HONDA CIVIC 2003 7.G Workshop Manual

Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 211 of 1139

Fuel and Emissions Systems

General Troubleshooting Information (cont'dl

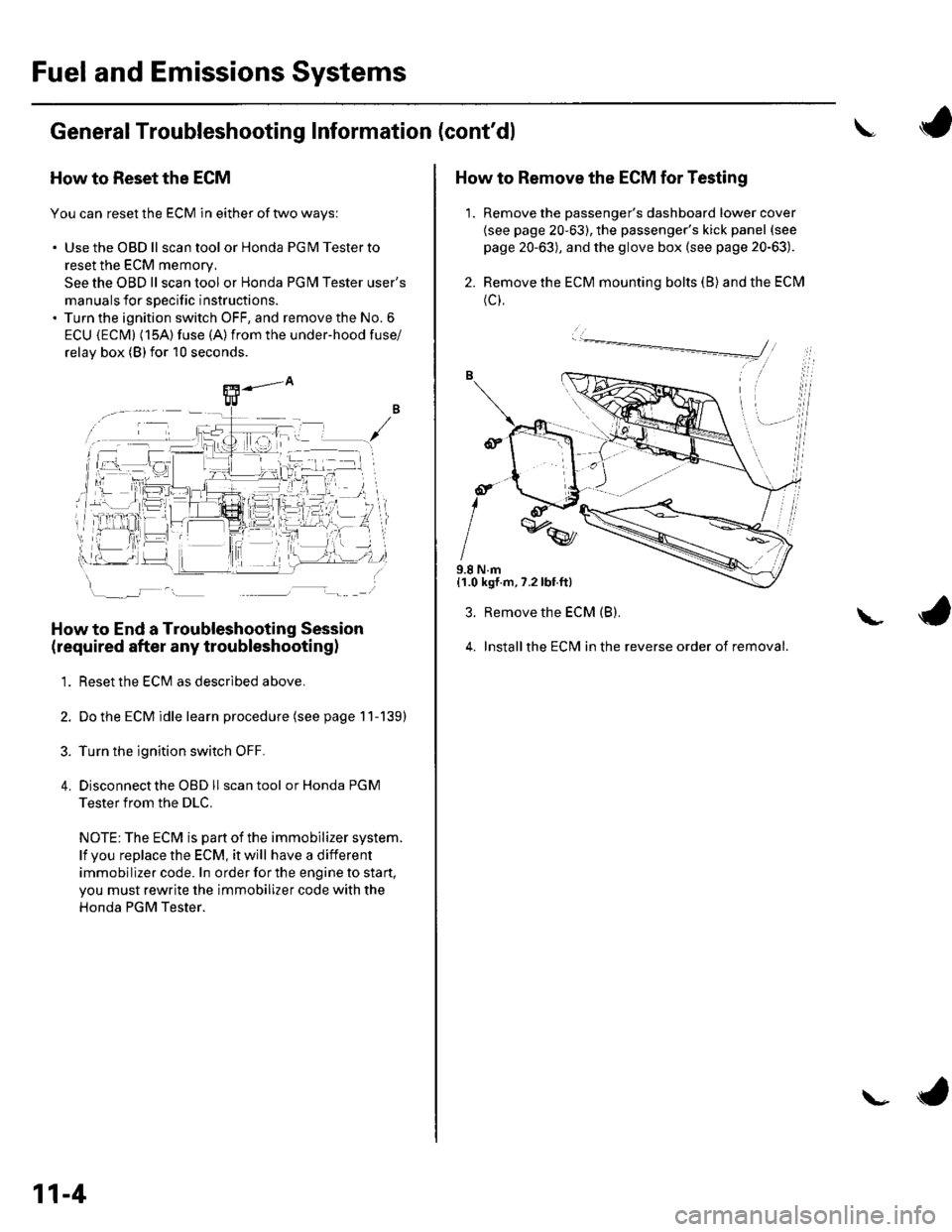

How to Reset the ECM

You can reset the ECM in either of two ways:

. Use the OBD ll scantool or Honda PGMTesterto

reset the ECM memory.

See the OBD ll scan tool or Honda PGI\4 Tester user's

manuals for specific instructions.' Turn the ignition switch OFF, and remove the No. 6

ECU {ECM} (15A) fuse (A)from the under-hood fuse/

relav box (Blfor 10 seconds.

How to End a Troubleshooting Session

(required after any troubleshootingl

1. Reset the ECM as described above.

2. Do the ECM idle learn procedure (see page 11-139)

3. Turn the ignition switch OFF.

4. Disconnectthe OBD ll scan tool or Honda PGM

Tester from the DLC.

NOTE: The ECM is part of the immobilizer system.

lf vou replace the ECM, it will have a different

immobilizer code. In order for the engine to start,

you must rewrite the immobilizer code with the

Honda PGM Tester.

11-4

\- ta

J

How to Remove the ECM for Testing

1. Remove the passenger's dashboard lower cover

{see page 20-63), the passenger's kick panel (see

page 20-63), and the glove box (see page 20-63).

