lock HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 989 of 1139

I

Keyless/Power Door Lock System

Door Lock Actuator Test

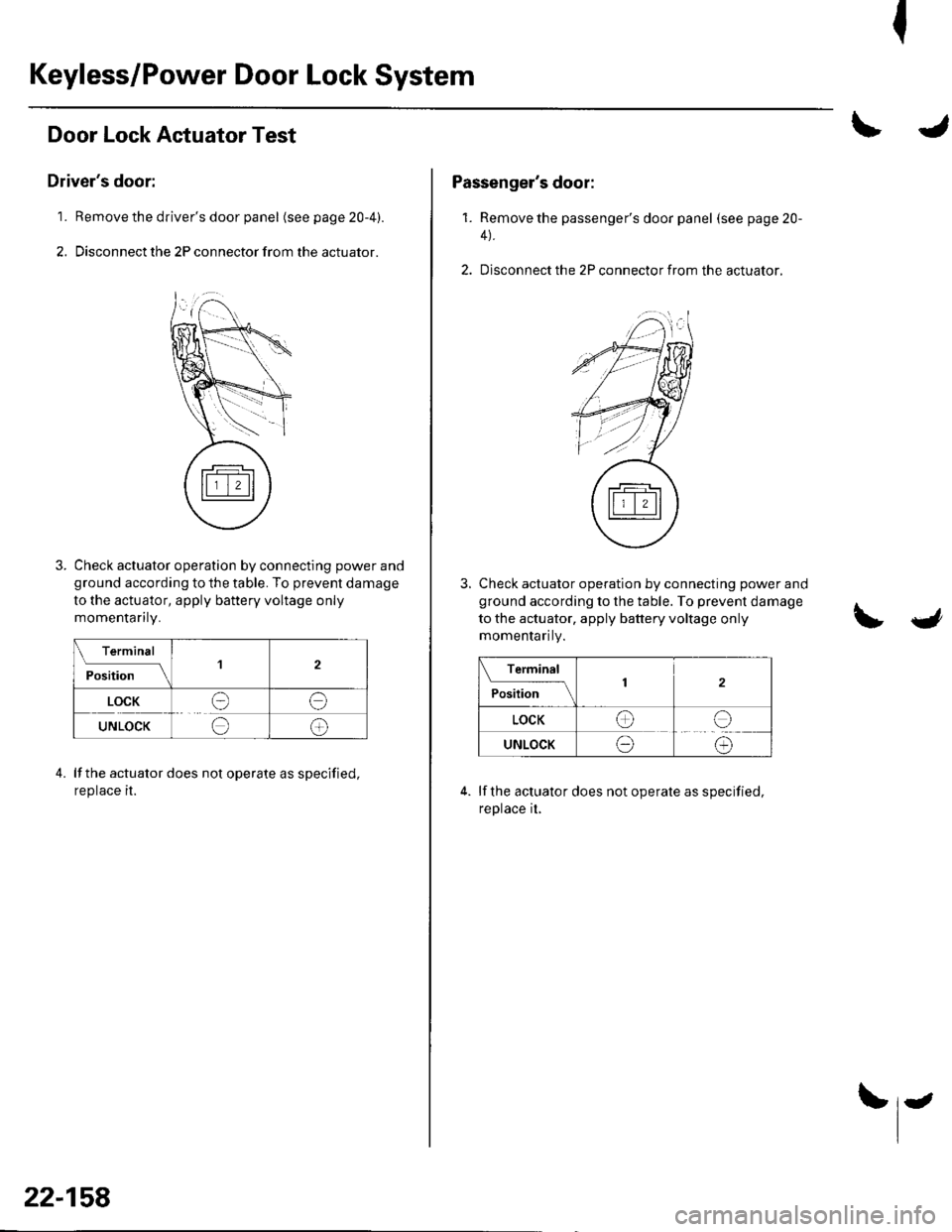

Driver's door:

1. Remove the driver's door panel (seepage20-4).

2. Disconnect the 2P connector from the actuator.

Check actuator operation by connecting power and

ground according to the table. To prevent damage

to the actuator, apply battery voltage only

momenlanry.

Terminal

ilil;lll

'l2

LOCKee

UNLOCKee

lf the actuator does not operate as specified,

reprace rr.

4.

22-158

Passenger's door:

1. Remove the passenger's door panel (seepage20-

4).

2. Disconnect the 2P connector from the actuator,

Check actuator operation by connecting power and

ground according to the table. To prevent damage

to the actuator, apply battery voltage only

momenlanty.

