head HONDA INTEGRA 1994 4.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 72 of 1413

Timing Belt

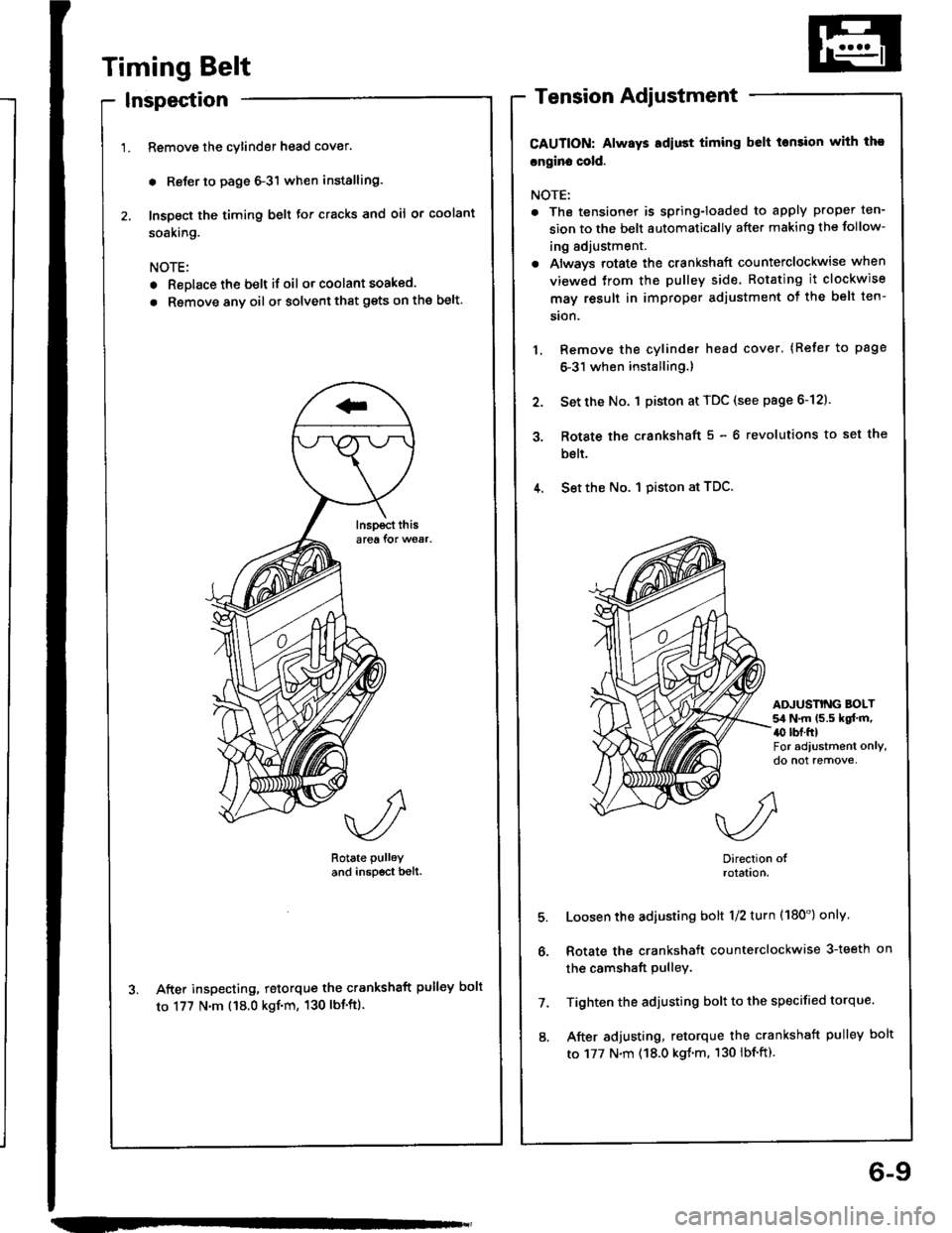

Inspection

Remove the cylinder head cover.

. Reler to page 6-3'l when installing.

Inspect the timing belt for cracks and oil or coolant

soaking.

NOTE:

. Replace the belt if oil or coolant soaked.

. Rsmove any oil or solvent that gets on the belt.

Rotate pulley

and inspscr bell.

After inspecting, retorque the crankshaft pulley bolt

to 177 N'm ('18.0 kgf'm, 130 lbt'ft).

Tension Adjustment

CAUTION: Always Ediust timing belt tonsion with tho

cngin. cold.

NOTE:

. The tensionet is spring-loaded to apply proper ten-

sion to the belt automaticallv after making the follow-

ing adjustment.

. Always rotate the crankshaft counterclockwise when

viewed trom the pulley side Rotating it clockwise

may result in improper adjustment ot the belt ten-

sion.

Remove the cylinder head cover. (Refer to page

6-31 when installing.)

Set the No. 1 piston at TDC (see page 6-12).

Rotate the c.ankshaft 5 - 6 revolutions to set the

bslt.

4. Set the No. I piston at TDC.

3.

ADJUSNNG BOLT54 N.m (5.5 kqf.m,a0 rbr.ftlFor adiustment only,do not remove,

5.

6.

7.

8.

Direction olrolatlon.

Loosen the adiusting bolt 1/2 turn (180') onlv

Rotate the crankshaft counterclockwise 3-teeth on

the camshaft pulley.

Tighten the adjusting bolt to the specified torque.

After adjusting, retorque the crankshaft pulley bolt

to 177 N.m (18.0 kgl.m. 130 lbf.ft).

