Engine mount HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 110 of 1413

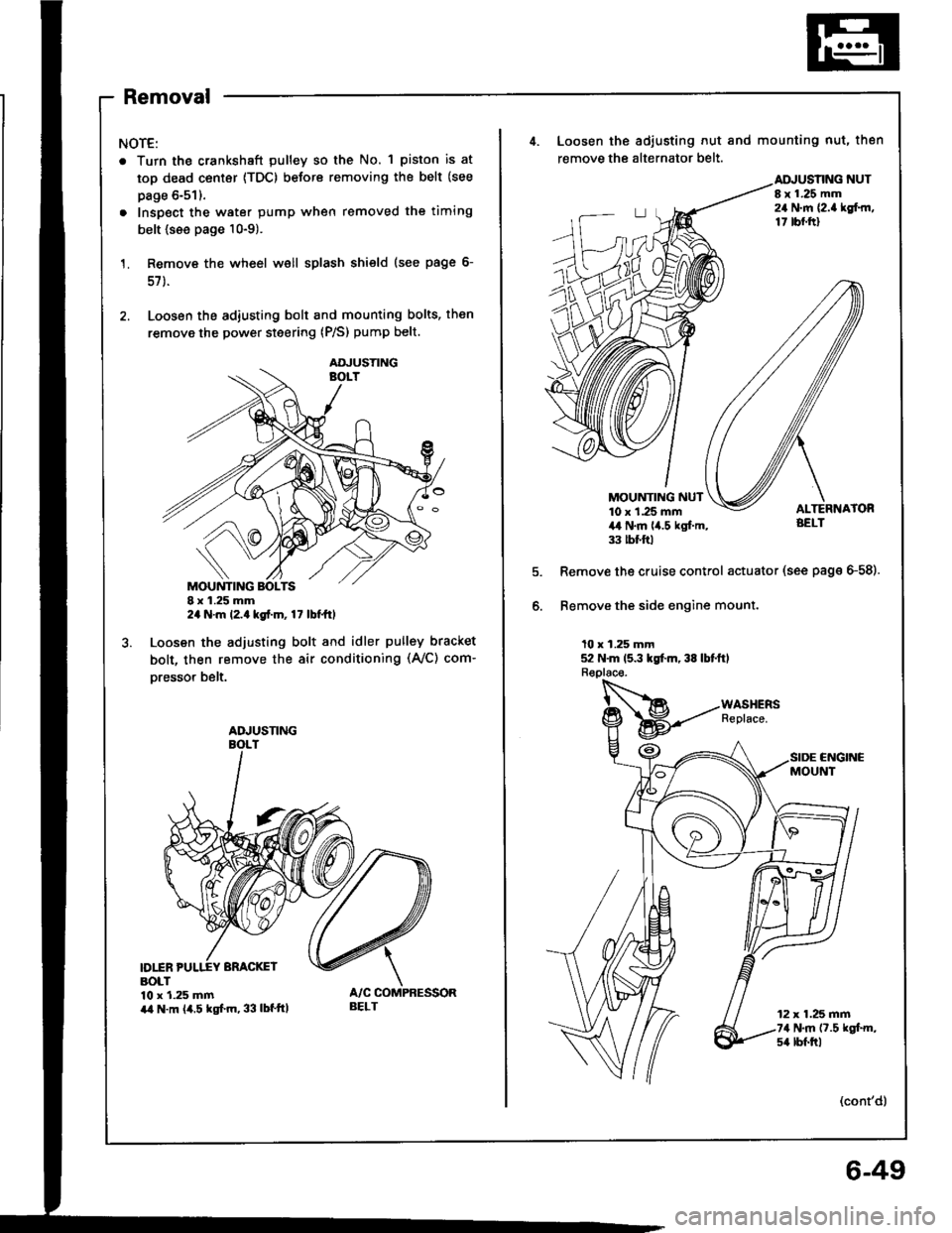

Removal

NOTE:

. Turn the crankshaft pulley so the No. 1 piston is at

top dead center {TDC) before removing the belt (see

page 6-51).

. Inspect the water pump when removed the timing

belt {see page 10-9).

Remove the wheel well splash shield (see page 6-

57 ).

Loosen the adiusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt.

I x 1.25 mm2a N.m l2.a kgt.m, 17 lbt ttl

Loosen the adjusting bolt and idler pulley bracket

bolt, then remove the air conditioning (Ay'C) com-

oresso. belt.

D1INBOLT10 x 1.25 mmira N.m (4.5 kgf.m, 33 lbf'ttl

AOJUSTING

ADJUSNNG

BELT

4. Loosen the adiusting nut and mounting nut, then

remove the alternator belt.

NUTI x 1.25 mm24 N.m {2.a lgf.rn,17 tbf.ftl

MOUNTING NUT10 x 1.25 mm4,t N.m lia.5 kgl.m,33 tbt ftl

Remove the cruise control actuator (see page G58).

Bemove the side engine mount.

10 x 1.25 mm52 N.m 15.3 kgt m, 38 lbtftl

CNGINCMOUNT

12 x 1.25 mm74 N.m (7.5 kgt m,s4 lbf.trl

(cont'd)

