Control HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 816 of 1139

13. Installthe heater core and the evaporator core in

the reverse order of removal.

14. Installthe heater unit in the reverse order of

removal, and note these items:

. Do not interchange the inlet and outlet heater

hoses, and installthe hose clamps securely.. Refillthe cooling system with engine coolant (see

page 10-6).. Adjust the heater valve cable (see page 2'l-461.. Make sure that there is no coolant leakage.. Make sure that there is no air leakage.. Refer to evaporator core replacement {see step 6

on page 21-42).. Do the engine control module (ECl\4) idle learn

procedure (see page 11-139).. Enter the anti-theft code for the radio, then enter

the customer's radio station Dresets.

21-45

Page 817 of 1139

Heating and Air Conditioning

Heater Valve Cable Adjustment

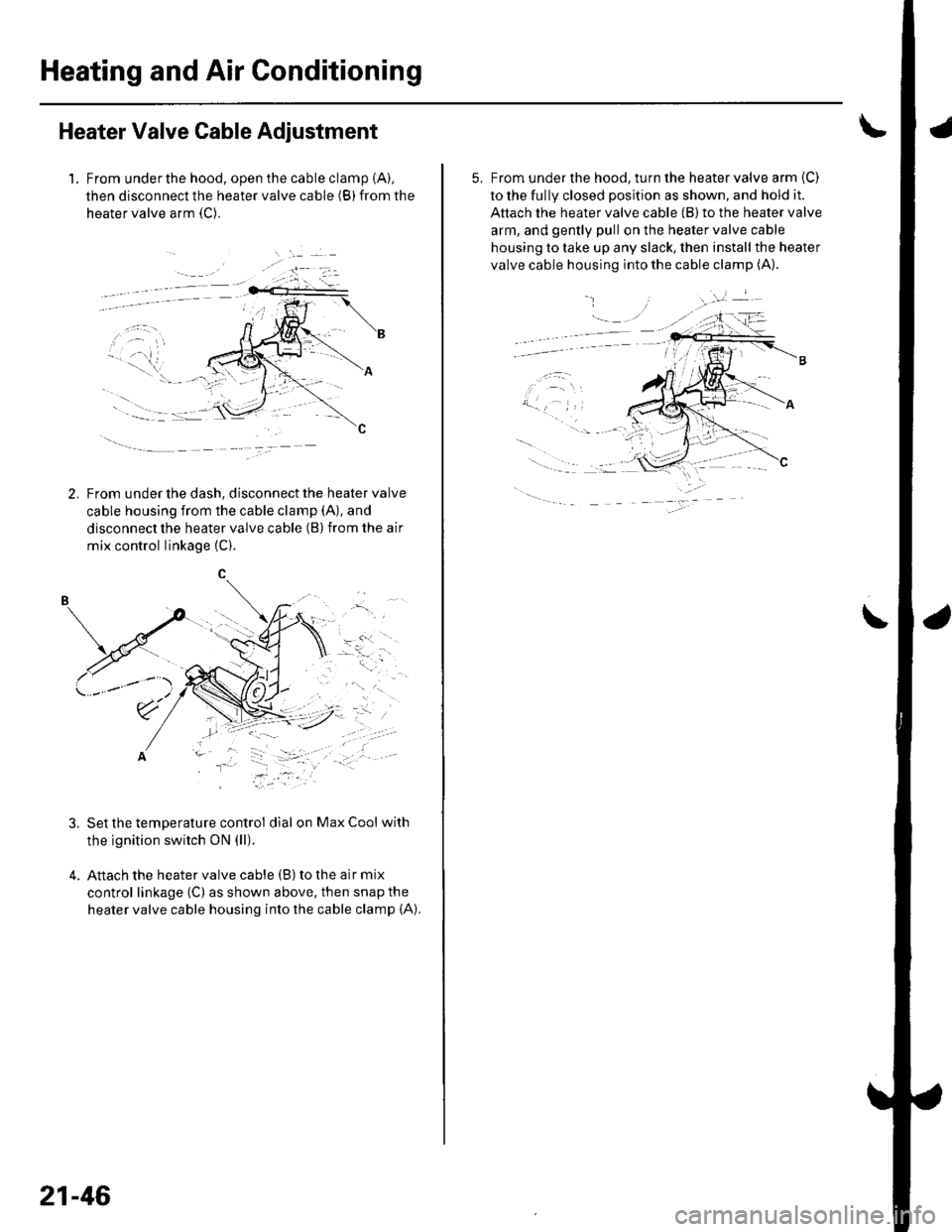

1. From underthe hood, open the cable clamp {A),

then disconnect the heater valve cable (B) from the

heater valve arm {C).

tFrom under the dash, disconnect the heater valve

cable housing from the cable clamp (A), and

disconnect the heater valve cable (B) from the air

mix control linkage {C).

, t.- l

\'r2t' ''' '

' ::"'

Set the temperature control dial on Max Cool with

the ignition switch ON (ll).