6-9

Page 74 of 1413

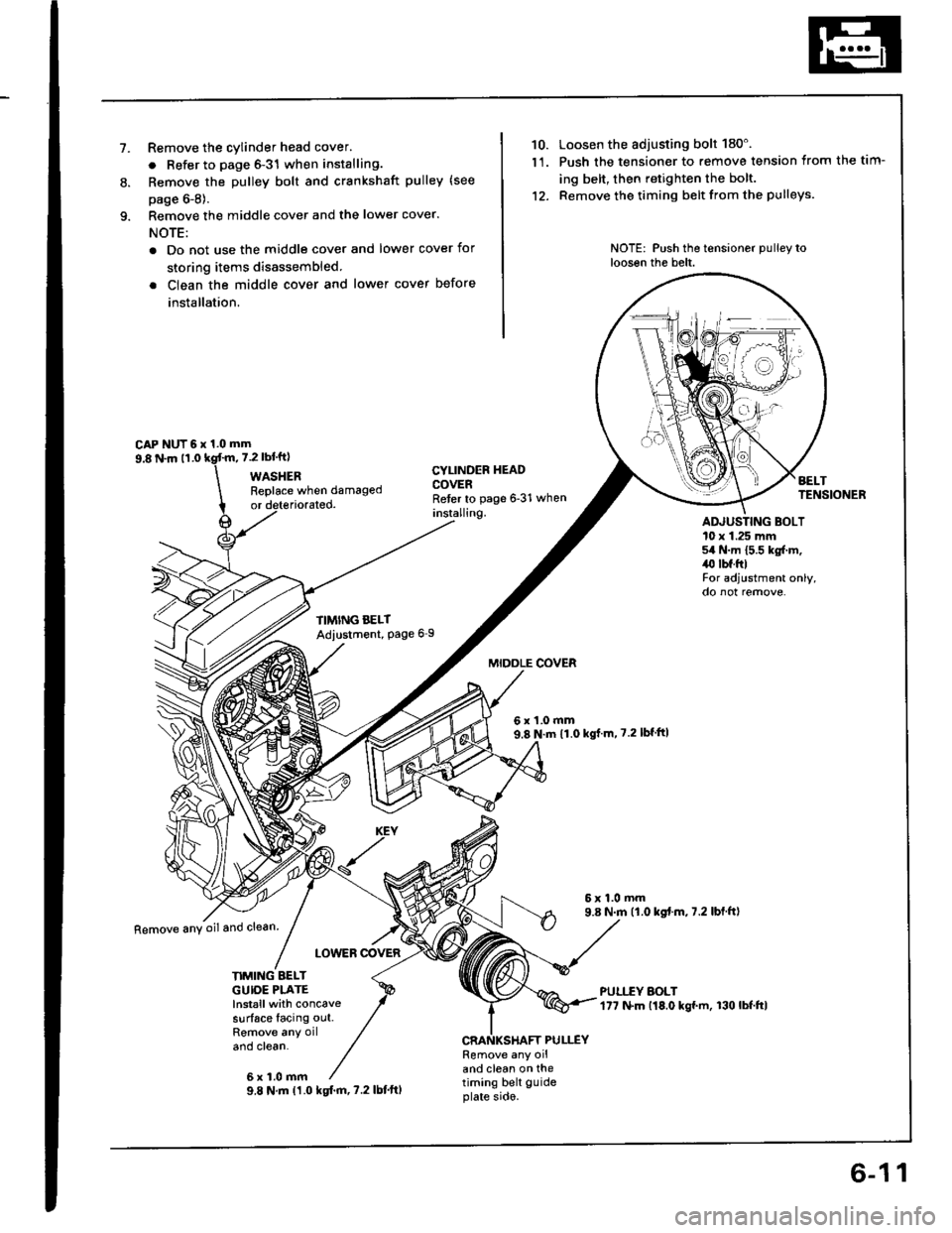

1.Remove the cylinder head cover.

. Refer to page 6-31 when installing.

Remove the Dulley bolt and crankshaft pulley (see

page 6-8).

Remove the middle cover and the lower cover.

NOTE:

. Do not use the middle cover and lower cover for

storing items disassembled.

. Clean the middle cover and lower cover before

installation.

CAP NUT 6 x 1.0 mm

10. Loosen the adjusting bolt 180'.

1'1. Push the tensioner to remove tension from the tim-

ing belt, then retighten the bolt.

12. Remove the timing belt from the pulleys.

NOTE: Push the tensioner pulley toloosen the belt.

8.

9.8 N.m 11.07.2 rbl.ftl

WASHER

orReplace when damaged

CYLINDEF HEADCOVERReter to page 6-31 wheninstalling.ADJUSTING BOLT10 x 1.25 mm54 N.m 15.5 kg{.m,/r0 lbf.ftlFor adjustment only,

TIMING BELTAdiustment, Page 6I

LOWEB @VER

MIDOLE COVER

6x1.0mm9.8 N.m 11.0 kgJ m, 7.2 lblftl

6x1.0mm9.8 N.m ('1.0 kgt.m,7.2 lbl fr)

Remove anY oiland clean

KE

6x1.0mm

NMING BELTGUIOE PLATElnstallwith concavesurface facing out.

and clean.CRANKSHAFT PULLEYRemove any oiland clean on ihetiming belt guideplate sido.9.8 N.m (1.0 kgtm,7.2lbt'ftl

