lock HONDA INTEGRA 1994 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 1211 of 1413

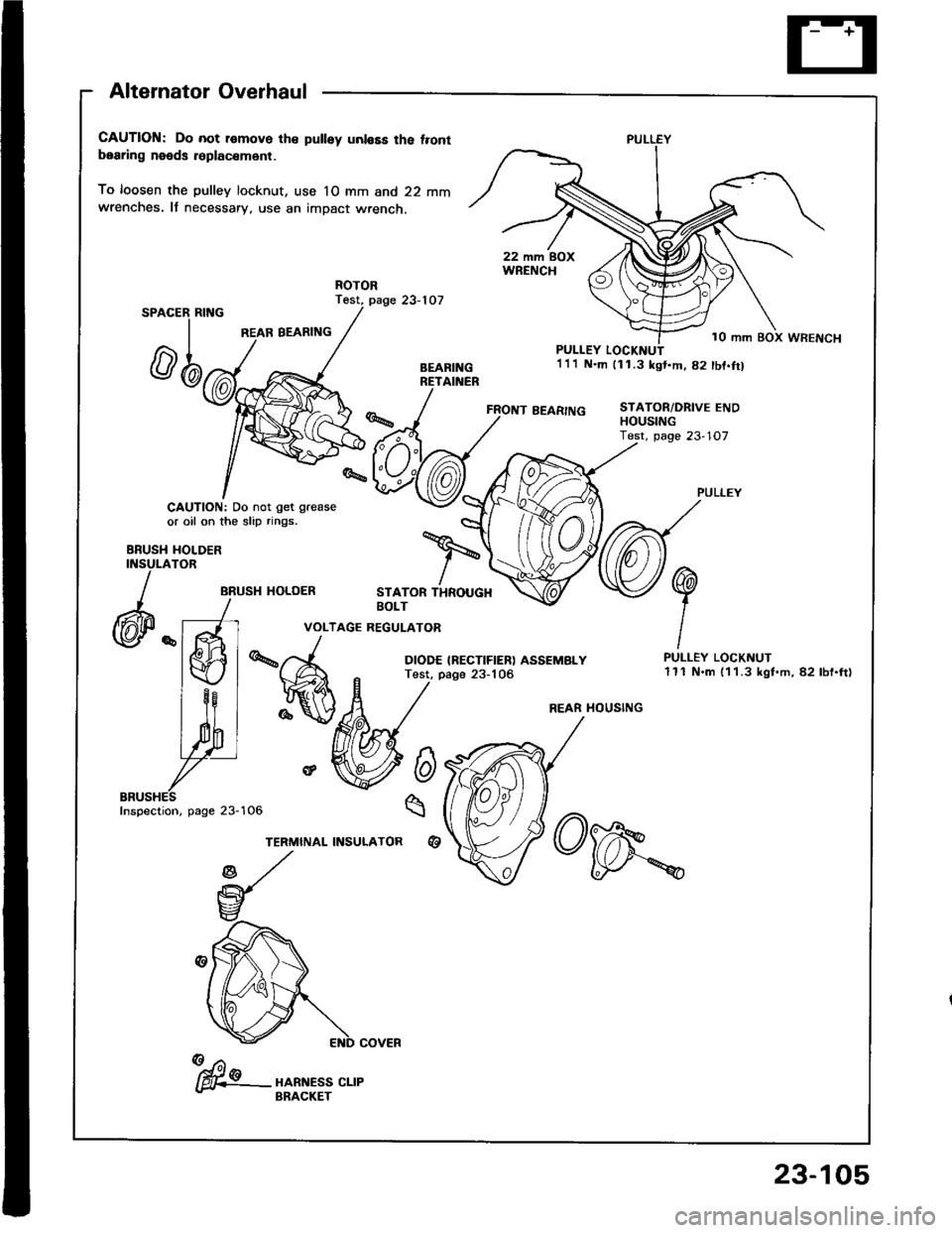

Alternator Overhaul

CAUTION: Do not r€move th€ pulley unl€Es the t.ontbearing needs r6placsm6nt.

To loosen the pulley locknut, use 10 mm and 22 mmwrenches. It necessary, use an impact wrench.

Test, page 23-107SPAC

REAR BEARING

ER RING

rl

@n

CAUTION: Do not get grease

or oil on the slip rings.

HOLDERTOR

ARUSH HOLOER

FRONT BEARING

PULLEY LOCKI{UT1'll N.m 111.3 kgt.m,82 tbf.trl

STATOR/DRIVE ENDHOUStt{G

BBUSHINSULA

)

(@P "

STATOR THROUGHBOLT

VOLTAGE REGULATOR

DIODE IRECTIFIER) ASSEMBLYTest, page 23-106

6

q

%A

re

TERMINAL INSULATORqt

PULLEY LOCKNUT111 N.m (1 1.3 kgt.m, 82 lbf.ft)