Attach the heater valve cable (B) to the air mix

control linkage (C) as shown above, then snap the

heater valve cable housing into the cable clamp (A).

.'.-:',,

-"ll

.....-

21-46

5, From under the hood, turn the heater valve arm {C)

to the fully closed position as shown, and hold it.

Attach the heater valve cable (B) to the heater valve

arm, and gently pull on the heater valve cable

housing to take up any slack, then install the heater

valve cable housing into the cable clamp (A).

.

\

Page 818 of 1139

Compressor Replacement

1. lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioning

work for a few minutes, then shut the engine off.

2. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio's

preset buttons.

3. Disconnect the negative cable from the battery.

4. Recover the refrigerant with a recovery/recycling/

charging station (see page 21-53).

5. Remove the alternator (see page 4-29).

6. Remove the Ay'C condenser fan assembly (see page

10-10).

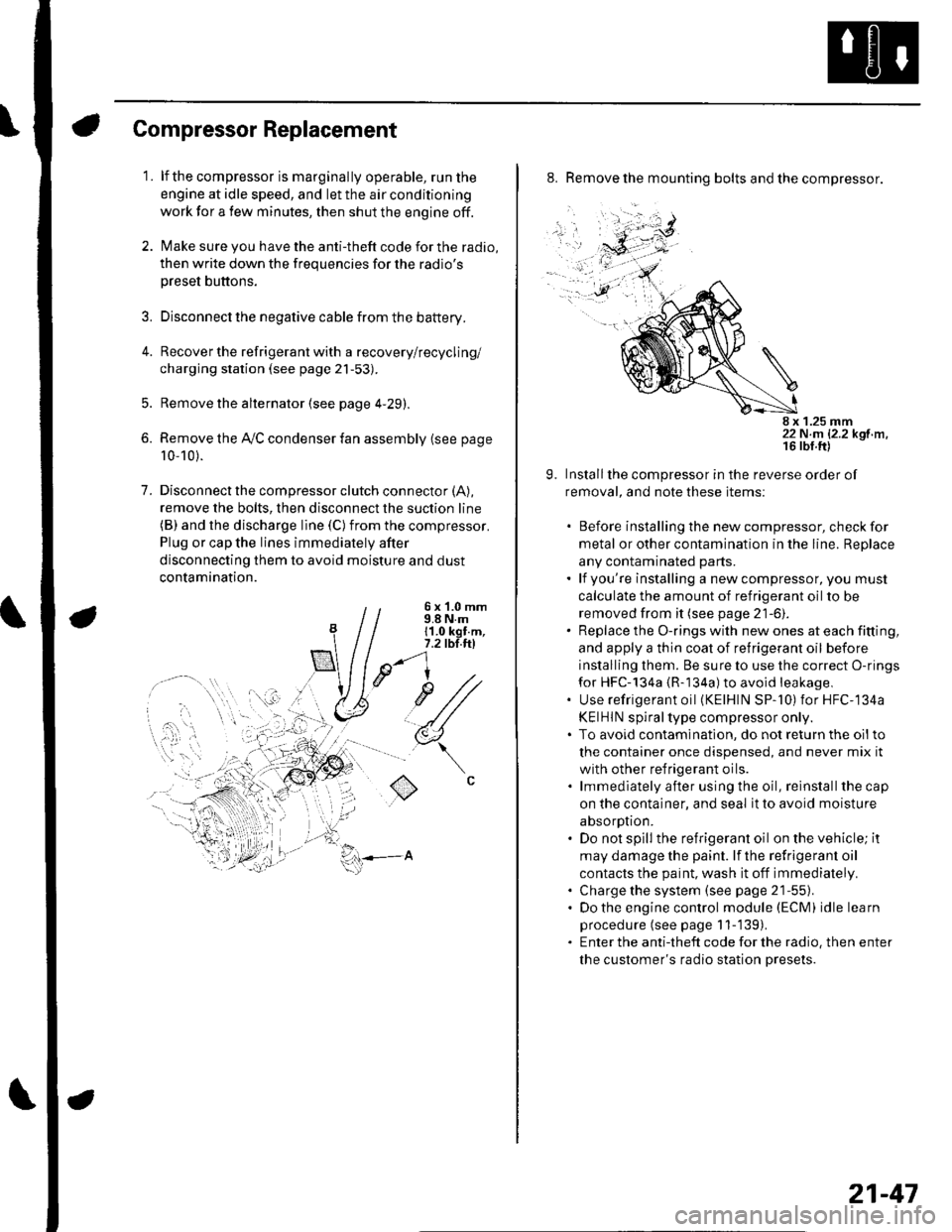

7. Disconnectthe compressor clutch connector (A),

remove the bolts, then disconnect the suction line(B) and the discharge line (C)from the compressor.

Plug or cap the lines immediately after

disconnecting them to avoid moisture and dust

contamination.

6 x '1.0 mm9.8 N.m11.0 kgt.m,7.2 tbl.ttl

u1/

(

o

8. Remove the mounting bolts and the compressor.

8 x 1.25 mm22 N.m 12.2 kgf.m.

