check engine HONDA INTEGRA 1994 4.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1994, Model line: INTEGRA, Model: HONDA INTEGRA 1994 4.GPages: 1413, PDF Size: 37.94 MB

Page 235 of 1413

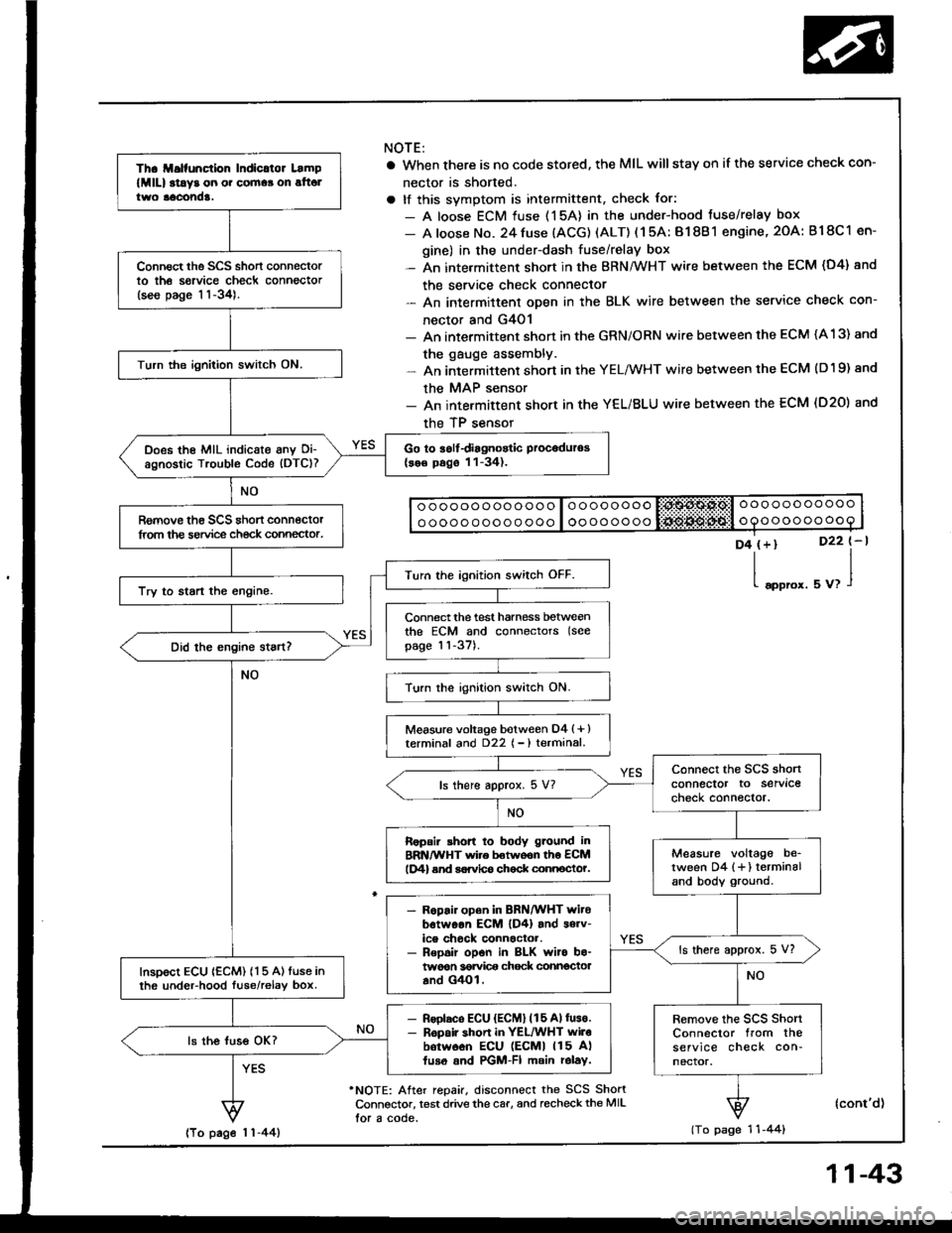

Th. ll.lfunction Indicltor Lamp

lMlll at!y3 on o. cornaa on alt6ltwo aacond!.

Connect the SCS short connectorto th6 sorvice check connector(see page 11-34).

Turn the ignition switch ON.

Go to iolfdiagnostic Proceduros(se€ pago 11-34).Does the MIL indicate anv Oi-agnostic Trouble Code (DTC)?

Romove th€ SCS shon connectorlrom the service ch€ck connector.

Turn the ignition switch OFF.

Try to start the engine.

Connect the test harness betweenthe ECM and connectors (see

page 11-37).

Turn the ignition switch ON.

Measure voltage botween D4 (+ )terminal and D22 { - ) terminal.

connect the SCS shonconnector to servlcecheck connector.ls there approx. 5 V?

Ropair shon to body g.ound inBRN/WHT wire betwoon th6 ECMlD4) end sorvlco chock connocto?.Measure voltage be_tween D4 {+} terminaland body ground.

- R6pair open in BRN/WHT witobotwoon EcM lD4) and s6rv-ice chock connactor.- Repoir opon in BLK wiro bo-twoon 36rvi@ chock connectoaand G4Ol.

ls there approx. 5 V?

InsDoct ECU {ECM) 115 A) tuse inth6 undeFhood luse/relav box.

- Rsolaco ECU {ECM} (15 Allus€.- R6pair shon in YEL/WHT wilobotw6on ECU lEcMl 115 A)fuso and PGM-FI main rolay.

Remove the scs shortConnector from theservice check con-nector.

ls the luss OK?

NOTE:

a When there is no code stored, the MIL willstay on if the service check con-

nector is shorted.

a tf this svmotom is intermittent, check for:

- A loose ECM fuse (15A) in the under-hood tuse/relay box

- A loose No. 24 fuse (ACG) (ALT) ( 1 5A: B1 8B 1 engine, 2OA: B18C 1 en-

gine) in the under-dash fuse/relay box- An intermittent short in the BRN/WHT wire between the ECM (D4) and

the service check connector- An intermittent oDen in the BLK wire between the service check con-

nector and G4O1- An intermittent shon in the GRN/ORN wire between the ECM (A 13) and

the gauge assembly.- An intermittent short in the YELMHT wire between the ECM (D19) and

the MAP sensor- An intermittent short in the YEL/BLU wire between the ECM (D20) and

the TP sensor

o ooooo ooo ooo o loooooooo liii:$A$.Ps,l o oo ooo ooooo

o oooo ooo o o ooo I oooooooooooooooooo

D4 (+)

l"oo,o'.

D22 t-l

uu,l

'NOTE: After repair, disconnect the SCS ShortConnsctor, test drive the car, and recheckthe MIL

lor a code.