2. Remove the ECM mounting bolts (B) and the ECM

(c),

9.8 N.m{1.0 kgf.m,7.2lbt.ft}

3. Remove the ECM (B).

4. Installthe ECM in the reverse order of removal.

L

Page 212 of 1139

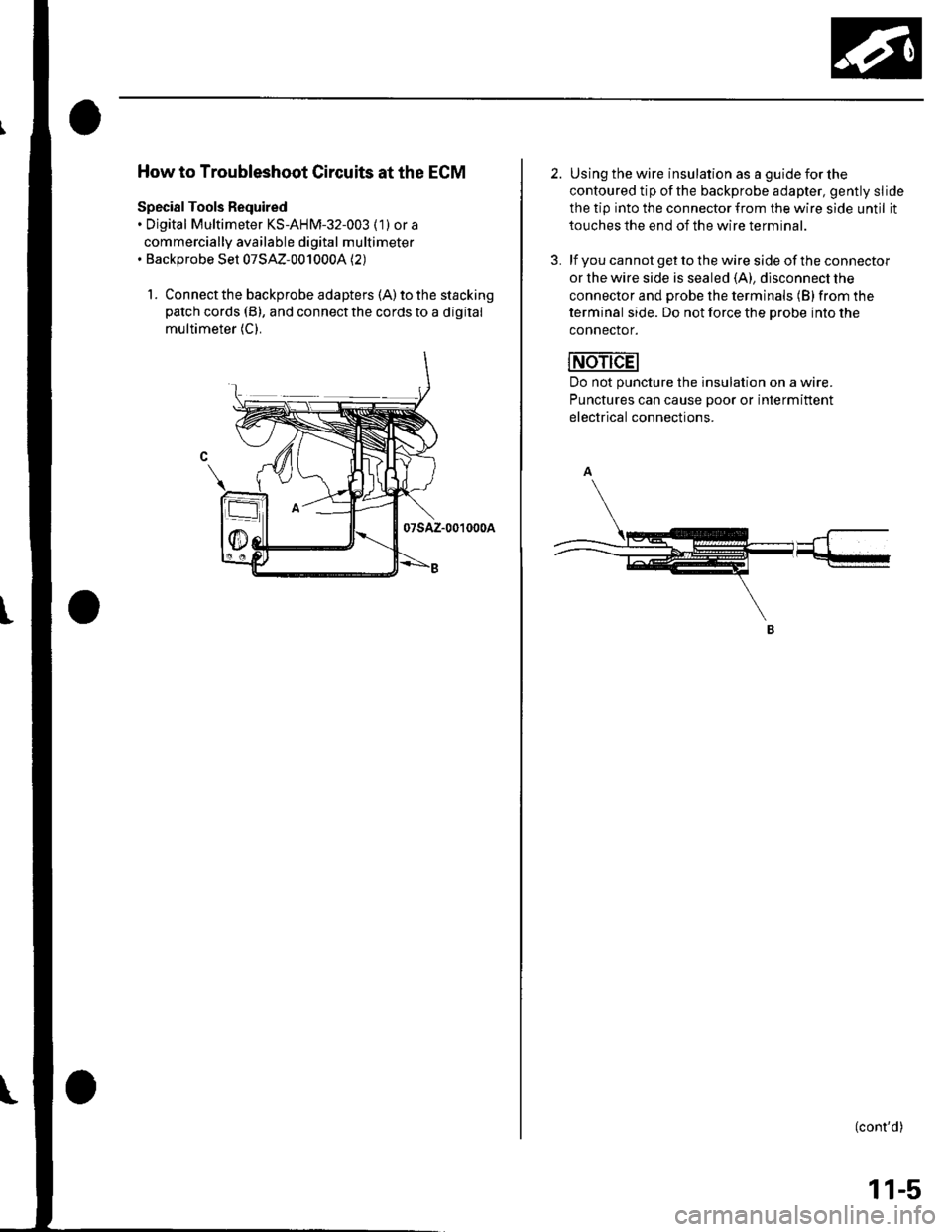

How to Troubleshoot Circuits at the ECM

Special Tools Required. Digital Multimeter KS-AHM-32-003 (1) or a

commercially available digital multimeter. Backprobe Set 07SAZ-0010004 (2)

1. Connect the backprobe adapters (A) to the stacking

patch cords (B), and connect the cords to a digital

multimeter (C).

07sAz-001000A

2. Using the wire insulation as a guide for the

contoured tip ofthe backprobe adapter, gently slide

the tip into the connector from the wire side until it

touches the end of the wire terminal.

3. lf you cannot get to the wire side of the connector

or the wire side is sealed (A), disconnect the

connector and probe the terminals (B) from the

terminal side. Do not force the Drobe into the

connector.

Do not puncture the insulation on a wire.

Punctures can cause Door or intermittent

electrical connections.

(cont'd)

11-5

Page 213 of 1139

Fuel and Emissions Systems

General Troubleshooting Information (cont'd)

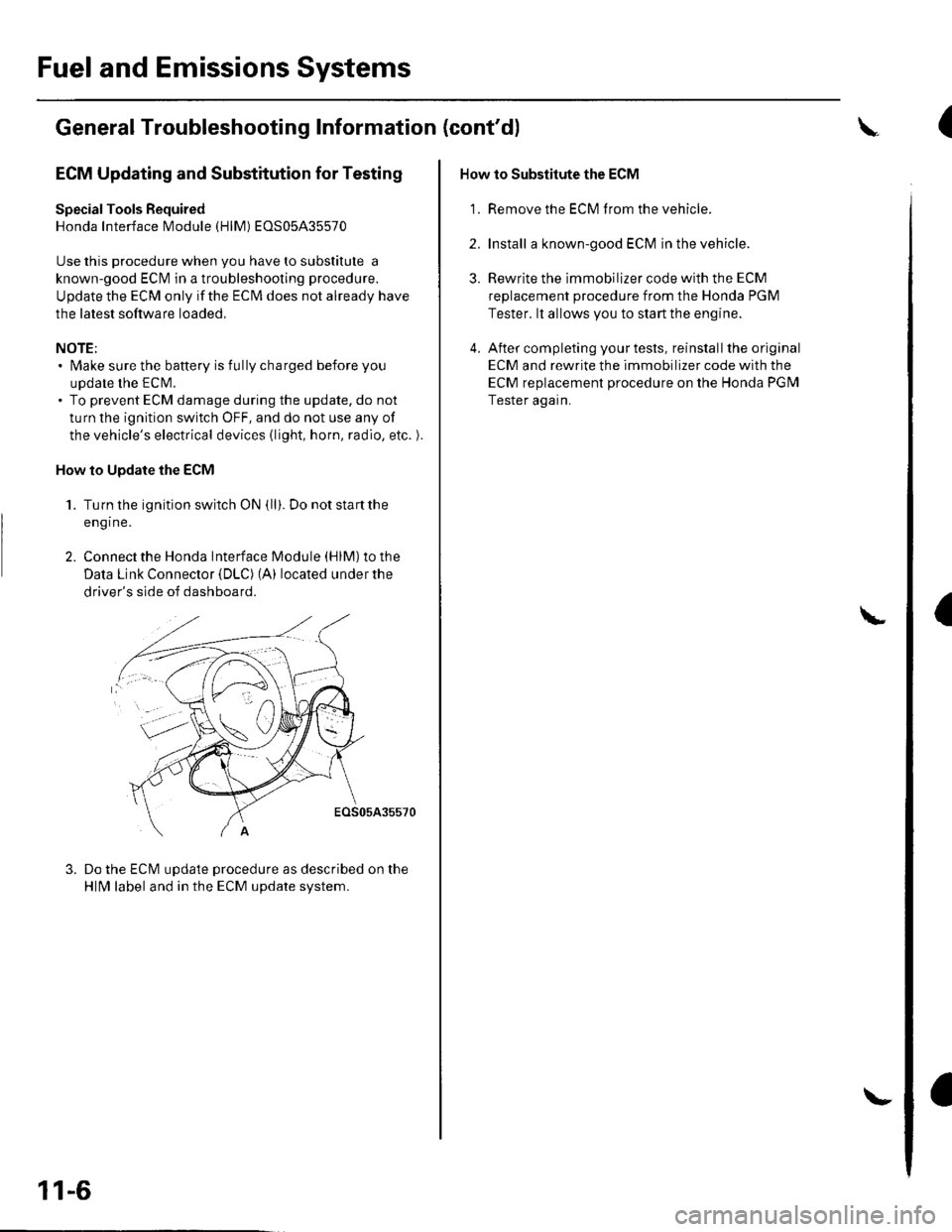

ECM Updating and Substitution for Testing

Special Tools Bequired

Honda Interface Module (HlM) EOS05435570

Use this procedure when you have to substitute a

known-good ECM in a troubleshooting procedure.

