battery HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1253 of 1681

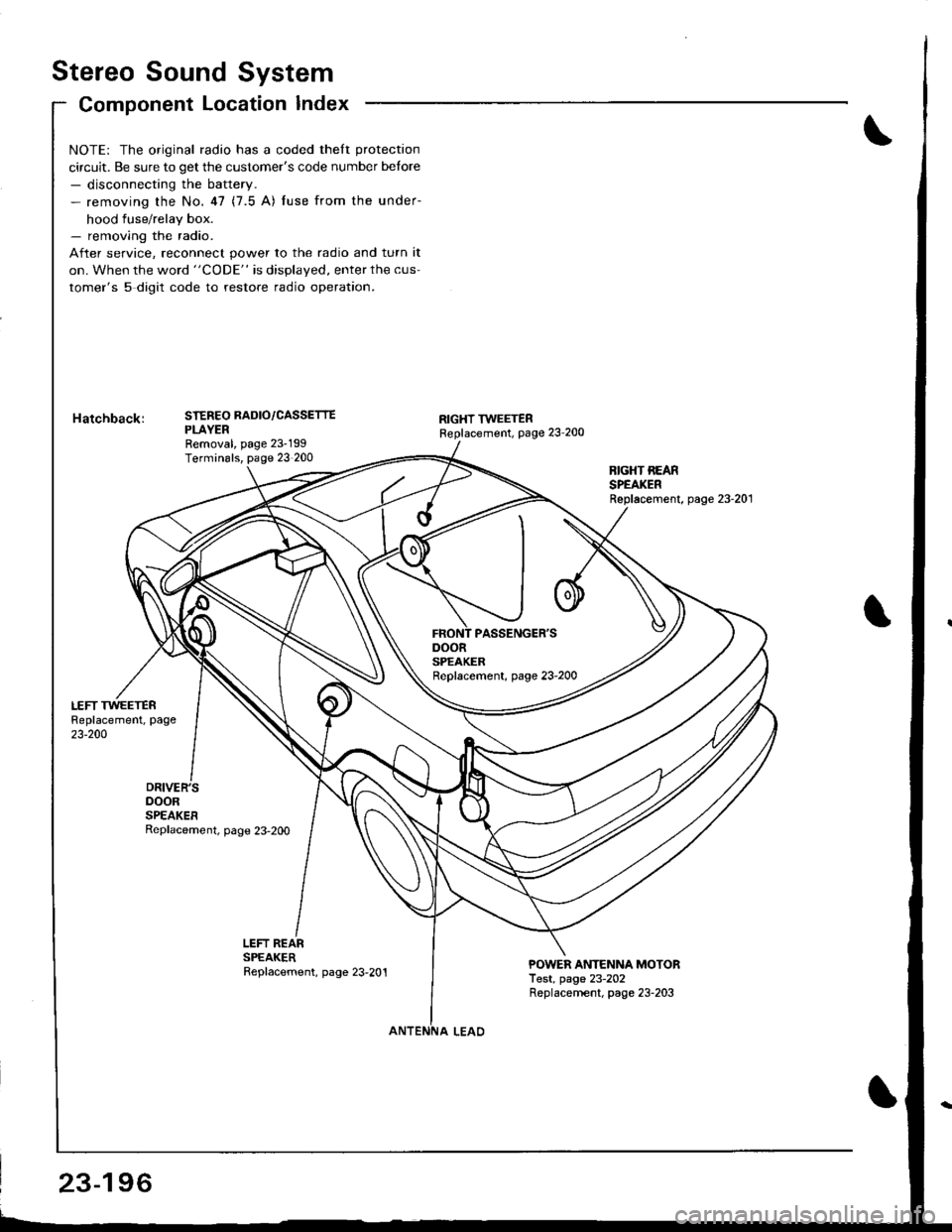

Stereo Sound System

Component Location Index

DOORSPEAKERReplacement, page 23-2OO

NOTE: The original radio has a coded theft protection

circuit. Be sure to get the customer's code number betore- disconnecting the battery.- removing the No.47 (7.5 A) fuse from the under-

hood fuse/relay box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's 5 digit code to restore radio operation.

STEREO RADIO/CASSETTEPLAYERRemoval, page 23-199Terminals, page 23 200

RIGHT TWEETERReplacement, page 23'200

BIGHT REARSPEAKERReplacement, page 23-201

LEFT REARSPEAKERReplacement, page 23,201POWER ANTENNA MOTORTest, page 23-202Replacernent, page 23-203

