oil HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 957 of 1681

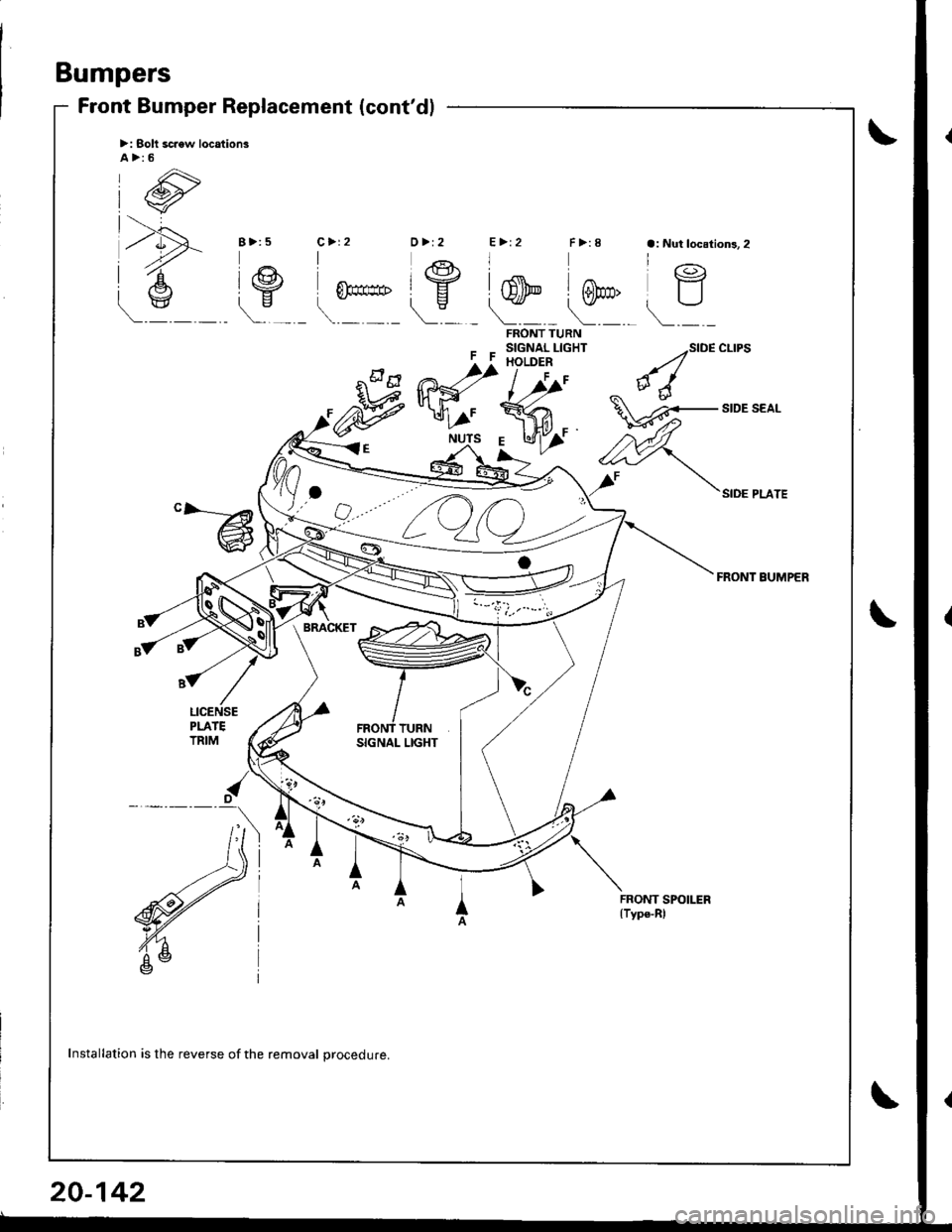

Bumpers

Front Bumper Replacement (cont'dl

>: Solt scaew location3A>:5

FF

FRONT TURNSIGNAL LIGHTHOLDER

l,r/'

SIDE CLIPS

SIDE PLATE

FRONT BUMPER

Mffi

l//'

R<"

,-wf

"-@

SIGNAL LIGHT

FRONT SPOILER{Type-Rl

Installation is the reverse of the removal procedure.

