Automatic HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 34 of 1413

![HONDA INTEGRA 1994 4.G User Guide Design Specifications

]TEMMETRICENGLISHNOIES

: vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.38 HONDA INTEGRA 1994 4.G User Guide Design Specifications

]TEMMETRICENGLISHNOIES

: vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.38](/img/13/6067/w960_6067-33.png)

Design Specifications

]TEMMETRICENGLISHNOIES

:' vENSTONSOveralllength 3 DOOR

4 DOOR

Ov€rallWidth

Overall Height 3 DOOR

4 DOOR

Wheelbase 3 DOOR

4 DOOR

Track F/R

Ground Clearance

Seating Capacity

4.380 mm

4.525 mm

'1,710 mm

1,335 mm

1,370 mm

2,570 mm

2,620 mm

't,475/1,470 mm

150 mm

Four (3 DOOR)

172.1in

178.1 in

67.3 in

52.6 in

101.2 in

103.1 in

5|8.1/57.9 in

Five (4 DOOR)

,rerght (usA)cross V€hicle Weight Rating {GVWR)3,680lbs

'le,ght {CANADA)Gross Vehicls Weight Rating {GVWR)1,670 kg

:\GINEType81881 engine

818C1 engine

Cylinder Arrangement

Bore and Stroke

Displacement

Compression Ratio

81881

818C1

81881

B18C I

81881

B 18C1

81881

818C1

engrne

engane

engrne

engine

engine

engine

engine

engine

L!brication Systom

OilPump Displacement

Wster Pump Displacement

FuelRequired

81881

B18C 1

81881

B 18C1

91881

engrne

engrne

engine

engine

engine

818C1 engine

Water-cooled, 4-stroke DOHC

gasoline engine

Watercooled, 4-stroke DOHC

VTEC gasoline engine

Inline 4-cylinder, transverse

81.0 x 89.0 mm

81.0 x 87.2 mm

1,834 cm3 (mf )

1,797 cm3 (m{)

3.19 x 3.50 in

3.19 x 3.43 in

112 cu-in

110 cu-in

9.2:1

10.0 : 1

Eelt driven, OOHC 4 valve per cylinder

Belt driven, DOHC VTEC

4 valve per cylinder

Forced and wet sump, trochoid pump

50, {53 US qt, 44 lmp qt)/minute'l

71 f {75 US qt, 62 lmp qt)/minute"

140 f (148 US qt, 123 lmp qt)/minute*!

140 f (148 US qt. 123 lmp qt)/minute*'

UNLEADED gasoline with 86 Pump

Octane Numb€r or higher

Premium UNLEADED gasoline wilh

91 Pump Octane Number or higher

STARTERTypo

NormalOutput

NominalVoltage

Hour Rating

Direction of Rotation

Weight

Gear reduction

1.4 kW

12V

30 seconds

Clockwise as viewed lrom g6ar end

3.7 k9 | 8.3lbs

CLUTCHClutch Type

Clutch Facing Area

M/TSingle plate dry, diaphragm spring

Torq!e converter

203 cm'� I 31 sq-in

TRANSMISSIONTransmission Type M/T

Primary Reduction

Synchronized 5-speed forward, 1 reverse

Electronically controlled

4-speed automatic. 1 rcverse

Diract 1 : 1

'1: At 6,000 engine

'2: At 7,600 engine

rpm

rpm

(cont'd)

