oil HONDA INTEGRA 1998 4.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 615 of 1681

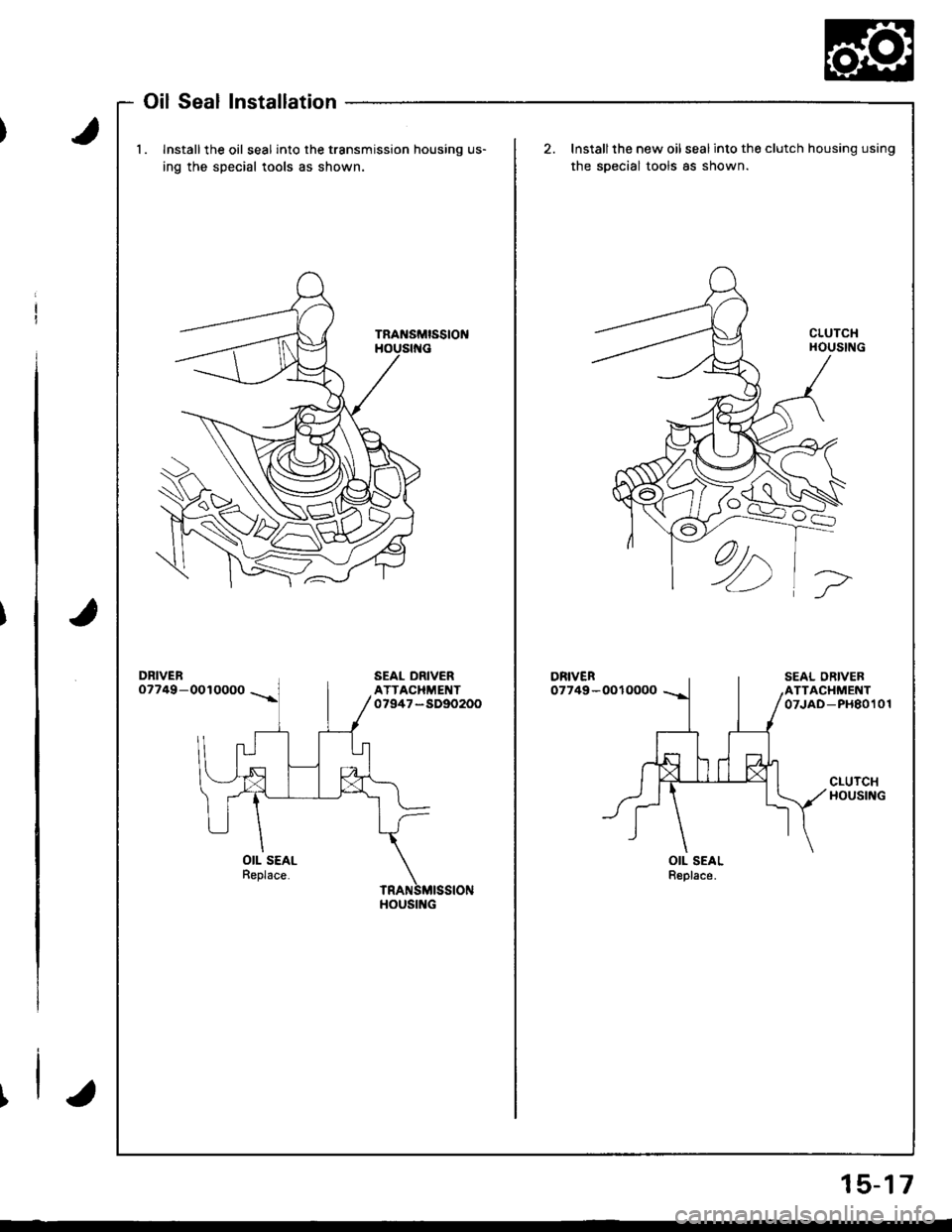

l.lnstallthe oil seal into the transmission housing us-

ing the special tools as shown.

Installthe new oil seal into the clutch housing using

the soecial tools as shown.

DR|vENo7749-0010000DRIVER07749-OOIOOOO

OIL SEALReplace.OIL SEALReplace.

