clutch HONDA INTEGRA 1994 4.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 442 of 1413

![HONDA INTEGRA 1994 4.G Manual Online Symptom-to-Component Chart

Electrical System

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@] indicaror

lightPossible CauseSymptomRefer to

page

Bl HONDA INTEGRA 1994 4.G Manual Online Symptom-to-Component Chart

Electrical System

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@] indicaror

lightPossible CauseSymptomRefer to

page

Bl](/img/13/6067/w960_6067-441.png)

Symptom-to-Component Chart

Electrical System

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@] indicaror

lightPossible CauseSymptomRefer to

page

BlinksDisconnected lock-up control solenoidvalve A connector

Short or open in lock-up control sole-noid valve A wire

Faulty lock-up control solenoid valve A

Lock-up clutch does not

engage.

Lock-up clutch does not

disengage.

Unstable idle speed.

14-52

BlinksDisconnected lock-up control solenoidvalve B connector

Short or open in lock-up control sole-noid valve B wire

Faulty lock-up cont.ol solenoid valve B

. Lock-up clutch does not

enga9e.

14-54

Blinks or

OFF

Disconnected throttle position (Tp)

sensor connector

Short or open in TP sensor wireFaully TP sensor

. Lock-up clutch does not

engage.14-56

4BlinksDisconnected vehicle speed sensor(VSS) connector

Short or open in VSS wire

Faulty VSS

. Lock-up clutch does not

engage.'t 4-57

Blinks. Short in A/T gear position switch wire. Faulty A/T gear position switch

. Fails to shift other than

2nde4th gears.. Lock-up clutch does not

engage.

14-58

OFFDisconnected A/T gear position switch

connector

Open in A/T gear position switch wireFaulty A/T gear position switch

Fails to shift other than

2nd-4th gears.

Lock-up clutch does not

en98ge.

Lock-up clutch engages

and disengages alter-

nately.

14-60

7BlinksDisconnected shift control solenoidvalve A connector

Short or open in shitt control solenoidvalve A wire

Faulty shift control solenoid valve A

. Fails to shift (between

1st-4th, 2nd-4th or

2nd-3rd gears only).. Fails to shift (stuck in

4th gear).

14-62

8BlinksDisconnected shitt control solenoid

valve B connector

Shon or open in shift control solenoidvalve B wi.e

Faulty shift control solenoid valve B

. Fails to shiJt (stuck in

lst or 4th gears).'t 4-64

aBlinksDisconnected countershatt speed sen-sor connector

Short or open in the countershaft

speed sensor wire

Faulty countershaft speed sensor

. Lock-up clutch does not

engage_

14-50

Page 443 of 1413

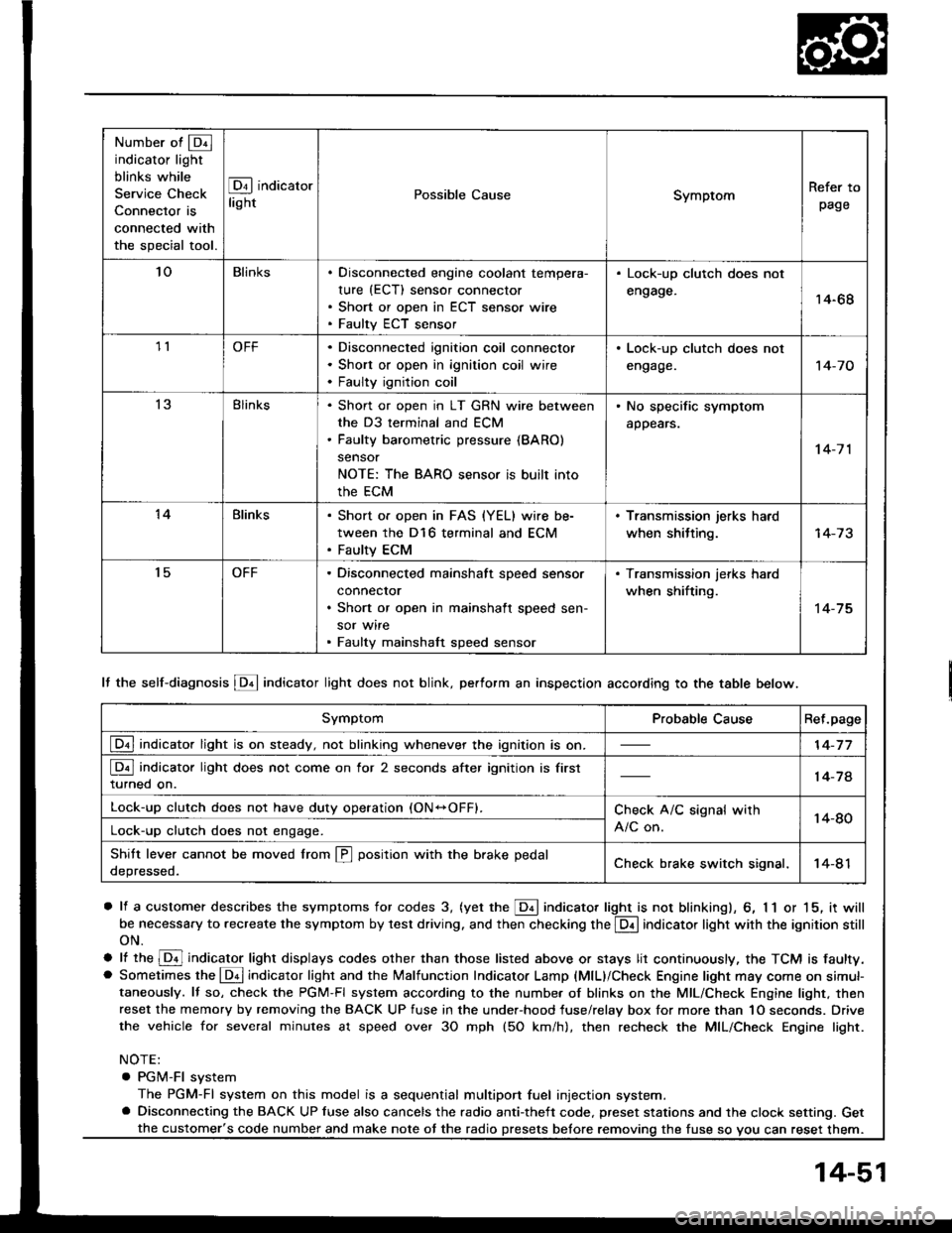

Number of @indicator light

blinks while

Service Check

Connector is

connected with

the special tool.