3-17

Page 35 of 1413

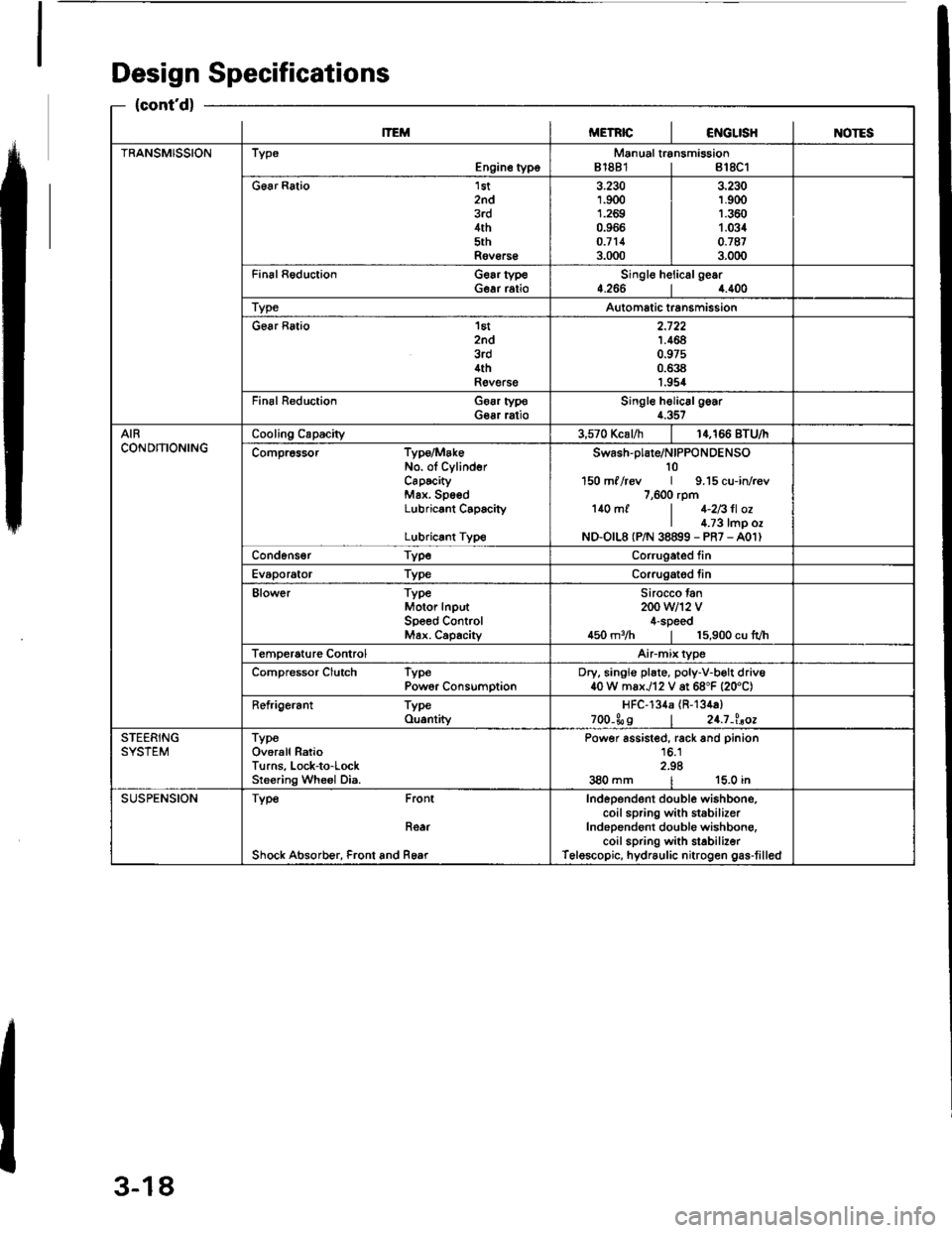

Design Specifications

{cont'd}

lTEMMETRICI€iIGLISHINOTES

TRANSMISSIONTypeEngine typoManual transmission81881 | 818C1

G6ar Ratio 1st2nd3rd4th5thRov€rs€

3.2301.9001.2690.966o.7113.000

3.230r.9(X)1.3601.0340.'t873.000

Fin6l Reduction Gear typeGear ratioSingle helicalge.r4.2664.400

TypeAutomatic transmission

Gear Ratio 'l6t

znd3rd4thRevelse

2.7221.4640.97s0.6381.954

Final R€duction Goar typoGear ratioSingle helic6lgoar4.357

AIRCONDITIONINGCooling Capacity3,570 Kcal/h14,166 BTU/I

Compr6ssor Type/MakeNo. ol CylinderCaPtcityMax. SpsedLubricant C6pacity

Lubricrnt Type

swash-plare/NIPPoNDENSO10150 ml /rcv | 9.15 cu-in/r€v7,600 rpm140 mf | 1-2Bll ozI l.;3 tmp ozND-O|L8 (P/N 38899 - PR7 - A01)

Cond6ns€r TypeCorrugated fin

Evaporator TypeCorrugatod tin

Blower TypeMotor InputSpeed ControMax. Capachy

Sirocco tan200 w12 v4-speed450 m3/h | 15,900 cu lvh

Temperature ControlAirmix type

Compressor Clutch TypePowor ConsumptionDry, singlo plate, poly-V-b€lt driv640 W max./12 V at 68"F {20'C)

Refrigerant TypeOu.ntityHFC-134a (R-134a)

zoo-Ss I 24.7-l.aoe

STEERINGSYSTEMTypeOverall RatioTurns, Lock-to-LockSreering Wheel Dia.

Power assisted, rack and pinion16.12.98380 mm | 15.0 in

SUSPENSIONType Front

Roar

Shock Absorb€r, Front and Rear

Independent double wishbono,coil spring with st6bilizerIndependont double wishbong.coil spring with stabilizerTelescopic, hydraulic nitrogen gas-tilled

3-18

Page 40 of 1413

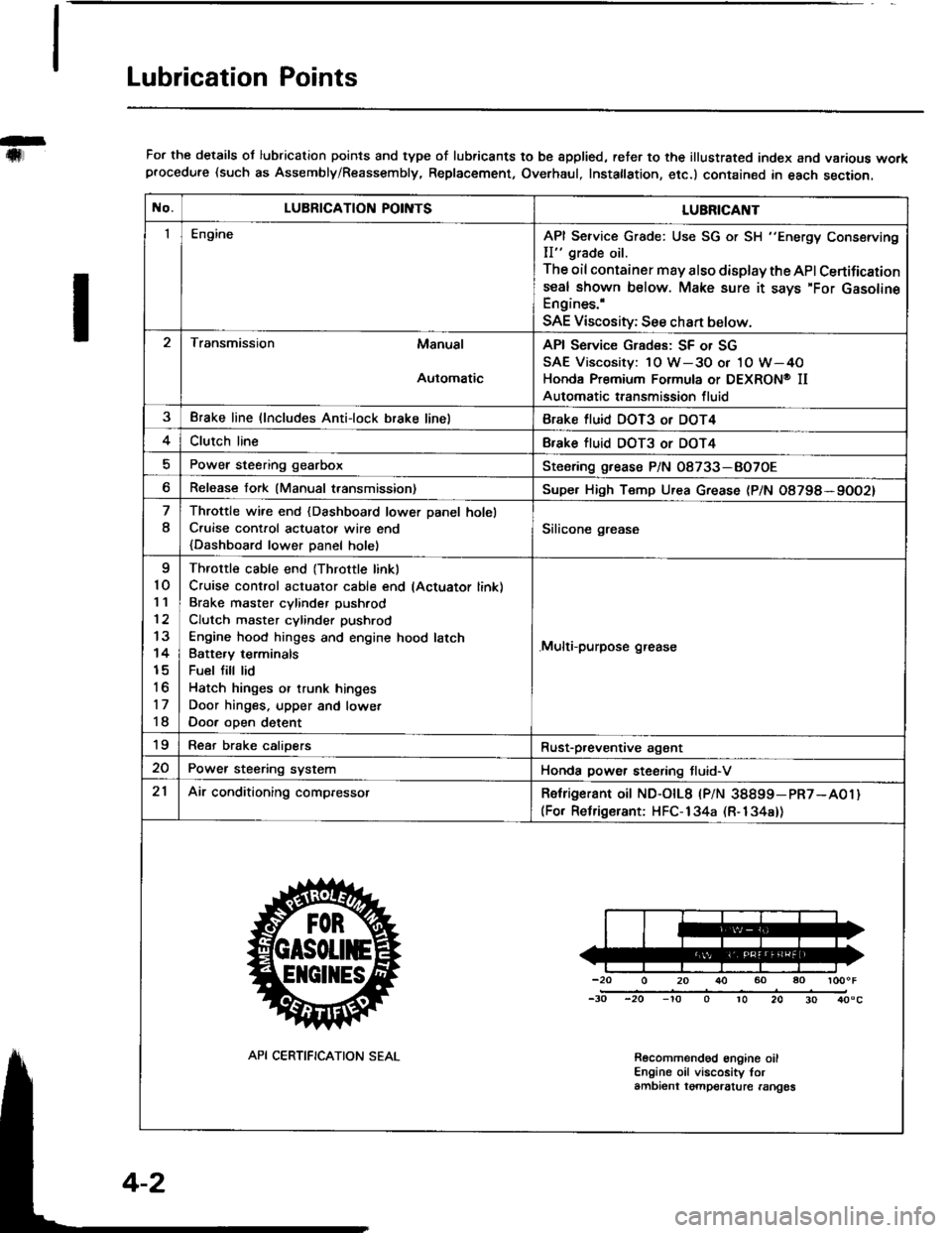

Lubrication Points

For the details ol lubrication points and type of lubricants to be spplied, reter to the illustrated index and various workprocedure (such as Assembly/Reassembly, Replacement, Overhaul, Instatlation, etc.) contained in each section.