HOUSING

SealInstallation

15-17

Page 621 of 1681

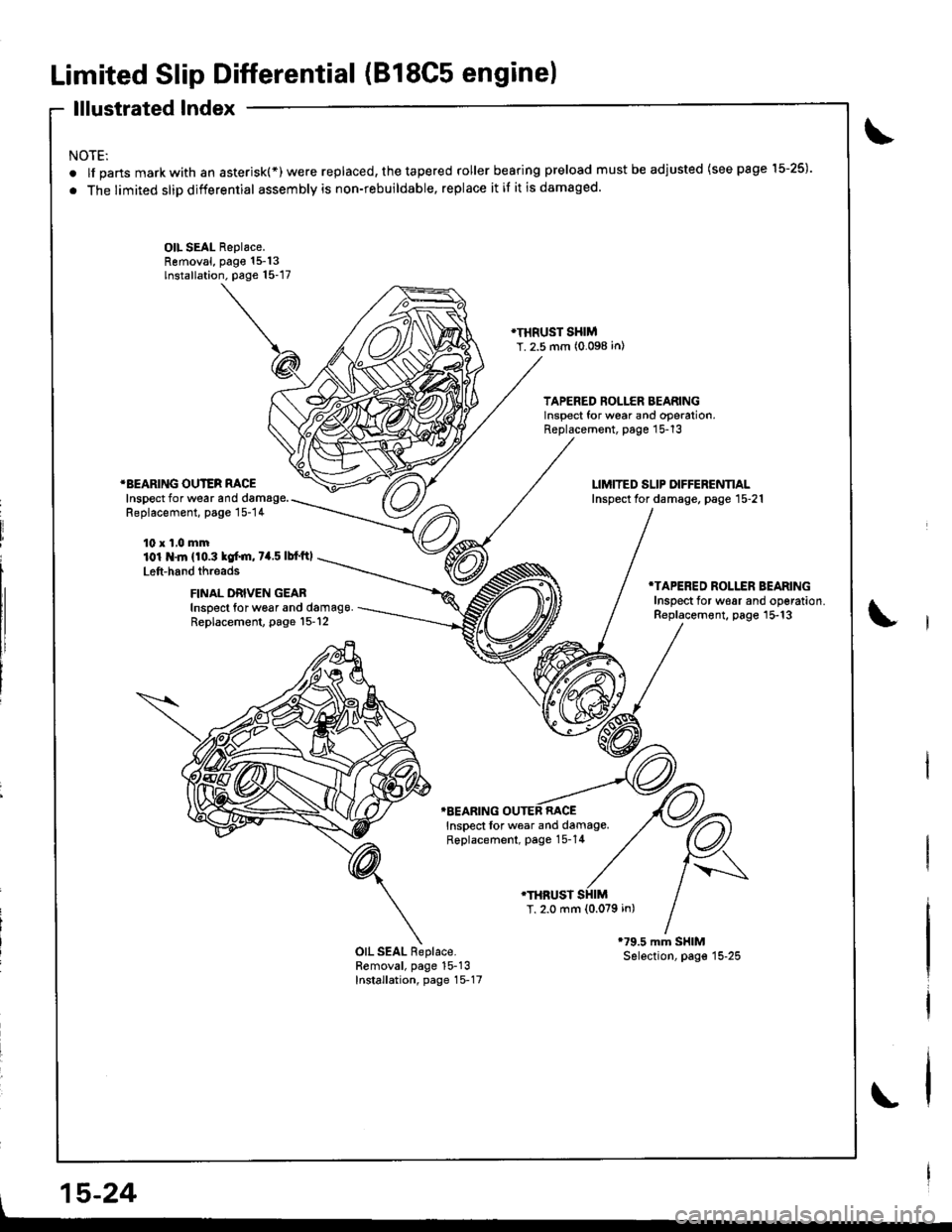

Limited Slip Differential (B18C5 engine)

lllustrated Index

NOTE:

.lfpartsmarkwithanasterisk(*)werereplaced,thetaperedrollerbearingpreloadmustbeadjusted(seepagel5-25).

. The limited slip differential assembly is non-rebuildable, replace it if it is damaged.

OIL SEAL Replace.Removal, page 15-13lnstallation. page 15-17

}I}IRUST SHIMT. 2.5 mm (0.098 in)

TAPERED ROLLER BEARINGlnsoect for wear and ooeration,Replacement, page 15-13

*BEARING OUTER RACEInspect for wear and damage.Replacement, page 15-14

10 x 1,0 mm101 .ln {10.3 kof.m, 7a.5 lbf'ftl

Left-hand threads

FINAL DRIVEN GEABInspect for w6ar and damag9.Replacement, page l5-12

*TAPERED ROLLER BEARINGInsDect for w€ar and oo€ration.Replacement, page 15-13

TBEARING OUTEB RACEInspect lor wear and damage.Replacement, page 15-14

.THRUST

T, 2.0 mm {0.079 in)

OIL SEAL Replace.Removal, page 15-13Installation, page 15-17

l,

, 15-24

Page 624 of 1681

Differential (Automatic Transmission)