6-49

Page 118 of 1413

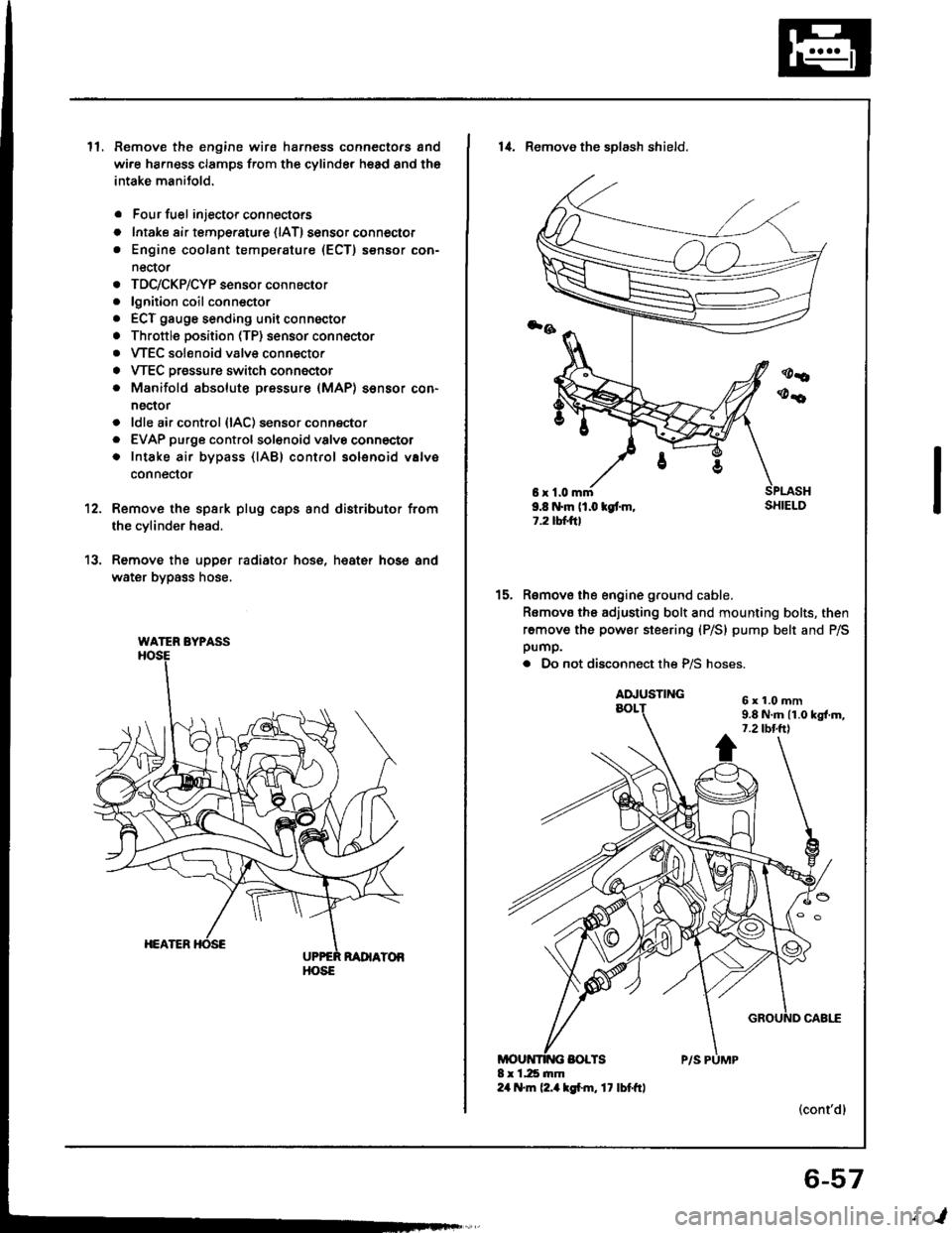

ll.Remove the engine wire harness connectors and

wi.e ha.ness clamps from the cylinder head and the

intake manitold.

Four fuel injector connectors

Intake air tempe.ature {lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

nector

TDC/CKP/CYP sensor connector

lgnition coil conn€ctor

ECT gauge sending unit connector

Throttle position (TP) sensor connector

VTEC solenoid valve connector

VTEC Dressure switch connector

Manifold absolute pressure (MAP) sensor con-

nector

ldle air control {lAC) sensor connector

EVAP purge controlsol€noid valvo connector

Intake air bypass {lABl control solenoid valve

conneclor

a

o

a

o

a

a

a

a

a

a

a

a

a

12.

13.

Remove the spsrk plug caps and distributor from

the cylinder head.

Remove the upper radiator hose, heat€r hose and

water bypass hose.

WATER BYPASS

HOSE

6r1.0mm9.8 N.m (1.0 kgt m,1.2 tbtftl

14. Remove the sDlash shield.

Remove the engine ground cable.

Romovo the adjusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt and P/Spump.

. Do not disconnect the P/S hoses.