@ indicator

lightPossible CauseSymptomRefer to

page

'loBlinksDisconnected engine coolant tempera-

rure (ECT) sensor connector

Short or open in ECT sensor wire

Faulty ECT sensor

Lock-up clutch does not

engage.14-68

1lOFFDisconnected ignition coil connector

Short or open in ignition coil wire

Faulty ignition coil

. Lock-up clutch does not

engage.'t 4-7 0

13Blinks. Shon or open in LT GRN wire between

the D3 terminal and ECM. Faulty barometric pressure {BARO)

sensor

NOTE: The BARO sensor is built into

the ECM

. No specific symptom

appears.

14-7 1

14Blinks. Short of open in FAS {YEL} wire be-

tween the D16 terminal and ECM. Faulty ECM

. Transmission jerks hard

when shitting.

't5OFFDisconnected mainshaft speed sensor

connecror

Short or open in mainshaft speed sen-

sor wire

Faulty mainshaft speed sensor

. Transmission jerks hard

when shifting.

14-75

SymptomProbable CauseRet.page

LQ! indicator light is on steady, not blinking whenever the ignition is on.14-77

[Q3] indicator light does not come on for 2 seconds after ignition is first

turned on.14-78

Lock-up clutch does not have duty operation (ON-OFFI.Check A/C signal with

A/C on.14-80Lock-up clutch does not engage.

Shitt leve. cannot be moved lrom @ position with the brake pedal

depressed.Check brake switch signal,14-41

It the self-diagnosis LQ4 indicator light does not blink, perform an inspection according to the table below.

a lf a customer describes the symptoms for codes 3, (yet the LQ! indicator light is not blinkingl, 6, 1 1 or 15, it will

be necessa.y to recreate the symptom by test driving. and then checking the @ indicator light with the ignition still

oN.

e lt ttre @ indicator light displays codes olher than those listed above or stays lit continuously, the TCM is faulty.. Sometimes the Lqd indicator light and the Malfunction Indicator Lamp (MlL)/Check Engine light may come on simul-taneously. lf so, check the PGM-Fl system according to the numbe. of blinks on the MIL/Check Engine light. thenreset the memory by removing the BACK UP fuse in the unde.-hood fuse/relay box for more than 1O seconds. Drive

the vehicle for several minutes at speed over 30 mph (5O km/h), then recheck the MIL/Check Engine light.

NOTE:

. PGM-FI system

The PGM-Fl system on this model is a sequential multiport fuel injection system.a Disconnecting the BACK UP luse also cancels the radio anti-theft code. preset stations and the clock setting. Get

the fuse so vou can reset them.the customer's code number and make note ot the radio

14-51

Page 472 of 1413

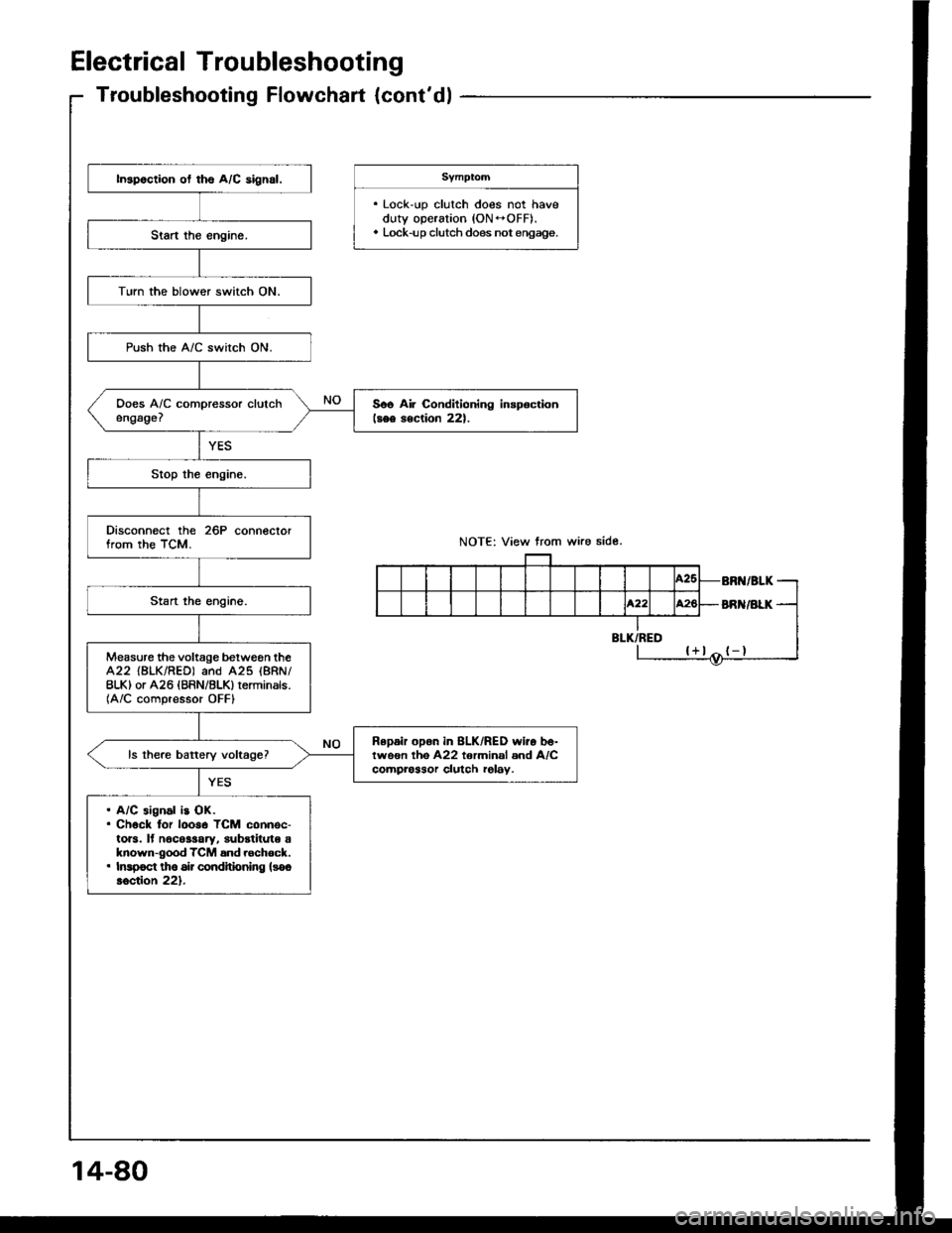

Electrical Troubleshooting

Troubleshooting Flowchart {cont'dl

. Lock-up clutch does not haveduty operation (ON -OFF).. Lock-up clutch does not engage.

