battery HONDA INTEGRA 1998 4.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 1070 of 1681

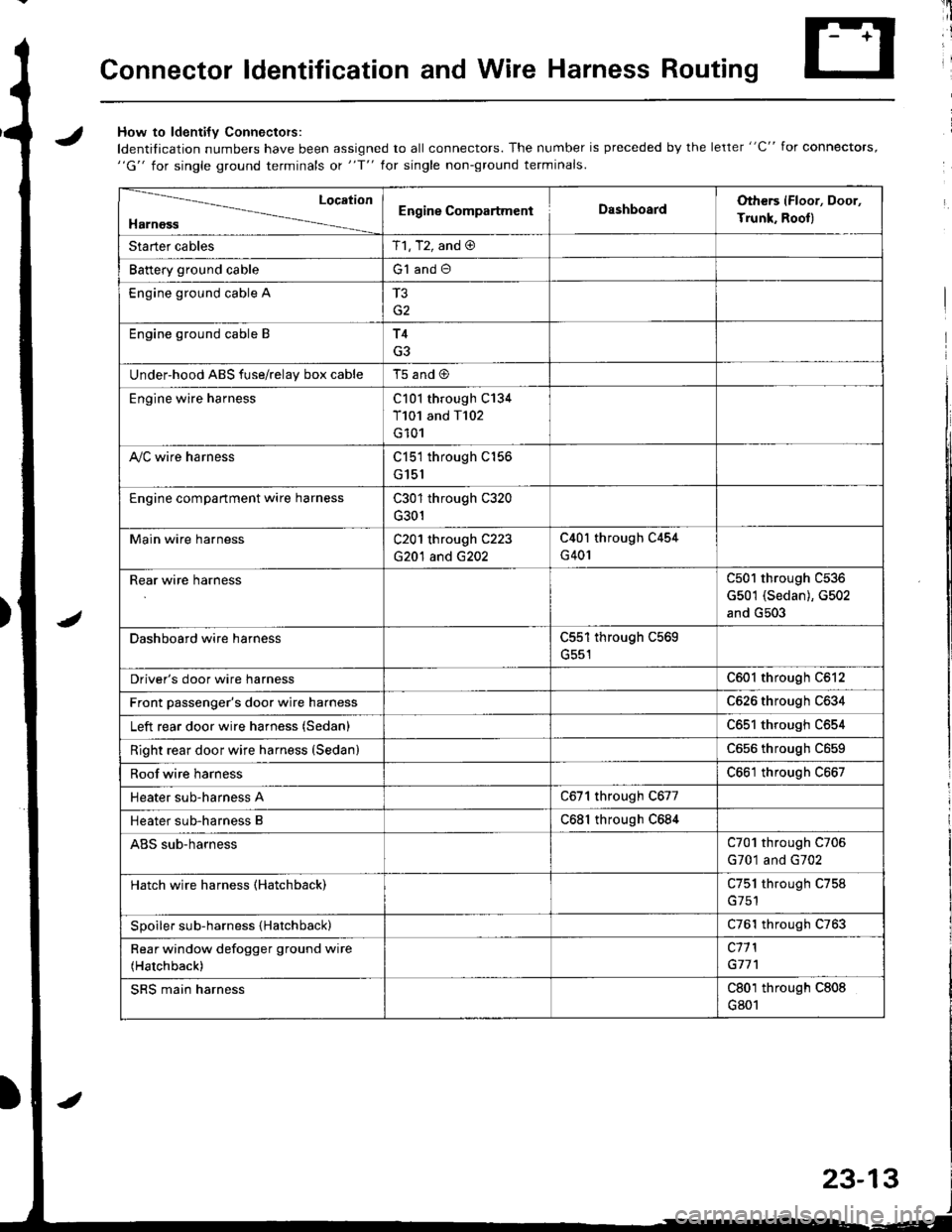

Connector ldentification and Wire Harness Routing

JHow to ldenti{v Connectors:

ldentification numbers have been assigned to all connectors. The number is preceded by the letter "C" for connectors,"G" for single ground terminals ot "f" lor single non-ground terminals.

/

Location

HarnossEngine CompartmentDashboardOthers (Floor, Door,

Trunk. Rooll

Starter cablesT1, T2, and @

Battery ground cableG1 and O

Engine ground cable A

G2

Engine ground cable BT4

G3

Under-hood ABS fuse/relav box cableT5 and @

Engine wire harnessC101 through C134

T101 and T102

G101

A,/C wire harnessC151 through C156

G151

Engine compartment wire harnessC301 through C320

G301

Main wire harnessC201 through C223

G20'l and G202

C40l through C454

G401

Rear wire harnessC501 through C536

G501 (Sedan), G502

and G503

Dashboard wire harnessC551 through C569

G551

Driver's door wire harnessC601 through C612

Front passenger's door wire harnessC626 through C634

Left rear door wire harness (Sedan)C65l through C654

Right rear door wire harness (SedanlC656 throughc659

Roof wire harnessC661 through C667

Heater sub-harness AC671 through C677

Heater sub-harness BC68l through C684

ABS sub-harnessC701 through C706

G701 and G702

Hatch wire harness (Hatchback)C751 through C758

Spoiler sub-harness {Hatchback)C761 through C763

Rear window defogger ground wire

(Hatchback)