(cont'dl

15.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 tbt.ttl

6-57

,l

Page 119 of 1413

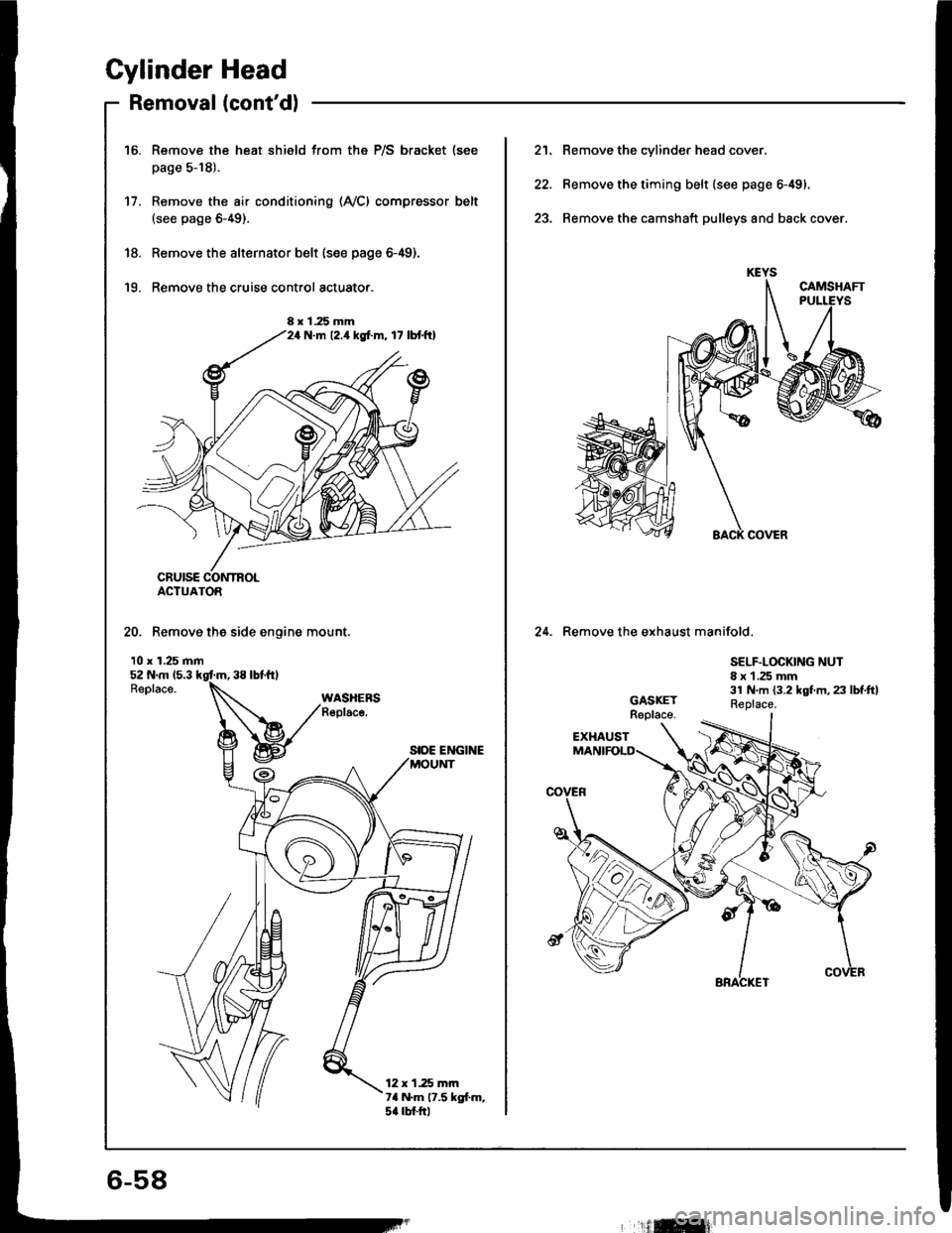

Cylinder Head

Removal (cont'dl

Remove the heat shield from the P/S bracket (see

page 5-18).

Remove the air conditioning (Ay'Cl compressor belt(see page 6-49).

Remove the alternator belt {s€e page 6-49).

Remove the cruise control actuato..

16.

17.

'18.

'19.

ACTUATOR

20. Remove the side engine mount.

10 x 1.25 mm

SIDE ENGINE

12 x 1.25 mrn7a N.m 17.5 kgl.m,5a rbtftl

8 x 1.25 mmN.m 12.4 kgf.m, 17 lbtftl

21. Remove the cylinder head cover.

22. Remove the timing belt (see page 6-49).

23. Remove the camshaft pulleys and back cover.

24. Remove the exhaust manifold.

SELF.LOCKING NUT8 x 1 .25 mm31 N.m {3.2 kgt m, 23 lbf.ftlReplace.

6-58

'ilffi{

Page 174 of 1413

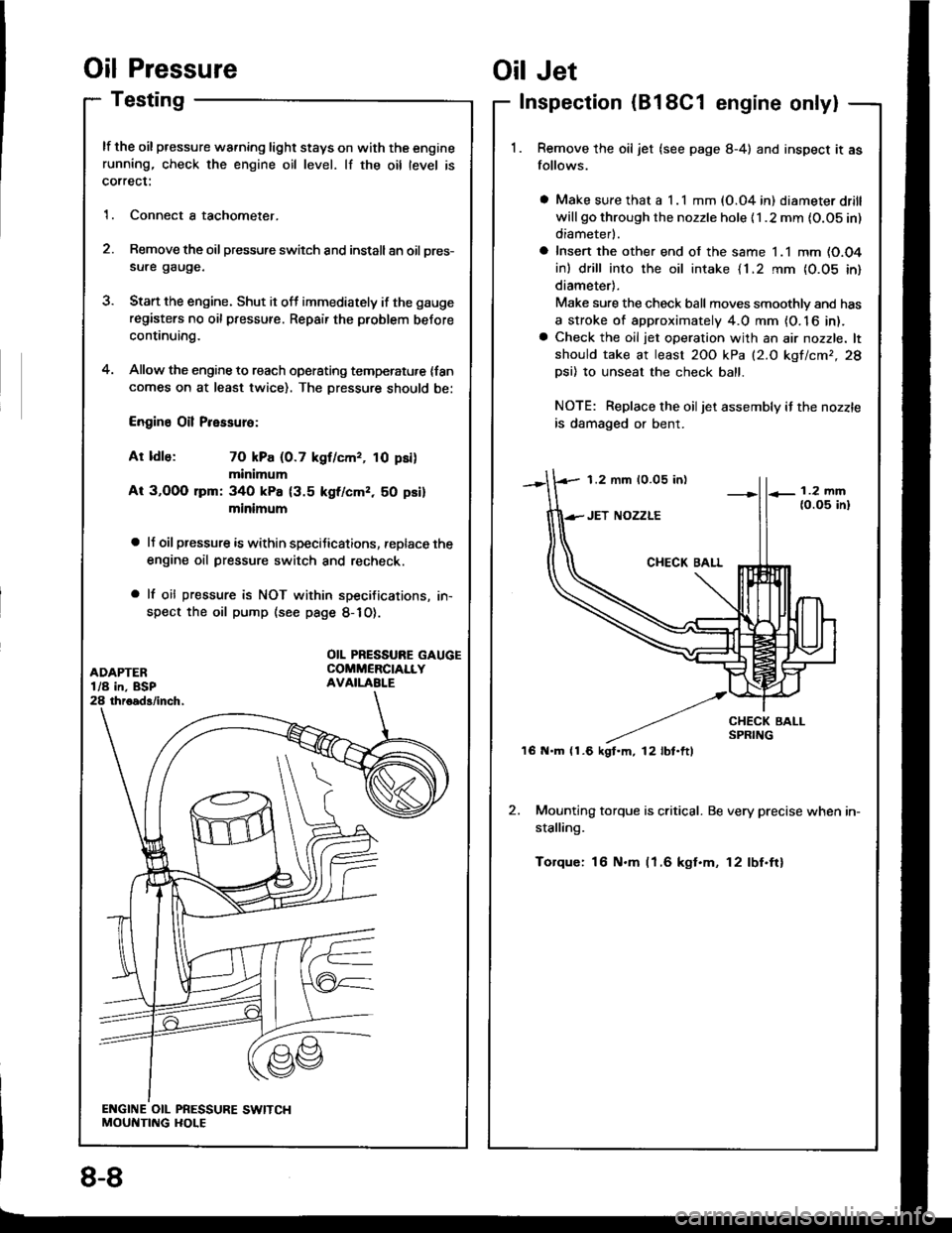

Oil Pressure

Testing

lf the oil pressure warning light stays on with the enginerunning, check the engine oil level. lf the oil level is

correct:

1. Connect a tachometer.

2. Remove the oil pressure switch and install an oil pres-

sure gauge.

3. Stan the engine. Shut it off immediately if the gauge

registers no oil pressure. Repair the problem before

continuing.

