check engine HONDA INTEGRA 1998 4.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 779 of 1681

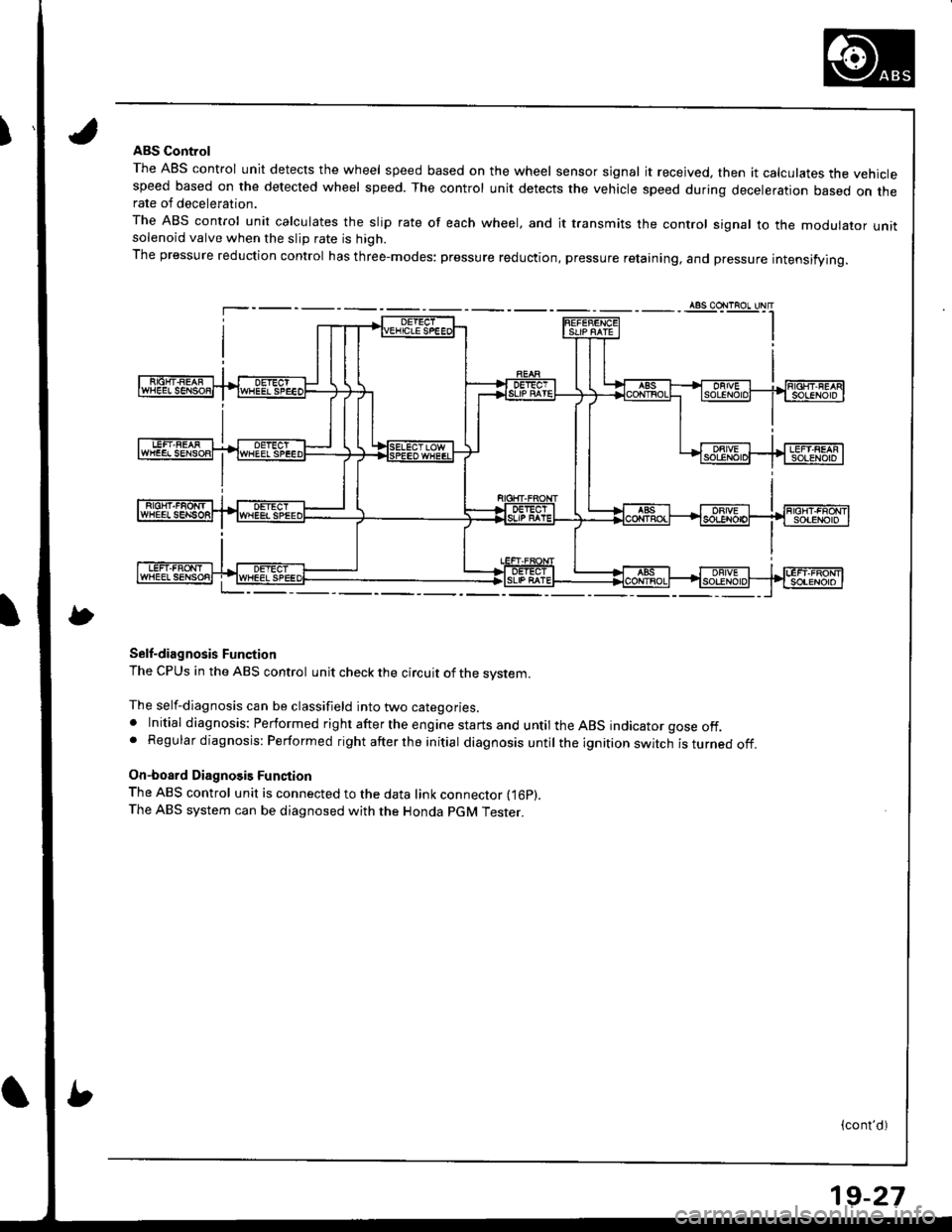

IABS Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the vehiclespeed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration based on therate of deceleration.

The ABS control unit calculates the slip rate of each wheel, and it transmits the control signal to the modulator unitsolenoid valve when the slip rate is high.

The pressure reduction control has three-modes: pressure reduction, pressure retaining, and pressure intensifying.

Self-diagnosis Function

The CPUS in the ABS control unit check the circuit of the system.

The self-diagnosis can be classifield into two categories.. Initial diagnosis: Performed right after the engine starts and until the ABS indicator gose off.. Regular diagnosis: Performed right after the initial diagnosis until the ignition switch isturnedoff.

On-board Diagnosis Function

The ABS control unit is connected to the data link connector fi6p).The ABS system can be diagnosed with the Honda PGM Tester.

(cont'd)

19-27

Page 789 of 1681

I

\

I

Diagnostic Trouble Code (DTC)