No.LUBRICATION POII\ITSLUBRICAI\IT

IEngineAPI Service Grade: Use SG or SH "Energy Conserving

II" grade oil.

The oil container may also display the API Certifications€al shown below. Make sure it says'For GasolineEngines.'

SAE Viscosity; See chan below.

Transmission Manual

Automatic

API Service Grades: SF or SG

SAE Viscosity: 1O W-3O or 1O W-4O

Honda Premium Formula or DEXRON@ II

Automatic transmission fluid

3Brake line (lncludes Anti-lock brake linelBrake fluid DOT3 or DOT4

4Clutch lineBfake tluid DOT3 or DOT4

Power steering gearboxSteoring grease P/N 08733-BO7OE

Release fork (Manual transmission)Supe. High Temp Urea Grease (P/N O8798*9OO2)

8

Throttle wire end {Dashboard lower Danel holel

C.uise cont.ol actuatot wire end

{Dashboard lower Danel holel

Silicone grease

I

10'I '�l

12

13

14

15

to

17

18

Throttle cable end (Throttle linkl

Cruise control actuator cable end lActuator link)

Brake master cvlinder Dushrod

Clutch master cylinder pushrod

Engine hood hinges and engine hood latch

Batte.v terminals

Fuel fill lid

Hatch hinges or trunk hinges

Door hinges. upper and lowet

Door oDen detent

.Multi-purpose grease

19Rear brake calioersRust-p,eventive agant

20Power steering systemHonda power steering tluid-V

21Air conditioning compressorRetrigerant oit ND-otL8 |PlN 38899-pR7-A01)(For Relrigerant: HFC-134a (R-134a))

-20 0 20 r}() 60 ao loooF

-30 -20 -'to o 10 20 30 40"c

Recolnmendod engine oilEngine oil viscosity torambient tgmpelalure rangos

API CERTIFICATION SEAL

Page 52 of 1413

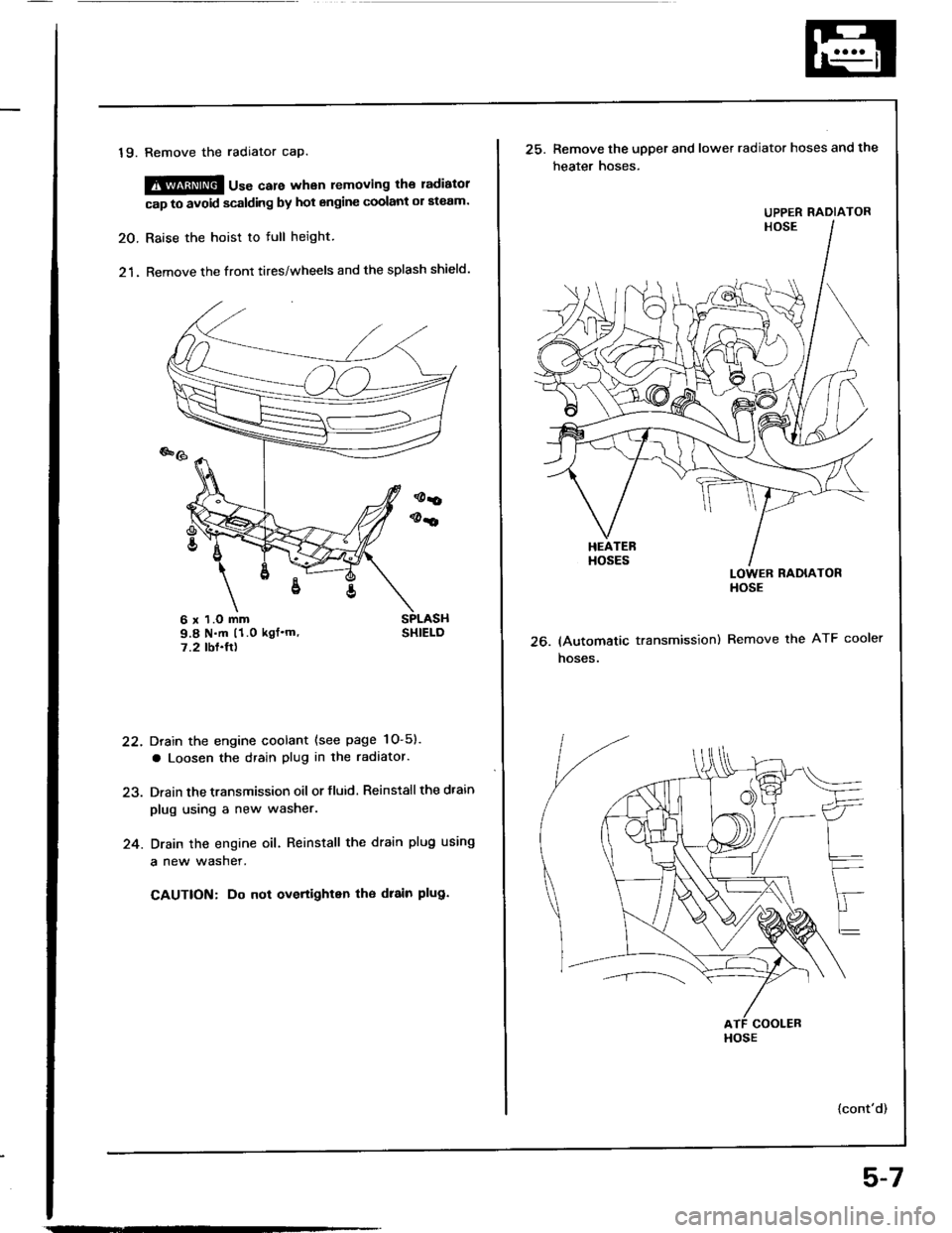

19. Remove the radiator cap.

@@ u"" care whan removing the ladiatol

cap to avoid scalding by hot engine coolant ol ateam.

20. Raise the hoist to full height.

21. Remove the front tires/wheels and the splash shield.

Drain the engine coolant (see page 1O-5).

a Loosen the drain plug in the radaator.