Speciaf Tools ........... ..........15-2A

Differential (Automatic Transmissionl

lllustrated Index .......... .. 15-29

Backlash Inspection ...... 15-30

Bearing Rep|acement ......................... I 5-30

Differential Carrier Replacement ...... l5-31

Oil SealRemoval ........... 15-32

Oil Seal Installation/

Side G|earance ................................. 1 5-32

Page 629 of 1681

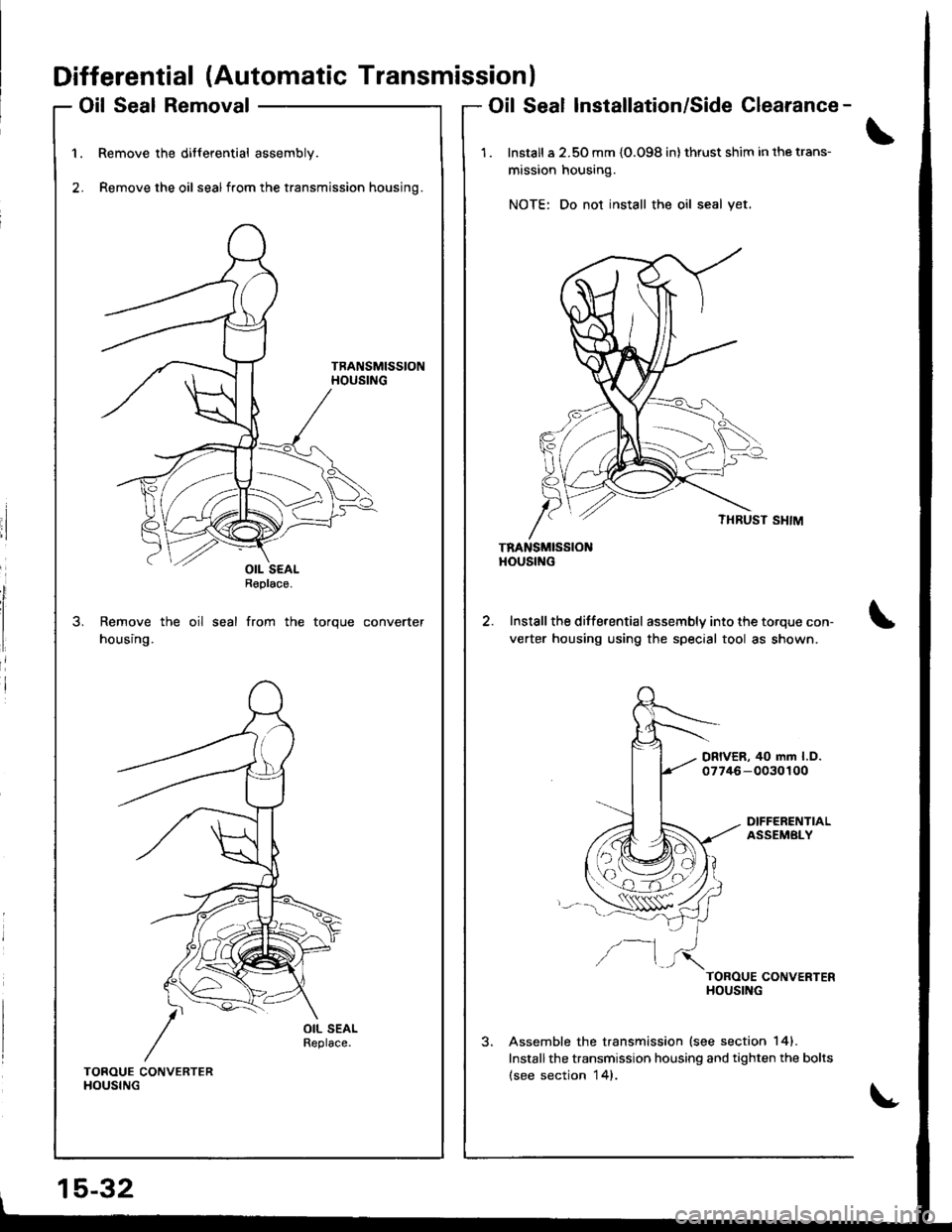

Differential (Automatic Transmissionl

Oil Seal Removal

Remove the differential assembly.

Remove the oil sealfrom the transmission housing.

Remove the oil seal from the torque converter

housing.

Oil Seal Installation/Side Clearance-

1 . Install a 2.50 mm {O.O98 in} thrust shim in the trans-

mission housing.

NOTE: Do not install the oil seal yet.

TRANSMISSIONHOUStf{G

Install the differential assembly into the torque con-

verter housing using the special tool as shown.

DRIVER, 40 mm l.D.07746-0030100

DIFFERENTIALASSEMBLY

/--1TOROUE CONVERTERHOUSING

Assemble the transmission lsee section 141.

Installthe transmission housing and tighten the bolts(see section 14).TOROUE CONVERTERHOUSING

15-32

OIL SEALReplace.