DTG lndication

a

t

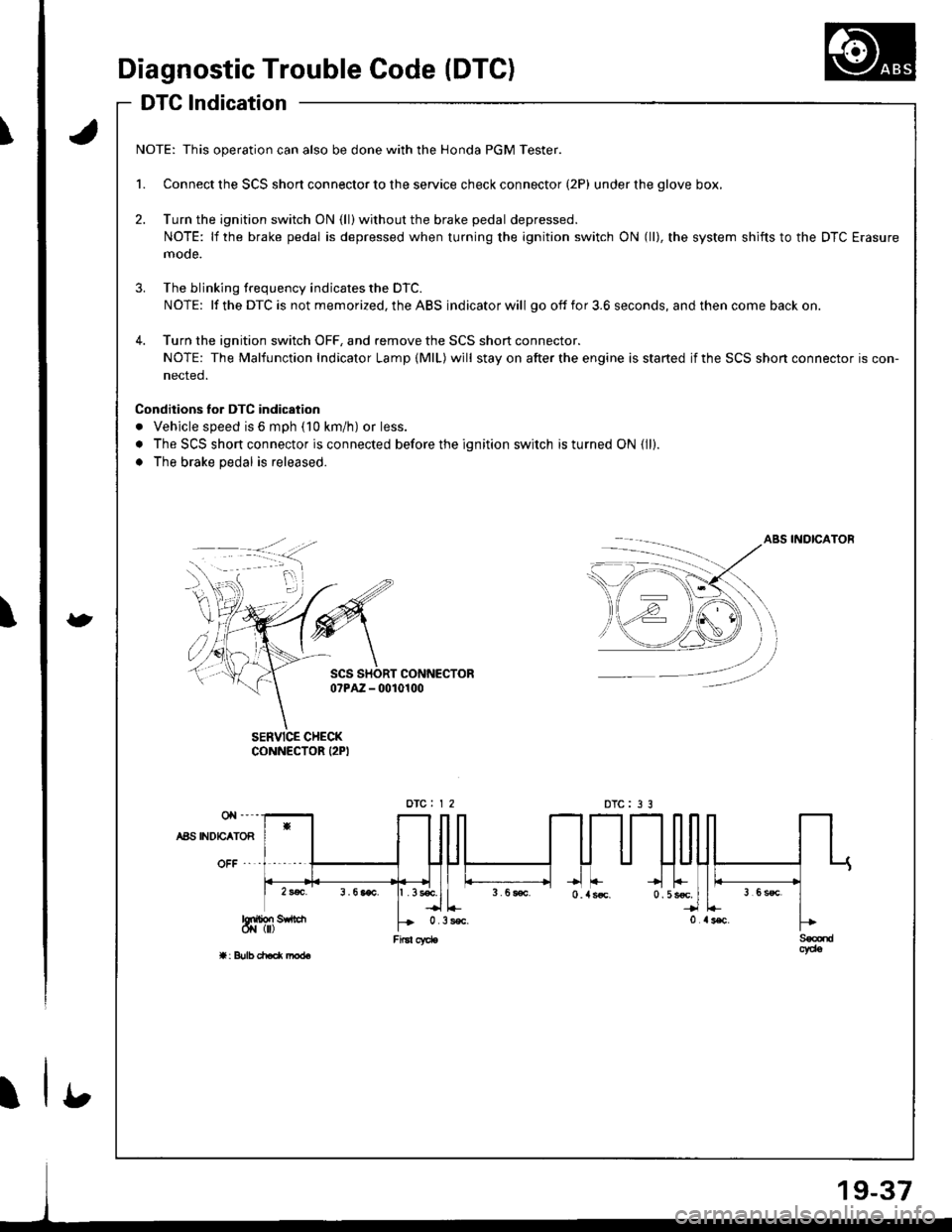

NOTE: This operation can also be done with the Honda PGM Tester.

1. Connect the SCS short connector to the service check connector (2P) under the glove box,

2. Turn the ignition switch ON (ll) without the brake pedal depressed.

NOTE: lf the brake pedal is depressed when turning the ignition switch ON (ll), the system shifts to the DTC Erasure

mode.

3. The blinking frequency indicates the DTC.

NOTE: lf the DTC is not memorized, the ABS indicator will go off fo r 3.6 seconds, and then come back on.

4. Turn the ignition switch OFF, and remove the SCS short connector.

NOTE: The Malfunction Indicator Lamp (MlL) will stay on after the engine is started if the SCS shon connector is con-

nected.

Conditions lor DTC indication

. Vehicle speed is 6 mph (10 km/h) or less.

. The SCS short connector is connected before the ignition switch is turned ON {ll).

. The brake pedal is released.