Drain the transmission oil or fluid. Reinstall the dtain

plug using a new washer.

Drain the engine oil. Reinstall the drain plug using

a new wasner.

CAUTION: Do not overtighten tho drain plug.

22.

24.

6 x 1.O mm9.8 N.m (1.0 kgf'm'7.2 tbf.ft)26.

25. Remove the upper and lower radiator hoses and the

heater hoses.

LOWER RADIATORHOSE

(Automatic transmission) Remove the ATF cooler

hoses.

{cont'd)

UPPER RADIATOR

HOSE

5-7

Page 72 of 1413

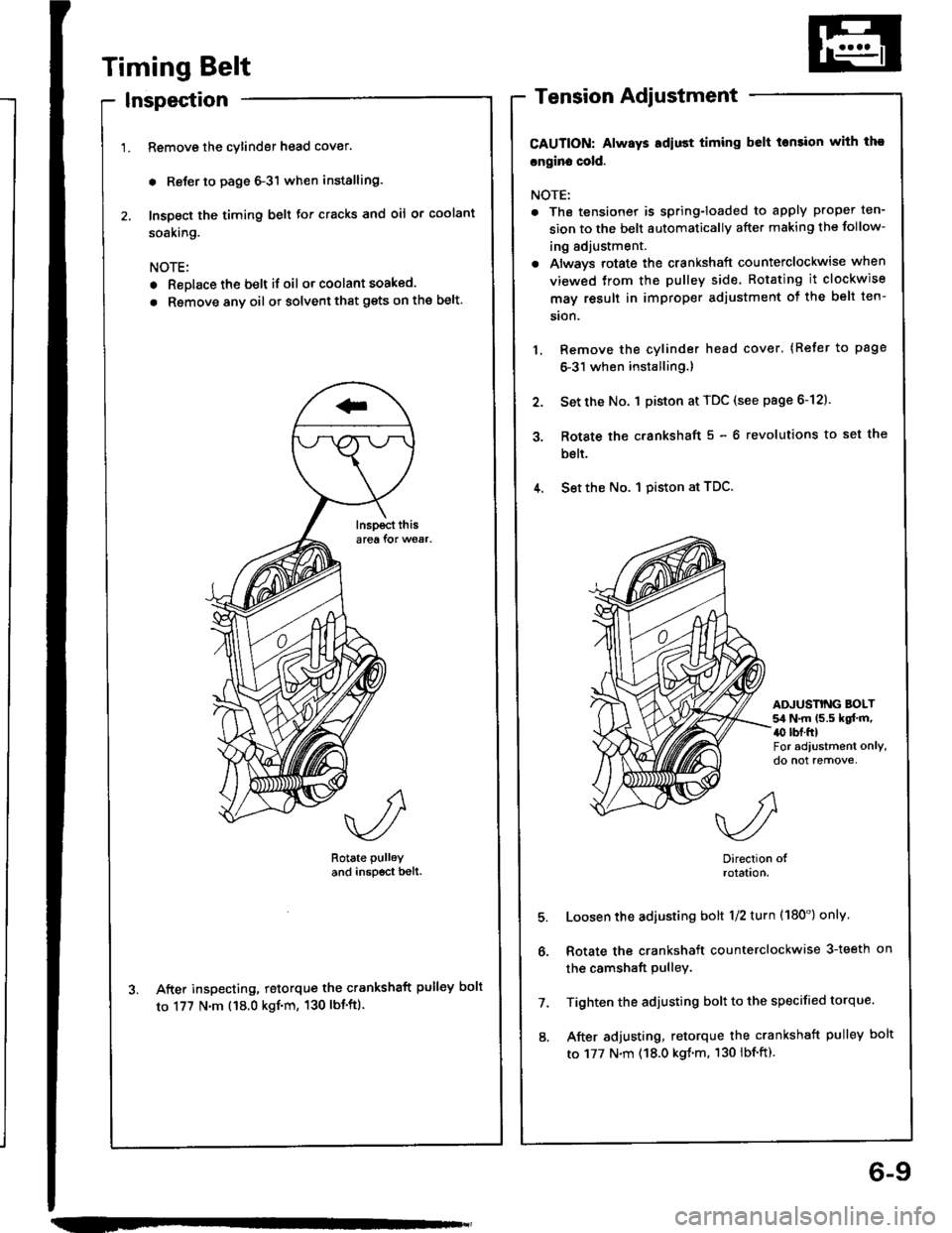

Timing Belt

Inspection

Remove the cylinder head cover.

. Reler to page 6-3'l when installing.

Inspect the timing belt for cracks and oil or coolant

soaking.

NOTE:

. Replace the belt if oil or coolant soaked.

. Rsmove any oil or solvent that gets on the belt.

Rotate pulley

and inspscr bell.

After inspecting, retorque the crankshaft pulley bolt

to 177 N'm ('18.0 kgf'm, 130 lbt'ft).

Tension Adjustment

CAUTION: Always Ediust timing belt tonsion with tho

cngin. cold.

NOTE:

. The tensionet is spring-loaded to apply proper ten-

sion to the belt automaticallv after making the follow-

ing adjustment.

. Always rotate the crankshaft counterclockwise when

viewed trom the pulley side Rotating it clockwise

may result in improper adjustment ot the belt ten-

sion.

Remove the cylinder head cover. (Refer to page

6-31 when installing.)

Set the No. 1 piston at TDC (see page 6-12).

Rotate the c.ankshaft 5 - 6 revolutions to set the

bslt.

4. Set the No. I piston at TDC.

3.

ADJUSNNG BOLT54 N.m (5.5 kqf.m,a0 rbr.ftlFor adiustment only,do not remove,

5.

6.

7.

8.

Direction olrolatlon.

Loosen the adiusting bolt 1/2 turn (180') onlv

Rotate the crankshaft counterclockwise 3-teeth on

the camshaft pulley.

Tighten the adjusting bolt to the specified torque.

After adjusting, retorque the crankshaft pulley bolt

to 177 N.m (18.0 kgl.m. 130 lbf.ft).