U pdate the ECM only if the ECN4 does not already have

the latest software loaded,

NOTE;. lMake sure the battery is fully charged before you

update the ECN4.. To prevent ECM damage during the update, do not

turn the ignition switch OFF, and do not use any of

the vehicle's electrical devices (light, horn, radio, etc. ).

How to Update the ECM

1. Turn the ignition switch ON (ll). Do not startthe

eng Ine.

2. Connect the Honda lnterface Module (HlM) to the

Data Link Connector {DLC) (A) located under the

driver's side of dashboard.

EOS05A35570

Do the ECM update procedure as described on the

HlN4 label and in the ECM update system.

11-6

\-

How to Substitute the ECM

'1. Remove the ECM f rom the vehicle.

2. Install a known-good ECM in the vehicle.

3. Rewrite the immobilizer code with the ECM

replacement procedure from the Honda PGM

Tester. lt allows you to start the engine.

4. After completing your tests, reinstall the original

ECM and rewrite the immobilizer code with the

ECM replacement procedure on the Honda PGM

Tester again.

L

(

I

Page 214 of 1139

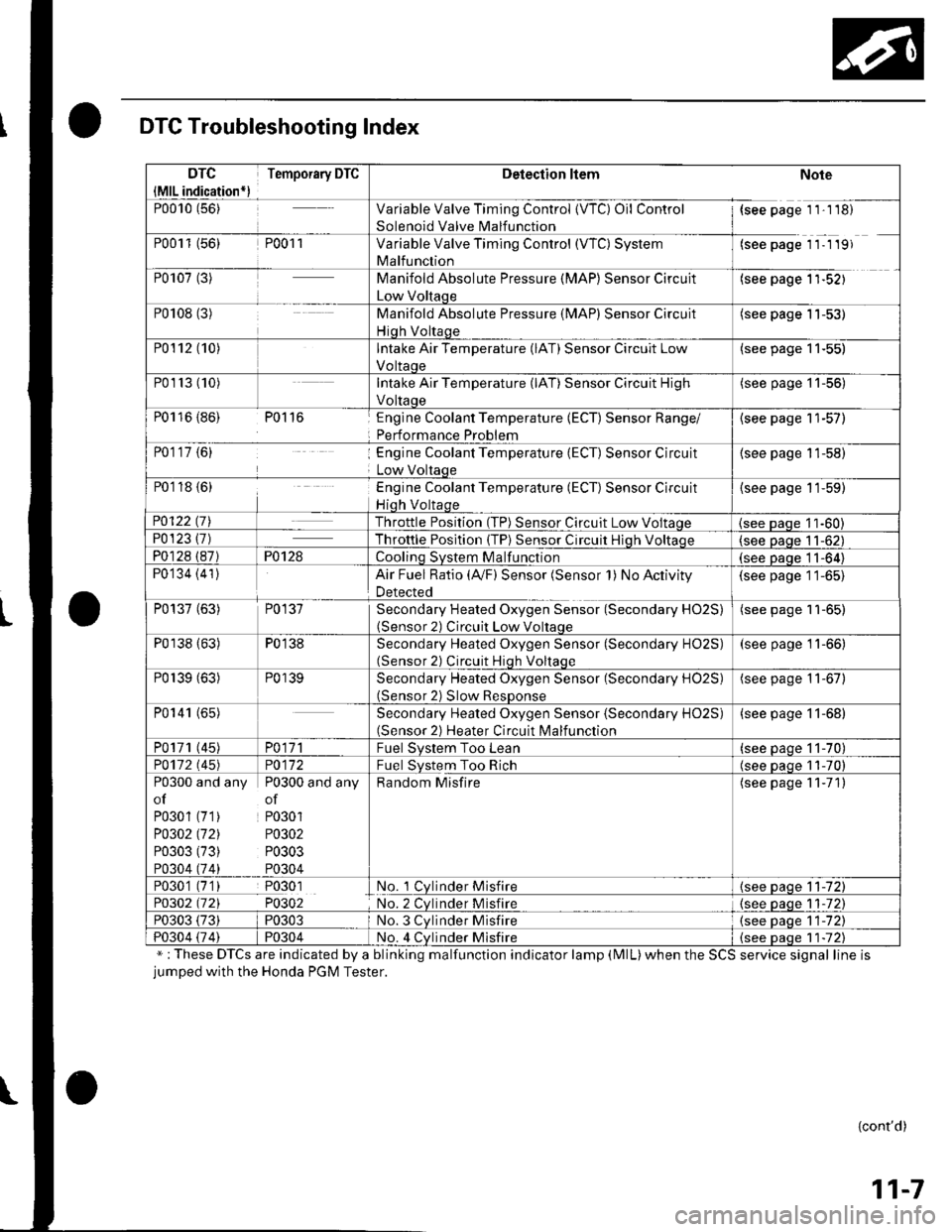

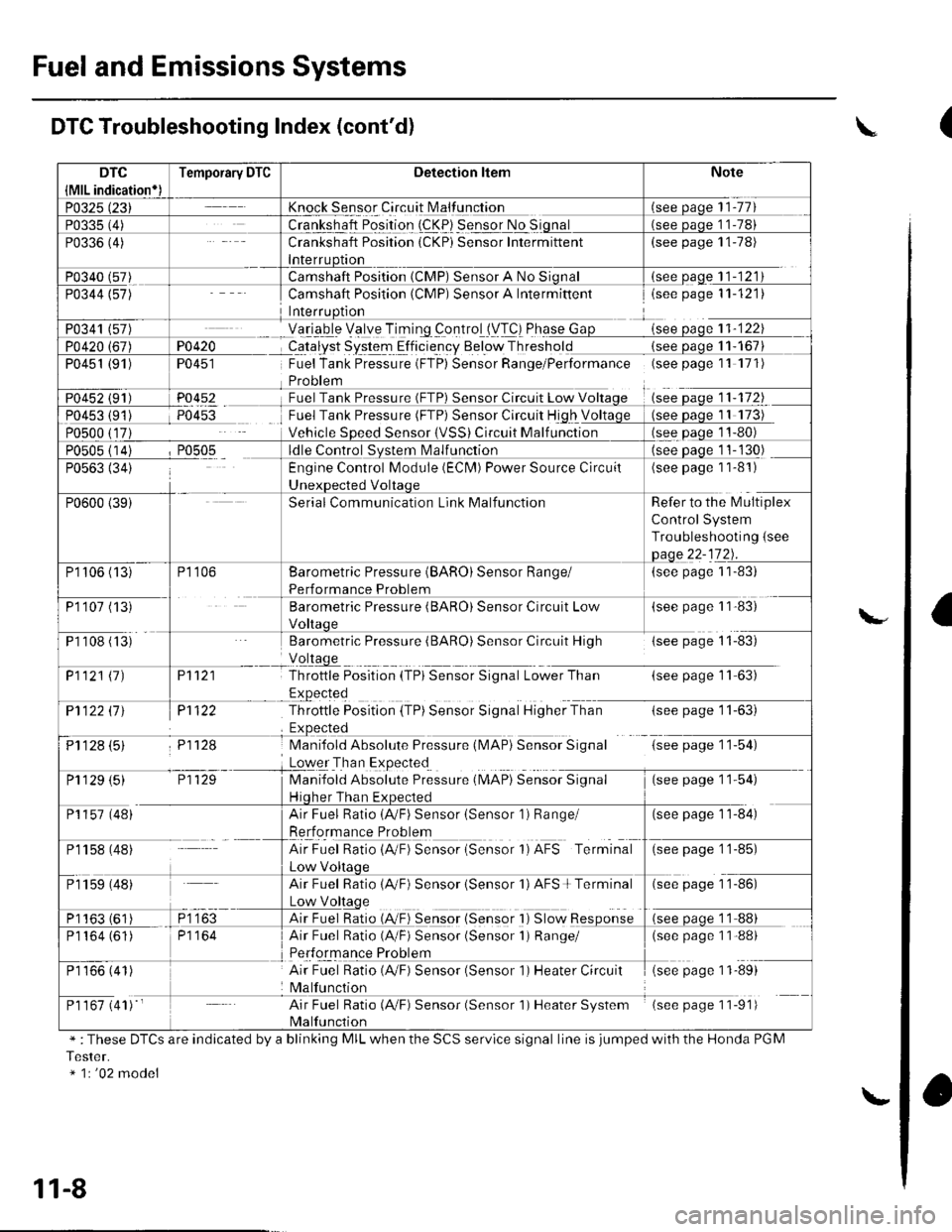

DTC Troubleshooting Index

";These DTCs are indicated by a blinking malfunction indicator lamp (MlL)when the SCS service signal line isjumped with the Honda PGM Tester.

{cont'd)

11-7

DTC

{MlL indication*)

Temporary DTCDetection ltemNote

P0010 (56)Variable Valve Timing Control {VTC) Oil Control

Solenoid Valve Malfunction

{see page 1 1'1 18)

P0011 (56)P001 1Variable Valve Timing Control (WC) System

Malfunction

(see page 11- 1 19)

P0107 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Low Voltaqe

(see page 1'l-521

P0108 (3)Manifold Absolute Pressure (MAP) Sensor Circuit

Hiqh Voltaqe

(see page 11-53)

P0112 (10)Intake Air Temperature (lAT) Sensor Circuit Low

Voltaoe

(see page 11-55)

P01r3 (10)Intake Air Temperature (lAT) Sensor Circuit High

Voltaoe

(see page '11-56)

P0116 {86) P0116Englne Coolant Temperature (ECT) Sensor Range/

Performance Problem

{see page 11-57)