(cont'd)

(To page 1 'l -44)lTo page 1 1-44)

11-43

Page 236 of 1413

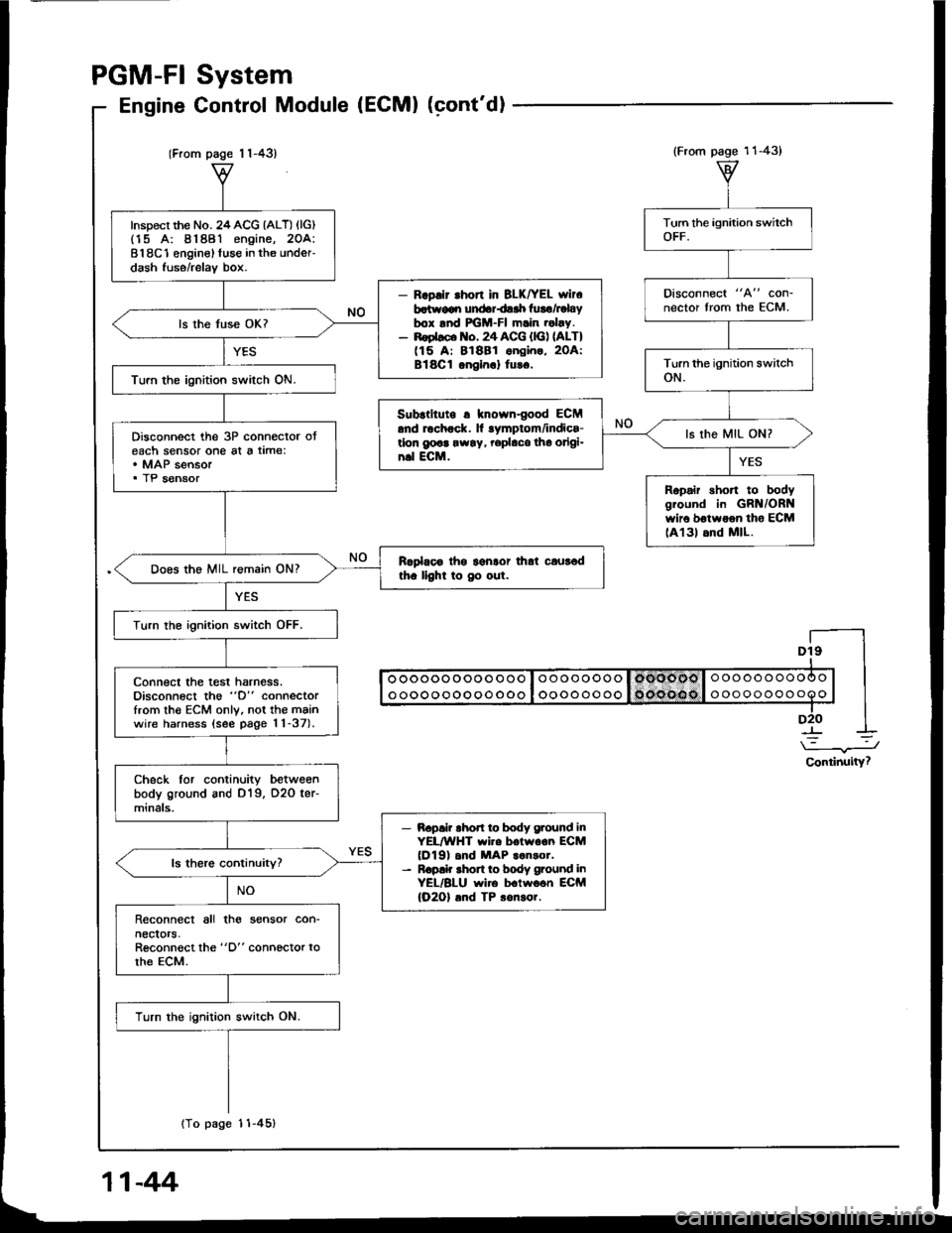

(From page 1 1-43)

Inspect the No. 24ACG {ALT) (lG)(15 A: 81881 engine, 2OA:818C1 enginel fuse in the under-dash fuse/relav box.

- R.pllr .hon in BLK|rEL wlr6batr.v€qr undariair luro/Fbybox lnd FGM-FI m.in .obv.- noebco lto. 24 ACG {lG) nLT)(15 A: 81881 ongin., 2OA:Bl8Cl onein.l tu!6.

ls the fuse OK?

Turn the ignition switch ON.

Disconnect the 3P connector oteach sensor one al a time:. MAP sensor. TP sensor

Rcplaoo thg lgnlor that caur6dth. llght to Oo out.Does the MIL remain ON?

Turn the ignition switch OFF.

connect the test harness.Disconnect the "D" connectorfrom th€ ECM only, not the mainwire harness (see page 11-37).

Check tor continuity betweenbody ground and D19, O2O ter-minals,

- Bapai? rhod ro body g.ound inYEL/WHT wi.e boiwoon ECM(Dl9) .nd MAP ..n3or.- R.p!k shon to body ground inYEL/BLU wire b.lwo6n ECM(O2Ol .nd TP 3on!or.

Reconnect all tho sensor con-necrors,Reconnect the "D" connector torhe ECM.

Turn the ignition switch ON.

{To page 11-45}

System

Control Module (ECMI (cont'dl

PGM-FI

Engine

Dt9I

I oooooooooo ooo I oooooooo I omoool o oooooooooo | |I ooooooooooooo I oooooooo 1o('oe(lo I ooooooooooo | |-lD2O I

\-.J

Continuity?

(From page 11-43)

Disconnect "A" con-nector from the ECM.

Subrtltute r knowngood ECM.nd rochock. ll lymptom/indics-tlon g@a rw!y, rephco tho origi-n.l ECM.

ls the MIL ON?

Ropair short to bodygiound in GRN/ORNwir6 botwoon tho ECMlA131 6nd MlL.

