Oil HONDA INTEGRA 1994 4.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 244 of 1413

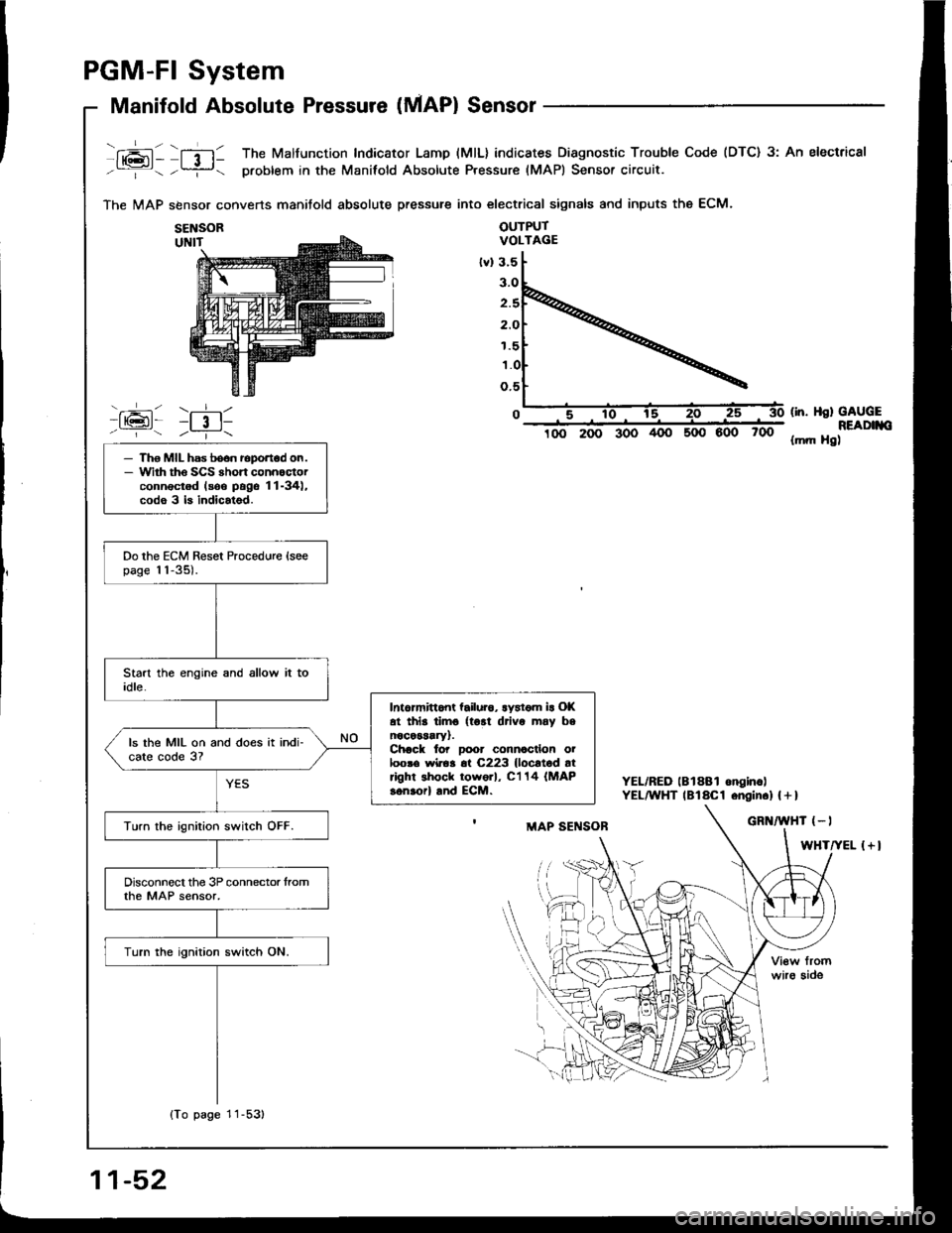

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor

fxai - lfil1 The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) 3: An electrical

-:- -?- problem in the Manifold Absolute Pressure (MAPI Sensor circuit.

The MAP sbnsor converts manitold absolute pressure into electrical signals and inputs the ECM.

OUTPUTVOLTAGE

600 700

(in. Hsl GAUGEREADIIIO{mft Hg)

YEL/RED lBlSBl onginc)YEL^YHT lBlaCl .ngin.l | + I

{+l

SENSOR

1.5

- Tho MIL has boon roportod on.- Wirh tho SCS rhort connoctorconnectod lsoo pags 11-34),codo 3 b indicatsd.

Do the ECM Reset Procedure {soepage 11-35).

Intormittont tailuro, lystom ir Ol(at thls timo {tort drivo may bsnocessary).Chack to? Door connocllon oiloosa wiroa 6t C223 {locltod atright shock tow6rl, C'l 14 (MAP

sonaorl and ECM.

ls the MIL on and does it indi-cate code 3?

Turn the ignition switch OFF.

Disconnect the 3P connector tromthe MAP sensor,

Turn the ignition switch ON.

{To page 11-53)