9. Installthe compressor in the reverse order of

removal, and note these items:

. Before installing the new compressor, check for

metal or other contamination in the line. Replace

any contaminated parts.. lf you're installing a newcompressor, you must

calculate the amount of refrigerant oil to be

removed from it (see page 21-6).. Replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil before

installing them. Be sure to use the correct O-rings

for HFC-134a {R-134a) to avoid leakage,. Use refrigerant oil (KElHlN SP-'10) for HFC-134a

KEIHIN spiral type compressor only.. To avoid contaminatlon, do not return the oilto

the container once dispensed, and never mix it

with other refrigerant oils.. lmmediately after using the oil, reinstallthe cap

on the container, and seal it to avoid moisture

absorption.. Do not spill the refrigerant oil on the vehicle; it

may damage the paint. lf the refrlgerant oil

contacts the paint, wash it off immediately.. Charge the system (see page 21-55).. Do the engine control module (ECM) idle learn

procedure (see page 11-'139).. Enter the antitheft code for the radio, then enter

the customer's radio station presets.

21-47

Page 829 of 1139

Heating and Air Conditioning

A/C System Tests (cont'd)

1.

Performance Test

Air conditioning refrigerant or lubricant vapor

can irritate your eyes, nose, or throar.

Be carefulwhen connecting service equipment.

Do not breathe refrigerant or vapor.

The performance test will help determine if the air

conditioner system is operating within specifications.

Use only service equipment that is U.L.-listed and is

cenified to meet the requirements of SAE J2210 toremove HFC-134a (R-134alfrom the air conditioning

system.

lf accidental system discharge occurs, ventilate the

work area before resuming service

R-134a service equipment or vehicle air conditioning

systems should not be pressure tested or leak testedwith compressed air.

Additional health and safety information may be

obtained from the refrigerant and lubricant

manufacturers.

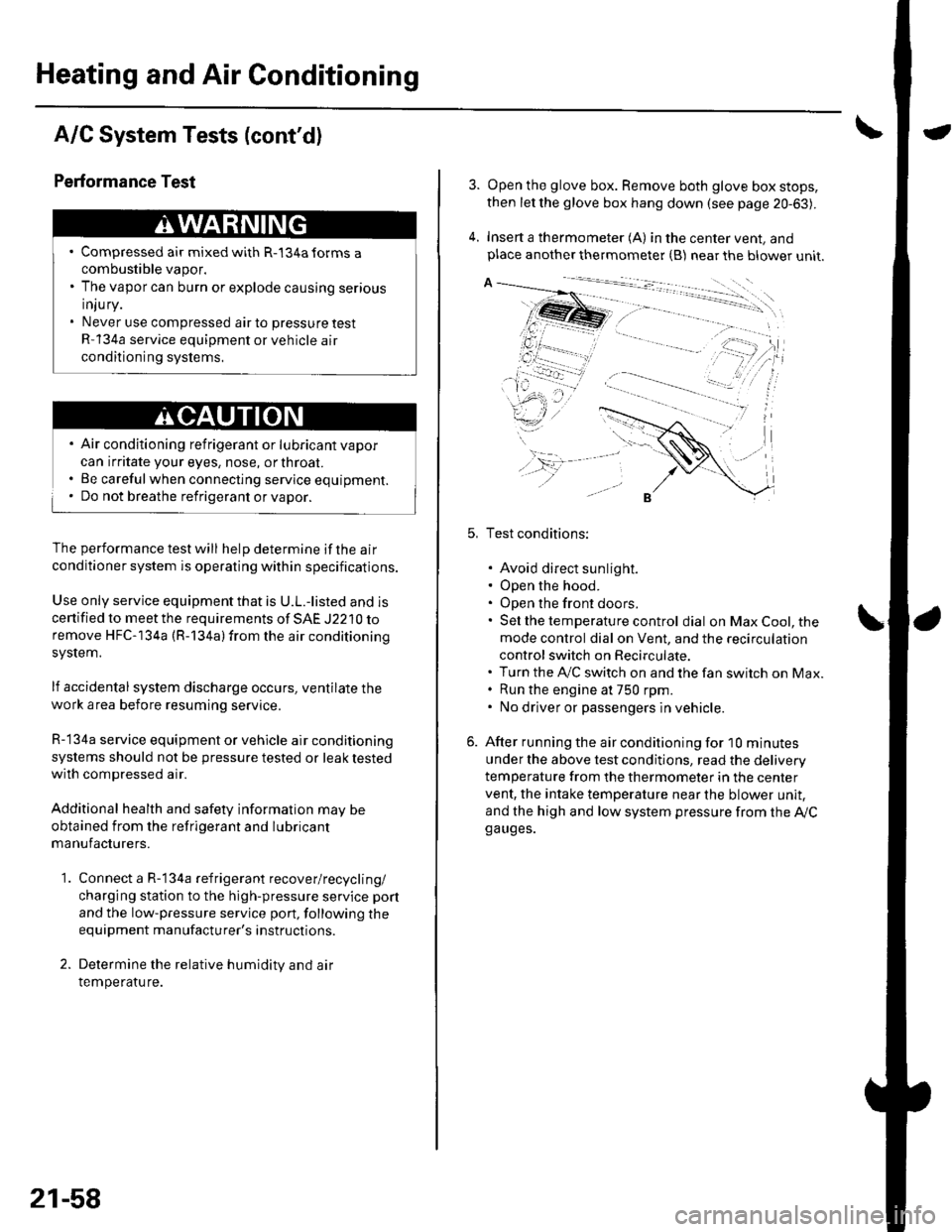

Connect a R-134a refrigerant recover/recycling/

charging station to the high-pressure service port

and the low-pressure service port, following the

equipment manufacturer's instructions.

