HONDA INTEGRA 1994 4.G Workshop Manual

INTEGRA 1994 4.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/6067/w960_6067-0.png

HONDA INTEGRA 1994 4.G Workshop Manual

Page 523 of 1413

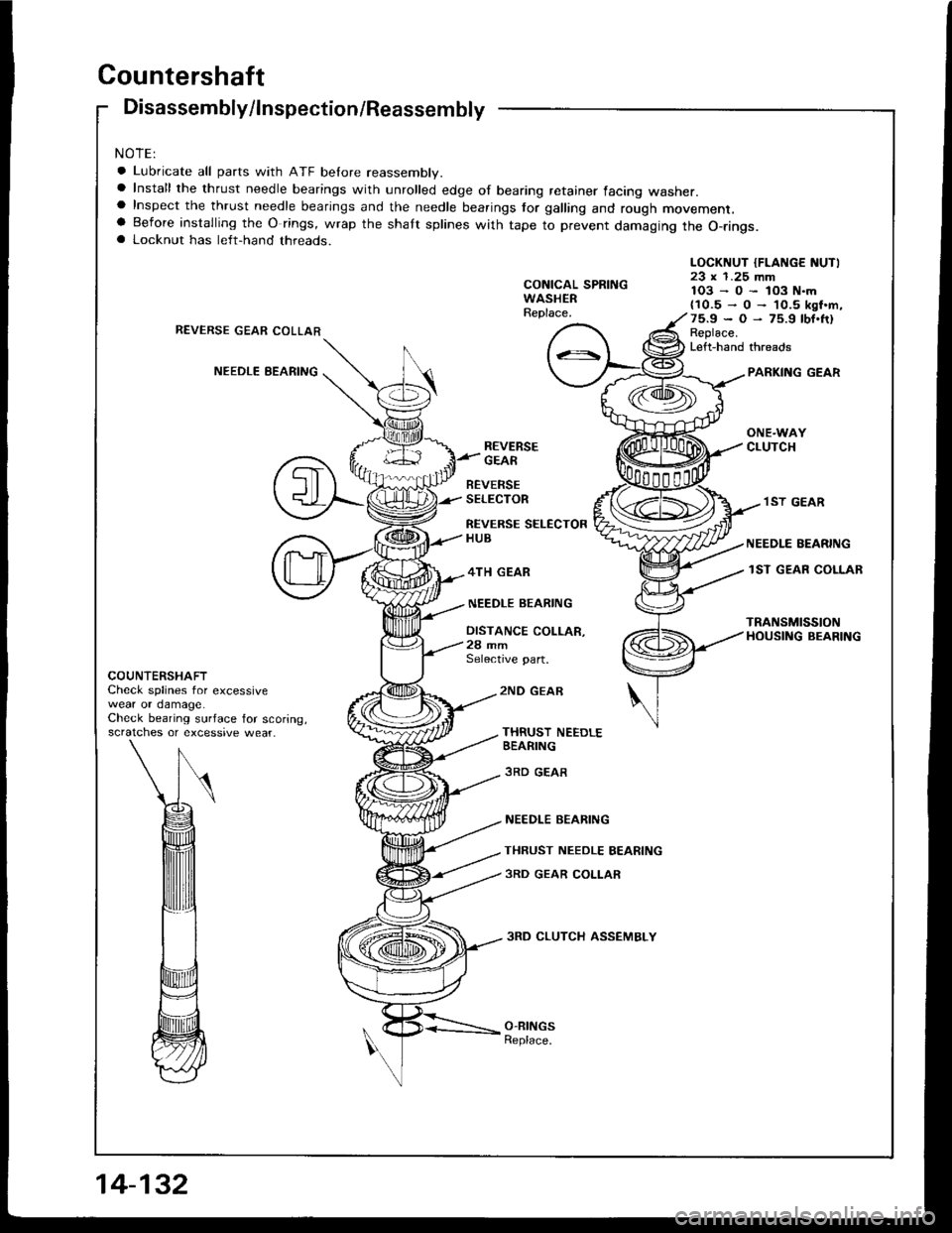

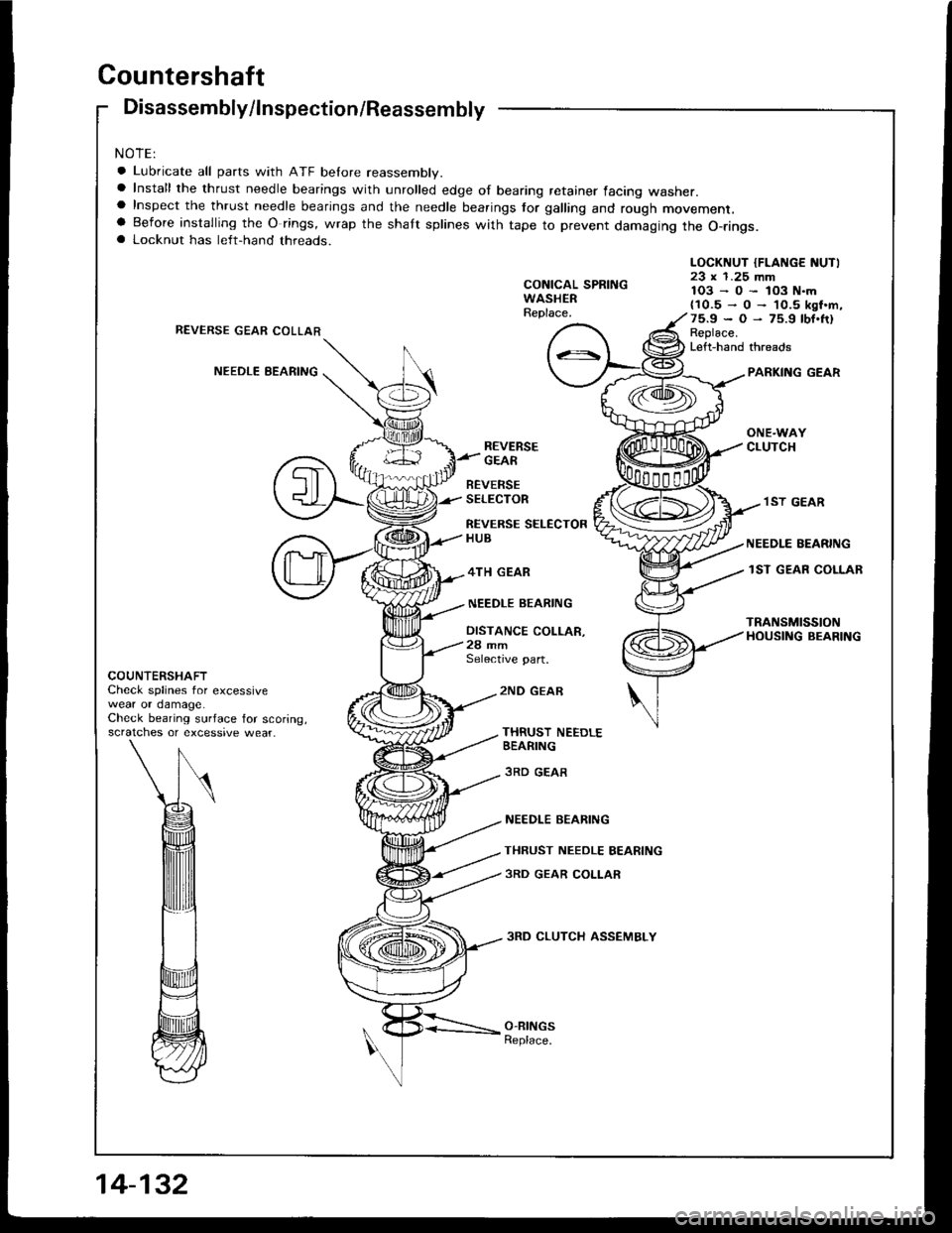

Countershaft

Disassembly/lnspection/Reassembly

NOTE:

a Lubricate all parts with ATF belore reassembly.a Install the thrust needle bearings with unrolled edge of bearing retainer facing washer.a Inspect the thrust needle bearings and the needle bearings tor galling and rough movement.a Before installing the O rings, wrap the shaft splines with tape to prevent damaging the O-rings.a Locknut has left-hand threads.

CONICAL SPRINGWASHERReplace.

