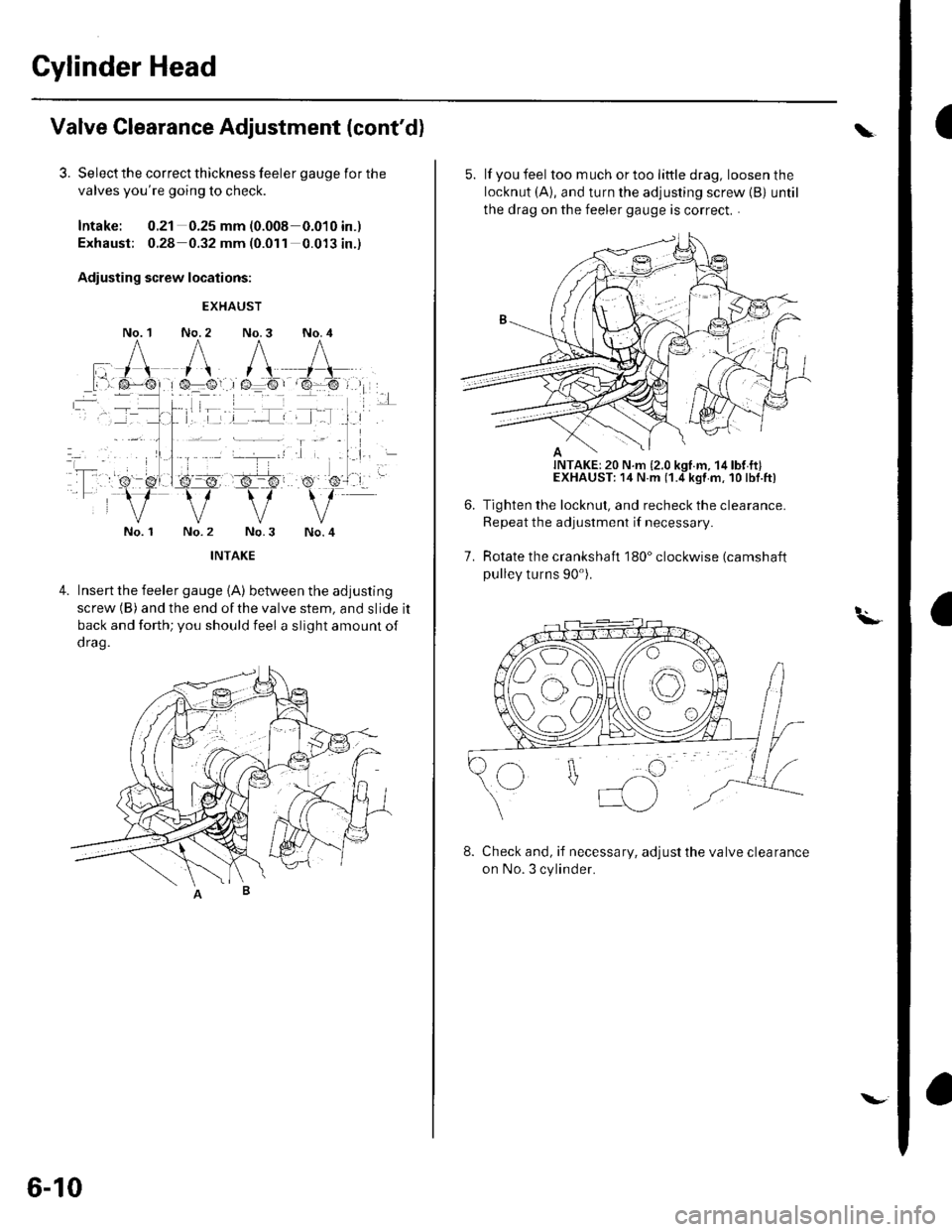

Valve Glearance Adiustment

NOTE: Adjust the valves only when the cylinder head

temperature is less than 100'F (38'C).

1. Remove the cylinder head cover (see page 6-22).

2. Set the No. 1 piston at top dead center (TDC). The

punch mark (A) on the variable valve timing control

(VTC) actuator and the punch mark (B) on the

exhaust camshaft sprocket should be at the top.

Align the TDC marks (C) on the VTC actuator and

exhaust camshaft sprocket.

{cont'd)

6-9

Page 105 of 1139

Gylinder Head

IValve Clearance Adjustment (cont'd)

3. Select the correct thickness feeler gauge for the

valves you're going to check.

Intake: 0.21 0.25 mm (0.008-0.010 in.)

Exhaust; 0.28 0.32 mm (0.011 0.013 in.)