Terminal

P."I,l.;--\2

LOCKee

UNLOCKeo

lf the actuator does not operate as specified,

reprace [,

Page 990 of 1139

J

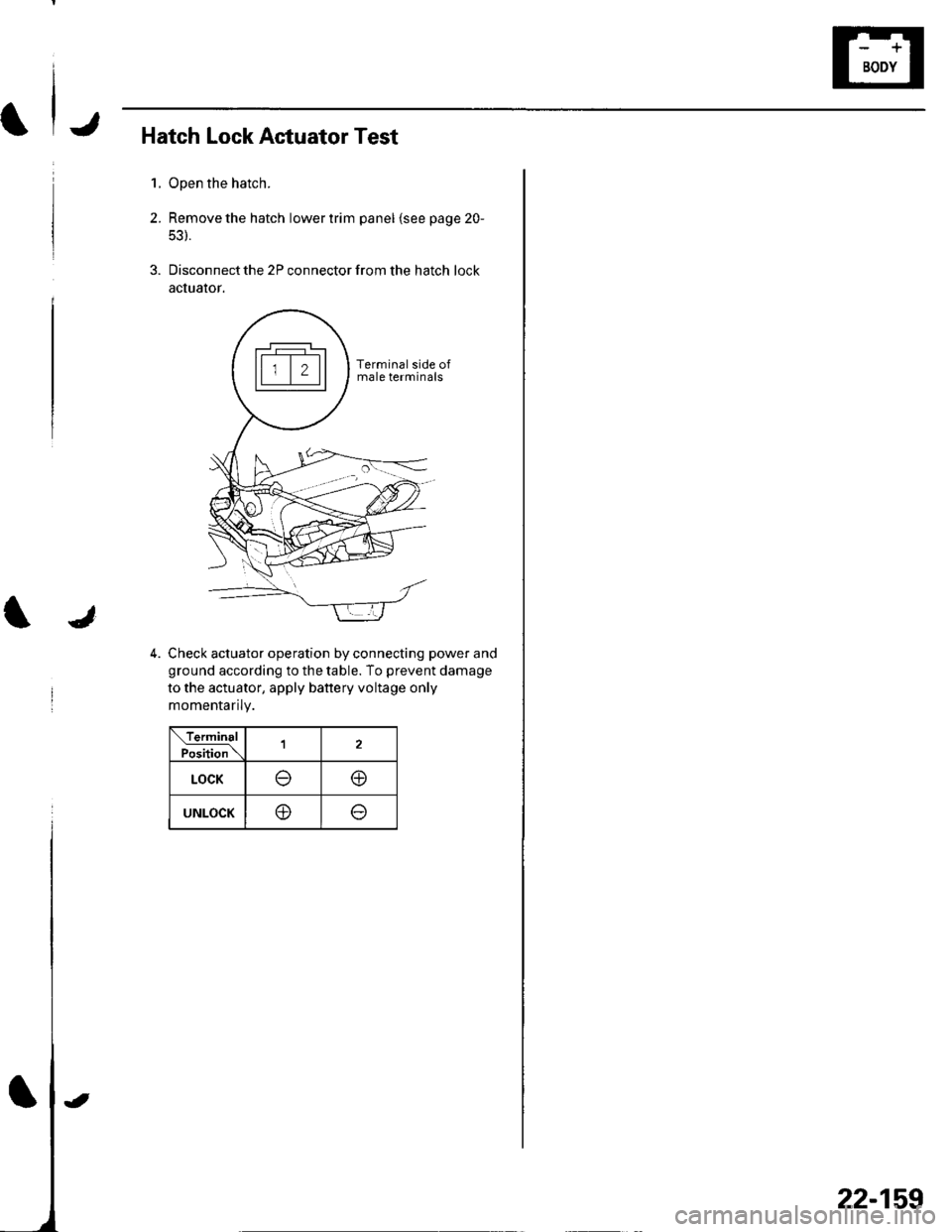

Hatch Lock Actuator Test

1. Open the hatch.

2. Remove the hatch lower trim panel lsee page 20-

53).

3. Disconnect the 2P connector from the hatch lock

actualor.

4. Check actuator operation by connecting power and

ground according to the table. To prevent damage

to the actuator, apply battery voltage only

momentaflty.

\TerminalPo.irion\1

LOCK@

UNLOCKo

Terminal side ofmale terminals

22-159

Page 991 of 1139

Keyless/Power Door Lock System

1.

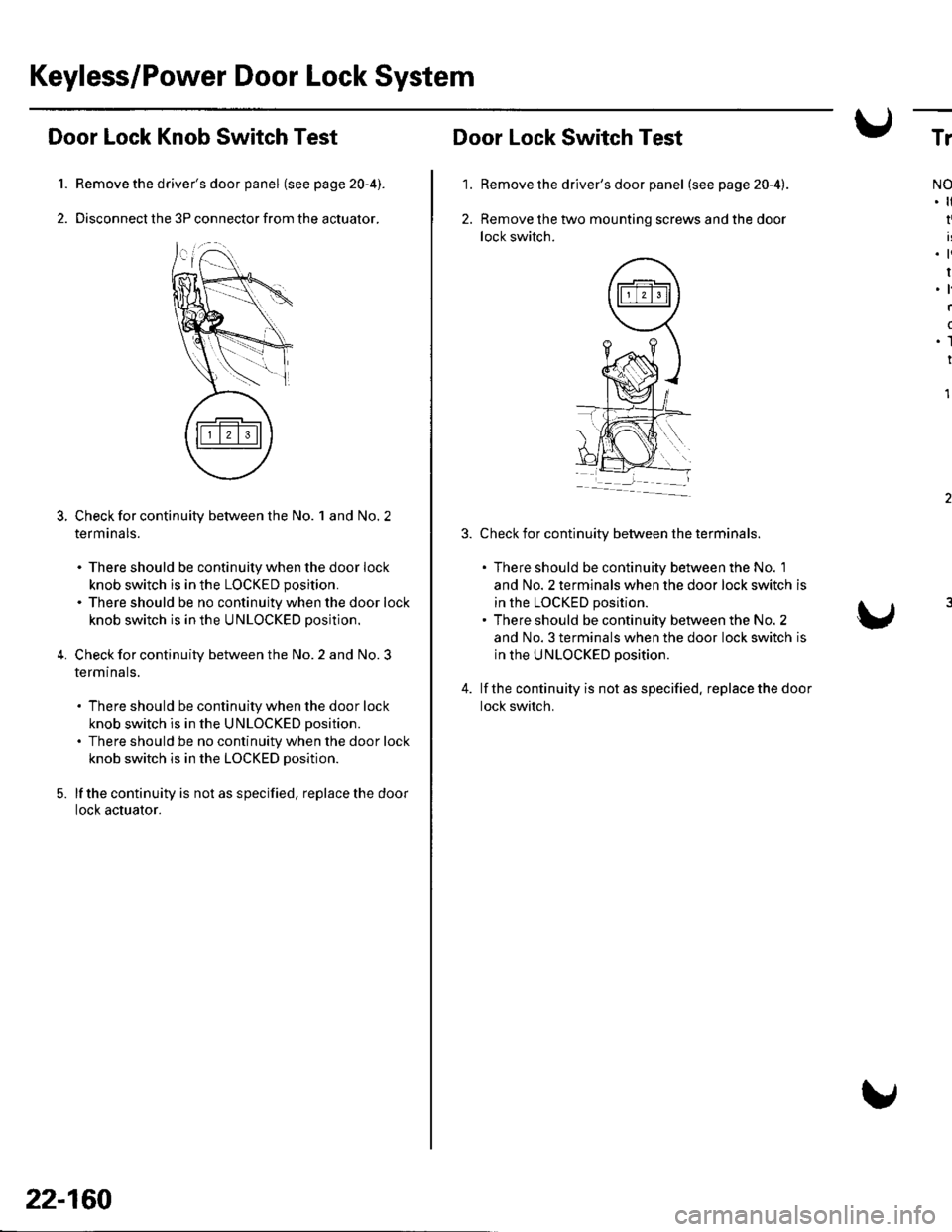

Door Lock Knob Switch Test

Remove the driver's door panel (see page 20-4).