20-142

Page 963 of 1681

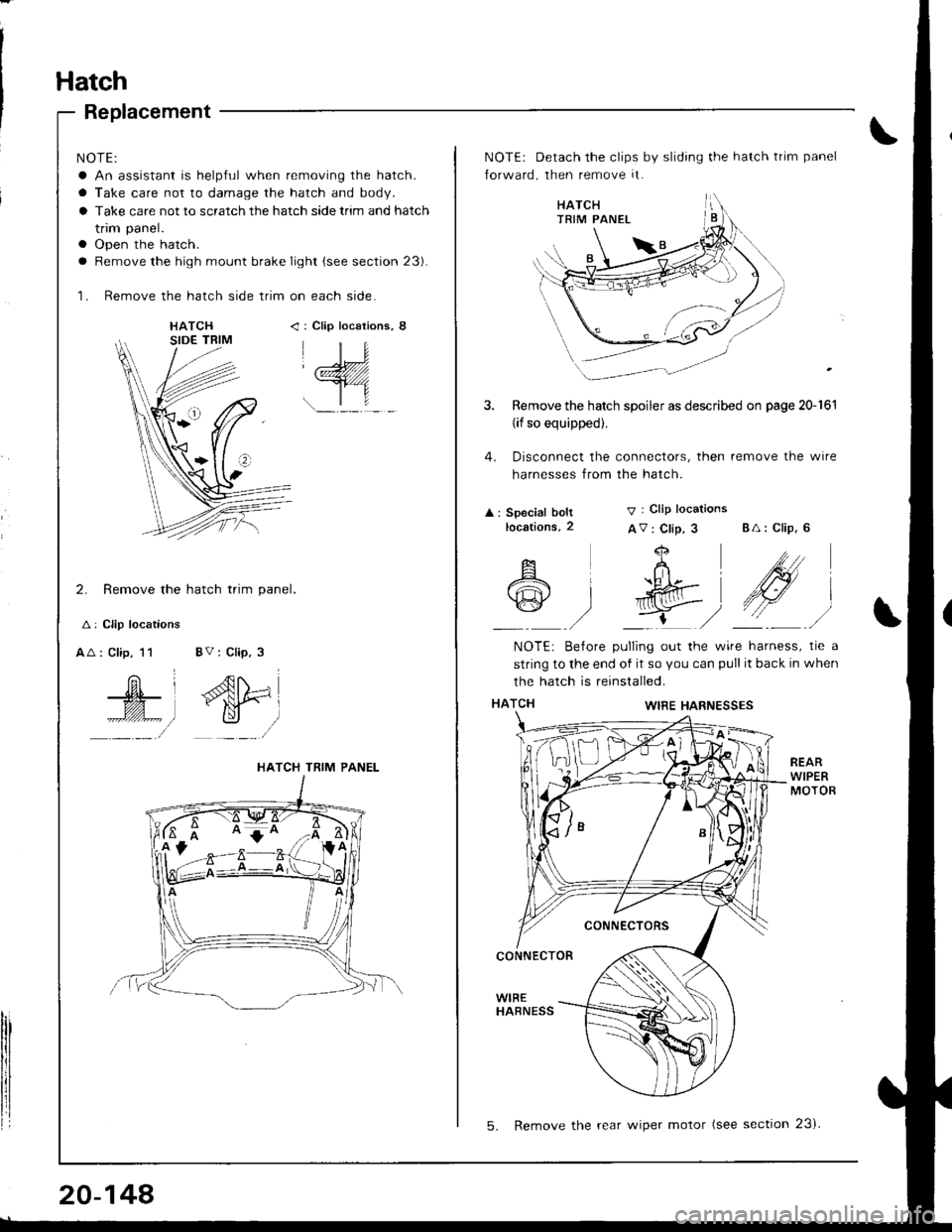

Hatch

Replacement

NOTE:

a An assistant is helpful when removing the hatch.

a Take care not to damage the hatch and body.

a Take care not to scratch the hatch side trim and hatch

trim panel.

a Open the hatch.

a Remove the high mount brake Iight {see section 23).

'1. Remove the hatch side trim on each side.

: Clip locaiions,

_);(zZZ////1

r.-lf

2. Remove the hatch trim panel

A: Clip locations

AA : Clip, 11 8V : Clip, 3

Ar^{N

# fN#=l*l y /

lrl

HATCH TRIM PANEL

20-148

5. Remove the rear wiper motor (see section 23i

NOTE: Detach the clips by sliding the hatch trim panel

forward, then remove it.

Remove the hatch spoiler as described on page 20-161

(if so equipped).

Disconnect the connectors, then remove the wire

harnesses from the hatch.

4.

A : Special boltlocations,2

V I Clip locations

AV: Clip, 3 BA: Clip. 6

i

I

A

A

w

+

..h [-

g)

bll

/\

NOTE: Betore pulling out the wire harness, tie a

string to the end of it so you can pull it back in when

the hatch is reinstalled.

WIRE HARNESSES

CONNECTORS

CONNECTOR

WIBEHABNESS

Page 976 of 1681

J

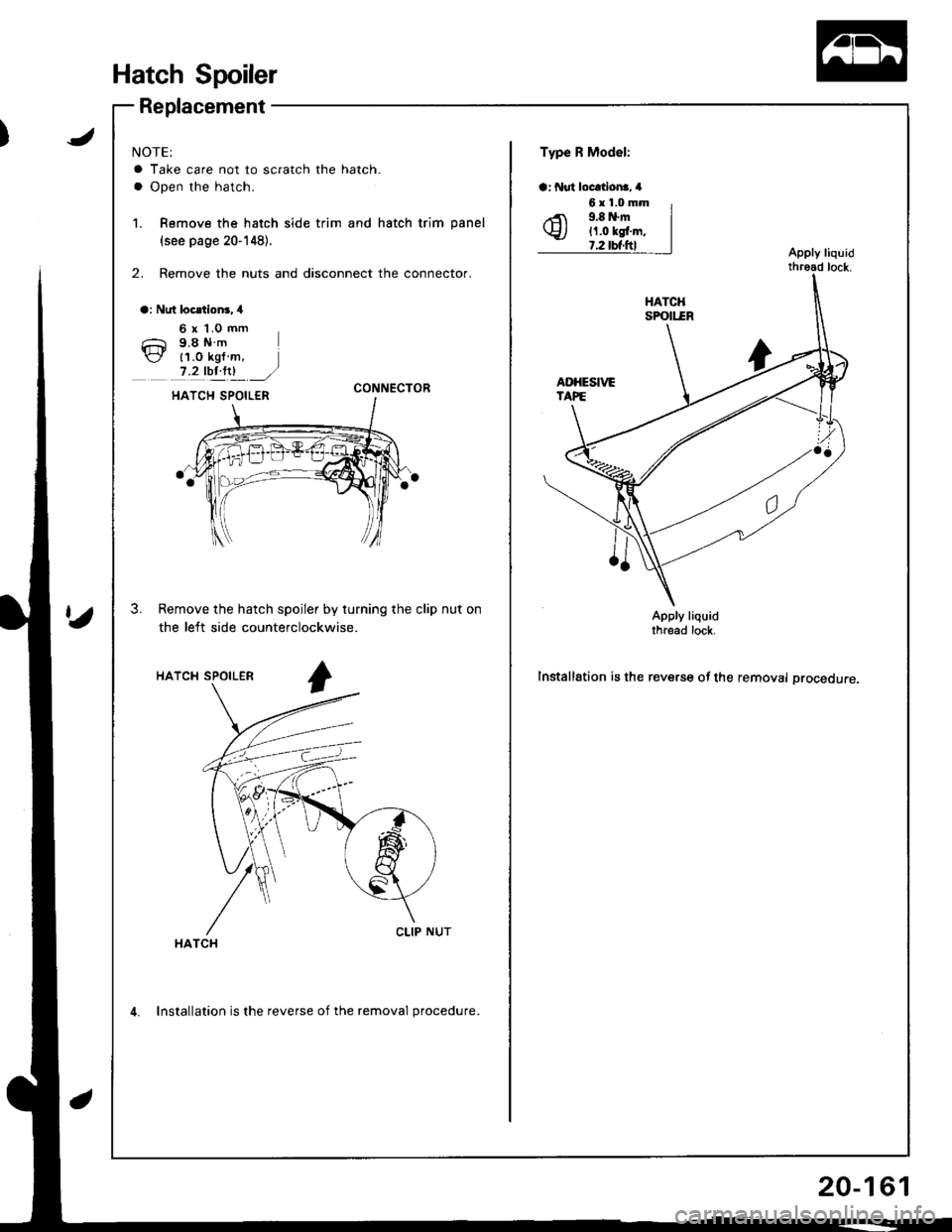

Hatch Spoiler

Replacement

NOTE:

a Take care not to scratch the hatch.

a Open the hatch.