4. Allow the engine to reach operating temperatu,e {fancomes on at least twice). The Dressure should be:

Engine Oil Pressure:

At ldle: 70 kPa (0.7 kgf/cmr, 10 psi)

minimum

At 3,OOO lpm: 340 kPa {3.5 kgf/cmz, 50 psi}

minimum

a lJ oil pressure is within speciJications, replace the

engine oil pressure switch and recheck.

a lf oil pressure is NOT within specifications, in-

spect the oil pump (see page 8-1O).

1.2 mm 10.05 in)

'16 N.m (1.6 kgt.m, l2lbt.ftl

Oil Jet

Inspection (B18C1 engine only|

Remove the oil jet (see page 8-4) and inspect it as

follows.

a Make sure that a I .l mm (O.04 in) diameter drill

will go through the nozzle hole {1 .2 mm {O.OS in)

diameterl.

a Insert the other end of the same 1.1 mm (O.O4

in) drill into the oil intake {1.2 rnm {0.05 in}

diameter).

Make sure the check ball moves smoothlv and has

a stroke of approximately 4.0 mm {O. 16 in).a Check the oil jet operation with an air nozzle. lt

should take at least 2OO kPa (2.O kgf/cmr,28

Dsi) 10 unseat the check ball.

NOTE: Replace the oiljet assembly if the nozzle

is damaged or bent.

2. Mounting torque is critical. Be very precise when in-

stalling.

Torque: 16 N.m (1.6 kgt.m, 12lbf.ftl

OIL PRESSURE GAUGECOMMERCIALLYAVAILABI.E

8-8

Page 189 of 1413

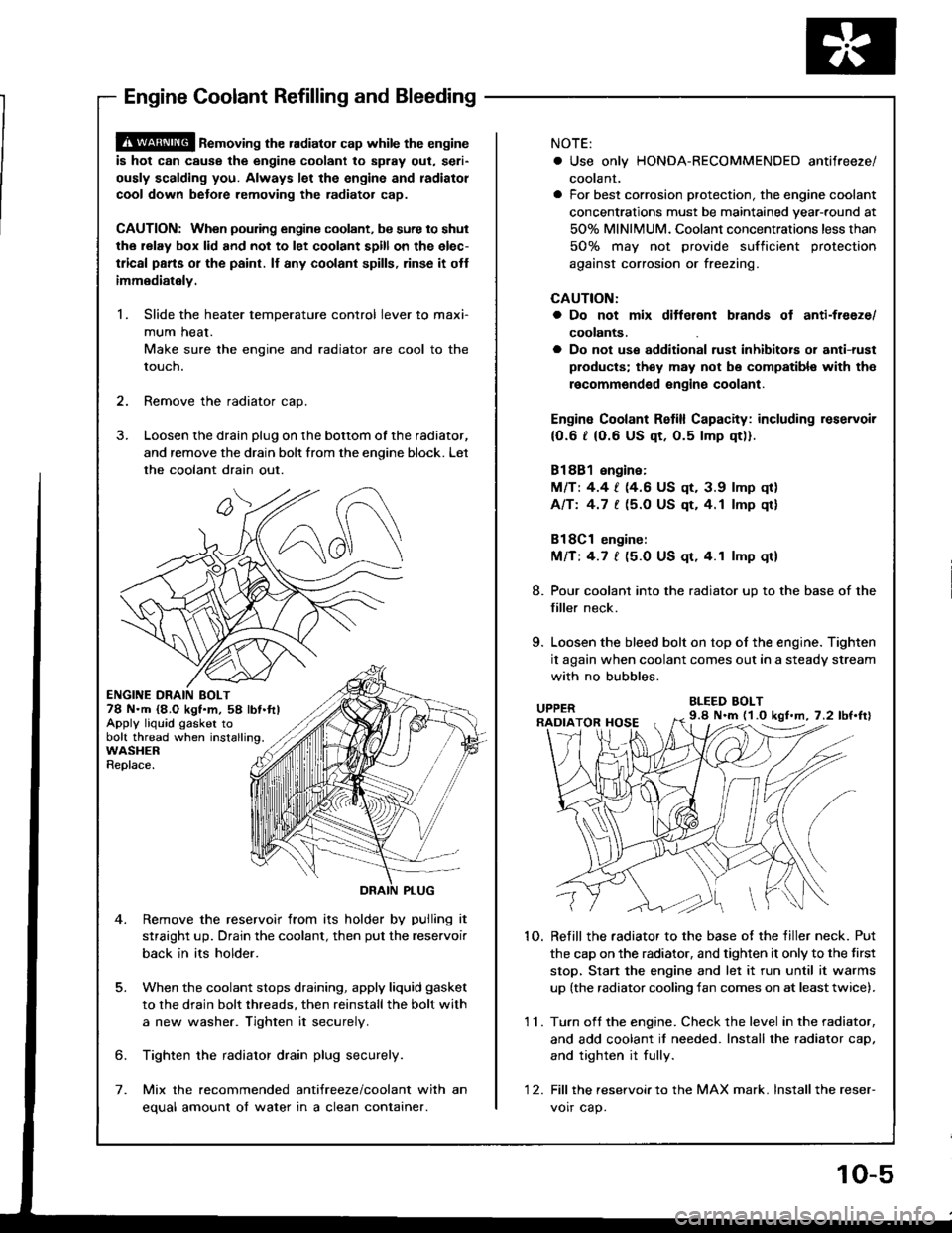

@ ne-oving the radiator cap while the engine

is hot can cause the engine coolant to splay out, seri-

ously scalding you. Always let the engine and radiatol

cool down betore removing the radiator cap.

CAUTION: When poudng engine coolant, be sure to shut

the relay box lid and not to let coolant spill on the elec-

tlical pans or the paint. ll any coolant spills, rinse it otf

immediately.

1. Slide the heater temperature control lever to maxi-

mum heat.

Make sure the engine and radiator are cool to the

touch.

2. Remove the radiator cao.

3. Loosen the drain plug on the bottom of the radiator,

and remove the drain bolt from the enoine block. Let

the coolant drain out.

ENGINE DRAIN BOLT78 N.m {8,O kgt.m, 58 lbt.ftlApply liquid gasker tobolt thread when installing.WASHERReplace.

5.

Remove the reservoir from its holder by pulling it

straight up. Drain the coolant, then put the reservoir

back in its holder.

When the coolant stops draining, apply liquid gasket

to the drain bolt threads, then reinstallthe bolt with

a new washer. Tighten it securely

6. Tighten the radiator drain plug securely.

7. Mix the recommended antifreeze/coolant with an

equal amount of water in a clean container.