Disconnect the 3P connector from the actuator.

Check for continuity between the No. 1 and No. 2

term ana ls.

. There should be continuity when the door lock

knob switch is in the LOCKED position.

. There should be no continuity when the door lock

knob switch is in the UNLOCKED position.

Check for continuity between the No. 2 and No. 3

termtnals.

. There should be continuity when the door lock

knob switch is in the UNLOCKED position.

. There should be no continuity when the door lock

knob switch is in the LOCKED position.

lf the continuity is not as specified, replace the door

locl( actuator.

5.

22-160

'1.

Door Lock Switch Test

Remove the driver's door panel (see page 20-4).

Remove the two mounting screws and the door

lock switch.

Check for continuity between the terminals.

. There should be continuity between the No. 1

and No. 2 terminals when the door lock switch is

in the LOCKED position.. There should be continuity between the No. 2

and No. 3 terminals when the door lock switch is

in the UNLOCKED position.

lf the continuity is not as specified. replace the door

lock switch.

Tr

NO

I

.ti

I.l

I

(

.1

I

1

Page 992 of 1139

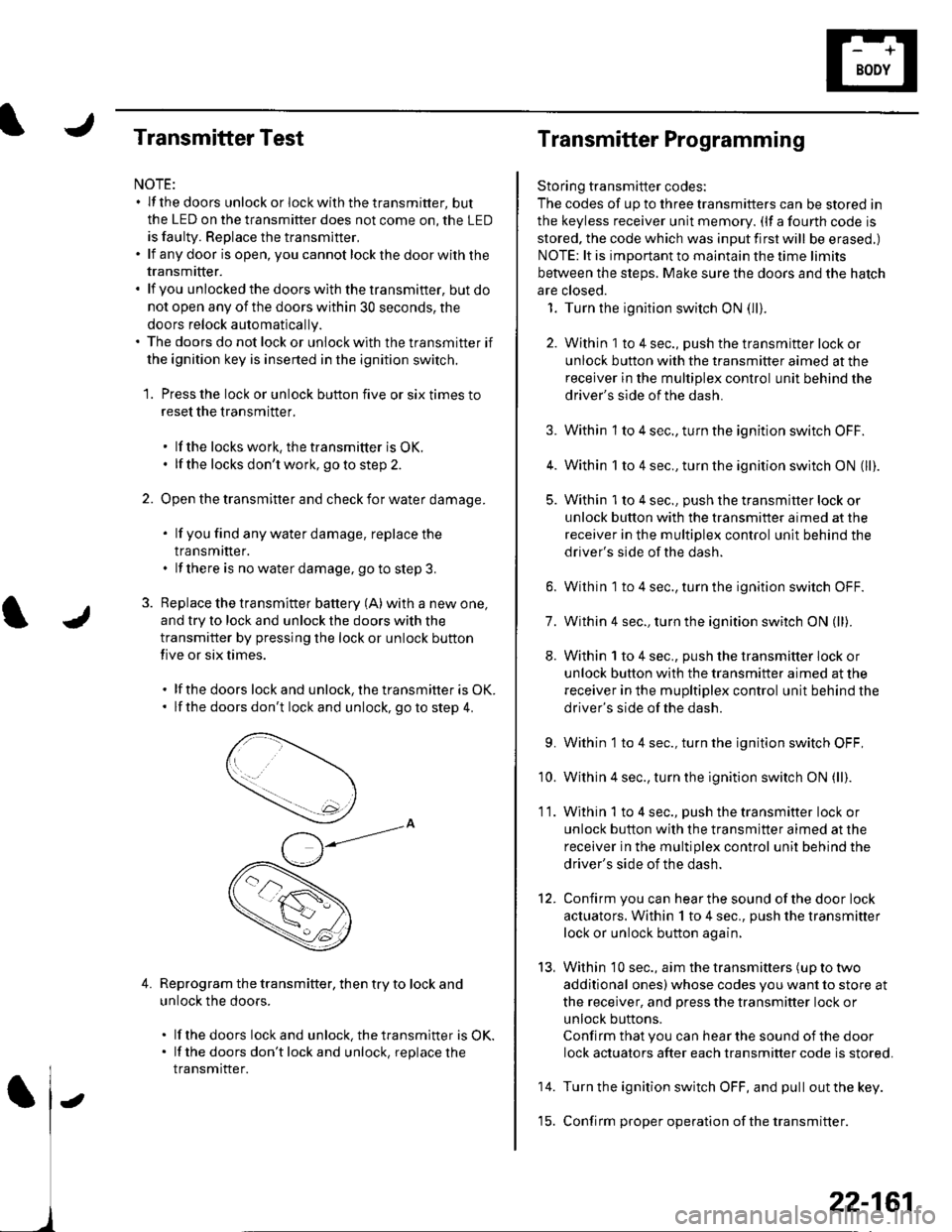

Transmitter Test

NOTE:. lf the doors unlockorlockwiththetransmitter, but

the LED on the transmitter does not come on, the LED

is faulty. Replace the transmitter,. lf anydoor isopen, you cannotlockthedoorwiththe

transmrtter.. lf you unlocked the doors with the transmitter, but do

not open any of the doors within 30 seconds, the

doors relock automatically.. The doors do not lock or unlock with the transmitter if

the ignition key is inserted in the ignition switch.

1. Press the lock or unlock button five or six times to

reset the transmitter.

. lf the locks work, the transmitter is OK.. lf the locks don't work, go to step 2.