LOCKNUT {FLANGE NUTI23 x 1.25 mm1O3-0-lO3N.m{10.5-O-'l0.5ksf.m,75.9*O-75.9tbf.fr)Replace.Left-hand threads

REVERSE GEAR COLLAR

NEEDLE EEARINGPARKING GEAR

ONE.WAYCLUTCHREVERSEGEAR

BEVERSESELECTOR

REVERSE SELECTORHUB

4TH GEAR

NEEDLE BEARING

DISTANCE COLLAR,28 mmSelective part.

.I ST GEAR

NEEDLE EEARING

lST GEAR COLLAR

TRANSMISSIONHOUSING BEARING

COUNTERSHAFTCheck splines for excessivewear or damage.Check bearing surface for scoring,scratches or excessive wear_

2ND GEAE

THRUST NEEDLEBEARING

3RD GEAR

NEEDLE BEARING

THRUST NEEDLE BEARING

3RD GEAR COLLAR

3RD CLUTCH ASSEMBLY

O-RINGSReplace.

Page 524 of 1413

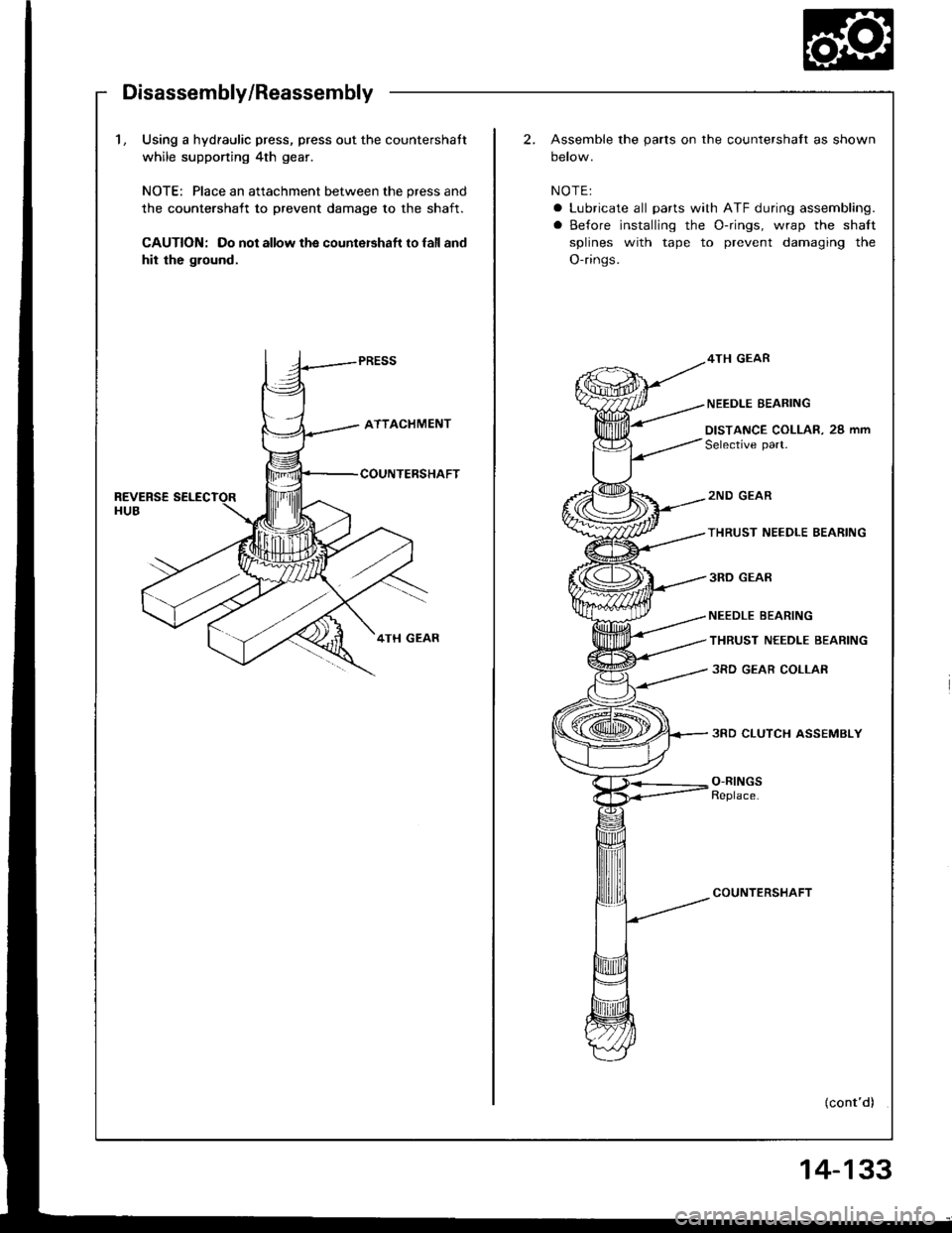

Disassembly/Reassembly

1, Using a hydraulic press, press out the countershatt

while supponing 4th gear.