In3poction ol ths A/C aign6l.

TLrrn the blower switch ON.

Push the A/C switch ON.

Soe Air Condilioning inspoctionlsee rection 221.

Disconnect the 26P conneclorfrom the TCM.

Measure the voltage between theA22 {BLK/RED) and A25 (8RN/

BLKI or A26 IBRN/BLK) terminals.(A/C compressor OFFI

Repair opon in 8LK/RED wiio b6-twoon lho A22 torminal and A/Ccomprossor clulch rel6y.

. A/C aignal ls OK.. Chock lor looso TCM connec-toB. lf n6co$ary, substitute aknown-good TCM and rschock.. Inrpoct tho 6ir condhioning lsooloction 221.

BR /ALK

Page 478 of 1413

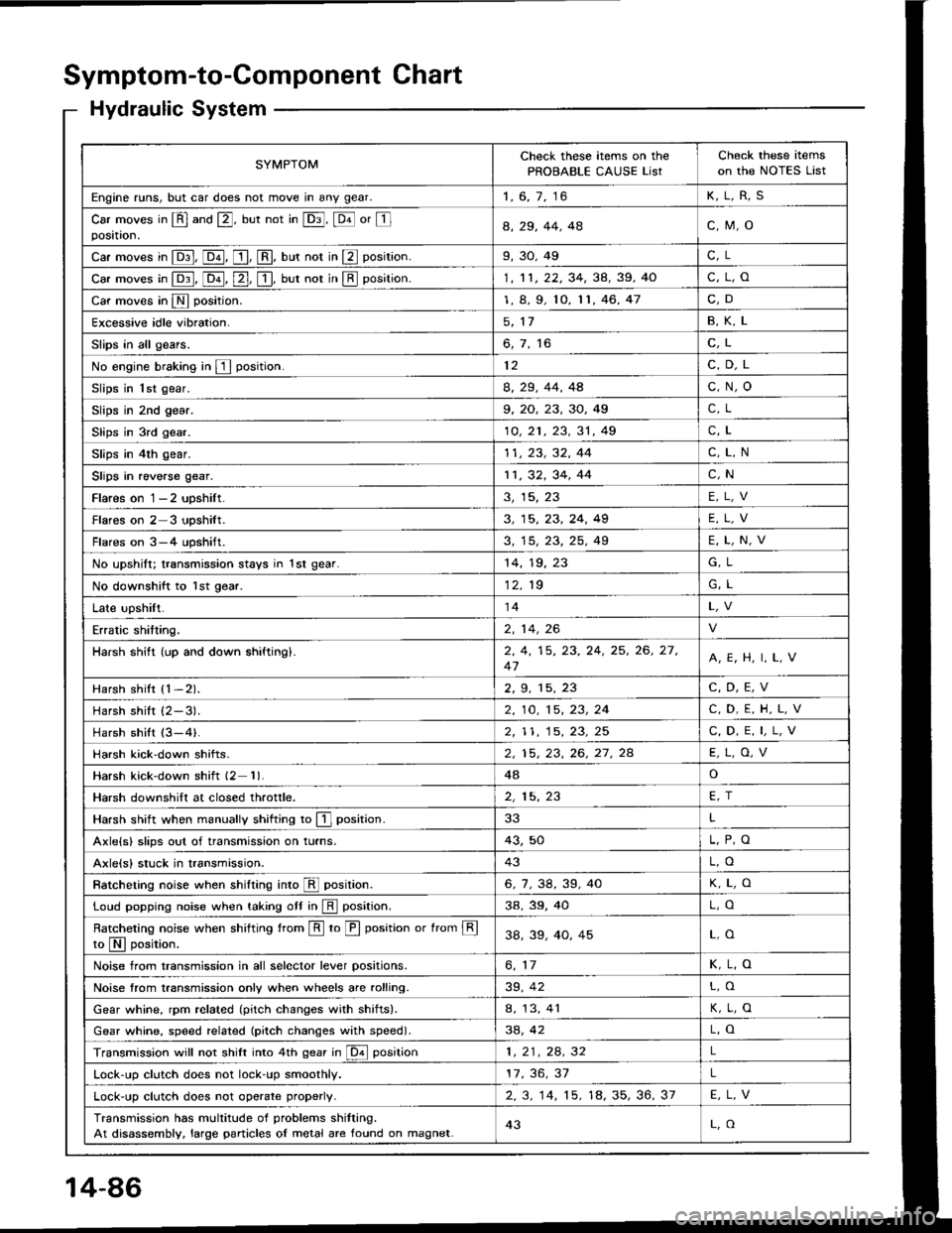

Symptom-to-Component Chart

Hydraulic System

SYMPTOMCheck these items on the

PROBABLE CAUSE ListCheck these items

on the NOTES List

Engine runs, but car does not move in any gear.1, 6, 7, 16K,L,R,S

Car moves in @ and @, but not in @, @ or Iposataon.a, 29, 44. 4ac,M,o

Car moves in E, @, [, @, uut not in E position.9,30,49C, L

car moves in p:1, [o-il, [2-], [!, uut not in E position.1, 11, 22, 34, 38, 39, 40c,L,o

Car moves in N position.1, 8, 9, 10, 11,46,47C,D

Excessive idle vibration.5, 1'1B,K,L

Slips in all gears.6, 7, 16C,L

No engine braking in E position.12C,D,L

Slips in 1st gear.8, 29, 44, 4Ac,N,o

Slips in 2nd gear.9, 20, 23, 30, 49C, L

Slips in 3rd gear.10, 21 , 23, 31 , 49C,L

Slips in 4th gear.11, 23, 32, 44C,L,N

Slips in reverse gear.11,32,34,44C,N

Flares on 1-2 upshilt.3, 15, 23E,L,V

Flareson2 3 upshilt.3, 15, 23, 24, 49E,L,V

Flares on 3-4 upshift.3, 15, 23, 25, 49E,L,N,V

No upshift; transmission stays in 1st gear.14,19,G, L

No downshift to lst gear.12. 19G, L

Late upshift.14

Erratic shitting.2, 14,26

Harsh shift (up and down shiftingl.2, 4, 15, 23, 24, 25, 26, 27,

47A,E, H, I, L,V

Harsh shitt {1-2).2, 9. 15, 23C,D,E,V

Harshshilt (2-3).2, 10, 15, 23, 24C,D,E,H,L,V

Harsh shift (3-4).2,| 1, 15, 23, 25C, D, E, I,L,V

Harsh kick'down shifts.2, 15, 23, 26, 27. 2AE,L,O,V

Harsh kick-down shift 12 1)48o

Harsh downshift at closed throttle.2, 15, 23FT

Harsh shift when manually shifting to E] position.33L

Axle{s} slips out of transmission on turns.43,50

Axlels) stuck in transmission.43L,O

Ratcheting noise when shifting inro E position.6,7,38,39,40K,L,O

Loud popping noise when taking ott in E position.3a,39,40L,O

Ratcheting noise when shifting from E to E position or from Eto N I oosition.38,33,40,45L,O