NOTE:

. Use only HONDA-RECOMMENOED antifreeze/

coolant.

a For best corrosion protection, the engine coolant

concentrations must be maintained year-round at

50% MINIMUM. Coolant concentrations less than

50% may not provide sufficient protection

against corrosion or freezing.

CAUTION:

a Do not mix ditterent blands ot anti-freeze/

coolants.

a Do not use additional rust inhibitois or anti-rust

products; they may not bs compatibl€ with the

recommgndsd engins coolant.

Engin€ Coolant Retill Capacity: including reservoir

{0.6 t (0.6 US qt, 0.5 lmp qt)).

81881 engine:

MlTt 4.4 | (4.6 US qt, 3.9 lmp qr)

Afft 4.7 [ (5.O US qt,4.1 lmp qt]

Bl8Cl engine:

Mnt 4.7 | (5.0 US qt.4.1 lmp qt)

8. Pour coolant into the radiator up to the base of the

filler neck.

9. Loosen the bleed bolt on top of the engine. Tighten

it again when coolant comes out in a steady stream

with no bubbles.

BLEED BOLT

1O. Refill the radiator to the base of the tiller neck. Put

the cap on the radiator. and tighten it only to the tirst

stop, Stan the engine and let it run until it warms

up (the radiator cooling fan comes on at leasttwice).

11. Turn oft the engine. Check the level in the radiator,

and add coolant it needed. Install the radiator caD,

and tighten it fully.

'1 2. Fill thereservoirto the MAX mark. lnstallthe reser-

voir cap.

9.8 N.m (1.O kgl.m, 7.2 lbf.ftl

Engine Coolant Refilling and Bleeding

10-5

Page 193 of 1413

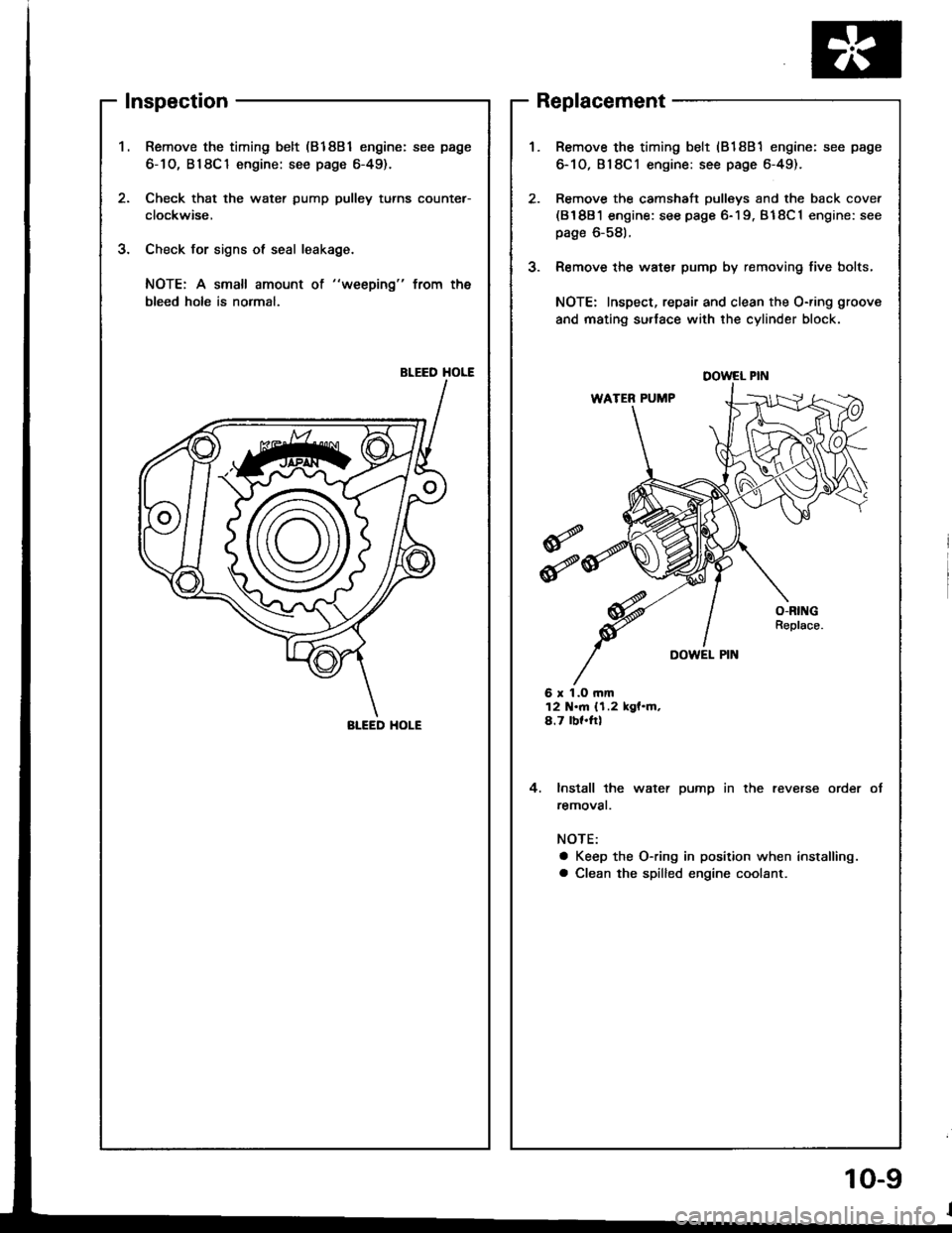

Inspection

Remove the timing belt (81881 engine: see page

6-1O, B18C1 engine: see page 6-49).

Check that the water pump pulley turns counter-

clockwise,

Check for signs ol seal leakage.

NOTE: A small amount ot "weeping" from the

bleed holo is normal,

BLEED HOLE

2.

J.

J.

Replacement

6 r 1.O rnm12 N.m {1.2 kgf.m,4.7 bf.ftl

4. lnstall the water pump in the reverse order

removat.

NOTE:

a Keep the O-ring in position when installing.

a Clean the spilled engine coolant.

Remove the timing belt (818B1 engine: see page

6-10,818C1 engine: see page 6-49).

Remove the camshaft pulleys and the back cover(81881 engine: see page 6-19. B18C1 engine: see

page 6-581.