c11 l

G77'l

SRS main harnessC801 through C808

G801

23-13

Page 1071 of 1681

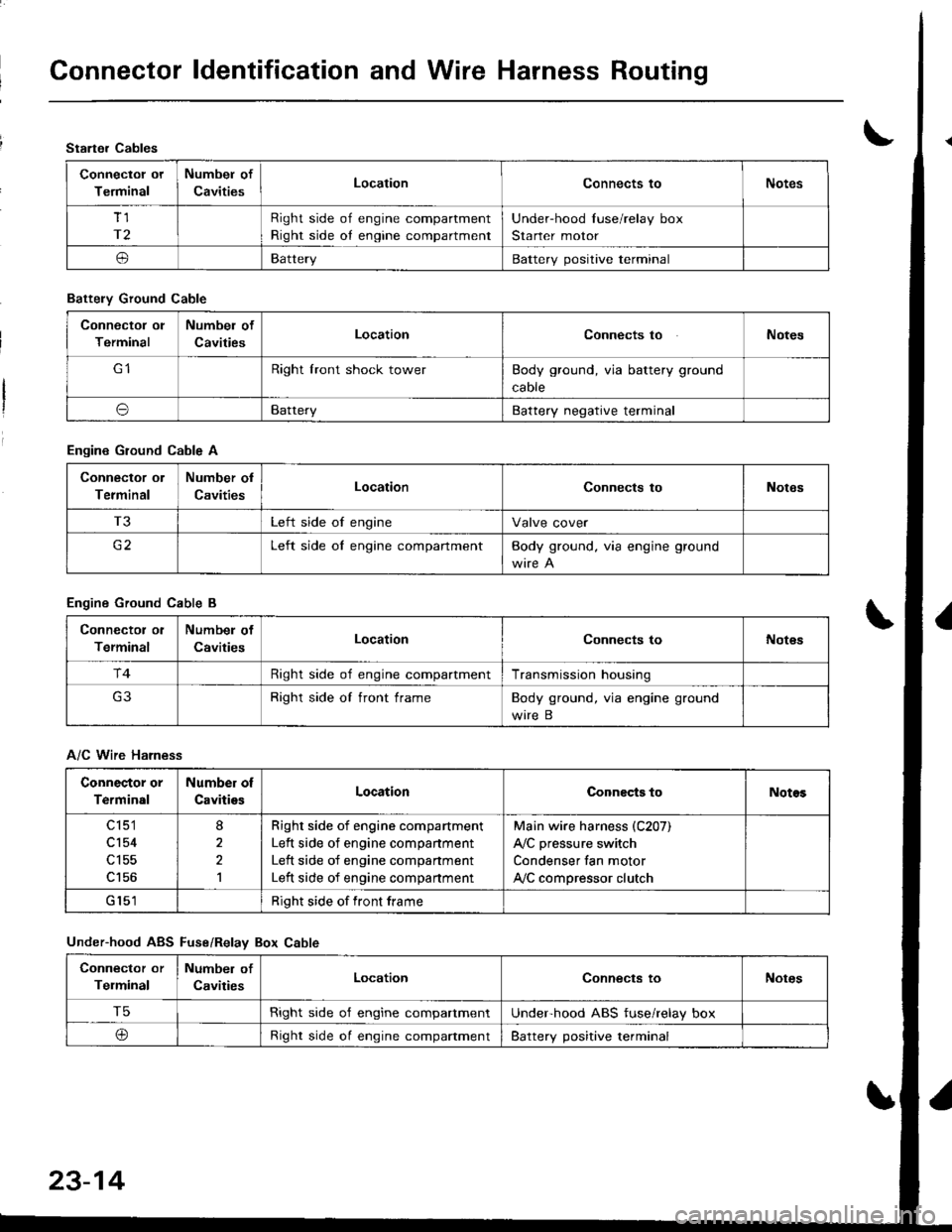

Connector ldentification and Wire Harness Routing

Starter Cables

Connectol ot

Terminal

Numbel of

CavitiesLocationConnects toNotes

Tl

r2

Right side of engine compartment

Right side oI engine compartment

Under-hood Iuse/relay box

Starter motor

oBatteryBattery positive terminal

Battely Ground Cable

Connector ol

Terminal

Numbel of

CavitiesLocationConnects toNotes

Right lront shock towerBody ground, via battery ground

caore

oBatteryBattery negative terminal

Engine Ground Cable A

Connector ol

Terminal

Number ol

CavitiesLocationConnects toNotes

T3Left side of engineValve cover

c2Left side oI engine compartmentBody ground. via engine ground

Engine Ground Cable B

Connector ol

Terminal

Numbel of

CavitiesLocationConnects toNot€s

r4Right side of engine compartmentTransmission housing

Right side of front frameBody ground, via engine ground

wire B

A/C Wire Harness

Connector or

Terminal

Number of

CavitiesLocationConnects toNotos

c 151

cl54

c156

8

2,l

Righr side of engine compartment

Left side of engine companment

Left side of engine compartment

Left side of engine compartment

Main wire harness (C207)

A,/C pressure switch

Condenser fan motor

ly'C compressor clutch

Right side of front frame

Under-hood ABS Fuse/Relav Box Cable

Connector or

Telminal

Number of

CavitiesLocationConnects toNotes

T5Right side o'f engine compartmentUnderhood ABS fuse/relay box

@Right side oI engine compaftmentBattery positive terminal

23-14

Page 1109 of 1681

![HONDA INTEGRA 1998 4.G Manual PDF Fuses

Under-hood Fuse/Relay Box

AITEFNATOR[To .ngine wiro hrrn83 1T101)l

BATTERYlTo stano. csblca lTlll

C!104 [To condenso] fan relayl

*: Not u6edclutch l.hyl

NOTE: View from the backside of the under HONDA INTEGRA 1998 4.G Manual PDF Fuses

Under-hood Fuse/Relay Box

AITEFNATOR[To .ngine wiro hrrn83 1T101)l

BATTERYlTo stano. csblca lTlll

C!104 [To condenso] fan relayl

*: Not u6edclutch l.hyl

NOTE: View from the backside of the under](/img/13/6069/w960_6069-1108.png)

Fuses

Under-hood Fuse/Relay Box

AITEFNATOR[To .ngine wiro hrrn83 1T101)l

BATTERYlTo stano. csblca lTlll

C!104 [To condenso] fan relayl

*: Not u6edclutch l.hyl

NOTE: View from the backside of the under-hood fuse/relav box.