Page 631 of 1681

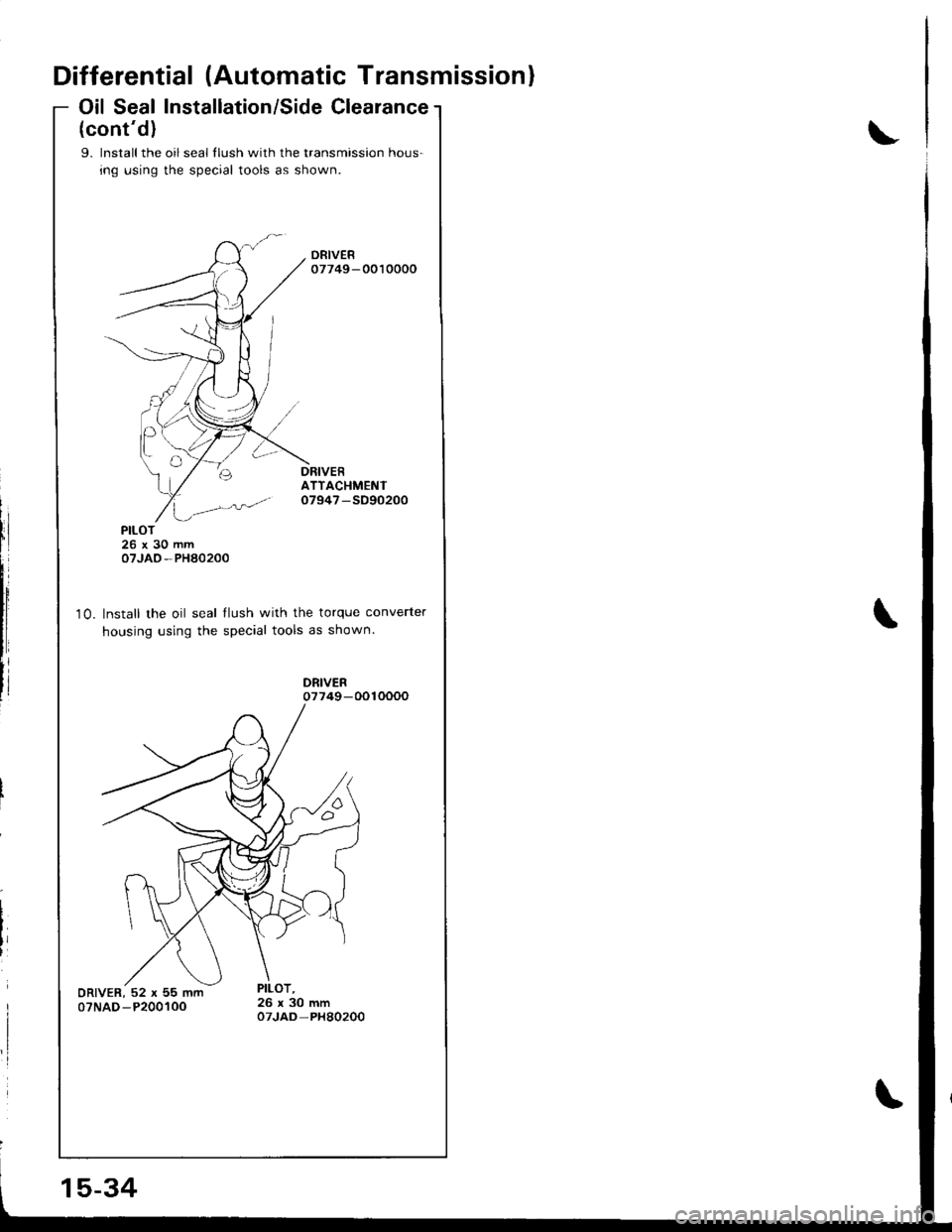

Differential (Automatic Transmission)

Oil Seal Installation/Side Clearance

(cont'd)

9. lnstall the oil seal llush with the transmission hous-

ing using the special tools as shown.

ATTACHMENTo7947 -SD90200

10.

PILOT26x30mmoTJAO-PHA0200

Install the oil seal llush with the torque converter

housing using the special tools as shown.

15-34

Page 634 of 1681

t

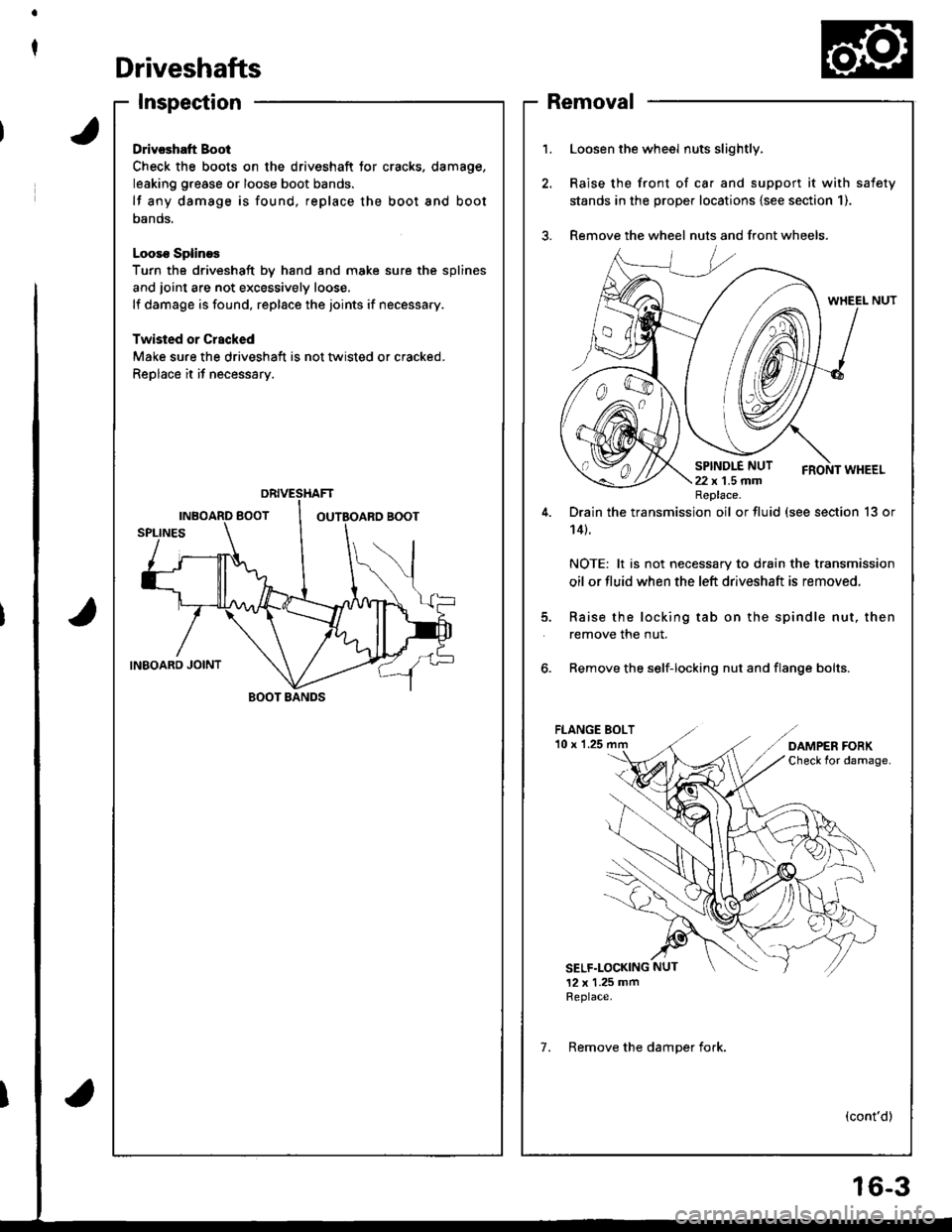

Driveshafts

Inspection

Drivcshatt Boot

Check the boots on the driveshaft tor cracks. damage,

leaking grease or loose boot bands.

lf any damage is found, replace the boot and boot

oanos.