PULLEY

10 mm BOX WRENCH

REAR HOUSING

Inspection, page 23-

fu"- "o*n.r" ".,"- BRACKET

23-105

Page 1212 of 1413

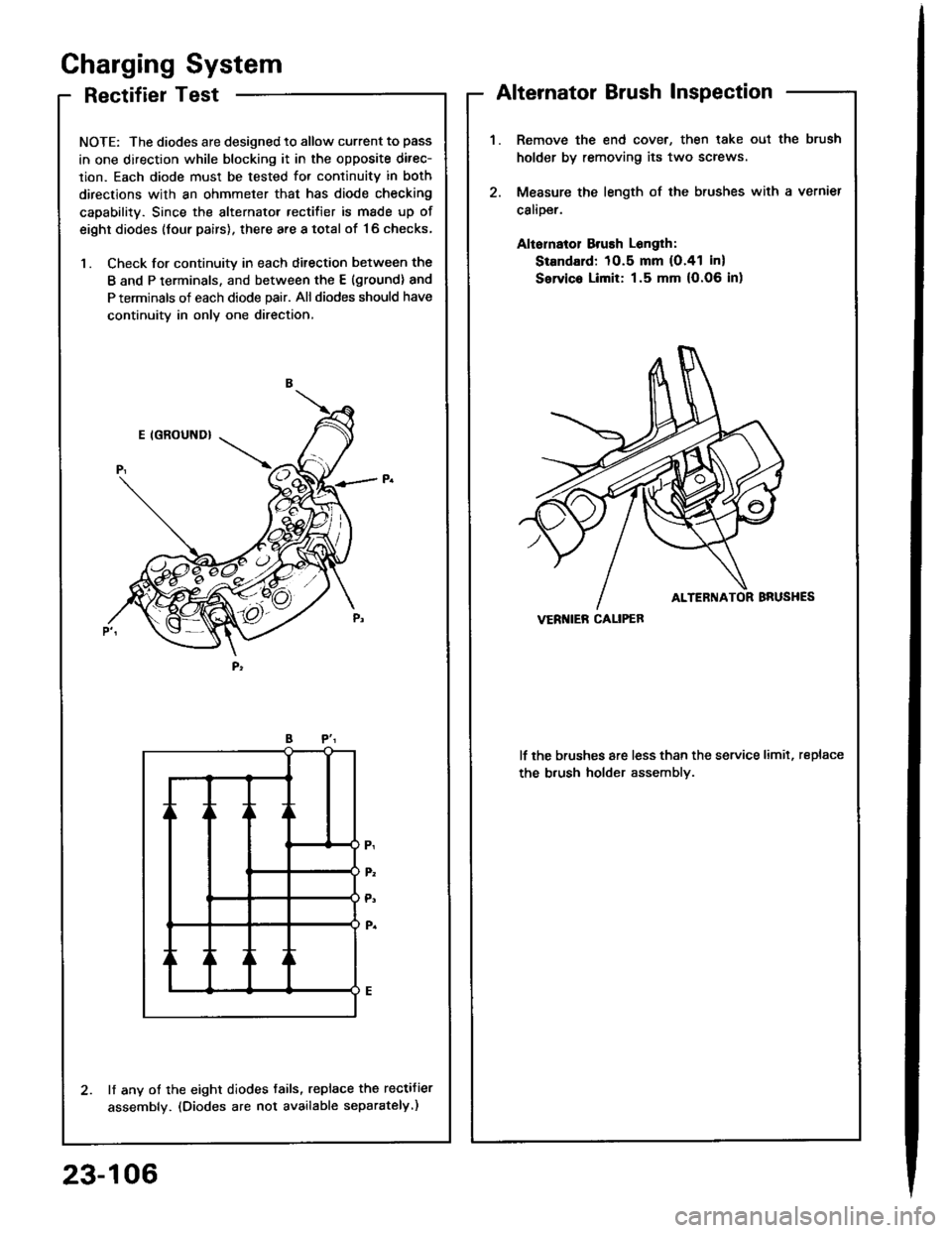

RectifierTest

NOTE: The diodes are designed to allow current to pass

in one direction while blocking it in the opposite direc-

lion. Each diode must be tested for continuitv in both

directions with an ohmmeter that has diode checking

capability. Since the alternator rectifier is made up of

eight diodes (four pairs), there are a total of '16 checks,

1. Check for continuity in each ditection between the

B and P terminals, and between the E (ground) and

P terminals of each diode pair. All diodes should have

continuity in only one direction,

lf any of the eight diodes tails, replace the rectifier

assembly. (Diodes are not available separately.)

Gharging System

Alternator Brush Inspection

Remove the end cover, then lake oul the brush

holder by removing its two screws

Measure the length of the brushes with a vernier

calioer.

Aliornatol Brush Longlh:

Standard: 10.5 mm (O.41 in)

Servic. Limit: 1.5 mm (O.06 in)

lf the brushes are less than the service limit, replace

the b.ush holder assemblv.