1. Remove the hatch side trim and hatch trim panel

{see page 20-148}.

2. Remove the nuts and disconnect the connector.

a: Nut locltion3,4

Type R Model:

a: f{ut locltlona, 4

Apply liquidthread lock.

6 x 1.0 mm9.8Nm

{1.0 kgf m,7.2 tbt.ltl ./CONNECTOR

3. Remove the hatch spoiler by turning the clip nut on

the left side counterclockwise.Apply liquidthread lock.

Installation is the reverse of the removal procedure.HATCH SPOILER

HATCH

6x1.0mm9.8 N.m11.0 kgt.m,?.2 tbt.ftl

4. Installation is the reverse of the removal procedure.

20-161

Page 977 of 1681

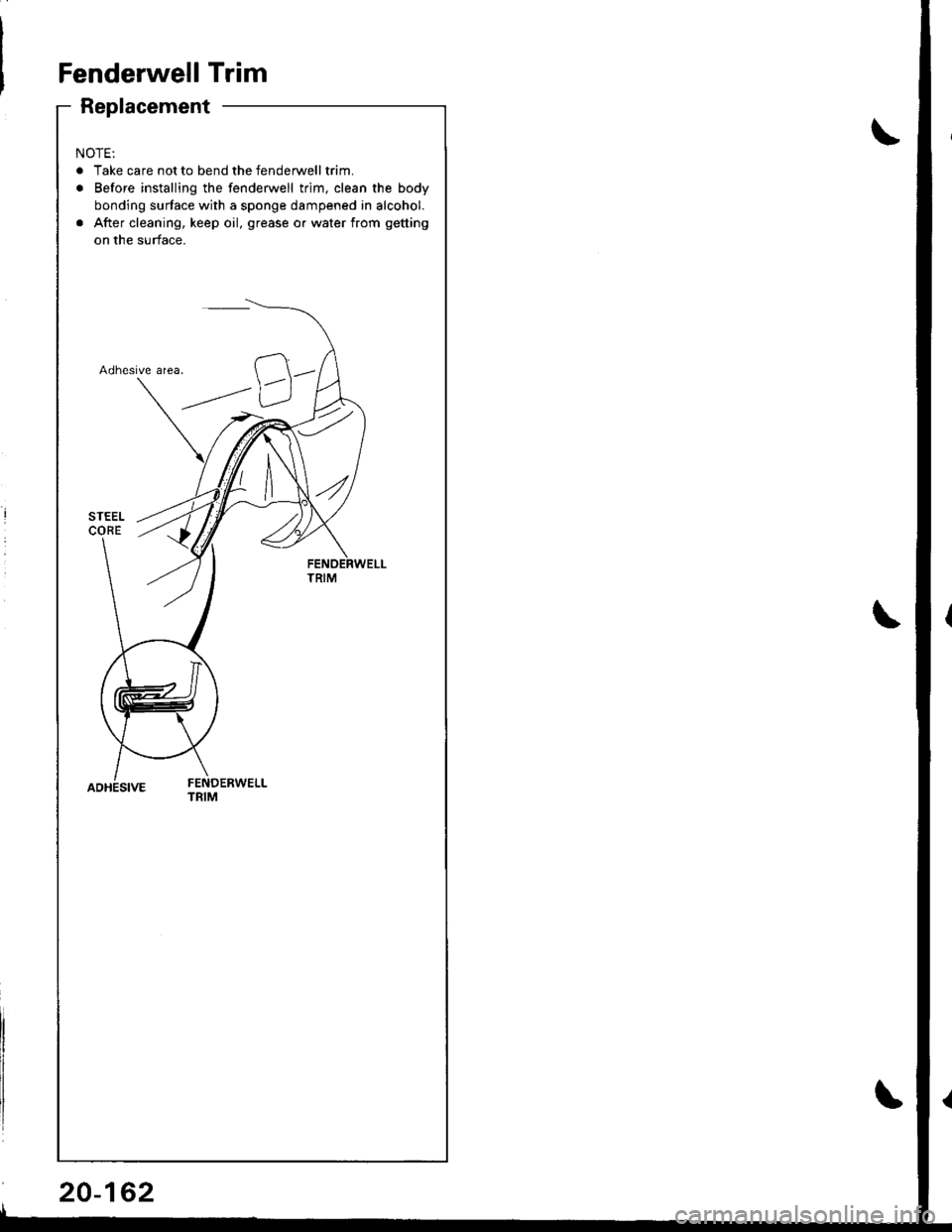

Fenderwell Trim

Replacement

NOTE:

. Take care not to bend the fenderwelltrim.

. Before installing the fenderwell trim, clean the body

bonding surface with a sponge dampened in alcohol.

. After cleaning, keep oil, grease o. water from getting

on the surface.

Adhesive area.