23-196

Page 1256 of 1681

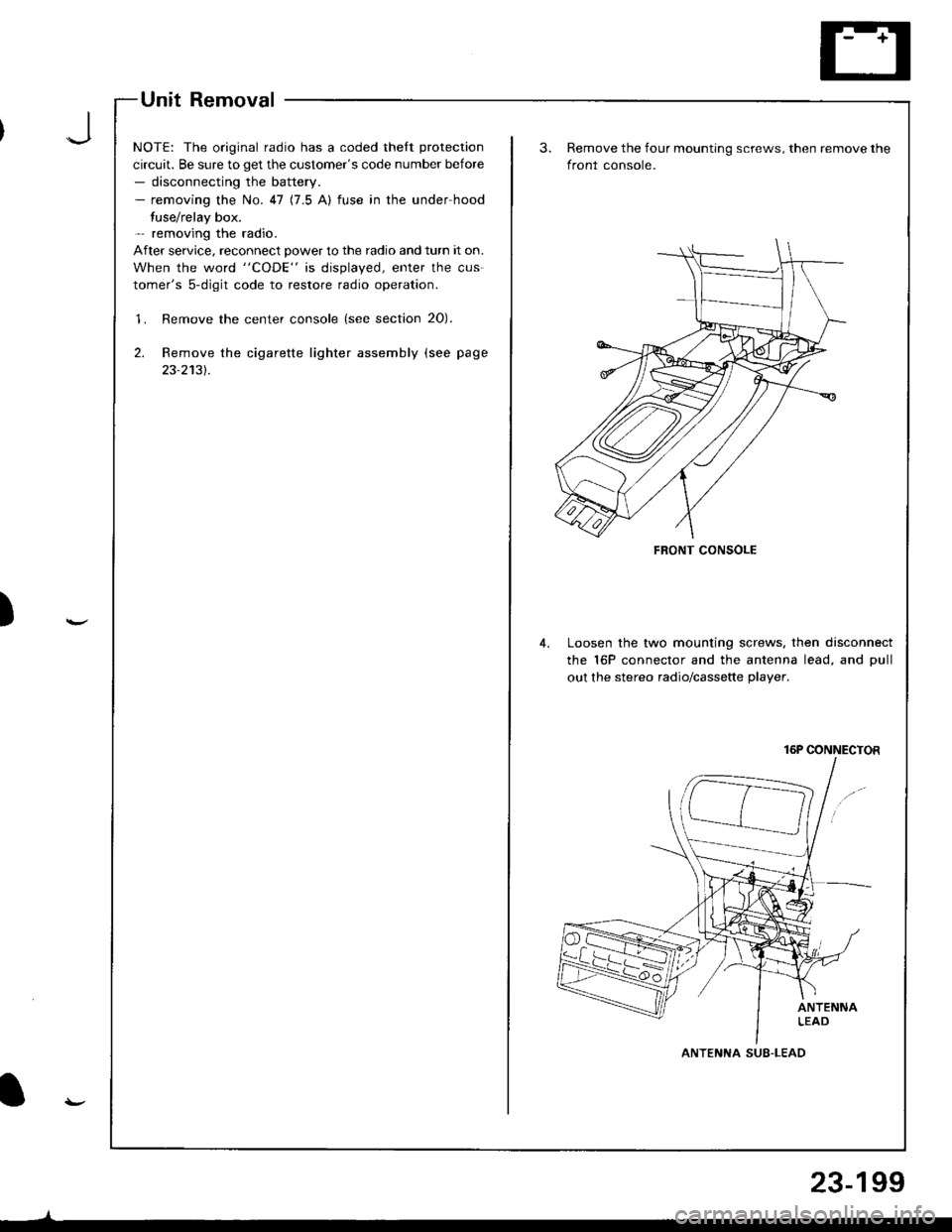

Unit Removal

NOTE: The original radio has a coded thelt protection

circuit. Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 47 (7.5 A) fuse in the under-hood

fuse/relay box.- removing the radio.

After service. reconnect power to the radio and turn it on.

When the word "CODE" is displayed, enter the cus-

tomer's 5-digit code to restore radio operation.

'1. Remove the center console (see section 20).

2. Remove the cigarette lighter assembly (see page

23-2131.

)

FRONT CONSOLE

Remove the four mounting screws, then remove the

front console.

Loosen the two mounting screws. then disconnect

the 16P connector and the antenna lead, and Dull

out the stereo radio/cassette plaver.

16P CONNECTOR

ANTENNA SUB-LEAD

23-199

Page 1259 of 1681

3.

1.

wel

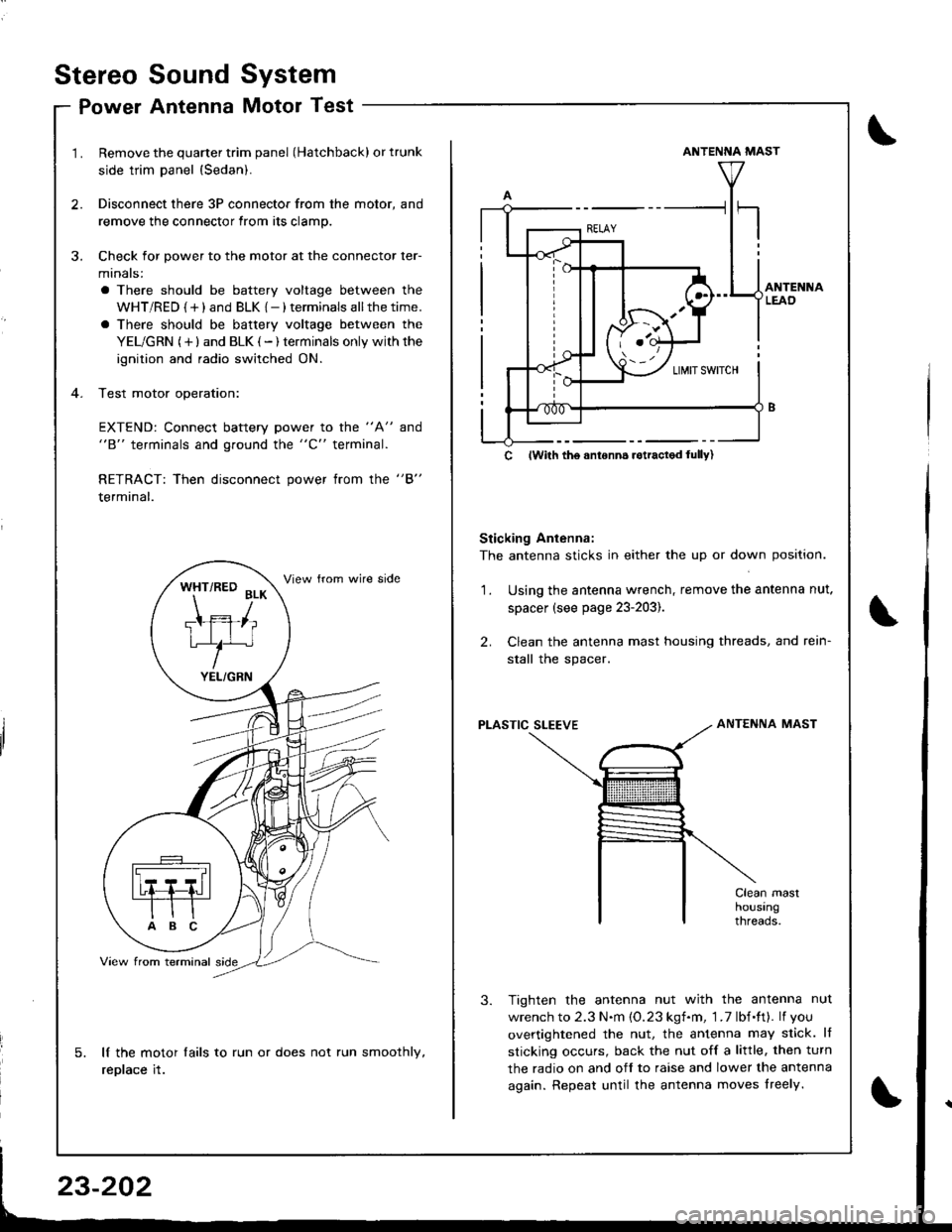

Remove the quarter trim panel (Hatchback) or trunk

side trim panel {Sedan).