6-11

Page 76 of 1413

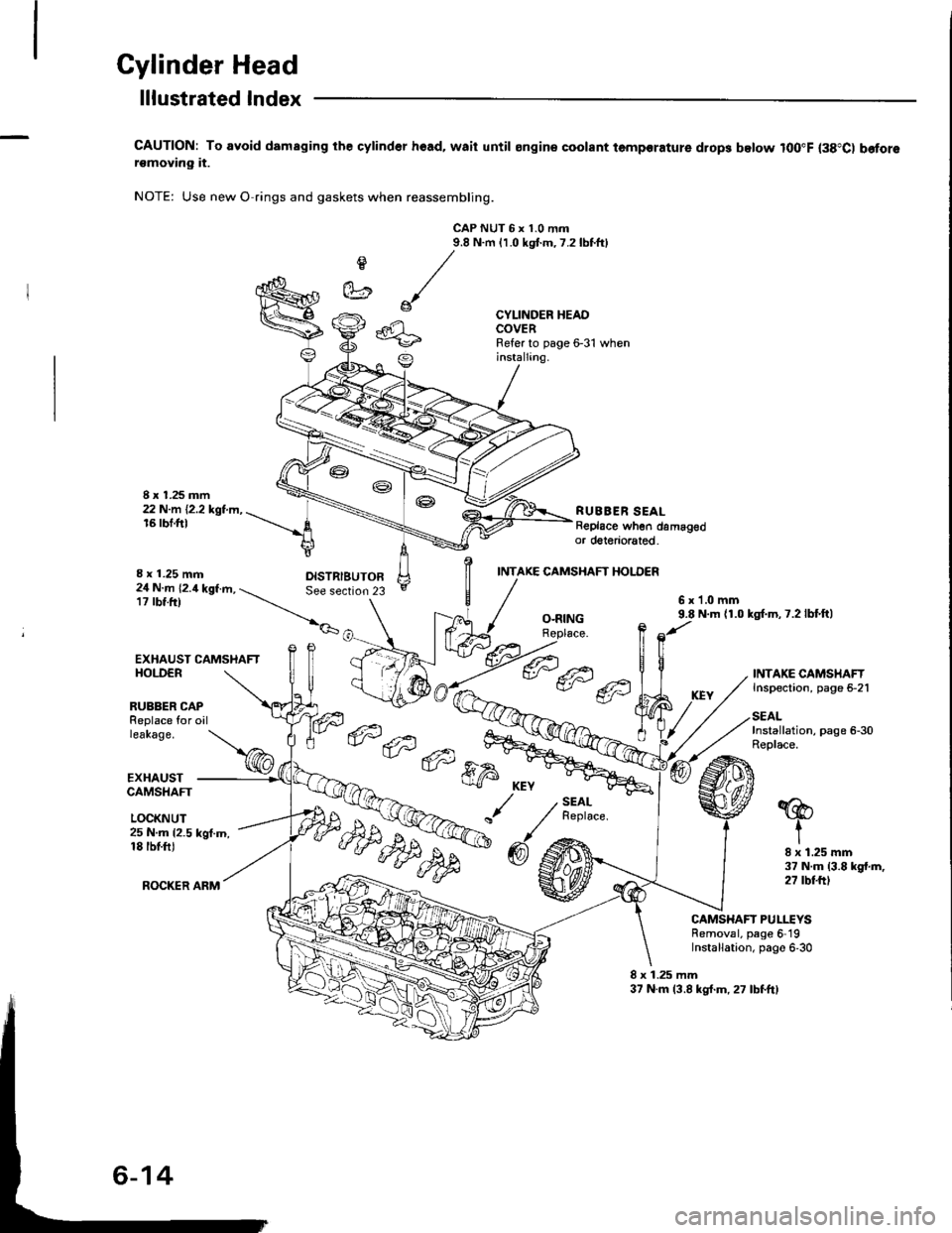

Cylinder Head

I x 1.25 mm22 N.m 12.2 kgt.m,16 rbf.ft)

lllustrated lndex

CAUTION: To avoid damaging the cylind6r hoad, waii until ongin€ coolant temporature drop3 below lOO"F (38"C) b€forersmoving it.

NOTE: Use new O rings and gaskets when reassembling.

CAP NUT 6 x 1.0 mtn9.8 N.m 11.0 kgtm,7.2lbtftl

e

et

CYLINDER HEADCOVERRefer to page 6-31 wheninstallang.

RUBBER SEALReplace when damagedor doteriorated.

I x 1.25 mm

EXHAUST CAMSHAFTHOI.DER

INTAKE CAMSHAFT HOI.DER

24 N.m 12.4 kgf.m, -. See section17 rbt.tr) --_r,_

__.|._6x1.0mm9.8 N.m {1.0 kgl.m,7.2lbf.ft)O-RINGRoplace.

RUBBER CAPReplace for oilleakage.

EXHAUSTCAMSHAFT

LOCKNUT

INTAKE CAMSHAFTInspection, page 5-21

SEALInstallation, page 6-30Replace.- 6tal --,

ffi;r

KEY

/./

"

@6

SEALReplace.'@

t25 N.m {2.5 kgf.m,18 tbtfiJ

ROCKER ARM

I x 1.25 mm37 N.m (3.8 kgt.m,27 rbtftt

CAMSHAFT PULLEYSRemoval, page 6 19Installation, page 6,30

8 x 1.25 mm37 N.m 13.8 kg{.m,27 lbfftl

Page 77 of 1413

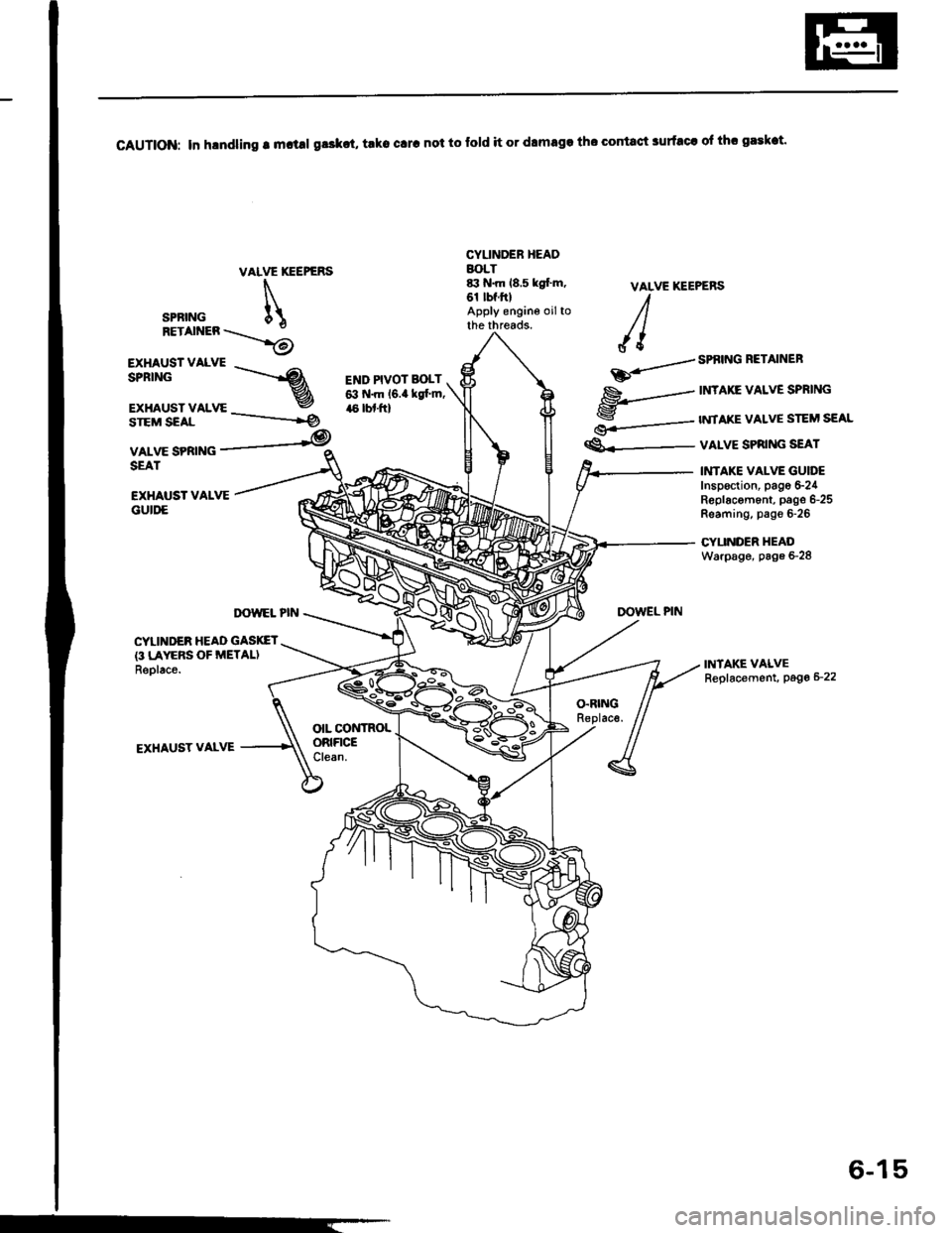

CAUTION: In h.ndling r m.t!l gr3kct, trko clrc not to fold it or dlmaga tho contact surfacr ol thr gaskat.