NOTE: Place an attachment between the press and

the countershatt to prevent damage to the shaft.

CAUTION: Do not allow the countershaft to lall and

hit the ground.

2.Assemble the parts on the countershaft as shown

oetow.

NOTE:

a Lubricate all parts with ATF during assembling.

a Before installing the O-rings, wrap the shalt

splines with tape to prevent damaging the

O-rings.

4TH GEAR

NEEDLE BEARING

DISTANCE COLLAR. 29 mm

Selective part.

2ND GEAR

THRUST NEEDLE BEARING

3RD GEAR

NEEDLE BEARING

THRUST NEEDLE BEARING

3RD GEAR COLLAR

3RD CLUTCH ASSEMBLY

O-RINGSReplace.

COUNTERSHAFT

{cont'd)

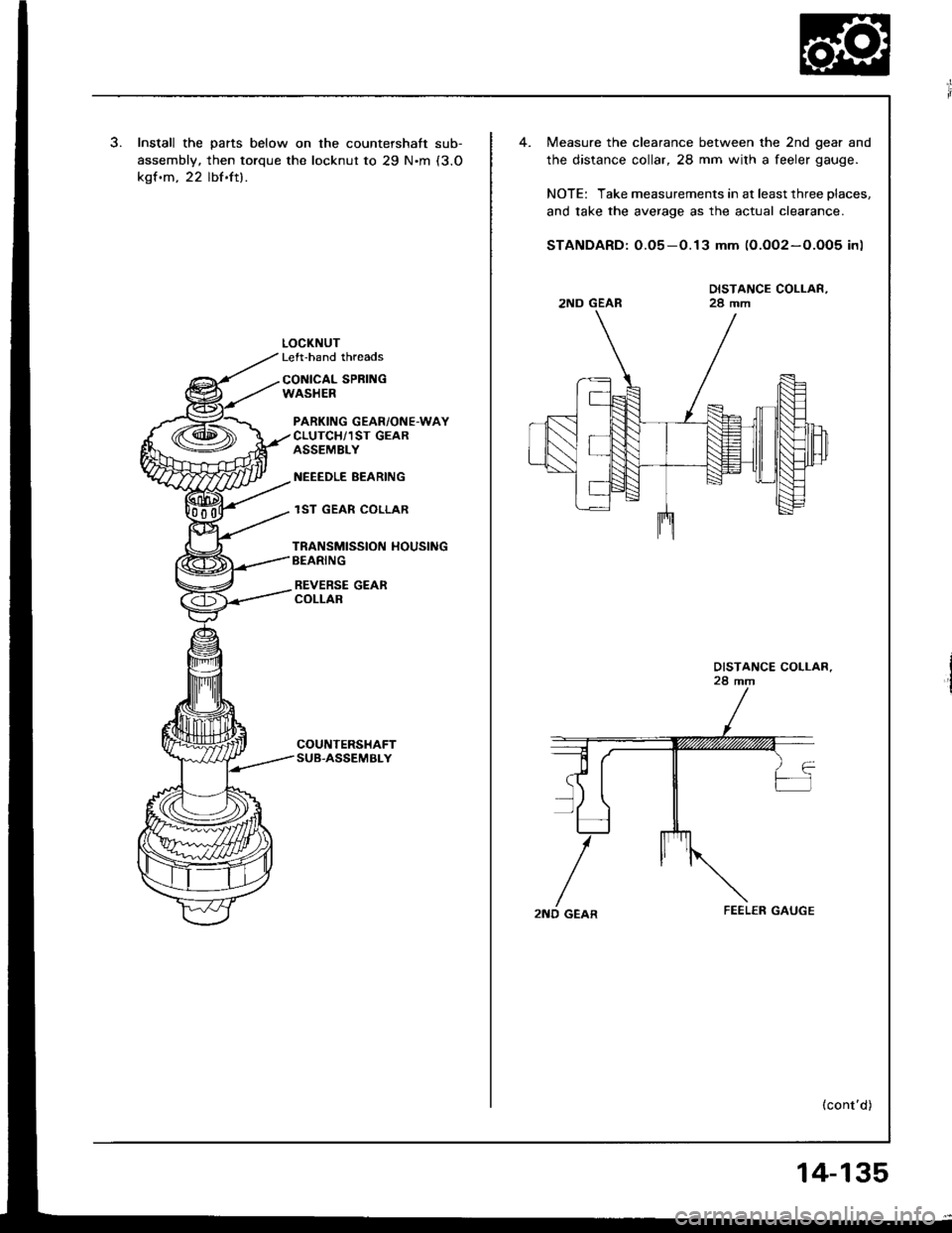

Page 526 of 1413

Install the parts below on the countershaft sub-

assembly, then torque the locknut to 29 N'm (3.O

kgf.m, 22 lbf.ft).

LOCKNUTLeft-hand threads

CONICAL SPRI GWASHER

PARKING GEAR/ONE-WAYCLUTCH/1ST GEARASSEMBLY

NEEEDLE BEARING

lST GEAR COLLAR

TRANSMISSION HOUSINGBEARING

REVERSE GEARCOLLAR

Measure the clearance between the 2nd gear and

the distance collar, 28 mm wilh a feeler gauge.

NOTE: Take measurements in at least three places.

and take the average as the actual clearance.