Disconnect there 3P connector from the motor, and

remove the connector from its clamp.

Check for power to the motor at the connector ler-

minals:

a There should be battery voltage between the

WHT/RED {+) and BLK {-) terminals allthetime.

a There should be battery voltage between the

YEL/GRN (+) and BLK (-) terminals only withthe

ignition and radio switched ON.

Test motor operation:

EXTEND: Connect battery power to the "A" and"B" terminals and ground the "C" terminal.

RETRACT: Then disconnect power from the "B"

terminal.

lf the motor lails to run or does not run smoothly,

replace it.

WHT/RED BLK

Ttffiliu/^

YEL/GRN

ANTENNA MAST

Sticking Antenna:

The antenna sticks in either the up or down position.

Using the antenna wrench, remove the antenna nut.

spacer (see page 23-203).

Clean the antenna mast housing threads, and rein-

stall the spacer.

2.

1.

PLASTIC SLEEVEANTENNA MAST

Tighten the antenna nut with the antenna nut

wrench to 2.3 N.m {O.23 kgf.m, 1 .7 lbf.ft}. lf you

overtightened the nut, the antenna may slick. lf

sticking occurs, back the nut off a little, then turn

the radio on and off to raise and lower the antenna

again. Repeat until the antenna moves lreely.

c lwith tho anronn6 rotractod lully)

Stereo

Po

Sound

Antenna

System

Motor Test

\

Page 1263 of 1681

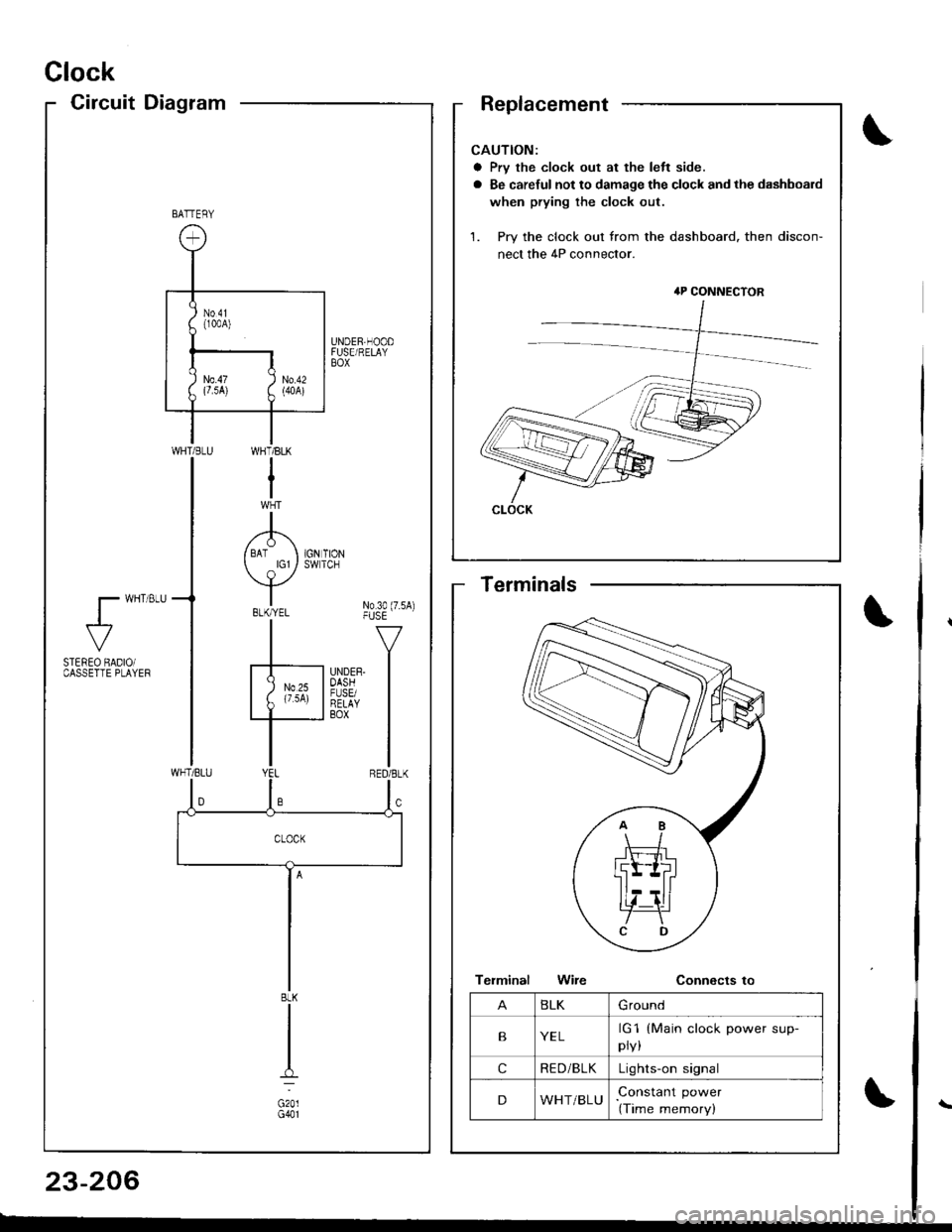

Clock

CircuitDiagram

CAUTION:

a Prv the clock out at the left side.

a Be careful not to damage the clock and the dashboard

when prying the clock out.

1. Pry the clock out from the dashboard. then discon-

nect the 4P connector.