11-44

Page 238 of 1413

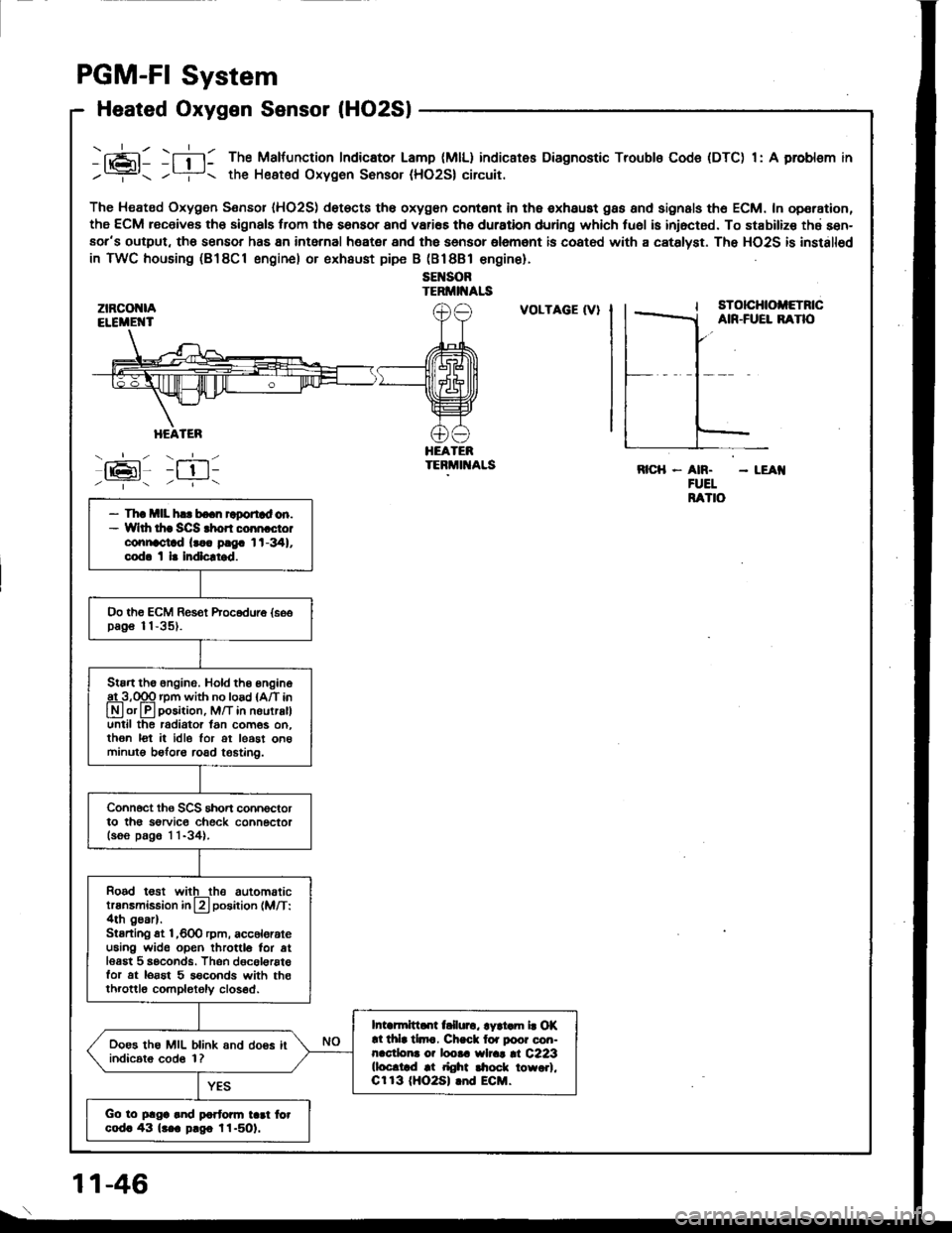

PGM-FI System

Heated Oxygen Sensor lHO2Sl

ztRcot{lAELEiIE'{T

HEATER

- --.'!- - -__-

lrPl _l !l-

-fi-l: The Malfunction Indicator Lamp (MlL) indicates Diagnostic Troubls Code (DTC) 1: A problsm in

/? the Heated Oxygen Sonsor (HO2S| circuit.

The Heated Oxygen Sensor IHO2S) det€cts th6 oxygon contont in th6 exhaust gas and signals th6 ECM. In operation,

the ECM receiv€s th6 signals trom the sensor and vari€s the duration during which tu6l is iniocted. To stabilize thd sen-aor's output, tho sensor has 8n intarnal heater and the sensor olemant is coatod with a catslyst. The HO2S is installod

in TWC housing (B18Cl engine) or exhaust pipe B (Bl8Bl €ngine).

sEl{SORTERMII{ALS

:tz-t6l-/ --.- \

VOLTAGE (V}sTotcHtoltETncAIR-FUEL BANO

HEATEBTEBMIT{ALSRICH - AN. - LEAI{FUELRATIO- Th! mll h.. bo.n raportad on.- Wlth thr SCS rhon coon cto.connoctad lr.. p!9. 1t-341,cod. t l. Indlcltrd.

Oo th€ ECM Res€t Procodure {soopag€ 11-35).

Stan the 6ngine. Hold th6 engine

A3,qgq rpm with no load {A/T in

Lryl or lll position, M/T in nourralluntil the radiator lan com6s on.then lot it idle lor ot least on6minutg beforo road t€6tin0.

Connoct ths SCS short connoctorto th6 sorvic€ check connectorlsoo p.g6 1 1-34).

Rood t€st witlthe automatictransmission in L?l position (M/T:4th gear).Stsrting st l,600 rpm, acc6lorateu6ing wide open throttlo for atlesgt 5 seconds. Thsn dgcol€rstefor at lorst 5 s€conds with th€throttlo completoly closed.

Intarmittd[ t llurc, lyri.m b Of!l thla tlmc. Ch.ck lor poor con-nacdona o? loota wlrat |l C223(loc.trd at right $ock towo.l,Cr 13 (HO2S| lnd ECM.

Ooes the MIL blink and doos itindic6t6 cod6 1?

Go to plga and partonn tad fotcod. 43 lr.a p.go l1-501.