Noise from transmission in all selector lever positions.6, 11K,L,O

Noise trom transmission only when wheels are rolling.39, 42L,O

Gear whine, rpm related (pitch changes with shitts).a, 13, 41K,L,O

Gear whine, speed rel6ted (pitch changes with speed).38, 42L,O

Transmission will not shift into 4th gear in @ position1,21,24.32L

Lock-up clutch does not lock-up smoothly.17, 36, 37L

Lock-up clutch does not operate properlV.2.3. 14, 15. 18, 35, 36, 37E,L,V

Transmission has multitude of problems shitting.

At disassembly, large particles oI metal are found on magnet.43L,O

14-86

Page 479 of 1413

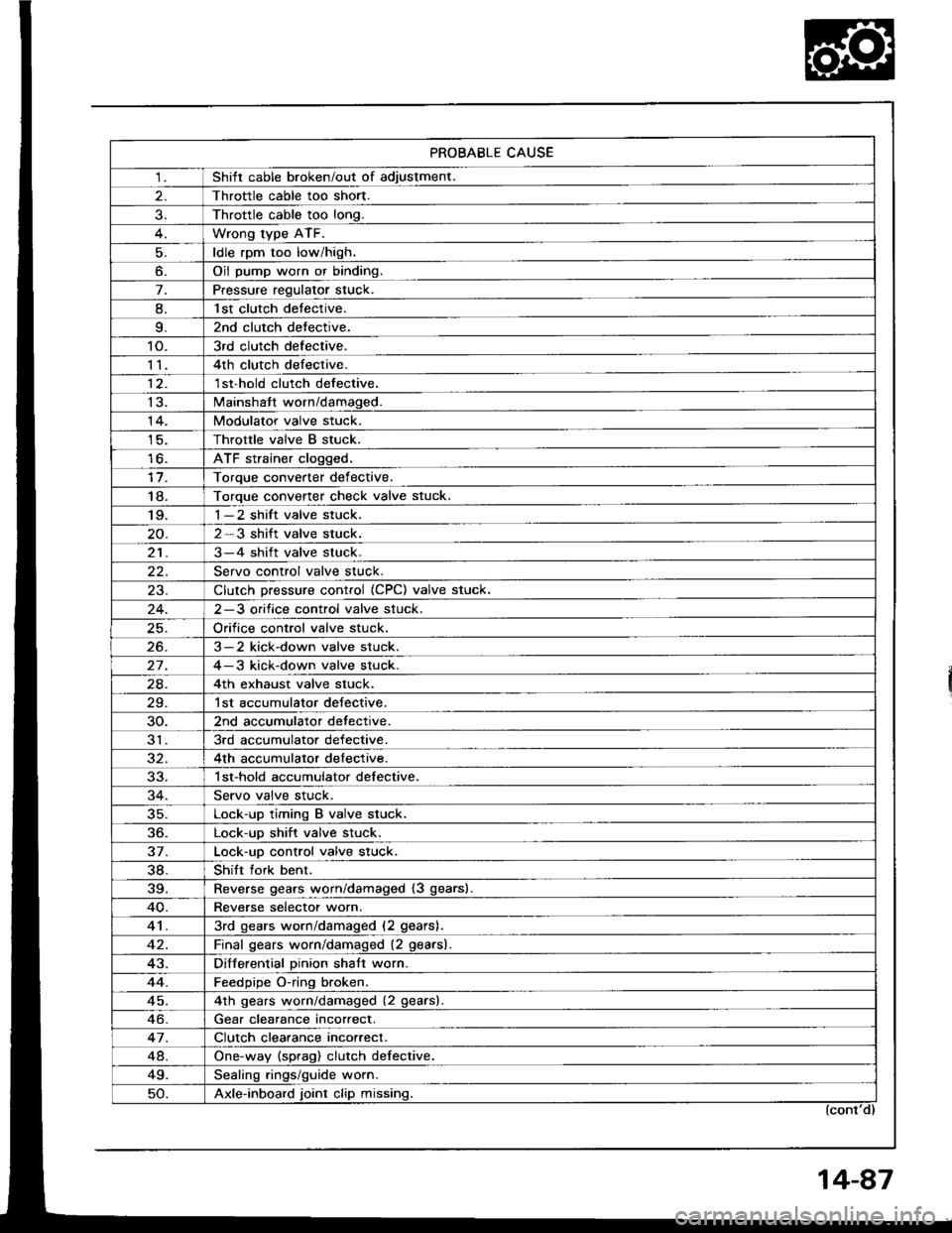

PROBABLE CAUSE

1Shitt cable broken/out of adiustment.

Throttle cable too short.

Throttle cable too long.

Wrong type ATF.

ldle rpm too low/high.

o.Oil pump worn or binding.

7.Pressure regulator stuck.

8.l st clutch detective.

9.2nd clutch detective.

10.3rd clutch defective.

114th clutch defective.

12.1 st'hold clutch defective.

13.Mainshatt worn/damaged.

14.Modulator valve stuck.

Throttle valve B stuck.

lo.ATF strainer clogged.

Toroue converter def ective.

18.Torque converter check valve stuck.'I 9.1-2 shift valve stuck.

2-3 shift valve stuck.

213-4 shift valve stuck.

Servo control valve stuck.

23.Clutch Dressure control (CPC) valve stuck.

2-3 orifice control valve stuck.

Orifice control valve stuck.

26.3-2 kick-down valve stuck.

27.4-3 kick-down valve stuck.

24.4th exhaust valve stuck.

29.1st accumulator detective.

30.2nd accumulator detective.

313rd accumulator defective.

4th accumulator defective.

1 st-hold accumulator defective.

Servo valve stuck.

35.Lock-up timing B valve stuck.

36.Lock-up shift valve stuck.

37.Lock-uo control valve stuck.

38.Shift fork benr.

39.Reverse gears worn/damaged (3 gears).

40.Reverse selectot worn.

413rd gears worn/damaged (2 gears).

Final qears worn/damaged (2 gearsl.