VAIVE XEEPERS

SPRING

RETAINER \.\...i6

r*#:-3STEM SEAL

VALVE SPRINGSEAT

CYUNDEB HEADBOLT&t N.m 18,5 kgl'm,61 tbf.ftlApply engine oiltothe threads.

END PIVOT BOLT6:t N.m l6.a kst'm,,16 lbl.ftl

VALVE KEEPERSI

JI

--../ SPf,ING RETAINEB

ED..-

$----

nrAxE vaLvE SPRING

S---- twtAKE vALvE STEM SEAL

€.---- valvE SPRING sEAT

EXHAUST VALVEGUII'E

INTAKE VAI-VE GUIT'EInsp€ction, pago S24R6placom6nt, pago 6-25Reaming, pag€ 6-26

CYUNDER HEADWarpage, page 6-28

INTAKE VALVEReplacement, Page 6_22

TX)WEL PINDOWEL PIN

CYLINDER HEAD GASKET{3 LAYERS OF METALIReolac6.

O.RINGReplac€.

EXHAUST VALVE

OIL CONTROLORIFICEClean.

--------ig

6-15

Page 78 of 1413

Gylinder Head

Removal

I

t

Engine removal is not required for this procedure.

CAUTION: To avoid damaging tho cylinder head, wait

until tho ongino coolant temporature drops bolow 100"F

{38"C) beforo loo36ning the rotainin0 bolts.

NOTE:

. Inspect the timing belt before removing the cylinder

neao.

. Turn the crankshaft pulley so that the No. 1 piston is

at top dead center (TDCI (page 6-12).

. Mark all emissions hoses before disconnecting them.. Anti-theft radios have a coded theft protection circuit.

Be sure to get the customer's code number before.- Disconnecting the battery.- Removing the No. 32 (7.5 A) fuse irom the under-

hood fuse/relay box.- Removing the radio.

After service, reconnect oower to the radio and turn it

on.

When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

1. Disconnect the negative terminalfrom the battery.

2. Drain the engine coolant (see page 10-5).

. Remove the radiator cap to speed draining.

3. Relieve fuel pressure (see Section 1 1).

@ Do not smoke whils working on tusl

systom, keep opon flame or spark away trom work

area. Drain fuol only inlo an approvod containsr.

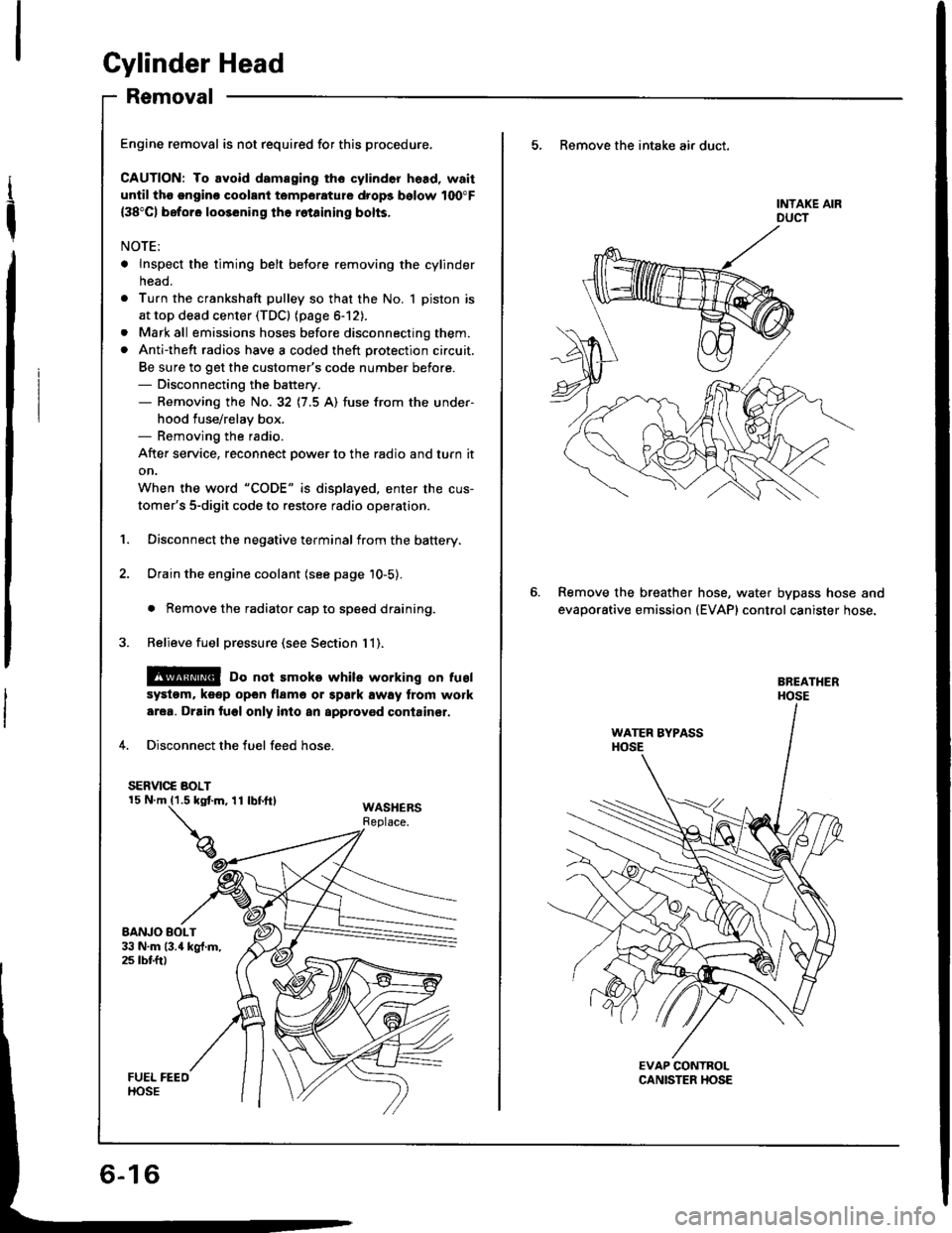

4. Disconnect the fuel feed hose.

SERVIC€ BOLT

WASHERSReplace.