STANDARD: O.O5-0.13 mm (0.OO2-O.O05 in)

DISTANCE COLLAR,28 mm2ND GEAR

2ND GEAR

(cont'd)

14-135

Page 528 of 1413

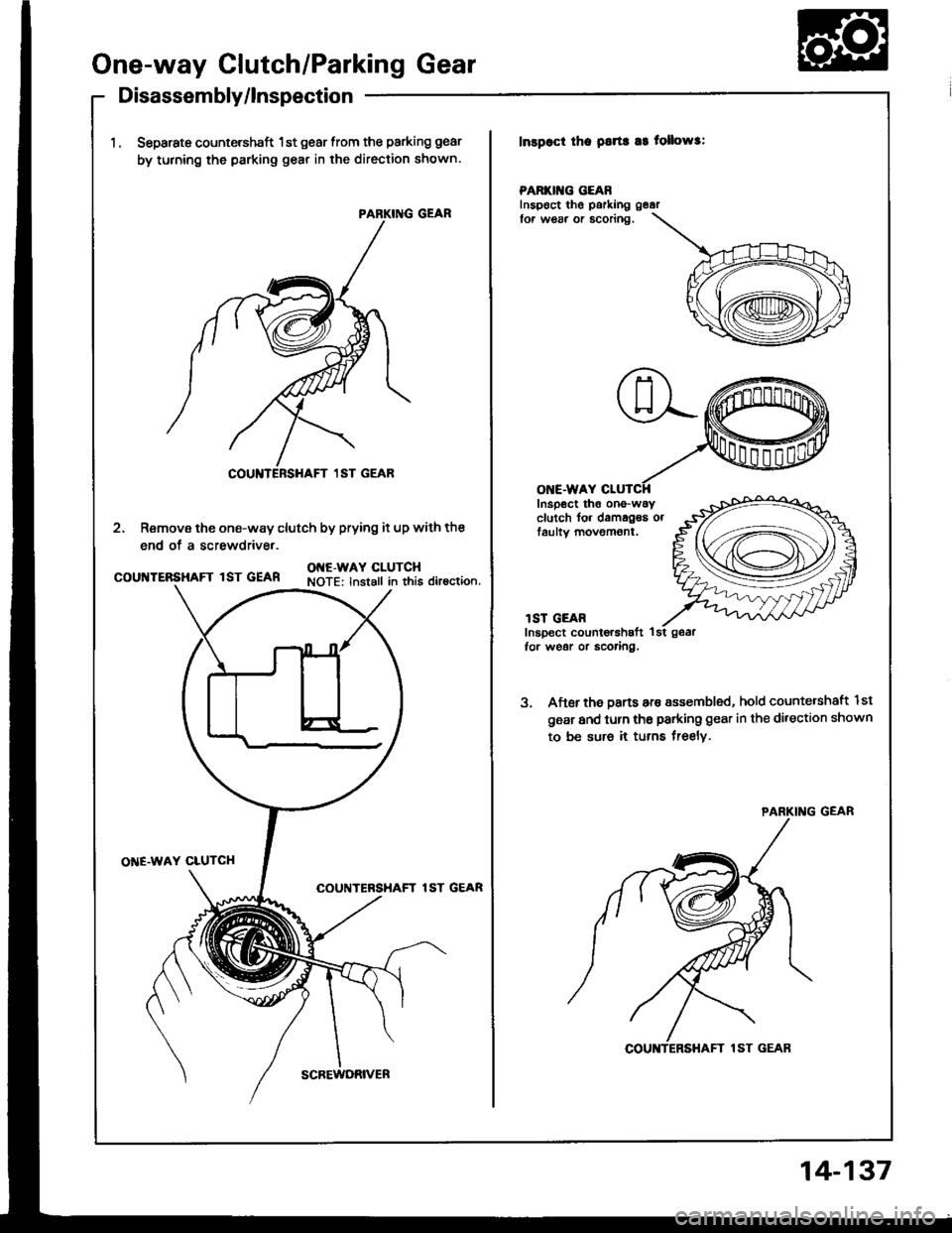

One-way Clutch/Parking Gear

Disassembly/lnspection

1.Separate countershaft 1st gear from the parking gear

by turning the parking gear in the direction shown.

Inspoct tha psrta a3 tollows:

PARKII{G GEARInspect thg parking

tor w€s. or acoring.

O E.WAY

2. Remove the one-way clutch by prying it up with the

end of a screwdrive..

Inspect tho ono-wayclutch fo. damagea orfaultv movement.

courrERsHAFrlsr.EAR 9IlYlL9iY^t.?INOTE: lnstall in this direction.

l ST GEARInspect counior6haft 1tor wegr or scoaing.