1 1-46

Page 242 of 1413

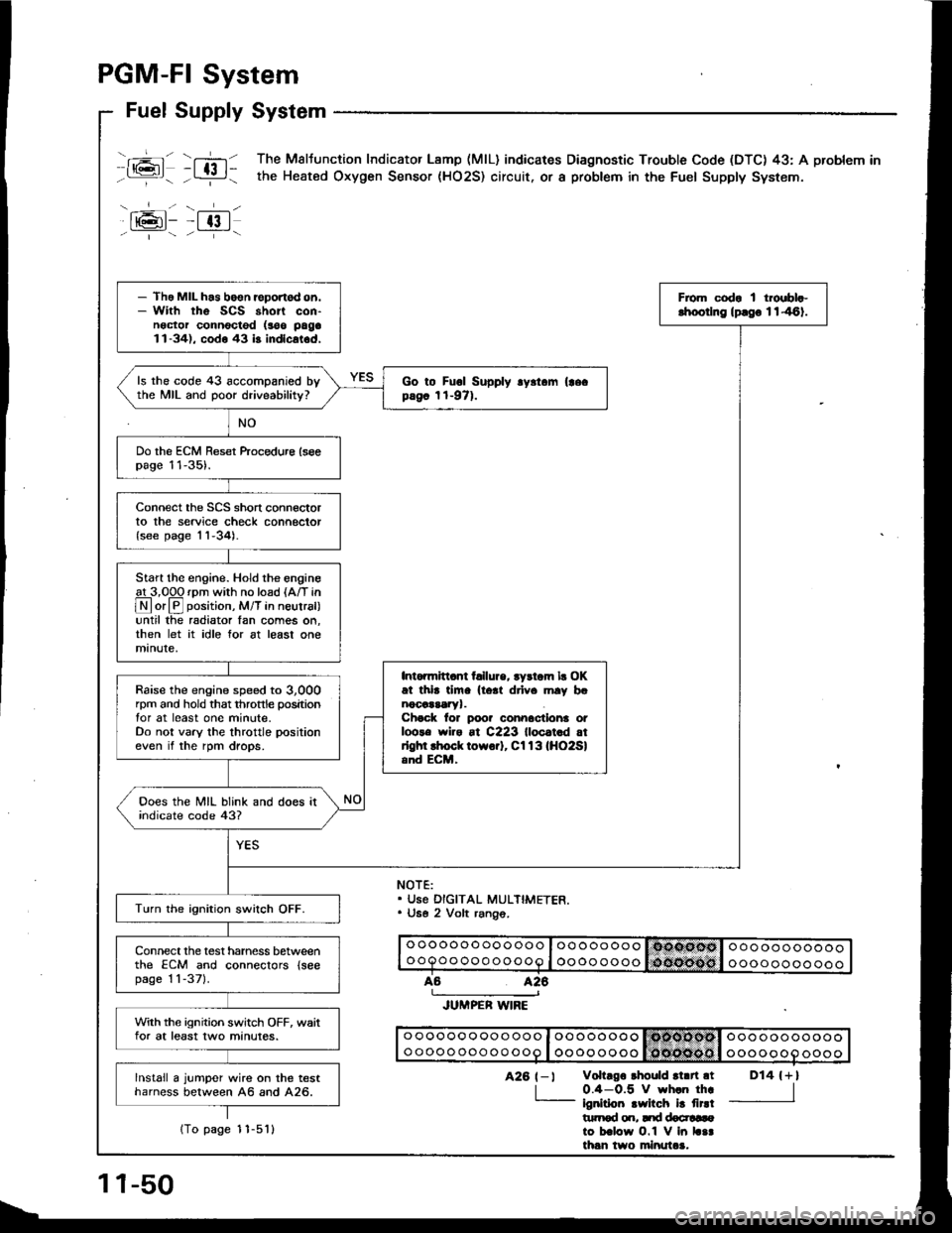

PGM-FI System

rj-t

--t-.

Fuel Supply System

-+-lt@t- -t 13 |- ' "- - --i--

T,-n The Maltunction Indicator Lamp (MlL) indicares Diagnostic Trouble Code (DTC) 43: A problem in

- L:!-i - the Heated Oxygen Sensor (HO2S) circuit. or a probtem in the Fuel Supply System.

NOTE:. Use DIGITAL MULTIMETER.. U6e 2 Volt rang6.

o oooooo oooooo I oo oooooooooooooooooooQoo ooo ooooo I oooo ooooooooooooooo

426

JUMPER WIRE

o ooooo oooo ooo I oo oooooo Isdtcllodsl ooo ooooooooo oooo ooo oo ooo I oooo ooooooooooooooo

D14 {+l

I

426 t-l vohrgo rhould rl.n.t

| 0.4-0.5 V wh.n th..- ignirioo .wilch i! firdt|rtrod o.r, Itd docr!6ato b.low O.1 V in L..th6n two minutaa.

- Tho MIL h.s boen reportod on.- With rhe SCS short con-noctor connocted (soo paga1l-34), codo 43 b indlcat.d,

From codr I troebl.-lhoorlng lprgo 1146).

ls the code 43 accompanied bythe MIL and poor driveability?Go to Fuol Supply .y.t.m (|ecpag6 1t-971.

Do the ECM Reset ftocedure lseepage 11-35).

Connect the SCS short connectorto the service check connector{see page 'l1-34).

Start the engine. Hold the engineat 3,00O rDm with no load {A/T in

@or@ position, M/T in neutral)until the radiator Ian comes on,then let it idle for at least onemanute,

Intonnitl.nt t llure, tydom lr OKat thi. tim. lto.t drlv. mly b.nocaararyr.Chock lor poo? connactlona otloots wiro at C223 lloc.t.d atrlghl lhock towo.]. Cl13lHO2Sland ECM,

Raise the engine speed to 3,000rpm and hold that throttle positiontor at least one minute.Do not vary the throttle positioneven if the rpm drops.

Ooes the MIL blink and does itindicate code 43?

Turn the ignition swilch OFF.

Connect the test harness betweenthe ECM and conneclors {seepage 1 1-371.

With the ignition switch OFF, waitfor at least two minutes.

lnstall a jumper wire on the testharness between A6 and A26.

11-50

1To page 1 1-5'l l

Page 263 of 1413

PGM-FI System

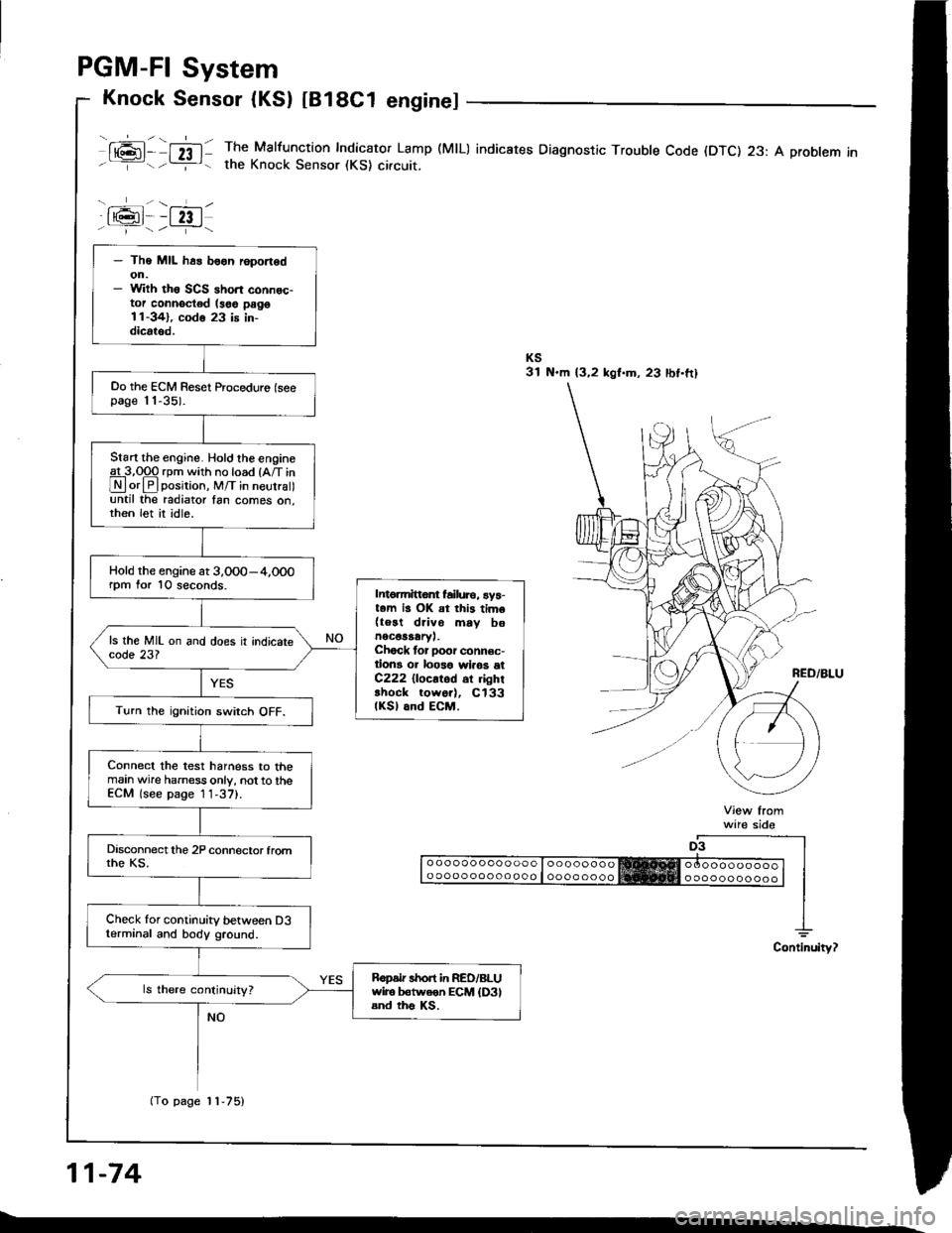

Knock Sensor (KS) tB18C1 enginel

ml- nl: The Malfunction Indicator Lamp (MlL) indicates Diagnostic Troubte Code (DTC) 23: A probtem inthe Knock Sensor (KS) circuit.

