lock HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1247 of 1413

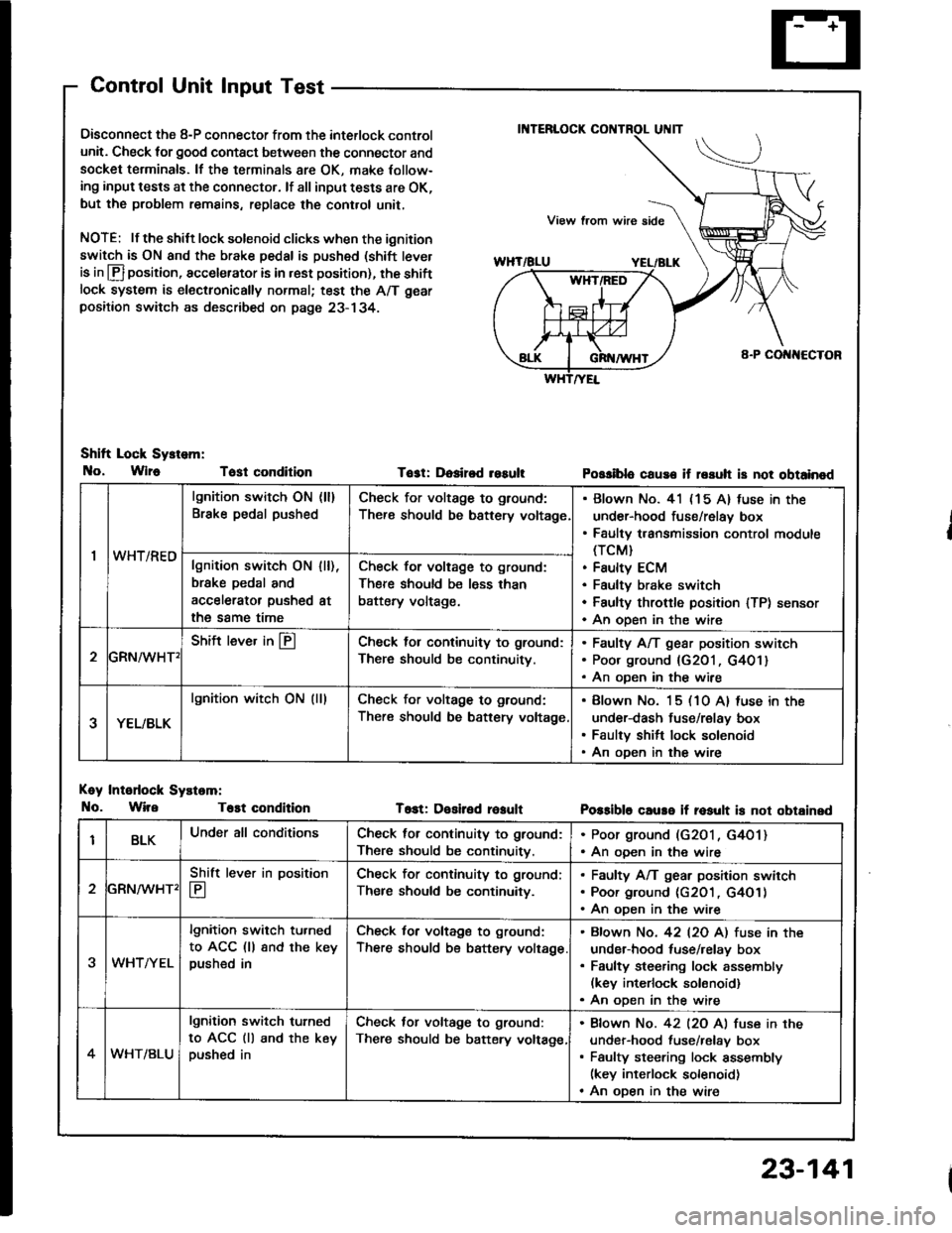

Control Unit Input Test

Oisconnect the 8-P connector from the interlock control

unit. Check for good contact between the connector and

socket terminals. lf the terminals 8re OK, make Iollow-

ing input tests at the connector. lf all input tests are OK,

but the problem remains, replace the cont.ol unit,

NOTE: lf the shilt lock solenoid clicks when the ignition

switch is ON and the brake pedal is pushed (shift tever

is in lfl position, accelerator is in rest position), the shiftlock system is electronically normal; test the A/T gear

positaon switch as described on page 23- 134.

Shift Lock Sy.tem:

No, Wlr6 Tost condition

Koy Intodock Systam:

No. WireT6st condition

Tost: Dosired resultPossiblo cause if rssuh is not obtainod

T6st: Desiled reaultPossible caure if rosult is not obtainsd

'I

lgnition switch ON (ll)

Brake pedal pushedCheck for voltage to ground:

There should be bsttery voltage

Blown No. 41 (15 A) fuse in the

under-hood fuse/relay box

Faulty transmission control module(TCM}

Faulty ECM

Faultv brake switch

Faulty throftle position lTP) sensor

An oDen in the wire

wn t/hEulgnition switch ON

brske pedal and

accelerator pushed

the same time

I [),

at

Check for voltage to ground:

There should be less than

battery voltage.

GRN^/vHT'

Shift lever in @Check lol continuity to ground:

There should be continuity.

Faulty A/T gear position switch

Poor ground {G201, G401}

An oDen in the wire

YEL/BLK

lgnition witch ON (lllCheck for voltage to ground:

There should be battery voltage

Blown No. 15 (10 A) luse in the

under-dash fuse/relay box

Faulty shift lock solenoid

An oDen in the wire

BLKUnder all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G2O1, G4O1). An ooen in the wire

2

Shift lever in position

E

Check for continuity to ground;

Ther€ should be continuity.