2. Open the transmitter and check for water damage.

. lf you find any water damage, replace the

transmrtter.. lf there is no waterdamage, go to step 3.

3. Replace the transmitter battery (A) with a new one,

and try to lock and unlock the doors with the

transmitter by pressing the lock or unlock button

five or six times.

. lf the doors lock and unlock, the transmifter is OK.. lf the doors don't lock and unlock, go to step 4.

Reprogram the transmitter, then try to lock and

unlock the doors.

. lf thedoors lockand unlock.thetransmitter is OK.. lf the doors don'tlockand unlock, replacethe

transmitter.

4.

Transmitter Programming

Storing transmitter codes:

The codes of up to three transmitters can be stored in

the keyless receiver unit memory. (lf a fourth code is

stored. the code which was input first will be erased.)

NOTE: lt is important to maintain the time limits

between the steps. Make sure the doors and the hatch

are closed.

1. Turn the ignition switch ON (lli.

2. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the

receiver in the multiplex control unit behind the

driver's side of the dash.

3. Within 1 to 4 sec., turn the ignition switch OFF.

4. Within 1 to 4 sec., turn the ignition switch ON (ll).

5. Within 'l to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the

receiver in the multiplex control unit behind the

driver's side of the dash.

6. Within 1 to 4 sec., turn the ignition switch OFF.

7. Within 4 sec., turn the ignition switch ON (ll).

8. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmifter aimed at the

receiver in the mupltiplex control unit behind the

driver's side of the dash.

9. Within 1 to 4 sec., turn the ignition switch OFF,

'10. Within 4 sec., turn the ignition switch ON (ll).

11. Within 1 to 4 sec., push the transmitter lock or

unlock button with the transmitter aimed at the

receiver in the multiplex control unit behind the

driver's side of the dash.

12. Confirm you can hearthe sound ofthe door lock

actuators. Within 1 to 4 sec., push the transmitter

lock or unlock button again,

13, Within 10 sec., aim the transmitters (up to two

additional ones) whose codes you want to store at

the receiver, and press the transmitter lock or

unlock buttons.

Confirm that you can hear the sound of the door

lock actuators after each transmitter code is stored.

14. Turn the ignition switch OFF, and pull out the key.

'15. Confirm proper operation ofthe transmitter.

22-161

Page 1002 of 1139

ISystem Descriptions

The Multiplex Control System has four internal

functions:. Multiplexing (send multiple signals over sharedwtres). Wake up/sleep (runs at full power only on demand toreduce battery draw). Fail-safe (fixes or ignores faulty signals). Self-diagnosis (Mode 1 for the system, Mode 2 for

input lines)

The system controls the function of these circuits:. Entry lightcontrol (ignition key lightandceiting light). Wiper/washer intermittent wipe and park functions. Keyless/power door lock. Meter assembly, temperature gauge, and indicator

lights. HVAC (compressor and fan control). Key-in reminder. Headlight reminder. Seatbelt reminder

JI

/ar

22-171

Multiplex Communication

To reduce the number of wire harnesses, digital signals

are sent via shared multiplex communication linesrather than sending normal electrical signals throughindividual wires.. The input signals from each switch are converted todigital signals at the central processing unit (CpU).. The digital signalsaresentfromthetransmitting unitto the receiving unit as serial signals.. The transmitted signal is converted to a switch signalat the receiving unit, and it operates the related

component or monitors a swltch.. There are exclusive communicalion lines between

the ECM, the gauge assembly, and the under,dash

fuse/relay box.

Wake-up and Sleep

The multiplex control system has "wake-up" and"sleep" functions to decrease parasitic draw on the

battery when the ignition switch is OFF.. ln the sleep mode, the multiplex control unit stops

functioning (communication and CPU control) when it

is not necessary for the system to operate.. As soon as any operation is requested (for example, adoor is unlocked), the related control unit in the sleep

mode immediately wakes up and begins to function.. When the ignition switch is turned OFF, and the

driver's or front passenger's door is opened, then

closed, there is about a 10 second delay before the

control unit goes from the wake-up mode to the sleepmode.. lf any door is open, the sleep mode will not function.. lf a key is in the ignition switch, the sleep mode will

not function.. When in sleep mode, the draw is reduced from

70 80 mA to less than 10 mA.

Fail-safe

To prevent improper operation, the multiplex controlsystem has a fail-safe function. In the fail-safe mode,

the output signal js fixed when any part of the systemmalfunctions (for example a faulty control unit orcommunication line).

Each control unit has a hardware fail-safe function thatfixes the output signal when there is any CPUmalfunction, and a software fail-safe function thatignores the signal from the malfunctioning control unitand allows the system to operate normally.