Determine the relative humidity and air

Iemperaru re.

' Compressed air mixed with R-134a forms a

combustible vapor.. The vapor can burn or explode causing serious

Injury.. Never use compressed air to pressure test

R-134a service equipment or vehicle air

conditioning systems.

21-58

4.

Open the glove box. Remove both glove box stops,

then let the glove box hang down (see page 20-63).

Insert a thermometer (A) in the center vent, andplace another thermometer {B) near the blower unit.

Test conditions:

. Avoid direct sunlight.. Open the hood.. Open the front doors.. Sel the temperature control dial on Max Cool, the

mode control dial on Vent, and the recirculation

control switch on Recirculate.. Turn the A,/C switch on and the fan switch on Max.. Run the engine at 750 rpm.. No driver or passengers in vehicle.

After running the air conditioning for I0 minutes

under the above test conditjons, read the delivery

temperature from the thermometer in the center

vent, the intake temperature near the blower unit,

and the high and low system pressure from the Ay'Cga uges.

Page 831 of 1139

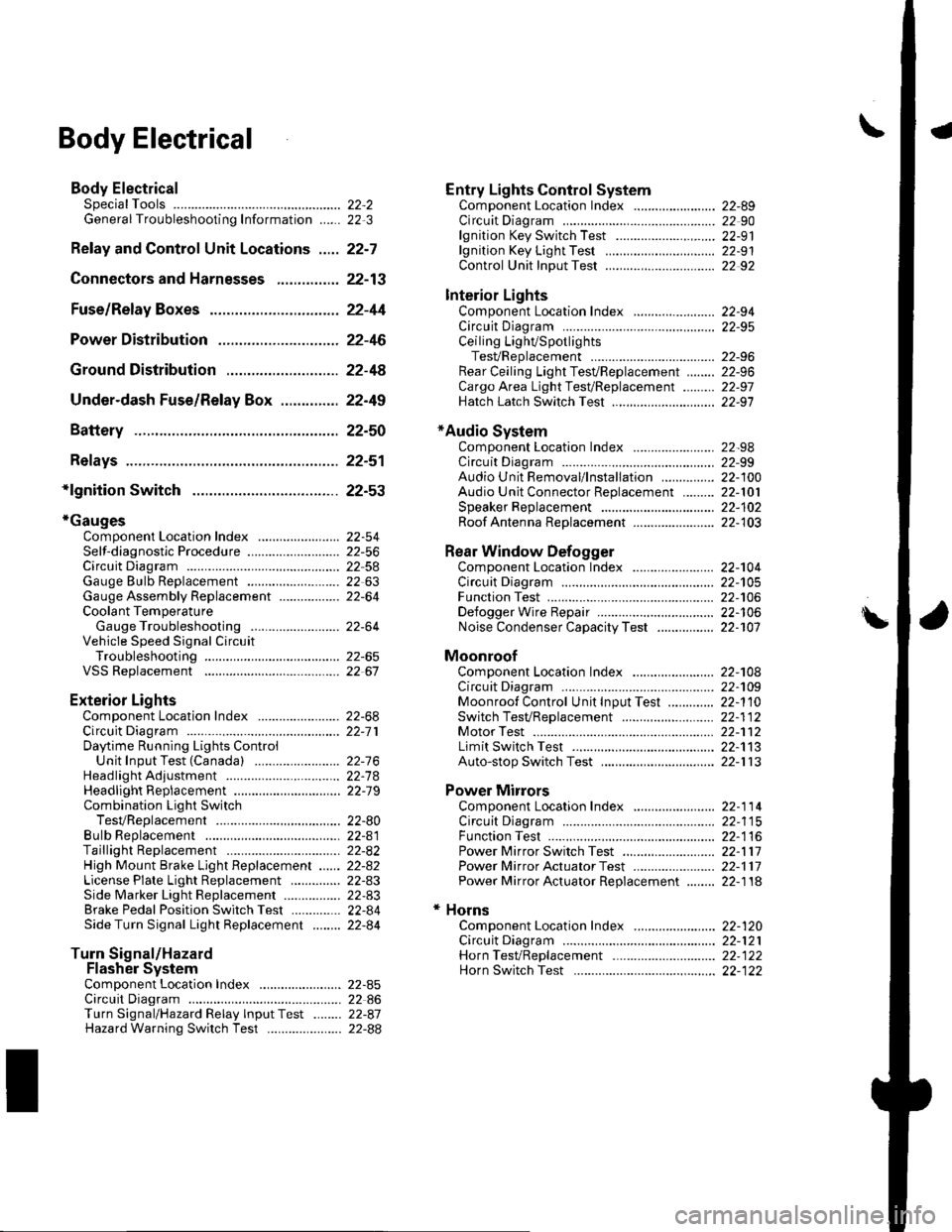

\Body Electrical

Body ElectricalSpecialToolsGeneral Troubleshooting tntorrnaiion.'......