11-52

Page 254 of 1413

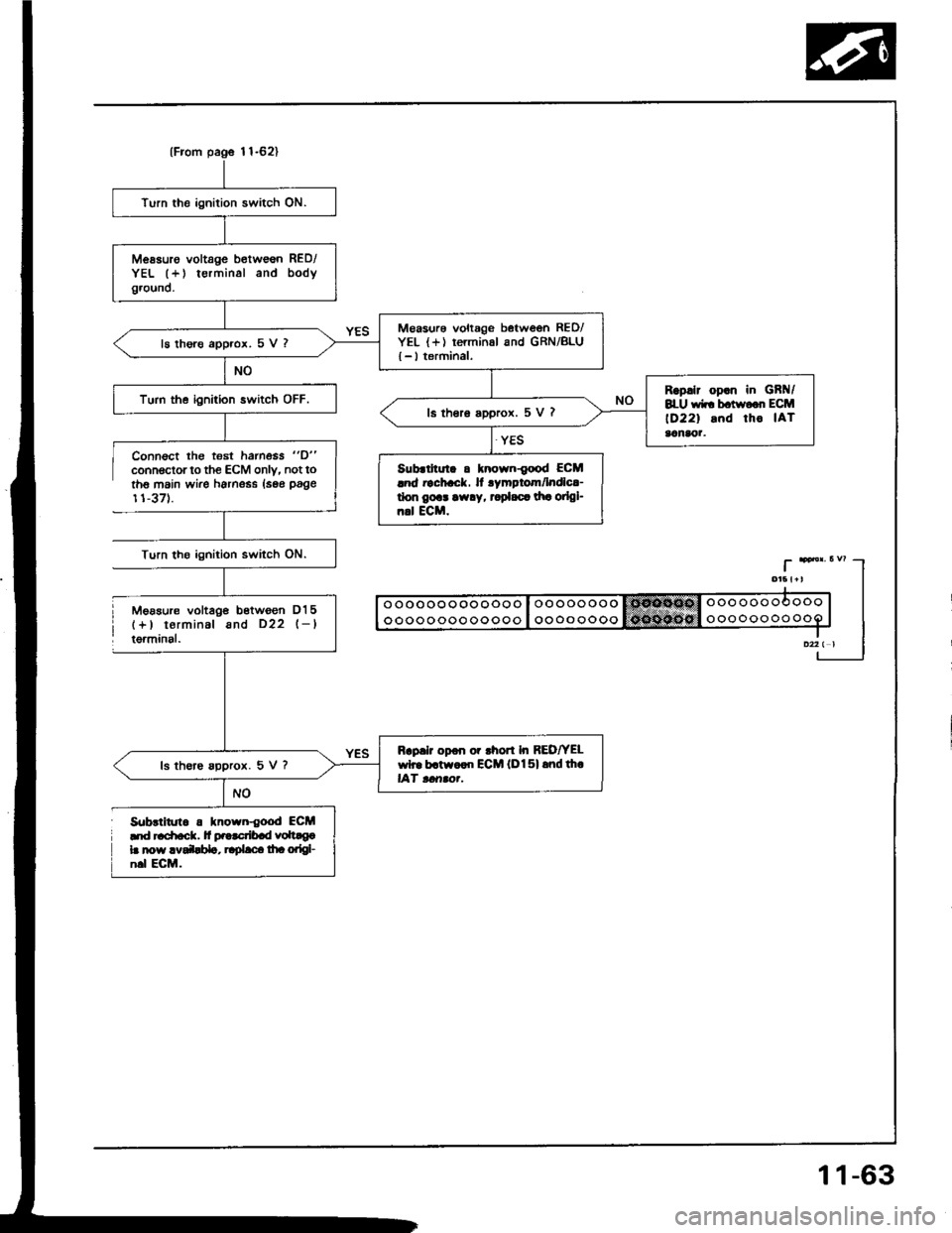

{From pag6 l1-62}

Turn the ignition switch ON.

Messuro voltage b€tw€6n RED/YEL (+) terminal and bodyground.

M€asurs voltage between RED/YEL {+) rerminal and GRN/BLU{ - I terminal,ls thore approx. 5 V ?

Rsp.lr op.n in GBt{/8LU wir bctwo.r ECM

lD22l snd tho IATaanaor.

Turn the ignition switch OFF.ls thero a99rox. 5 V ?

Sub.lhul. a tnown{ood ECMlnd rachack. It rymptom/lndlc!-don gort arv.y, t pl.c. dr! oilgl-n.l ECM.

Rap.lr opon or rhon In REDfYELwh. b.tw..n ECM lDl5l rnd th.lAf tcrrao.-ls th€re spprox. 5 V ?

Connsct lhg t€st hamess "D"

connoctor to the ECM only. not toth6 main wire harness lsse page

11-371.

Turn tho ignition switch ON.

Mgasur€ voltag€ bstwgon D15(+) terminal and D22 l-ltgrminal.

S0brlitrrt. . lnown{ood ECM'|d '.