Page 1013 of 1139

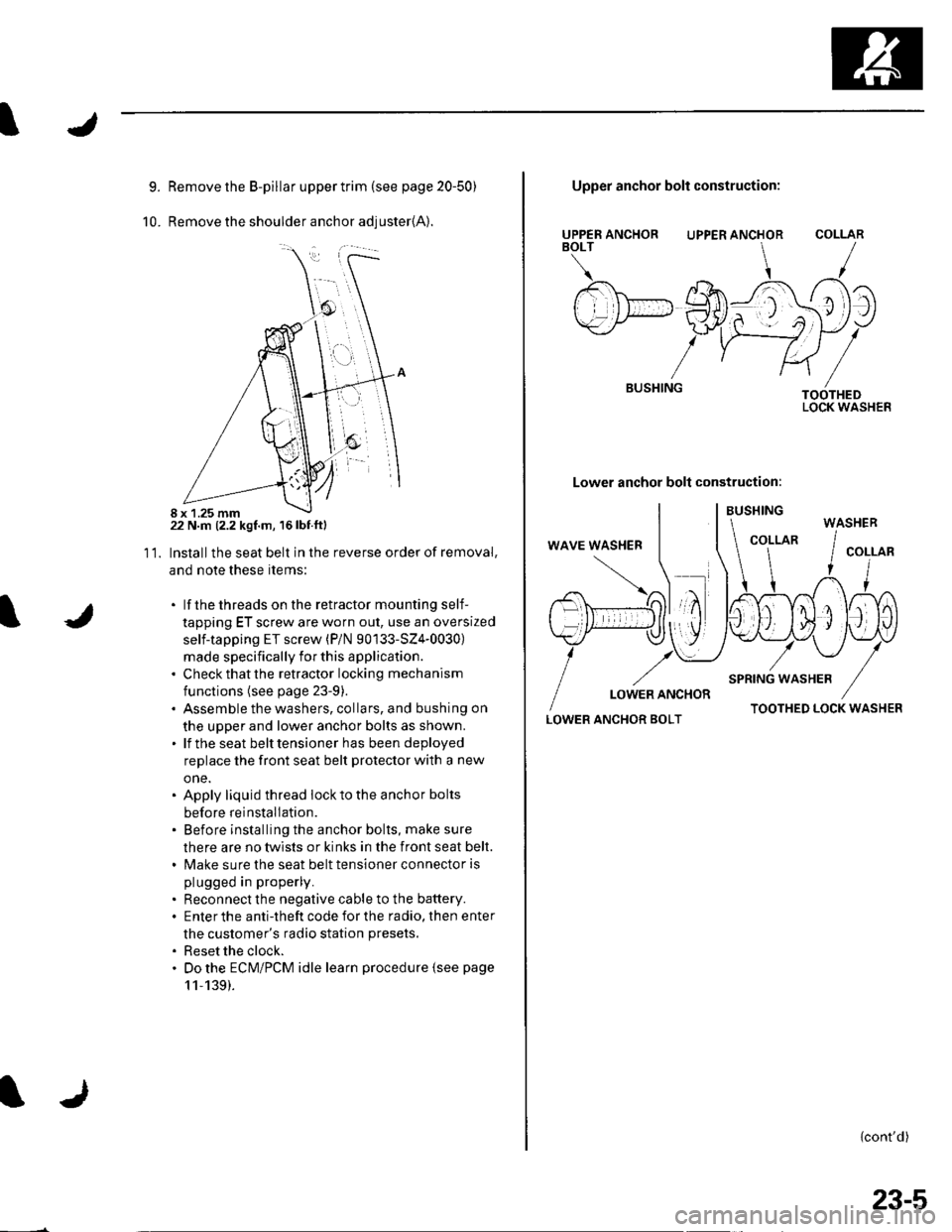

9.

10.

Remove the B-pillar upper trim {see page 20-50)

Remove the shoulder anchor adjuster{A).

22 N.m (2.2 kgf.m, 16lbf.ftl

Installthe seat belt in the reverse order of removal,

and note these items:

. lf thethreads on the retractor mounting self-

tapping ET screw are worn out, use an oversized

self-tapping ET screw (P/N 90133-SZ4-0030)

made specifically for this application.. Check that the retractor locking mechanism

functions (see page 23-9).. Assemble the washers, collars, and bushing on

the upper and lower anchor bolts as shown.. lf the seat belt tensioner has been deployed

replace the front seat belt protector with a new

one.. Apply liquid thread lock to the anchor bolts

before reinstallation.. Before installing the anchor bolts, make sure

there are no twists or kinks in the front seat belt.. Make sure the seat belt tensioner connector is

plugged in properly.

. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

. Reset the clock.. Do the ECM/PCM idle learn procedure {see page

11,139).

11.

8 x 1.25 mm

UPPER ANCHORBOLT

BUSHING

Upper anchor bolt construction:

UPPER ANCHOR

Lower anchor bolt construction:

COLLAR

TOOTHEDLOCK WASHER

LOWER ANCHOR BOLTTOOTHED LOCK WASHER

{cont'd)

WASHER

23-5

Page 1014 of 1139

Seat Belts

Front Seat Belt Replacement (cont'd)