Relay and Control Unit Locations .....

Connectors and Harnesses

Fuse/Relay Boxes ...............................

Power Distribution .............................

Ground Distribution ...........................

Under-dash Fuse/Relay Box ..............

Battery ..............

Relays ................

*lgnition Switch ..............

*Gauges

Component Location Index .......................Self-diagnostic Procedure ..........................Circuit DiagramGauge Bulb Replacement ..........................Gauge Assembly ReplacementCoolant Temperature

Gauge Troubleshooting .... ....................Vehicle Speed Signal CircuitTroubleshootingVSS Replacement

Exterior LightsComponent Location Index .......................Circuit DiagramDaytime Running Lights ControiUnit Input Test (Canada) ........................Headlight Ad,ustment .................. .. .....Headlighr Replacement ..............................Combination Light SwitchTest/ReplacementBulb ReplacementTaillight Replacement ..........................High Mount Brake Light Replacement ......License Plate Light Replacement ..............Side Marker Light Replacement ................Brake Pedal Position Switch Test ..............Side Turn Signal Light Replacement ........

Turn Signal/HazardFlasher SystemComponent Location Index .......................Circuit DiagramTurn Signal/Hazard Relay lnputTest ........Hazard Warning Switch Test

22,3

22-7

22-13

22-44

22-46

22-4A

22-49

22-50

22-51

22-53

22-5422-5622-5422 6322-64

22-64

22-6522 61

22-6822--71

22-7 622-7422-79

22-AO22-4122-8222-4222-4322-4322-4422-84

22-8�522 A622-8722-88

22-10422-105

22-10622-107

Entry Lights control systemComponent Location Index ....................... 22-89Circuit Diagram ......... 22 90lgnition Key Switch Test .....................,...... 22-9'llgnition Key Light Test ............................... 22-91Control Unit Input Test ..........,.................... 22 92

Interior LightsComponent Location Index ....................... 22-94Circuit Diagram ......... 22-95Ceiling LighVSpotlightsTesVReplacement ................................... 22-96Rear Ceiling Light TesVReplacem ent ........ 22-96Cargo Area Light Test/Replacem ent ......... 22-97Hatch Latch Switch Test ..,..,....................... 22-97

*Audio SystemComponent Location Index ....................... 22-98Circuit Diagram ......... 22,99Audio Unit Removal/lnstallation ............... 22-1OOAudio Unit Connector Replacement ......... 22-101Speaker Replacement ................................ 22-102Roof Antenna Rep1acement ....................-.. 22-103

Rear Window DefoggerComponent Location Index ...........Circuit Diasram .. ....... .. ..... ....... ...:::::.::.::.Function TestDefogger Wire Repair .................................Noise Condenser CapacityTest ................

MoonroofComponent Location Index ....................... 22-1OBCircuit Diagram ......... 22-109Moonroof Control Unit Input Test ............. 22-'l10Switch TesVReplacement ........,.....,........... 22-1 12Motor Test ................. 22-112Limit Swilch Test ...... 22-'l'13Auto-stop Switch Test ................................ 22-1 13

Power MirrorsComponent Location Index ....................... 22-114Circuit Diagram ......... 22-115Function Test ............. 22-116Power Mirror Switch Test .......................... 22-ll7Power Mirror Actuator Test ....................... 22-117Power Mirror Actuator Replacement ........ 22-11A

* HornsComponent Location Index ....................... 22-120Circuit Diagram ......... 22-121Horn TesVReplacement ...........................-. 22-122Horn Switch Test .,.... 22-122

\

Page 832 of 1139

Power WindowsComponent Location Index ..........

circuit Diagram . .. ............... .........:.::::.::::.:Master Switch Input Test ...........................Master Switch TestDriver's Window Motor Test .....................

Passenger's Window Switch lnput Test ...Passenger's Window Switch Test .............

Passenger's Window Motor Test ..............

lMaster Switch Replacement ......................

Passenger's Window SwitchReplacement

Wipers/WashersComponent Location Index .......................

Circuit DiagramRear Window Wiper Intermiftent

Control Unit Input Test ...........................Wiper/Washer SwitchTesVReplacementControl Unit Input Test ...............................Wiper Motor Test

Washer Motor TestWasher Fluid Level Switch TesV

Replacement (Canadal ..........................

Windshield Wiper Motor Replacement ....

Rear Window Wiper MotorReplacementWasher Reservoir Replacement ................