ClOg [To main wiro ha]ne3s {C215ll

C!107 [To blow.r motor r.l.yl

C908 [To m.in wiro h.rn.$ (C2l7ll

rr17

LI

Fl51

LI

rl56

lJ

rr51

IJ

C905 [To A/C compr.ssor C9O6 [To radirto] fan

23-52

Cltl1 lTo main wire harness lc218ll: USA

C€10 [To mrin wir. hlrnoit lC216ll

Page 1110 of 1681

J

)1 -

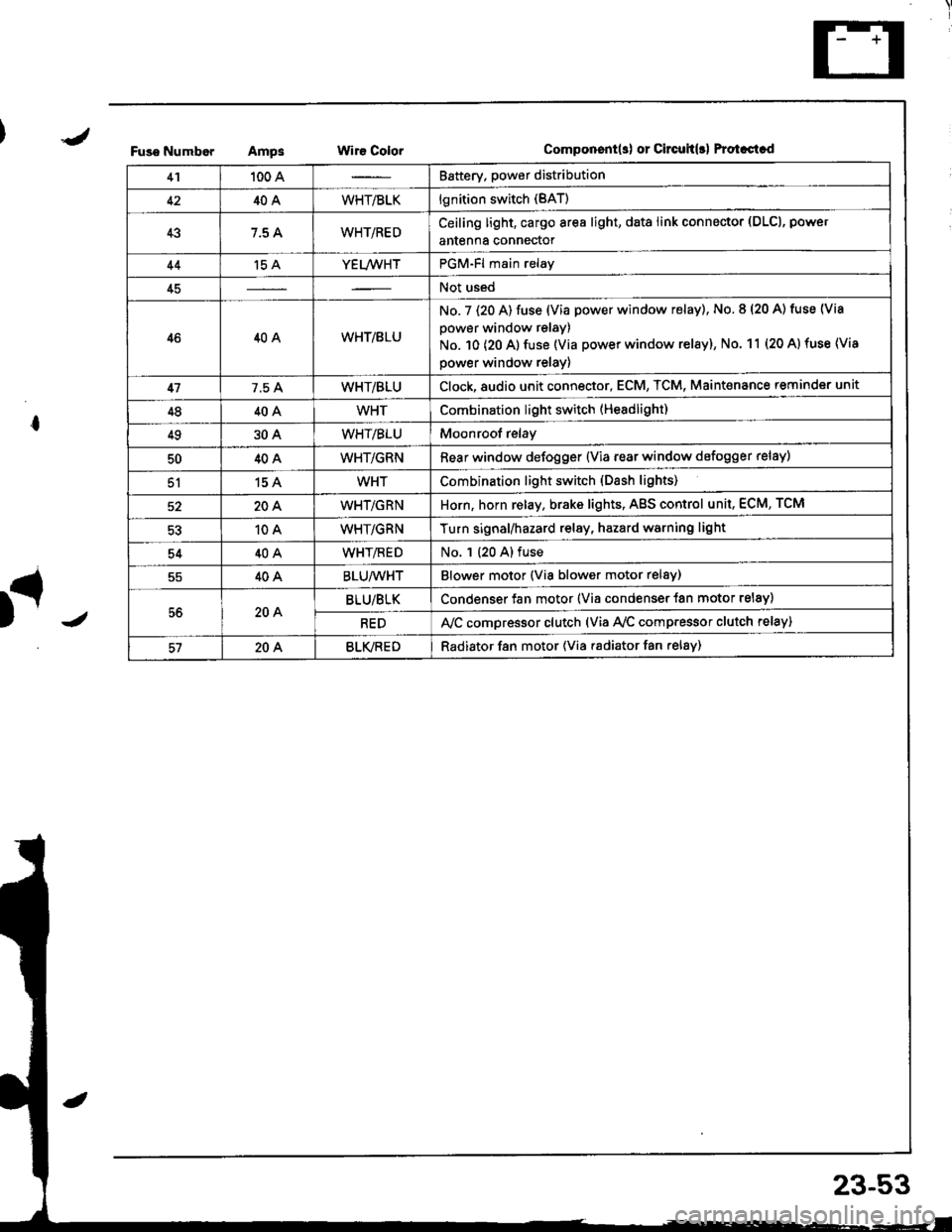

Fuso NumborAmpsWir€ ColorComponent(s) or Circuh(rl Protastcd

41100 ABattery. power distribution

4240AWHT/BLKlgnition switch (BAT)

437.5 AWHT/REDCeiling light, cargo area light, data link connector (DLCl, power

antenna connector

44't5 AYEL/WHTPGM-Fl main relay

45Not used

4640AWHT/8LU

No. 7 (20 A) fuse (Via power window relay), No. 8 (20 A) tuse (Via

power window relay)

No. 10 (20 A) fuse (Via power window relay), No. 11 (20 A) fuse (Via

power window relay)

417.5 AWHT/BLUClock,8udio unit connector, ECM, TCM, Maint€nance reminder unit

4840AWHTCombination light switch (Headlight)

4930AWHT/BLUMoonroof relay

5040AWHT/GRNRear window defogger {Via rear window defogger relay)

51154WHTCombination light switch (Dash lights)

20AWHT/GRNHorn, horn relay, brake lights, AgS control unit, ECM, TCM

10AWHT/GRNTurn signal/hazard relay, hazard warning light

5440AWHT/flEDNo. 1 (20 A) fuse

40ABLU/WHTBlower motor (Via blower motor relsy)

56204BLU/BLKCondenser fan motor (Via condenser {an motor relay)

REDA,/C compressor clutch (via Ay'c comp.essor clutch relay)

57204BLVREDRadiator f8n motor (Via radiator fan relay)