ABS INOICATOB

SCS SHORT CONNECTORo?PAZ - 0010100

SERVICE CHECKCONNECTOR I2PI

DTC : 3 3

b

Page 794 of 1681

Troubleshooting

ABS Indicator Does Not Go Off

JUMPERWIRE

ABS OO TNOL UMT 22P OO'{NECTOR

Wire side of temalo terminalg

A8S COI{TROL Ut{lT 12P OO I{ECTOR

JUMPEFWIRE

Wire side of femal€ terminala

|G2 IALK/YELI

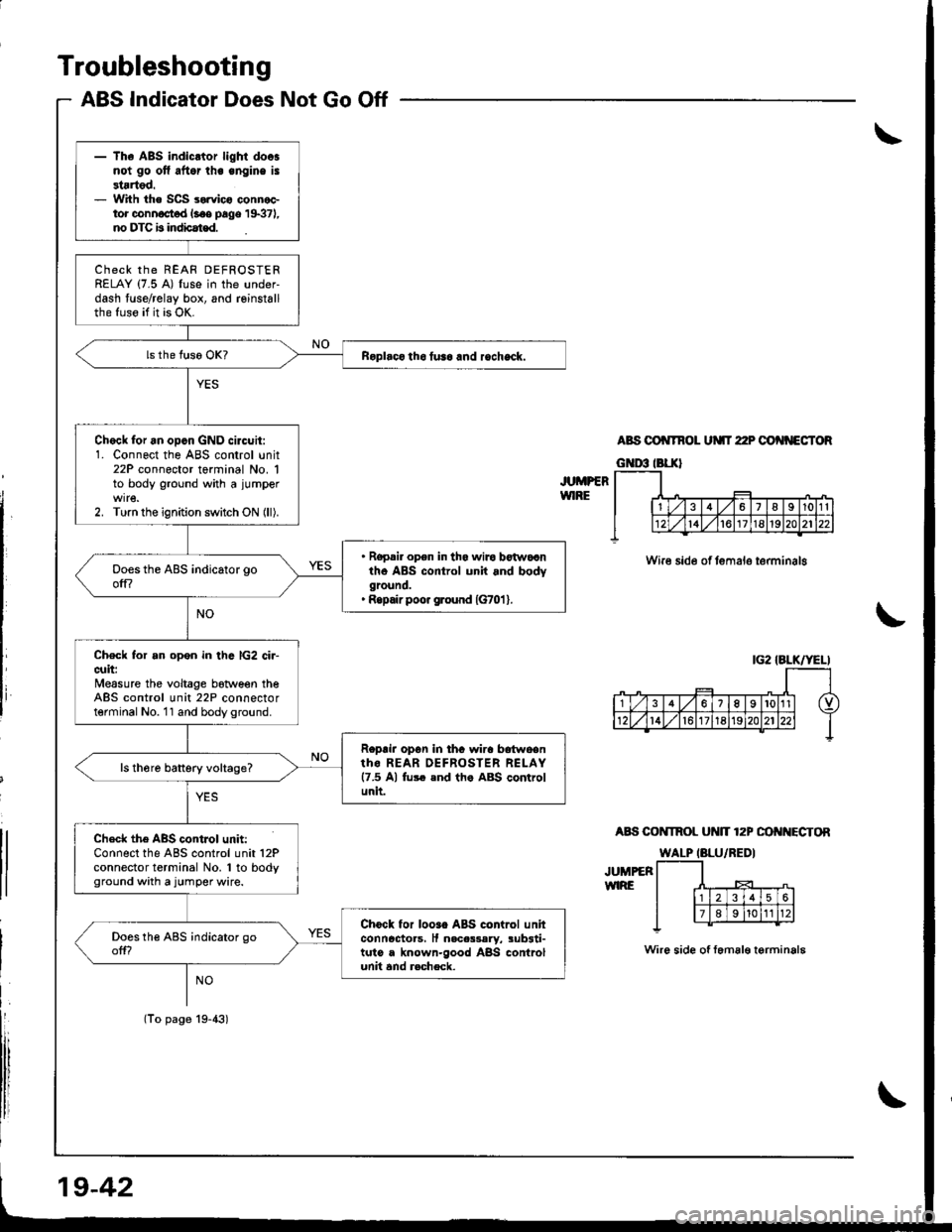

- The ABS indicltor light doosnot go ofl aftor lhe engine is3tartod.- With the SCS sorvico connoctor connoct d l.oe page 19371,no DTC b indbat€d.

ChECK thE REAF DEFROSTERRELAY (7.5 A) fuse in the under-dash fuse/relay box, and reinstallthe fuso if it is OK.

Roplaco tho tusa and rocheck.

Chock for an opcn GND circuit:1. Connect the ABS control unit22P connector terminal No. 1to body ground with a jumper

2. Turn the ignition switch ON (ll).

. Ropair opon in tha wiro botwocntho ABS control unit and bodyground.' Ropair poo. ground {G701 }.

Check for an open in thc lG2 ci.-cuit:Measure the voltage botween theABS control unit 22P connectorterminal No. 11 and body ground.

Roprir opon in thc wira bdtwoentho REAR OEFROSTER RELAY17.5 Al fu$ end th. ABS controlunit.

ls th6re battery voltage?

Check the ABS contJol unit:Connect the ABS control unit 12Pconnector terminal No. 1 to bodyground with a jumper wire.

Chock for looao ABS control unhconncctoas, It nacas3aly, sub3ti-tuto a known-good ABS controlunit and r.check.

(To page 19-43)

19-42

Page 796 of 1681

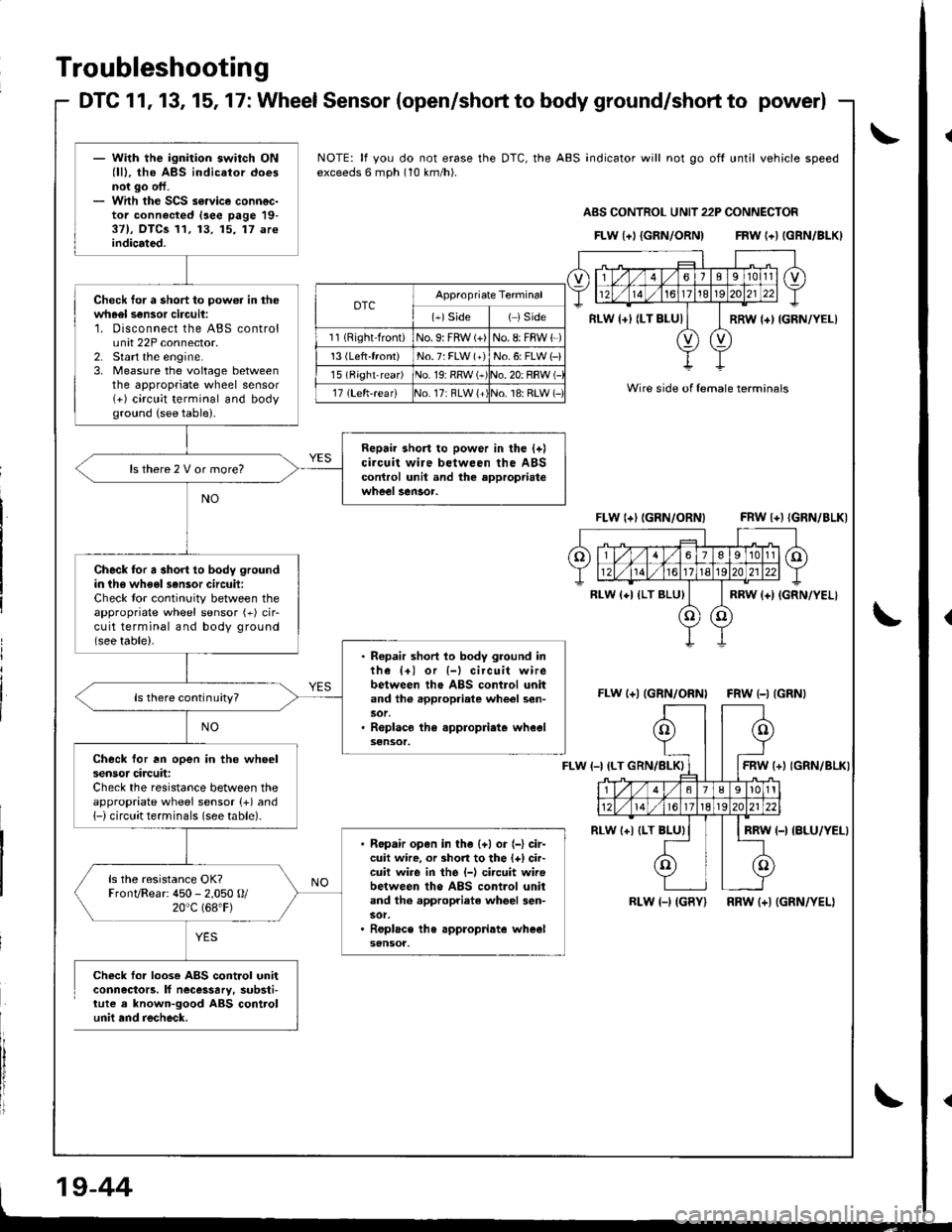

- With the ignition switch ON(lll, the ABS indicator doesnot go off.- With the SCS s€.vice connec-tor connected lsee page 19-37), OTCS 11, 13, 15, 17 areindicated.