Washer Tubes Beplacement ......................

Accessory Power SocketCircuit Diagram ......... 22-149

Accessory Power Socket

TesVReplacement ................................... 22-1 49

Keyless/Power Door Lock System

Component Location Index ....................... 22-150

Circuit Diagram ......... 22-151Keyless Receiver Unit InputTest ............... 22-153

Control Unit Input Test ............................... 22-155

Door LockActuatorTest .........,.......,..,.,..... 22-158Hatch LockActuatorTest ........................... 22-159

Door Lock Knob Switch Test ...................... 22-160

Door Lock Switch Test ................................ 22-160

Transmitter Test ....... 22-161

Transmitter Programming ......................... 22-161

Multiplex Control SystemComponent Location Index ...........

circuit Diagram ...... ........................::.:..:.::.:

Svstem DescriDtionTroubleshootingMultiolex Control Unit InDut Test .............

22 12422-12522-12622-12822-129

22- t30

22-13222 13222-133

22-133

22-134

22-138

22-14022-14122-14322-144

22-14422-145

22-14622-14622 147

22,16422-16922-17'l22,11222-175

lmmobilizer Systemcomponent Location Index ...........

System Description ....... ............. ..:..:..:.:...

Circuit DiagramTroubleshootinglmmobilizer Control Unit-Receiver Replacement ...........................

22-16222-16322-164

22-167

Page 838 of 1139

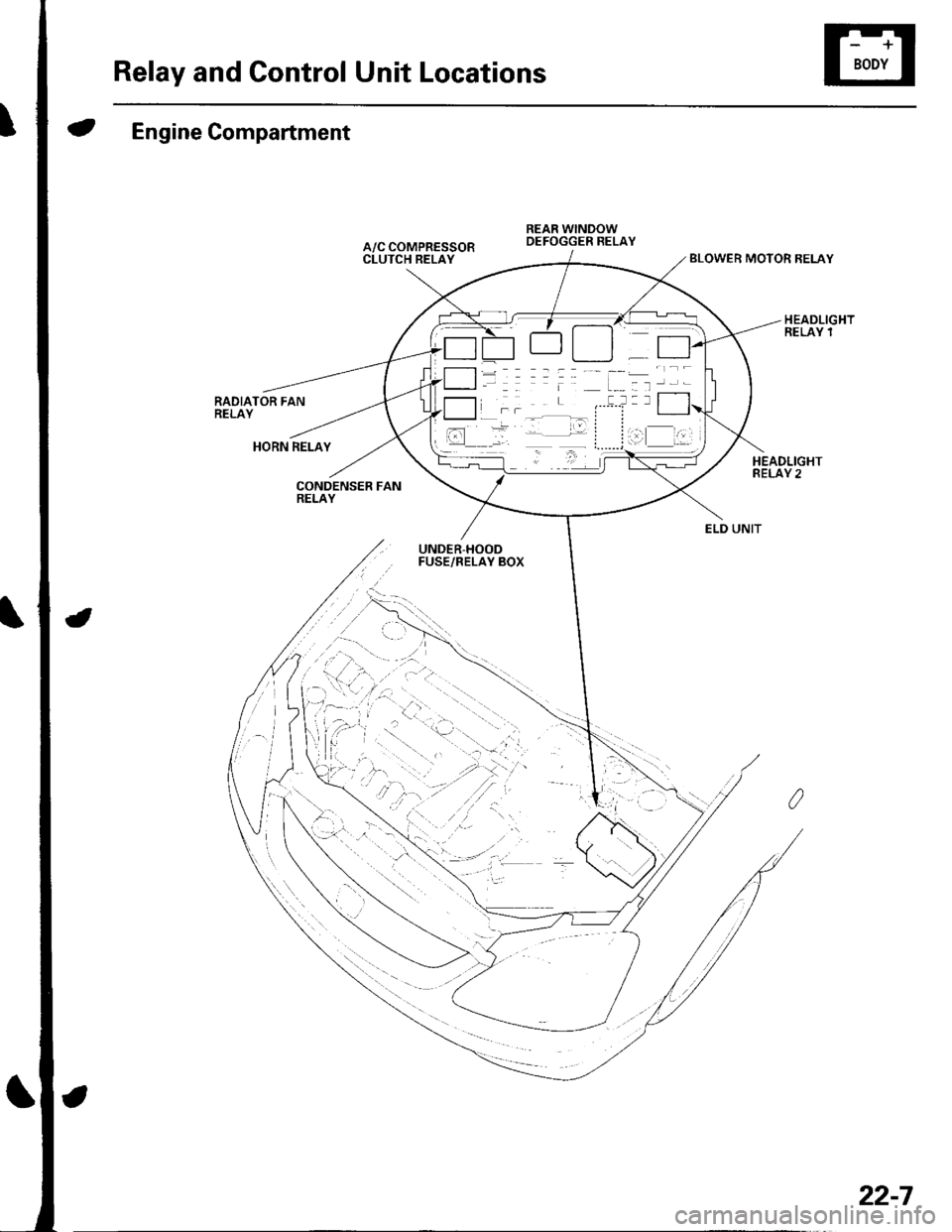

Relay and Control Unit Locations

Engine Compartment

RADIATOR FANRELAY

BLOWER MOTOR RELAY

HORN RELAY

CONDENSER FANRELAY

UNDER-HOODFUSE/RELAY BOX

\...