ADHESIVEFENDERWELLTRIM

20-162

Page 980 of 1681

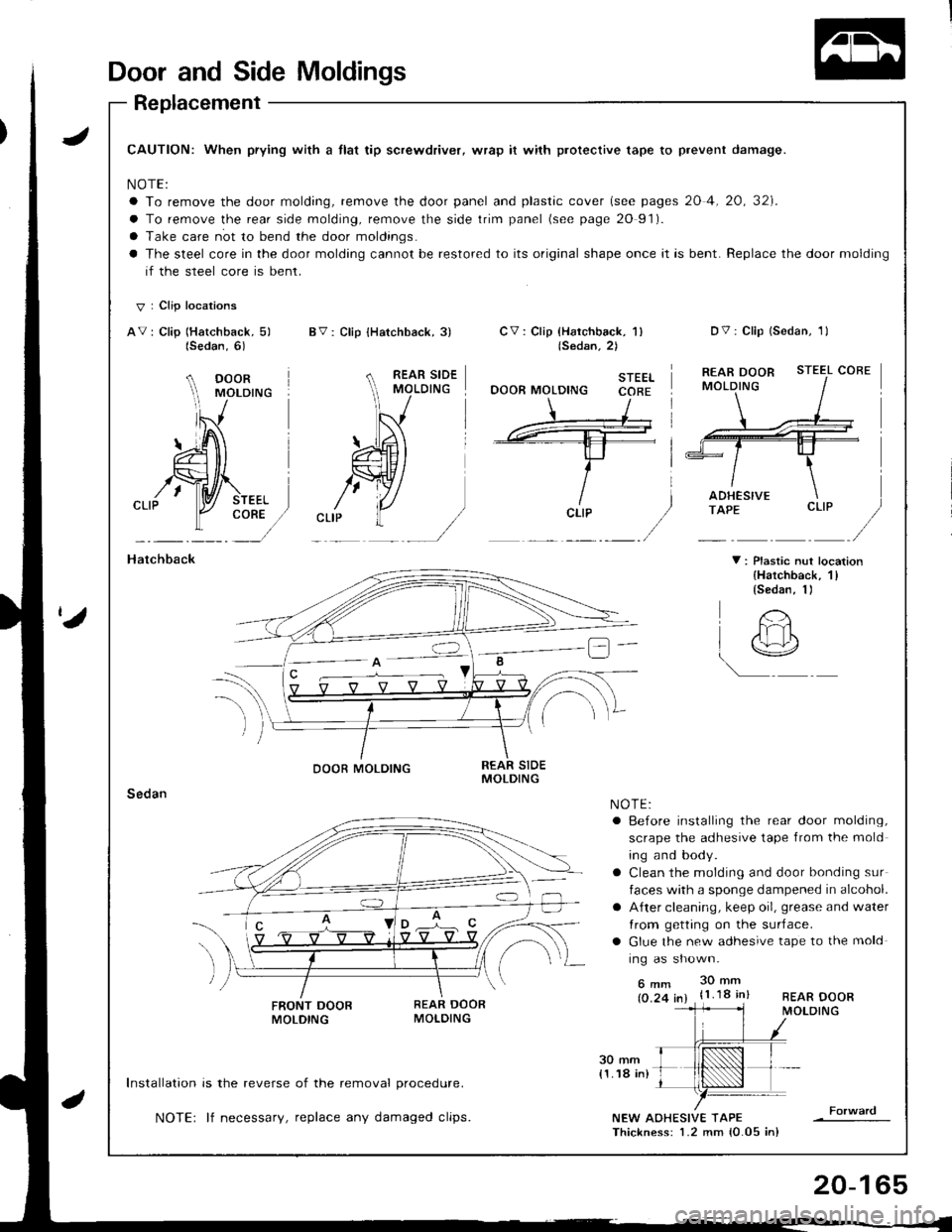

Door and Side Moldings

Replacement

JCAUTION: When prying with a tlat tip screwdriver, wrap it with protective tape to prevent damage.

NOTE:

a To remove the door molding, remove the door panel and plastic cover (see pages 20 4, 20, 32]'.

a To remove the rear side molding, remove the side trim panel (see page 20 91).

a Take care not to bend the door moldings.

a The steel core in the door molding cannot be restored to its original shape once it is bent. Replace the door molding

if the steel core is bent.

V I Clip locations

AV: Clip (Hatchback, 5) BV: Clip {Hatchback, 3)Dv: Clip lsedan, 1lCV : Clip {Harchback, 'l )(Sedan.2)

STEELOOOR MOLDING CORE

STEEL COBE

CORE

Hatchback

Sedan

V : Plastic nut location{Hatchback, 1llsedan, 1)

FRONT DOOBMOLDING

Installation is the reverse of the removal procedure.

NOTE: lf necessary, replace any damaged clips.NEW AOHESIVE TAPEThickness: 1.2 mm {0.05 in}

(Sedan,6)

A DOOR rvrororuc

lS

#'\---- -tl-t-f- i

ricLrP

/

REAR DOORMOLDING

O'

t

DOOR MOLDING

!@

NOTE:a Before installing the rear door molding,

scrape the adhesive tape from the mold

ing and body.

a Clean the molding and door bonding sur

faces with a sponge dampened in alcohol.

a A{ter cleaning, keep oil, grease and water

Irom getting on the surJace.

a Glue the new adhesive tape to the mold

ing as shown.

6mm 30mm

(0.24 in) {1.18 in}

20-165

Page 982 of 1681

,'t

il

ii

II

APPLICATIONTAPEDOHC VTEC (GSR'