23-53

Page 1124 of 1681

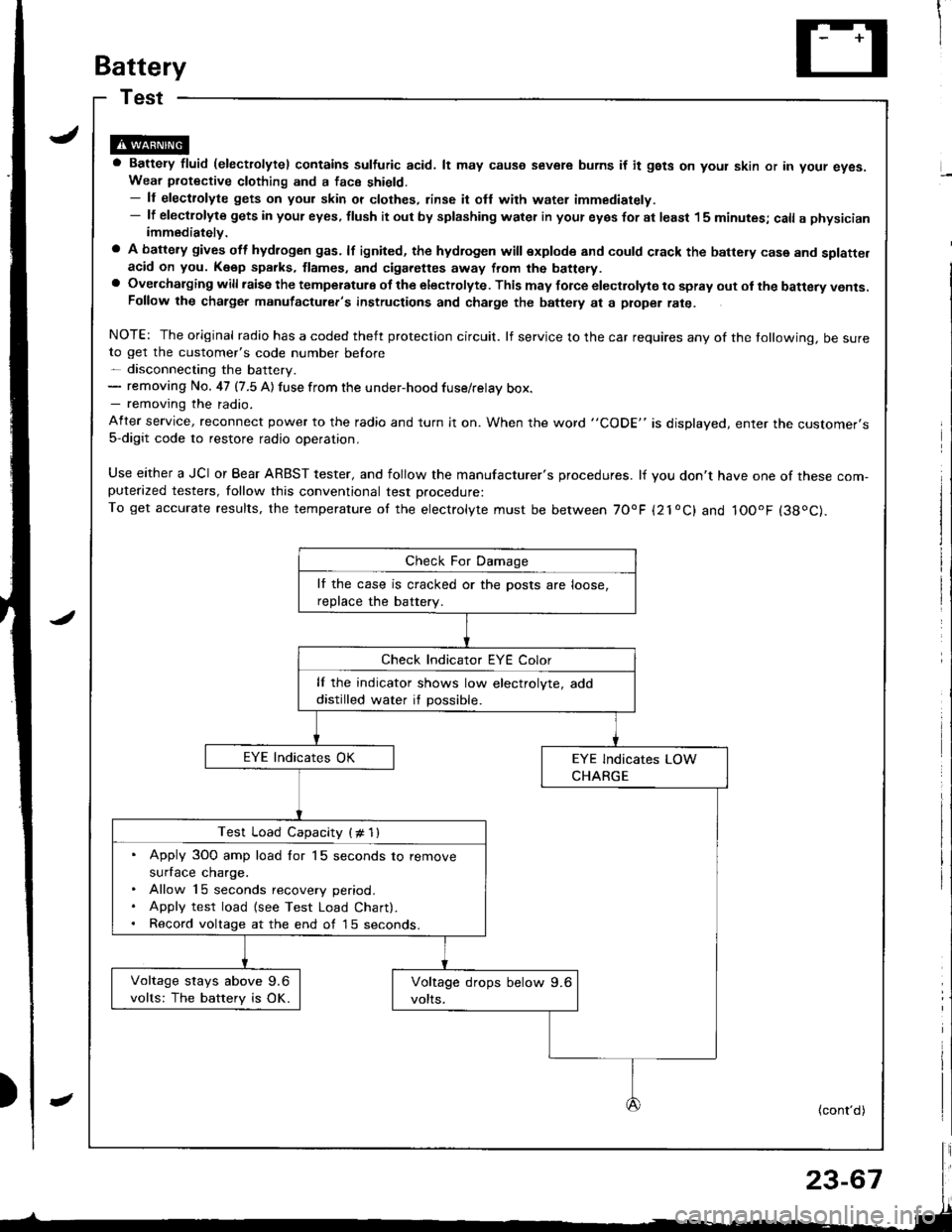

Battery

a Battery fluid (electrolytel contains sulfuric acid. lt may causo severe burns if it gsts on yout skin or in your eyes.Wear piotective clothing and a face shield.- ll electrolyte gets on your skin or clothes, rinse it ofl with water immediately.- lf electlolyte gets in your eyes, tlush it out by splashing water in your eyes for at least 15 minutes; call a physicianimmediately.

a A battery gives off hydlogen gas. lf ignited, the hydrogen will explode and could crack the battery case and splatte.acid on you. K6ep sparks, flames, and cigarettes away from the battery.a Overchalging will raisc the temperatulg of the electrolyte. This may force electrolyte to spray out ol the battery vents.Follow the chatge. manutacturer's instructions and charge the baftely at a ptope. rate.

NOTE: The original radio has a coded theft protection circuit. lf service to the car requires any of the tollowing, be sureto get the customer's code number before- disconnecting the battery.- removing No. 47 (7.5 A) fuse from the under-hood fuse/relay box.- removing the radio.

After service, reconnect power to the radio and turn it on. When the word "CODE" is displayed, enter tne customer's5-digit code to restore radio operation,

Use either a JCI or Bear ARBST tester, and follow the manufacturer's procedures. lf you don't have one of these com-puterazed testers, follow this conventional test Drocedure:To get accurate results, the temperature of the electrolyte must be between 70'F {21oC} and IOOoF (38oC).

lf the case is cracked or the posts are loose,

reDlace the batterv.

lf the indicator shows low electrolyte, add

distilled water if possible.

Test Load Capacity (# 1l

. Apply 3O0 amp load for 15 seconds to remove

surface charge.. Allow 15 seconds recovery period.. Apply test load {see Test Load Chart).. Record voltage at the end of l5 seconds.

Voltage stays above 9.6

volts: The battery is OK.