Check for a short to pow6r in thewheel sensor circuii:1. Disconnect the ABS controlu nit 22P connector.2. Start the engine.3, Measure the voltage betweenthe appropriate wheel sensor(+) circlit terminal and bodyground (see table).

Repair short to power in the {+)circuit wire between the ABScontrol unil and the approprialewheel sensor.

ls there 2 V or more?

Check for a short to body groundin th6 wheel sensor circuil:Check tor continuity between theappropriate wheel sensor (+) cir-cuit terminal and body ground(see table).. Ropair short lo body ground inthe {+) or {-l circuit wirebetween tho ABS contlol unitand th6 .ppropriate whe€l sen-

. Roplaco the .ppropliate wheelsensot.

ls there continuity?

Check for an open in the wheelsensor circuit:Check the resistance between theappropriate wheel sensor (+) and1-) circuit terminals (see table).

Ropair open in the {+) or (-} cir-cuit wire, or 3hort to the l+) cir-cuit wire in the l-l circuit wirebetween tho ABS control unitand th6 appropriate whgel 3en-

Replace th6 appropdate wh€elsensot.

ls the resistance OK?FronvRear: 450 - 2,050 O/20"c (68.F)

NOTE: lf you do not erase the DTC, the ABS indicator will not go off until vehicle speedexceeds 6 mph (10 km/h).

ABS CONTNOL UNIT 22P CONNECTOF

FLw {+l {GRN/ORN) FRw {+} (GRN/BLKI

oTcAppropriate Terminal

(+)Side( )side

11 (Right-front)No. 9: FRW (+)No. 8: FBW {-)

13 (Left'front)No.7: FLW (+)No.6: FLW 1-)

l5lBight-rear) iNo. 19:RRW (+!o. 20: RBW (-

17 (Left'r€af)17: RLW {+',1o. 18: RLW (-Wire side of lemale terminals

FLW (+) (GRN/ORN) FRW l+){GRN/BLK)

FLw l+l (GRN/ORNI FRW {-) {GRN}

FLW t-l(+l (GRN/BLKI

RL(-I {BLU/YELI

RLW l-) (GBY) RRW (+) (GRN/YEL)

Check for loose ABS control unitconnectors. lf necessary. substi-tute a known-good ABS controlunii and recheck.

RLW {+l (LT BLUI

RLw (+l {LT BLU}

-t(o

___r

l'!*

6l89l01t

1417t8t920

| ***-t

(()

Y

Troubleshooting

DTC 1 1, 13, 15, 17 : Wheel Sensor (open/short to body ground/short to power)

\

L

9-44

\

Page 806 of 1681

Troubleshooting

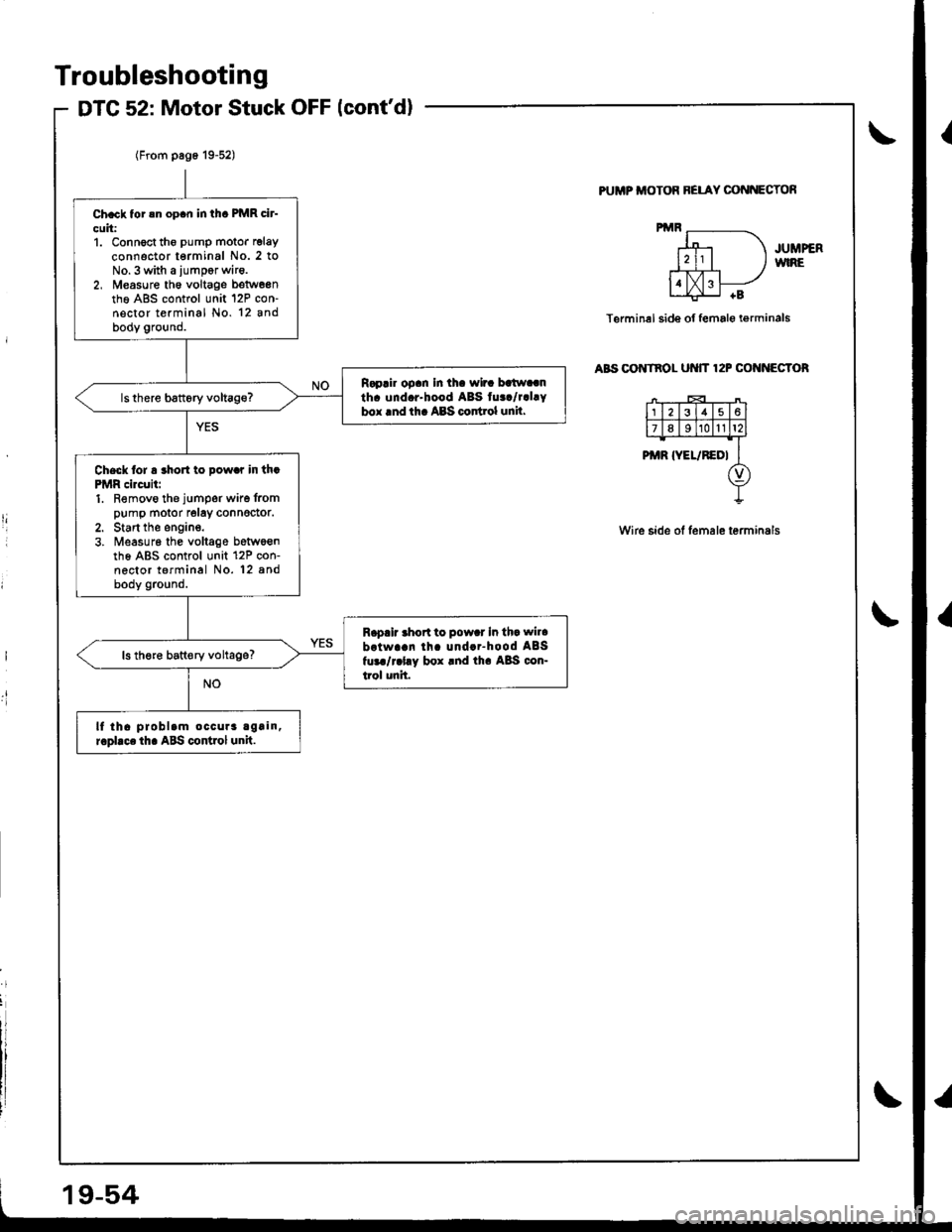

DTG 52: Motor Stuck OFF lcont'd)

PUMP ITIOTOR BELAY CONNECTOf,

JUMPERWIRE

Terminel side of female i€rminals

aBs oo tnol ut{tT 12P cof{f{EGToR

Wire side of lemale terminals

I

.t!