VERI{IEB CALIPEB

23-106

Page 1227 of 1413

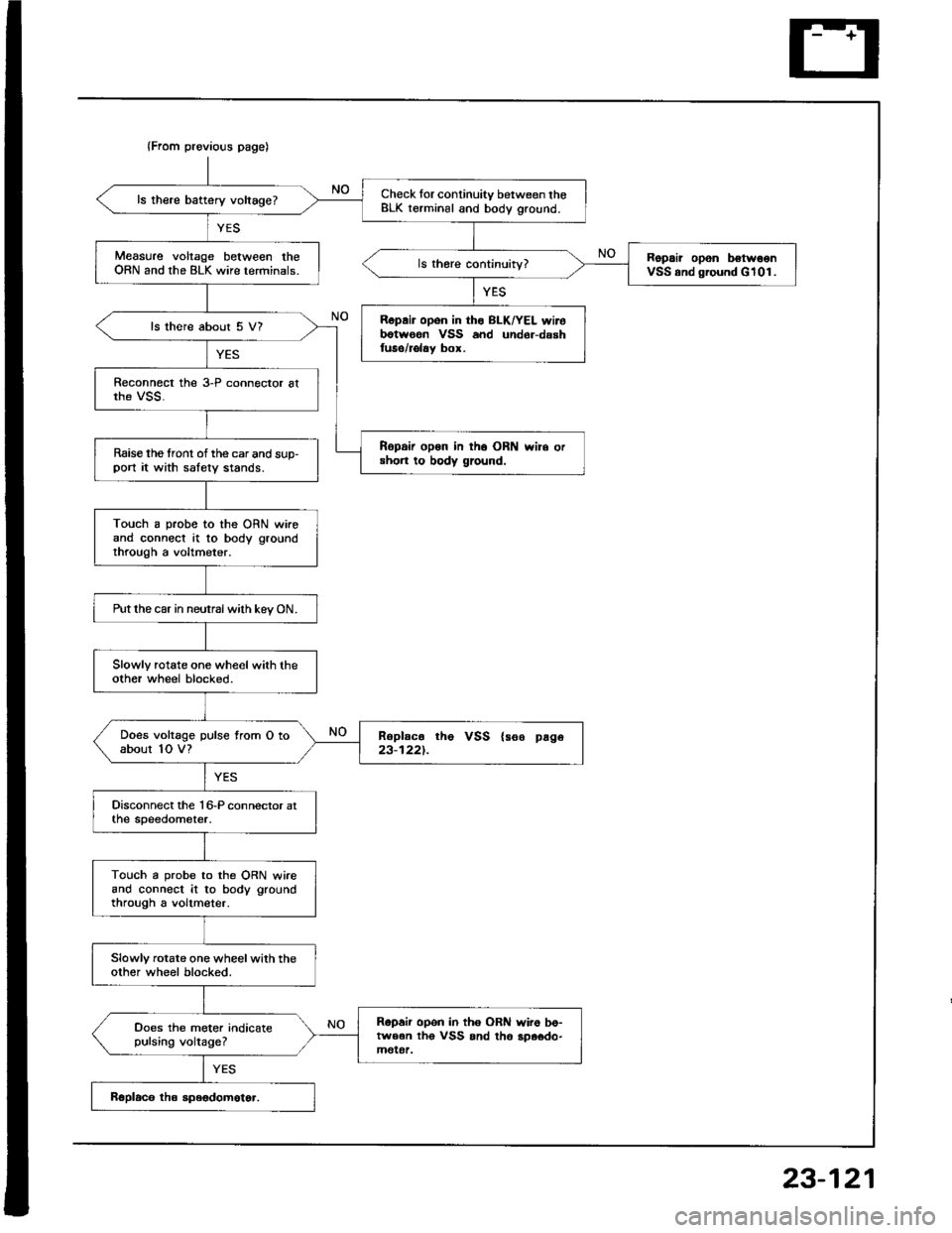

{From previous page)

Check tor continuity between theBLK terminal and body ground.ls there battery voltage?

Measure voltage between theORN and the BLK wire terminals.Ropair opon belw€onVSS and ground G101.

Ropair opon in tho BLKrYEL wirobotwoen VSS and undor-dsshluse/rolay box.

ls there about 5 V?

Ropair op6n in th6 ORN wire orshon to body ground.Raise the tront of the car and sup-port it with salety stands.

Touch a probe to the ORN wireand connect at to body groundthrough a voltmeter.

Putthe car in neutralwith kev ON.

Slowly rotate one wheel with theother wheel blocked.

Does voltage pulse from O toabout 1O V?Roplac. tho VSS {see page23-1221.

Touch a probe to the ORN wireand connect it to body groundthrough a voltmeter.

Slowly rotate one wheelwith theother wheel blocked.

Ropair opon in th6 OBil wire bo-tween tho VSS and th6 3p.odo-molgt.

Ooes the meter indicatepulsing voltage?

23-121

Page 1237 of 1413

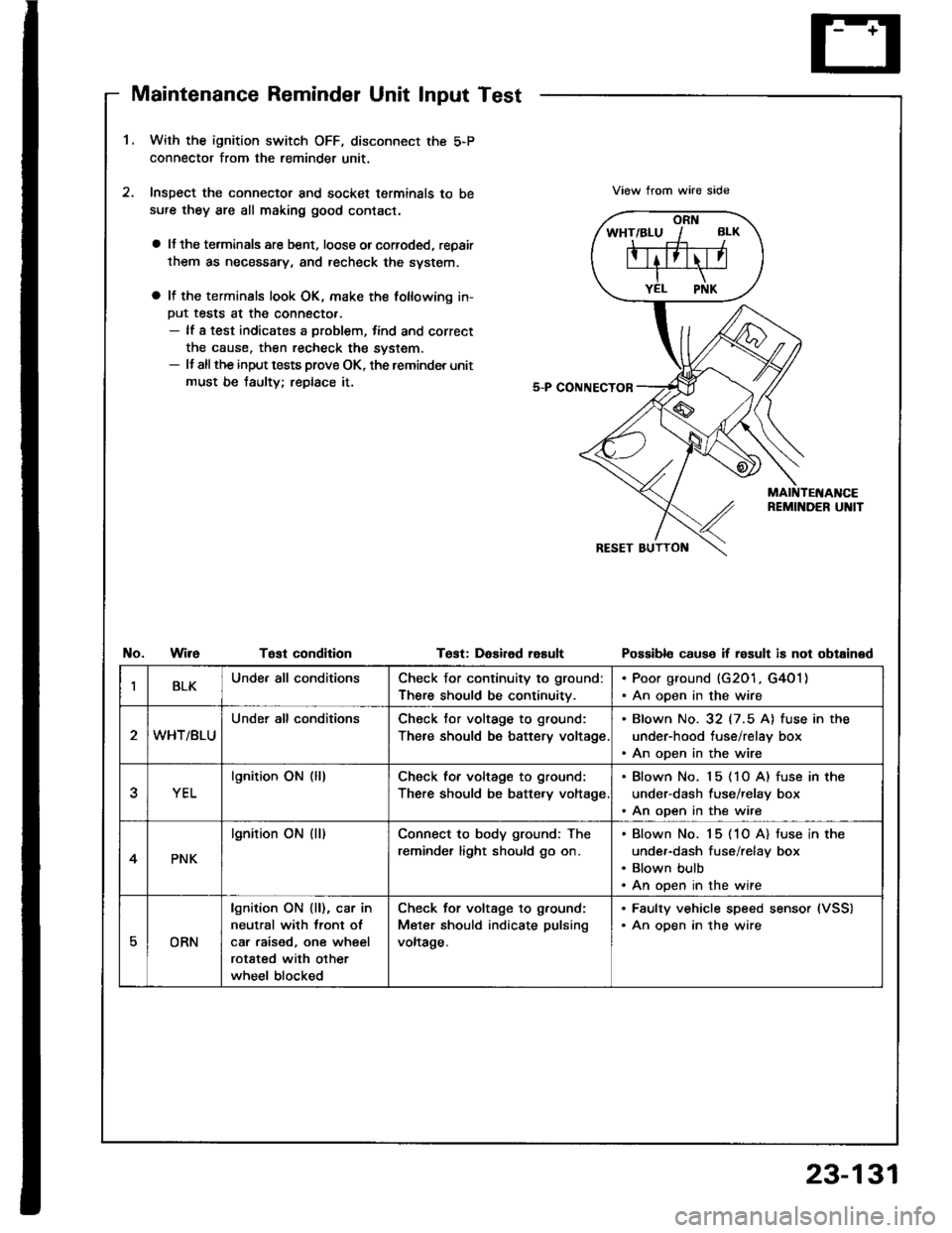

Maintenance Reminder Unit Input Test

1.With the ignition switch OFF, disconnect the 5-P

connector from the reminder unit,

Inspect the connector and socket terminals to be

sufe they are all making good contact.

a lJ the terminals are bent, loose orcorroded, repair

them as necessary, and recheck the svstem.

a It the terminals look OK, make the following in-

Put tests at the connecto..- lf a test indicates a problem, tind and correct

the cause, then recheck the system.- It allthe input tests prove OK, the reminder unit

must be taulty; replace it.