Adiusting screw locations:

No. 1

EXHAUST

No. 2 No.3 No. 4

No. 1No.4

4.Insert the feeler gauge {A) between the adjusting

screw (B) and the end ofthe valve stem, and slide it

back and forth; you should feel a slight amount of

d rag.

6-10

\.

5. lf you feel toomuchortoolittledrag, loosenthe

locknut (A), and turn the adjusting screw {B) until

the drag on the feeler gauge is correct. .

Tighten the locknut, and recheck the clearance.

Repeat the adjustment if necessary

Rotate the crankshaft 180" clockwise (camshaft

pulley turns 90').

7.

t.\-

8. Check and, if necessary, adjust the valve clearance

on No. 3 cylinder.

Page 106 of 1139

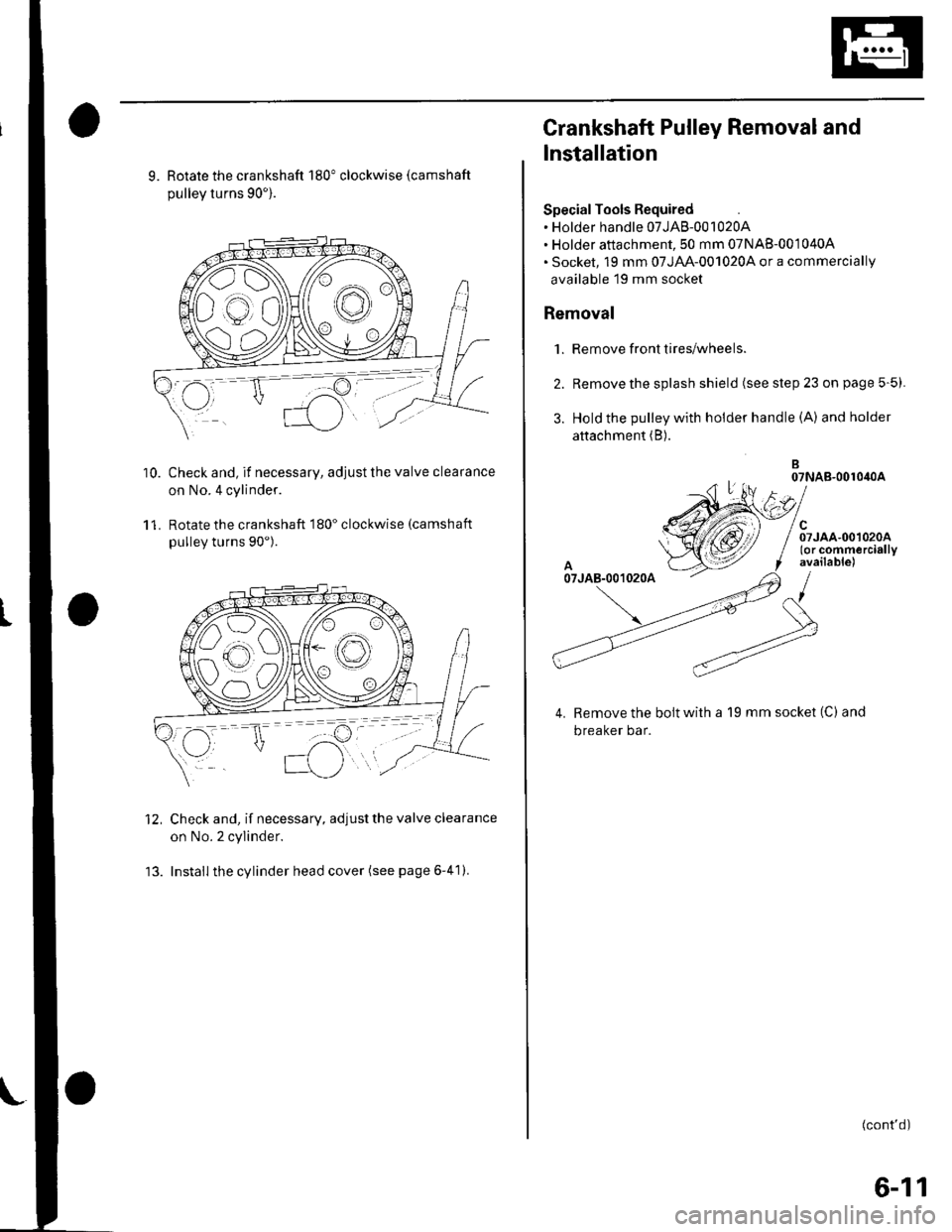

10.

9. Rotate the crankshaft 180" clockwise (camshaft

pullev turns 90').

Check and, if necessary, adjust the valve clearance

on No.4 cylinder.