Ch.ck tor !n op.n in thc PMR cir-

cuit:1. Connoct tho pump motor relay

connector terminal No. 2 toNo.3 with a iumpor wir6.2, M€asure th6 voltage betw6entho A8S control unit 12P con-nector terminal No. 12 andbody ground.

R.p.ir op.n In th. wir. batw..nth. und.r-hood ABS tu../r.l.Ybox lnd th. ABS codrol unil.

Check lor a rho to pow.r in th.PMR circuii:1. Removo the jumper wire frompump motor relay connedor.2. Start the engine.3. ireasur6 the voltage betwoenth6 ABS control unit 12P con-nector terminal No. 12 8ndbody ground.

R.p.ir .hort to pow.r In th. wil.

brtwa!n lh. und..-hood ABSfur./r.l.y box rnd th. A8S con-trol unit.

ls th€re batt€ry voltage?

lf tha problam occura again,r.pllce th. ABS control unit.

Page 813 of 1681

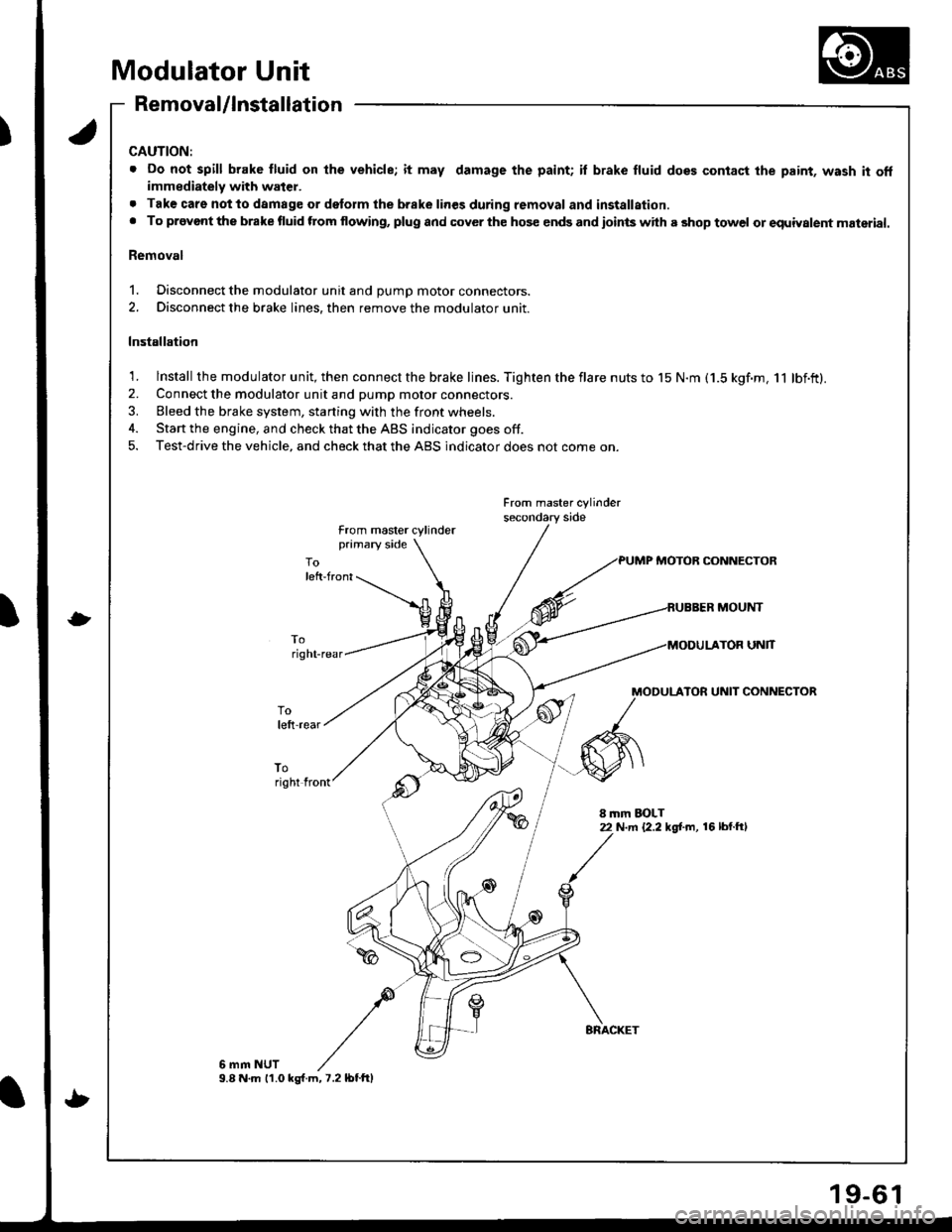

Modulator Unit

Removal/lnstallation

CAUTION:

. Do not spill brake fluid on lhe vehicle; it may damage the paint; il brake fluid does contact the paint, wash it offimmediately with water.

. Tak€ care notto damage or delorm the brake lines during removal and installation.. To provont the brake fluid ftom flowing, plug and cover the hos€ ends and ioints with a shop towel or equiyalent material.

Removal

1. Disconnect the modulator unit and DUmD motor connectors.

2. Disconnect the brake lines, then remove the modulator unit.

Installation

1. lnstall the modulator unit, then connect the brake lines. Tighten the flare nuts to 15 N.m (1.5 kgf.m, 11 lbf.ft).2. Connect the modulator unit and pump motor connectors.