View trom wire side

No.WireTost condltionTest: DaEired rasultPossibl€ cause if result is not obtained

IBLKUnde. all conditionsCheck for continuity to ground:

There should be continuitv.

. Poor ground (G201, G4O1). An open in the wire

WHT/BLU

Under all conditionsCheck tor voltage to ground:

There should be battery voltage

. Blown No. 32 (7.5 A) fuse in the

under-hood tuse/relay box. An open in the wire

YEL

lgnition ON (lllCheck for voltage to ground:

There should be batte.y voltage

. Blown No. 15 (1O A) fuse in the

under-dash fuse/relay box. An open in the wire

4PNK

lgnition ON (ll)Connect to body ground; The

reminder light should go on.

Blown No. 15 (1O A) tuse in the

under-dash fuse/relay box

Blown bulb

An open in the wire

EORN

lgnition ON {ll), car in

neutral with lront ol

car raised, one wheel

rotated with other

wheel blocked

Check for voltage to g.ound:

Meter should indicate pulsing

voltage.

. Faulty vehicle speed sensor (VSS)

. An oDen in the wire

23-131

Page 1238 of 1413

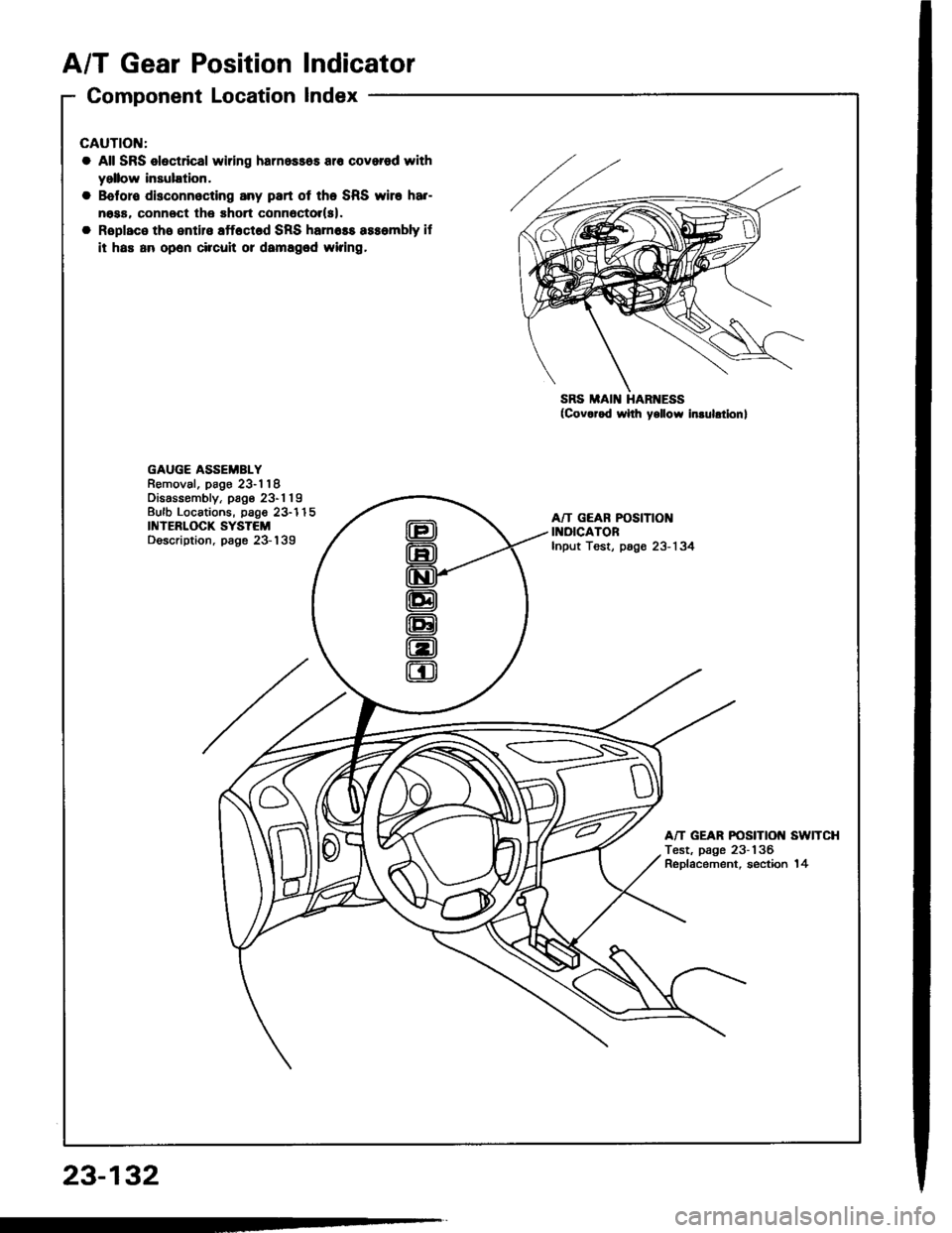

A/T Gear PositionIndicator

Component Locationlndex

23-132

cAUTtOt{:

a All SRS olectdcal wiring harnossos a16 covarod with

yellow insulation.

Boforo disconnocting any part ot the SRS wlr. har-

noaa, conngct the short conn6ctor(sl.