Faulty A/T gear position swirch

Poor ground (c2O1 , G4O1)

An oDen in the wire

3WHTAYEL

lgnition switch tu.ned

to ACC (ll 8nd the keypushed in

Check for voltage to ground:

There should be battery voltage

Bfown No. 42 l2O Al fuse in the

under-hood tuse/relay box

Faulty steering lock assembly(kev interlock solonoid)

An oDen in the wire

4WHT/BLU

lgnition switch turned

to ACC (ll and the keypushed in

Check tor voltage to ground:

There should be batery voltage,

Bfown No. 42 l2O Al fuse in the

under-hood fuse/relav box

Faulty steering lock assembly(key interlock solenoid)

An oDen in the wire

23-141

Page 1248 of 1413

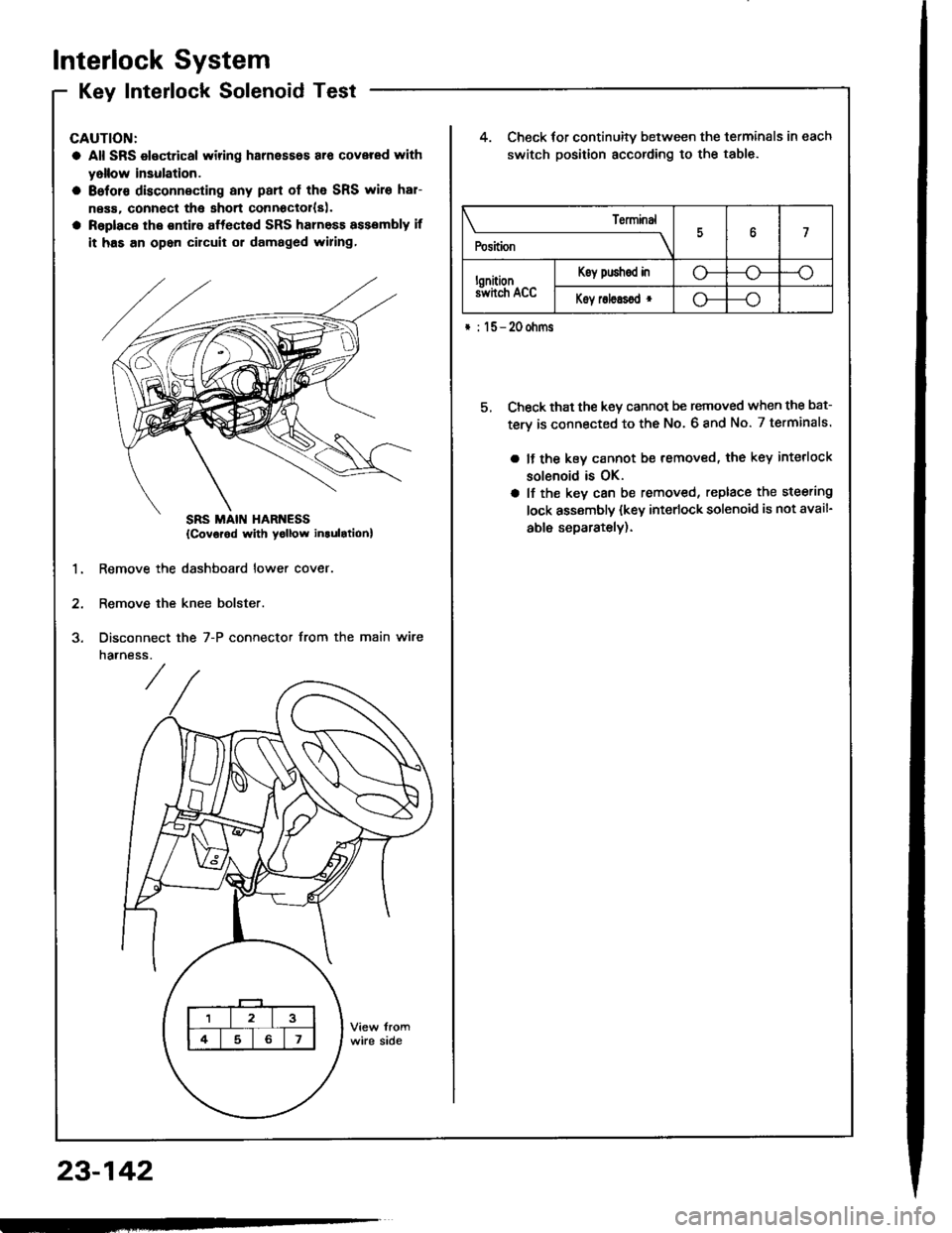

Interlock System

Kev Interlock SolenoidTestKey IntenocK Dorenoro I esr -

CAUTION:

a All SRS electrical wiring harnesses ar€ covered rYith

yollow insulation.

a 8eforc disconnecting any pan of the SRS wire har-

ness. connecl tha short connoclol{s|.

a Raplace the ontire affected SRS harness assembly if

it has an opon circuit or damaged wiring,

4. Check for continuitv between the terminals in each

switch position according to the table.

5, Check that the key cannot be removed when the bat-

tery is connected to the No. 6 8nd No. 7 terminals.

a It the kev cannot be removed, the key interlock

solenoid is OK.

a lf the key can be removed, replace the steering

lock assembly (key interlock solenoid is not avail-

able separately).

1.Remove the dashboard lower cover

Remove the knee bolster.

Disconnect

narness.