4P CONNECTOR

CLOCK

BATTERY

UNDER,HOODFUSE/RELAYBOX

WI-]T/BLK

I

A/ BAT I 1GN TION

Y*"t No3o(7.sA)-|" -v

F'nrrn l

I

WHT/BLU

l- wHT 8LU

al-

STEREO BADIOiCASSETTE PLAYEF

BLK

G201G401

BLKGround

BYELrG1

pry,

(Main clock power sup-

cRE D/BLKLights-on signal

DWHT/BLUConstant power

(Time memory)

Terminals

23-206

Page 1266 of 1681

SwitchTest

SRS comDonents are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (23) before performing repairs or ser-

vtce.

NOTE: The original radio has a coded thett protection cir-

cuit. Be sure to get the customer's code number beJore- disconnecting the battery.- removing the No. 47 (7.5 A) fuse from the under-hood

fuse/relay box.- removing the radio.

After service, reconnect Dower to the radio and turn it on.

When the word "CODE" is displayed, enter the customer's

5-digit code to restore radio operation

Disconnect the battery negative cable, then discon-

nect the positive cable, and wait at least three min-

uIes.

Disconnect each airbag connector.

Driver's Side:

a Remove the access panel from the steering wheel,

then disconnect the 2P connector between the

driver's airbag and cable reel.

Front Passenger's Side:

. Remove the glove box,

a Disconnect the 2P connector between the front

passenger's airbag and SRS main harness.

1.

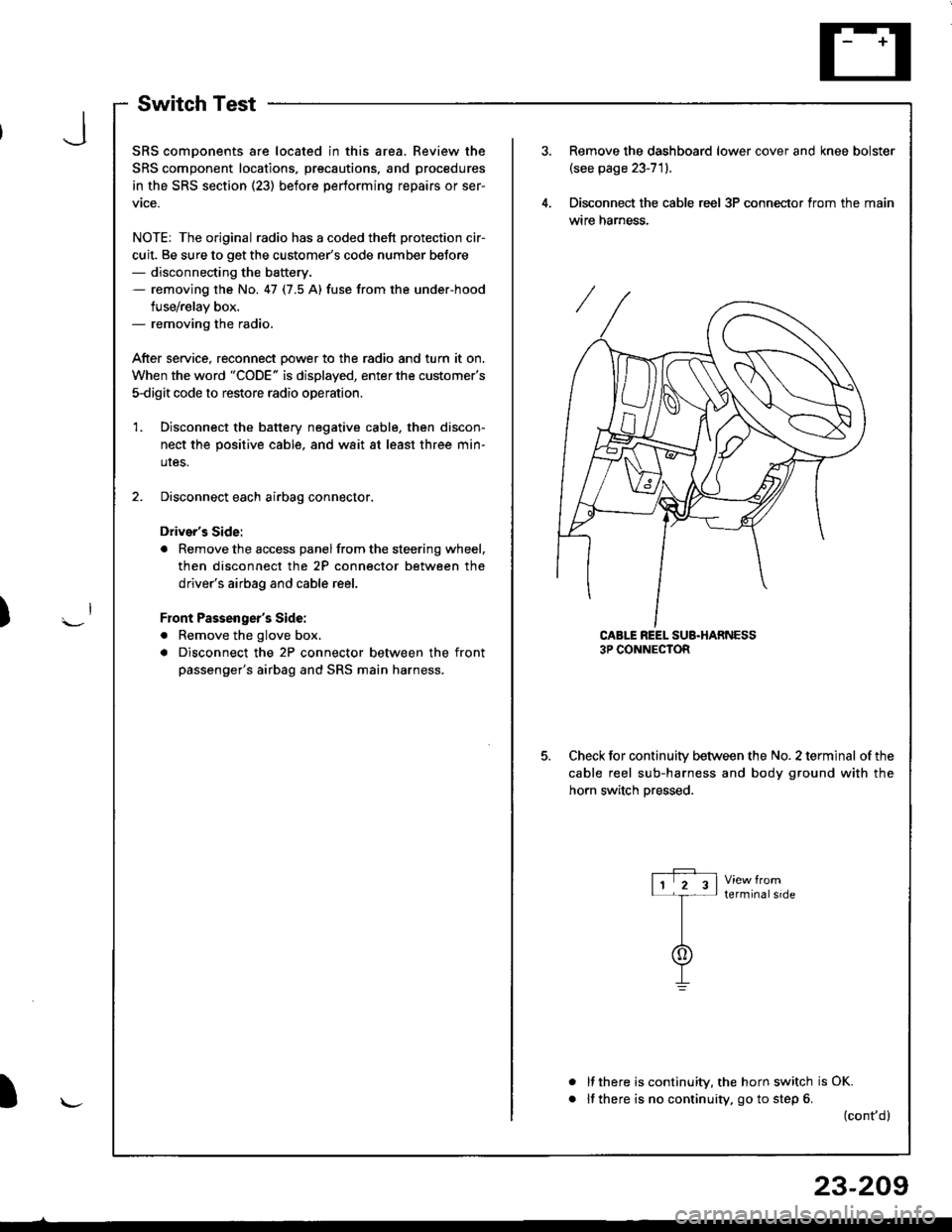

Remove the dashboard lower cover and knee bolster(see page 23-71).

Disconnect the cable reel 3P conneclor from the main

wtre narness.

CABLE REEL SUB.HARNESS3P CONNECTOR

Check for continuitv between the No. 2 terminal of the

cable reel sub-harness and body ground with the

horn switch Dressed.

terminalside

a

It there is continuity, the horn switch is OK.

lf there is no continuity, go to step 6. (cont,d)

r-P r11 2 3l-t-

I

I\-J

)

I

23-209

Page 1267 of 1681

Horn

Switch Test (cont'd)