a6l--fzt.i--1/.---r+\

ware sido

o ooooo ooo ooo o looooooooo oooo ooo oo ooo I oooo oooo

11-74

- The MIL h6s boon r6port6don.- With th6 SCS ahort connec-tor connoctod (soe pago11-341, codo 23 is in-dicrtod.

Oo the ECM Reset Proceduro (seepage 11-35).

Start the engine. Hold the engineg!-3,Opq rpm with no load {A/T in

Lryl orlPlposirion, M/T in neurra until the radiator fan comes on,then let it idle.

Hold the engine at 3,0O0-4,000rpm for 10 seconds.Intomittor failure, ay5-t.m is OK at this tim6(teat drivo mav bonec€saary,.Chock tor Door connec-tion3 or loo3o wlaos etC222 {locatod 6r ghrshock tow6r), Cl33(KSl and ECM.Turn the ignition swirch OFF.

Connect the test harness to themain wire harness only, not to theECM (see page 1 1-37).

Check for continuity between D3terminal and body ground.

Ropdr short in RED/BLUwiro b€tweon ECM {D3land ths Ks.

(To page 11-75)

Page 283 of 1413

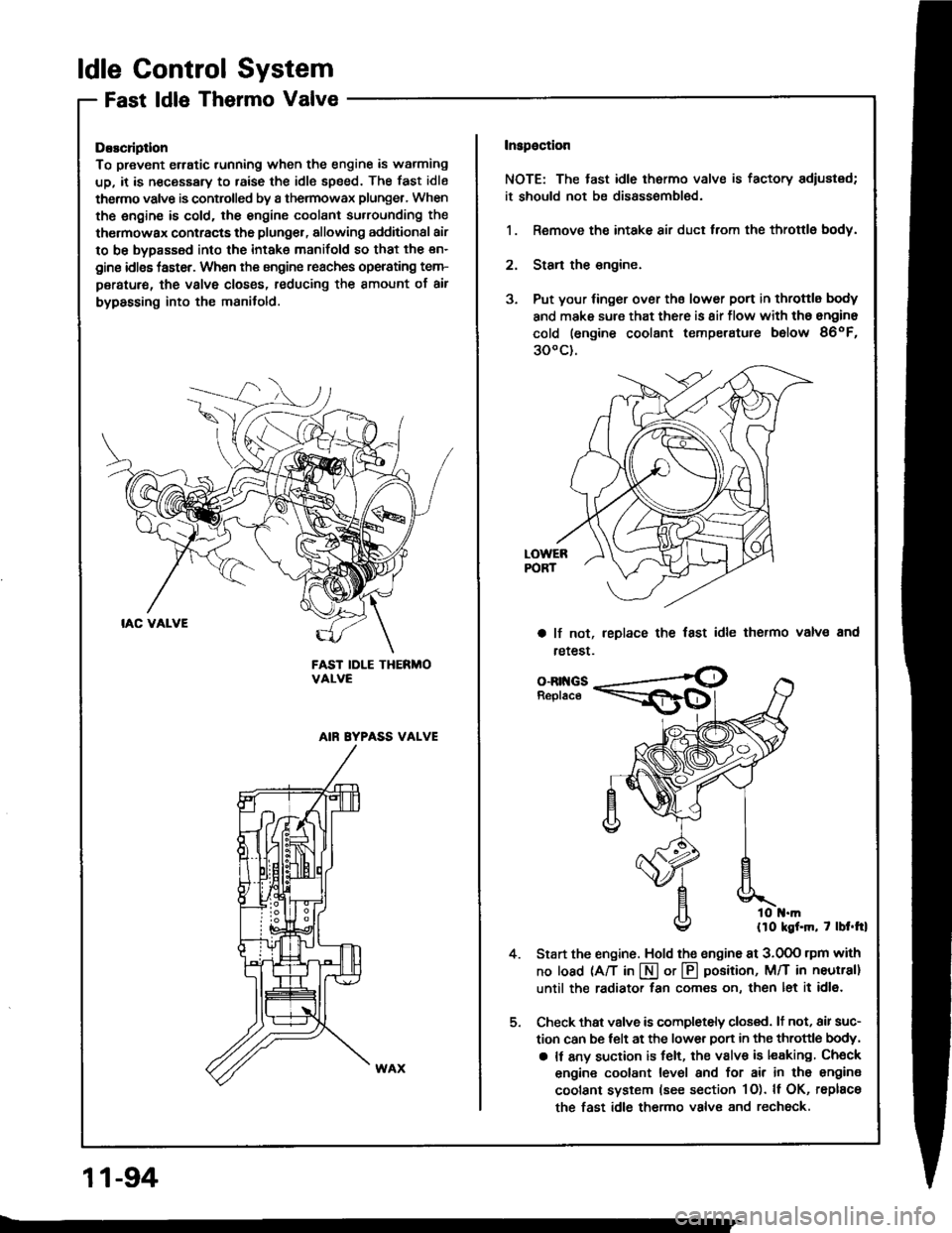

ldle Control System

Fast ldle Thermo Valve

DEscliptlon

To prevent erratic running when the engine is warming

up, it is n€cessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger, When

the engine is cold. the engine coolant su.rounding the

thermowax contracts the plunger, allowing additional air

to be bypassed into the intake manifold so that the en-

gine idlss taster. When the engine reaches operating tem-

peratur€, the valve closss, reducing the amount of air

bypassing into the manifold.

FAST IDLE THERMOVALVE

AIN EYPASS VALVE

Inspaction

NOTE: The tast idle thermo valve is factory adiustsd;

it should not be disassombl€d.

1. Remove the intake air duct from the throttlg body.

2. Stan the engine.

3. Put your finger over ths lower port in throttle body

and make sure that there is 8ir flow with tho engine

cold (engine coolant temperatute below 86oF,

300c).

a lf not,

retest.

leplace the fast idle thermo valvs and

4.

o-Rr{GsReplace

llo kgf.m, 7 lbt.trl

Start the engine. Hold the sngine at 3.0OO rpm with

no load (A/T in I or @ position, M/T in neutral]

until the radiator fan comes on, then let it idl6.

Check thst valve is completely closed. lt not, air suc-

tion can be telt at the lower Don in the throttle body,

a It any suction is felt, the valve is leaking Check

engine coolant level and for air in tho engine

coolant system (see section 1O). ll OK, rsplace

the fast idle thermo valve and rechock.