the 7-P connector from the main wire

\______________rry

Position7

lonitionS hch Acc

Koy push€d ino---o

Koy roleEsod r--o

* : l5-20ohms

{Covorod with yollow inlulrtionl

23-142

Page 1249 of 1413

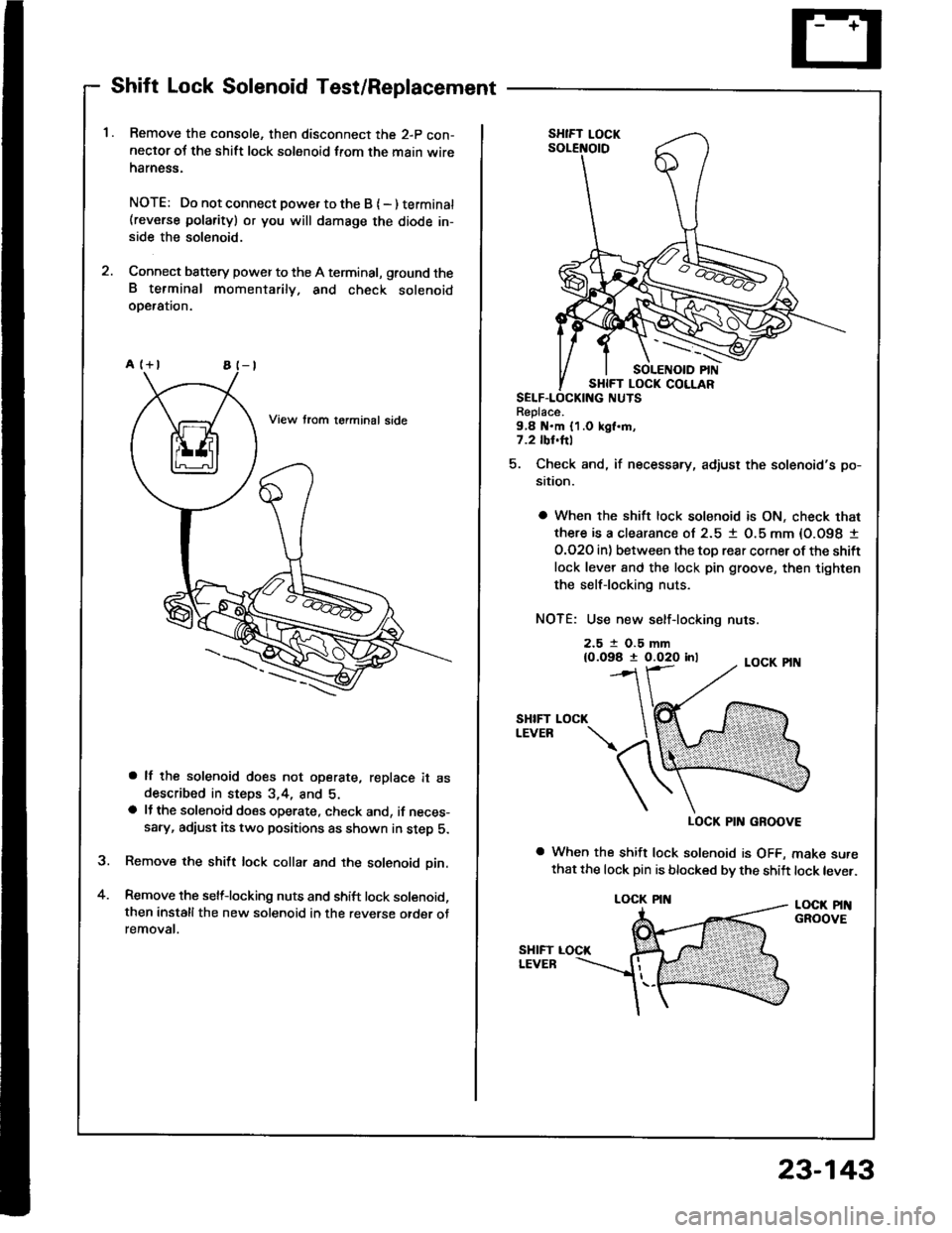

Shift Lock Solenoid Test/Replacement

Remove the console, then disconnect the 2-p con-neclor oJ the shift lock solenoid from the main wireharness.

NOTE: Do not connect powe. to the B { - ) terminat(reverse polarity) or you will damsge the diode in-side the solenoid.

Connect battery power to the A terminal, ground theB terminal momentarily. and check solenoidoDeralron.

a lf the solenoid does not operate, replace it asdescribed in steps 3,4, and 5.a lJ the solenoid does operate, check and, if neces-sary, adiust its two positions as shown in step 5.

Remove the shift lock collar and the solenoid pin.

Remove the selflocking nuts and shift lock solenoid,then installthe new solenoid in the reverse otder otremovat.

a

Replace.9,8 N.m {1.0 kgl.m,7.2 tbl.hl

5. Check and, if necessary, adjust the solenoid's po-

sition.

a When the shift lock solenoid is ON, check that

there is a clearance ol 2.5 1 O.5 mm {O.O98 I

O.O2O in) between the toD rear corner ot the shift

lock lever 8nd the lock pin groove, then tighten

the selflocking nuts.

NOTE: Use new self-locking nuts.

2.5 t O.5 mm{0.098 t 0.020 inl

SHIFTLEVEB

LOCK PIN GROOVE

a When the shift lock solenoid is OFF, make surethat the lock pin is blocked bv the shift lock lever.