43.Differential Dinion shatt worn.

44.Feedpipe O-ring broken.

45.4th qears worn/damaged (2 gearsl

Gear clearance incorrect.

47.Clutch clearance incorrect.

48.One-way (sprag) clutch defective.

49.Sealinq rings/quide worn.

50.Axle-inboard joint clip missing.

Page 480 of 1413

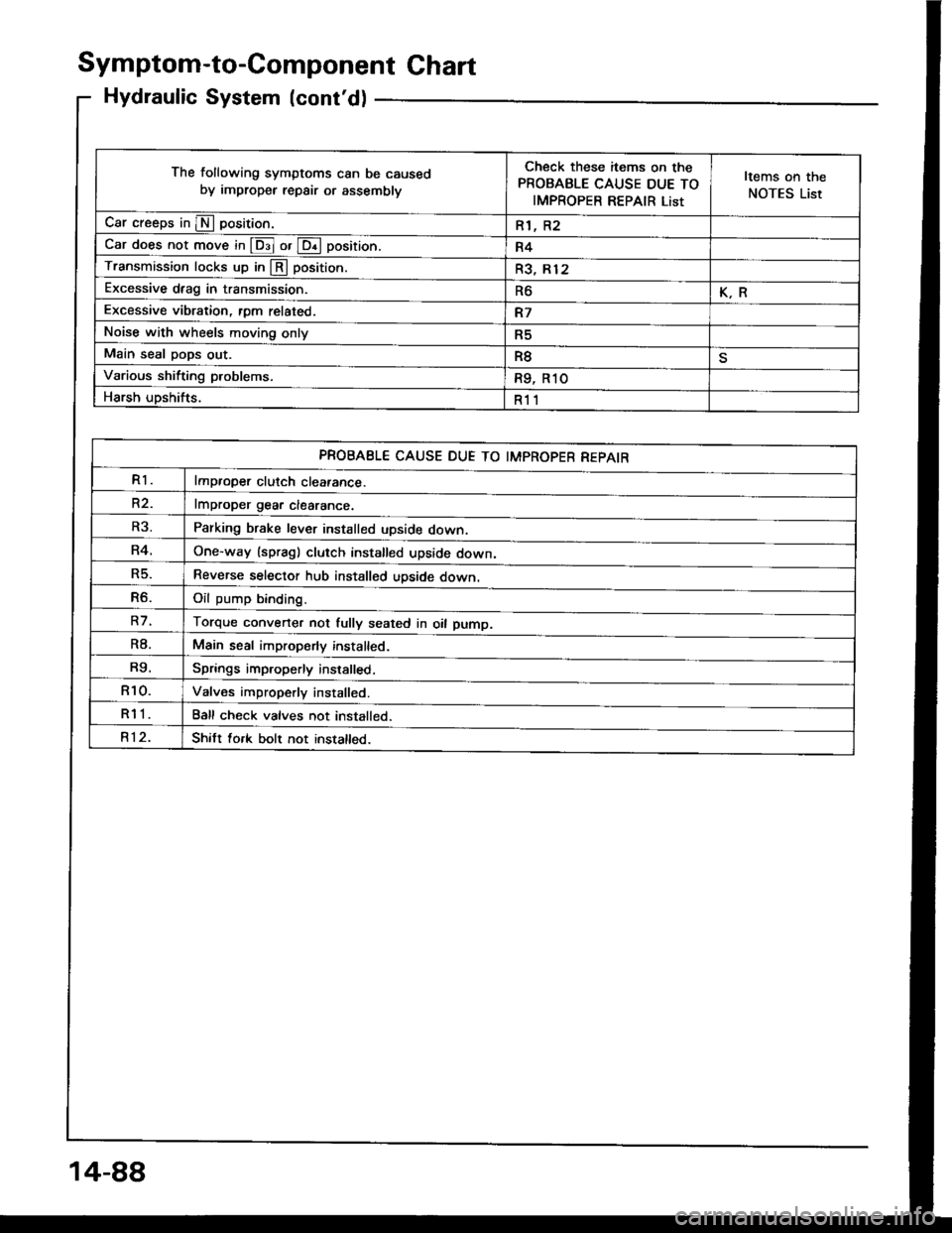

Symptom-to-Component Ghart

Hydraulic System (cont'd)

The following symptoms can be caused

by improper repair or assemblv

Check these items on the

PROBABLE CAUSE DUE TO

IMPROPER REPAIR List

Items on the

NOTES List

Car creeps in E position.R1, R2

Car does not move in @ or @ position.R4

Transmission locks up in @ position.R3, Rl2

Excessive drag in transmission.R6K.R

Excessive vibration, rom related.R7

Noise with wheels moving onlyR5

Main seal pops out.R8

Various shifting problems.R9, R1O

Harsh upshifts.R11

PROBABLE CAUSE DUE TO IMPROPER REPAIR

R1lmproper clutch cleatance.

R2.lmDroDer qear clearance.

Parking brake lever installed upside down.

One-way (spragl clutch installed upside down,

Reverse selector hub installed upside down.

Oil oumo bindind

Torque converter not fully seated in oil pump.

Main seal improperly installed.

Springs improperly installed,

Valves improperly installed.

Ball check valves not installed.

Shitt fork bolt not installed.

R3.

R4.

R5.

R6.

R7.

R8.

R9.

R10.

R11

R12.