11-94

Page 284 of 1413

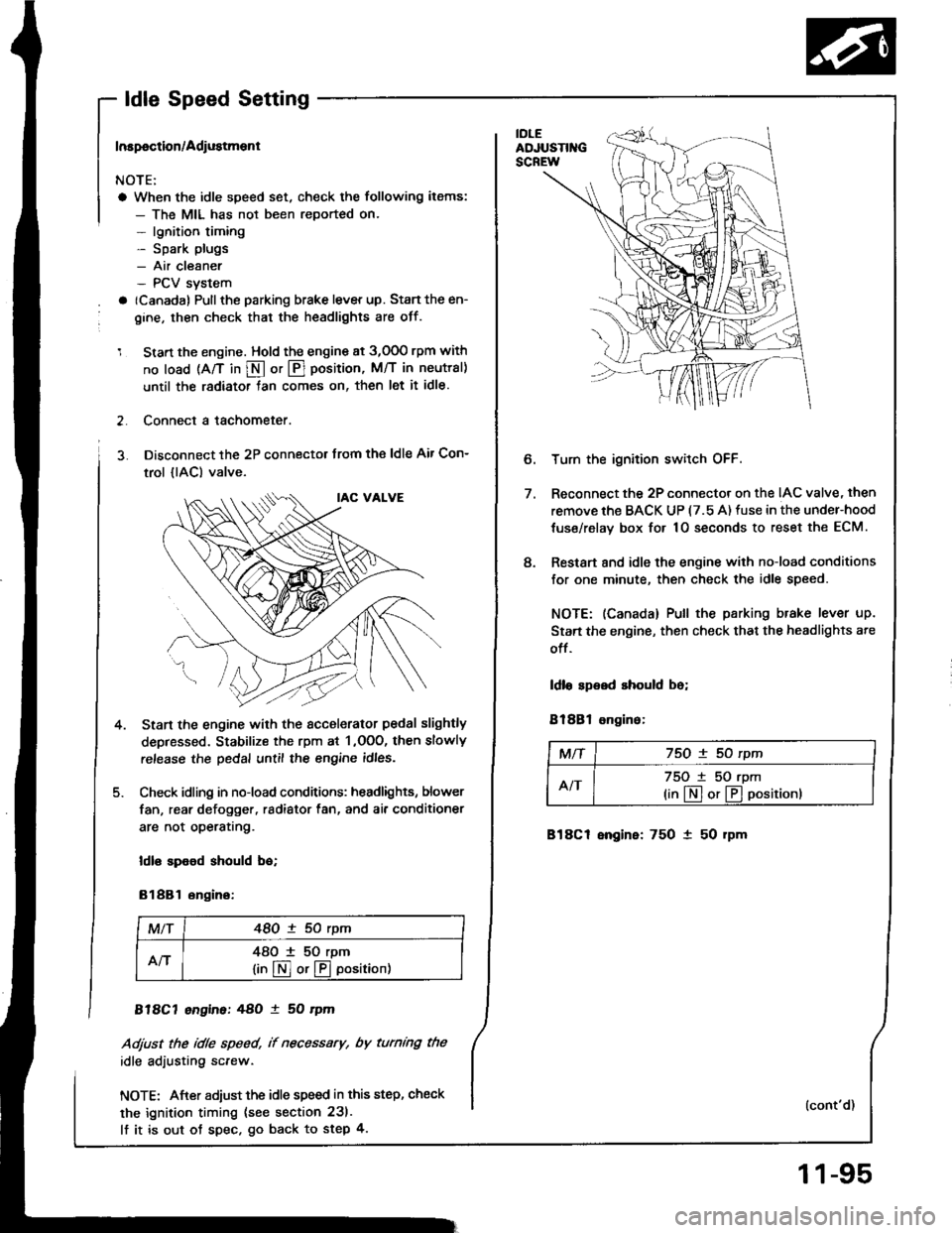

- ldle Speed Setting

Inspoction/Adiustment

NOTE:

a When the idle speed set, check the following items:

- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV svstem

a (Canada) Pullthe parking brake lever up. Stan the en-

gine, then check that the headlights are off.

1 Start the engine. Hold the engine at 3,000 rpm with

no load (A/T in S or @ position, M/T in neutral)

until the radiator tan comes on, then let it idle.

2. Connect a tachometer.

3. Disconnect the 2P connectot trom the ldle Air Con-

trol {lAC) valve.

Start the engine with the sccelerator pedal slightly

depressed. Stabilize the rpm at 1 ,OOO, then slowly

release the pedal until the engine idles.

Check idling in no-load conditions: headlights, blower

fan, rear defogger, radiator fan, and ai. conditioner

are not operatrng.

ldl€ spood should bo;

81881 ongino:

MlT48O ! 50 rym

An48O I 50 rpm

lin@or@oosition)

818C7 engine:48O ! 50 rym

Adjust the idle speed, if necessary, by turnmg the

idle adiusting screw.

NOTE: After adiust the idle speed in this step, check

the ignition timing (see section 231.

lf it is out ot spec. go back to step 4.

4.

e

Turn the ignition switch OFF.

Reconnect the 2P connector on the IAC valve, then

remove the BACK UP (7.5 A) fuse in the under-hood

tuse/relav box for 1O seconds to reset the ECM.

Restart 8nd idle the engine with no-load conditions

for one minute, then check the idle speed.

NOTE: (Canada) Pull the parking brake lever up.

Start the engine, then check that the headlights ate

off.

ldlo speed should be;

81881 ongino:

MTf75O ! 50 rpm

AIT75O t 50 rpm

(in[]or@positionl

818C1 engine: 750 1 50 rpm

(cont'd)