(cont'd)

Page 1125 of 1681

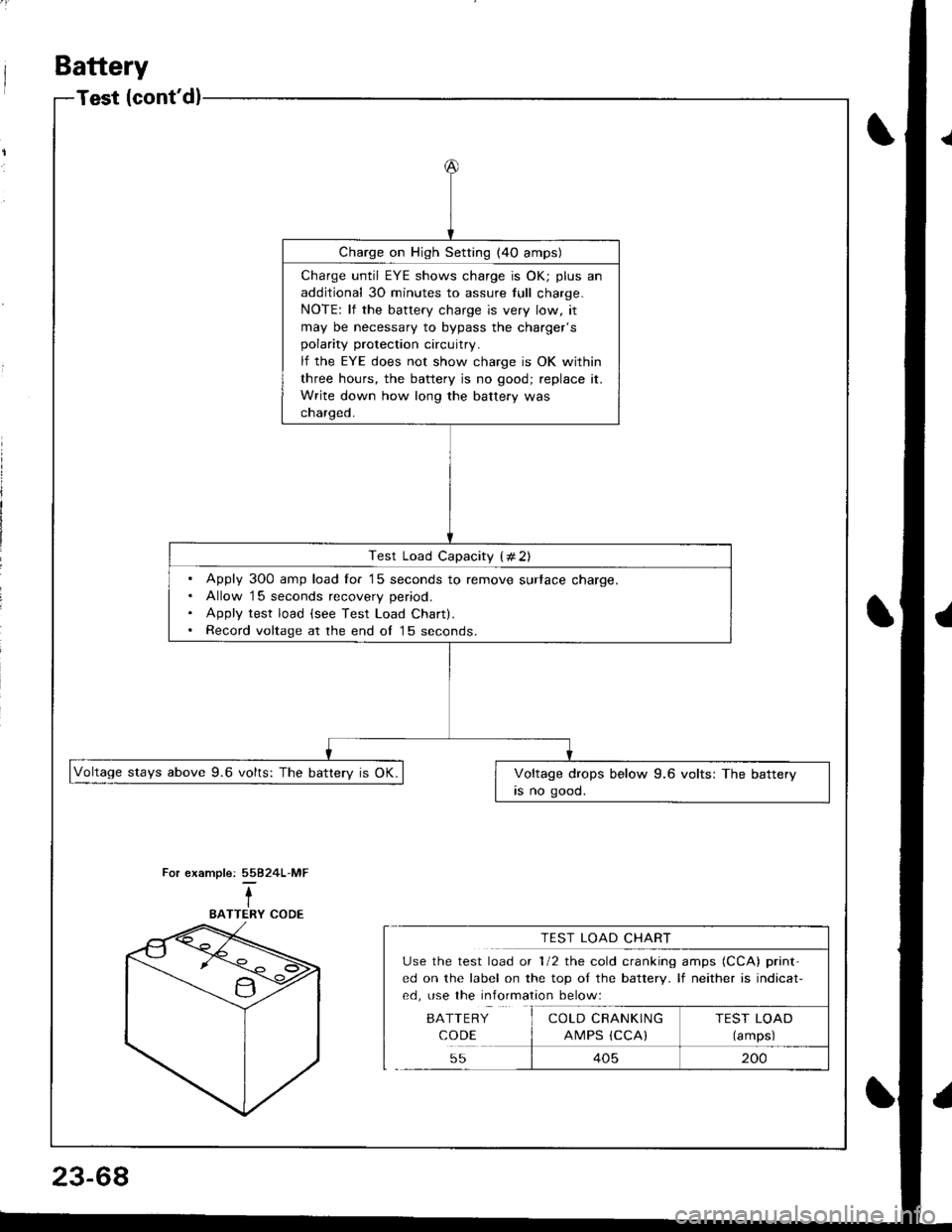

Battery

Test (cont'dl

Charge on High Setting (4O amps)

Charge until EYE shows charge is OK; plus an

additional 30 minutes to assure tull charge.

NOTE: lf the battery charge is very low, it

may be necessary to bypass the charger's

polarity protection circuitry.

lf the EYE does not show charge is OK within

three hours, the battery is no good; replace it.

Write down how long the battery was

charged.

Test Load Capacity (# 2)

Apply 3O0 amp load for '15 seconds to remove surtace charge.

Allow '15 seconds recoverv oeriod.

Apply test load (see Test Load Chart).

Record voltage at the end ol 15 seconds.

Voltage stays above 9.6 volts: The battery is OK. IVoltage drops below 9.6 volts: The battery

rs no good.

For example:

BATT

55B24L.MF

TIERY CODE

TEST LOAD CHART

Use the test load ot 112 the cold cranking amps (CCA) print-

ed on the label on the top oI the battery. lf neither is indicat-

ed, use the information below:

23-68

Page 1129 of 1681

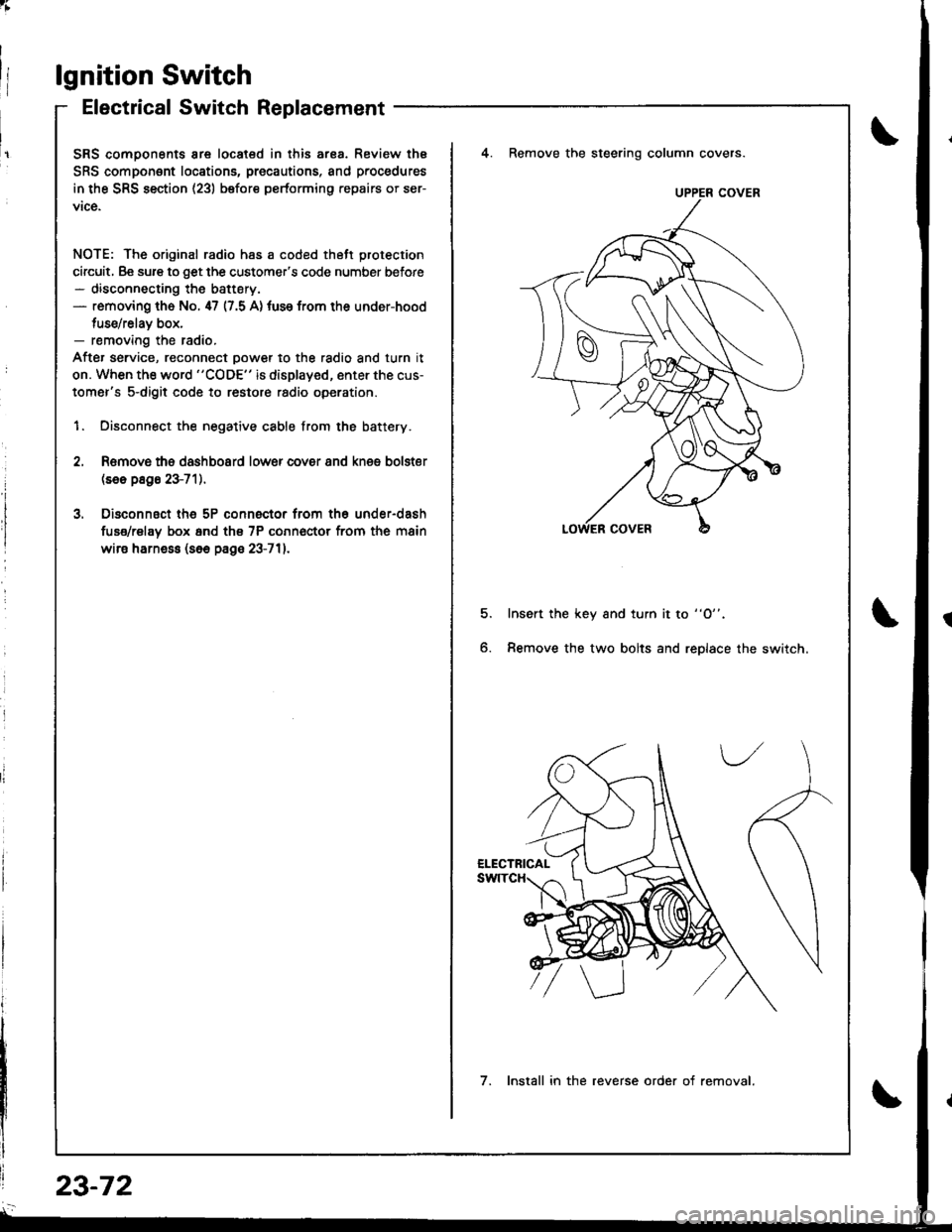

lgnition Switch

Electrical Switch Replacement

SRS comoonents are located in this ar8a. Review thE

SRS component locations, precautions, and procedures

in the SRS section (23) before performing repairs or ser-

vice.

NOTE: The original radio has a coded thett protection

circuit, Be sure to get the customer's code number before- disconnecting the battery.- removing th6 No. 47 (7.5 A) tuse from the under-hood

tuse/relav box,- removing the radio.

After service, reconnect oower to the radio and turn it

on. When the word "CODE" is displayed, enter the cus-

tomer's s-digit code to restore radio operation.

1. Disconnect the negative cable from the battery.

4. Remove the steering column covers.

Romovs ths dashboard lower cover 8nd knes bolster(se6 p8g6 23-71).

Disconnsct th6 5P connector from th6 under-dash

fuse/rel8y box 6nd th€ 7P conn€ctor from the main

wire harne$ (s6e page 23-711.

5.Insert the key and turn it to "O".

Remove the two bolts and replace the switch6.

UPPER COVER

7. Install in the reverse order of removal.

23-72

Page 1130 of 1681

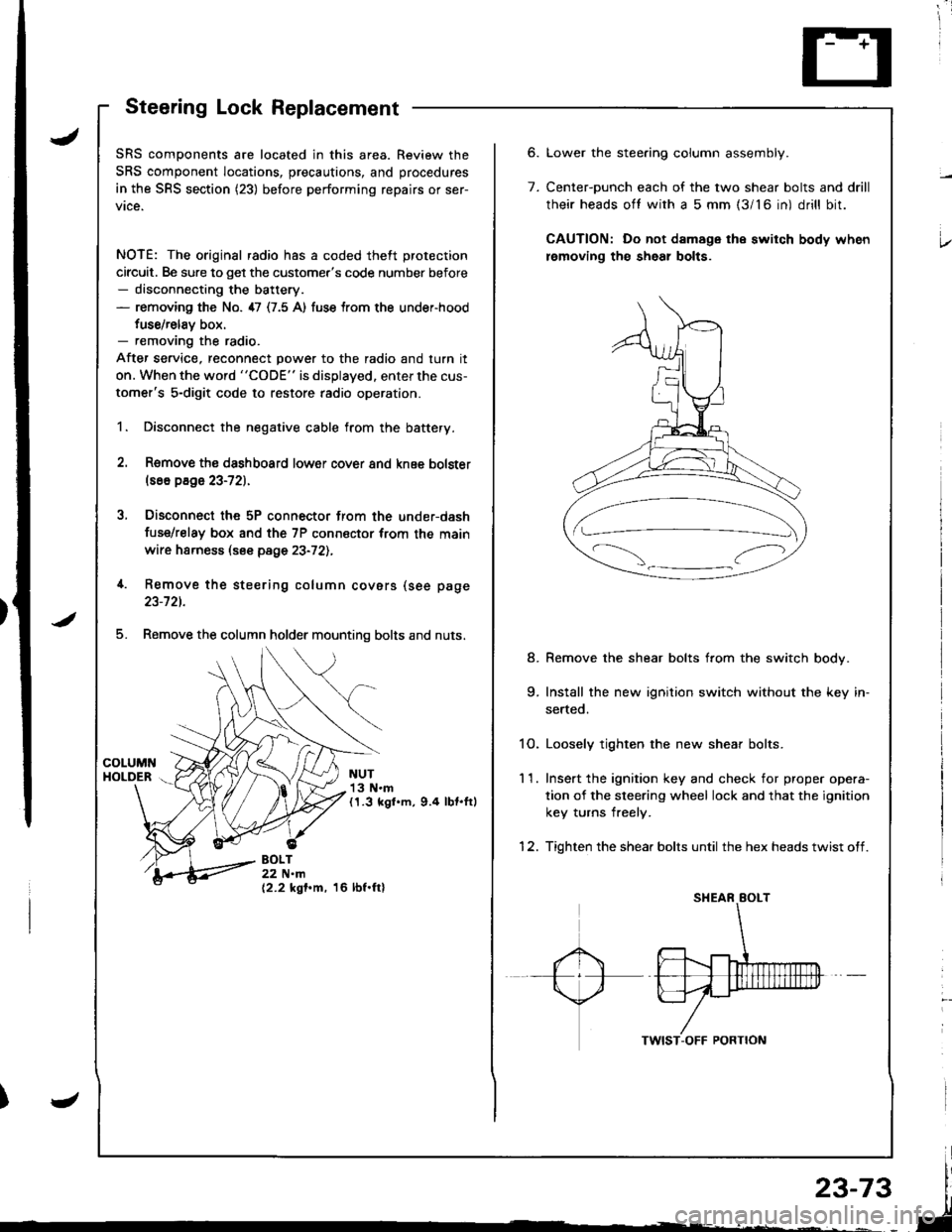

;

Steering Lock Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (23) before performing repairs or ser-

vice.