,-:1-'...

ELD UNIT

22-7

Page 839 of 1139

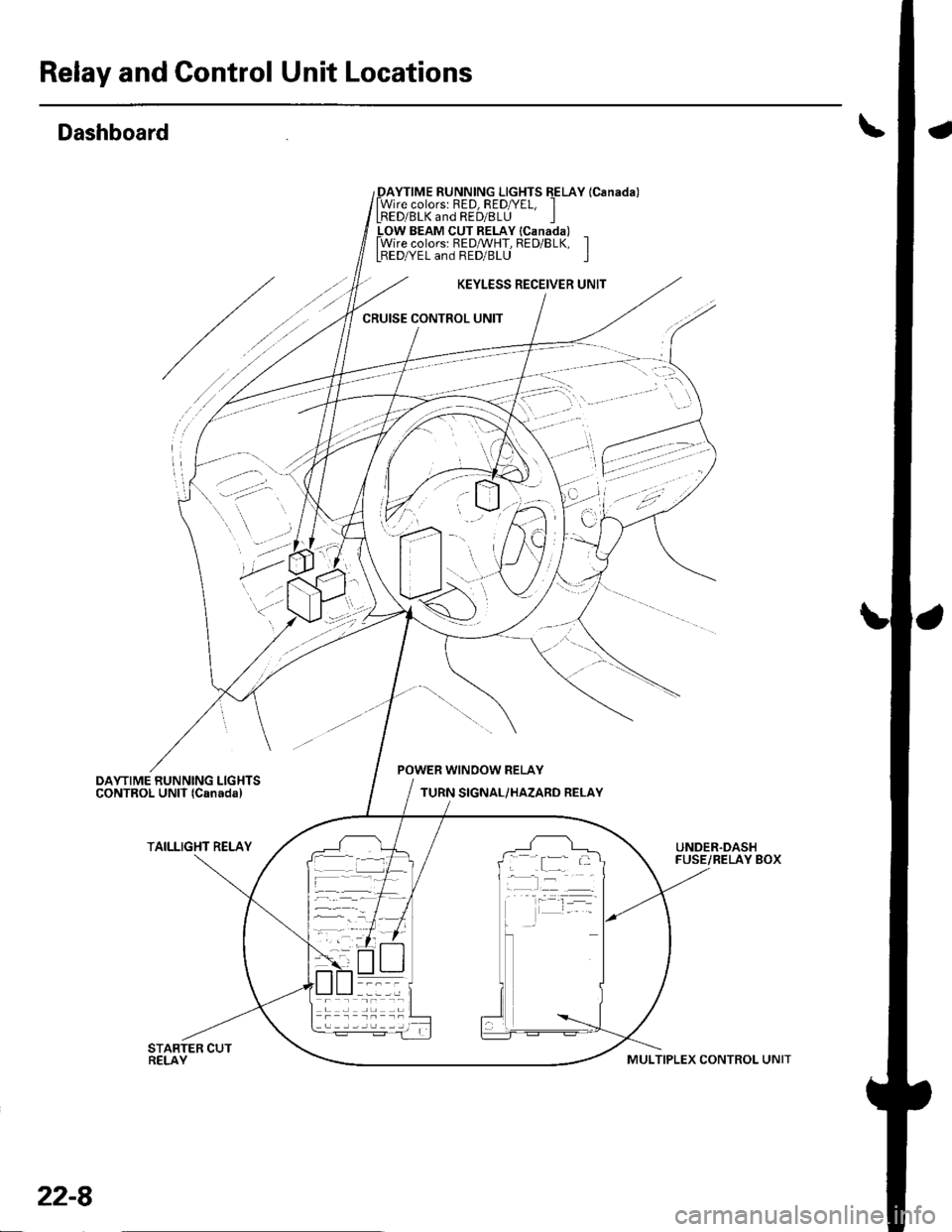

Relay and Gontrol Unit Locations

Dashboard

_DAYTIME RUNNING LIGHTS EELAY lCanada)lWire colorsr RED, RED/YEL, ILRED/BLK and RED/8LU I_LOW BEAM CUT RELAY lcanada) _lWire colors: REDMHT, RED/BLK, ILBEDA/EL and RED/BLU I

KEYLESS RECEIVER UNIT

CRUISE CONTROL UNIT

'

'-.:- ':