11-95

Page 285 of 1413

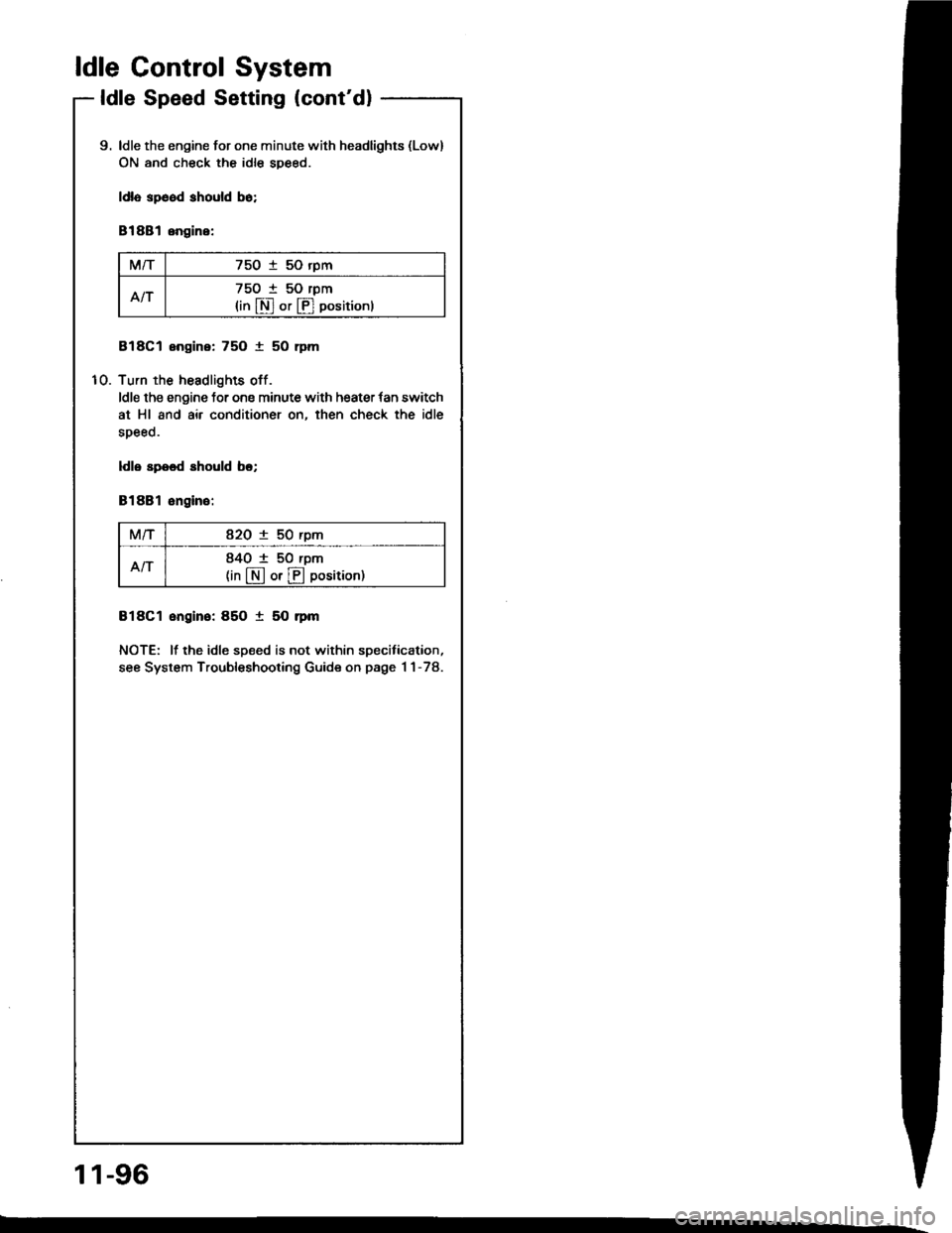

ldle Control System

ldle Speed Setting (cont'd)

10.

9. ldle the engine for one minute with headlights {Low}

ON and check the idle sDeed.

ldla sp6od should bo;

81881 engine:

M/T750 i 50 rpm

An75O t 50 rpm

{in $ or p] positionl

818C1 engine: 75O 1 50 rpm

Turn the headlights off.

ldle the engine for one minute with heater tan switch

at Hl and air conditioner on, then check the idle

speeo.

ldls spood should bo;

81881 ongino:

M/T82O 1 50 rpm

AN840 1 50 rpm(in [N] or lll position)

818C1 engino: 85O t 50 nm

NOTE: lf the idle speed is not within specitication,

see System Troubleshooting Guide on page 1 1-78.

11-96

Page 290 of 1413

Insp6ction

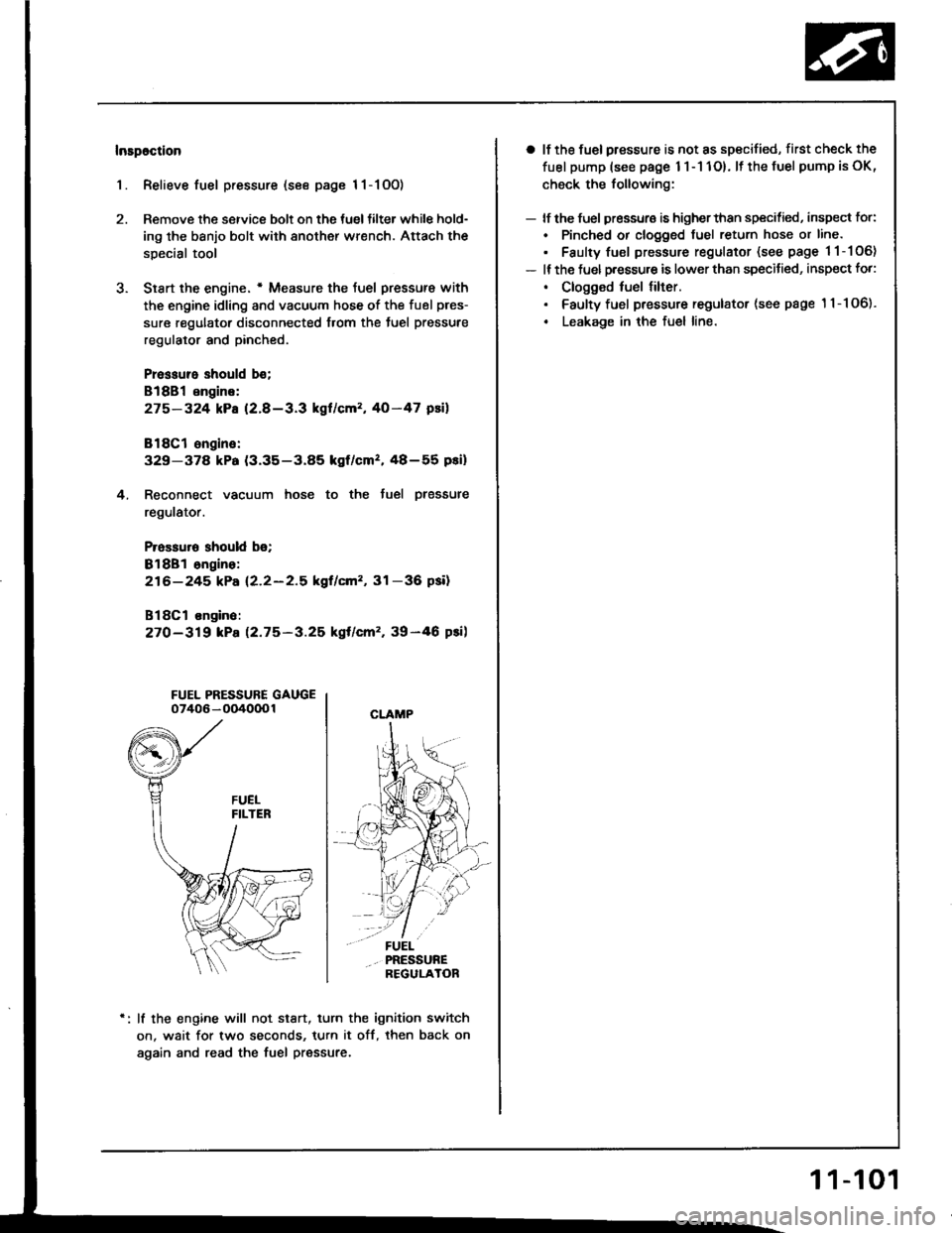

1. Relieve fuel pressure (see page 11-1OO)

2. Remove the service bolt on the tueltilter while hold-

ing the banjo bolt with another wrench. Attach the

special tool

3. Siart the engine. * Measure the {uel pressur€ with

the engine idling and vacuum hose of the fuel pres-

sure regulator disconnected from the tuel pressure

regulator and pinched.