Rotate the crankshaft 180" clockwise (camshaft

pulley turns 90").

Check and, if necessary, adjust the valve clearance

on No. 2 cylinder.

Install the cylinder head cover (see page 6-41).

11.

12.

Crankshaft Pulley Removal and

Installation

Special Tools Required. Holder handle 07JAB-001020A. Holder attachment, 50 mm 07NAB-001040A. Socket, 19 mm 07JAA-001020,4 or a commercially

available 19 mm socket

Removal

1. Remove front tires/wheels.

2. Remove the splash shield (see step 23 on page 5-5).

3. Hold the pulley with holder handle (A) andholder

attachment (B).

B07NAB-001040A

el

/ Srroo.oo,oroo/ (or commercially

f available)

/

Remove the bolt with a 19 mm socket (C) and

breaker bar.

(cont'd)

6-11

Page 108 of 1139

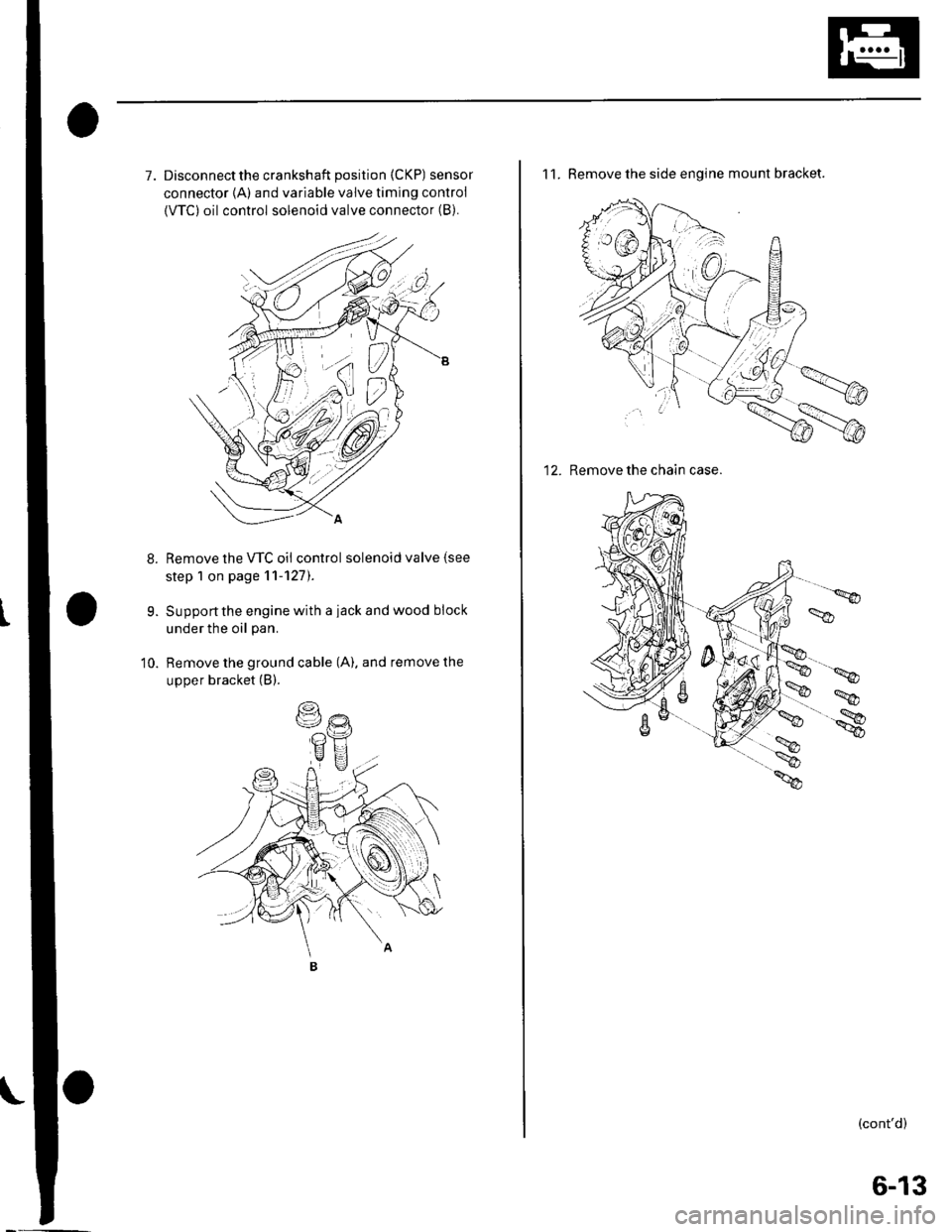

7. Disconnectthe crankshaft position (CKP) sensor

connector {A) and variable valve timing control

{VTC) oil control solenoid valve connector (B).