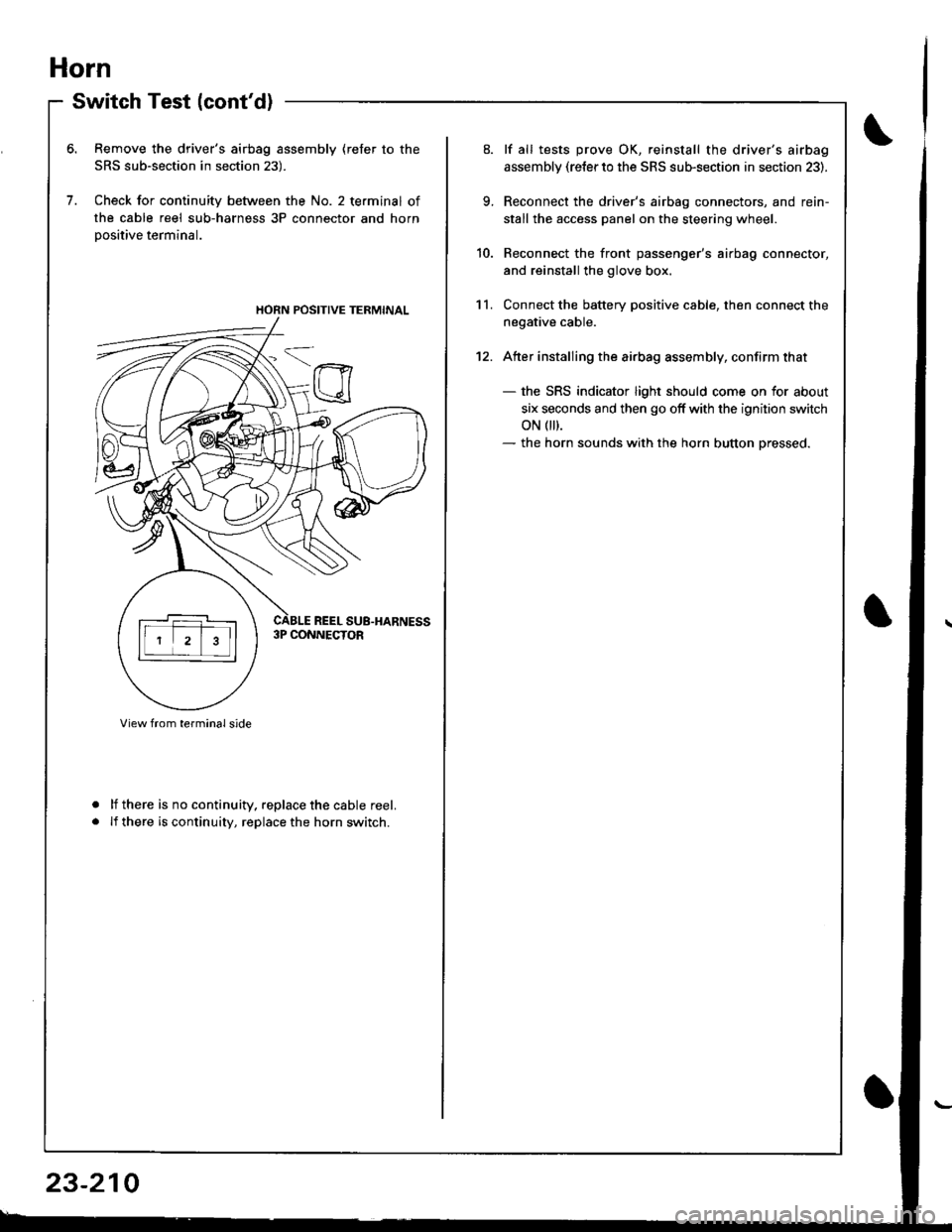

Remove the driver's airbag assembly (refer to the

SRS sub-section in section 23).

Check for continuity between the No. 2 terminal of

the cable reel sub-harness 3P connector and horn

Dositive terminal.

lf there is no continuity. replace the cable reel.

lf there is continuity, replace the horn switch.

a

a

HORN POSITIVE TERMINAL

23-210

9.

10.

11.

12.

lf all tests prove OK, reinstall the driver's airbag

assembly (re{er to the SRS sub-section in section 23).

Reconnect the driver's airbag connectors, and rein-

stall the access panel on the steering wheel.

Reconnect the front passenger's airbag connector,

and reinstall the glove box.

Connect the battery positive cable, then connect the

negative cable.

Atter installing the airbag assembly, confirm that

- the SRS indicator light should come on for about

six seconds and then go off with the ignition switch

oN 0t).- the horn sounds with the horn button pressed.