Roplaco tho entire aff6ct6d SRS harn$s assombly il

it has an op6n cilcuit or damagod wiling,

SRS MAIN HARI{ESS(Cov.rod whh ygllow io.ul.tlonl

GAUGE ASSEMBLYBemoval, page 23-1 18Disassombly, pag€ 23'1 19Bulb Locations, pago 23-1 15IiIIERLOCK SYSTEMDGscription. page 23-139

A/T GEAR POSITIONIlTDICATORInput Test, pago 23-134

A/T GEAR P('SITIOI{ SWITCHTest, page 23-136ReDlacement, 6ection 14

Page 1239 of 1413

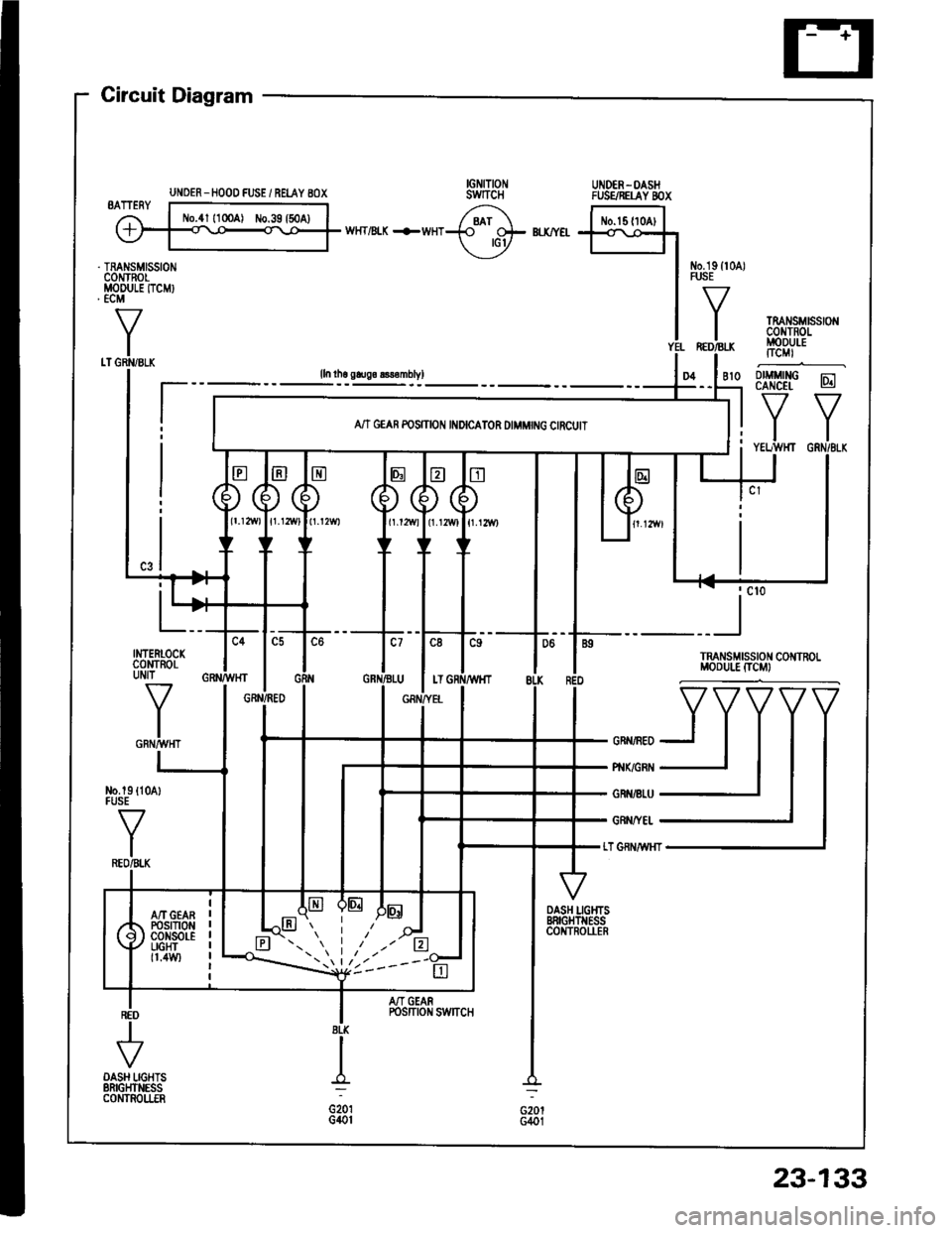

UNOER_HOOD FUSE / REI.AY 8OX

Circuit Diagram

IGNITIONswrTcHUNOER-OASHFUSSREI-AY 8OX

No.19ll0A)FUSE

TMI{SMrSSr0r,lc0IJTRori.IODULEITCMI

fitMritc-;-CANCEL lgll

tlYELTWHT GRN/8L|(

D4

II._l

TRANSMISSIONMODU|.! [TCM}

t

INTERLOCKcoMtRotUNJ]_

IGRT'IMHTo*nn,o_yTT

pr{x/cR1 -J

IGR €|-U -l

GRiITYEt

LT GNNiW{T

No.19 {lFUSE

V

I

I

DASH I-IGHTSBRIGHTNESSCONTROI.IERG2o lG401

I

G201G40t

/-?t ftrt*lwHT/BLX +wHT+ CH- Bl.x/Y€t -+<.\-o+!

y "l

IYEL

lln tho gtugo 8ls€mbvl

AN GEAR POSITION INDICATOR DIMMING CIRCUIT

A/T GEANPOStTt0NcoNsot-ELIGHT0.4w)