P0117 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Low Voltaqe

(see page 11-58)

P0118 {6)Engine Coolant Temperature (ECT) Sensor Circuit

Hiqh Voltaqe

{see page 11-59)

P0122 t7\Throttle Position (TP) Sensor Circuit Low Voltaqe(see Daqe 11-60)P0123 {7)Throttle Posltion (TP) Sensor Circuit Hiqh Voltaoe(see paqe 11-62)

P0128 (87)P0128Coolinq SVStem Malfunction(see Daqe 11-64)

P0134 (41)Air Fuel Ratio (Ay'F) Sensor (Sensor 1) No Activity

Detected

(see page 11-65)

P0137 (63)P0137Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Low Voltaqe

(see page 11-65)

P0138 (63)P0138Secondary Heated Oxygen Sensor (Secondary HO2S)(Sensor 2) Circuit Hiqh Voltaqe

(see page 11-66)

P0139 (63)P0139Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Slow ResDonse

(see page 11-67)

P0141 (65)Secondary Heated Oxygen Sensor (Secondary H02S)(Sensor 2) Heater Circuit Malfunction

(see page 11-68)

P0171 (45)PO\11Fuel Svstem Too Lean(see paqe 11-70)

PO112 l'45)PO\l2Fuel System Too Rich(see oaoe 11-70)

P0300 and any P0300 and any

of of

P0301 (71) P0301

PO302 (721 P0302

P0303 (73) P0303

P0304 (74) P0304

Random Misfire(see page 11-71)

P0301 (7'1) P0301No. 1 Cylnder Misfire{see page 11-72)

P0302 (721 P0302No. 2 Cvlnder Misfire{see paqe 1 1-72)

P0303 (73)P0303No. 3 Cvlnder Misfire(see oaqe 11-72)

P0304 {74)P0304No. 4 Cvlnder Misfire{see Daqe 1 1-72)

Page 215 of 1139

Fuel and Emissions Systems

Knock Sensor Circuit N4alfunction

Crankshaft Position (CKP) Sensor Intermittent(see page 11-78)

(see oaqe 11-121

PO4i{�

TU45I

P0452

Camshaft Position (CMP) Sensor A Intermiftentisee page 11-121)

Yetrgb-le Velye TiTing _controlll/T!) Phqse Gsee oaoe 11-122

CqJalyst System Elficie-ncy Below Thresholdsee oaqe 1 1- 167

Fuel Tank Pressure (FTP) Sensor Range/Performance (seepagell 171)

Sensor Circuit Low V11-172

Fuel Tank Pressure (FTP) Sensor Circuit High V

Vehicle SDeed SensorCircuit Malf unction

Camshaft Position (CMP) Sensor A No

P0451 (91)

see Daqe 11-130)

(see page 1 1-81)

Refer to the l\4ultiplex

Control System

Troubleshooting {see

(see page 1 1-83)

(see paSe 1 1'83)