Remove the water pump by removing five bolts,

NOTE: Inspect, repair and clean the O-ring groove

and mating su.lace with the cylinder block.

DOWEL PIN

BI-EED HOI-E

10-9

Page 268 of 1413

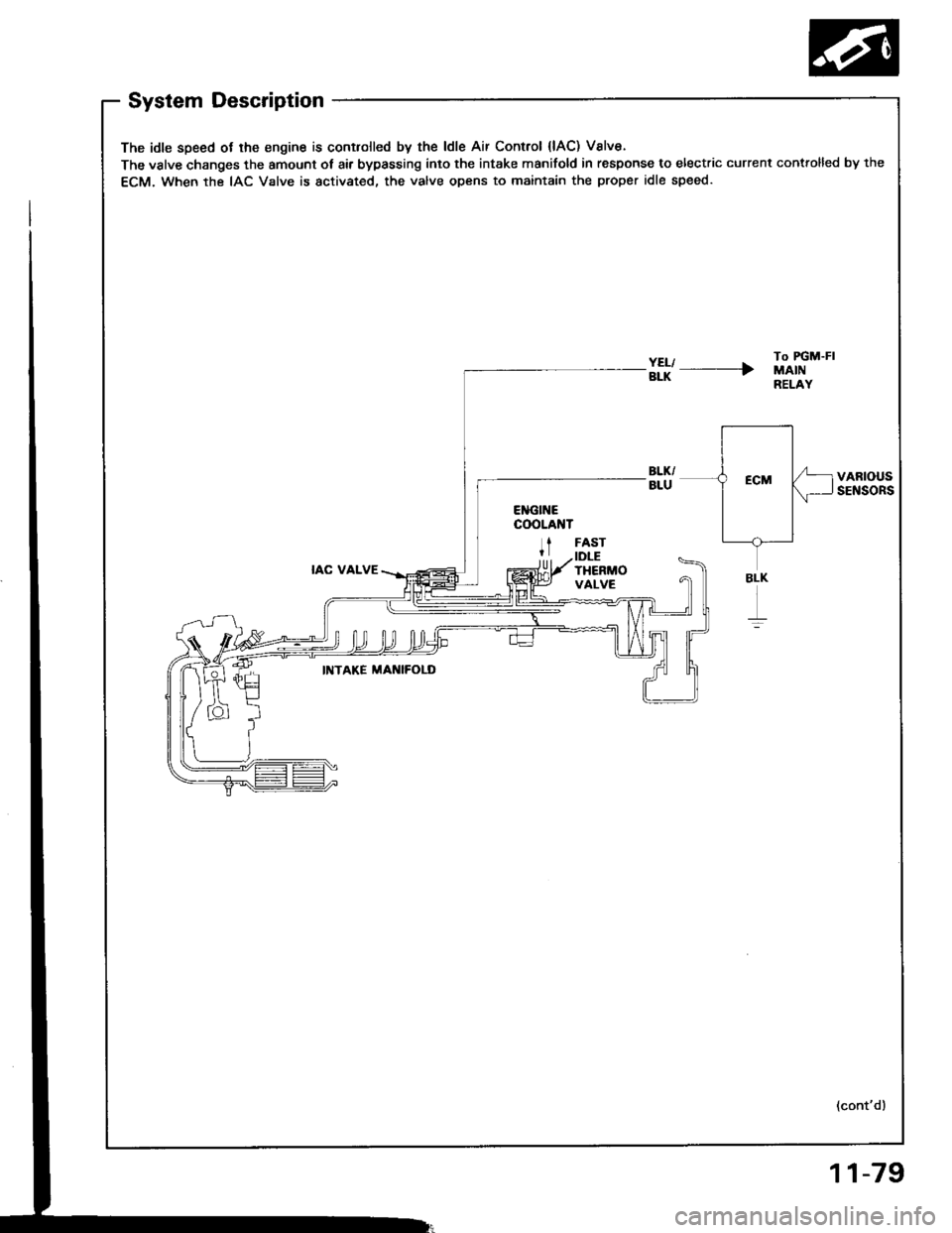

System Description

The idle speed ot lhe engine is controlled by the ldle Air Control {lAC) Valve.

The valve changes the amount ot air bypassing into the intake manifold in response to electric current controlled by the

ECM. When the IAC Valve is activated, the valve opens to maintain the proper idle speed.

#l' ----rTo FGM-FIMAINRELAY

VARIOUSSENSORS

IAC VALVE

FASTIDLETHERMOVALVE

INTAKE MAI{IFOLD

(cont'd)