Looso SplineE

Turn the driveshaft by hand and moke sure the splines

and joint are not excessively loose.

lf damage is found, replace the joints if necessary.

Twisled or Crscked

Make sure the driveshaft is not tlvisted or cracked.

Replace it if necessary.

BOOT BANDS

1.Loosen the wheel nuts slightly,

Raise the front of ca. and support it with safety

stands in the prope. locations {see section 1).

Remove the wheel nuts and front wheels.

5.

Drain the transmission oil or fluid (see section 13 or

14t.

NOTE: lt is not necessary to drain the transmission

oil or fluid when the left driveshaft is removed.

Raise the locking tab on the spindle nut, then

remove the nut.

6. Remove the self-locking nut and flange bolts.

FLANGE BOLT'10 x 1.25

SELF.LOCKING NUT

12 x 1.25 mmReplace.

(cont'd)

Replace.

7. Remove the damoer fork.

Removal

6-3

Page 635 of 1681

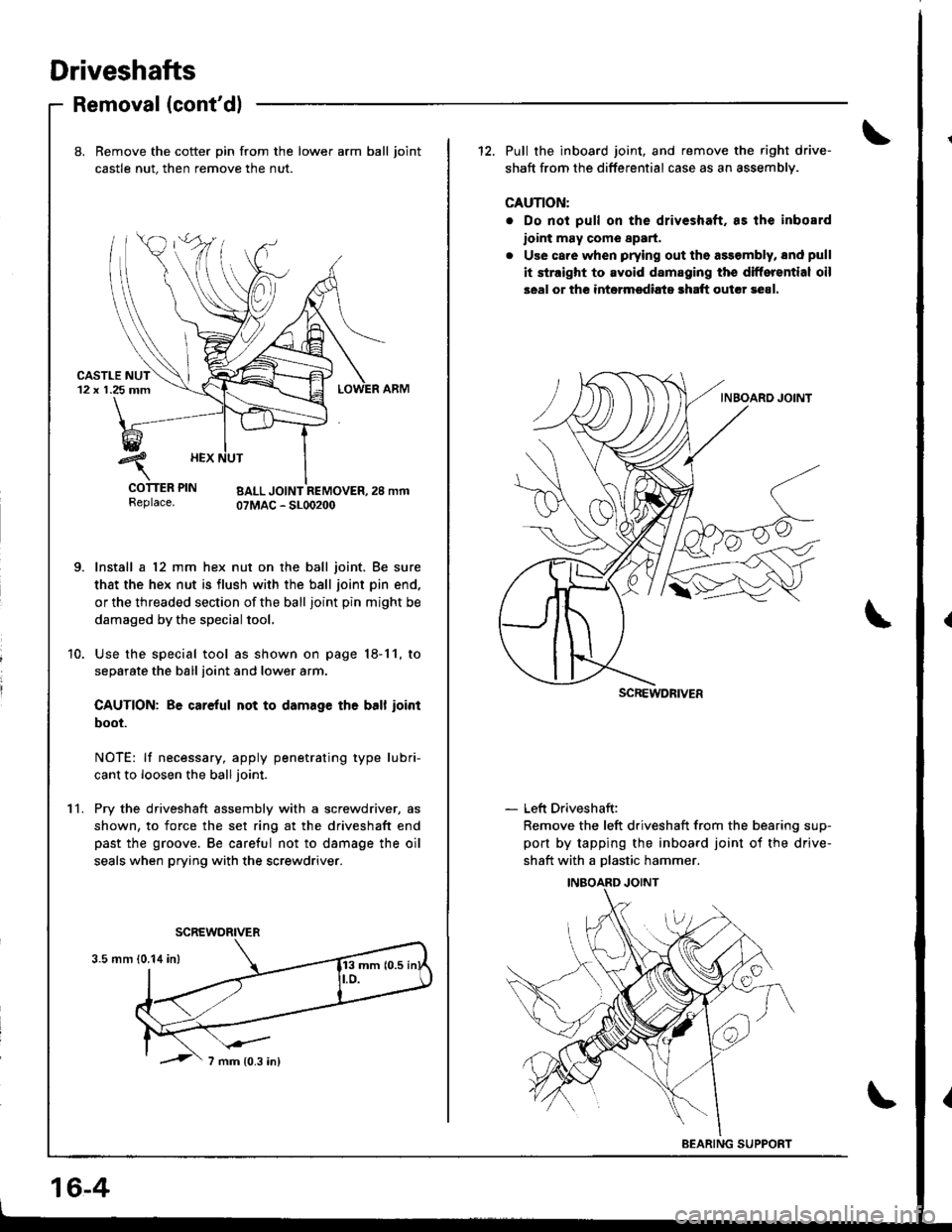

Driveshafts

Removal (cont'dl

11.

8. Bemove the cotter pin from the lower arm ball joint

castle nut. then remove the nut.

urJr rEr rrN BALL JOINT REMOVER,2S mmReplace. OTMAC - SLOO2OO

Install a 12 mm hex nut on the ball joint. Be sure

that the hex nut is flush with the ball joint pin end.

or the threaded section of the ball joint pin might be

damaged by the special tool.

Use the special tool as shown on page 18-11, to

separate the ball ioint and lower arm.