5, Remove the intake air duct.

Remove the breather

evaporative emission

hose, water bypass hose and(EVAP) control canister hose.

Page 79 of 1413

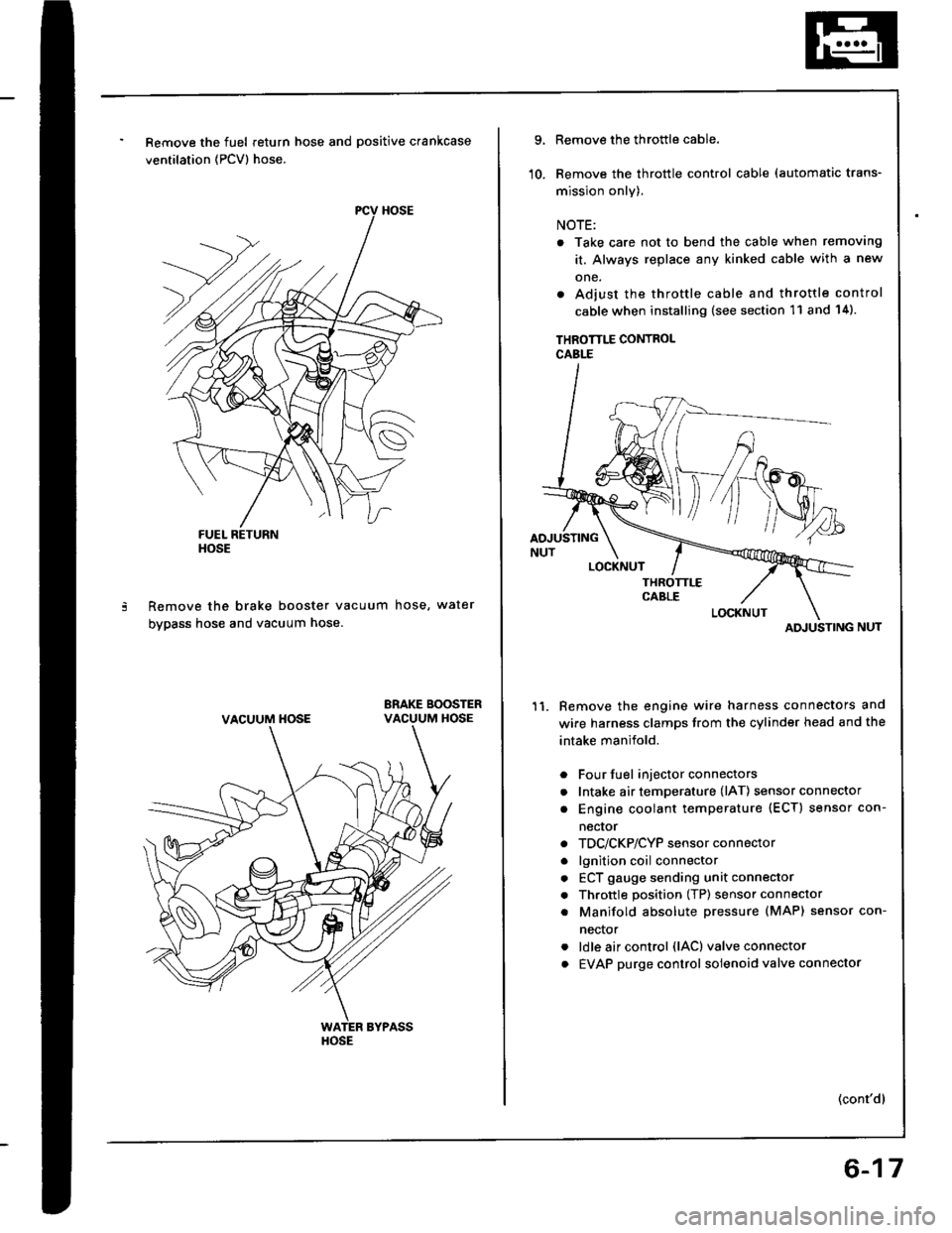

Remove the fuel return hose and positive crankcase

ventilation (PCV) hose.

Remove the brake booster vacuum hose, water

bypass hose and vacuum hose.

ERAKE BOOSTERVACUUM HOSE

HOSE

VACUUM HOSE

HOSE

9.

10.

Remove the throttle cable.

Remove the throttle control cable (automatic trans-

mission only).

NOTE:

. Take care not to bend the cable when removing

it. Always replace any kinked cable with a new

one.

. Adjust the throttle cable and throttle control

cable when installing (see section 11 and 14).

THROTTLE CONTROLCABLE

Remove the engine wire harness connectors and

wire harness clamps trom the cylinder head and the

intake manifold.

Four fuel injector connectors

Intake air temperature (lAT) sensor connector

Engine coolant temperature (ECT) sensor con-

necror

TDC/CKP/CYP sensor connector

lgnition coil connector

ECT gauge sending unit connector

Throttle position (TP) sensor connector

Manifold absolute Dressure (MAP) sensor con-

nector

ldle air control (lAC) valve connector

EVAP purge control solenoid valve connector

11.