3. After the Darts are sssembled, hold counte.shaft lst

gear and turn tho parking gear in the direction shown

to be sur6 it turns freelv,

O'TE.WAY CLUTCH

COUNTERSHAFT lST GEAR

COUNTERSHAFT 1ST GEAR

COU TERSHAFT 1ST GEAR

SCREWDRIVER

14-137

Page 529 of 1413

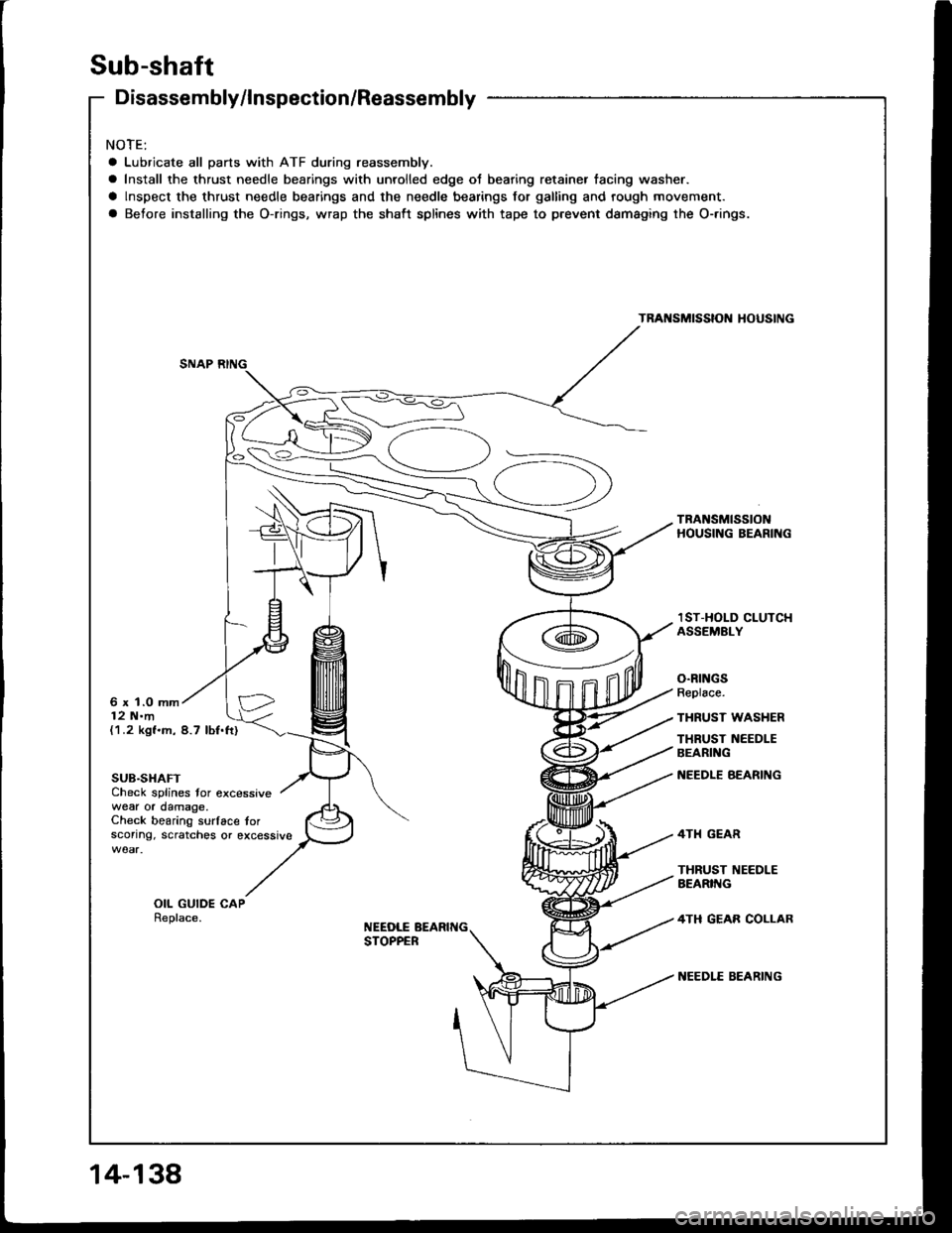

Sub-shaft

Disassembly/lnspection/Reassembly

NOTE:

a Lubricate all parts with ATF during reassembly.

a Install the thrust needle bearings with unrolled edge ot bearing retainer tacing washer.

a lnspect the thrust needle bearings and the needle bearings for galling and rough movement.

a Before installing the O-rings, wrap the shaft splines with tape to prevent dsmaging the O-.ings.

TRANSMISSIOI{ HOUSING

TRANSMISSIONHOUSING BEARING

6 x 1.0 mm12 N.m

lST-HOLD CLUTCHASSEMELY

O.RINGSReplace.

THRUST WASHER

THRUST NEEDLEBEARING

NEEDLE BEARING

4TH GEAR

THRUST I{EEDLEAEARIIIG

4TH GEAB COLLAR

NEEDLE EEARING

(1.2 kgf.m, 8.7 lbf.ft)

SUB.SHAFTCheck splines tor excessivewear or damage.Check bearing surlace torsconng. scratches or excessive

OIL GUIDE CAPReplace.NEEDLE BEARIT{GSTOPPER

Page 530 of 1413

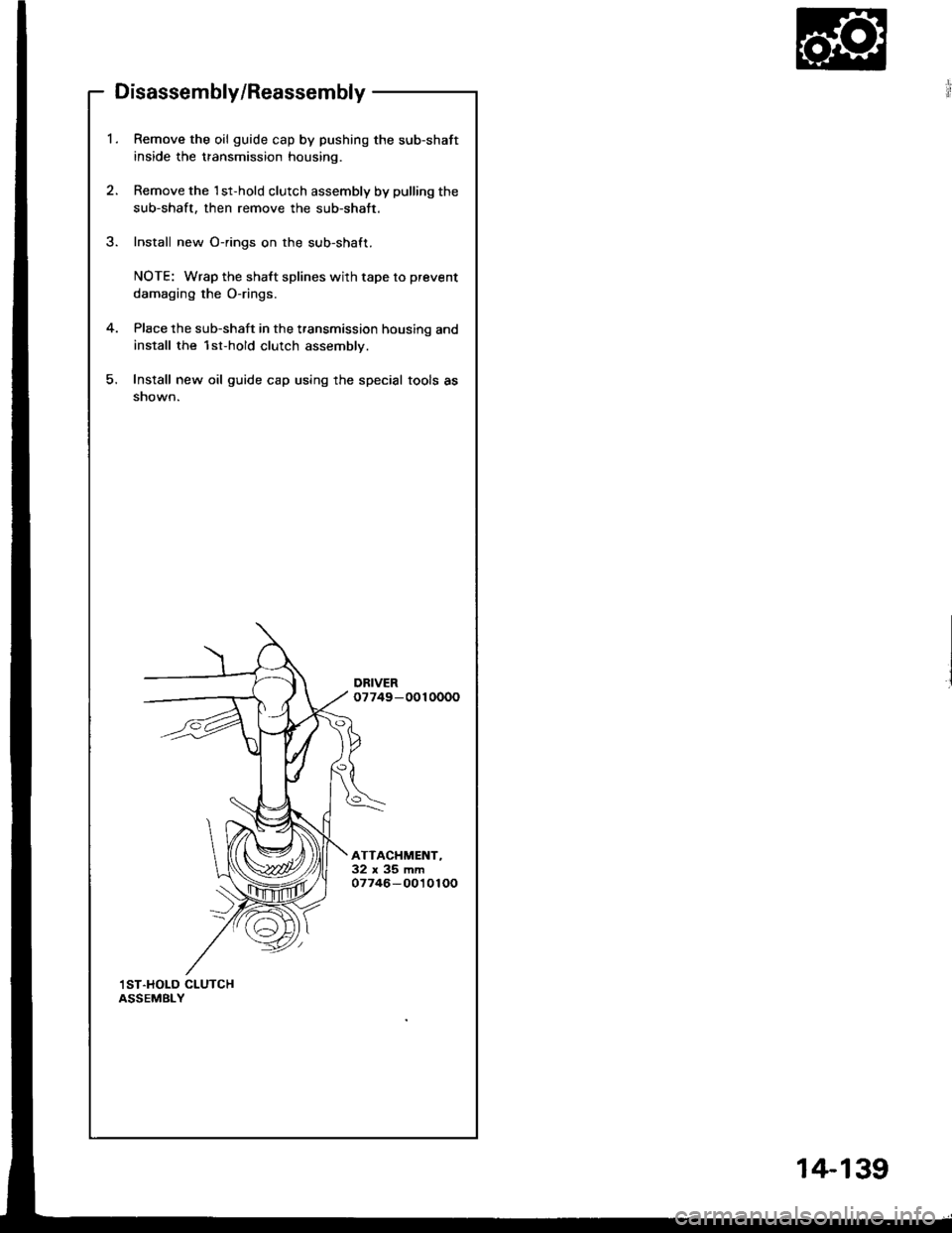

Disassembly/Reassembly

Remove the oil guide cap by pushing the sub-shaft

inside the transmission housing.