LOCK PINGROOVE

LOCK

LOCK PIN

23-143

Page 1255 of 1413

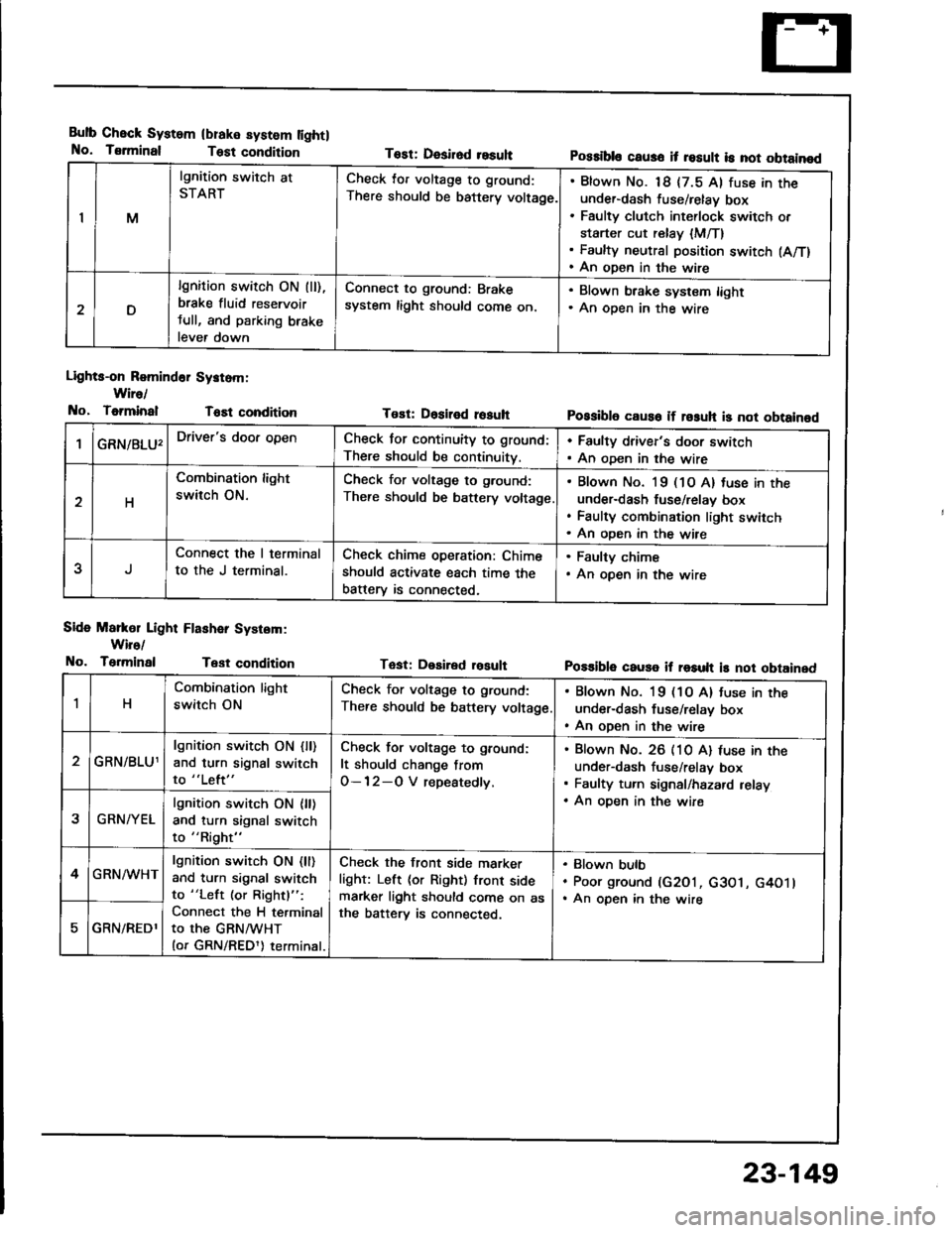

Bulb Check System

No. Tsrminal

(blake system lightl

Test condition

Lights-on Romind6r Systom:

Wire/

No, ToiminalT6Et condition

Side Markol Light Flashar System:

Wiro/

No. TerminalTest condition

Tost: Desirod resuhPossibls caus6 it result is not obtainod

Tost: Dositod rosuhPossibl6 caus6 if rosuh is not obtainod

Tast: Desired rosultPo$ible cause if result is not obtained

IM

lgnition switch at

STARTCheck lor voltage to ground:

There should be battery voltage.

Blown No. 18 {7.5 Al fuse in theunder-dash fuse/relay box

Faulty clutch int€rlock switch or

starter cut relay {M/T}Faulty neutral position switch (A/T)

An open in the wire

D

lgnition switch ON (ll),

brake fluid reservoir

tull, and parking brake

lever down

Connect to ground: Brake

system light should come on.

. Blown brake system light. An oDen in the wire

GRN/8LU'Driver's door openCheck for continuity to ground:

There should be continuity.

. Faulty driver's door switch. An oDen in the wire

H

Combination light

switch ON.

Check for voltage to g.ound:

There should be battery voltage

Blown No. l9 (1O A) tuse in the

under-dash fuse/relav box

Faulty combination light switch

An oDen in the wire

5

Connect the I terminal

to the J terminal.

Check chime operation: Chime

should activate each time the

batterv is connected,

. Faulty chime. An open in the wire

1H

Combination light

switch ON

Check for voltage to ground:

There should be battery voltage

. Blown No. 19 (1O A) tuse in the

under-dash fuse/relay box. An open in the wire

GRN/BLU1

lgnition switch ON {ll)and turn signal switch

to "Left"

Check for voltage to ground:

It should change from

O-12-O V repeatedly.

Blown No. 26 (10 A) luse in theunder-dash fuse/relav box

Faulty turn signal/hazard relay

An oDen in the wire2GRN/YEL

lgnition switch ON {ll)and turn signal switch

to "Right"

4GRN/WHTlgnition switch ON (ll)

and turn signal switch

to "Left (or Rightl":

Connect the H terminal

to the GRNMHT(or GRN/REDl) terminal.

Check the front side marker

light: Left (or Right) front sidemarker light should come on asthe batterv is connected.