a

a

a

a

a

a

a

a

a

(cont'dl

ATI'USTING

6-17

Page 80 of 1413

Cylinder Head

Removal (cont'dlI

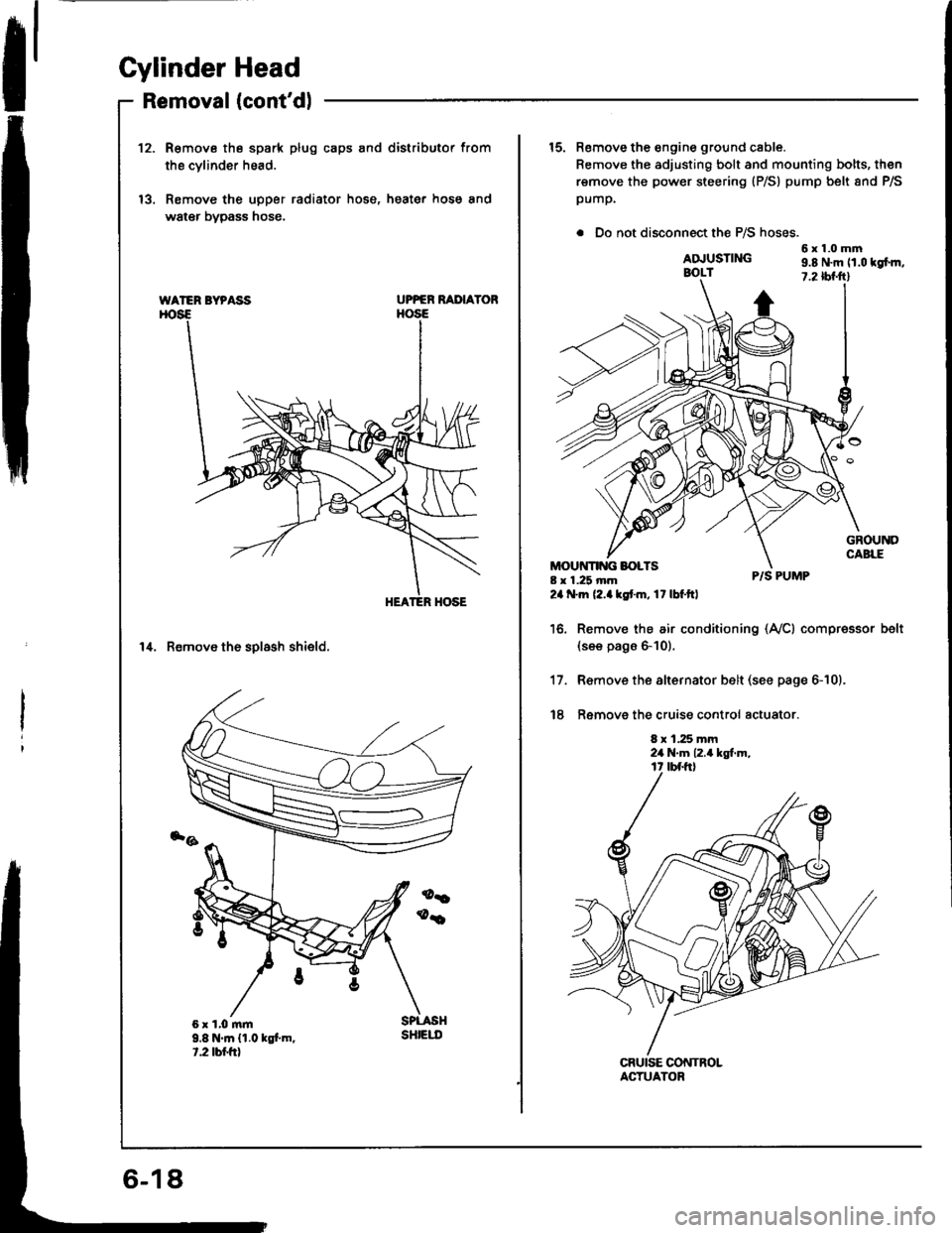

12.R€move the spark plug caps and distributor from

the cvlinder head.

Remove the upper radiator hose, heater hose and

water bypass hose.

UPPER RAI'IAYOR

14. Remove th6 solash shield.

WATER BYPASS

9.8 N.m {1.0 kgt m.t.2 tbr.frt

sHtEut

15. Remove the engine ground cable.

Remove the adjusting bolt and mounting bolts, then

remove the power steering (P/S) pump belt 8nd P/S

pump.

. Do not disconnect the P/S hoses.

6x1.0mmADJUSTINGBOLT9.8 N.m 11.0 tgfm,7.2 tbf.ftl

8 x 1.25 mm24 .m (2.akstm, 17lbf.ftl

P/S PUMP

Remov€ the air conditioning (Ay'Cl compressor(see pags 6-10).

R€move the alternator belt (see page 6-10).

Ramove the cruise control actuator.

8 x 1.25 mm2a N.m 12.4 kgt m,

belt

17.