Page 291 of 1413

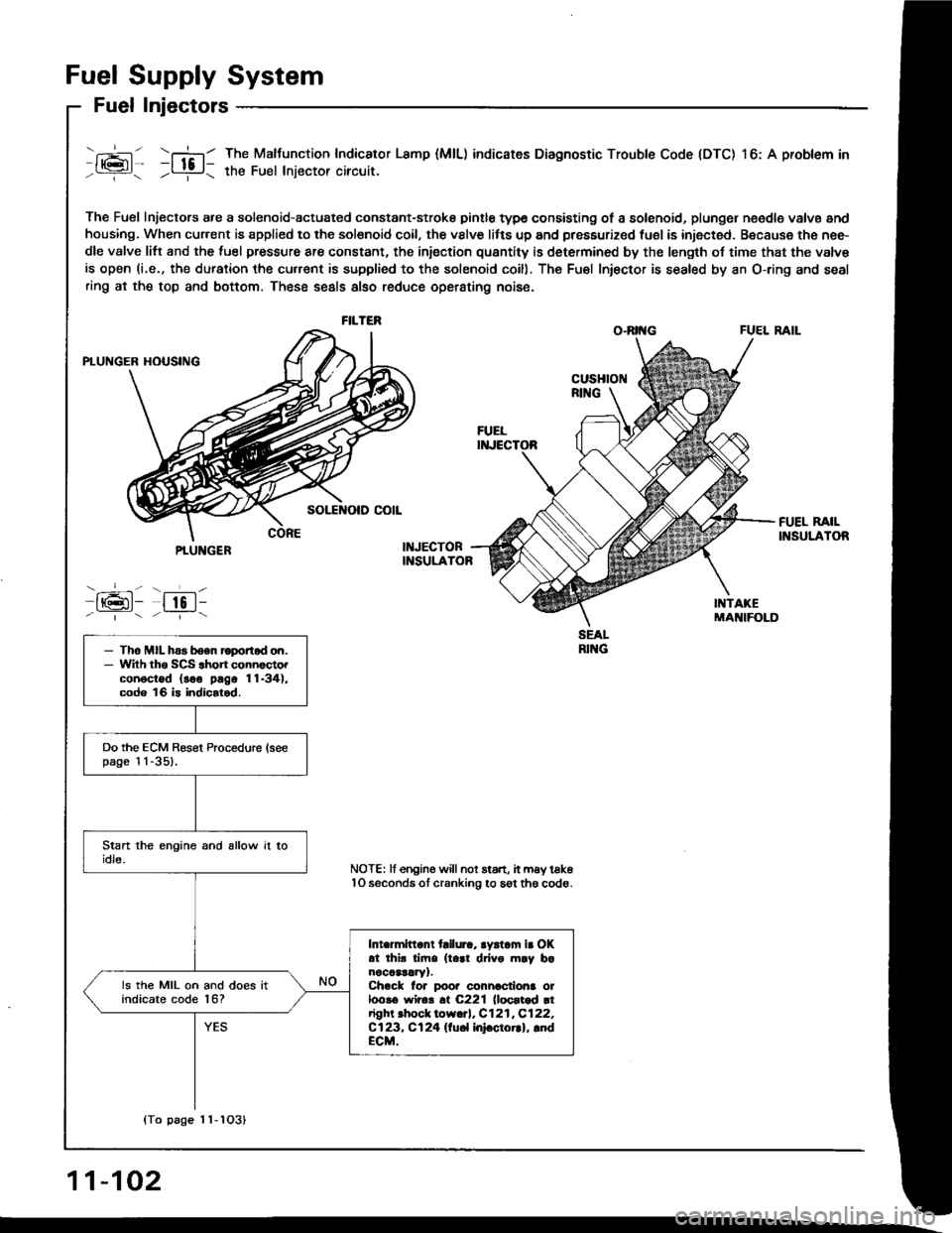

Fuel Supply System

Fuel Injectors

- --l- - \-l-l

116l- -ltc l-/---r- / ---i- \

The Fuel Injectors a.e a solenoid-actuated constant-stroke pintle type consisting of a solenoid, plungel n€edle valvs and

housing. When cur.ent is applied to the solsnoid coil, the vslve litts up and pressurized fuel is injected. Because the nee-

dle valve litt and the luel pressure are constant, the iniection quantity is determined by the length of time that the valv€

is open (i.e., the duration the cu.rent is supplied to the solenoid coill. The Fu€l Iniector is sealed by an O-ring and seal

ring at the top and bottom. These seals also reduce operating nois6.

O.RII{G FUEL RAIL

The Malfunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code (DTC) l6: A problem in

the Fuel lniector circuit.

FILTER

PTUNGER

-_-- - ___L-

IrGl- lto l--|.---:_-

- Tho MIL has boen roportod on.- Wilh tho SCS .hon connocto.conoctod (soo pago 11-34),code 16 is indicalod.

Do the ECM Besel Procedure (seepage l l -351.

Intermittant tailura, aystam ir OKat thir tim. (t..1 drivo m.y b.nocaar!ry1.Ch.ck lor poor connactiona ot100!6 wir6!.t C221 (loortod rtright .hock low.rl, C121,C122,Cl23, Cl24 llu6l InFctorrl, lndECM.

ls the MIL on and does itindicate code l6?

NOTE: lf engine willnot start, it may tak6lO seconds ol cranking to sgt th6 code.

{To page 1 1-1O31

11-102

Page 294 of 1413

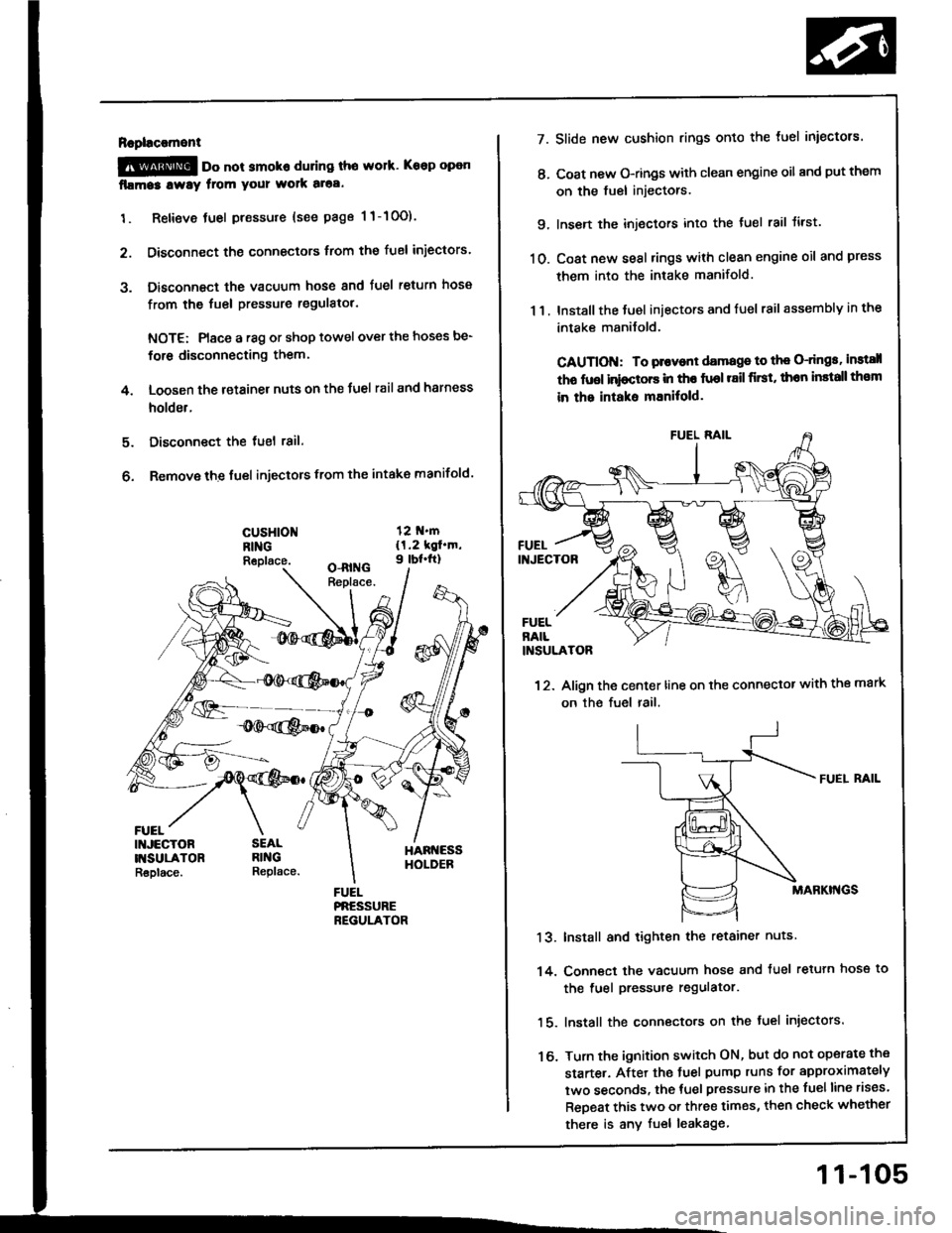

Rapl!c!ment

@ oo not smoko during tho work. Keep open

fllma3 lway from your wolk aloa.