CAUTION: Be careful not to damage th6 ball ioint

boot.

NOTE: lf necessary, apply penetrating type lubri-

cant to loosen the ball joint.

Pry the driveshaft assembly with a screwdriver, as

shown, to force the set ring at the driveshaft end

past the groove. Be careful not to damage the oil

seals when prying with the screwdriver.

12. Pull the inboard joint, and remove the right drive-

shaft from the differential case as an assemblv.

CAUTION:

. Do not pull on the driveshaft. as lhe inbosrd

ioint may come 8p8rt.

. Use care when prying out the assembly, snd pull

it straight to avoid damaging the differential oil

seal or the intermsdiats rhaft outcr 3e81.

- Left Driveshaft:

Remove the left driveshaft from the bearing sup-

port by tapping the inboard joint of the drive-

shaft with a Dlastic hammer.

SCREWDRIVER

BEARING SUPPORT

16-4

Page 646 of 1681

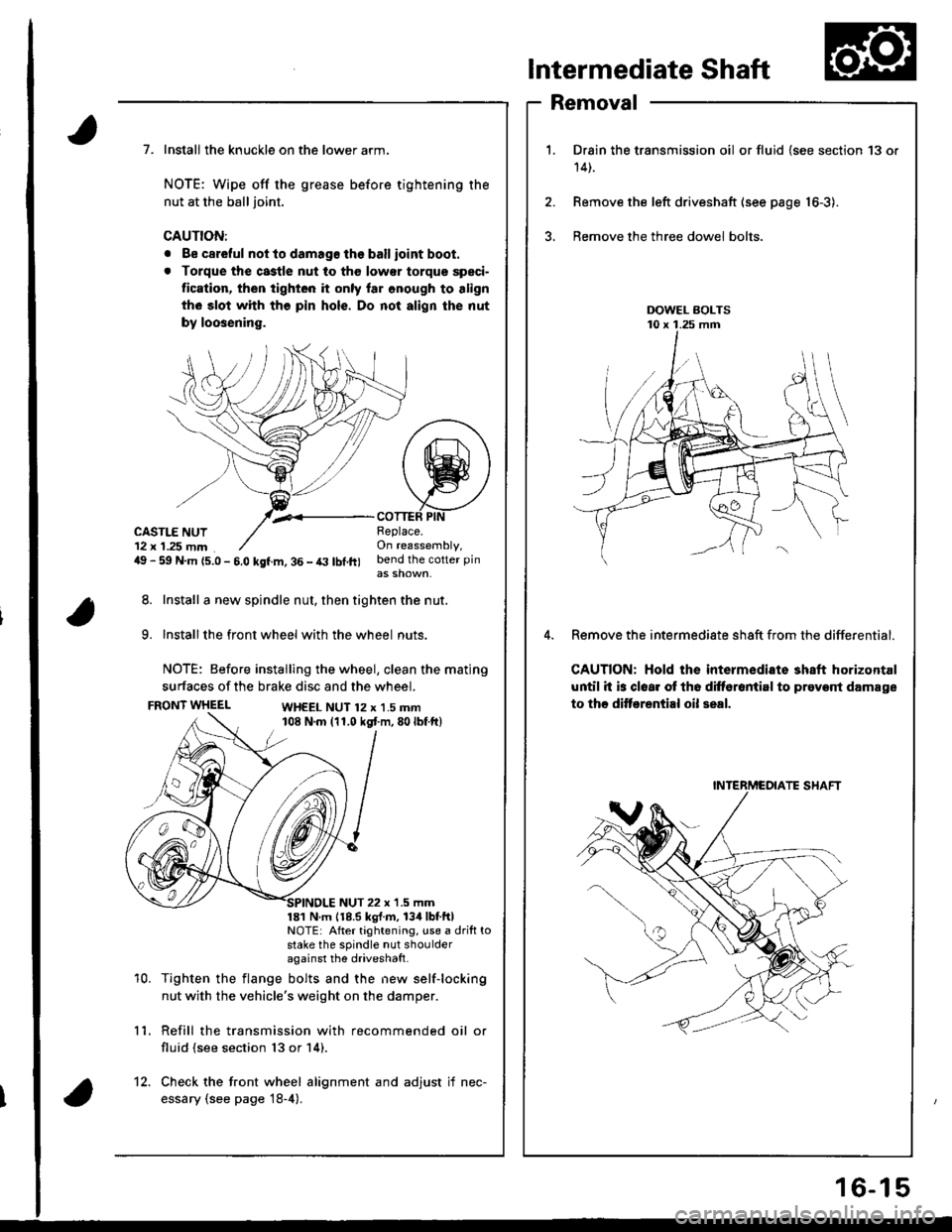

Intermediate Shaft

Removal

Drain the transmission oil or fluid {see section 13 or

14t.

Remove the left driveshaft (see page 16-3).

Bemove the three dowel bolts.

Remove the intermediate sh8ft from the differential.

CAUTION: Hold the intermediate shaft horizontal

until it is clear ot th6 difforantirl to prevont damage

to thc ditf€rential oil seal.

7. Install the knuckle on the lower arm.

NOTE: Wipe off the grease before tightening the

nut at the ball joint.

CAUTION:

. Be careful not to damago the ballioint boot.

. Torque the castle nut to tho low€r torque speci-

tication, then tighten it only lar onough to align

th6 slot whh tho pin hols. Do not align the nut

by loosening.