14-88

Page 481 of 1413

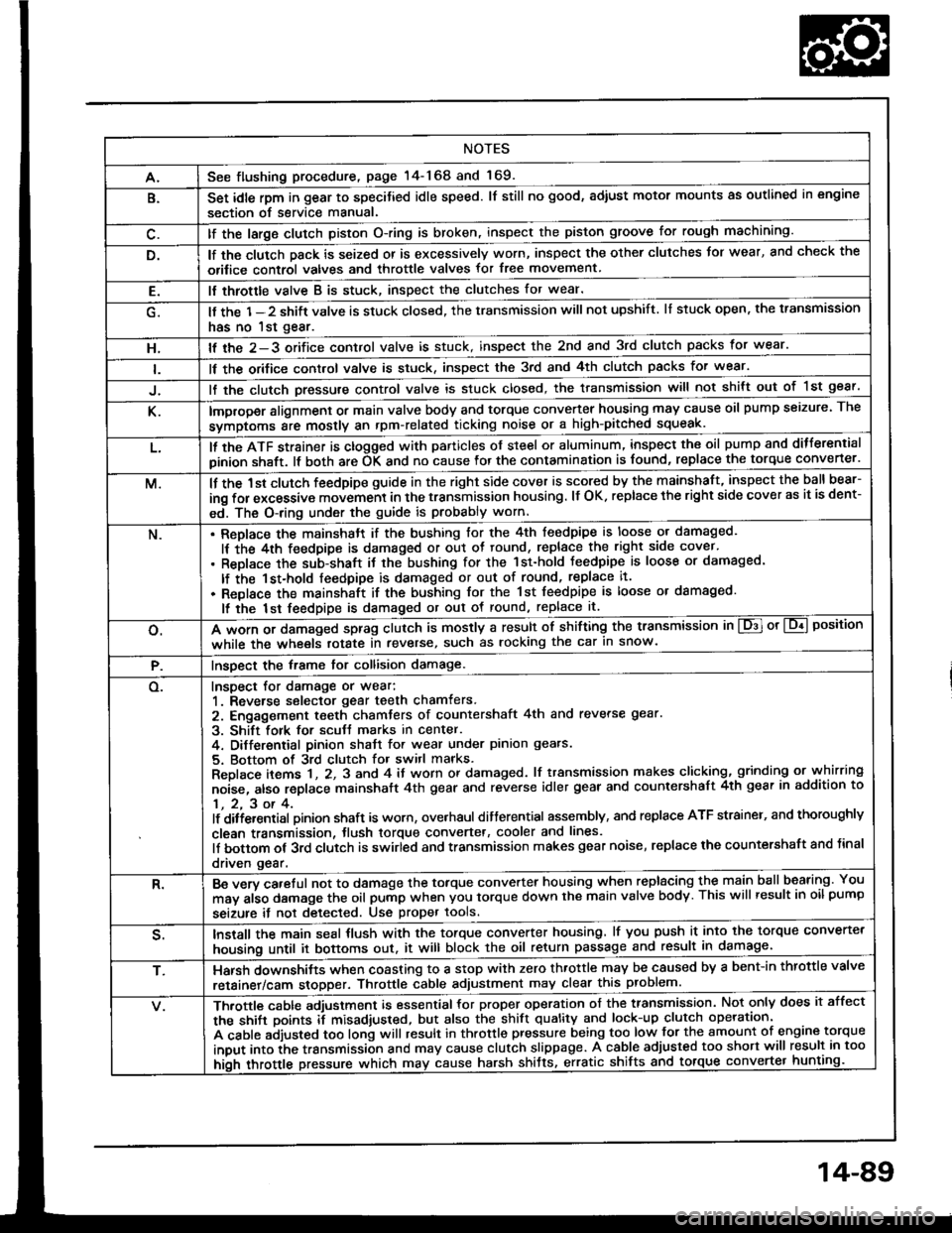

NOTES

A.See flushing procedure, page l4-168 and 169.

B.Set idle rpm in gear to specitied idle speed. lf still no good, adiust motor mounts as outlined in engine

section of service manual.

lf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

lf the clutch pack is seized or is excessively worn, inspect the other clutches Jor wear, and check the

orifice control valves and throttle valves for free movement.

E.It throttle valve B is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed, the transmission will not upshift. lI stuck open, the transmission

has no lst gear.

H.lf the 2-3 orifice control valve is stuck, inspect the 2nd and 3rd clutch packs for wear.

ll the orifice cont.ol valve is stuck, inspect the 3rd and 4th clutch packs for wear.

lf the clutch Dressure control valve is stuck closed, the transmission will not shilt out of 1st gear.

K.improper alignment or main valve body and torque converter housing may cause oil pump seizure. The

symptoms ale mostly an rpm-related ticking noise or a high-pitched squeak.

L.ll the ATF strainer is ctogged with panicles of steel or aluminum, inspect the oil pump and ditferential

pinion shaft. lt both are OK and no cause lor the contamination is found, replace the torque converter.

M.lf the 1st clutch feedpipe guide in the right side cover is scored by the mainshaft, inspect the ball bear-

ing for excessive movement in the transmission housing. lf OK. replace the right side cover as it is dent-

ed. The O-ring under the guide is probably worn.

N.ReDlace the mainshstt if the bushing for the 4th feedpipe is loose or damaged.

It the 4th feedpipe is damaged or out ot tound, replace the right side cover'

Replace the subjshaft it thtbushing for the 1st-hold Jeedpipe is loose or damaged.

lf the 1st-hold feedpipe is damaged or out of round, replace it.

Replace the mainshaft if the bushing lor the 1st feedpipe is loose or damaged.

lf the lst feedpipe is damaged or out ot round, replace it.

o.A *o- r, da."s"d "p-g clutch is mostly a result of shifting the transmission in El or Lq! position

while the wheels rotate in reverse, such as rocking the car in snow.

P.InsDect the frame for collision damage.

o.Inspect for damage or wear:

1. Reverse selector gear teeth chamfers.

2. Engagement teeth chamters of countershaft 4th and reverse gear.

3. Shift fork for scutt marks in center.

4. Differential Dinion shaJt for wear under pinion gears.

5. Bottom of 3rd clutch for switl marks.

Replace items 1 , 2, 3 and 4 it worn or damaged. lf transmission makes clicking, grinding or.whirring

noise, atso replace mainshaft 4th gear and reverse idler gear and countershaft 4th gear in addition to

1,2,3ot4.lf ditiersntial Dinion shaft is worn, overhaul differential assembly, and replace ATF strainel, and thoroughly

clean transmission, tlush torque convertet, cooler and lines.

lf bottom of 3rd clutch is swirled and transmission makes gear noise, replace the countershaft and tinal

driven gear.

R.Be wry careful not to dsmage the torque converter housing when replacing the main ballbearing. You

may al;o damage the oil pump when you torque down the main valve body. This will result in oil pump

seizure it not detected. Use proper tools.

qInstall the main seal tlush with the torque converter housing, lf you push it into the torque converter

housing until it bottoms out. it will block the oil return passage and result in damage.

T,Harsh do\/vnshiJt"\./l,'hen coasting to a stop with zero th.ottle may be caused by a bent-in throttle valve

retainer/cam stopper. Throttle cable adjustment may clear this problem.

ifuitle cable adjustment is essential for proper operation of the transmission. Not only does it affect

the shift points if misad,usted, but also the shift quality and lock-up clutch operation'

A cable adjusted too long will result in throttle pressure being too low for the amount of engine torque

input into ihe trsnsmission and may cause clutch slippage. A cable adjusted too short will result in too

hi;h throttle pressure which may cause harsh shitts, erratic shrfts and torque con

14-89

Page 482 of 1413

![HONDA INTEGRA 1994 4.G Manual Online Road Test

NOTE: Warm up the engine to operating temperature (the cooling fan comes on).