BLK

r

11-79

Page 269 of 1413

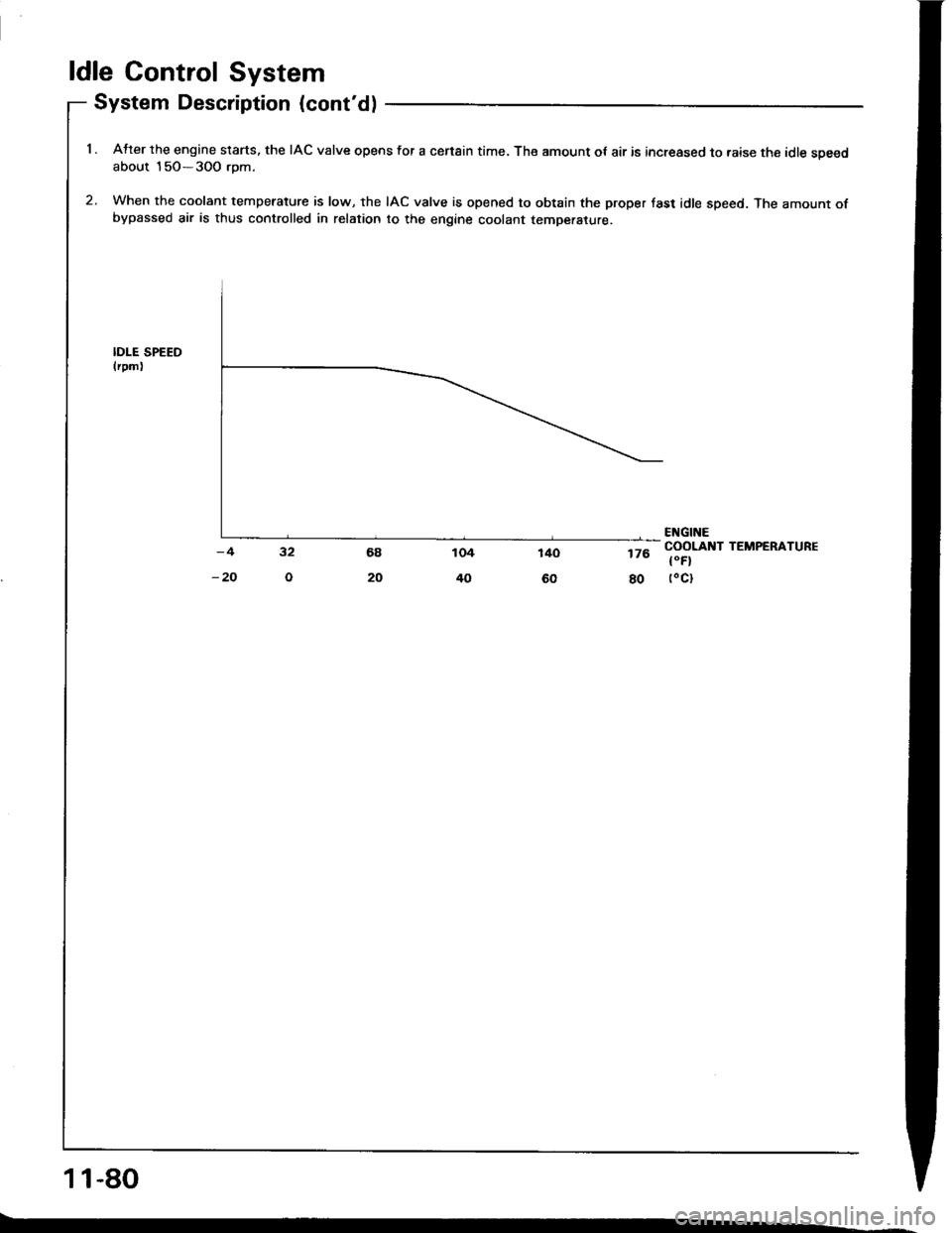

ldle Control System

System Description (cont'd)

1 . Atter the engine slarts. the IAC valve opens for a censin time, The amount ot air is increased to raise the idle soeedabout 15O-3OO rom.

2. When the coolant temperature is low, the IAC valve is opened to obtain the proper fast idle speed. The amount ofbypassed air is thus controlled in relation to the engine coolant temperature.

IDI-E SPEEDlrpm)

176

80

ENGINECOOLANT TEMPERATURE

t"Fl(oct

11-80

Page 271 of 1413

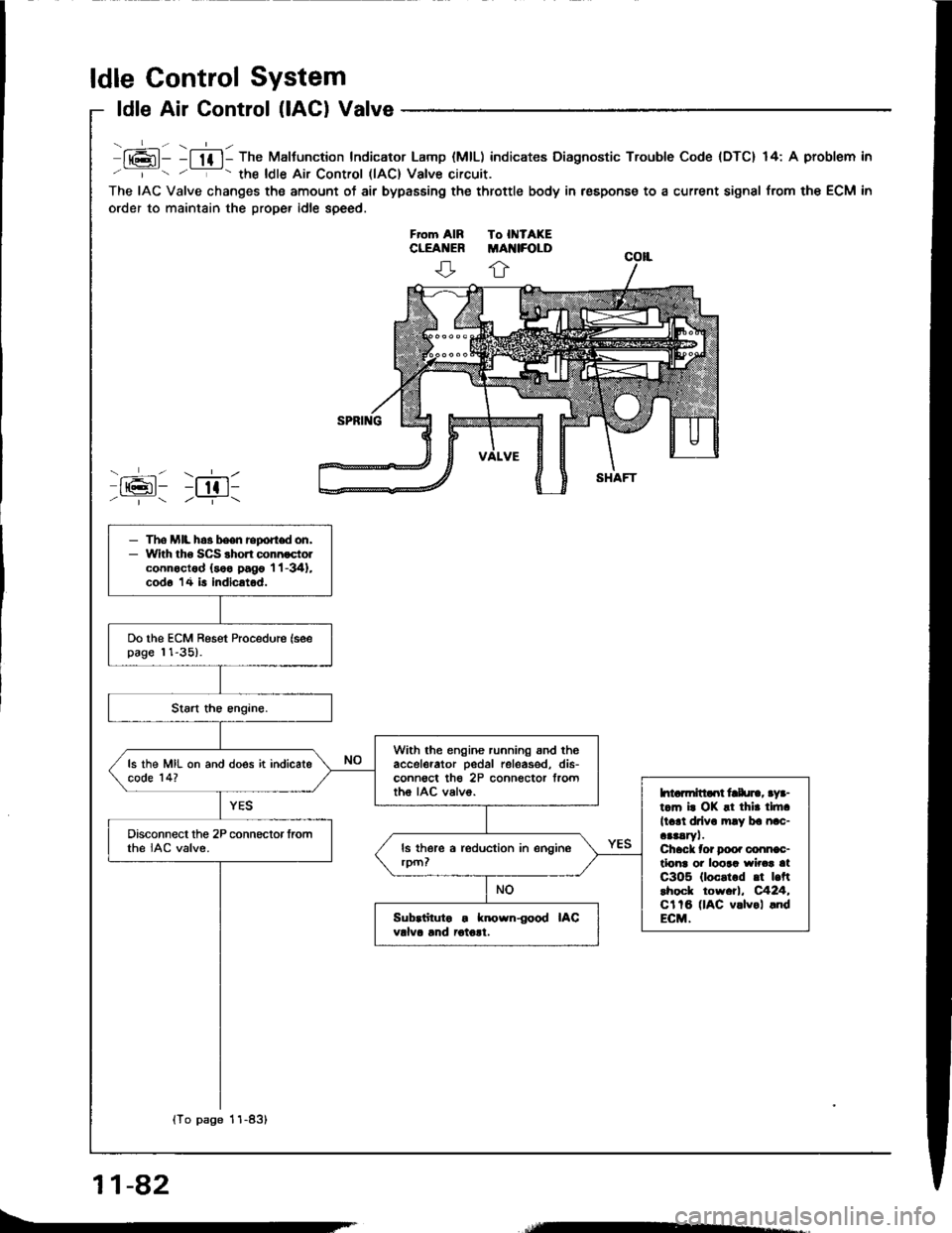

ldle Control System

ldle Air Control (lACl Valve

lt6l- -l lf l- The Maltunction Indicator Lamp (MlL) indicates Diagnostic Trouble Code {DTC} 14: A problem in

' '- the ldle Air Control llAC) Valve circuit.