Remove the VTC oil control solenoid valve (see

step 1 on page 11-127).

Support the engine with a iack and wood block

under the oil pan.

Remove the ground cable (A). and remove the

upper bracket (B).

9.

10.

11. Remove the side engine mount bracket.

12. Remove the chain case.

(cont'd)

6-13

Page 109 of 1139

Cylinder Head

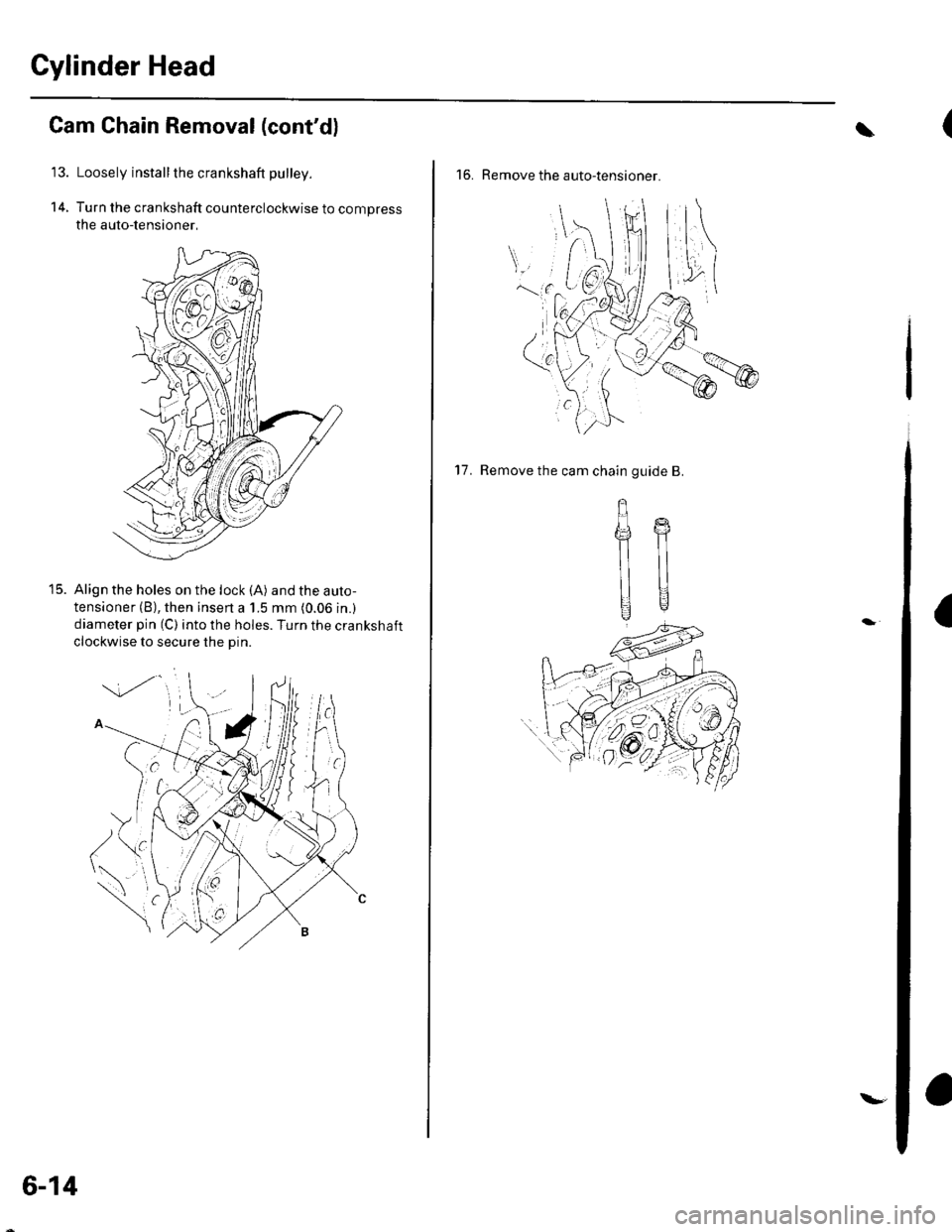

14.

Cam Chain Removal (cont'd)

Loosely install the crankshaft pulley.

Turn the crankshaft counterclockwise to compress

the auto-lensioner,

Align the holes on the lock (A) and the auto-

tensioner (B), then insen a 1.5 mm (0.06 in.)

diameter pin (C) into the holes. Turn the crankshaft

clockwise to secure the Din.

t5.