3. Bleed the brake system, starting with the front wheels.

4. Start the engine, and check that the ABS indicator goes off.

5. Test-drive the vehicle, and check that the ABS indicator does not come on.

From master cylinder

from master cylinderprimary side

PUMP MOTOB CONNECTOR

MOUNT

UNlT

MODULATOR UNIT CONNECTOR

toright front

8 mm EOLT22 N.m {2.2 kg[.m, 16 lbl.ftl

6 mm NUT9.8 N.m 11.0 ks{.m,7.2lbtftl

9-6

Page 814 of 1681

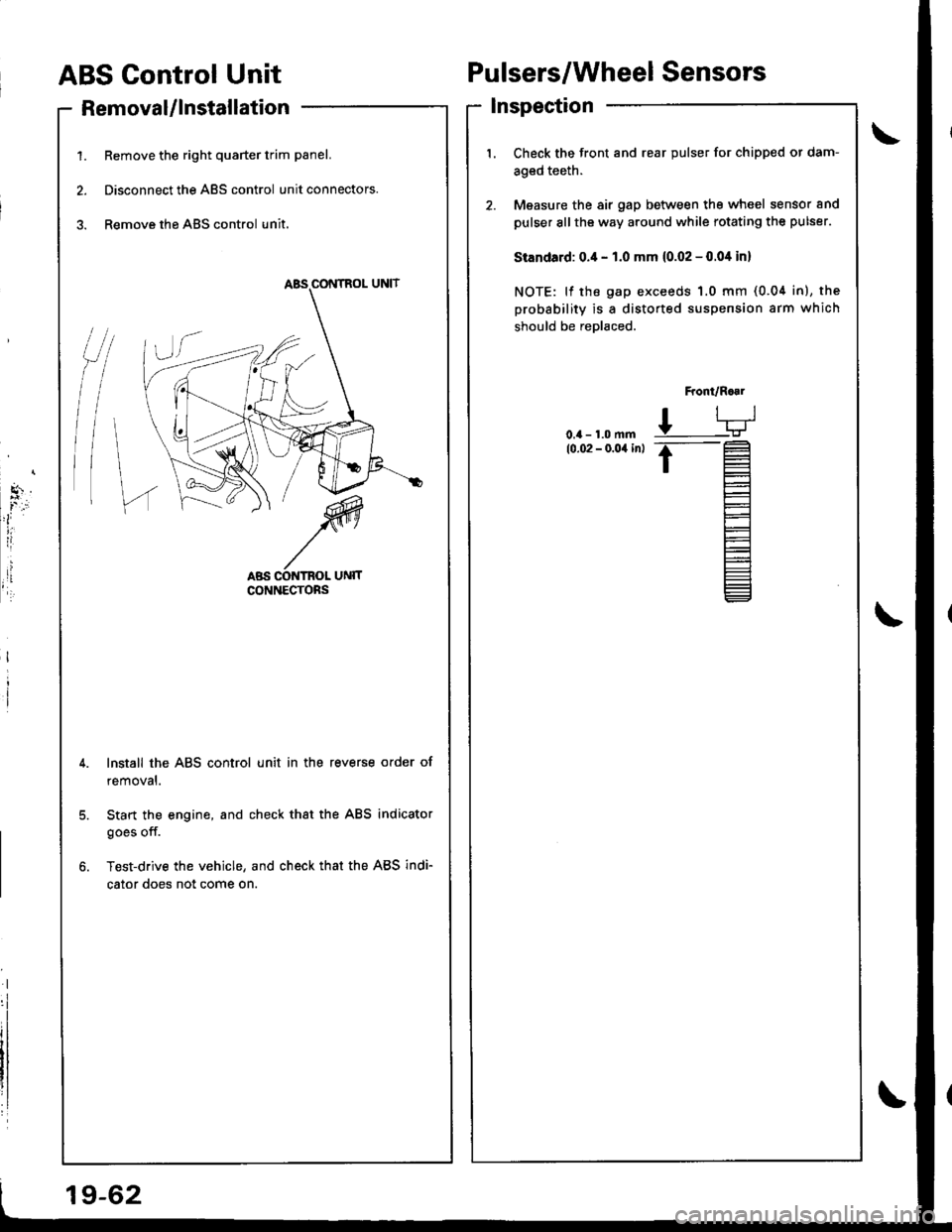

ABS Control Unit

RemovaUlnstallation

1. Remove the right quarter trim panel.

2. Disconnect the ABS control unit connectors.

3. Remove the ABS control unit.

Pulsers/Wheel Sensors

Inspection

/t

l\

I

Check the front and rear pulser for chipped or dam-

aged teeth.

Measure the air gap between tho wheel sensor and

pulser sllthe way around while rotating the pulser.

Standard: 0.4 - 1.0 mm (0.02 - 0.04 in)

NOTE: lf the gap exceeds 1.0 mm (0.04 in), the

probability is a distorted suspension arm which

should be reDlaced.

Front/R..1

L-TJ

.t-

t=

l-

Et-E_

Install the ABS control unit in the reverse order of

removal.

Start the engine, and check that the ABS indicator

goes off.

Test-drive the vehicle, and check that the ABS indi-

cator does not come on.