M GEARPosrTroN swncH

23-133

Page 1243 of 1413

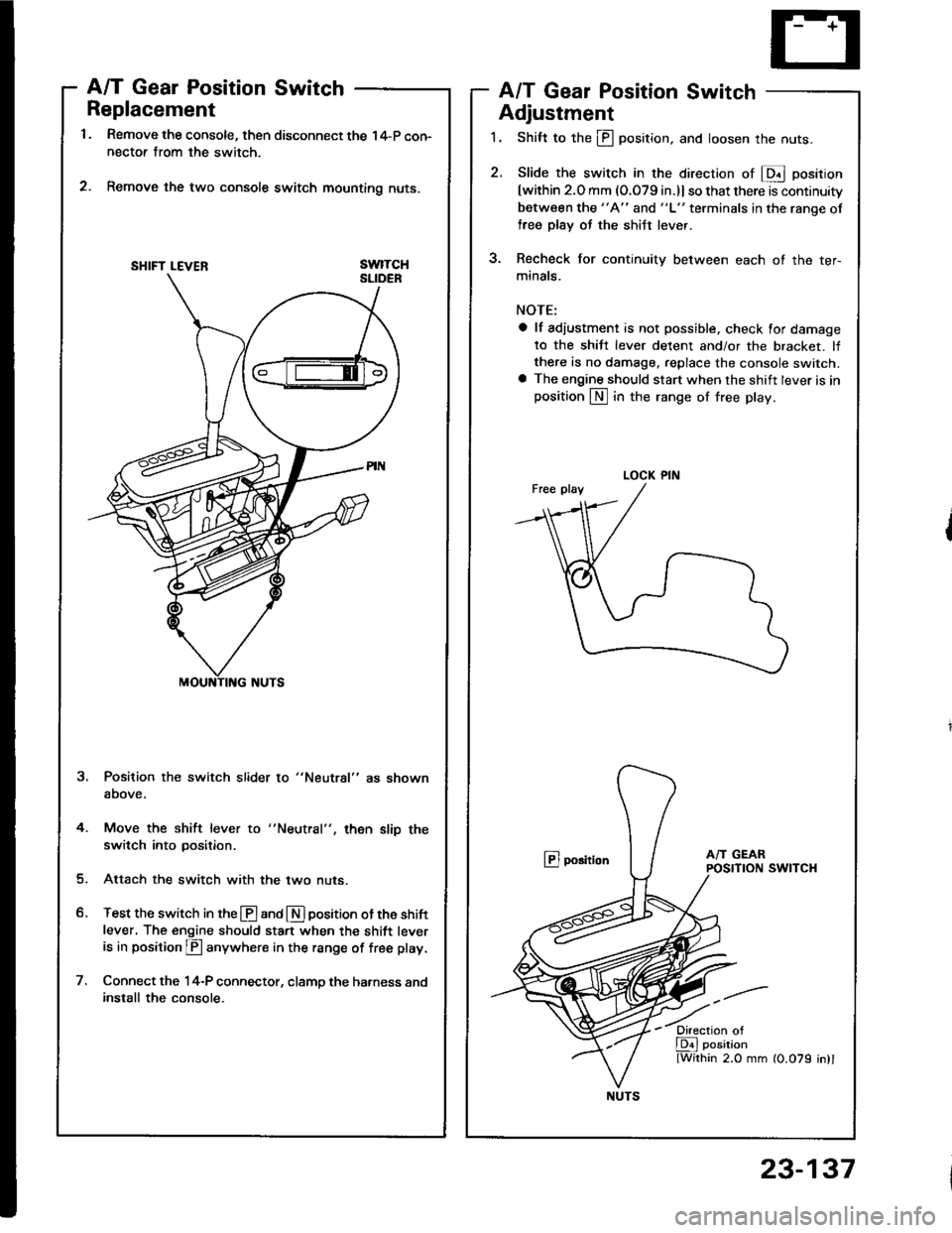

Replacement

Remove the console, then disconnect the 14-P con-nectof from the switch.

Remove the two console switch mounting nuts.

swtTcH

A/T Gear Position SwitchA/T Gear Position Switch

Adjustment

1. Shift to the ill position, and loosen the nuts.

2. Slide the switch in the direcrion of E position

[within 2.O mm (O.079 in.)l so that there is continuity

between the "A" and "L" terminals in the ranqe of

free plsy oJ the shiJt lever.

3. Recheck for continuity between each ot the ter-

minals.

NOTE:

a lf adiustment is not possible. check for damage

to the shiJt lever detent and/or the bracket. lfthere is no damage, replace the console switch.a The engine should start when the shift lever is inposition LN] in the range of free play.

@ porition

Position the switch slider to "Neutral" as shown

above.

4. Move the shift lever to

switch into position.then slip the

Attach the switch with the two nuts.

Test the switch in the @ and E] position ot the shift

lever. The engine should sta.t when the shift leveris in position p anywhere in the range of free play.

Connect the 14-P connector, clamp the harness andinstall the console.