Remove the 1st-hold clutch assembly by pulling the

sub-shaft, then remove the sub-shatt.

Install new O-rings on the sub-shaft.

NOTE: Wrap the shaft splines with tape to prevent

damaging the O-rings.

Place the sub-shaft in the transmission housing and

install the 1st-hold clutch assembly.

Install new oil guide cap using the special tools as

snown.

DRIVER07749-0010000

ATTACHMENT-32x35mm07746-0010100

,I ST.HOLD CLUTCHASSEMBLY

14-1 39

Page 532 of 1413

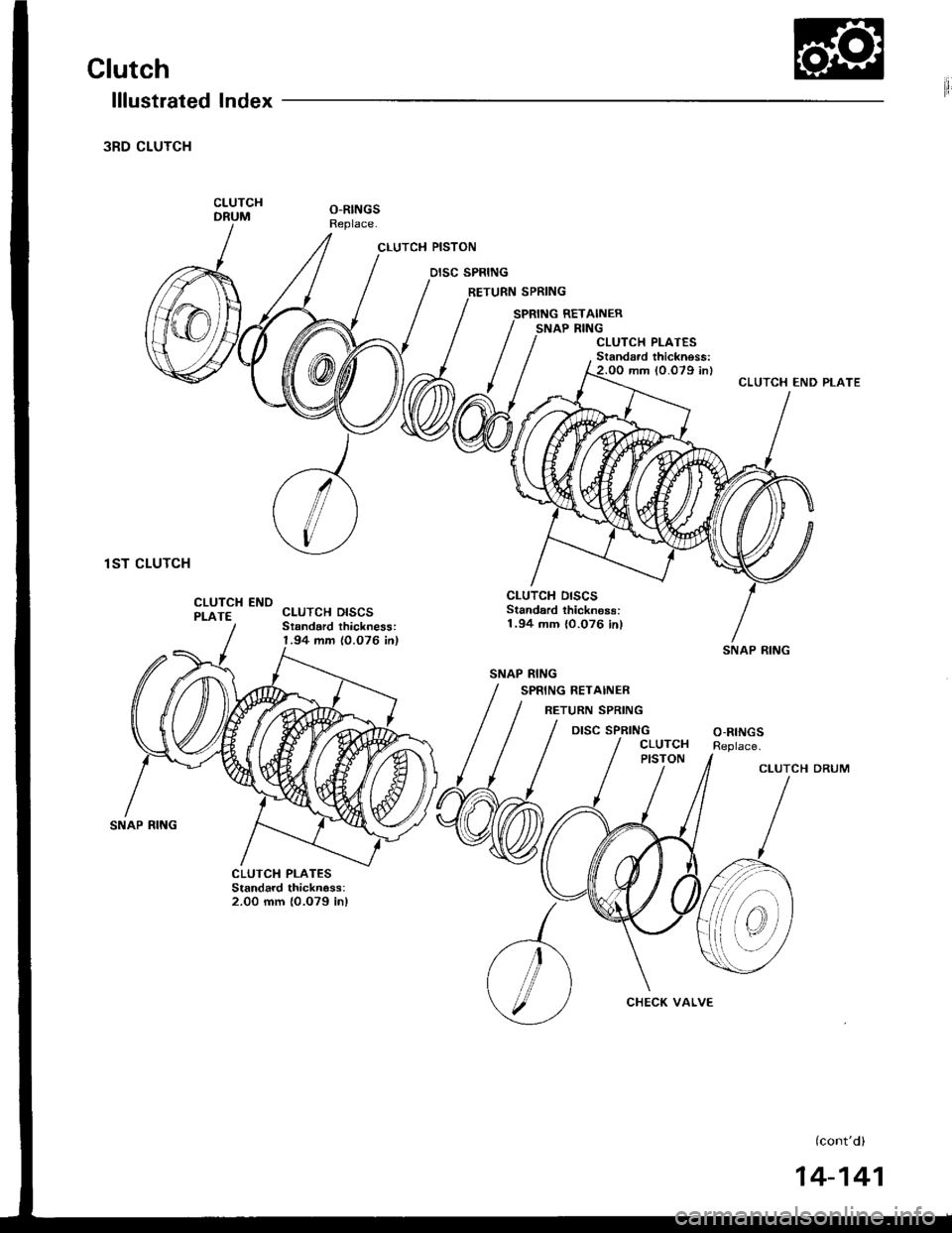

Clutch

lllustrated Index

3RD CLUTCH

CLUTCHDRUMO-RINGSReplace.

CLUTCH DISCSStsndard thickness:1.94 mm {0.076 in)

CLUTCH PISTON

DISC SPRING

RETURN SPRING

SPRING RETAINERSNAP RING

1ST CLUTCH

SNAP RING

CLUTCH ENDPLATE

O-RINGSReplace.