1. Retieve tuel pressure {see page 1 1-10O).

2. Disconnect the connectors trom the fuel iniectors.

3. Disconnect the vacuum hose and fuel return hosa

from the fuel pressure regulatol.

NOTE: Place a r8g or shop towel over the hoses be-

for6 disconnecting them.

4. Loosen the retainer nuts on the Juel rail and harness

holder.

Disconnect the tuel 18il.

Remove the fuel injectors from the intake manifold.

5.

6.

cusHloNRINGReplace.

FUEL

7.

t'.

9.

10.

13.

14.

16.

11.

Slide new cushion rings onto the luel iniectors.

Coat new O-rings with clean engine oil and put them

on the fuel injectors.

Insen the injectors into the tuel rail tirst.

Coat new seal rings with clean engine oil and press

them into the intake manifold.

Install the Juel iniectors and fuel rail assembly in the

intake manilold.

CAUTION: To plovont damage to th€ O-dngs, instsll

tho fuol inioctors in tho fuol r8il first, thon install th€m

in the intaks mEnitold.

12. Align the center line on the connector with the mark

on the fuel rail.

FUEI. RAIL

MABKI'{GS

Install and tighten the retainer nuts

Conn€ct the vacuum hose and tuel retuln hose to

the fuel pressure regulator.

lnstall the connecto.s on the fuel injectors.

Turn the ignition switch ON, but do not operate the

starte.. After the tuel pump runs for approximately

two seconds, the tuel pressure in the fuelline rises.

ReDeat this two or three times, then check whether

there is any fuel leakage

11-105

Page 296 of 1413

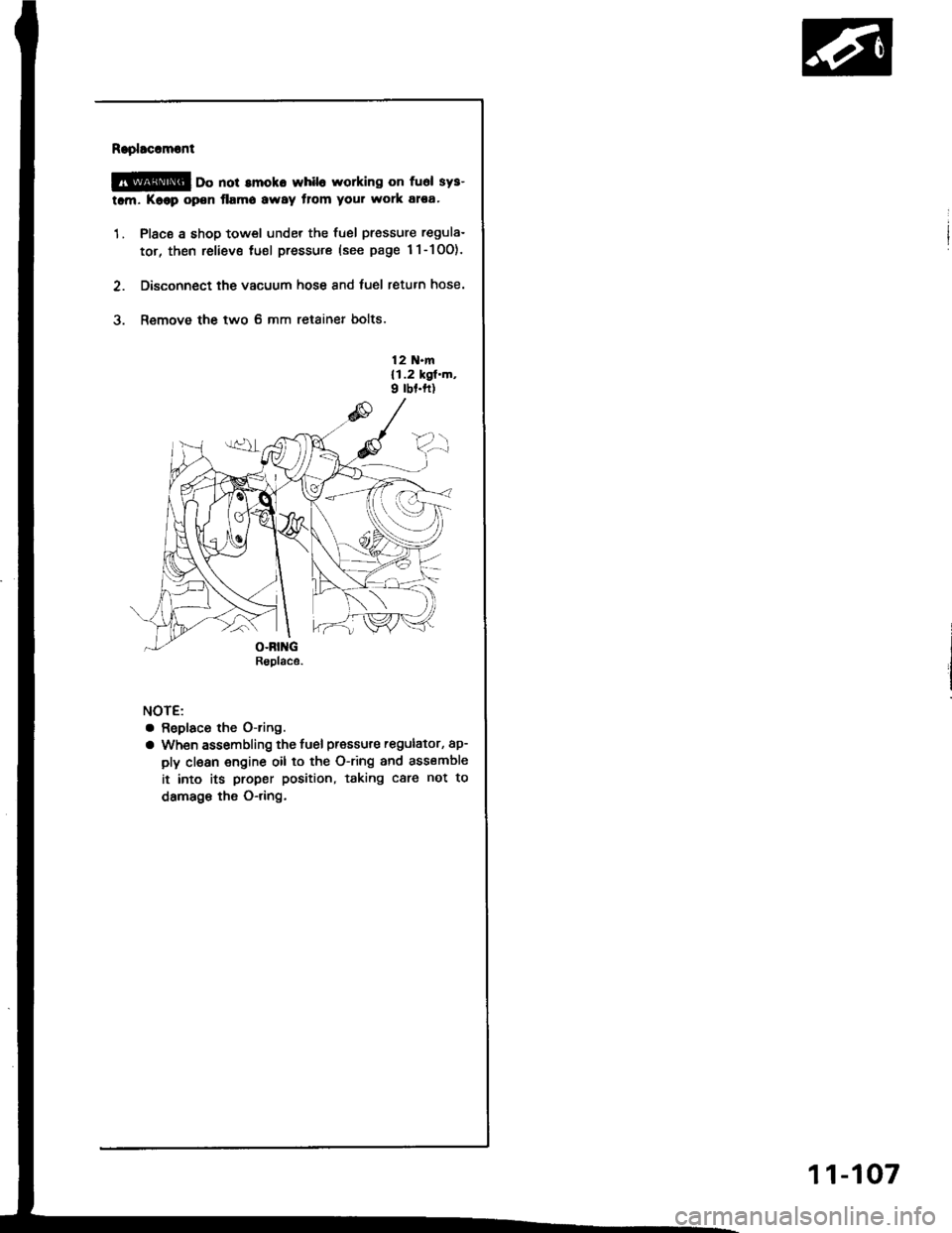

Raplacoment

@ oo not amoko whil6 working on fuel sys-

tam. Koop open flamo away tlom your work atea'

1. Place a shop towel under the fuel pressure regula-

tor, then reliev€ tuel pressure (see page 1l-10O).

2. Disconnect the vacuum hose and fuel return hose.

3. Remove the two 6 mm retainer bolts.

12 N.m{1.2 kgl.m,9 rbf.ft)

NOTE:

a Replaco the O-ring.

a When assembling the fuel pressure regulator, ap-

ply clean engine oil to the O-ring and assemble

it into its proper position, taking care not to

damage the O-dng.