SHIFT LEVER

LOCK PIN

NUTS

23-137

Page 1244 of 1413

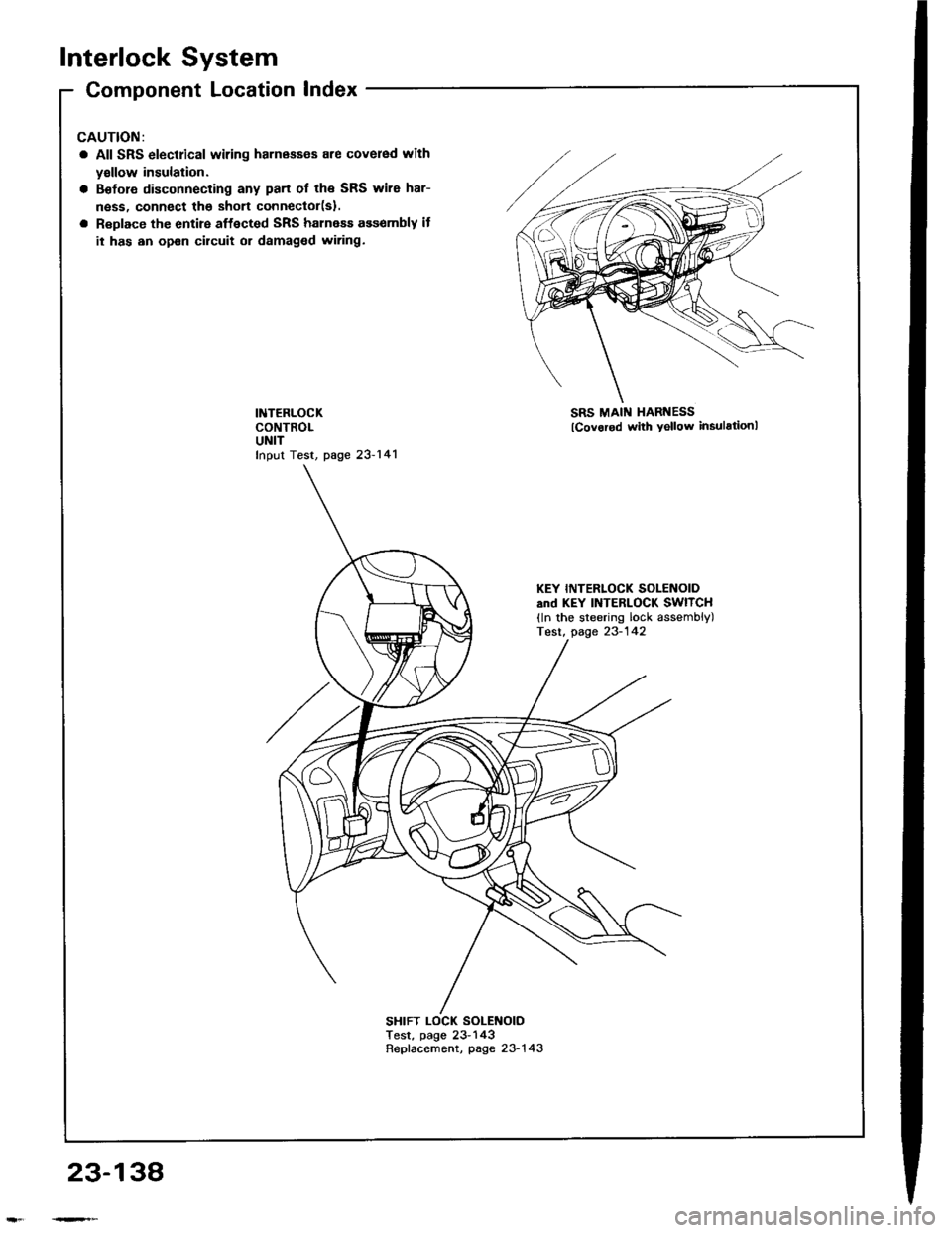

Interlock System

Component Location Index

All SRS electrical wiring harnass€s are covered with

yallow insulation.

Before disconnecting any part of the SRS wire har-

ness, connect the shon connector(sl.

Replace the entire affected SRS halness ass€mbly it

it has an open circuit or damaged wiring.

INTERLOCKCONTROLUNITfnput Test, page 23-141

SRS MAI[{ HARNESS

lcovorod with yellow insulstionl

SHIFT LOCK SOLENOIOTest, page 23- 143Repfacement, page 23-1 43

KEY INTERLOCK SOLENOIDsnd KEY INTERLOCK SWITCH(ln the steering lock assembly)Test, page 23-142

23-138

Page 1245 of 1413

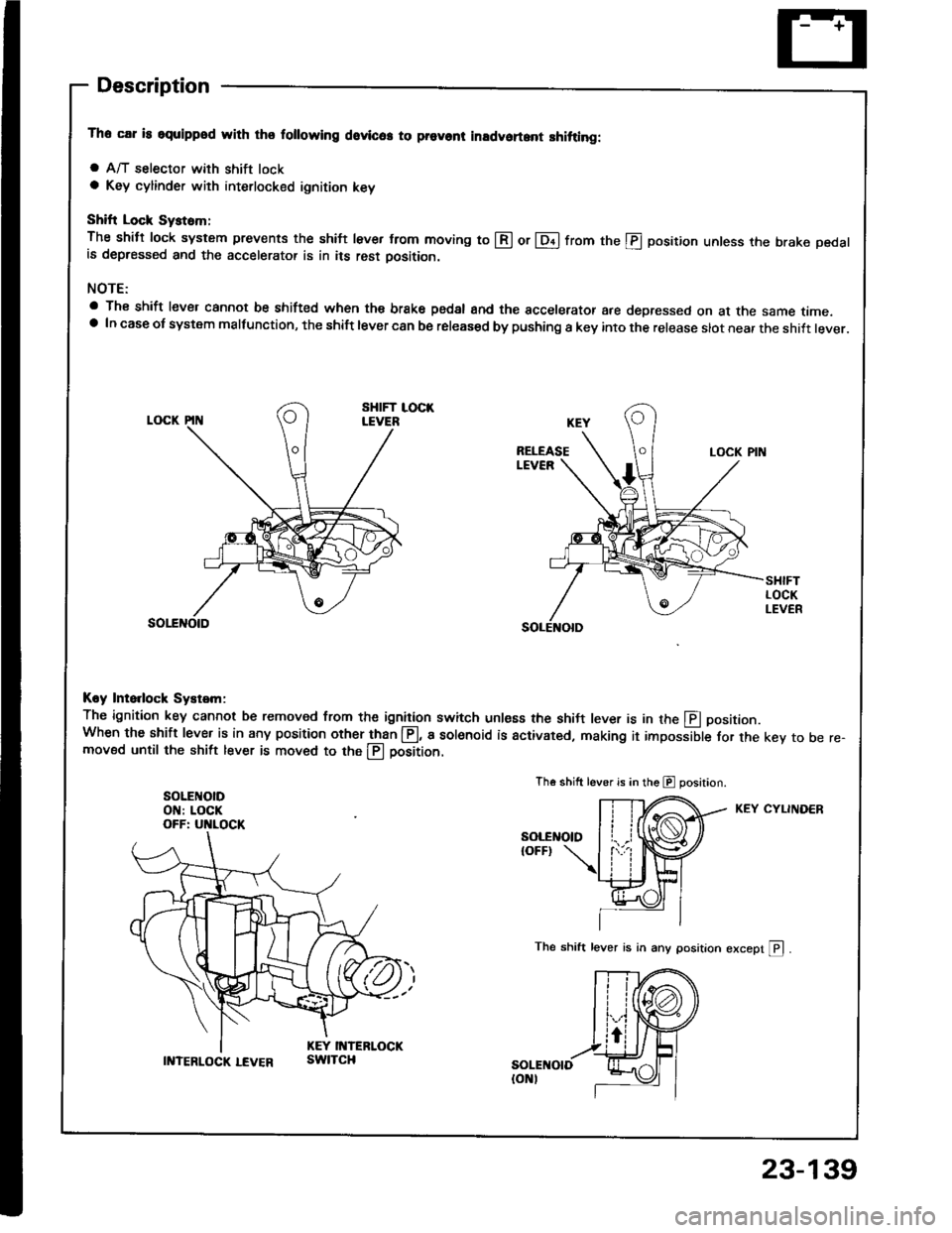

Descraption

The car is squippod with thq following dovlc6. to prevont inadvoft.nt shitting:

a A/T selector with shift locka Key cylinder with interlocked ignition key

Shift Lock Syst6m;