Blown bulb

Poor ground (G2O1, c3O1, G4O1lAn open in the wire

GRN/REDl

23-149

Page 1270 of 1413

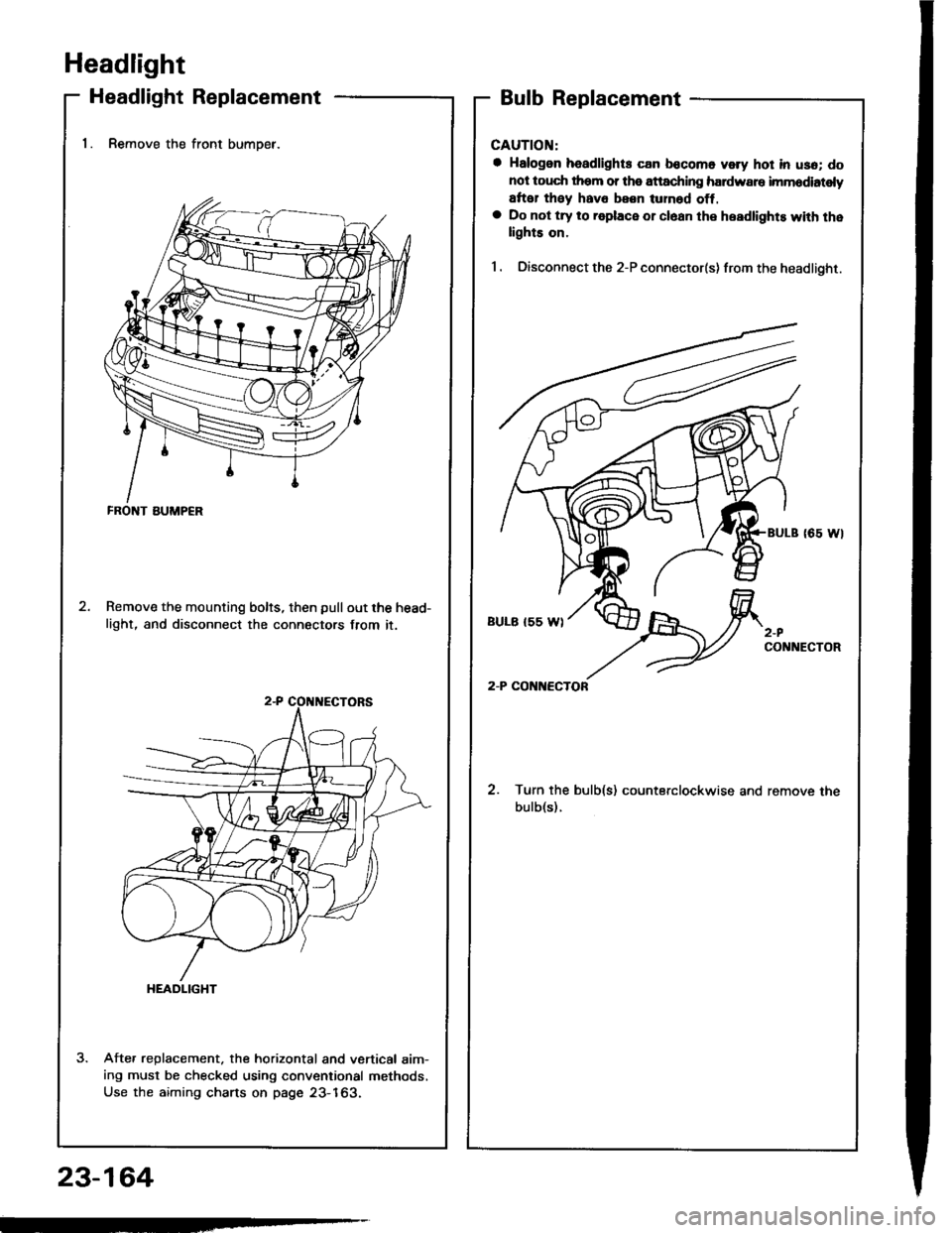

Headlight

Headlight Replacement

1. Remove the front bumoer.

Remove the mounting bolts, then pullout the head-

light, and disconnect the connectors from it.

Afte. replacement. the horizontal and vertical aim-ing must be checked using conventional methods,

Use the aiming charts on page 23-163.

Bulb Replacement

CAUTION:

a Halogon headlights can bocomo voly hot in usa; do

not touc$ them or tho attaching hardware imm6diatoly

arter they hava been lurnod off,a Do not try to roplace or cl6an the headlights with thelights on.

I . Oisconnect the 2-P connector(s) from the headlight.

coNlrtEcToR

2. Turn the bulb(s) counterclockwise and remove the

bulb(s).

FRONT BUMP€R

HEADLIGHT

23-164

Page 1271 of 1413

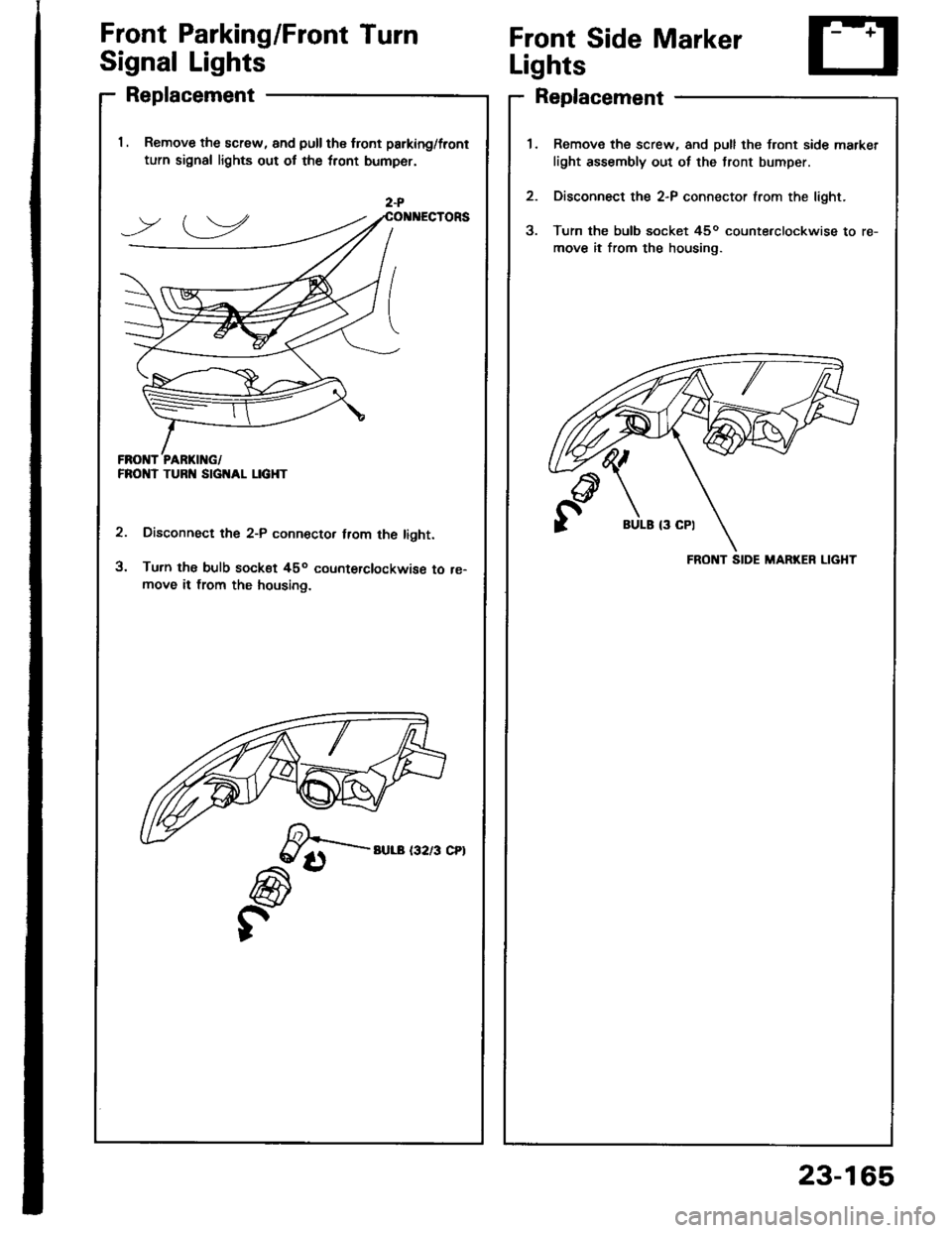

Front Parking/Front TurnFront Side Marker

LightsSignal Lights

Replacement

l. Remove the screw, and pull the front parking/front

turn signal lights out ot the tront bump6r.