6-9

Page 79 of 1413

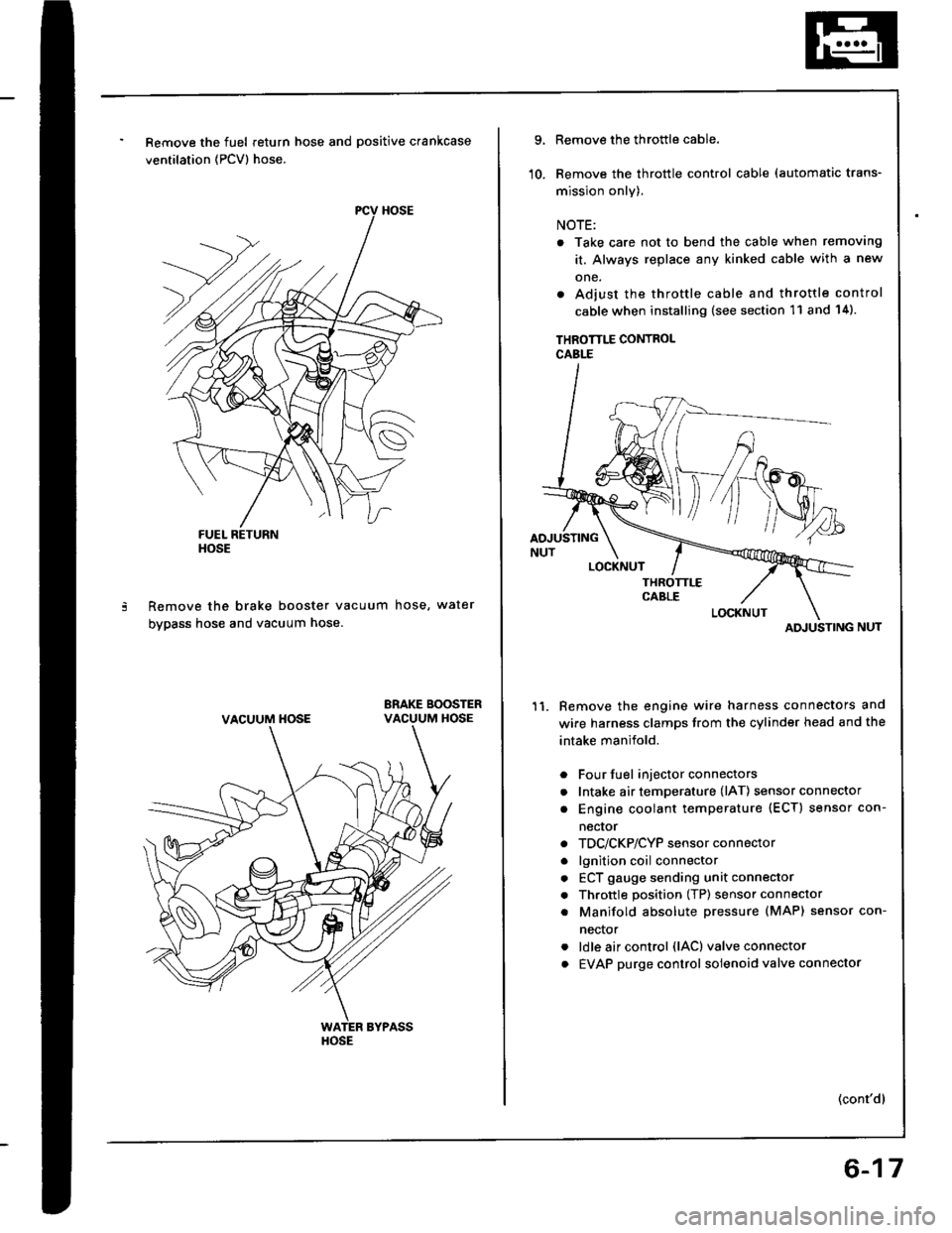

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ERAKE BOOSTERVACUUM HOSE

HOSE

VACUUM HOSE

HOSE

9.

10.

Remove the throttle cable.

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (see section 11 and 14).

THROTTLE CONTROLCABLE

Remove the engine wire harness connectors and

wire harness clamps trom the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

necror

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute Dressure (MAP) sensor con-

nector

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

11.