Special Edition {USA LS-S)EMBLEM

REAR TURNSIGNAL LIGHT

APPLICATIONTAPEOUTERTAILLIGHT

J

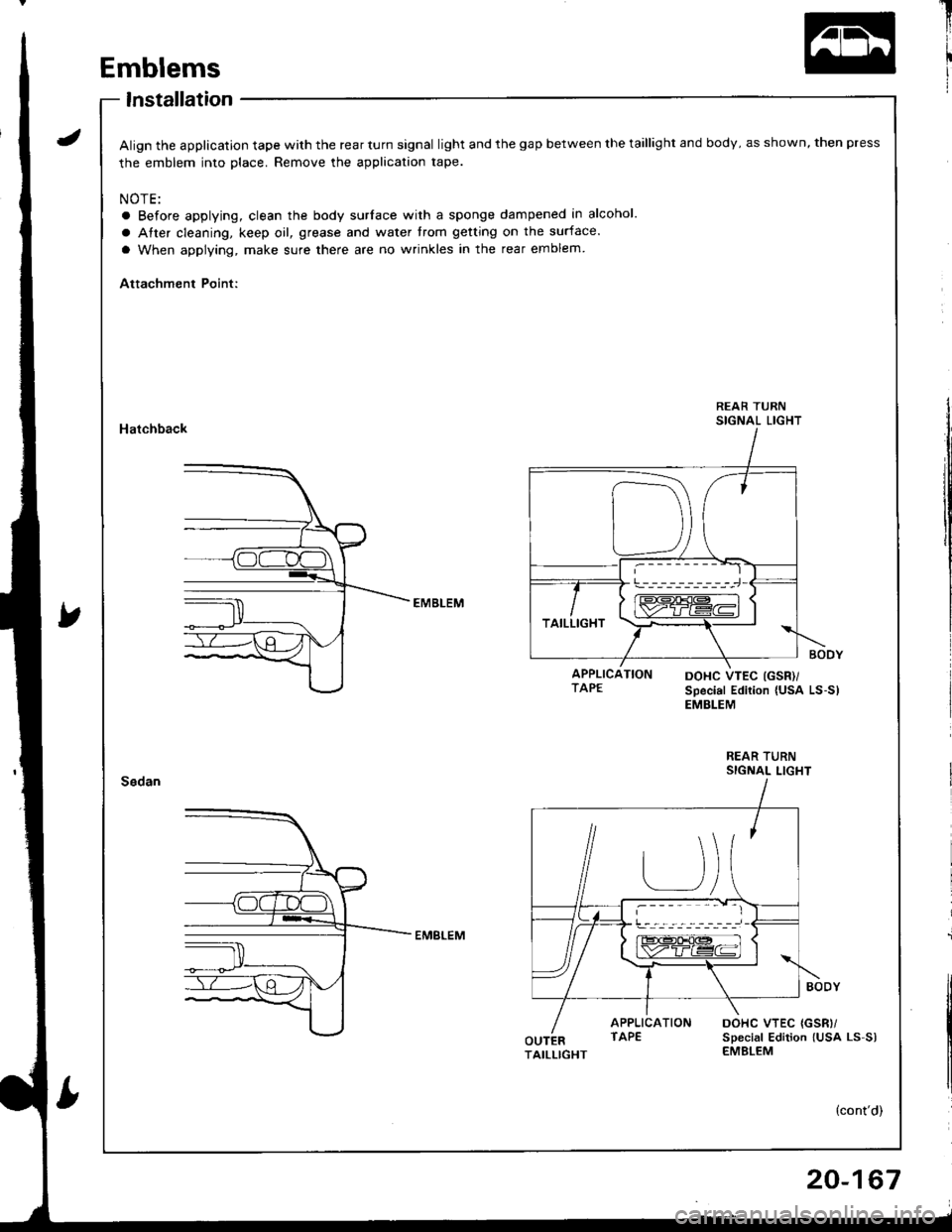

Emblems

lnstallation

Align the application tape with the rear turn signal light and the gap between the taillight and body, as shown, then press

the emblem into place. Remove the application tape.

NOTE:

a Before applying, clean the body surlace with a sponge dampened in alcohol.

a Atter cleaning, keep oil, grease and water trom getting on the surface.

a When applying, make sure there are no wrinkles in the rear emblem

Attachment Point:

Hatchback

REAR TURNSIGNAL LIGHT

DOHC VTEC {GSR)/sDecial Edition lUsa Ls-s)EMBLEM

20-167

Page 983 of 1681

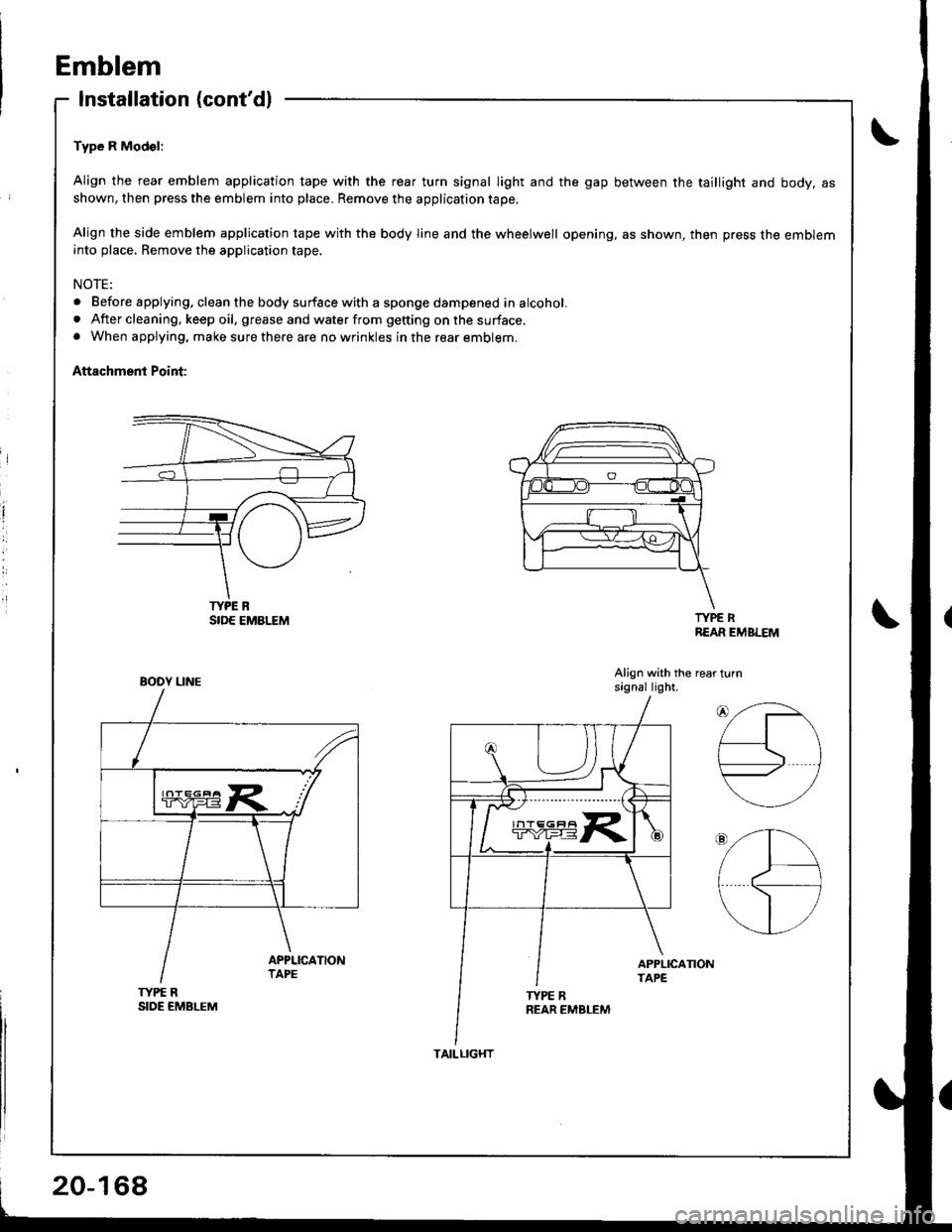

Emblem

Installation (cont'dl

Type R Mod€l:

Align the rear emblem application tape with the reaf turn signal light and the gap between the taillight and body, asshown, then press the emblem into place. Remove the application tape.