6-14

\-

(\

16. Remove the auto-tensioner.

a

17. Remove the cam chain guide B.

gffi

llll

UU

Page 110 of 1139

t

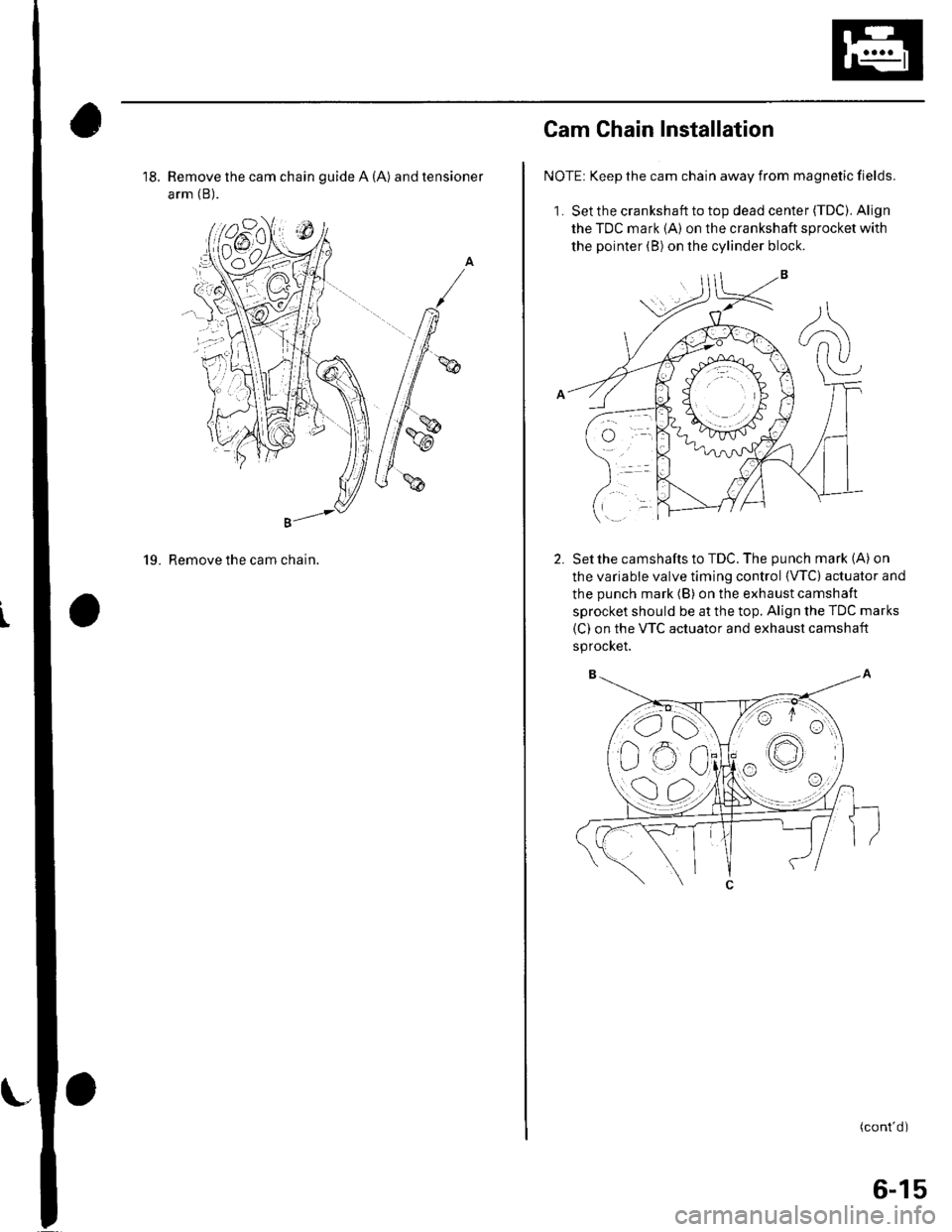

18. Remove the cam chain guide A (A) and tensioner

arm (B).

g"'-

19. Remove the cam chain.

,ot./6. | \{n$1J;

Cam Chain Installation

NOTE: Keep the cam chain away from magnetic fields.

1. Set the crankshaft to top dead center (TDC). Align

the TDC mark {A) on the crankshaft sprocket with

the pointer (B) on the cylinder block.

Setthe camshafts to TDC. The punch mark (A) on

the variable valve timing control {VTC) actuator and

the punch mark (B) on the exhaust camshaft

sprocket should be at the top. Align the TDC marks

(C) on the VTC actuator and exhaust camshaft

sprocKet.

(cont'd )

6-15