The shitt lock system prevents the shift lever from moving to @ or lDil from the @ position unless the brake pedalis depressed and the accelerator is in its rest oosition.

NOTE:

a The shift lever cannot be shifted when the brake pedsl and the accelerator are depressed on at the same time.a In case ot system malfunction, the shift lever can be released by pushing a key into the release slot near the shift lever.

Koy Ints.lock Systsm:

The ignition key cannot be removed from the ignition switch unless the shil-t lever is in the E positionWhen the shift lever is in any position other than @, a sol€noid is activated, making it impossible for the key to be re-moved until the shift lever is moved to the llj position.

SOLEI{OIDON: LOCKOFF: UNLOCK

Th€ shift lever is in the E position.

KEY CYLINDER

The shift lever is in any position except pl .

II{TERLOCK LEVERswtTcH

23-139

Page 1246 of 1413

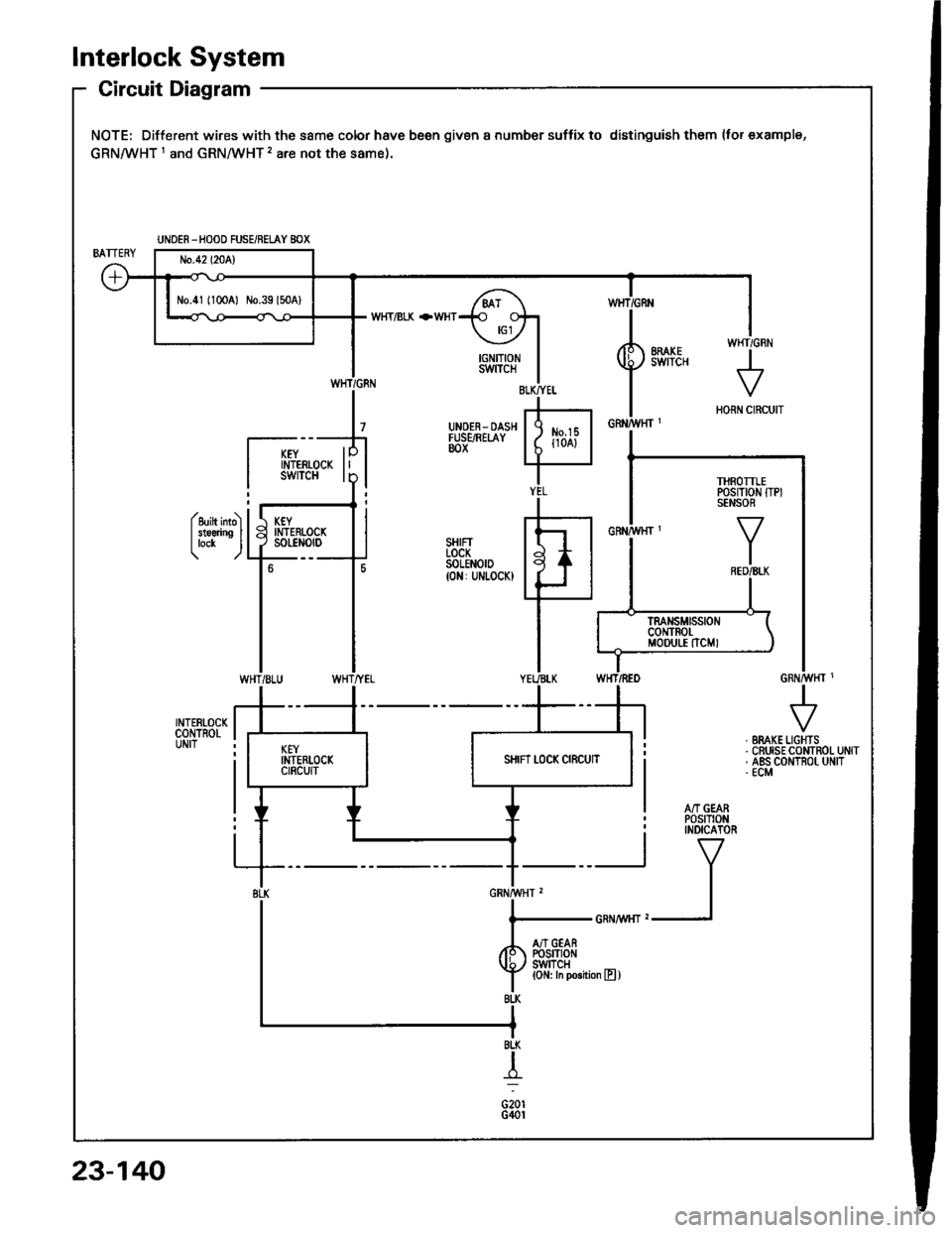

lnterlock System

Circuit Diagram

NOTE: Different wires with the same color have been given a number suffix to distinguish them (tor examplg,

GRNMHT 1 and GRNMHT 2 are not the same).

W}IT/BLK +WHT

Y I if,f,trfi

I i

^'v"'

IIN/vt,H] ,

I

l......................_GRNA,t/r{rz1

/r S'ftiei

f lJlT,ll*n""n,

UNOER -HOOD FUSE/REi.AY BOX

N0.41 (1OCA) No.39 l50A)

THROTTLEPOSITION ITPISENSOR

WHT/GRN

23-140