Pressure should b€;

818B1 engins:

275-324 kPa (2.8-3.3 kgl/cm2, 40-47 psil

818C1 ongine:

329-37a kPa (3.35-3.85 kgf/cmz, 48-55 pei)

4. Reconnect vacuum hose to the tuel plessure

regulator.

Prossuro should b€;

Bl8Bl ongino:

216-245 kPa (2.2-2.5 kgf/cm'�, 31 -36 psil

B18Cl on9in6:

27O-319 kPa 12.75-3.25 kgt/cm'�, 39-46 psi)

FUEL PRESSURE GAUGE07406 - OO4000 1

lf the engine will not stan, turn the ignition switch

on. wait for two seconds, turn it off, then back on

again and read the fuel pressure.

CLAMP

a lf the fuel pressure is not as specified, first check the

fuel pump (see page 1 l - 1 1O). lf the fuel pump is oK,

check the following:

- lf the fuel pressuro is higherthan specified, inspect for:

. Pinched or clogged tuel return hose or line.

. Faulty fuel pressure regulator (see page 11-106)

- It the fuel p.essu.e is lower than specitied, inspect fo.:

. Clogged fuel tilter.. Faulty fuel pressure regulator (see page '11-106).

. Leakage in the fuel line.

1 1-101

Page 294 of 1413

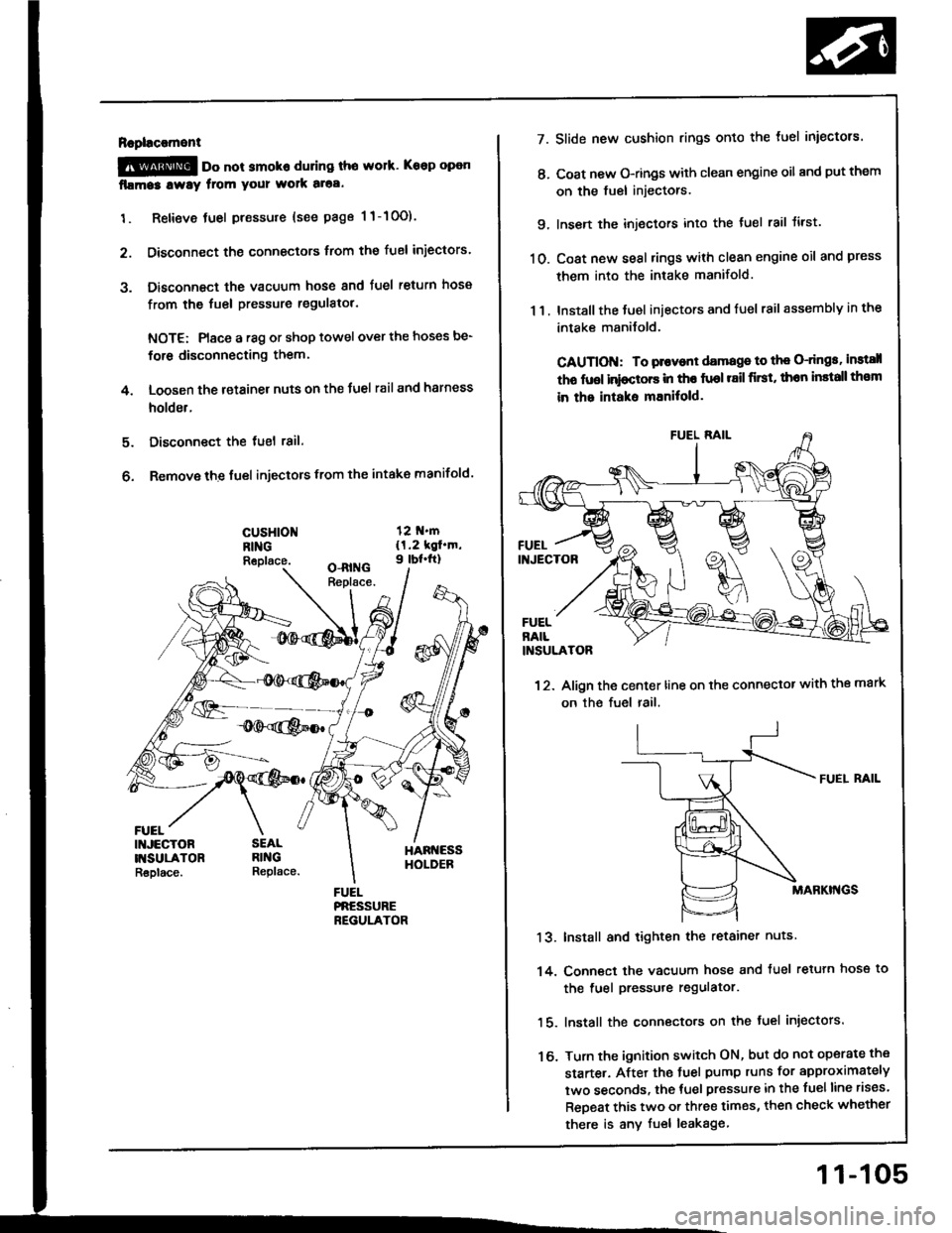

Rapl!c!ment

@ oo not smoko during tho work. Keep open

fllma3 lway from your wolk aloa.

1. Retieve tuel pressure {see page 1 1-10O).

2. Disconnect the connectors trom the fuel iniectors.

3. Disconnect the vacuum hose and fuel return hosa

from the fuel pressure regulatol.

NOTE: Place a r8g or shop towel over the hoses be-

for6 disconnecting them.

4. Loosen the retainer nuts on the Juel rail and harness

holder.

Disconnect the tuel 18il.

Remove the fuel injectors from the intake manifold.

5.

6.

cusHloNRINGReplace.

FUEL

7.

t'.

9.

10.

13.

14.

16.

11.

Slide new cushion rings onto the luel iniectors.

Coat new O-rings with clean engine oil and put them

on the fuel injectors.

Insen the injectors into the tuel rail tirst.

Coat new seal rings with clean engine oil and press

them into the intake manifold.

Install the Juel iniectors and fuel rail assembly in the

intake manilold.

CAUTION: To plovont damage to th€ O-dngs, instsll

tho fuol inioctors in tho fuol r8il first, thon install th€m

in the intaks mEnitold.

12. Align the center line on the connector with the mark

on the fuel rail.

FUEI. RAIL

MABKI'{GS

Install and tighten the retainer nuts

Conn€ct the vacuum hose and tuel retuln hose to

the fuel pressure regulator.

lnstall the connecto.s on the fuel injectors.

Turn the ignition switch ON, but do not operate the

starte.. After the tuel pump runs for approximately

two seconds, the tuel pressure in the fuelline rises.

ReDeat this two or three times, then check whether

there is any fuel leakage

11-105