a

a

a

a

a

a

a

a

a

(cont'dl

ATI'USTING

6-17

Page 109 of 1413

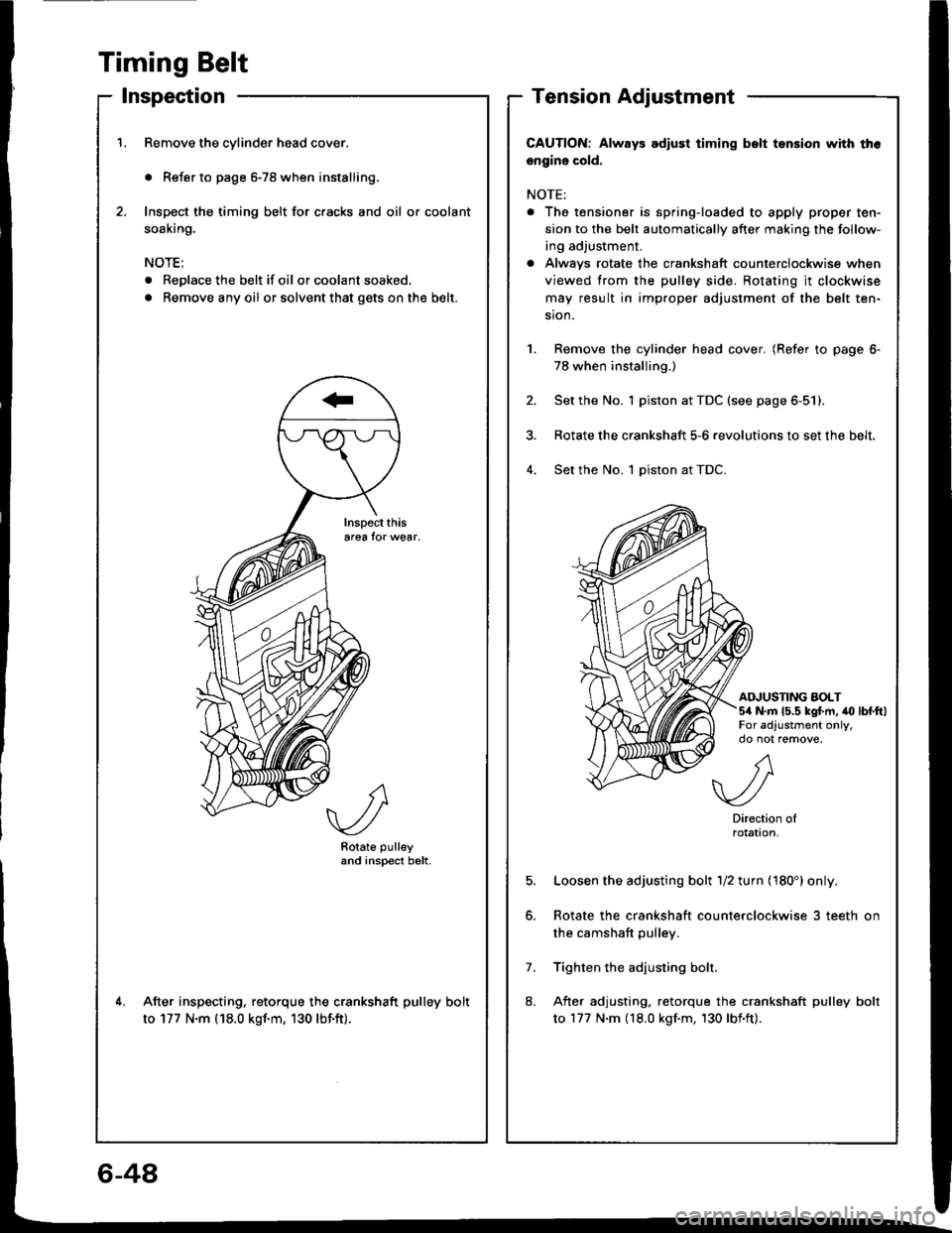

Timing Belt

lnspection

Remove the cylinder head cover.

. Refer to page 6-78 when installing.

Inspect the timing belt for cracks and oil or coolant

soaking.

NOTE:

. Replace the belt if oil or coolant soaked.

. Remove any oil or solvent that gets onthe b€lt.

Rotate pulleyand inspect b6lt.

After inspecting. retorque the crankshaft pulley bolt

to 177 N.m (18.0 kgf.m, 130 lbf.ft).

Tension Adjustment

CAUTION: Always adlust timing bslt tsnsion with th6

engine cold.

NOTE:

. The tensioner is spring-loaded to apply proper ten-

sion to the belt automatically after making the follow-

ing adjustment.

a Alwavs rotate the crankshaft counterclockwise when

viewed trom the pulley side. Rotating it clockwise

may result in improper adjustment of the belt ten-

sion.

Remove the cylinder head cover. (Refer to page 6-

78 when installing.)

Set the No. 1 piston at TDC (see page 6-51).

Rotate the crankshaft 5-6 revolutions to set the belt.

Set the No. 1 piston at TDC.4.

AINUSTING AOLT5/a N.m 15.5 kg{.m, to lbtftlFor adjustment only,

5.

7.

8.

A

.//\v-/

Directionrotat|on,

Loosen the adjusting bolt 1/2 turn (180') only.

Rotate the crankshaft counterclockwise 3 teeth on

the camshaft pulley.

Tighten the adjusting bolr.

After adjusting, retorque the crankshaft pulley bolt

to 177 N.m (18.0 kgf.m, 130 lbf'ft).

6-48

Page 143 of 1413

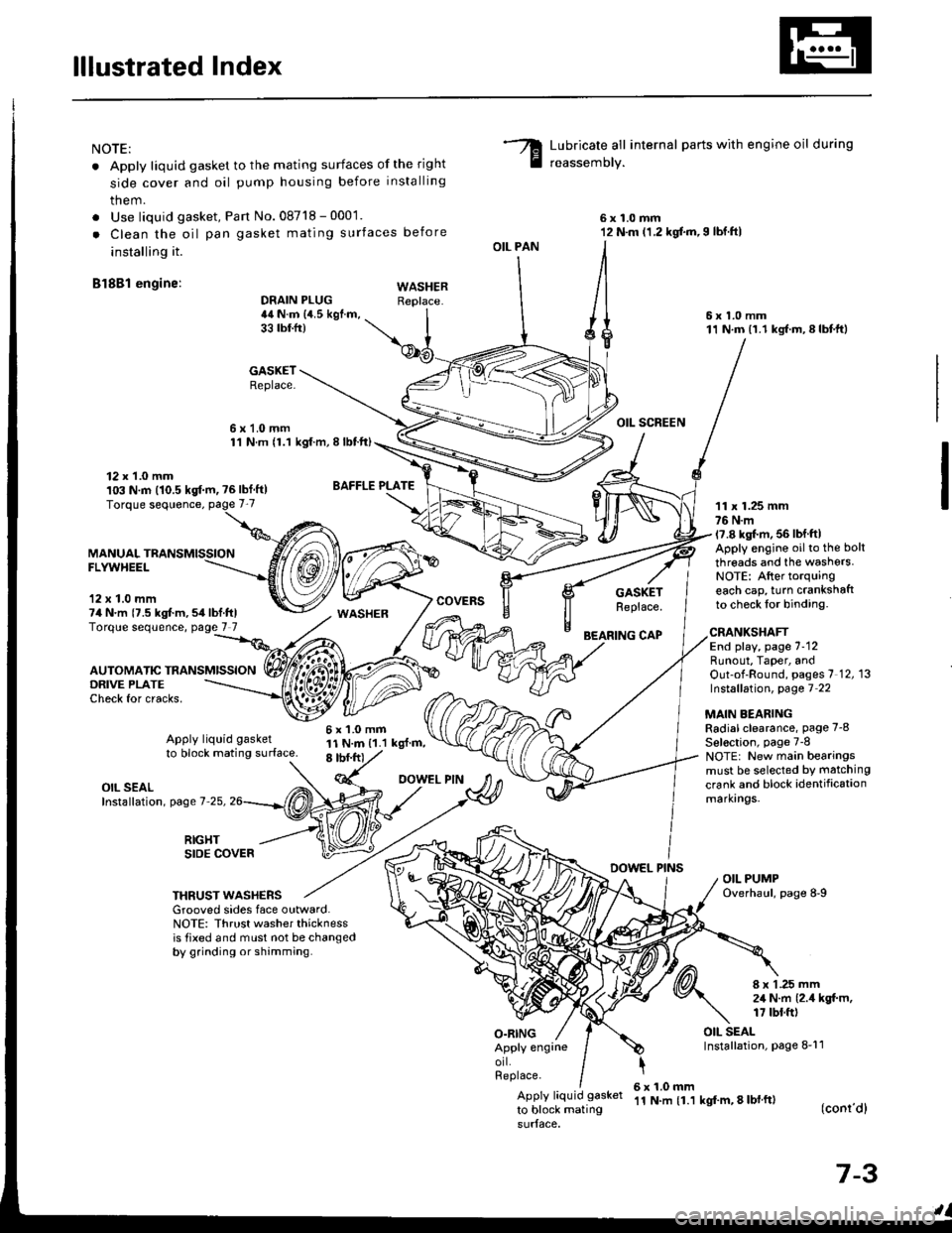

lllustrated Index

NOTE:

. Apply liquid gasket to the mating surfaces of the right

side cover and oil pump housing before installing

them.