..? ;,

POWER WINOOW RELAY

TURN SIGNAL/HAZARD RELAY

TAILLIGHT RELAYUNDER.DASHFUSE/RELAY BOX; .[:_- -

-l:r --

22-8

MULTIPLEX CONTROL UNIT

Page 841 of 1139

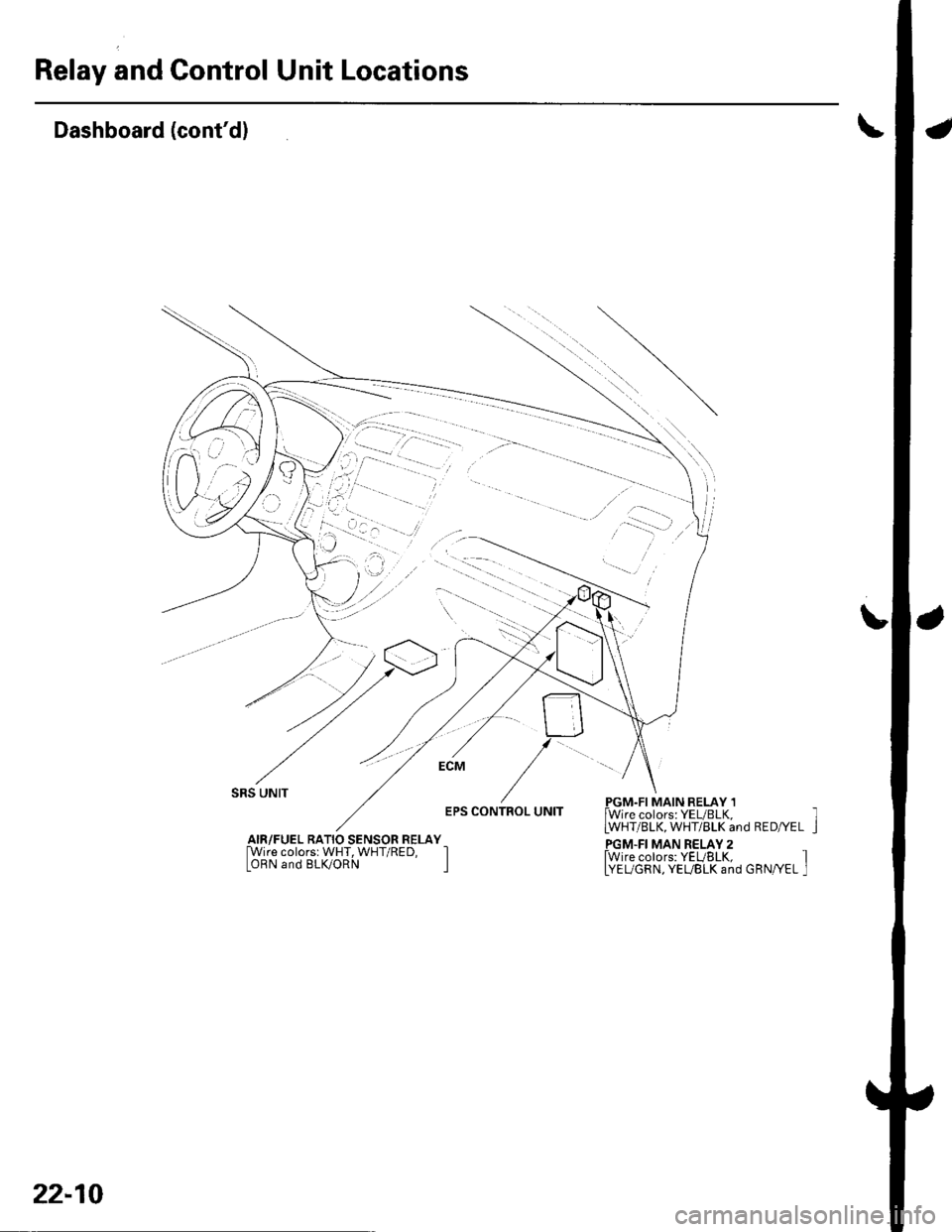

Relay and Control Unit Locations

a

\

Dashboard (cont'd)

L

SRS UNIT

EPS CONTROL UNITPGM.FI MAIN RELAY 1lWire colors: YEUBLK,LWHT/BLK, WHT/BLK and RED/YEL

PGM.FI MAN RELAY 2fwire colors: YEUBLK, ILYEUGRN, YEUBLK and GRN/YEL I

AIR/FUEL RATIO SENSOR RELAY[Wire colorsr WHT, WHT/RED, IOBN and BLK/ORN I

22-10

Page 843 of 1139

![HONDA CIVIC 2003 7.G Workshop Manual Relay and Control Unit Locations

Door and Seat

Drivers Door:

Passengers Seat:

l\:

].\

POWER WINDOW MASTER SWITCHlHas built-in control unit)

22-12 HONDA CIVIC 2003 7.G Workshop Manual Relay and Control Unit Locations

Door and Seat

Drivers Door:

Passengers Seat:

l\:

].\

POWER WINDOW MASTER SWITCHlHas built-in control unit)

22-12](/img/13/5744/w960_5744-842.png)

Relay and Control Unit Locations

Door and Seat

Driver's Door:

Passenger's Seat:

l\:

].\

POWER WINDOW MASTER SWITCHlHas built-in control unit)

22-12