Disconnect the 2-P conn€ctor trom the tight.

Turn the bulb sock€t 45o counterclockwise to re-move it from the housing.

Replacement

Remove the screw, and pull the front side marker

light assembly out of the tront bumper.

Disconnect the 2-P connector from the lioht.

Turn the bulb socket 45o counterclockwise to re-

move it from the housing.

BULE {3 CPI

FRONT SIDE MARKER LIGHT

23-165

Page 1275 of 1413

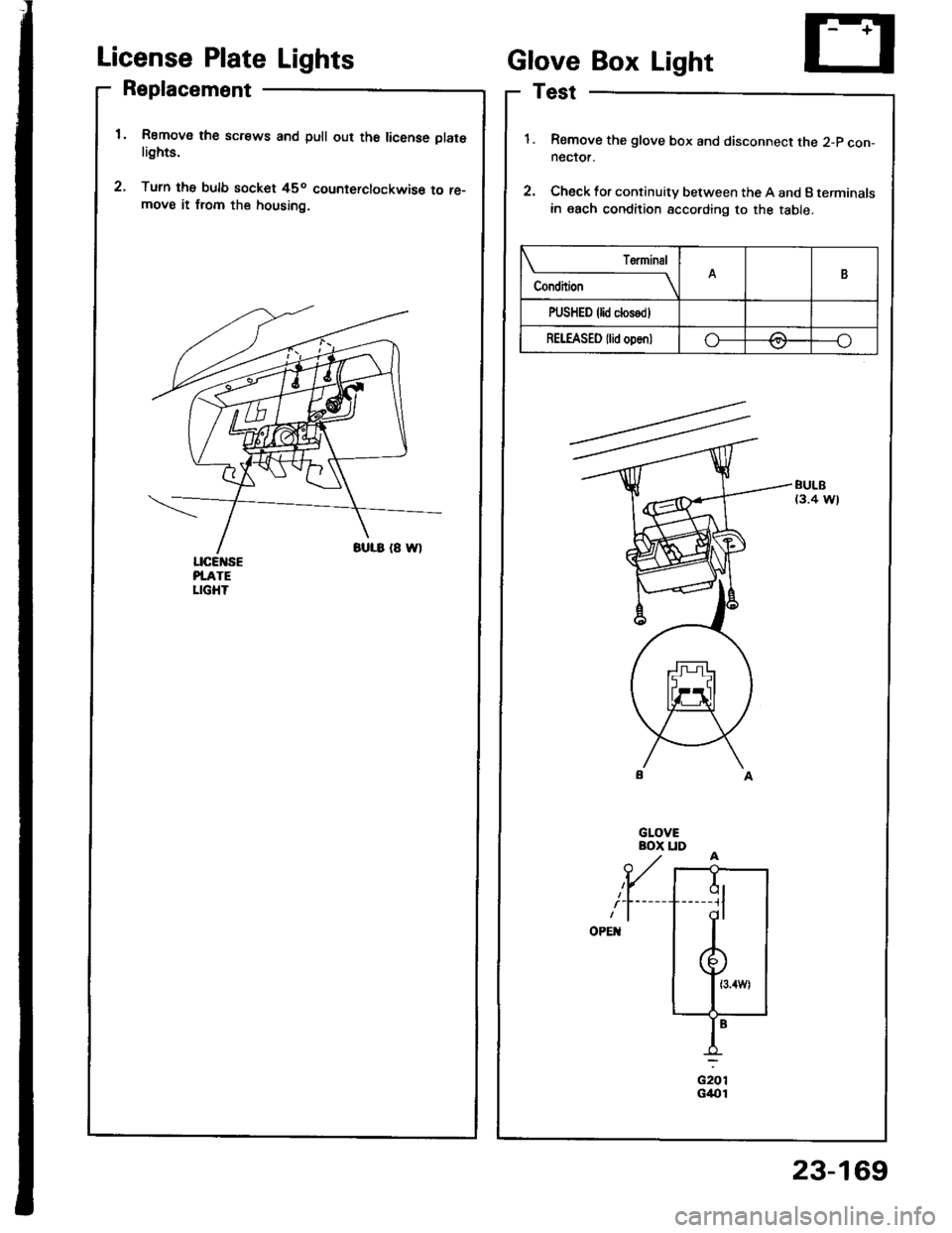

License Plate Lights

Replacement

Remov€ the screws and pull out th6 license platelights.

Turn the bulb socket 45o counterclockwise to re-move it from the housing.

ciorG4{t1

Glove Box Light

Test

Remove the glove box and disconnect the 2-p con-neclor.

Check for continuity between the A and B terminals

in each condition according to the table.

BULB(3.4 W)