The IAC Valve changes the amount of air bypasEing the throttle body in respons€ to a current signal from the ECM in

order to maintain the proper idle speed.

ffi: r;611/ | /--T-\

- The MIL h.3 been report don,- With tho SCS shon connoctolconnoctod (soo pago 'l 'l -341,

cod6 14 is indicatod.

Do the ECM Reset Procedure (seepage 11-35).

With the engine running snd theaccelerator pedal releas€d, dis-conn€ct th€ 2P connector frorttho IAC valvo.

ls the MIL on and does it indicatecode 14?

htarmitlaot frlu]., aya-t.m i. OK !t thir tlft.

ll.rl drlv. mly ba nac-aaaaryl.Chack tor Doo. conn€c-tlonr oi loora wirca atC3O5 (loc.t.d .t |.ftlhock tow.tl, C424,Cl tB (lAC v.lvol .ndECM.

Disconnect the 2P connector fromthe IAC valve.

Sub.iituto . known{ood IACvdva lnd iotolt.

{To page 11-83}

11-82

Page 283 of 1413

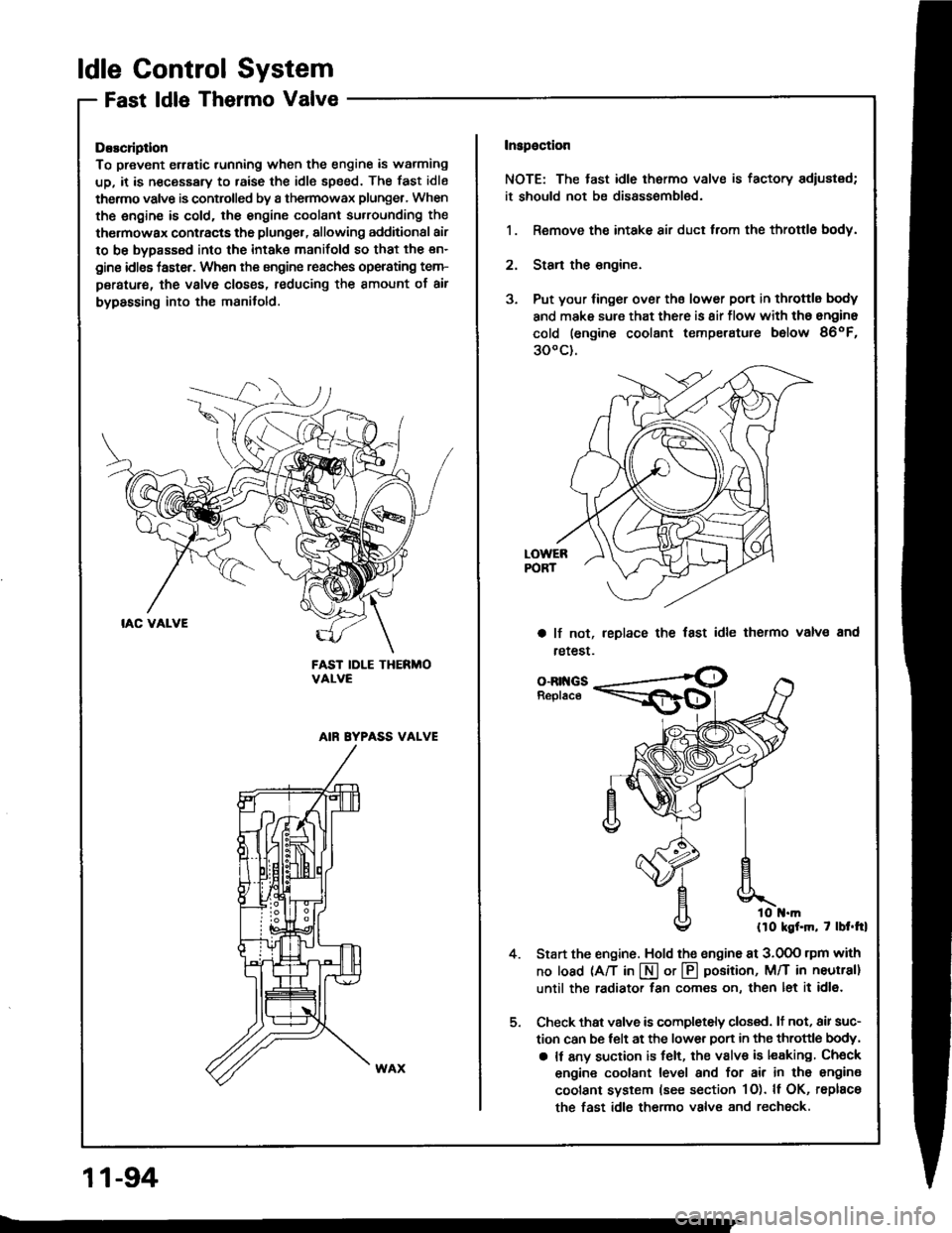

ldle Control System

Fast ldle Thermo Valve

DEscliptlon

To prevent erratic running when the engine is warming

up, it is n€cessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger, When

the engine is cold. the engine coolant su.rounding the

thermowax contracts the plunger, allowing additional air

to be bypassed into the intake manifold so that the en-

gine idlss taster. When the engine reaches operating tem-

peratur€, the valve closss, reducing the amount of air

bypassing into the manifold.

FAST IDLE THERMOVALVE

AIN EYPASS VALVE

Inspaction

NOTE: The tast idle thermo valve is factory adiustsd;

it should not be disassombl€d.

1. Remove the intake air duct from the throttlg body.

2. Stan the engine.

3. Put your finger over ths lower port in throttle body

and make sure that there is 8ir flow with tho engine

cold (engine coolant temperatute below 86oF,

300c).

a lf not,

retest.

leplace the fast idle thermo valvs and

4.

o-Rr{GsReplace

llo kgf.m, 7 lbt.trl

Start the engine. Hold the sngine at 3.0OO rpm with

no load (A/T in I or @ position, M/T in neutral]

until the radiator fan comes on, then let it idl6.

Check thst valve is completely closed. lt not, air suc-

tion can be telt at the lower Don in the throttle body,

a It any suction is felt, the valve is leaking Check

engine coolant level and for air in tho engine

coolant system (see section 1O). ll OK, rsplace

the fast idle thermo valve and rechock.

11-94