Barometric Pressure (BARO) Sensor Circuit High{see page 11-83)

P't 121

Pl122

P11f,.8

Throttle Position {TPi Sensor Signal Lower Than(see page 11-63)

-tsee page I r-oJ,

G;tp"s" 1 154)

(*" paSe 1 154)

P1122 ll J

ij1128 (5)

Throttle Position (TP) Sensor Signal Higher Than

Mani{old Absolute Pressure (l\,4AP} Sensor Signal

Loqer Tha n Expected

Manifold Absolute Preisure (MAP) SeiiioiSgnul

Hiqher Than Ex(see page 11-84)

Engine Control Module (ECN4) Power Source Circuil

Serial Communication Link Malfunction

P1106 (13)

P110? (13

P1 108 (ts'

Barometric Pressure (BARO) Sensor Range/

Performance Problem

Barometric Pressure (BARO) Sensor Circuit Low

P1121 11)

P1 129 (5)

P1157 (48)

Pr 158 (48)

Air Fuel Ratio (AVF) Sensor (Sensor 1) Range/

Rerformance Problem

AirFuel Ratio{A"F) Sensor {Sensor 1)AFS Terminal(see page 1 1-85)

Air Fuel Ratio 1AVF) Sensor isensor 'l) AFS + Terminal(see page 1 1-86)

Air Fuel Ratio {A,/F) Sensor {Sensor I ) Slow Response

Air Fuel Ratio (A/F) Sensor (Sensor 1) Range/(see page 1 1-88)

Air Fuel Ratio (4,/F) Sensor (Sensor 1) Heater Circuit

Malfunction

(see page 11-89)

Air Fuel Ratio (A,/F) Sensor (Sensor 1) Heater System

Malfunction

(see page 11-91)

P1 159 (48)

P1163 (61

P1164 (61)

P1 166 (41)

P1 167 (41) '

DTC Troubleshooting Index (cont'd)

" :These DTCS are indicated by a blinking MIL when the SCS servlce signal line is jumped with the Honda PGM

Tester.* 1r '02 model

\

l\."

11-8

\.

(

a

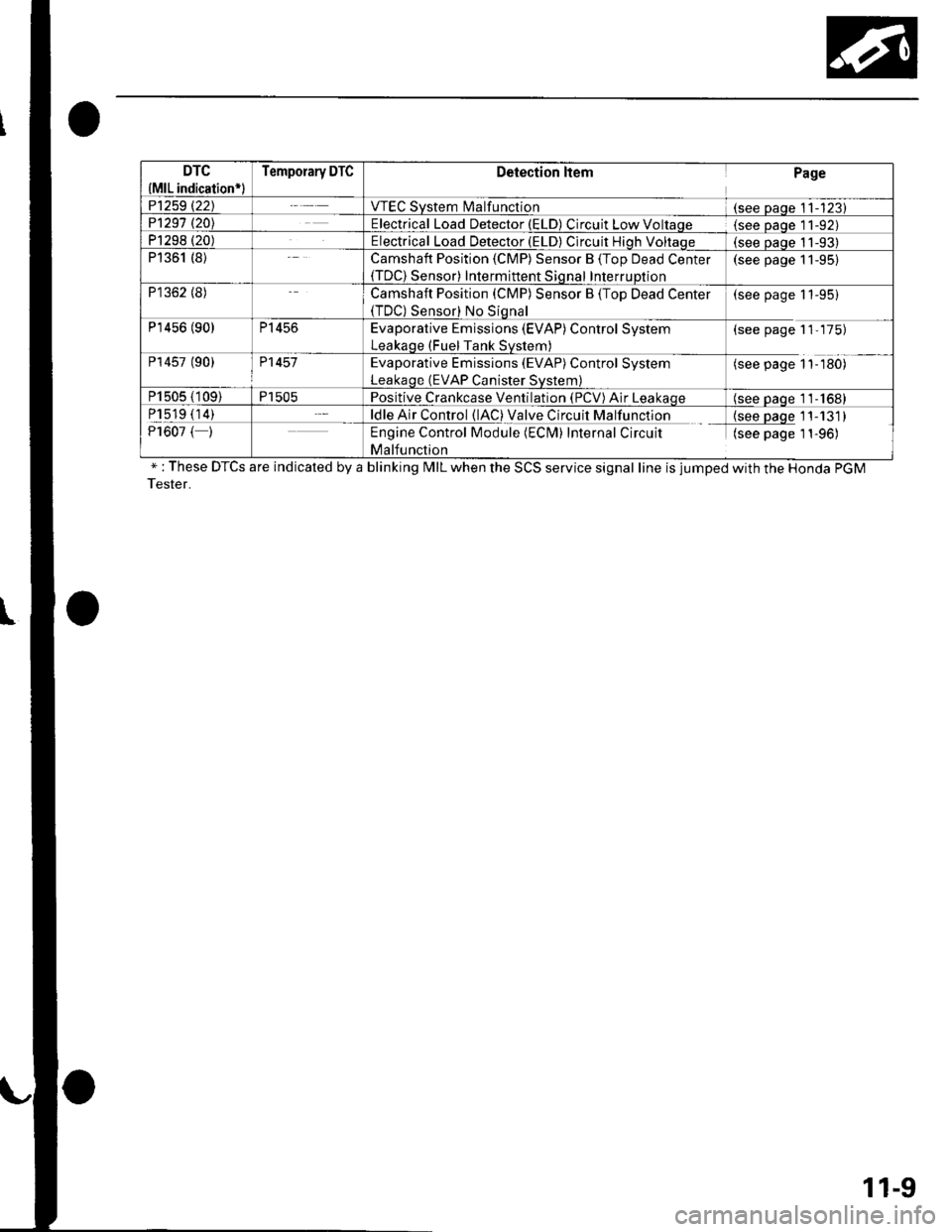

Page 216 of 1139

DTC

{MlL indication*l

Temporary DTCDetection ltemPage

P1259 t22JVTEC System l\4alfunction(see Daqe 11-123)P1291 t20\Electrical Load Detector (ELD) Circuit Low Voltaqe(see Daqe l1-92)P1298 (20)Electrical Load Detector (ELD) Circuit Hiqh Voltaqe(see oaoe 11-93)P1361 (8)Camshaft Position (CMP) Sensor B (Top Dead Center(TDC) Sensor) Intermittent Sional InterruDtion

(see page 11-95)

P1362 (8)Camshaft Position (CMP) Sensor B (Top Dead Center(TDC) Sensor) No Siqnal

(see page 11-95)

P'r456 (90)P1456Evaporative Emissions (EVAP) Control System

Leakaqe (Fuel Tank Svstem)

(see page 11-175)

P14s7 (90)P1457Evaporative Emissions (EVAP) Control System

Leakaqe (EVAP Canister Svstem)

(see page 1'l-180)

P1505 (109)P1505Positive Crankcase Ventilation (PCV) Air Leakaqe(see oaqe 11-1681

P1519 (14)ldle Air Control (lAC) Valve Circuit Malfunction{see paqe 11-131)P1607 ( )Engine Control Module (ECM) Internal Circuit

Malfunction

(see page 1 1-96)

" : These DTCS are indicated by a blinking MIL when the SCS service signal line is jumped with the Honda PGM

Tester.