Page 1268 of 1681

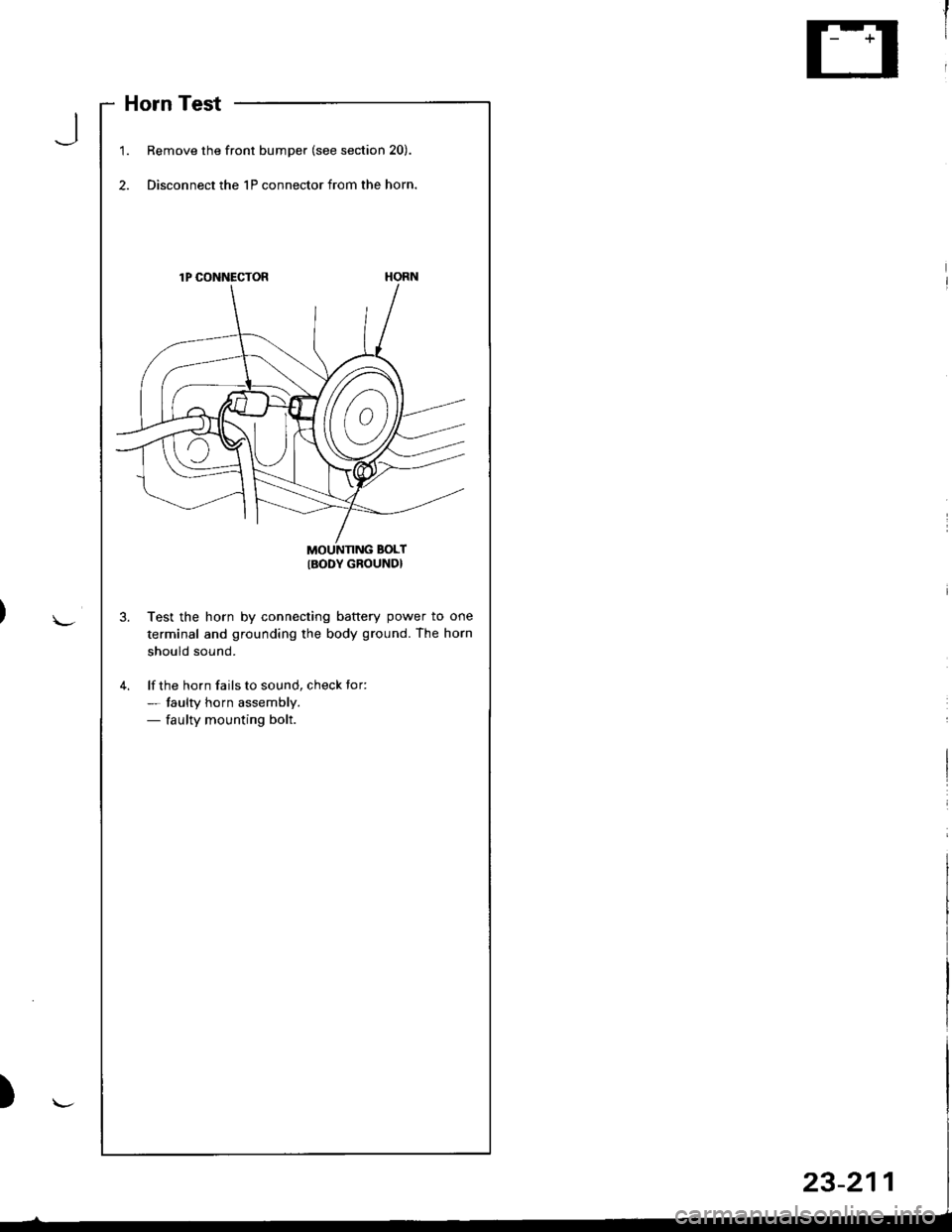

Horn Test

1.Remove the front bumper (see section 20).

Disconnect the 1P connector from the horn.

lP CONNECTOR

MOUNNNG BOLT

IBODY GROUND}

Test the horn by connecting battery power to one

terminal and grounding the body ground. The horn

should sound.

lf the horn fails to sound, check tor:- taulty horn assembly.- faulty mounting bolt.

J

Page 1275 of 1681

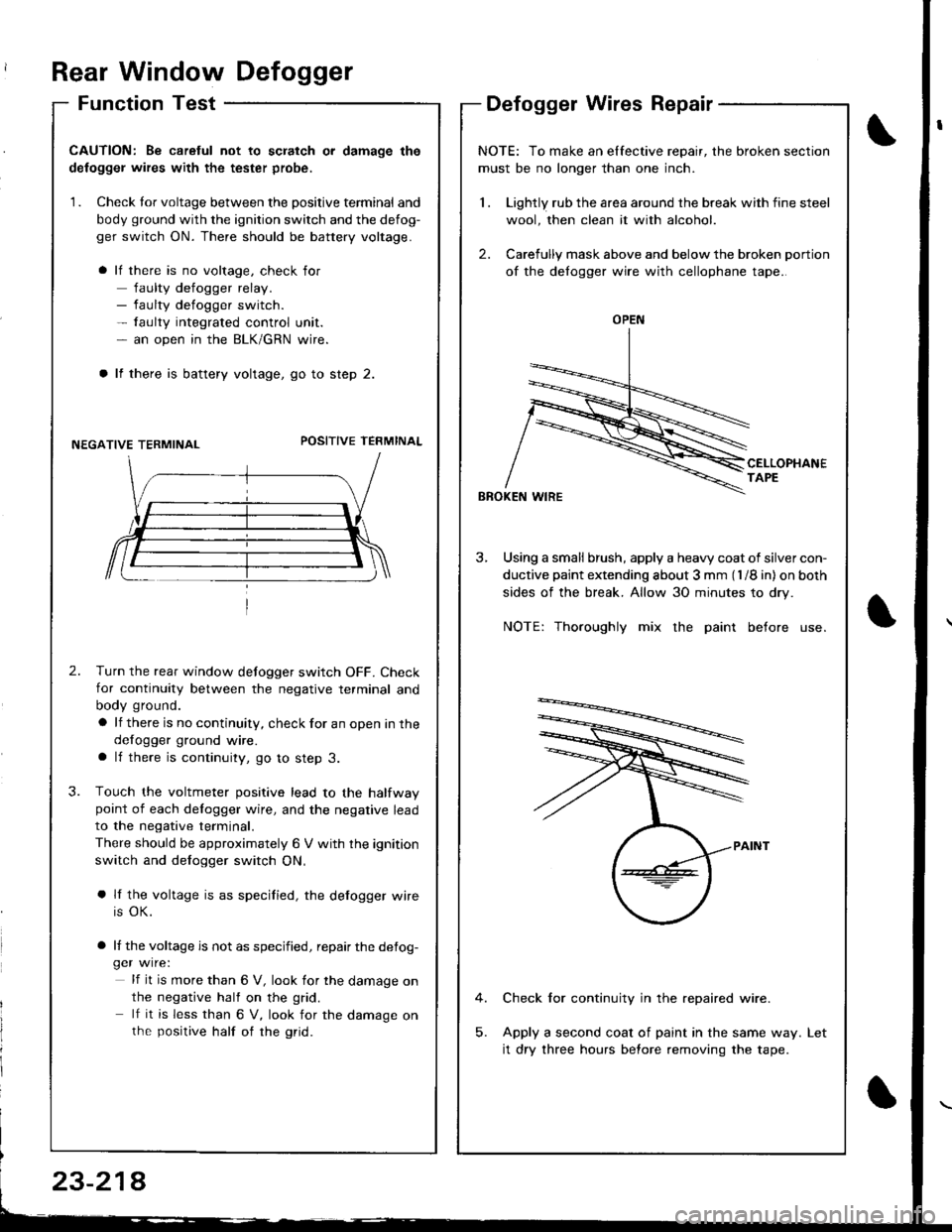

Rear Window Defogger

Function TestDefogger Wires Repair

I

I

CAUTION: Be caretul not to scratch or damage the

defogger wires with the tester probe,

1. Check tor voltage between the positive terminal and

body ground with the ignition switch and the defog-

ger switch ON. There should be battery voltage.

lf there is no voltage, check for

faulty defogger relay.- faulty defogger switch.- faulty integrated control unit.- an open in the BLK/GRN wire.

lf there is battery voltage, go to step 2.