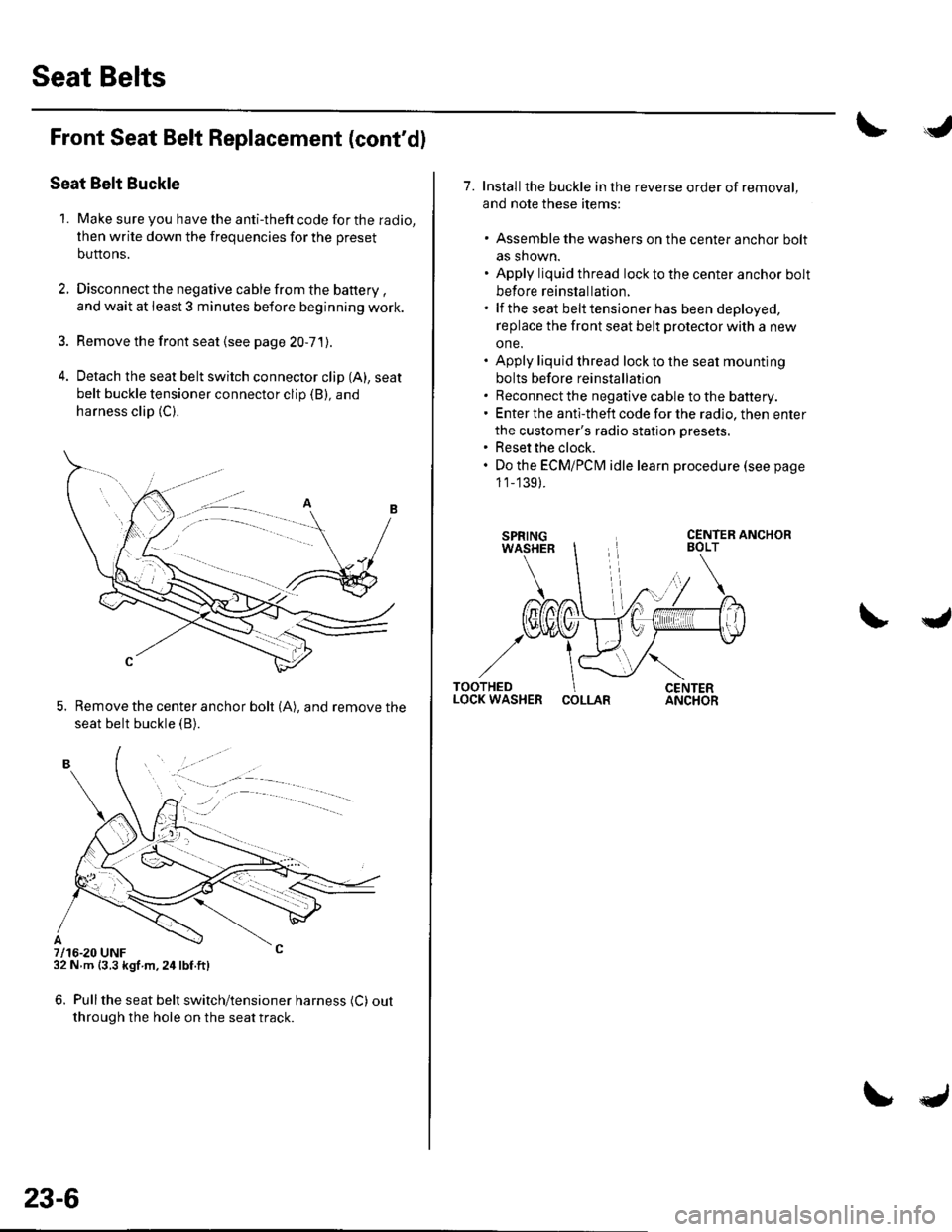

Seat Belt Buckle

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the preset

buttons.

2. Disconnect the negative cable from the battery ,and wait at least 3 minutes before beginning work.

3. Remove the front seat (see page 20-7'1).

4. Detach the seat belt switch connector clip (A), seat

belt buckle tensioner connector clip (B), and

harness clip (C).

5. Remove the center anchor bolt (A), and remove the

seat belt buckle {B).

7/16-20 UNF32 N m {3.3 kgf m,24lbf.ft)

6. Pullthe seat belt switch/tensioner harness (C) out

through the hole on the seat track.

. -.. :.a--

23-6

7. Installthe buckle in the reverse order of removal,

and note these items:

. Assemble the washers on the center anchor bolt

as shown.. Apply liquid thread lock to the center anchor bolt

before reinstallation.. lf the seat belt tensioner has been deployed,

replace the front seat belt protector with a new

one.. Apply liquid thread lock to the seat mounting

bolts before reinstallation. Reconnect the negative cable to the battery.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.. Reset the clock.. Do the ECMiPCM idle learn procedure (see page

1 1_139).

COLLAR

Page 1015 of 1139

I

I

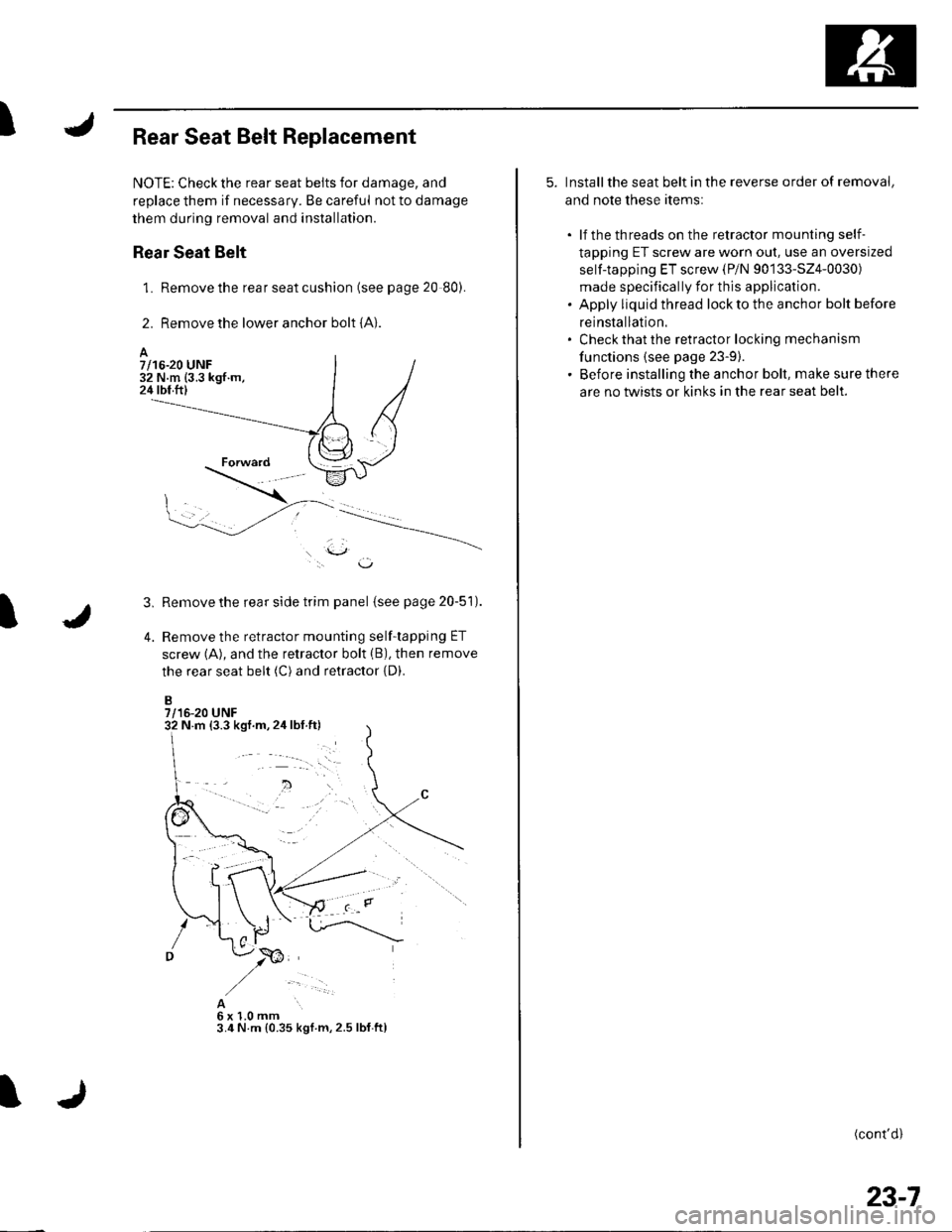

Rear Seat Belt Replacement

NOTE: Check the rear seat belts for damage, and

replace them if necessary. Be careful not to damage

them during removal and installation.