NOTE: The original radio has a coded theft protection

circuit. Be sure to get the customer's code number before- disconnecting the battery.- removing the No. 47 (7.5 A) fuse trom the under-hood

fuse/relav box.- removing the radio.

After service, reconnect power to the radio and turn it

on. When the word "CODE" is displayed. enter the cus-

tomer's 5-digit code to restore radio operation.

1. Disconnect the negative cable from the battery.

2. Remove ths dsshboard lower cover and knee bolster(s6o p8ge 23-72).

3, Disconnect the 5P connector from the under-dash

fuse/relay box and the 7P connsctor from th€ main

wire harness (see page 23-72l.,

4. Remove the steering column covars (see page

23-721.

5. Remove the column holder mounting bolts and nuts.

NUT13 N.m(1.3 kgl.m, 9.4 lbt.ftl

BOLT22 N.m(2.2 kgf.m, 16 lbf.ftl

6.

7.

Lower the stee.ing column assembly.

Center-ounch each of the two shear bolts and drill

their heads oft with a 5 mm {3/16 in) drill bit.

CAUTION: Do not damage the switch body when

lemoving th€ sheal bolts.

Remove the shear bolts from the switch body.

Install the new ignition switch without the key in-

serted.

1O. Loosely tighten the new shear bolts.

11. Ins€rt the ignition key and check for proper opera-

tion of the sleering wheel lock and that the ignition

key turns freely.

12. Tighten the shear bolts until the hex heads twist off.

8.

Page 1131 of 1681

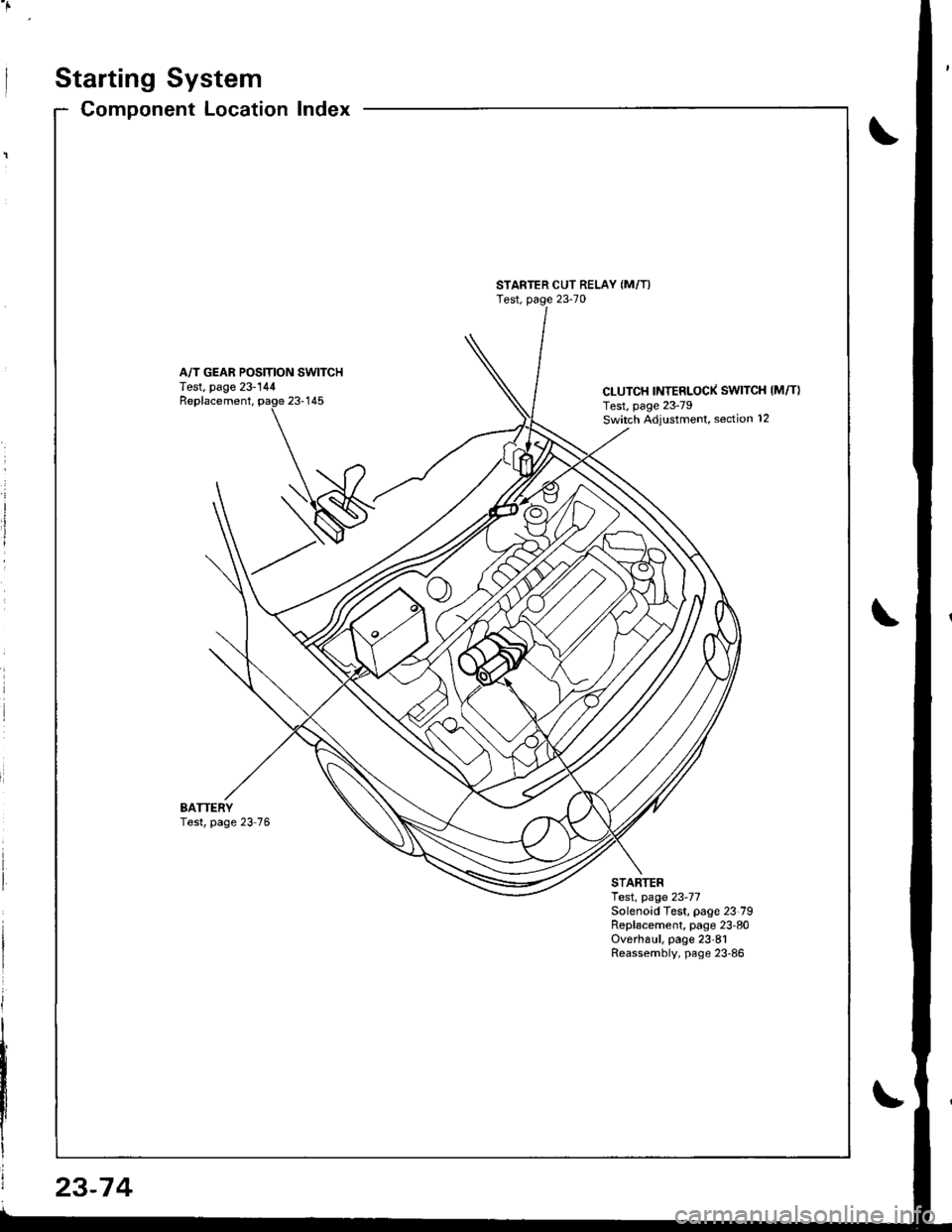

Starting System

Component LocationIndex

STARTER CUT RELAY (M/T)