11-9

Page 217 of 1139

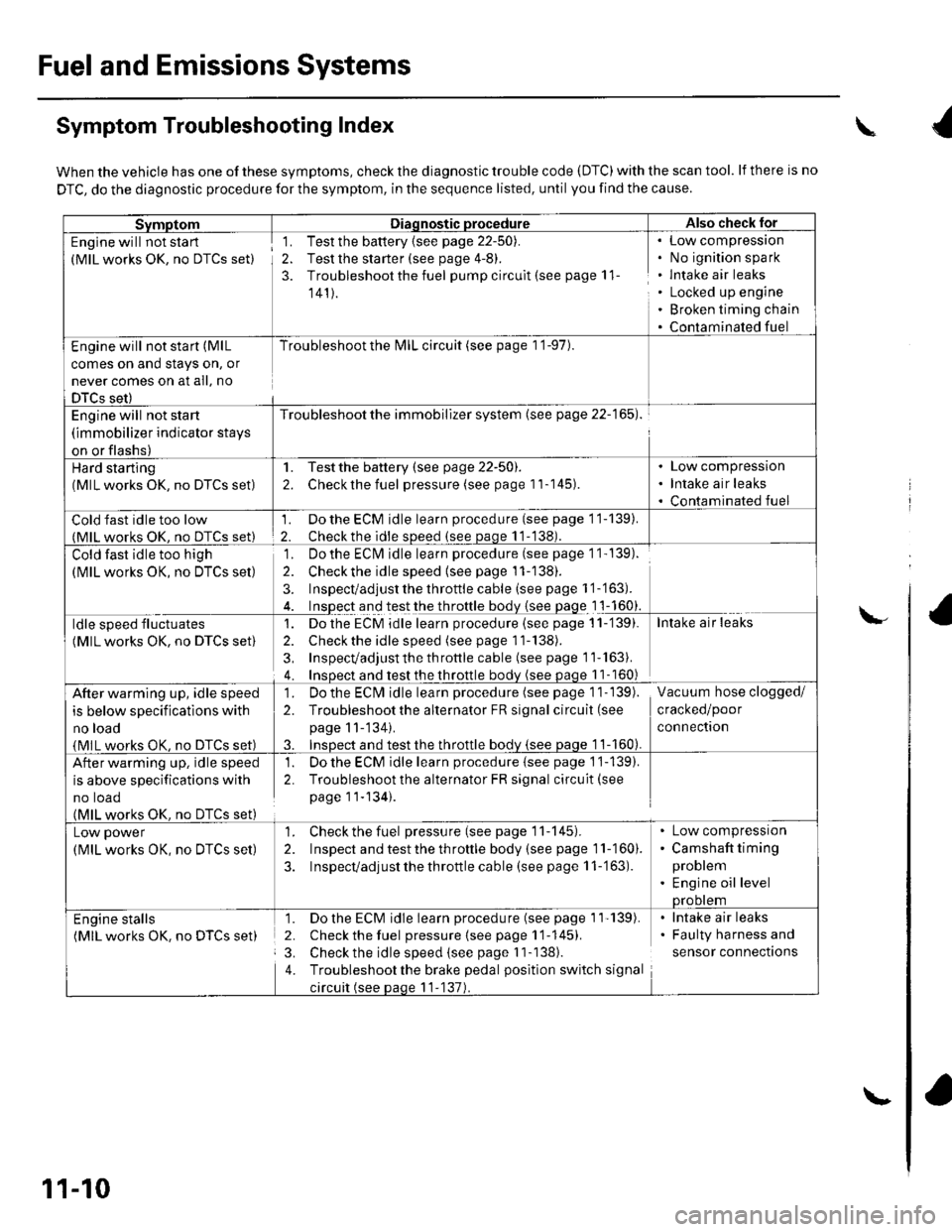

Fuel and Emissions Systems

Symptom Troubleshooting Index

When the vehicle has one of these symptoms, check the diagnostic trouble code (DTC) with the scan tool. lf there is no

DTC, do the diagnostic procedure for the symptom, in the sequence listed, until you find the cause.

SvmotomDiaqnostic procedureAlso check lor

Engine will not sta rt

(MlL works OK, no DTCS set)

1. Test the battery {see page 22-50).

2. Test the starter (see page 4-8).

3. Troubleshoot the fuel pump circult (see page 11

141).

Low compressron

No ignition spark

lntake air leaks

Locked up engine

Broken timing chain

Contaminated fuel

Engine will not start (MlL

comes on and stays on, or

never comes on at all, no

DTCS set)

Troubleshoot the l\4lL circuit (see page 1 '1-97).

Engine will not start

(immobilizer indicator stays

on or flashs)

Troubleshoot the immobilizer system (see page 22-165).

Hard starting(MlL works OK, no DTCS set)

1. Testthe battery (see page 22-50).

2. Checkthe fuel pressure (see page 11-145).

Low compression

Intake air leaks

Contaminated fuel

Cold fast idle too low(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 11-139).

2. Checkthe idle sDeed (see paqe 11-138).

Cold fast idle too high

(MlL works OK, no DTCS set)

Do the ECI\4 idle learn procedure (see page 1 1- 139).

Checkthe idle speed {see page 11-138).

Inspect/adjust the throttle cable (see page 1 '1-'163).

Inspect and test the throttle body {see page 1 1-160}.

']�

2.

3.

ldle speed fluctuates

(MlL works OK, no DTCS set)

1. Dothe ECM idle learn procedure (see page 11-'139).

2. Check the idle speed (see page 11-138).

3, Inspecvadjust th e throttle cable (see page 11''163).

4. Insoect and test the throttle bodv (see paqe 11- 160)

Intake air leaks

After warming up, idle speed

is below specifications with

no load

{MlL works OK, no DTCS set)

1. Do the ECIVI idle learn procedure (see page 1 1- 139).

2. Troubleshootthe alternator FR signal circuit (see

page 11-'134).