19-62

Page 995 of 1681

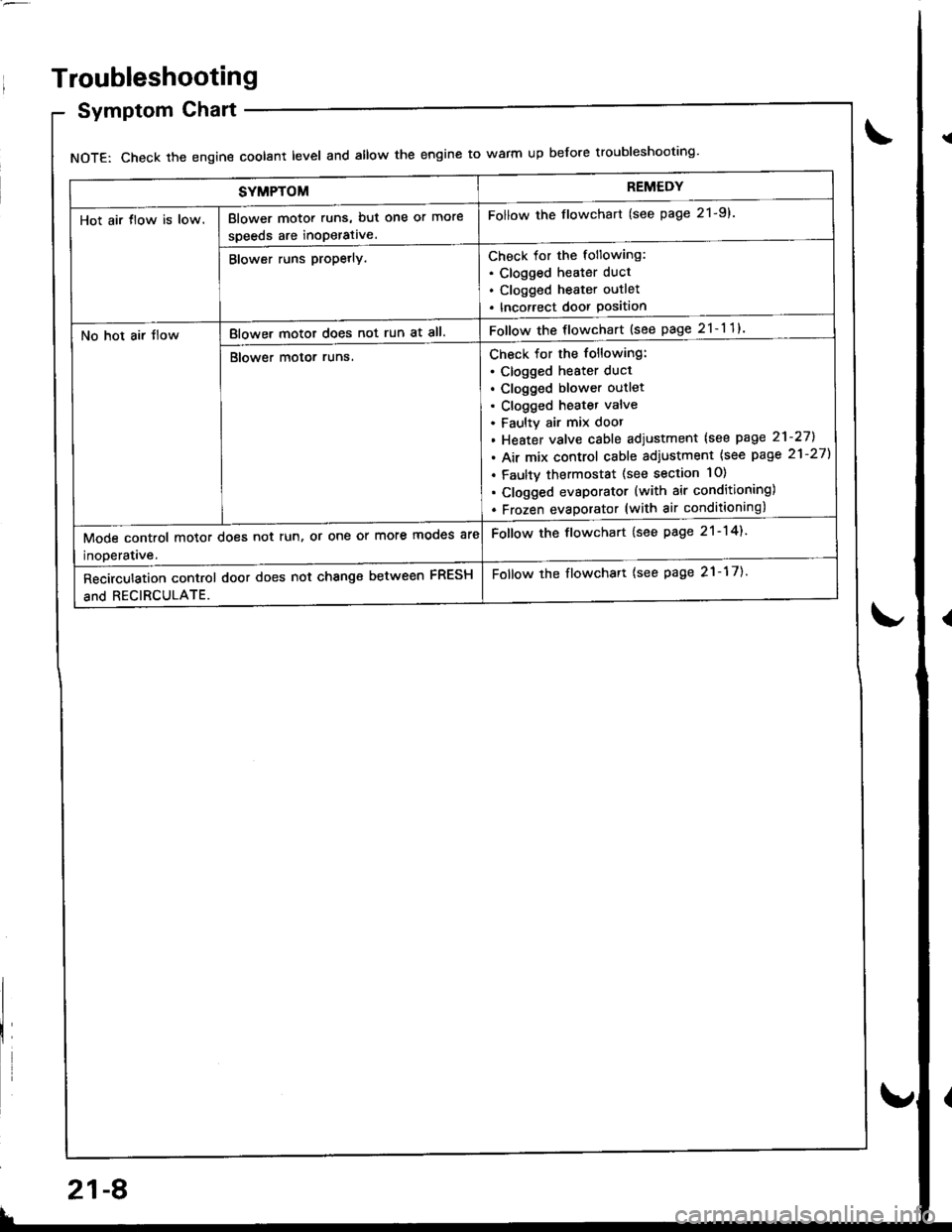

SYMPTOMREMEDY

Hot air tlow is low.Blower motor runs, but one or more

speeds are inoperative.

Follow the flowchart (see page 21-9).

Blower runs propetly.Check for the following:. Clogged heater duct

. Clogged heater outlet

. Incorrect door Position

No hot air tlowBlower motor does not run at all.Follow the flowchart {see page 21-11}

Blower motor runs.Check for the following:

. clogged heater duct

. Clogged blower outlet. Clogged heatet valve

. Faultv air mix door

. Heater valve cable adjustment lsee page 21-27].

. Air mix control cable adiustment {see page 21-27)

. Faulty thermostat (see section 10)

. Clogged evsporator (with air conditioning)

. Frozen evaDorator (with air conditioning)

Mode control motor does not run, or one or more mooes are

inoDeratave.

Follow the flowchart (see page 21-14).

Recirculation control door does not change between FRESH

and RECIRCULATE.

Follow the flowchart {see page 21-17).

Troubleshooting

Symptom Chart

NOTE: Check the engin€ coolant level and allow the engine to warm up before troubleshooting'

21-8

v

Page 1025 of 1681

J

Troubleshooting

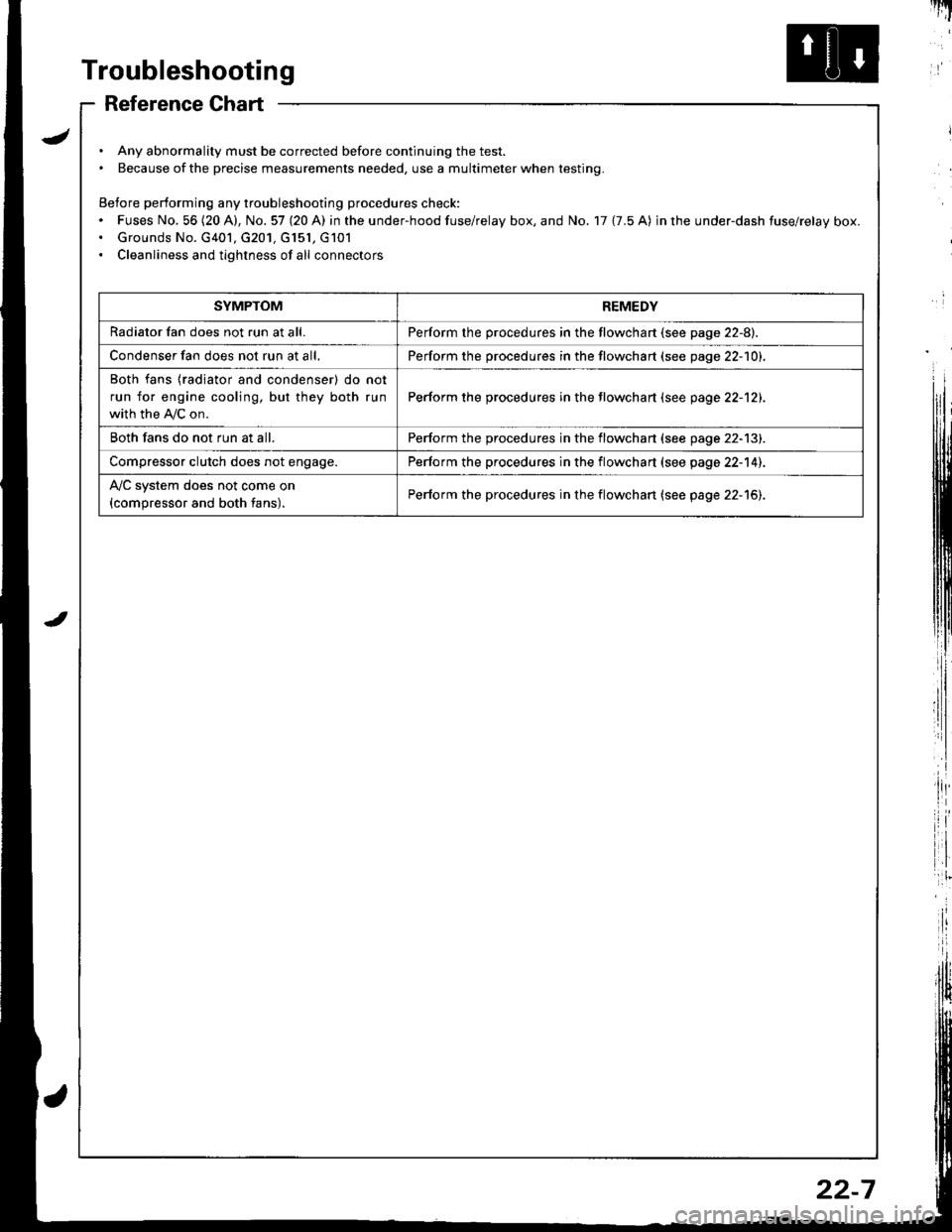

Reference Chart

. Any abnormality must be corrected before continuing the test.. Because of the precise measurements needed, use a multimeter when testing.