t8

ACTUATOR

Page 81 of 1413

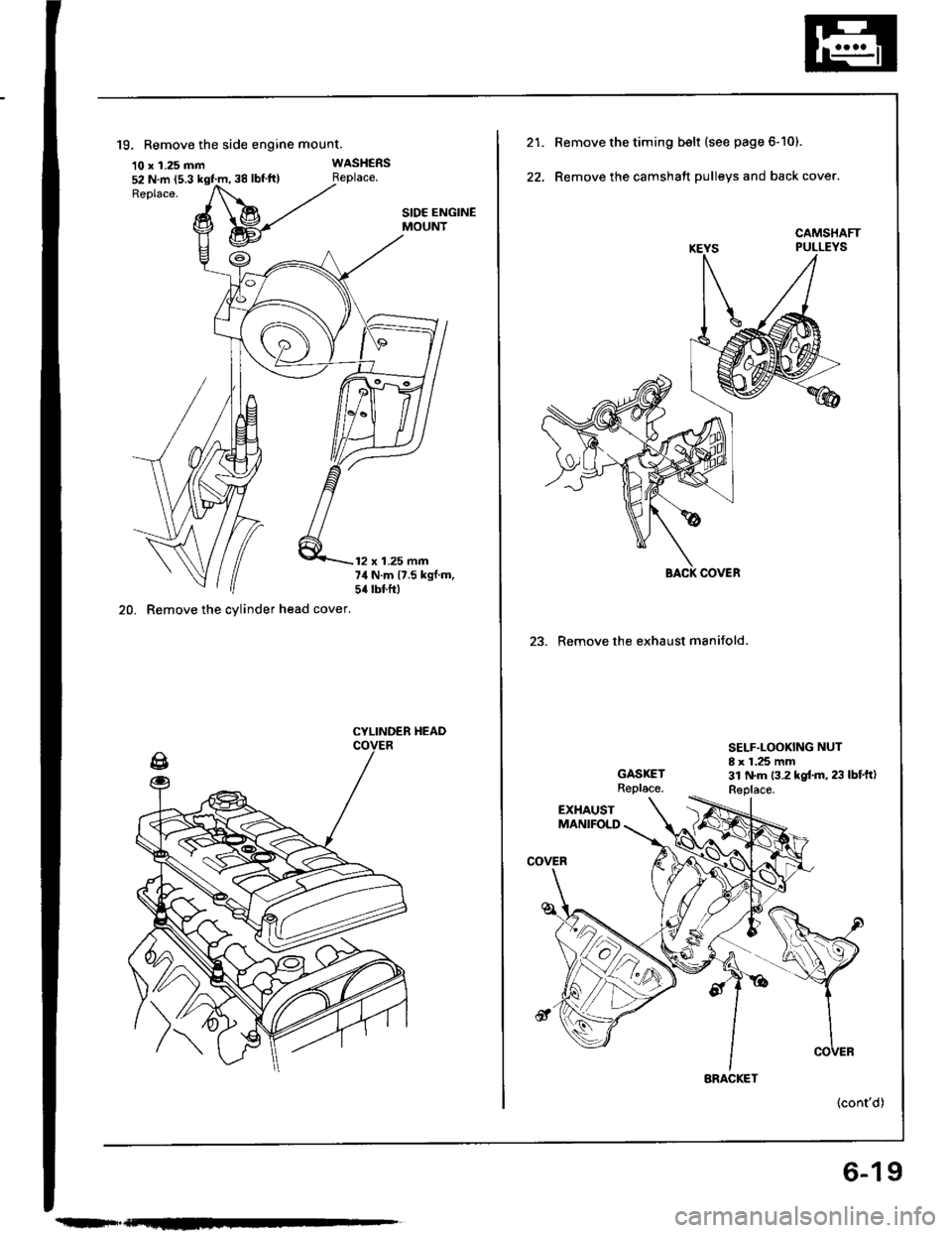

52 N.m (5.3 kgt'm, 38 lbf'ft)

19. Remove the side engine mount.

10 x 1.25 mm

20. Remove the cylinder head cover.

WASHERS

SIDE ENGINEMOUNT

12 x 1.25 mm74 N.m {7.5 kgf.m,5{ rbtftl

CYLINDEB HEAD

Remove the timing belt (see page 6-10).

Remove the camshaft pulleys and back cover.

23. Remove the exhaust manifold.

SELF.LOOKING NUT8 x 1.25 mm

BACK COVER

BRACKET

(cont'd)

6-19

Page 82 of 1413

Cylinder

Removal

Head

(cont'dl

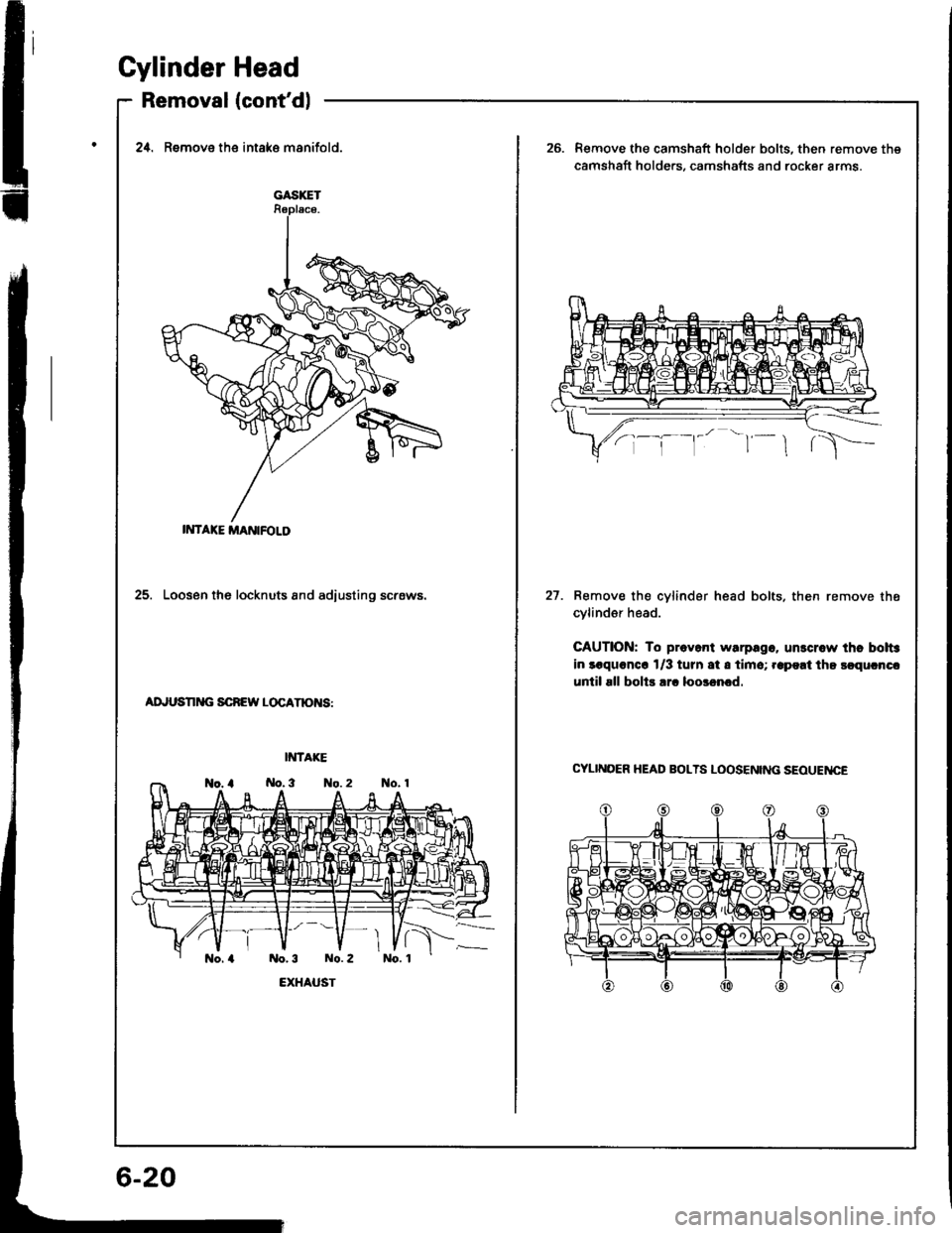

GASXET

IMTAXE MANIFOLD

2,0. Remove the intake msnifold.Remove the camshaft holder bolts, then remove the

camshaft holde.s. camshafts and rocker arms.

25. Loosen the locknuts and adiusting screws.27. Remove the cylinder head bolts. then remove the

cvlindsr head.