3. InsDect and test the throttle bodv {see paqe 1 1-160).

Vacuum hose clogged/

cracked/poor

connectron

After warming up, idle speed

is above specifications with

no toao(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure {see page 1'j-139).

2. Troubleshoot the alternator FR signal circuit(see

page 11-134).

Low power

(MlL works OK, no DTCS set)

1. Check the fuel pressure(seepagell-145).

2. Inspect and test the th roftle body (see page 11-160).

3. Inspecvadjust the throttle cable (see page 11-'163).

Low compressron

Camshaft timing

problem

Engine oil levelprootem

Engine stalls(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 1'l'139).

2. Check the fuel pressure{seepagell-145).

3. Check the idle speed (see page I 1-138).

4. Troubleshootthe brake pedal position switch signal

circuit (see paqe 11-137).

lntake air leaks

Faulty harness and

sensor connections

\

\-

11-10

\-

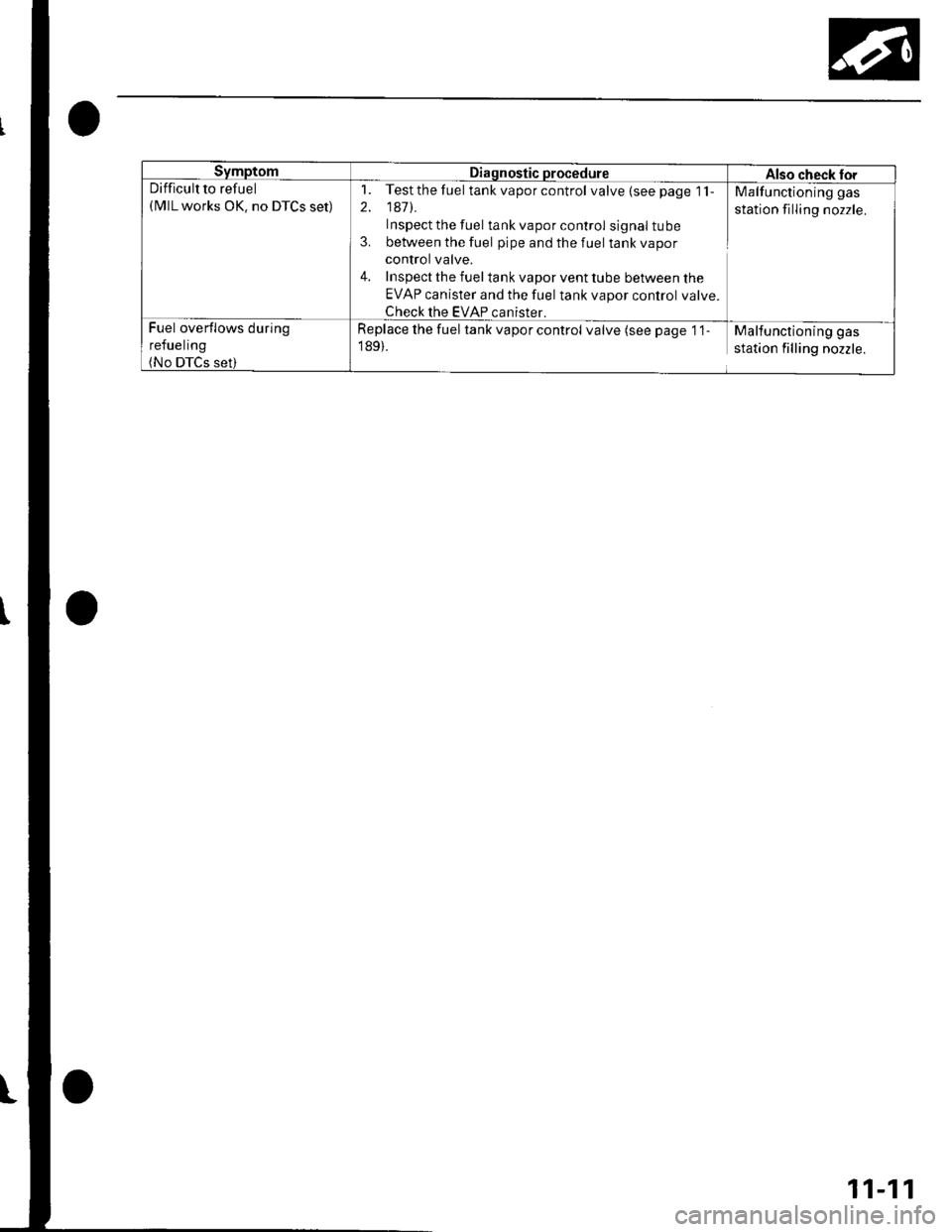

Page 218 of 1139

SymptomDiagnostic procedureAlso check torDifficult to refuel(MlL works OK. no DTCS set)

1. Testthefuel tank vapor control valve{seepage 1'l-

2. 1471.

Inspect the fuel tank vapor control signal tube

3. between the fuel pipe and the fuel tank vapor

control valve.

4. Inspect the fuel tank vapor vent tube between the

EVAP canister and the fuel tank vapor control valve.

Check the EVAP canister.

Malfunctioning gas

station filling nozzle.

Fuel overflows during

refueling(No DTCS set)

Replace the fuel tank vapor control valve (see page '1 1

189).

Malfunctioning gas

station filling nozzle.

11-11

Page 219 of 1139

Fuel and Emissions Systems

System Descriptions

Electronic Control System

The functions of the fuel and emlssion control systems are managed by the engine control module (ECM).

Fail-safe Function

When an abnormality occurs in the signal from a sensor, the ECI\4 ignores that signal and assumes a pre-programmed

value for that sensor that allows the enqine to continue to run.

Back-up Function

When an abnormality occurs in the ECM, the injectors are controlled by a back-up circuit independent of the system to

permit minimal driving.

Self-diagnosis

When an abnormality occurs in the signal from a sensor, the ECM supplies ground for the malfunction indicator lamp

{MlL) and stores the diagnostic trouble code {DTC) in erasable memory. When the ignition is first turned on, the EClvl

supplies ground to the l\4lL for 15 to 20 seconds to check the M lL bulb condition.

Two Driving Cycle Detection Method

To prevent false indications, the "two driving cycle detection method" is used for some self-diagnostic functions.

When an abnormality occurs, the ECM stores it in its memory. When the same abnormality recurs afterthe ignition

switch is turned OFF and ON (ll) again, the ECM turns on the MlL.

\

11-12

\.