NEGATIVE TERMINALPOSITIVE TEFMINAL

2.Turn the rear window defogger switch OFF. Check

for continuity between the negative terminal and

body ground.

a lf there is no continuity, check for an open in the

defogger ground wire.a lf there is continuity, go to step 3.

Touch the voltmeter positive lead to the halfwaypoint of each delogger wire, and the negative lead

to the negative terminal.

There should be approximately 6 V with the ignition

switch and defogger switch ON,

a lf the voltage is as specified, the defogger wire

is OK.

a lf the voltage is not as specified, repair the defog-ger wire:

lf it is more than 6 V, look for the damage on

the negative half on the grid.

lf it is less than 6 V, look for the damage onthe positive half of rhe grid.

3.

NOTE: To make an elfective repair, the broken section

must be no longer than one inch.

1 . Lightly rub the area around the break with fine steel

wool, then clean it with alcohol.

2. Carefully mask above and below the broken portion

of the defogger wire with cellophane tape.

CELLOPHANETAPE

BBOKEN WIRE

3, Using a small brush, apply a heavy coat of silver con-

ductive paint extending about 3 mm (l /8 in) on both

sides of the break. Allow 30 minutes to dry.

NOTE: Thoroughly mix the paint before use.

Check for continuity in the repaired wire.

Apply a second coat of paint in the same way.

it dry three hours before removing the tape.

Let

OPEN

23-214

Page 1279 of 1681

Moonroof

Function Test

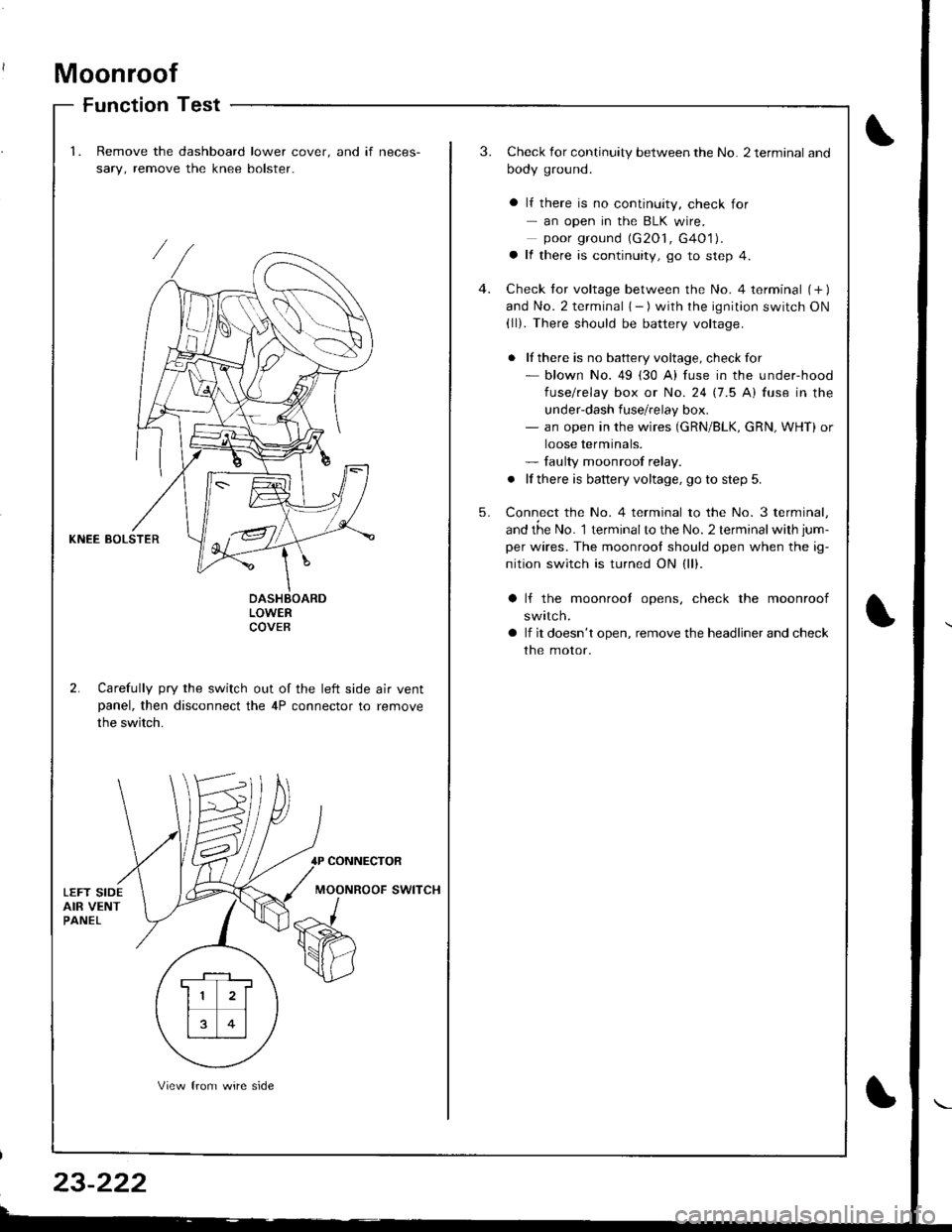

1.Remove the dashboard lower cover. and if neces-

sary, remove the knee bolster.

3.Check for continuity between the No. 2 terminal and

body ground.

a lf there is no continuity, check for- an open in the BLK wire.poor ground (G2O1, G4O1).a lf there is continuity, go to step 4.

Check tor voltage between the No. 4 terminal (+ )and No. 2 terminal { - ) with the ignition switch ON(ll). There should be battery voltage.

. lf there is no battery voltage, checkfor- blown No. 49 (30 A) fuse in the under-hood

fuse/relay box or No. 24 17.5 Al fuse in the

under-dash fuse/relay box.- an open in the wires (GRN/BLK, cRN, WHT) or

loose terminals.- faulty moonroof relay.

. lf there is battery voltage, go to step 5.

Connect the No. 4 terminal to the No. 3 terminal,

and the No. 1 terminalto the No. 2 terminal with jum-

per wires. The moonrool should open when the ig-

nition switch is turned ON (ll).

4.

5.

KNEE BOLSTER

LOWERCOVEB

2. Carefully pry the switch out of the left side air ventpanel, then disconnect the 4P connector to remove

the switch.

lf the moonrool opens, check the moonroof

swttcn.

lf it doesn't open, remove the headliner and check

the motor.