Align the side emblem application tape with the body line and the wheelwell opening, as shown, then press the embleminto place, Remove the application tape.

NOTE:

. Before applying. clean the body surface with a sponge dampened in alcohol.. After cleaning, keep oil, grease and water from getting on the surface.. When applying, make sure there are no wrinkles in the rear emblem.

Attachment Point:

i

l

TYPE RREAR EMBLEM

Align with the rear turnsagnal light.

TYPE RSIDE EMBLEM

TYPE R

BOOY UNE

20-168

TAILLIGHT

Page 1024 of 1681

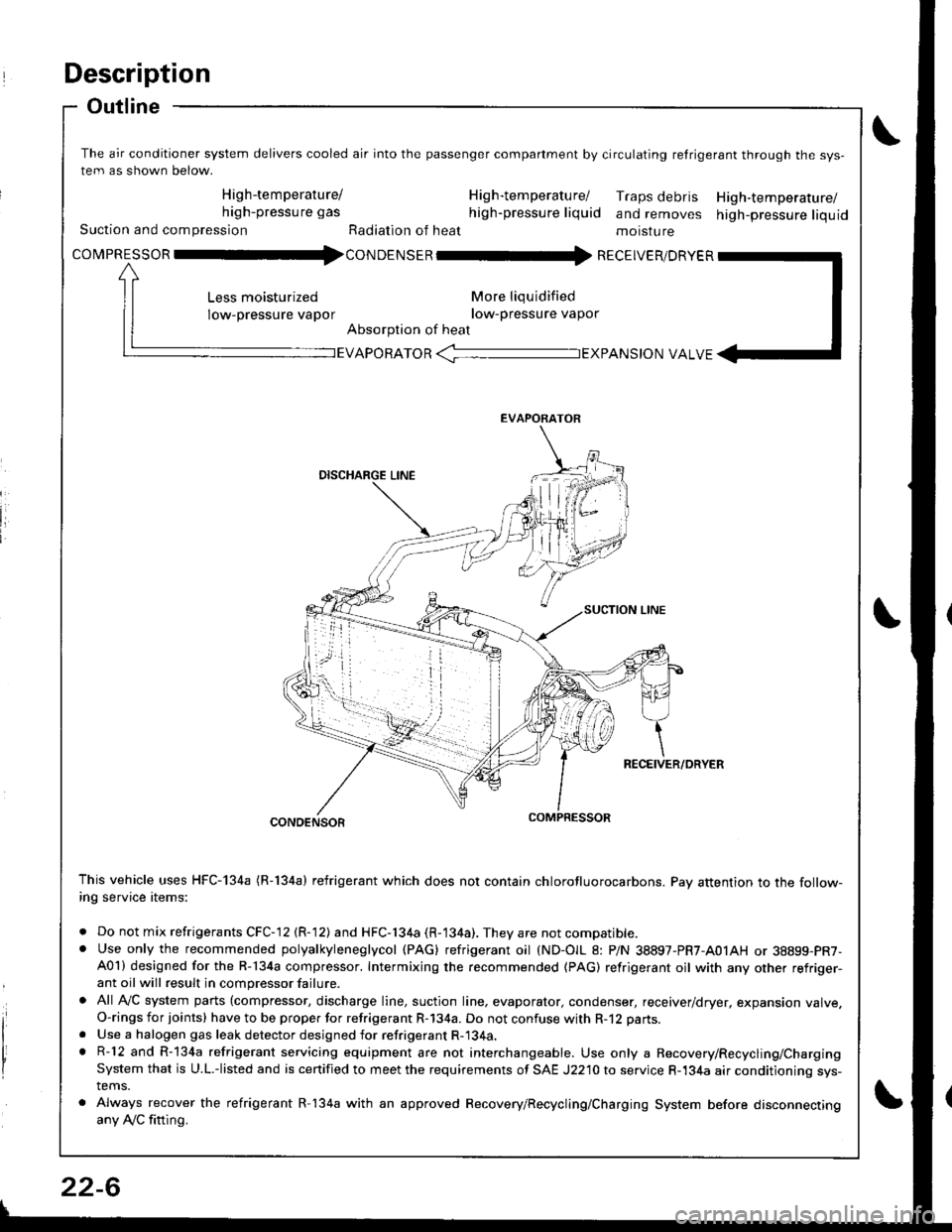

Description

Outline

The air conditioner system delivers cooled air into the passenger companment by circulating retrigerant through the sys-

tem as shown below.

High-temperature/ H ig h-tem peratu rel Traps debris High-temperature/high-pressure gas high-pressure liquid and removes high-pressure liquidSuction and compression Radiation of heat moisture

covpnEsson -tl4con oetsen -rr{ REcEIvER/DRvER

More liqu idified

low-pressure vapor

Absorption of heat

Less moisturized

low-pressure vapor

EVAPORATOR -TEXPANS|ON VALVE

EVAPORATOR

CONDENSOR

This vehicle uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-ing service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a). They are not compatible.. Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (ND-OIL 8: P/N 38897-PR7-A01AH or 38899-PR7-A01) designed for the R-134a compressor. Intermixing the recommended (PAG) refrigerant oil with any other refriger-ant oil will result in compressor failure.

. All AVC system parts (compressor, discharge line, suction line. evaporator, condenser, receiver/dryer, expansion valve.O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a Recovery/Recycling/ChargingSystem that is U.L.-listed and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning sys-tems.

. Always recover the refrigerant R-134a with an approved Recovery/Recycling/Charging System before disconnectingany Ay'C fitting.