\{

Page 220 of 1139

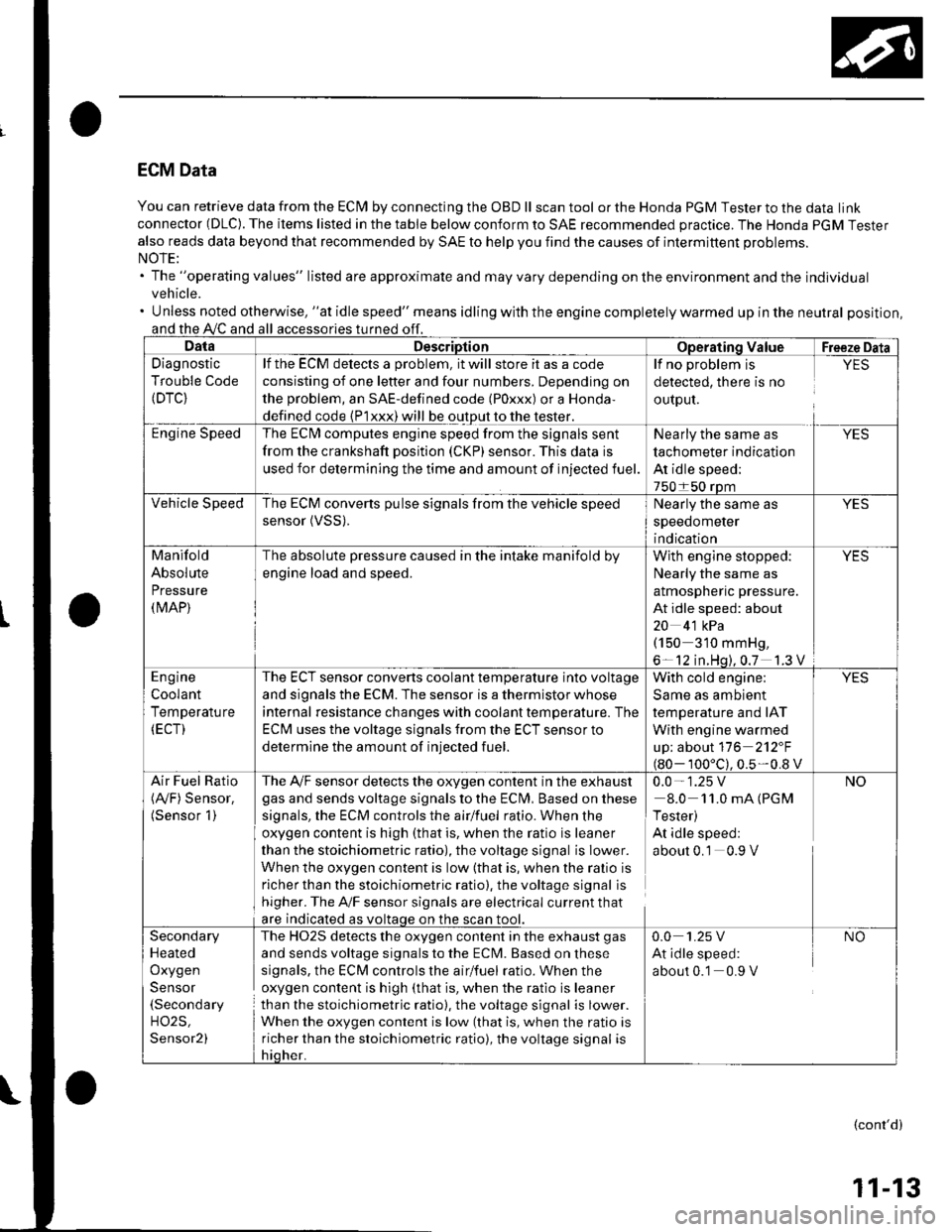

ECM Data

You can retrieve data from the ECI\4 by connecting the OBD ll scan tool or the Honda PGM Tester to the data link

connector (DLC). The items listed in the table below conform to SAE recommended practice. The Honda PGM Tester

also reads data beyond that recommended by SAE to help you find the causes of intermittent problems.

The "operating values" listed are approximate and may vary depending on the environment and the individual

vehicle.

Unless noted otherwise, "at idle speed" means idling with the engine completely warmed up in the neutral position,

and the A,/C and all

Diagnostic

Trouble Code(DTC}

lf the ECM delects a problem, it will store it as a code

consisting of one letter and four numbers. Depending on

the problem, an SAE-defined code (Poxxx) or a Honda,

defined code {P1xxx) will be output to the tester.

The ECI\4 computes engine speed from the signals sent

from the crankshaft position (CKP) sensor. This data is

used for determining the time and amount of injected fuel.

detected, there is no

ourpul.

lf no problem is YES

Nearly the same as

tachometer indication

At idle speed;

The ECM converts pulse signals from the vehicle speed

sensor (VSS).Nearly the same as

speedometer

indication

Manifold

Absolute

Pressure(MAP)

The absolute pressure caused in the intake manifold by

engine load and speed.

With engine stopped: YES

Nearly the same as

almospnenc pressure.

At idle speed: about

20 4'1 kPa(150 310 mmHg,

6- 12 in.Hq).0.7 1.3 V

The ECT sensor converts coolant temperature into voltage

and signals the ECM. The sensor is a thermistor whose

internal resistance changes with coolant tempetature. The

ECM uses the voltage signals from the ECT sensor to

determine the amount of injected fuel.

With cold engine:

Same as ambient

temperature and IAT

With engine warmed

up; about 116 2'12"F

100'c).0.5-0.8 v

Air Fuel Ratio The A,/F sensor detects the oxygen content in the exha ust 0.0 - 1 .25 V(Ay'F) Sensor. gas and sends voltage signals to the Eclvl, Basedonthese 8.0 11.0mA(PGM(Sensor 1) signals, the ECM controls the airlfuel ratio. When the I Tester)

oxygen content is high (that is, when the ratio is leaner At idle speed:

than the stoichiometric ratio), the voltage signal is Iower. about 0.1 0.9 V

When the oxygen content is low (that is, when the ralio is

richer than the stoichiometric ratio). the voltage signal is

higher. The A'lF sensor signals are electrical current that

are indicated as voltaqe on the

The HO2S detects the oxygen content in the exhaust gas

and sends voltage signals to the ECM. Based on these

signals, the ECM controls the airlfuel ratio. When the

oxygen content is high (that is, when the ratio is leaner

than the stoichiometric ratio), the voltage signal is lower.

When the oxygen content is low (that is, when the ratio is

richer than the stoichiometric ratio), the voltage signal is

Secondary

Heated

Oxygen

Sensor(Secondary

H02S,

Sensor2)

0.0 1.25 V NO

At idle speed:

about 0.1 0.9 V

(cont'd)

11-13