,.<__coTTEF PtNCASTLE NUT12 x 1.25 mm49 - 59 N.m {5.0 - 5.0 kgf.m, 36 - t3 lbl.ft)

Beplace.On reassembly,bend the cotter pin

8. Install a new spindle nut, then tighten the nut.

9. Installthe front wheel with the wheel nuts.

NOTE: Before installing the wheel, clean the mating

surfaces of the brake disc and the wheel.

FRONT WHEELWH€EL NUT 12 x 1.5 mm108 N.m (11.0 kgt m,80lbf ft)

10.

NUT 22 x '1.5 mm181 N m 118.5 kgl.m, 134lbtftlNOTE: After tightening, use a drift tostake the spindle nut shoulderagainst the driveshatt.

Tighten the flange bolts and the new self-locking

nut with the vehicle's weight on the damper.

Refill the transmission with recommended oil or

fluid (see section 13 or 14).

11.

12. Check the front wheel alignment and adjust if nec-

essary (see page 18-4).

INTERMCOIATE SHAFT

16-15

Page 649 of 1681

lntermediate Shaft

Reassembly (cont'dl

Pack the interiorof the outer seal.2,0-3.5 g (0.07 -0.12 ozl

Install the

groove.

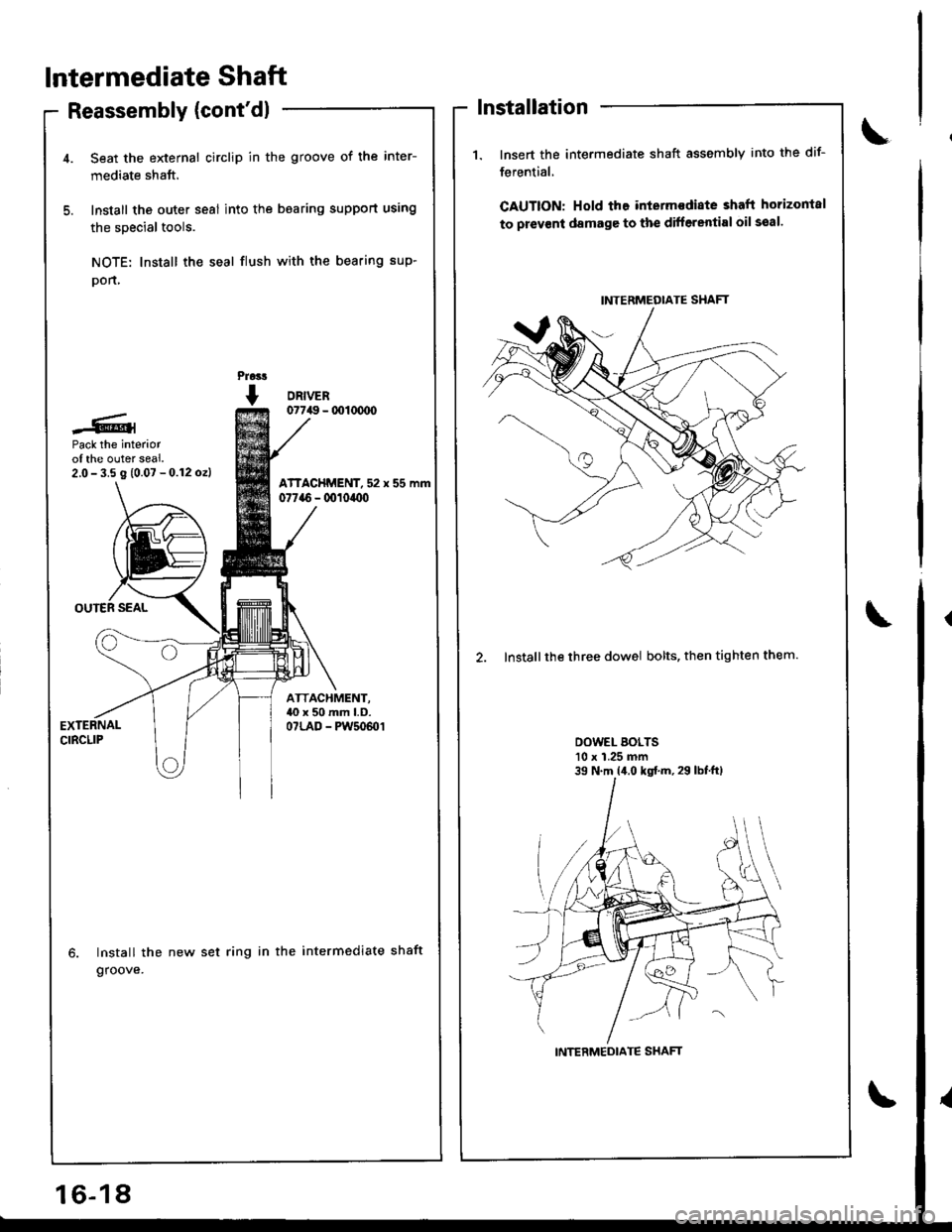

Seat the external circlip in the groove of the inter-

mediate shaft.

Install the outer seal into the boaring support using

the special tools.

NOTE: Install the seal flush with the bearing sup-

pon

lnstallation

1. Insert the intermediate shaft assembly into the dif-

ferential,

CAUTTON: Hold the interm€diate shaft horizontal

to prev€nt damage to the diff6rential oil soal.