Condition

T€rminalB

PUSHED {lid closodl

REI"EASED {lid oDen)o-/:\---o\7

ql-----11

dl

23-169

Page 1284 of 1413

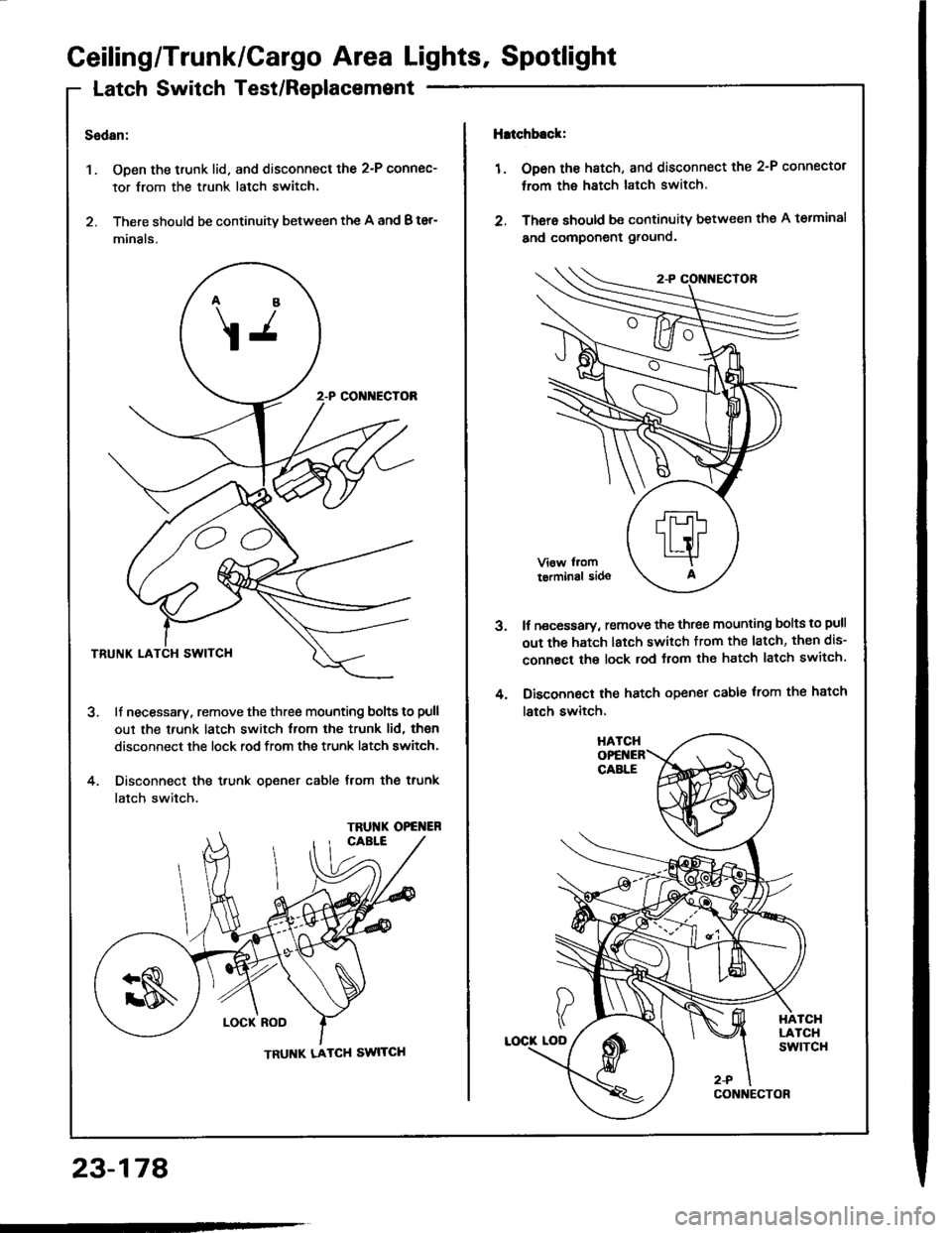

Ceiling/Trunk/Cargo Area Lights, Spotlight

Latch Switch Test/Replacemsnt

Sedan:

1. Open the trunk lid. and disconnect the 2-P connec-

tor from the trunk latch switch.

2. There should be continuity between the A and B ter-

minals.

ll necessary, remove the three mounting bolts to pull

out the trunk latch switch from the trunk lid, then

disconnect the lock rod from the trunk latch switch.

Disconnect the trunk opener cable from the trunk

latch switch.

4.

\j

CC

TRU'{K OPG ER

TRUNK LATCH SWITCH

lhtchb.ck:

1 . Op6n the hatch, and disconnect the 2-P connector

trom the hatch latch switch.

2. There should be continuity between thg A terminal

and component ground.

lf necessary, remove the three mounting bolts to pull

out the hatch latch switch trom the latch, then dis-

connact the lock rod Jrom the hatch latch switch

Disconnect the hatch opener cable trom the hatch

latch switch,

3.

4.