. Use liquid gasket, Pan No.08718 - 0001.

. Clean the oil pan gasket mating surfaces before

installing it.

Bl8Bl engine: wAsHEF

Lubricate all internal parts with engine oil during

reassemory.

6x1.0mm12 N.m (1.2 kgf.m,I lbf.ftl

6x1.0mm11 N.m (1.1 kgf.m,8lbtft)

OIL SCREEN

11 x 1.25 mm76 N.m17.8 kgl.m, 56 lbf ftlApply engine oilto the bolt

threads and the washers.NOTE: After torquingeach cap, turn crankshaftto check lor binding.

DRAIN PLUG44 N.m {4.5 kgf.m,33 tbtfr)

GASKETReplace.

6x1.0mm1'l N.m {1.1 kgt.m, I lbtft)

OIL PAN

O.RING

GASKETReplace.

BEARING CAP

12 x 1.0 mm103 N.m (10.5 kgf.m, ?6lbf ft)

MANUALFLYWHEEL

'12 x 1.0 mm74 N.m {7.5 kgt m,54lbf.ftlTorque sequence, page 7 7

DRIVE PLATECheck for cracks,

AUTOMATIC TRANSMISSION

WASHER

6x1.0mm11 N.m {1.1 kgl.m,8 tbf.frt

CRANKSHAFTEnd play, page 7-12Runout, Taper, andOut-of-Round, pages 7 12, 13Instsllation, page 7 22

MAIN BEARINGRadial clearance, page 7-8

Sel€ction, page 7-8NOTE: New main bearingsmust be selected by matching

crank and block identificationmarkrngs.

Apply liquid gasket

to block mating surface.

OIL SEALInstallation, page 7-25,

RIGHTSIDE COVERDOWEL PINSOIL PUMPOverhaul, page 8-9THRUST WASHERSGrooved sides face outward.NOTE: Thrust washer thicknessis tixed and must not be changedby grinding or shamming.

8 x 1 .25 mm2,1 N.m {2.4 kgt m,17 tbt.ft)

OIL SEALInstallation, page 8-11Apply engrneorl.Replace.

Apply liquid gasket

to block mating

6x1.0mm'11 N.m {1.1 kgf'm, 8 lbl ft)(conr'dl

7-3

Page 147 of 1413

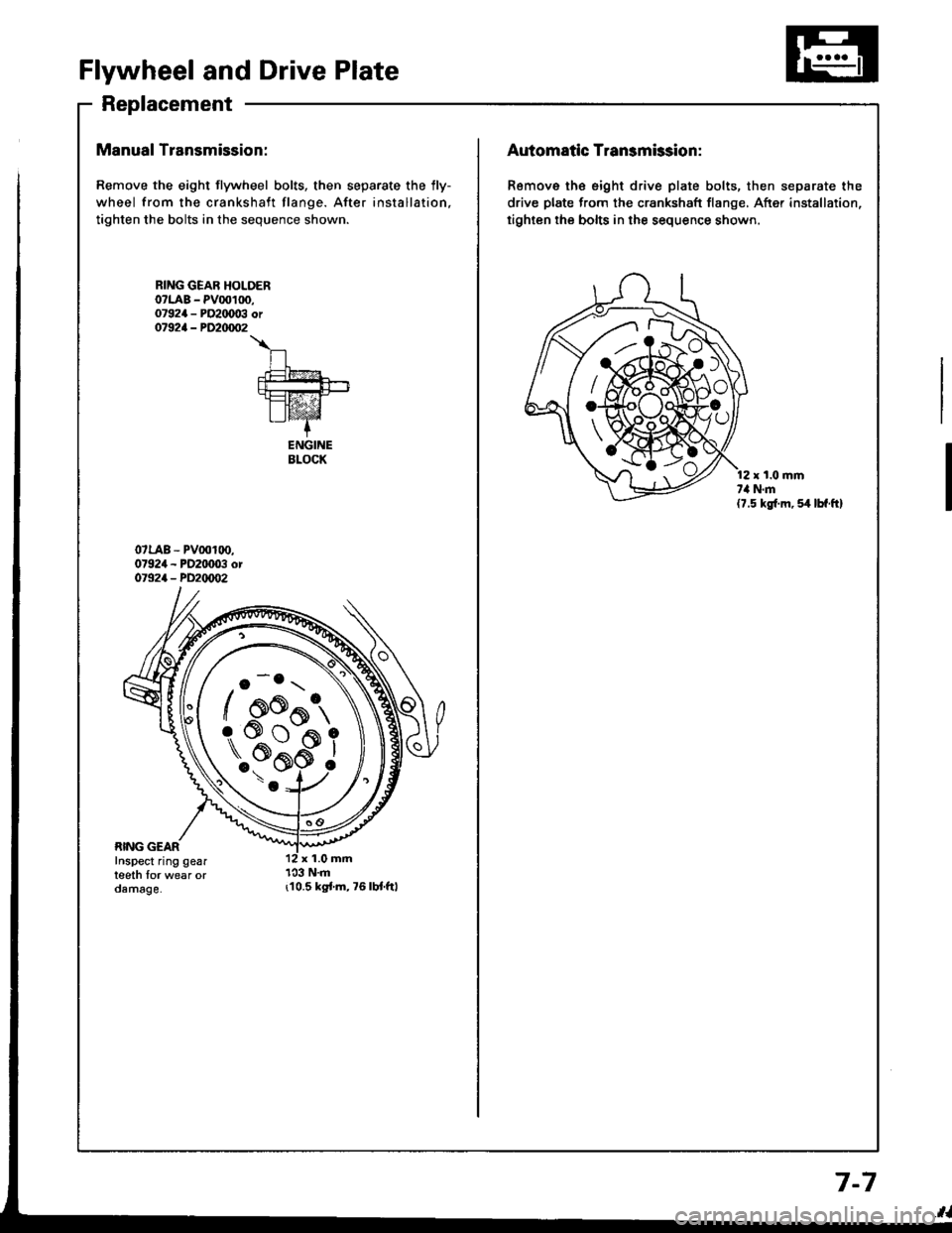

Flywheel and Drive Plate

Replacement

Manual Transmission:

Remove the eight flywheel bolts, then separate the lly-

wheel from the crankshaft flange. After installation,

tighten the bolts in the sequence shown.

r10.5 kgi.m,76lbt.ftl

RING GEAR HOLOERo?LAB - PV00100,07924 - PO2IX)03 or07924 - PD20/m�2

\

n.t=?4

fut!!-+-rt=tz-21I lvaz'Z-+

ENGINEBLOCK

o -o.r \

/ oo^t,

\..?bi

/ AK{:{AAo

rs#*ffi_9

Automatic Transmission:

Remove th€ eight drive plate bolts, then separate the

drive plate from the crankshaft flange, After installation,

tighten the bolts in the sequence shown.

r t.0 mmt,l N.m(7.5 kg{.m, 54 lbf.ft}

7-7

Page 186 of 1413

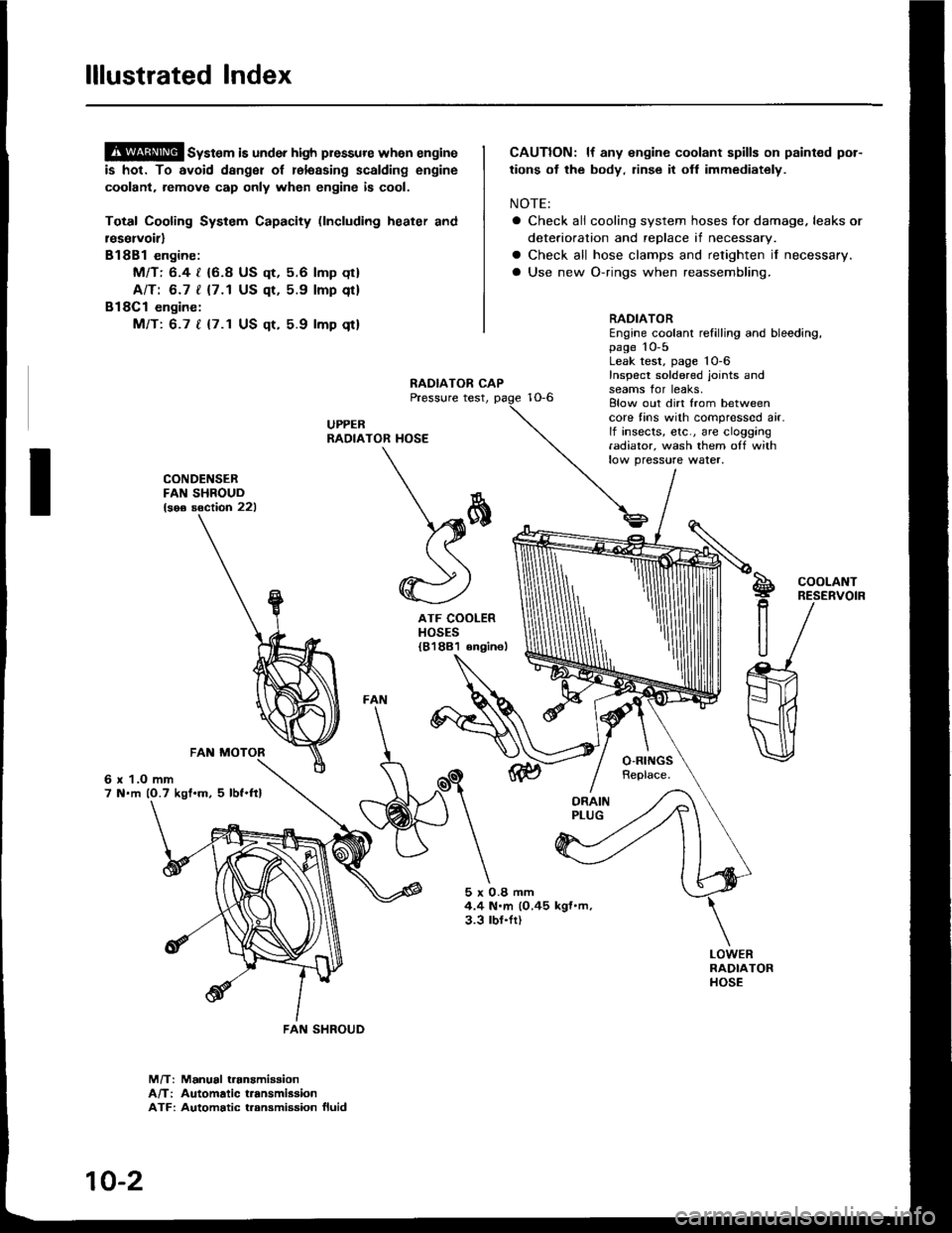

lllustrated Index

@ sy"t". is under high plessure when engine

is hot. To avoid dsnger of relsssing scalding engine

coolant. remove cap only when engine is cool.

Total Cooling System Capacity (lncluding heater and

r€servoirl

Bl8Bl engine:

Mfl: 6.4 | {6.8 US qt, 5.6 lmp qt}

AlTt 6.7 | {7.1 US qt, 5.9 lmp qt}

Bl8Cl engine:

Mfi: 6.7 t {7.1 US qt, 5.9 lmp qt}

CAUTION: lf any engine coolant spills on paint€d por-

tions ot the body, rinse it ofl immediately.

NOTE:

a Check all cooling system hoses for damage. leaks or

deterioration and replace if necessary.

a Check all hose clamps and retighten if necessary.

a Use new O-rings when reassembling.

CONDENSERFAN SHROUD{soe soction 221

6 x 1.O mm7 N.m (O.7 kgt.m. 5 lbf.ftl

ATF COOLERHOSES{81881 6ngine)

RADIATOREngine coolant refilling and bleeding,page 10-5Leak test, page 'l0-6

Inspect soldered joints andseams for leaks.Elow out dirt from betweencore fins with compressed air.lf insects, etc., are clogging.adiator, wash them off withlow pressure water,

S!

P

R

U

COOLANTRESERVOIR

5x0.8mm4.4 N.m (O.45 kgf.m,3.3 lbl.fr)

M/T: Manual t.anamiaaionA/T: Automatic t.ansmiasionATF: Automatic t.ansmission fluid

\*

*)

FAN SHROUD

10-2