CONNECTOR

MOONROOF SWITCH

. F-_1 ,

11 2l

rt�1

13 0l

View from wire side

Page 1284 of 1681

)

Function Test

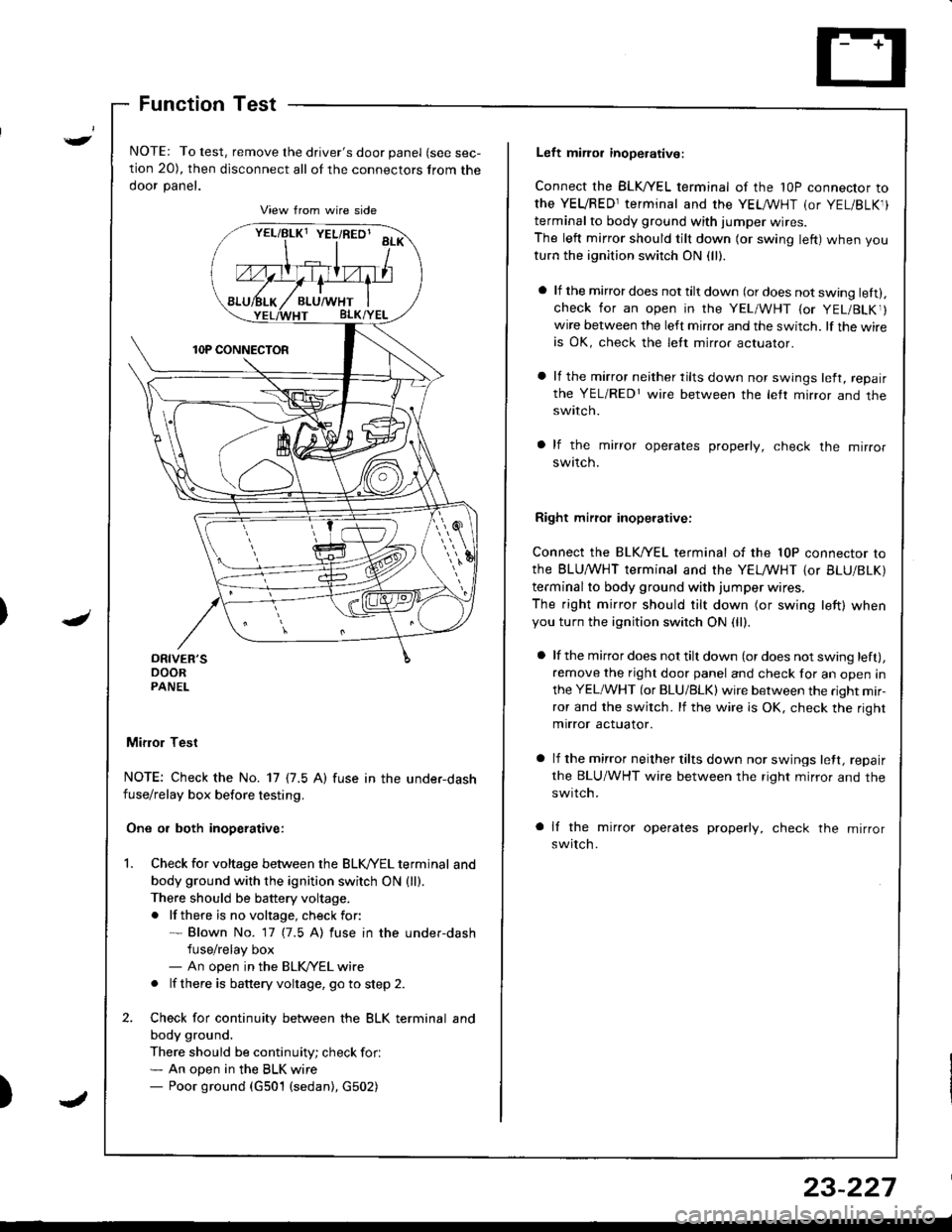

NOTE: To test, remove the driver's door panel (see sec-

tion 20), then disconnect all of the connectors from the

ooor panet.

Mifior Test

NOTE: Check the No. 17 {7.5 A) fuse in the under-dashfuse/relay box before testing.

One or both inoperative:

Check for voltage between the BLK//EL terminal and

body ground with the ignition switch ON {ll).There should be battery voltage.

. lf there is no voltage, check for:* Blown No. 17 (7.5 A) fuse in the under-dash

fuse/relay box- An open in the BLK/YEL wire

. lf there is battery voltage, go to step 2.

Check for continuity between the BLK terminal and

body ground.

There should be continuity; check for.* An open in the BLK wire- Poor ground (G501 (sedan), G502)

vrllBtxt YEL/RED' aa*\

Left miror inoperative:

Connect the BLK,^/EL terminal of the 1OP connector to

the YEVRED1terminal and the YEL /VHT (or YEL/BLK1)

terminal to body ground with iumper wires.

The left mirror should tilt down (or swing left) when you

turn the ignition switch ON (ll).

a lf the mirror does not tilt down (or does not swing lett).check for an open in the YEL/WHT {or YEL/BLKr}wire between the left mirror and the switch. lf the wireis OK, check the lett mirror actuaror.

a lf the mirror neither tilts down nor swings left, repair

the YEL/REDr wire between the letr mirror and theswtlcn.

a lf the mirror operates properly, check the mirror

swttcn.

Right mirrol inoperative:

Connect the BLK/YEL terminal of the 10P connector to

the BLU,^/VHT terminal and the YELMHT {or BLU/BLK)

terminal to body ground with jumper wires.

The right mirror should tilt down (or swing left) whenyou turn the ignition switch ON (ll).

a lf the mirror does not tilt down (or does not swing left),

remove the right door panel and check for an open in

the YEL/WHT (or BLU/BLK) wire between the right mir-

ror and the switch. lf the wire is OK, check the right

mirror actuator.

a lf the mirror neither tilts down nor swings lett, repair

the BLU/WHT wire between the right mirror and the

swrtch.

a lf the mirror operates properly, check the mirror

switch.

23-227