23-178

Page 1289 of 1413

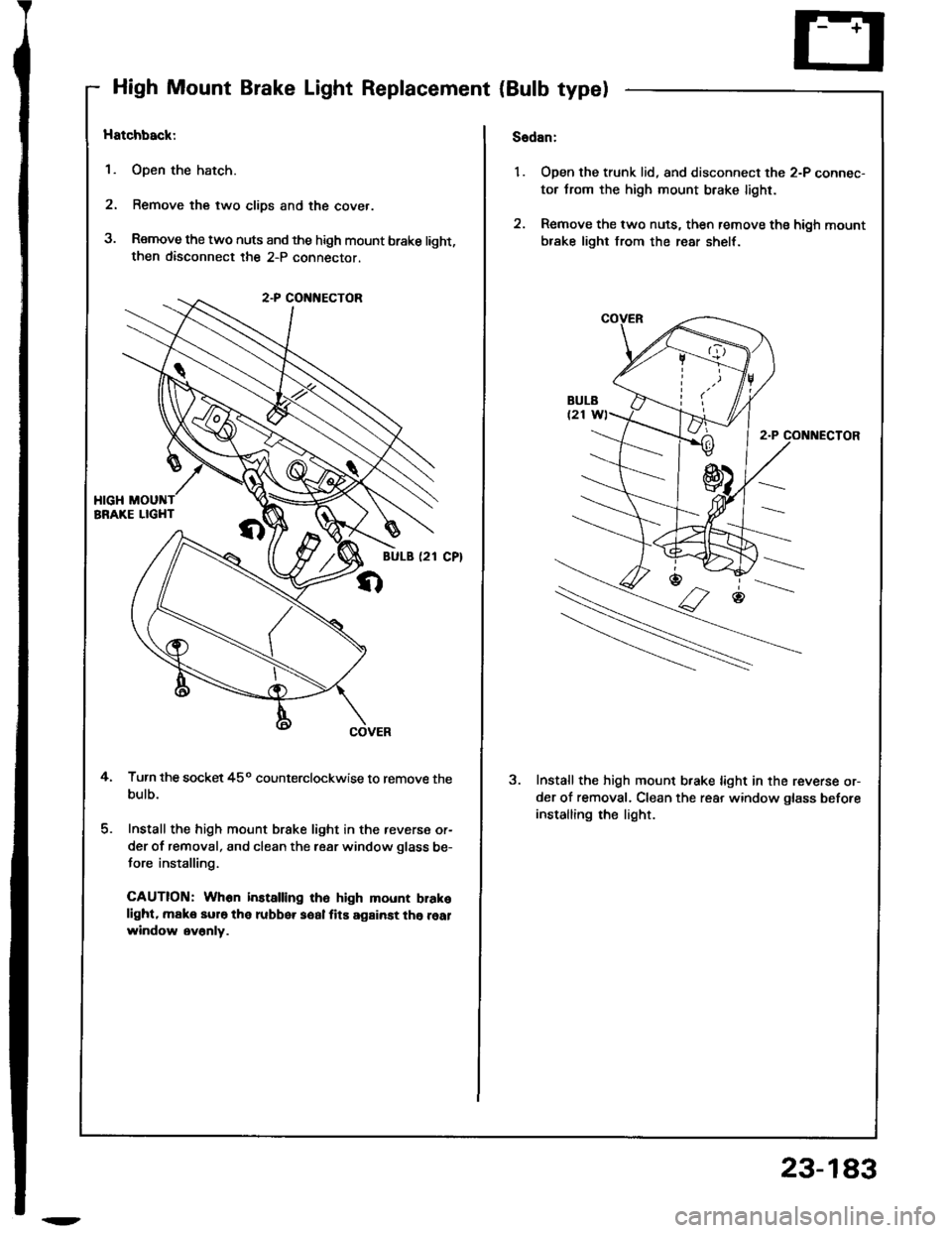

High Mount Brake Light Replacement {Bulb type)

Hatchback:

1. Open the hatch.

2. Remove the two clips and the cover.

3. Remove the two nuts and the high mount brake light,then disconnect the 2-P connector.

Turn the socket 45o counterclockwise to remove thebulb.

Install the high mount brake light in the reverse or-

der of removal, and clean the rear window glass be-

tore installing.

CAUTION: Whon installing ih6 high mount brakelight. make sur6 the rubber soal fits against the realwindow ev6nly.

4.

Sadan:

1. Open the trunk lid, and disconnect the 2-P connec-

tor trom the high mount brake light.

2. Remove the two nuts, then remove ths high mount

brake light from the rear shelt.

2-P CONt{ECTOR

Install the high mount brake light in the reverse or-

der of removal. Clean the rear window glass before

installing rhe light.

2

23-183

Page 1304 of 1413

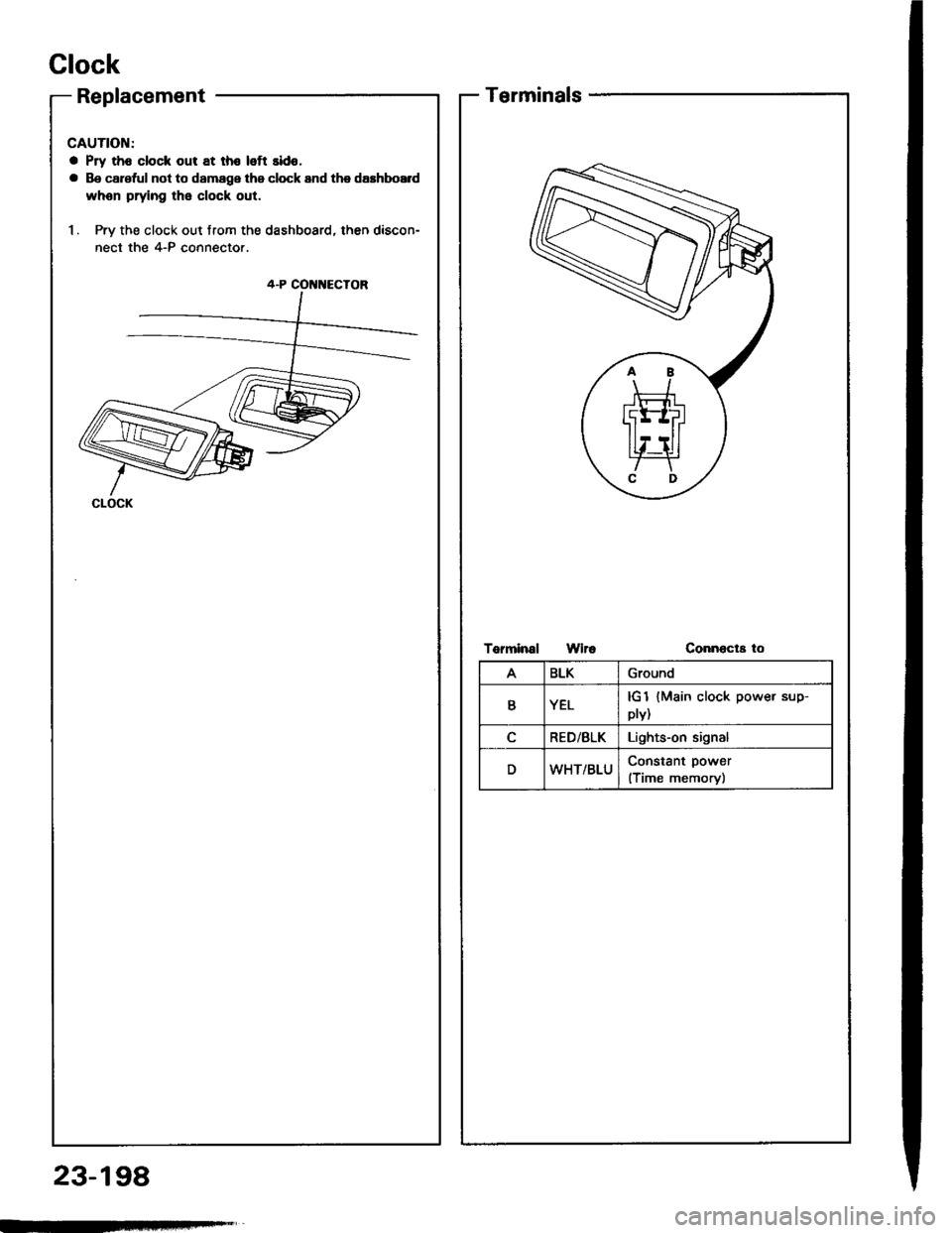

Clock

Replacement

CAUTION:

a Pry th6 clock out at th€ left sido,

a Be carsful not to damage the clock and the dashboE d

whon prying the clock out.

1. Pry the clock out from the dashboard, then discon-

nect the 4-P connector.

4-P COI{NECTOR

CLOCK

23-198

Terminals

Torminal WiroConnecta to

ABLKGround

YELplv){Main clock power sup-

RED/BLKLights-on signal

DWHT/BLUConstant power

(Time memory)