2. Installthe three dowel bolts, then tighten them.

\

ATTACHMENT,40 x q) mm l.D.07LAD - PW50601

DOWEL AOLTS'10 x 1.25 mm39 N.m (4.0 kgf.m,29lbtftl

new ser nngin the intermediate shaft

INTERMEDIATE SHAFT

Pr.3s

INTERMEDIATE SHAFT

16-18

Page 662 of 1681

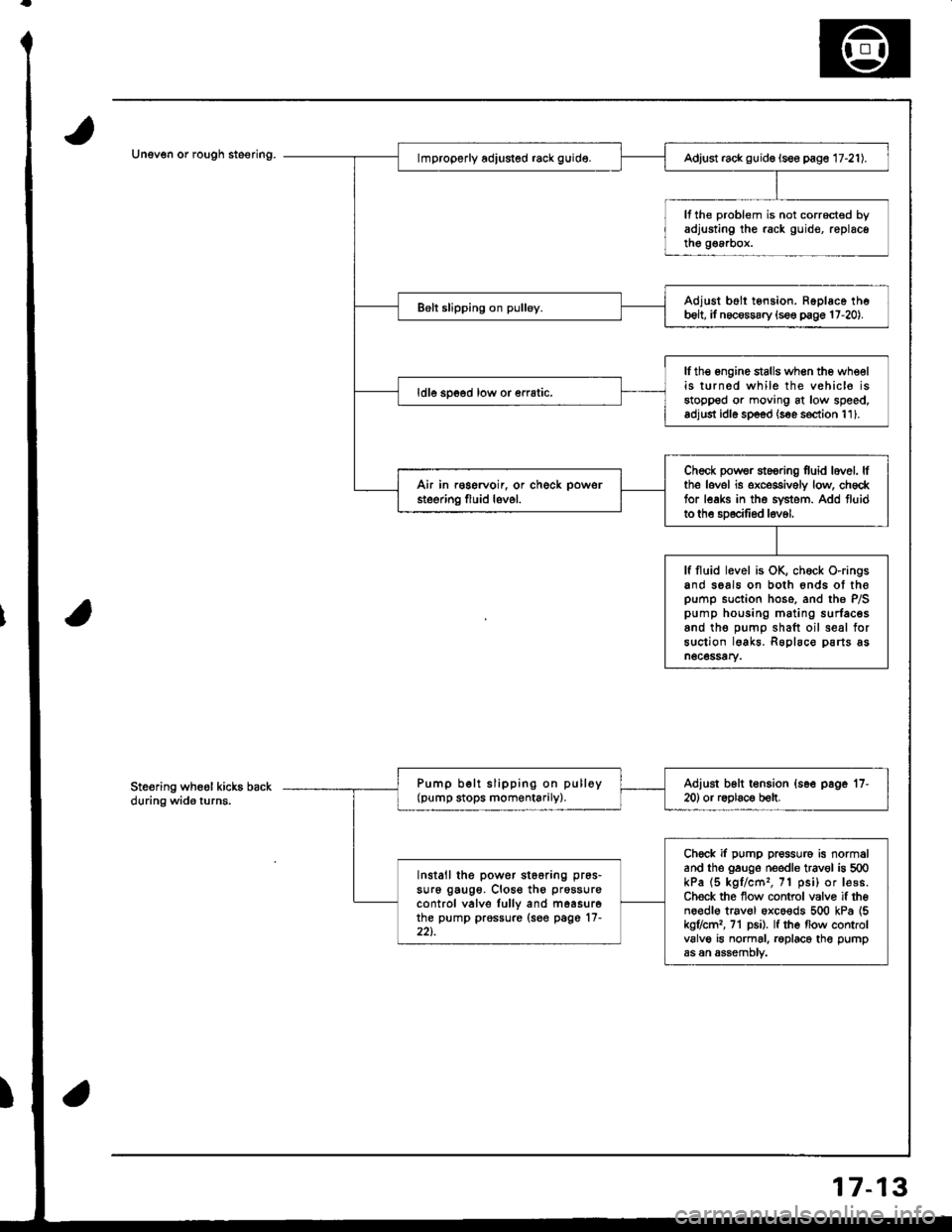

Unev€n or rough steering.Adjust rack guid€ (see page 17-21).

It the problem is not corrocted byadjusting the rack guid€, replacethe g€a.box.

Adjust b6ll tension. Ropl6ce theb6lt, it necossary {s€e p€ge 17-20).

lfth€ engine stalls when the wheelis turned while the vehic16 isstopped or moving at low speed.adjust idl6 sp6od (s€e s€ction 111.

ldle spoed low or €rratic.

Check powsr st6oring fuid lovel. lfthe lovel is exceggively low, ch6cktor leaks in the svstem. Add fluidto the sD6cilied l6v6l,

Air in r€gervoir, or check powsr

steering fluid lovel.

lf fluid level is OK, chock O-ringsand seals on both 6nds ot thepump suction hose. and the P/Spump housing mating surfacesand tho oumo shaft oil seal forsuction lgakr. Roplaco parts asn6c6ssary.

Pump b€lt slipping on pulloy(pump stops momentarily).Adiust b6lt t€nsion {s6e page '17-

20) or r6olac€ b€lt.

Chock if pump pressure is normaland the gauge needle trav€l is 500kPa (5 kgl/cm'�, 71 psi) or lesB.Ch€ck the flow control valvo if theno€dl€ trav€l oxco€ds 500 kPa {5kg7cml, 71 p6i). lf the flow controlvalve is normal. roplace the pumpas an assemDtv.

Install the power st66ring pr6s-

su16 gaug6. Close th6 prossure

control valve lully and m6asurethe pump prossure (see page'17-22t.

Ste€ring wheol kicks backduring wide turns.

7-13