Before performing any troubleshooting procedures check:. Fuses No, 56 (20 A), No. 57 (20 A) in the under-hood fuse/relay box, and No. 17 {7.5 A) in rhe under-dash fuse/relay box.. Grounds No. G401, G201, G151, G101. Cleanliness and tightness of all connectors

I'IT

I

I

SYMPTOMREMEDY

Radiator fan does not run at all.Perform the procedures in the flowchart {see page 22-8).

Condenser fan does not run at all,Perform the procedures in the flowchart (see page 22-1O1.

Both fans {radiator and condenser) do not

run for engine cooling, but they both run

with the IVC on.

Perform the procedures in the tlowchart (see page 22-12).

Both fans do not run at all.Perform the procedures in the flowchart (see page 22-13).

Compressor clutch does not engage.Perform the procedures in the flowchart (see page 22-14).

l'lc system does not come on

{compressor and both fans).Perform the procedures in the flowchart (see page 22-15).

22-7

Page 1030 of 1681

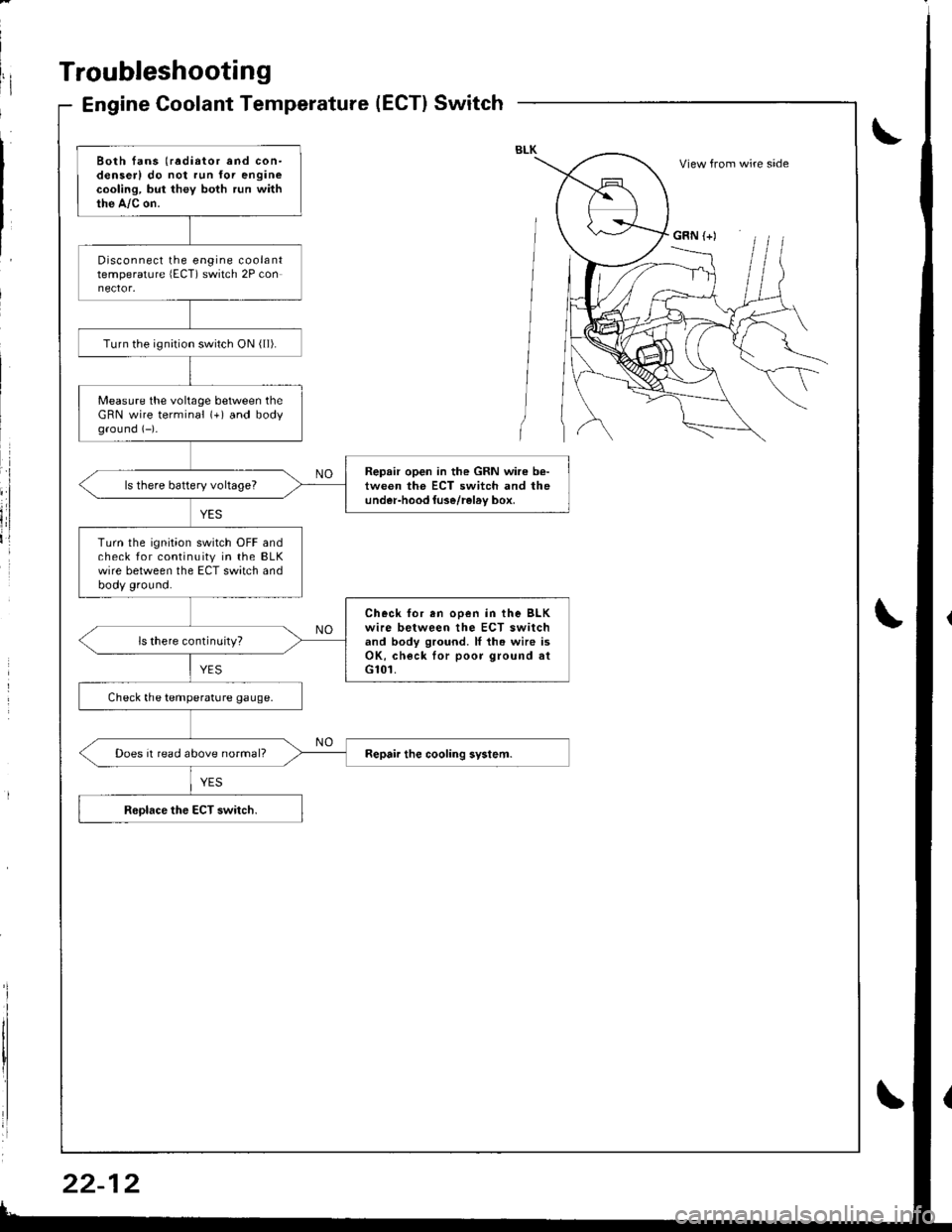

Troubleshooting

Engine Coolant Temperature(ECT}Switch

Both fans (radiator and con-denserl do not run for enginecooling, but they both run withthe A,/c on.

Disconnect the engine coolanttemperature lECT) switch 2P con

Turn the ignirion switch ON ( ll).

Measure the voltage between theGRN wire terminal (+) and bodyground (-)-

Repair open in the GRN wire b€-tween the ECT switch and theunder-hood luse/rel6v box,ls there battery voltageT

Turn the ignition switch OFF andcheck for continuity in the BLKwire between the ECT switch andbody ground.

Check for en ooen in the BLKwire between the ECT switchand body ground. ll th. wire isOK, check lor poor ground atG101.

ls there continuity?

Check the temperature gauge.

Does it read above normal?

View from wire side

GRN (+)