Rsplace.

11-107

Page 335 of 1413

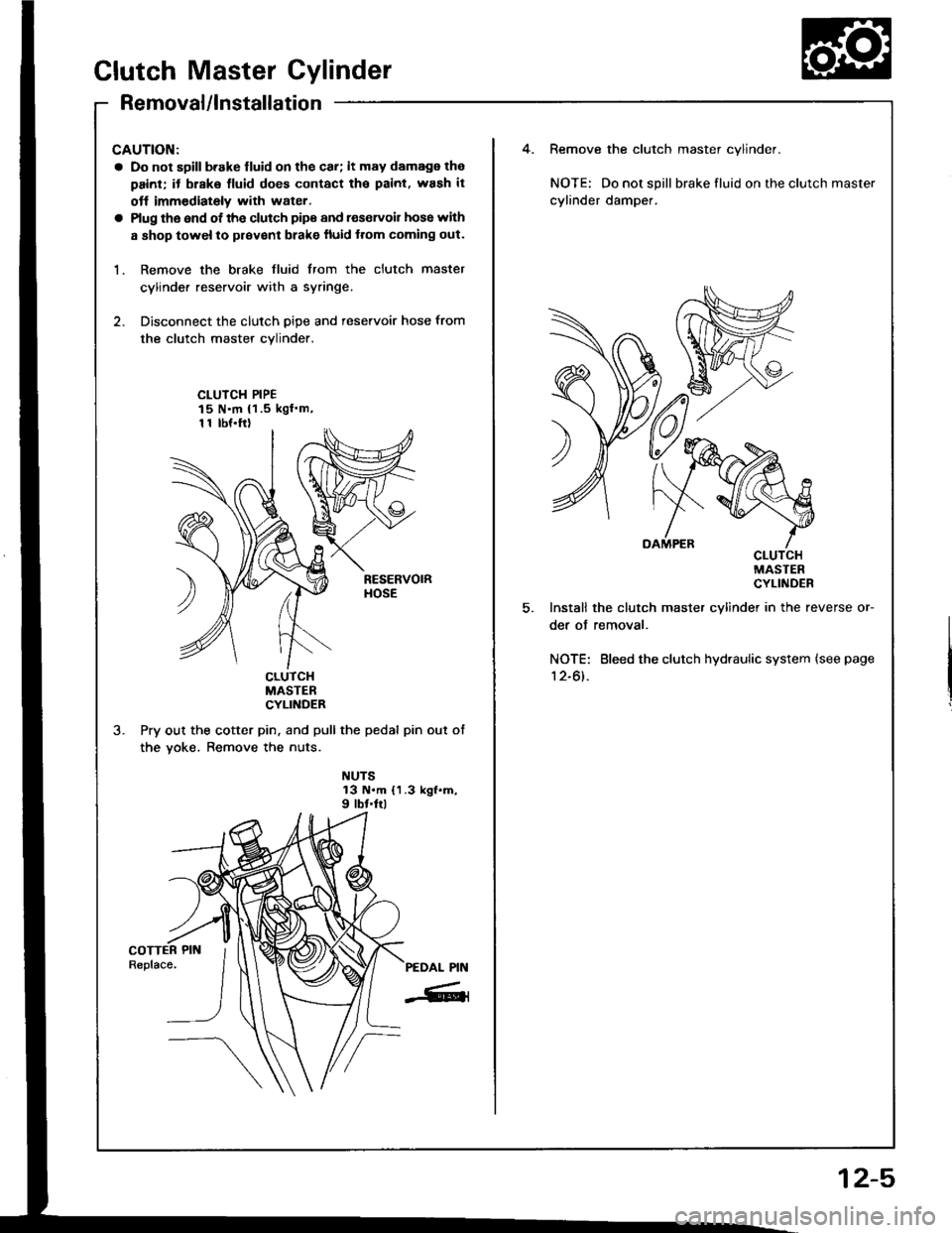

Clutch Master Cylinder

Removal/lnstallation

CAUTION:

a Do not sgill b.ake lluid on the car; it may damags the

painl; it biake fluid does contact tha paint. wash it

otf immediately with water.

a Plug lhe end ot the clutch pips and r€servoil hose with

a shop towel to prsvent blake fluid ttom coming out.

1. Remove the brake fluid from the clutch master

cylinde. reservoir with a syringe.

2. Disconnect the clutch oioe and reservoir hose from

the clutch master cvlinder.

CLUICH PIPE15 N'm {1.5 kgl.m,1 1 tbf.ftl

CLUTCHMASTERCYLINDER

Pry out the cotter pin. and pull the pedal pin out ot

the yoke. Remove the nuts.

NUTS13 N.m {1.3 kgf.m,9 lbt.frl

Remove the clutch master cylinder.

NOTE: Do not spill brake fluid on the

cylinder damper.

OAMPERCLUMAIcYL

Install the clutch master cylinder in

der of removal.

NOTE: Bleed the clutch hydraulic s\

12-61.