Rear Seat Belt

1. Remove the rear seat cushion (see page 20 80).

2. Remove the lower anchor bolt {A}.

l.\J,

Remove the rear side trim panel (see page 20-51).

Remove the retractor mounting self-tapping ET

screw (A), and the retractor bolt (B), then remove

the rear seat belt (C) and retractor {D).

B7/16-20 UNF

3,

4.

A6x1.0mm3.4 N.m {0.35 kgl m,2.5 lbf.ftl

A7/16-20 UNF32 N.m (3.3 kgf.m,24 tbf.ftl

N m {3.3 kgf.m,2ir lbf.ft)

5. Installthe seat belt in the reverse order of removal,

and note these items:

. lf the threads on the retractor mounting self-

tapping ET screw are worn out, use an oversized

self-tapping ET screw (P/N 90133-524-0030)

made specifically for this application.. Apply liquid thread lock to the anchor bolt before

reinstallation.' Check that the retractor locking mechanism

functions {see page 23-9).. Before installing the anchor bolt, make sure there

are no twists or kinks in the rear seat belt.

(cont'd)

23-7

Page 1017 of 1139

I

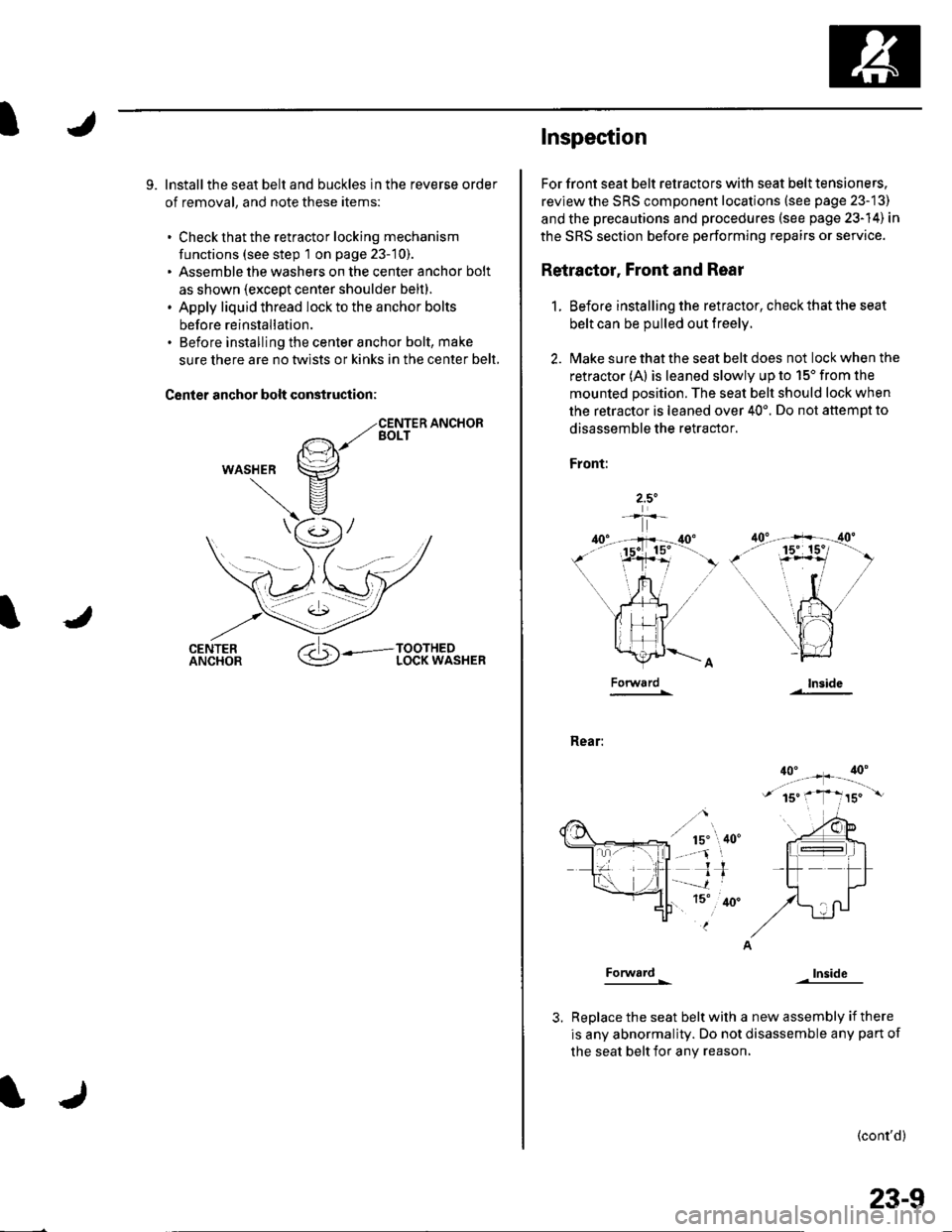

9. lnstallthe seat belt and buckles in the reverse order

of removal, and note these items:

. Check that the retractor locking mechanism

functions (see step 1 on page 23-10).. Assemble the washers on the center anchor bolt

as shown (except center shoulder belt).. Apply liquid thread lock to the anchor bolts

before reinstallation.. Before installing the center anchor bolt, make

sure there are no twlsts or kinks in the center belt,

Canler anchor bolt construction:

WASHER

Inspec'tion

For front seat belt retractors with seat belt tensioners.

reviewthe SRS component locations (see page 23-13)

and the precautions and procedures (see psge 23-14) in

the SRS section before performing repairs or service.

Retractor, Front and Rear

1. Before installing the retractor, check that the seat

belt can be pulled out freely.

2. l\4ake sure that the seat belt does not lock when the

retractor (A) is leaned slowly up to 15'from the

mounted position. The seat belt should lock when

the retractor is leaned over 40'. Do not attemDt to

disassemble the retractor.