CAUTION: To preyant warpago. unlcr.w thc bolt3

in laquoncc 1/3 turn at I tim6; .apeat the $qurnca

until sll boltr arc loosrncd.

ADJUSNNG SCNEW LOCATN)NS:

CYLINOER HEAD BOLTS LOOSENING SEOUENCE

Page 83 of 1413

!

1.

2.

Camshafts

Inspection

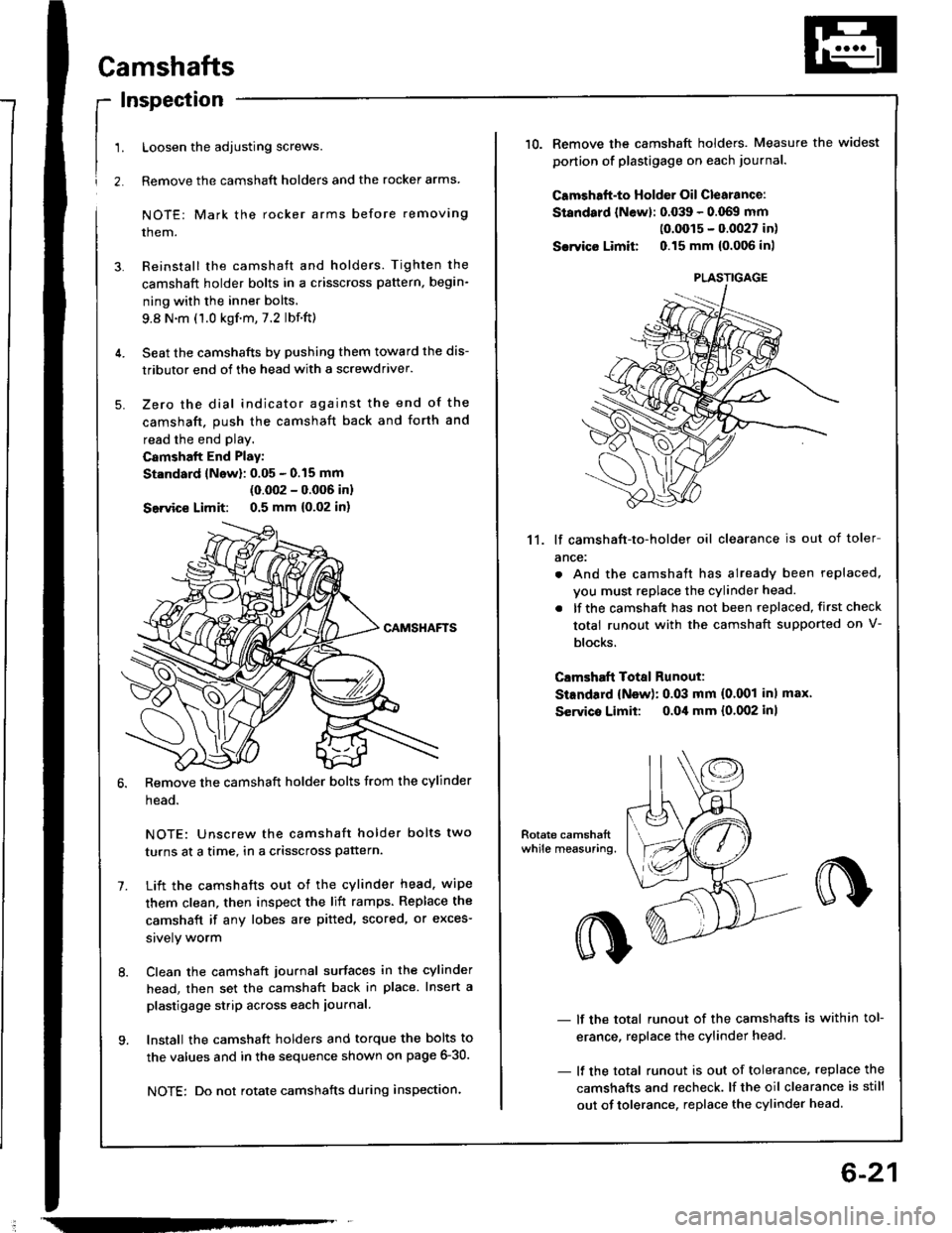

Loosen the adjusting screws.

Remove the camshaft holders and the rocker arms

NOTE: Mark the rocker arms before removing

them.

Reinstall the camshaft and holders. Tighten the

camshaft holder bolts in a crisscross pattern, begin-

ning with the inner bolts.

9.8 N.m (1.0 kgf.m,7.2 lbf.ft)

Seat the camshafts by pushing them toward the dis-

tributor end of the head with a screwdriver.

Zero the dial indicator against the end of the

camshaft. push the camshaft back and forth and

read the end play.

Camshalt End Play:

St.ndard lNow): 0.05 - 0.15 mm

(0.002 - 0.006 inl

Seivice Limit: 0.5 mm {0,02 in)

Remove the camshaft holder bolts from the cylinder

head.

NOTE: Unscrew the camshaft holder bolts two

turns at a time, in a crisscross pattern.

Lift the camshafts out ot the cylinder head. wipe

them clean, then inspect the lift ramps. Replace the

camshaft if any lobes are pitted, scored, or exces-

srvely worm

Clean the camshaft journal surfaces in the cylinder

head, then set the camshaft back in place. Insert a

plastigage strip across each iournal.

Install the camshaft holders and torque the bolts to

the values and in the sequence shown on page 6-30.

NOTE: Do not rotate camshafts during inspection.

-

6-21

10.Remove the camshaft holders. Measure the widest

ponion of plastigage on each journa..

Camshaft-to Holder Oil Clearance:

Standard lNewl: 0.039 - 0.069 mm(0.0015 - 0.0027 in)

Sarvico Limit 0.15 mm {0.006 inl

11. lf camshaft-to-holder oil clearance is out of toler

ance:

. And the camshaft has already been replaced,

vou must replace the cylinder head.

. lf the camshaft has not been replaced, first check

total runout with the camshaft supported on V-

blocks.

Clmshaft Total Runout:

StEndard {New): 0.03 mm (0.001 inl max'

Servico Limit: o.Oil mm {0.002 inl

- lf the total runout of the camshafts is within tol-

erance, replace the cylinder head.

- lf the total runout is out of tolerance, replace the

camshafts and recheck. lf the oil clearance is still

out of tolerance. replace the cylinder head.

PLASTIGAGE