CLUTCH PLATESStandard thicknass:2.00 mm {0.079 in}

(cont'd)

SNAP RING

SNAP RING

CHECK VALVE

14-141

Page 533 of 1413

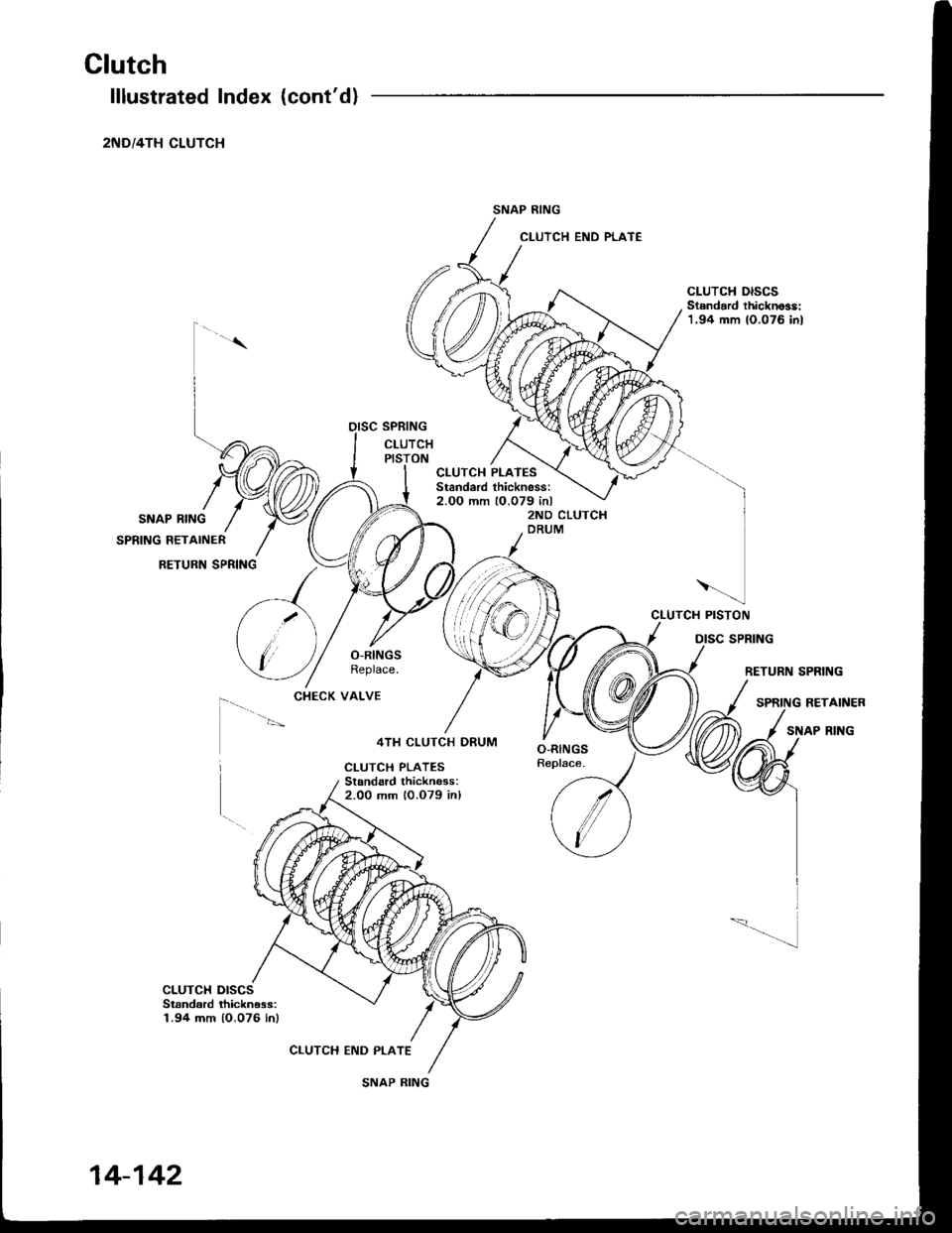

Clutch

lllustrated Index (cont'd)

2ND/4TH CLUTCH

SNAP RING

SPRING RETAINER

RETURN SPRING

CLUTCH END PLATE

4TH CLUTCH DRUM

CLUTCH PLATESStanda.d thickness:2.00 mm 10.079 in)

SNAP RING

CLUTCH DISCSStandard thickno3s:1.94 mm 10.076 in)

CLUTCH END PLATE

;;i;;; /

(/\

Y)

)

l

CLUTCH PISTON

CLUTCH PLATESStandard thickness:2.OO mm 10.079 inl

SPRING

RETURN SPRING

RETAINER

SNAP RING

CLUTCH DISCSStsndard ihickn€ss:1.94 mm 10.076 in)