22-6

Page 1032 of 1681

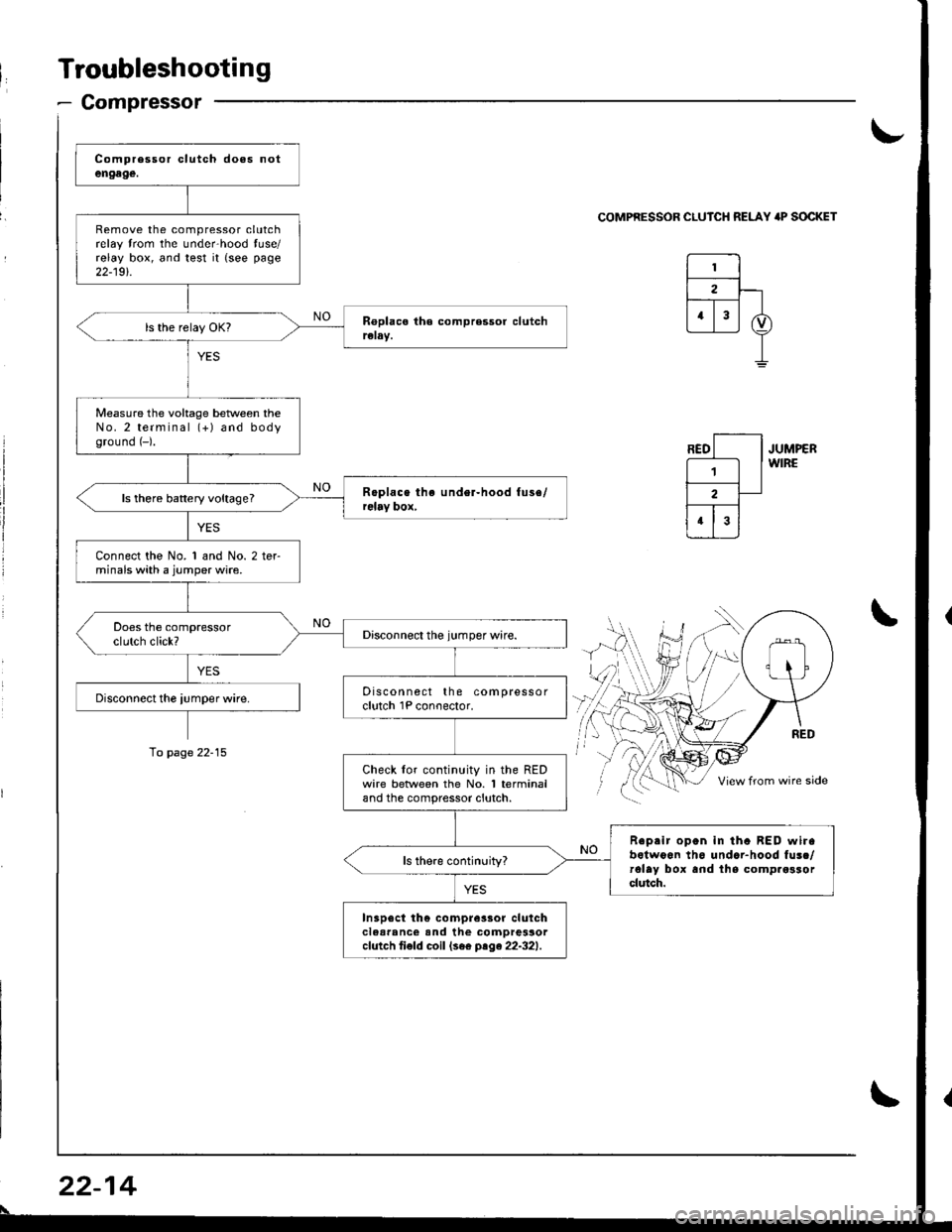

Troubleshooting

- Compressor

Remove the compressor clutchrelay trom the unde.hood tuse/relay box, and test it {see page

22-19t.

Measure the voltage beNveen theNo.2 terminal (+) and bodyground (-).

ls there battery voltage?

Connect the No. 1 and No. 2 terminals with a jumper wire.

Discon nect the compressorclutch 1P conoector.

Check lor continuity in the REDwire betlveen the No. 1 terminaland the compressor clutch.

Reprir open in tha BED wirabotwoon th6 undar-hood fusc/rolay box and lhs comp.osrorclutch.

In3p6ct th€ compre3sor clulchclear'nc€ and the comDressorcfutch ti€fd coil (se€ ptge22-321.

\-

COMPRESSOR CLUICH RELAY 'P SOCKET

JUMPERWIRE

\

To page 22-15

22-14

\

Page 1039 of 1681

A/C Service Tips and Precautions

The air conditioner system uses HFC-134a (R-134a) refrigerant and polyalkyleneglycol {PAG) refrigerant oil (ND-OlL 8: P/N

38897-PR7-A01AH or 38899 - PR7 - A01), which are not compatible with CFC-12 (R-12) refrigerant and mineral oil. Do not

use R-12 refrigerant or mineral oil in this system. and do not attempt to use R-12 servicing equipment; damage to the air

conditioner system or your servicing equipment will result.

Use only service equipment that is U.L.-listed and is certified to meet the requirements of SAE J2210 to remove R-l34a

from the air conditioner system.

CAUTION: Exposure to air conditioner refrigerant and lubricant vapor ot mist can irritate eyos, nose.nd throat, Avoid

breathing th€ air conditionsr rofrigerant 8nd lubricant vapo. or mist.

lf accidental system discharge occurs, ventilate work area before resuming service.

R-134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with comp.essed

atf,

@ some mixtures ol air and R-13i[a have been shown to be combustible at olevat6d pre3sures and cln resuh

in fire or explosion causing iniury or property damage. Nover uso compressed air to prossure te3t R-13,[8 service equip-

ment or vehicle air condition6r systems.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers,

1. Always disconnect the negative cable from the battery whenever replacing air conditioning parts.

2. Keep moisture and dust out of the system. When disconnecting any lines. plug or cap the Jittings immediately; don't

remove the caps or plugs until just before you reconnect each line.

3. Before connecting any hose or line, apply a few drops of refrigerant oilto the O-ring,

4. When tightening or loosening a fitting, use a second wrench to support the matching fitting.

5. When recovering the system. use a R-134a refrigerant Recovery/Recycling/Charging System; don't release refrigerant

into the atmosphere.

6. Add refrigerant oil after replacing the following parts.

NOTE:

. To avoid contamination, do not return the oil tothe container once dispensed, and never mix itwith other refriger-

ant oils.

.lmmediatelyafterusingtheoil,replacethecaponthecontainerandseal it to avoid moisture absorption.

. Do notspillthe refrigerant oil onthevehicle; it maydamagethe painu itthe refrigerant oil contacts the paint, wash

it off immediately.