clutch master

CLUTCHMASTERCYLINDER

!l rn Ine reverse or-

c system (see page

12-5

Page 338 of 1413

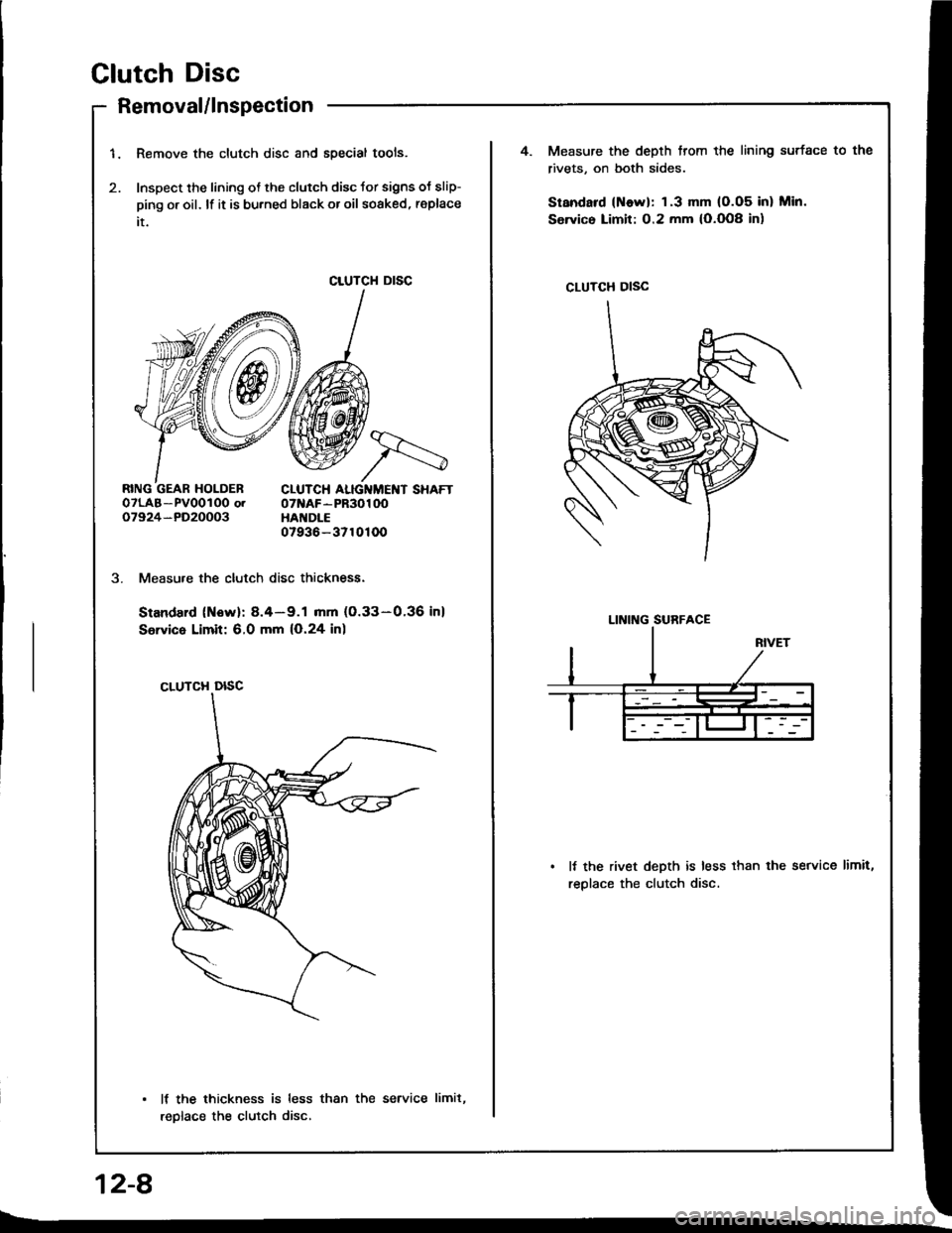

Glutch Disc

'1.Remove the clutch disc and special tools.

Inspect the lining of the clutch disc Jor signs oJ slip-

ping o. oil. lf it is bu.ned black or oil soaked, replace

it.

Measure the depth trom the lining surface to the

rivets, on both sides.

Standard (Now): 1.3 mm (O.05 inl Min.

Se.vice Limit: O.2 mm {O.OO8 inl

CLUTCH ALIGNMEI{T SHAFT07NAF-PR30100HAt{DLE07936-3710 t0O

Measu.e the clutch disc thickness.

Standard {Now}: 8.4-9.1 mm (o.33*0.36 inl

Sarvica Limit: 6.0 mm (O.24 in)

It the rivet deDth is less than the service limit,

reolace the clutch disc.

lf the thickness is less than the service limit,

reolace the clutch disc,

CLUTCH DISCCLUTCH DISC

LINING SURFACE

CLUTCH DISC

Removal/lnspection

ctutch Disc I

'.#fu;;

l''

"LUrcH Drsc |

""-*":'-- {o'oo8 inr

I I

=-.--']! ; i , n-

ll

W@*-l @

slbir":ix:l# Ii!fr..;*'::l;'"o^"