1 Apply parking brake and block th€ wheels. Start the engine, them move the selector lever to E] position whil HONDA INTEGRA 1994 4.G Manual Online Road Test

NOTE: Warm up the engine to operating temperature (the cooling fan comes on).

1 Apply parking brake and block th€ wheels. Start the engine, them move the selector lever to E] position whil](/img/13/6067/w960_6067-481.png)

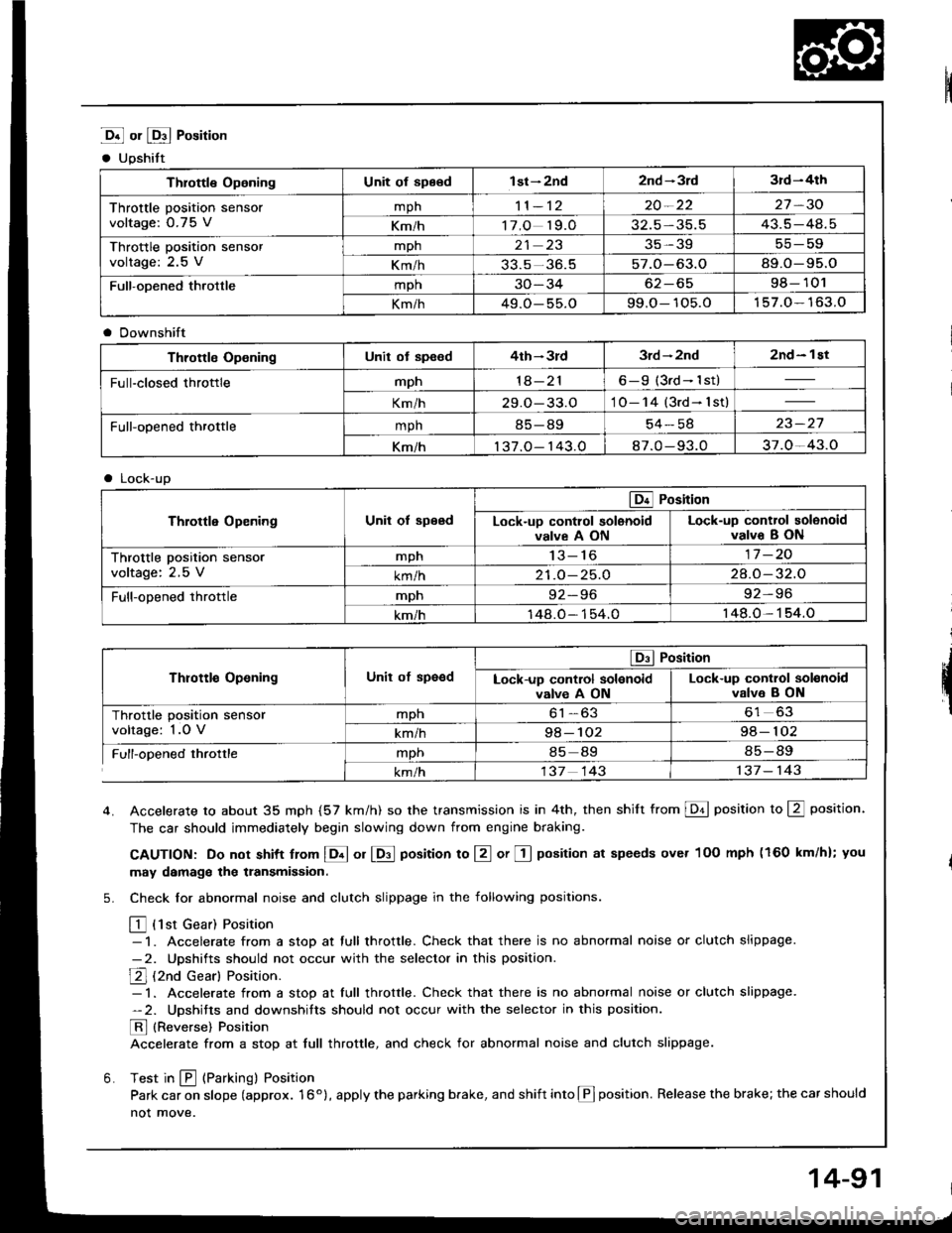

Road Test

NOTE: Warm up the engine to operating temperature (the cooling fan comes on).

1 Apply parking brake and block th€ wheels. Start the engine, them move the selector lever to E] position whiledepressing the brake pedal. Depress the accelerator pedal, and release it suddenly. The engine should not stall,

2. Repeat same test in @ position.

3. Shift the selecto. lever to E position, and chock that the shift points occur at approximate speeds shown. Alsocheck fof abnormal noise and clutch slippage.

NOTE: Throttle position sensor voltage fepresents the throttle opening.

- 1 . Connect the Test Harness between the ECM and connector (see section 1 1).-2. Setthe digital multimeter to check voltage between D1 1{+)terminal and D22 { - ) terminal for the throttle Dosi-tion sensor.

TESTHARI{ESSOTLAJ_PT3OlOA

DIGITAL MULTIMETERCommarcially avsilablo o.KS-AHM-32-OO3

011 {+oooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooooo

14-90

Page 483 of 1413

Throftle OpeningUnit of spe6dl st- 2nd2nd-3rd3rd-4th

Throttle position sensorvoltage: O.7 5 V

mph20-2227,30

Km/h17,O 19.O32.5 - 35.543.5-48.5

Throttle position sensorvoltage: 2.5 V

mpn

Km/h33.5 - 36.557.O-63.O89.O-95.O

Full-opened throttlemph30- 3462-6598- 101

Km/h49.O- 55.O99.O- 105.O1 57.O- 163.O

@ or @ Position

. Upshitt

Downshift

LOCK-Up

4. Accelerate to about 35 mph {57 km/h) so the transmission is in 4th, then shift from @ Oosition to E position.

The car should immediately begin slowing down from engine braking.

CAUTION: Do not shift from @ or @ position to @ of E position at speeds over 1OO mph (160 km/h); you

may damage the tlansmission,

5. Check lor abnormal noise and clutch slippage in the following positions.

E (1st Gear) Position- 1 . Accelerate from a stop at full throttle. Check that there is no abno.mal noise or clutch slippage.

-2. Upshifts should not occur with the selector in this position

E (2nd cear) Position.- 1 . Accelerate from a stop at full throttle. Check that there is no abnormal noise or clutch slippage.-2. Upshitts and downshitts should not occur with the selector in this position.