Front:

Rear:

Forward

Forward

lnside

Inside

Replace the seat belt with a new assembly if there

is any abnormality. Do not disassemble any pan of

the seat belt for any reason,

(cont'd)

23-9

Page 1018 of 1139

Seat Belts

Inspection (cont'd)

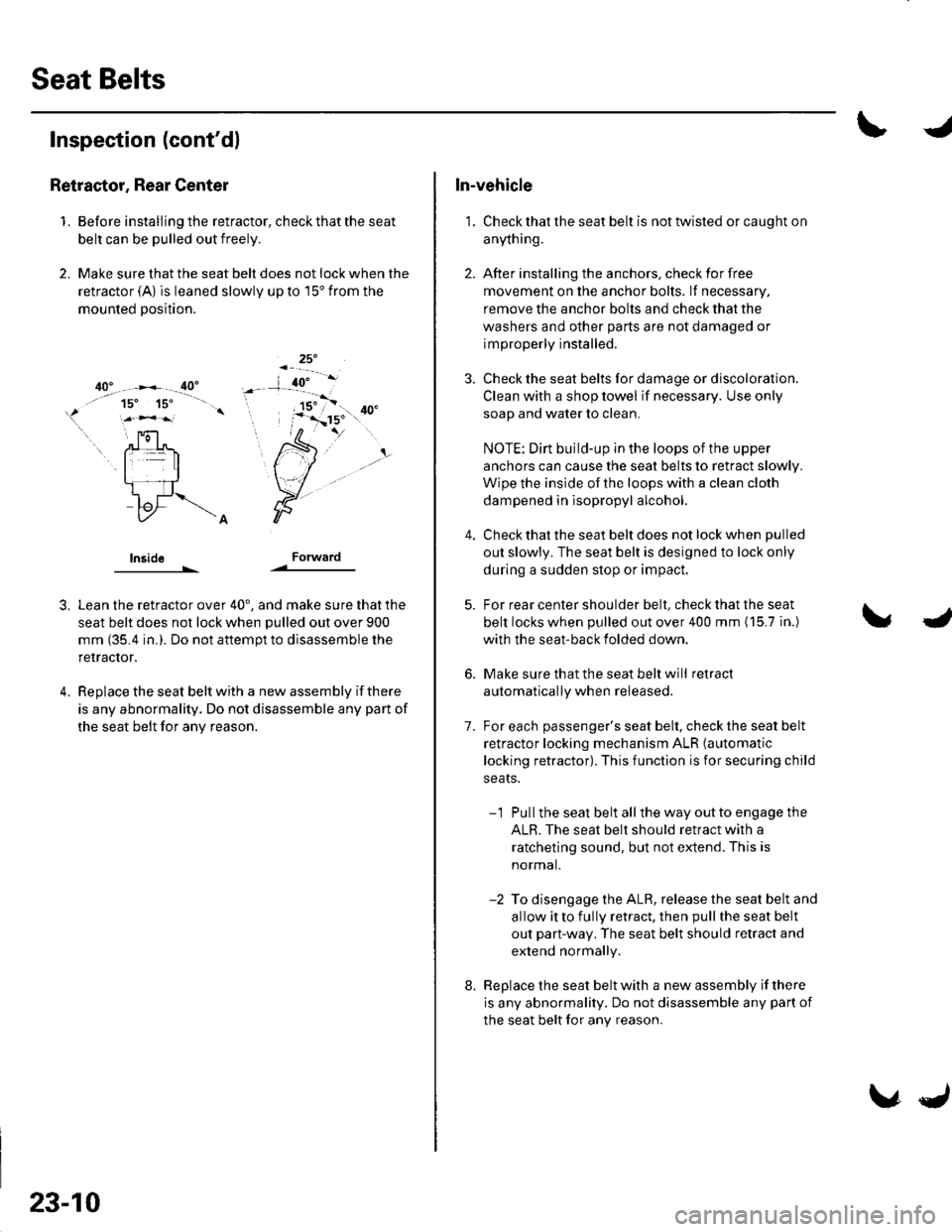

RetraEtor, Rear Center

1. Before installing the retractor, check that the seat

belt can be pulled out freely.

2, Make sure that the seat belt does not lock when the

retractor (A) is leaned slowly up to 15' from the

mounted position.

lnsideForward

3,

4.

Lean the retractor over 40', and make sure that the

seat belt does not lock when pulled out over 900

mm (35.4 in.). Do not aftempt to disassemble the

retractor.

Replace the seat belt with a new assembly if there

is any abnormality. Do not disassemble any part of

the seat belt for any reason.

23-10

\,J

In-vehicle

1. Check that the seat belt is not twisted or caught on

anything.

2. After installing the anchors. check for free

movement on the anchor bolts. lf necessary,

remove the anchor bolts and check that the

washers and other parts are not damaged or

improperly installed.

3. Check the seat belts for damage or discoloration.

Clean with a shop towel if necessary. Use only

soap and water to clean.

NOTE: Dirt build-up in the loops of the upper

anchors can cause the seat belts to retract slowly.

Wipe the inside of the loops with a clean cloth

dampened in lsopropyl alcohol.

Check that the seat belt does not lock when pulled

out slowly. The seat belt is designed to lock only

during a sudden stop or impact.

For rear center shoulder belt, check that the seat

belt locks when pulled out over 400 mm (15.7 in.)

with the seat-back folded down.

Make sure that the seat belt will retract

automatically when released.

For each passenger's seat belt, check the seat belt

retractor locking mechanism ALR (automatic

locking retractor). This function is for securing child

seats.

-1 Pullthe seat belt allthe way outto engage the

ALR. The seat belt should retract with a

ratcheting sound, but not extend. This is

normal.

-2 To disengage the ALR, release the seat belt and

allow itto fully retract, then pullthe seat belt

out part-way. The seat belt should retract and

extend normally.

Replace the seat belt with a new assembly if there

is any abnormality. Do not disassemble any part of

the seat belt for any reason.

7.

8.