|

'=f

I I

3. Measu.e the clutch disc thic

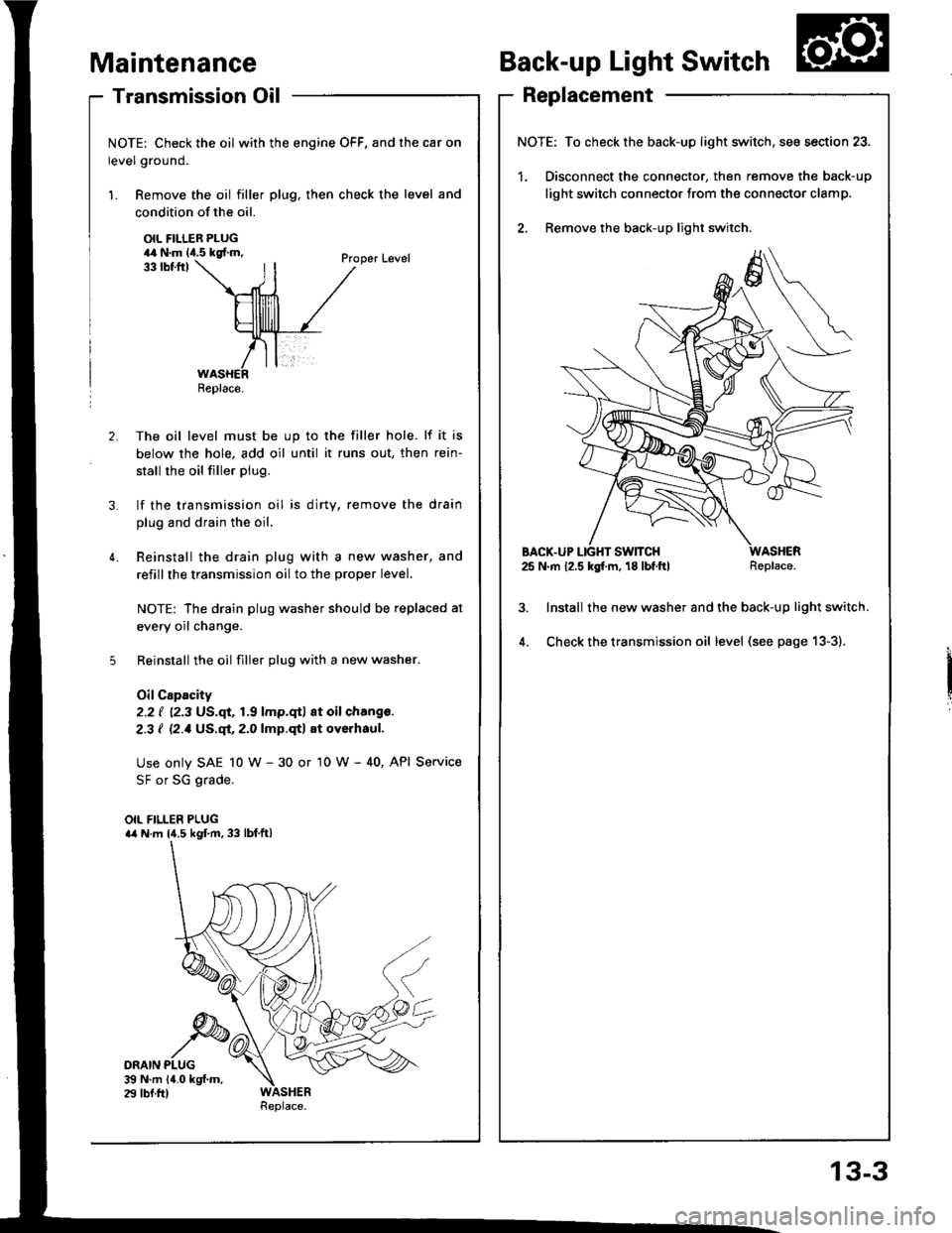

Page 345 of 1413

- Transmission Oil

NOTE: Check the oil with the engine OFF, and the car on

level ground.

1. Remove the oil filler plug, then check the level and

Maintenance

condition of the oil.

OIL FILLER PLUG44 N.m lia.5 kgf.m,

ORAIN PLUG$ N.m 14.0 kgf.m.29 lbf.fr)

33 tbtftlProper Level

2. The oil level must be up to the filler hole. lf it is

below the hole. add oil until it runs out, then rein-

stall rhe oil filler plug.

3. lf the transmission oil is dirty, remove the drain

plug and drain the oil.

4. Reinstall the drain plug with a new washer, and

refillthe transmission oil to the proper level.

NOTE: The drain plug washer should be replaced at

every oil change.

5 Reinstall the oil filler plug with a new washer.

OilCapacity

2.2 ( ''2.3 US.qt,1.9 lmp.qt) at oil chang€.

2-3 I l2.1Us.ql,2.0lmp.qtl at oyerhaul.

Use only SAE 10 w - 30 or '10 W - 40, API Service

SF or SG grade.

OIL FILLER PLUGa4 N.m l{.5 kgf.m, 33 lbf.ftl

Back-up Light Switch

Replacement

NOTE: To check the back-up light switch,

1. Disconnect the connector, then rem(

light switch connector trom the conn

2. Remove the back-up light switch.

BACX-UP LIGHT SWITCH25 N.m 12.5 kg[.m, 18 lbf.ftl

lnstall the new washer and the back-

Check the transmission oil level (see

Replace.

/itch, see section 23.

remove the back-up

]onnector clamp.

-up light switch.

) page 13-3).

Replace.

13-3

Page 346 of 1413

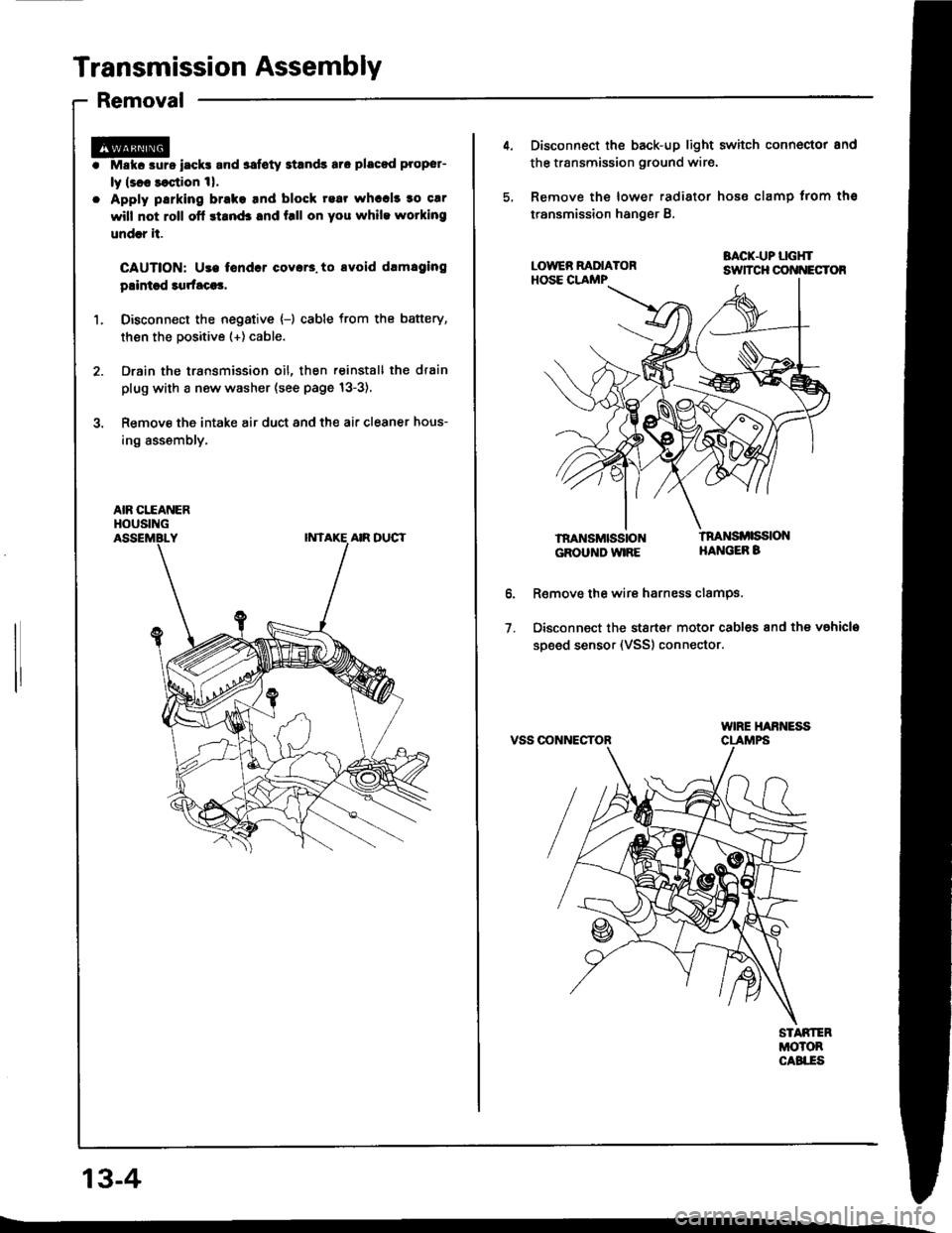

Transmission Assembly

Removal

Mskc aurs iack! and safoty Etands aro placod proper-

ly lsl8 saqtion 1|.