E {Reverse) Position

Accelerate from a stop at full throttle, and check for abnormal noise and clutch slippage.

6. Test in E {Parking) Position

Park car on slope (approx. 1 6o ), apply the parking brake, and shift into LE position. Release the brake; the car should

not move.

i

Throttle Op€ningUnit ot speed4th- 3rd3rd - 2nd2nd- l Et

Full-closed throttlemph1a-216-g (3rd- 1st)

Km/h29.O-33.O1O- 14 (3rd- lst)

Full-opened throttlemph85-8954- 5823-27

Km/h1 37.O- 143.08 7.0 - 93.037.0-43.O

Throttle OpeningUnit of speed

@ Position

Lock-uo control solenoidvalve A ON

Lock-up control solenoidvalve B ON

Throttle position sensorvoltage: 2,5 V

mpntJ- to17 -20

km/h21.O- 25.O2A.O-32.O

Full-opened throttlempn92-9692-96

km/h148.O - 1 54.0r 48.0,1 54.O

Throttlo OpeningUnit of sp6edE Position

Lock-up control solenoidvalve A ON

Lock-up control sol€noidvalv6 B ON

Throttle position sensorvoltage: 1.O Vmphb|-oJ61 63

kmih98- 10298- 102

Full-opened throttlemph85 8985-89

km/h137 143137 - 143

14-91

Page 484 of 1413

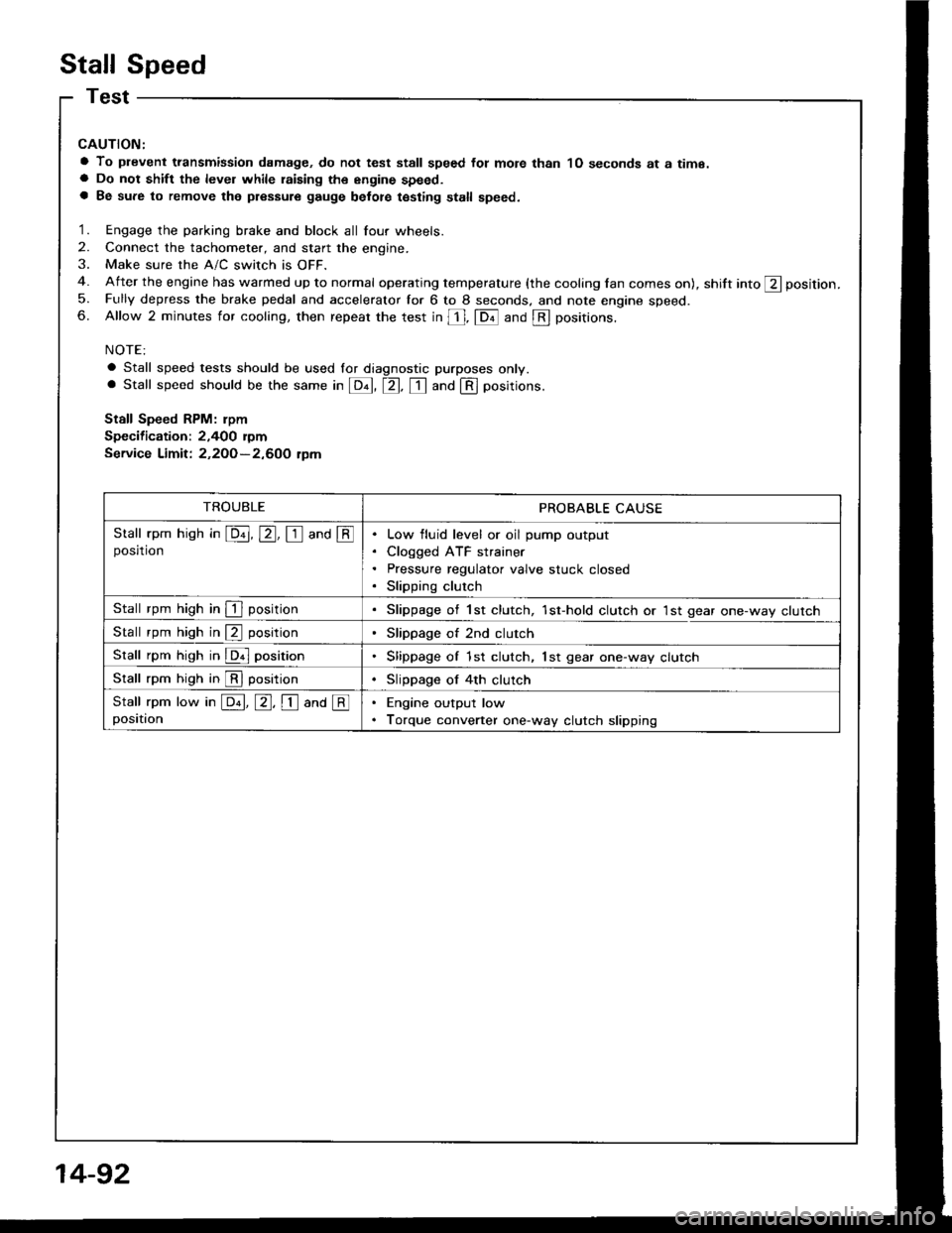

Stall Speed

CAUTION:

a To plevent transmission damage, do not test stall speed fot mote than 1O seconds at a time.a Do not shift the level while raising th€ engine speed.a Be sure to remove the pressure gauge belot€ testing stall speed.

1. Engage the parking brake and block all four wheels.

2. Connect the tachometer, and start the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the cooling lan comes on), shift into ft position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds. and note engine speed.6. Allow 2 minutes for cooling, then repeat the test in [, fDil and @ positions.

NOTE:

a Stall speed tests should be used lor diagnostic purposes only.. Stall speed should be the same in E, tr. tr and @ positions.

Stall Speed RPM: rpm

Specification: 2,400 rymService Limit: 2,2OO-2,600 tpm

TROUBLEPROBABLE CAUSE

Stall rpm hish in E, E, I and @posrtronLow fluid level or oil pump output

Cloqged ATF strainer

Pressure regulator valve stuck closed

Slipping clutch

Stall rpm high in I positionSlippage of 1st clutch, 1st-hold clutch or 1st gear one-way clutch

Stall rpm high in @ positionSlippage of 2nd clutch

Stall rpm high in @ positionSlippage of 1st clutch, lst gear one-way clutch

Stall rpm high in @ positionSlippage of 4th clutch

Stall rpm low in E, E, I ana @positionEngine output low

Torque converter one-way clutch slipping

14-92