CHECK VALVE

SNAP RING

14-142

Page 534 of 1413

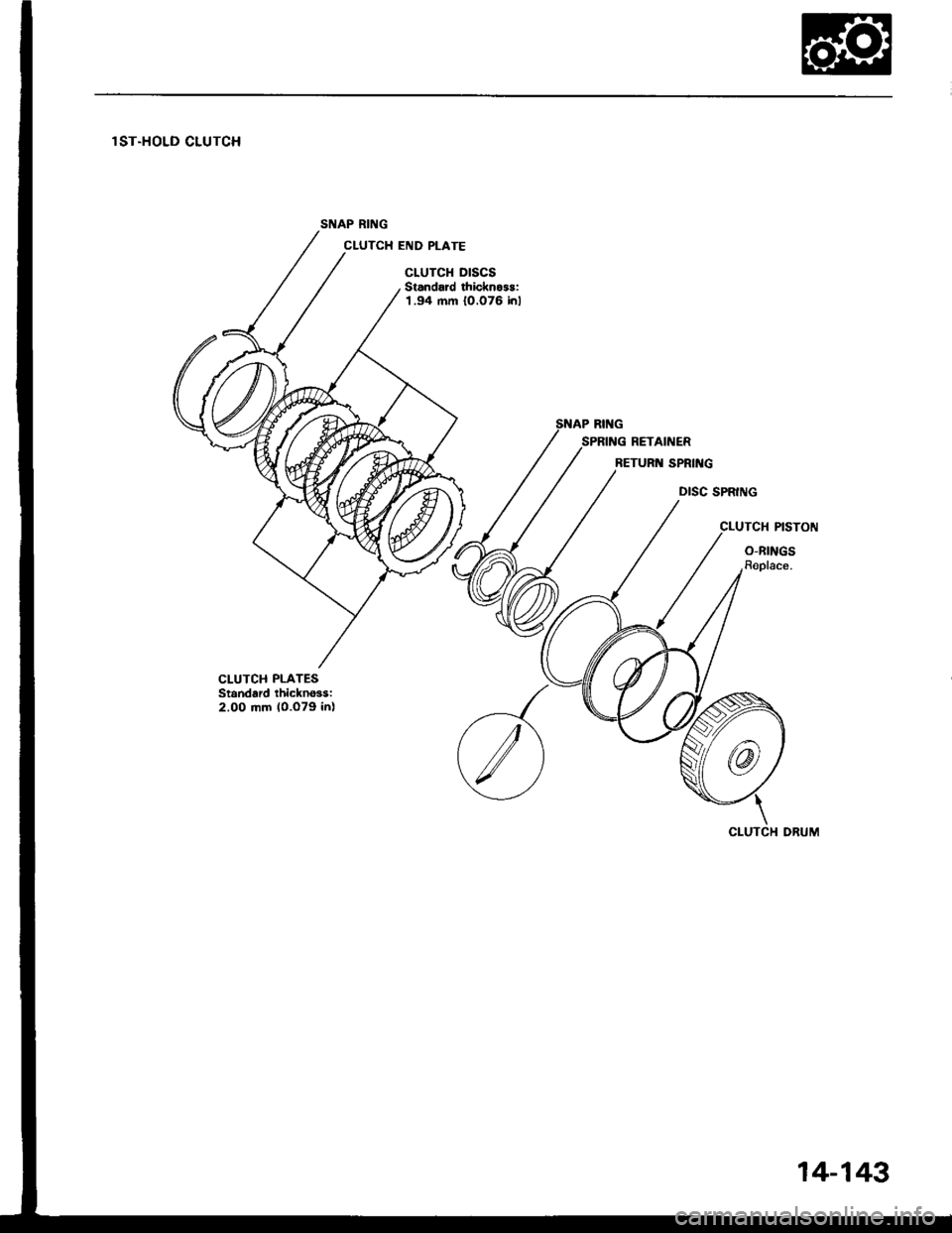

lST.HOLD CLUTCH

SNAP RING

CLUTCH END PLATE

CLUTCH DISCSStandard thicknoss:1.94 mm 10.076 inl

DISC SPRING

CLUTCH PISTON

O-RINGSRoplace.

CLUTCH PLATESStandard thickno3si2.00 mm (0.o79 in)

14-143

Page 535 of 1413

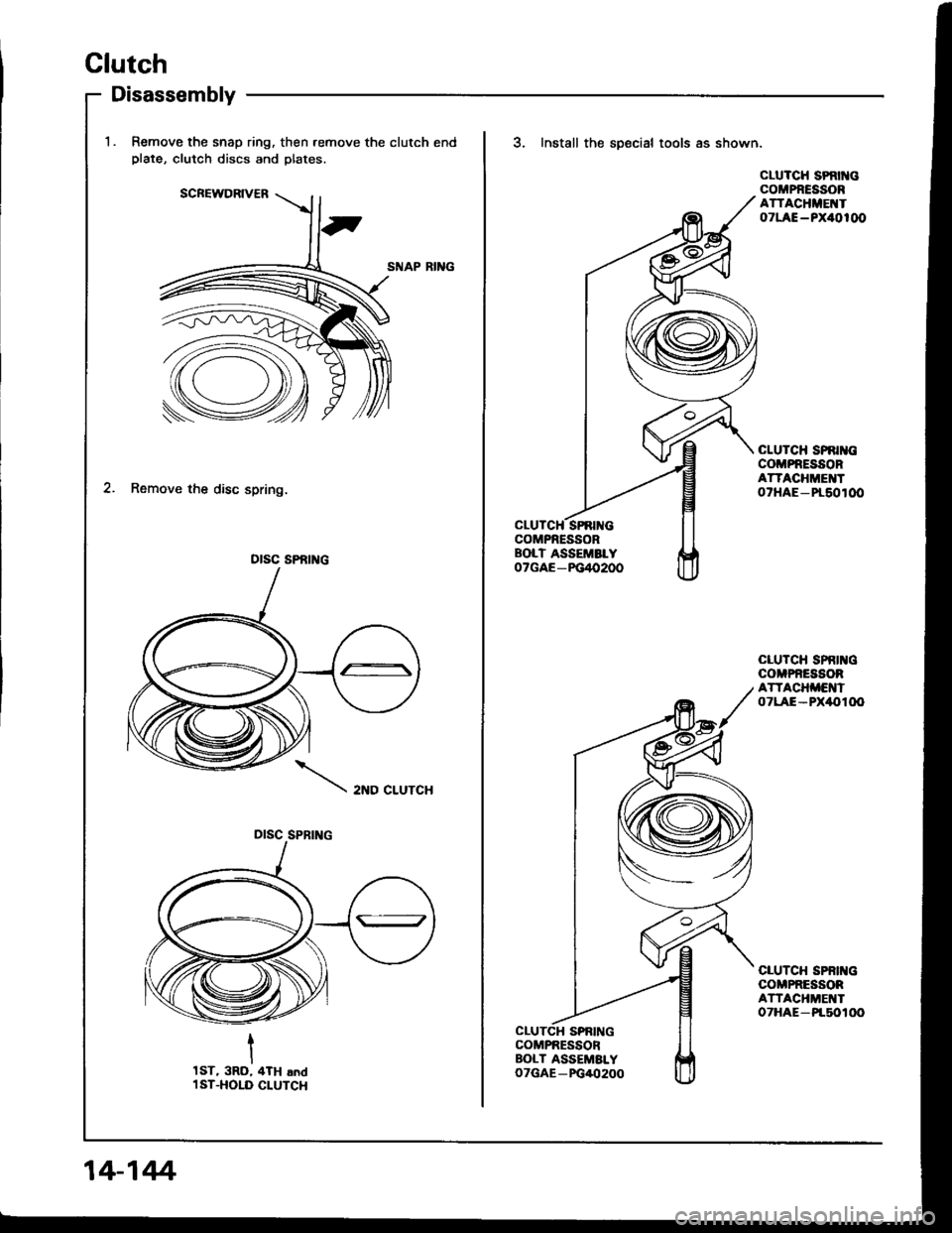

Disassembly

Clutch

Remove the snap ring. then.emove the clutch endplate, clutch discs and plates.

SNAP RII{G

2. Remove the disc spring.

2ND CLUTCH

otsc sPfit c

DISC SPBING

1ST, 3RD, 4TH .ndl ST.HOLD CLUTCH

14-144.

SPNING

3. Install the sDecial tools as shown.

CLUTCH SPRIT{GCOMPRESSORATTACHME ToTLAE-PX40100

cLuTcH spnr cCOMPNESSORATTACHME ToTHAE-Pr60tOO

CLUTCH SPRII{CCOMPNESSORATTACHi'ENTOTLAE-PX,l{,TOO

CLUTCH SPBII{GCOMPRESSORATTACHMEI{ToTHAE-Pt50100