Apply parking brake tnd block rear whccl! to car

will not roll ofl stand3 and f.ll on you while wotking

undrr it.

CAUTION: Use tondcr coyar3. to avoid drmlging

plintsd 3qrfaca3,

Disconn€ct the negative {-) cable from the battery,

then the positive (+) cable.

Drain the transmission oil, then reinstall the drain

plug with a new washer (see page 13-3),

Remove the intake air duct and the air cleaner hous-

ing assembly,

AIR CITANERHOUSING

13-4

4. Disconnect the back-up light switch connoctor and

the transmission ground wir€.

5, Remove the lower radiator hose clamp trom ths

transmission hanger B.

BACK.UP LGHTsuTcH cot{t{EcToR

lnaNsMttistoNGROUND WIRE

tnaNsi ssloNHANGEB B

o.

1.

R€move the wire harness clamPs.

Disconnect the stsrt€r motor cables and the vahicla

soeed sensor (VSS) connector.

VSS OONNECTOR

Page 350 of 1413

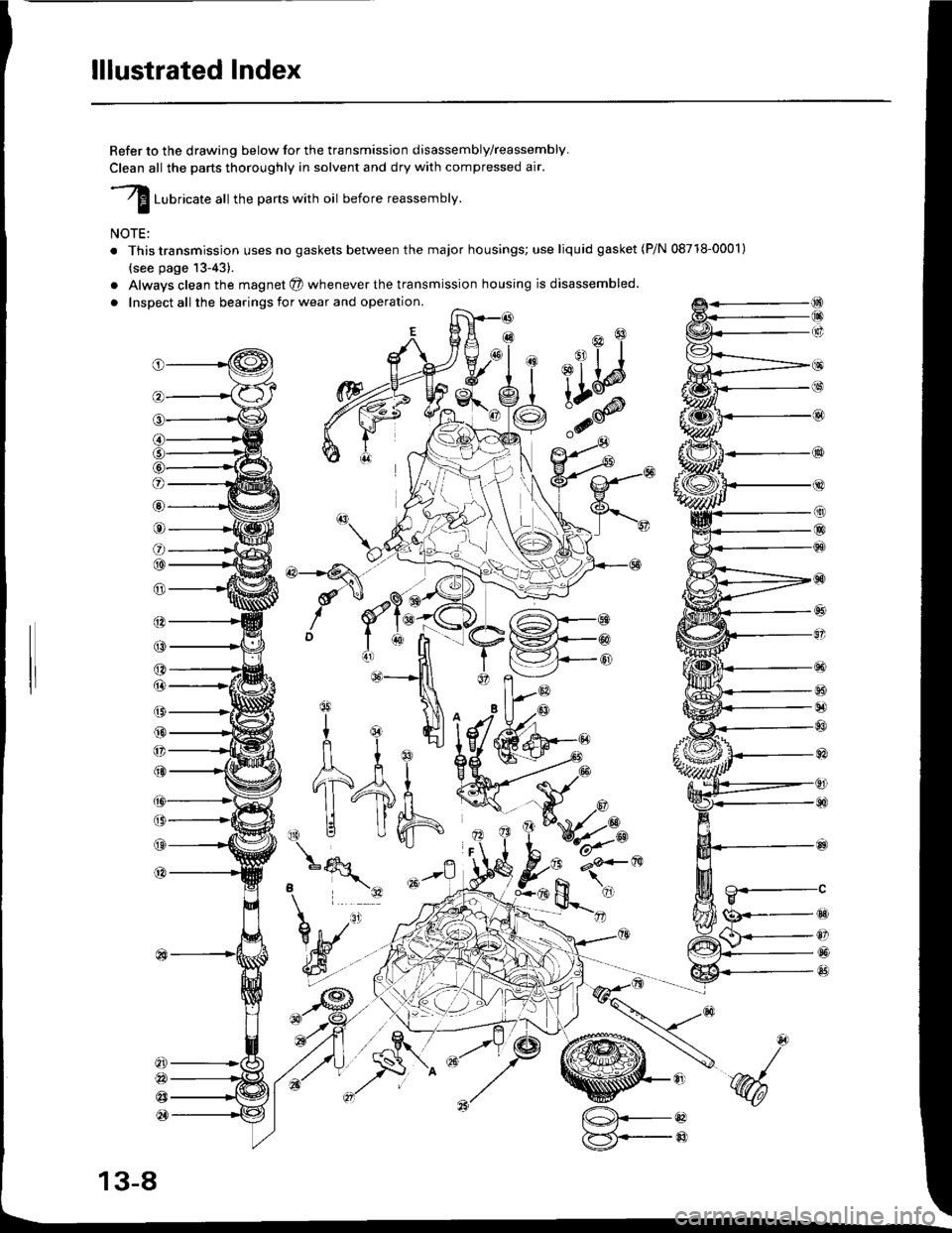

lllustrated Index

Refer to the drawing below for the transmission disassembly/reassembly.

Clean all the parts thoroughly in solvent and dry with compressed air.

I ruurlcate att the parts with oil before reassembly.

NOTE:

. This transmission uses no gaskets between the major housings; use liquid gasket (P/N 08718-0001)

{see page 13-43).

a

a

Alwavs clean the magnet @ whenever the transmission housing is disassembled.

Inspect all the bearings for wear and operation.

(9

@

@

tqqlnl^'1ult I Ej

nl

11-4fi

,\|j Uh

o

@

o

@@

@

@

(3

(,

@

@

@

a

@

@

@

@

B

tg

Y

o

@

@

@

*N

13-8

[@.--oaF5i,--@:7