Test, page 23-70

A/T GEAR POSITION SWITCHTest, page 23-144CLUTCH INTERLOCK SWITCH IM/T}Test, page 23-79Switch ,Adiustment, section 12

Replacement,

BATTERYTest, page 23 76

STARTERlest, page 23-77Solenoid Test, page 23 79Replacement, page 23'80Overha!1, page 23'81Reassembly, page 23'86

23-74

Page 1134 of 1681

Ch6ck Starter Engag€mont;

1. Remove the No. 44 (15 A) fuse from the under-hood

fuse/relay box,

Press the clutch pedal all the way in (M/T), and turn

the ignition switch to "St8rt". The staner should

crank the engine,

NOTE: On cars equipped with manual transmission,

the engine will not crank unless the clutch pedal is

fully depressed.

lf the starter does not crank the engine, go to step 3.

Check the battery, battery positive cable, ground,

and the wire connections for looseness and cor-

rosion.

Test again. lf the stsner stilldoes not crank the en-

gine, go to step 4.

Bypass the ignition switch circuit as follows {make

sure the transmission is in neutral)

Unplug the connector (BLKMHT wire and solenoid

terminal) trom the staner. Then connect a jumper

wire from the batterv positive (+ ) terminal to the

solenoid terminal. The starter should crank the

engine.

a It the stsrter still does not crank the engine,

replace it and diagnose its internal problems,

a lf the starter cranks the engine. go to step 5.

(cont'd)

4.

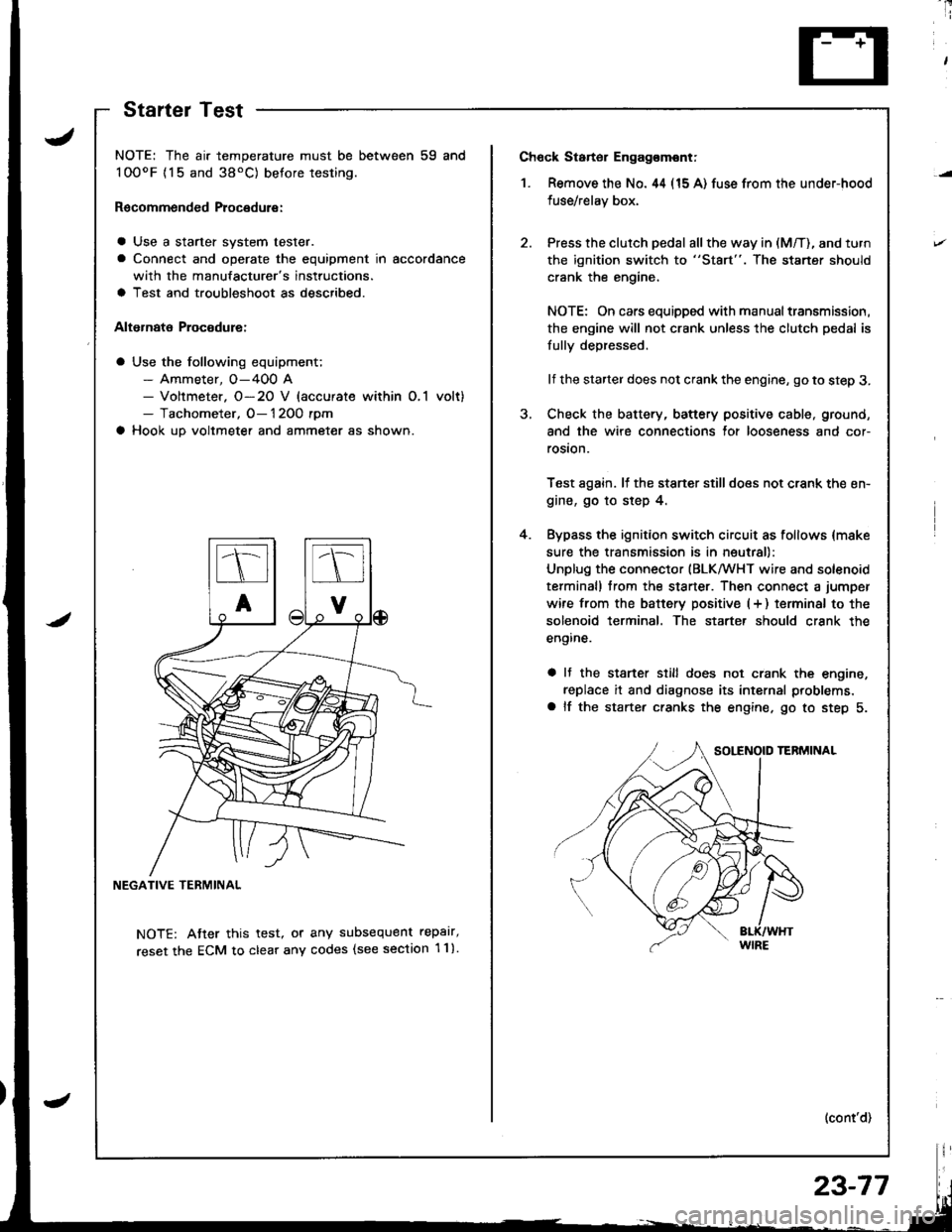

NOTE: The air temperature must be between 59 and

100oF {15 and 38'C) betore testing.

Recommended Procedure:

a Use a starter system tester.

a Connect and operate the equipment in accordance

with the manufacturer's instructions.

a Test and troubleshoot as described.

Alternate Procodure:

a Use the following equipment;- Ammeter, O-400 A- Voltmeter. O-20 V (accurate within O,1 volt)- Tachometer, O- 1 2OO rpm

a Hook up voltmeter and ammeter as shown.

NEGATIVE TERMINAL

NOTE: Atter this test, or any subsequent repalr,

reset the ECM to clear any codes (see section 1 1).

StartelTest

23-77