Coodansor ..-.-.-............. 25 mt (5/6 ll.oz. 0.9 lmp.oz)

Evaporator ................. ,[0 m/ (1 1/3 fl.oz, 1.4 lmp.ozl

Line or hoss .................. 10 m? {1/3fl.oz, 0.'l lmp.ozl

Receiver/Dryer ............. 10 m/ (1/3 fl.oz, 0.4 lmp.ozl

Leskage repair .............25 m/ {5/6 fl.oZ, 0.9 lmp.oz)

Compreigor .....,......,..Fo1 comprgssor replace-

ment, subtract the volum€ of oil drained from the

removed comprassor lrom l/t{l m[ (1 213 ll.oz, 1,9

imp'ozl, and drain the calculated volume ot oil from

the new compressor: 140 m/ 11 213 ll.oz, 1.9

imp.oz)-Volum€ oI removed comprsssor = Volum€

to drain trom n€w compressor.

NOTE: Even if no oil is drained from the removed

comDressor, don't drain more than 50 m{ {1 2/3

fl.oz. 1.8 lmp.oz) from the new compressor.

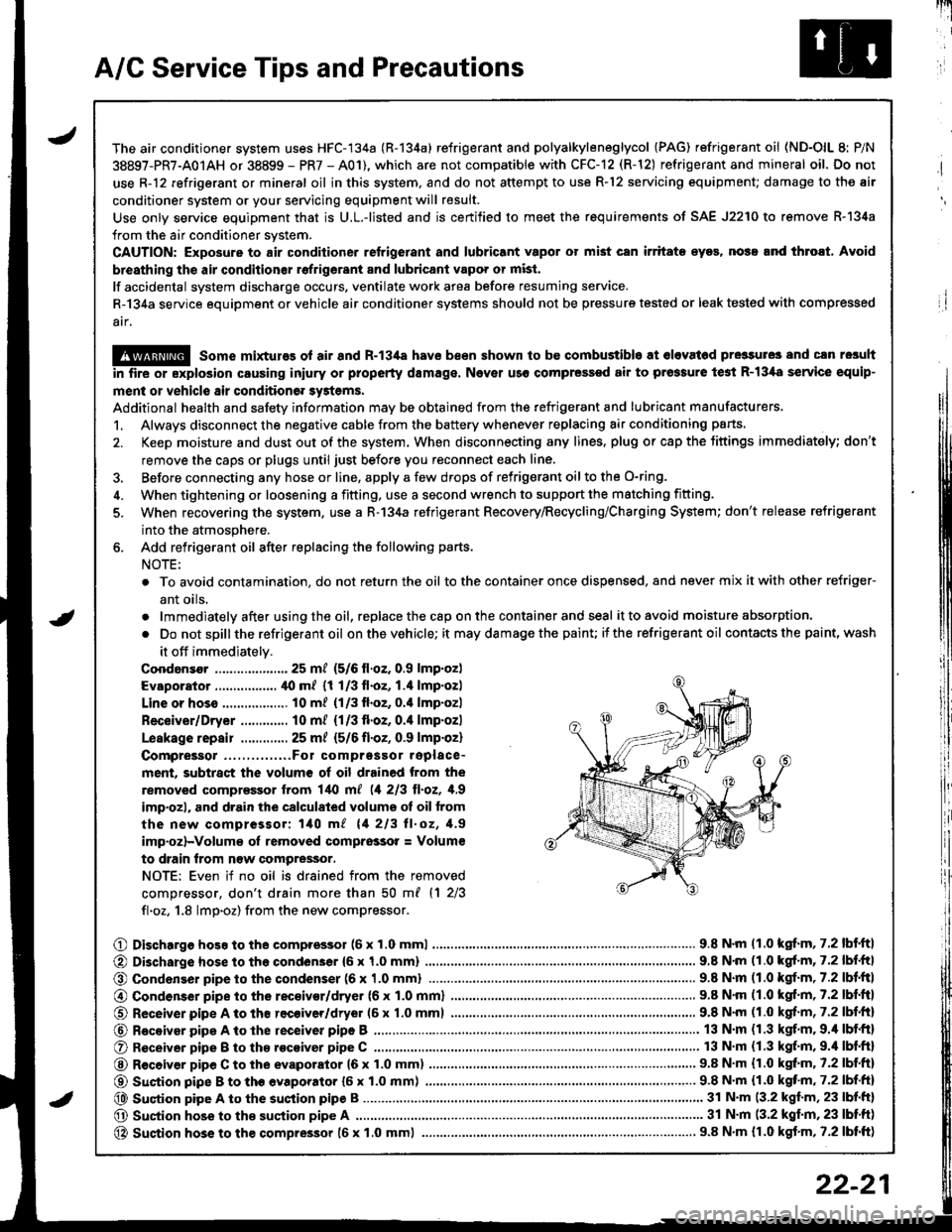

O Dischargo hoso to the compressol (6 x 1.0 mml............................... 9.8 N'm (1.0 kgf.m, 7.2 lbf'ftl

@ Di3charge hose to the condenser {6 x 1,0 mm)

@ Condonser pipe to the condenser (6 x '1.0 mml

9.8 N'm (1.0 kgl.m, 7.2 lbf.ftl

.. 9.8 N.m (1.0 kgf.m,7.2lbl.ltl

@ Condenser pipe to the rec€ivor/dryer (6 x 1.0 mml

O Receiver pipe A to th8 recoiver/dryer (6 x 1.0 mml

@ Receiyar pipe A to lhe receiver pipe B ,...........

O Receiver pipe B to th8 .ocoiver pipe C ............

@ R€ceiver pipe C to the evaporator 16 x 1.0 mm)

@ Suction pipe B to th€ evaporator {6 x 1.0 mm) .......,.

@ Suqtion pipe A to the suction pipe B

O Suction hose to the suction pipe A ...........,.

@ Suction hose to the compressor 16 x 1.0 mml

9.8 N.m (1.0 kgf.m, 7.2 lbf.ftl

9.8 N'm (1.0 kgf.m, 7.2 lbf.fr)

13 N.m (1.3 kgf.m. 9.4 lbf.ft)

13 N.m (1.3 kgf.m,9.'l lbf.ftl

9.8 N.m (1.0 kgt m. 7.2 lbf.ftl

...... 9.8 N.m {1.0 kqf'm, 7.2 lbf.ft)

........ 31 N'm (3.2 kgf.m, 23 lbf.ft)

............ 31 N.m (3.2 kgf.m,23 lbtft)

..................... 9.8 N.m {r.0 kgf.m, 7.2 lbtft)

22-21